Patents

Literature

184results about How to "EOR" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for driving crude oil out by microorgans in crude oil

Owner:OIL EXTRACTION TECH INST OF SINOPEC SHENGLI OILFIELD

Method for improving carbon dioxide displacement yield by using surfactants

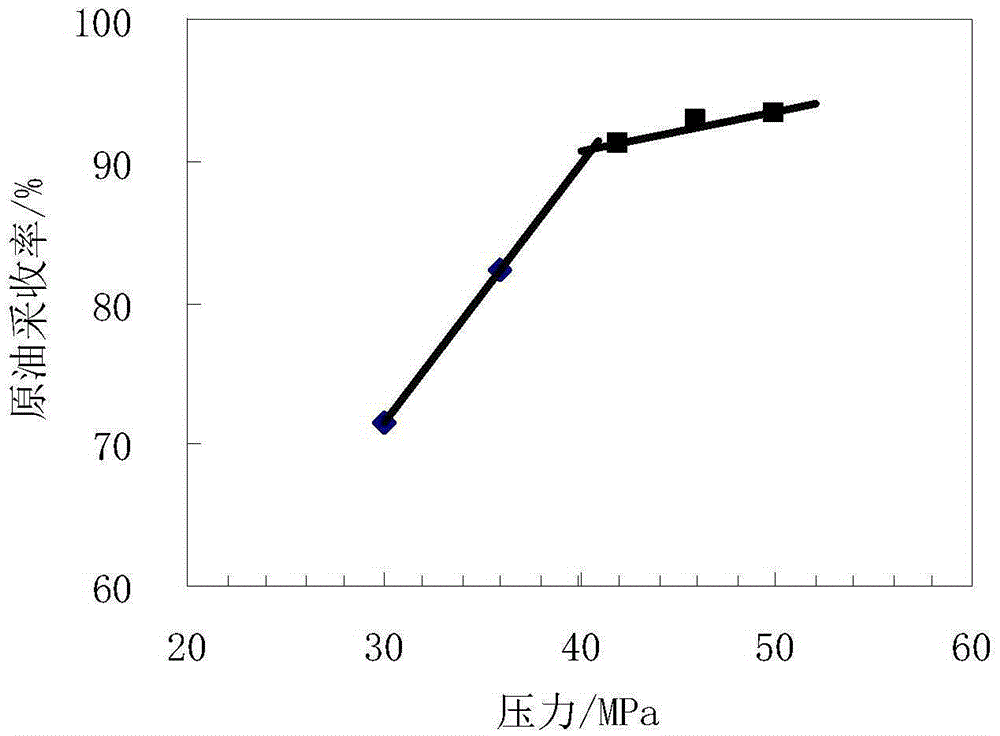

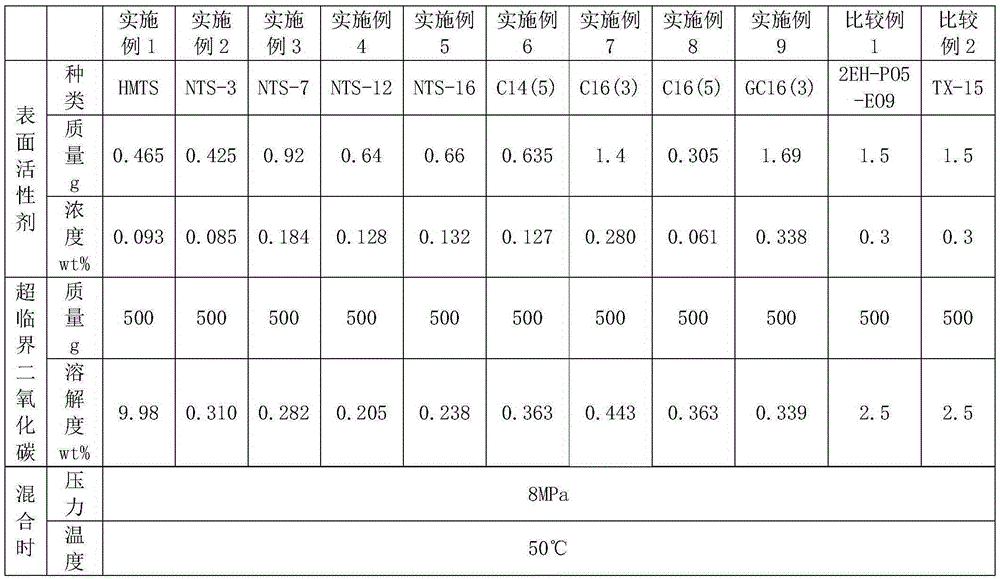

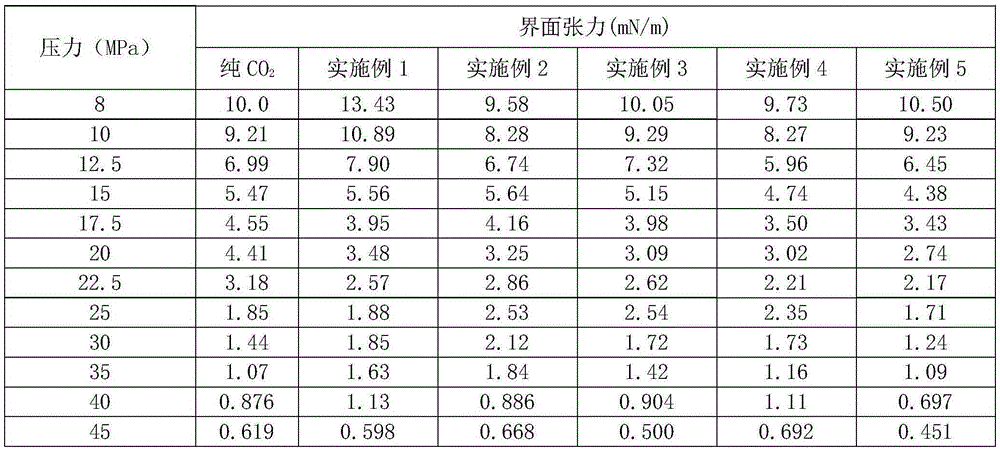

The invention discloses a method for improving the carbon dioxide displacement yield by using surfactants. The method comprises the following steps of: uniformly mixing selected surfactants and supercritical carbon dioxide according to a mass ratio being (0.00061:1) to (0.00338:1) under the conditions of the pressure being 8MPa and the temperature being 50 DEG C to be used as displacement agents; and injecting the displacement agents into an oil reservoir. The method has the advantages that the surfactants capable of reducing the minimum miscibility pressure of carbon dioxide and crude oil can be preferably selected; and when the surfactants are added in the injected carbon dioxide for carbon dioxide displacement operation, the carbon dioxide displacement yield can be improved.

Owner:PETROCHINA CO LTD +1

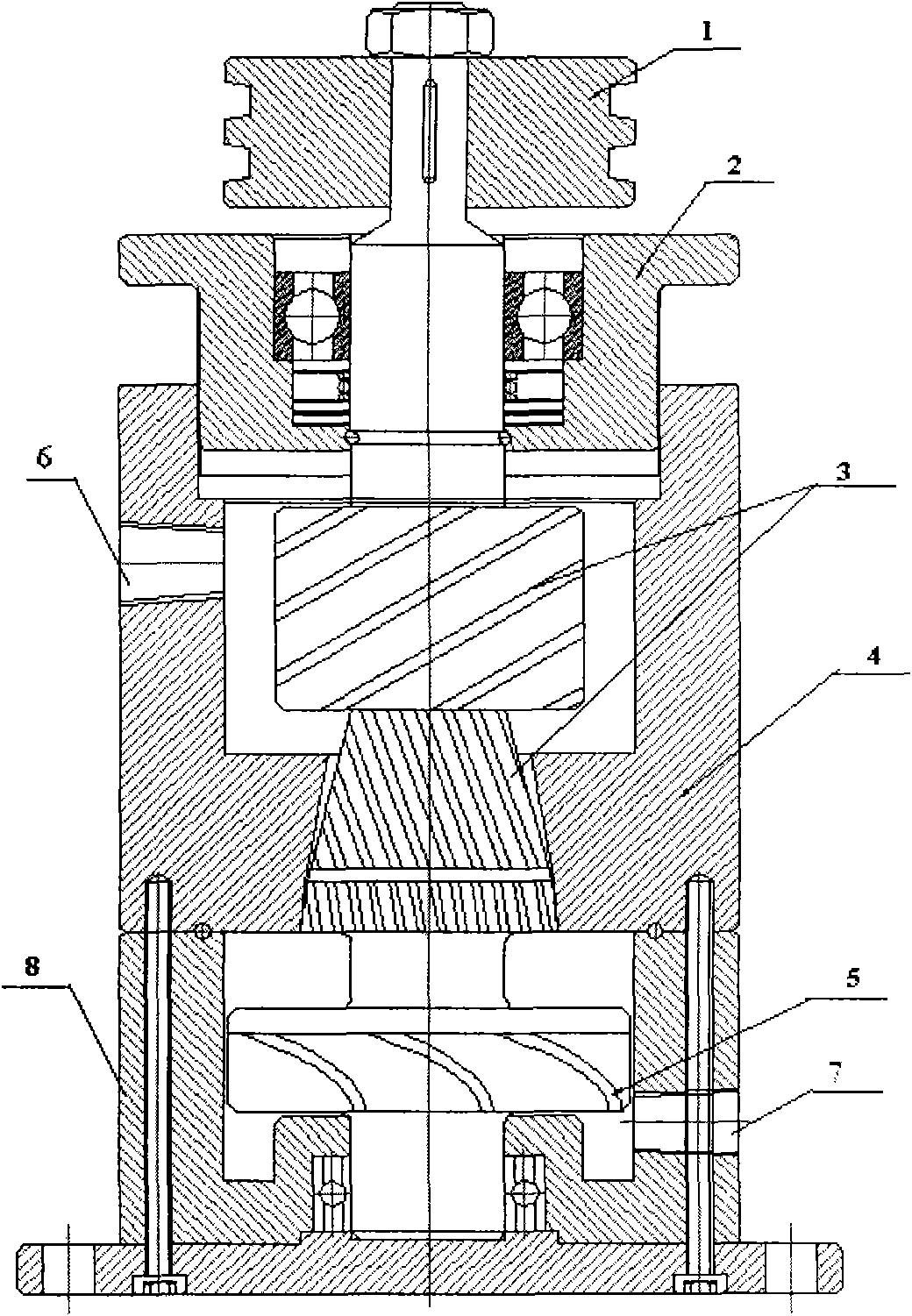

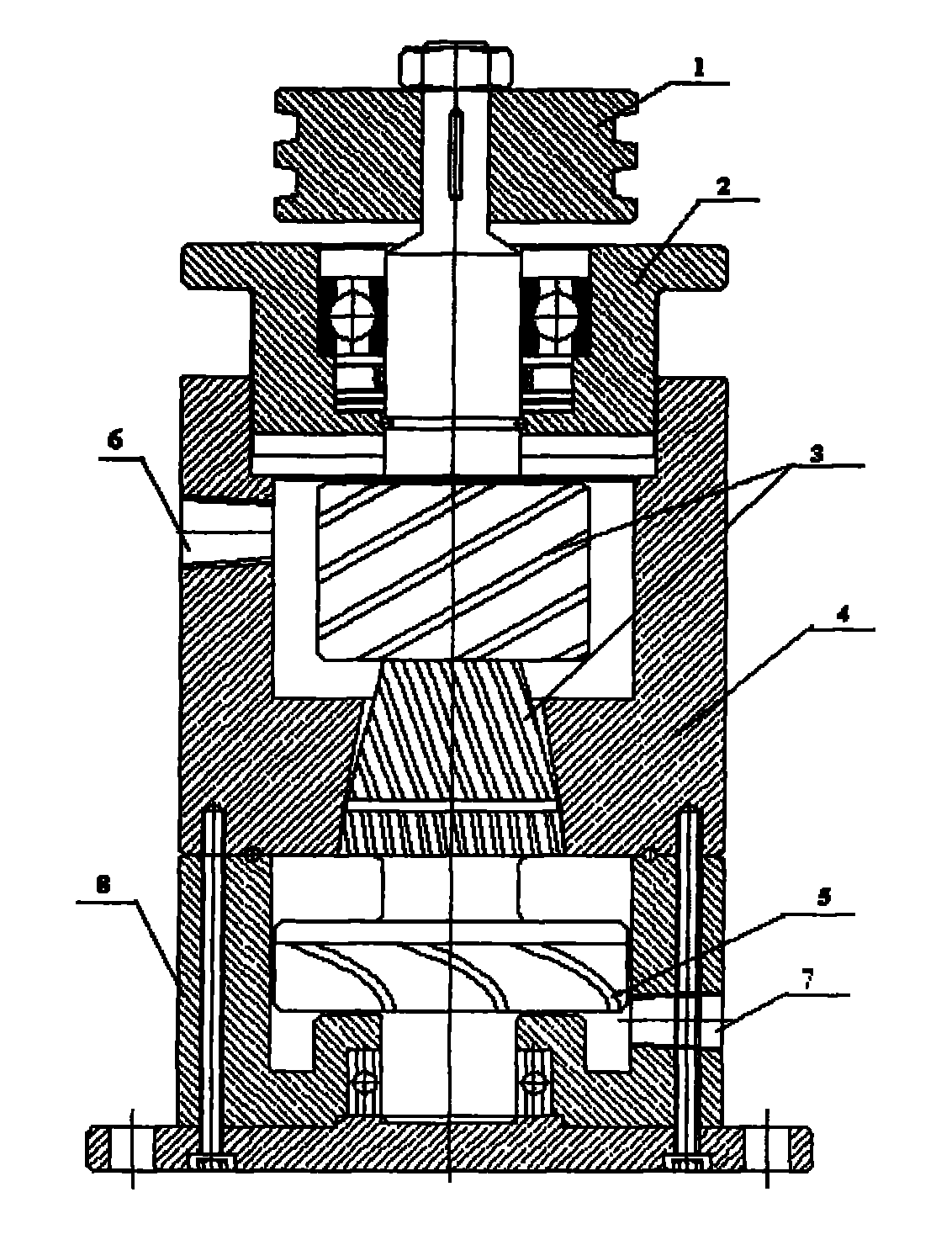

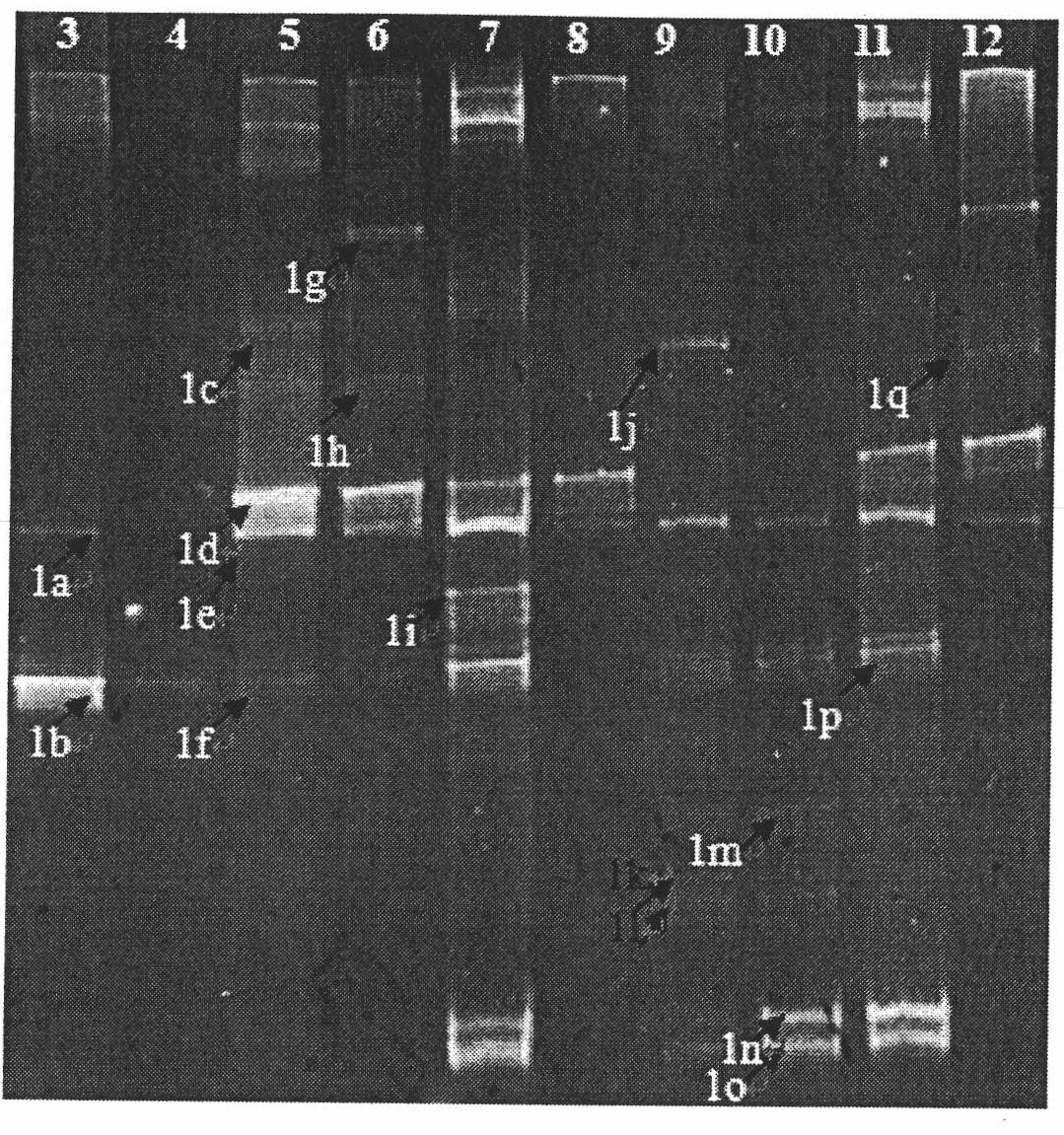

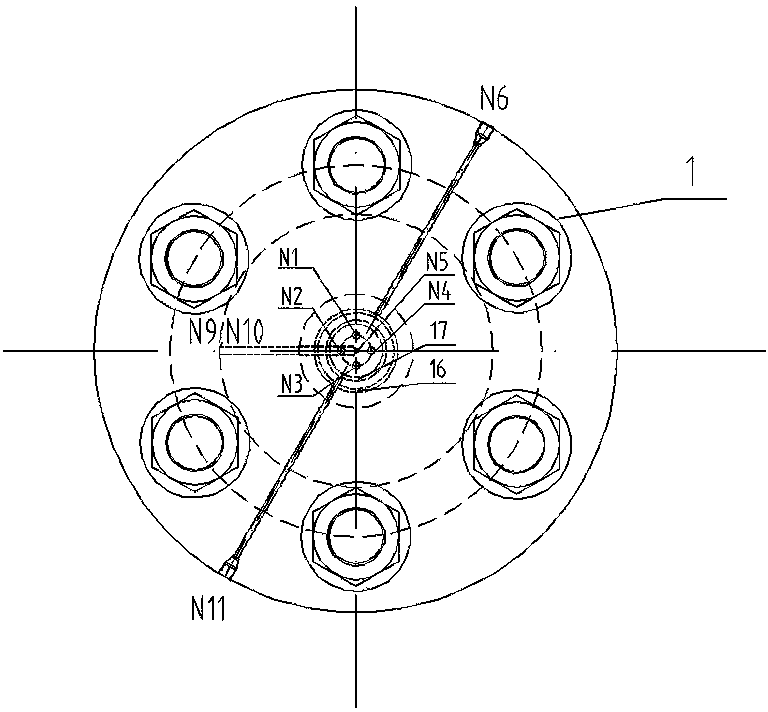

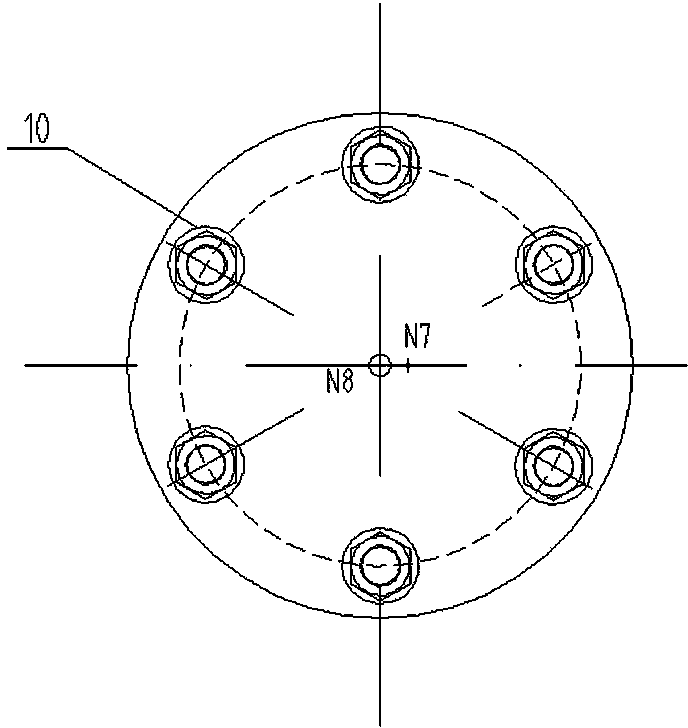

Dissolving method of hydrophobically associating polymer and special stretching device thereof

ActiveCN102059060AEORHigh application valueRotary stirring mixersEmulsificationImpellerPolymer flooding

The invention discloses a quick dissolving method of a hydrophobically associating polymer and a special stretching device thereof. The stretching device comprises a fixed grinding wheel fixed on a base and a moving grinding wheel arranged in the fixed grinding wheel, wherein a space is preserved between the moving grinding wheel and the fixed grinding wheel; the top of the moving grinding wheel is provided with a regulating ring; the moving grinding wheel is provided with grinding teeth; the bottom of the moving grinding wheel is provided with an impeller, and the impeller is arranged in theinner cavity of the base; the fixed grinding wheel is provided with an entrance corresponding to the moving grinding wheel; and the base is provided with an exit corresponding to the impeller. The invention also provides a method for applying the stretching device to dissolve the hydrophobically associating polymer. The hydrophobically associating polymer obtained by using the method can be used for a polymer flooding technologies under a high mineralization condition so as to improve the recovery efficiency of petroleum.

Owner:CHINA NAT OFFSHORE OIL CORP +1

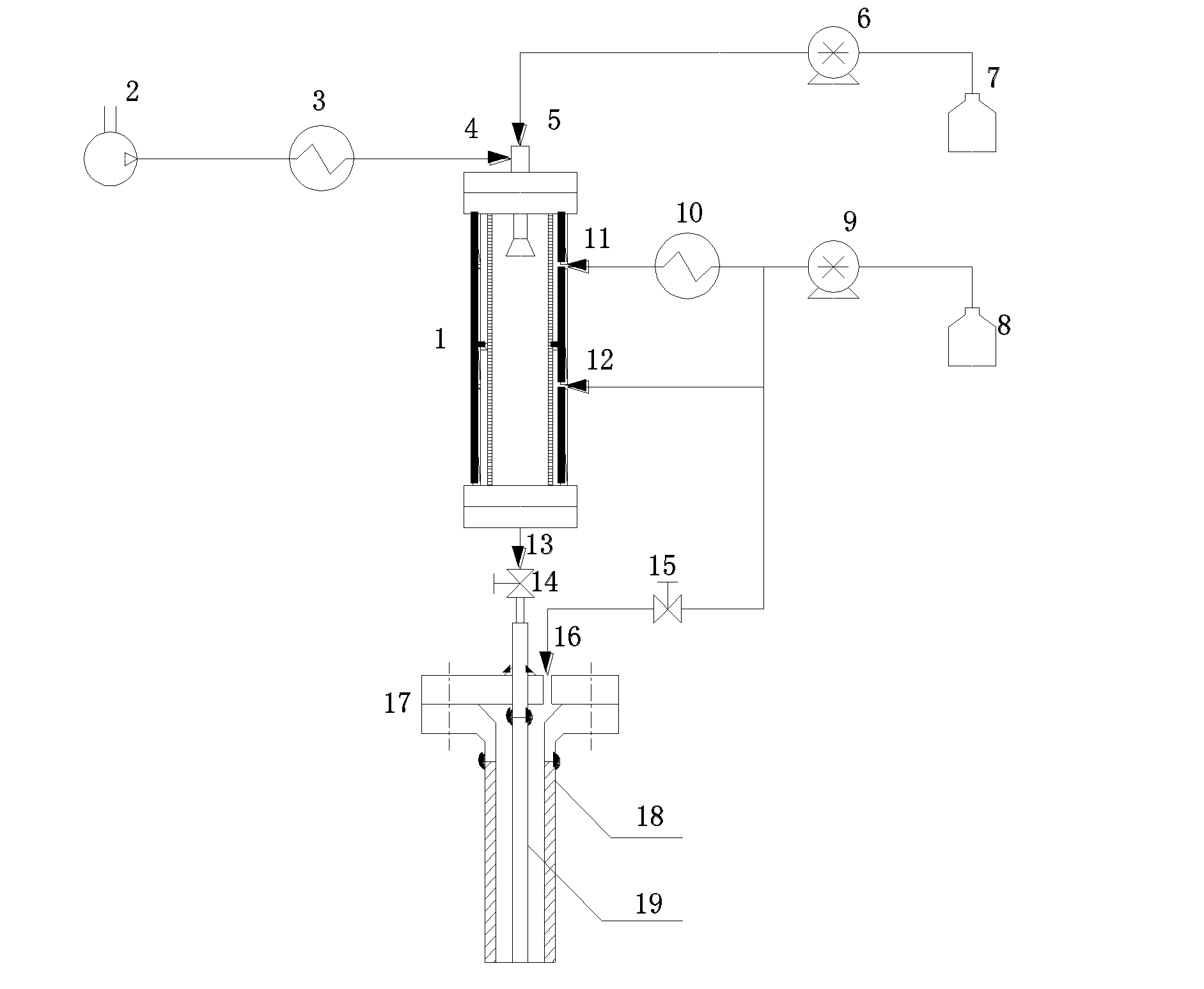

Injection production process of fluids produced by supercritical water oxidation

The invention relates to an injection production process of fluids produced by supercritical water oxidation fluids. The fuel is injected from the top of an evaporation wall reactor after being boosted to 22.1-30 MPa; the air is injected from the top of the reactor after being boosted to the same pressure and pre-heated to reach 300-500 DEG C. Evaporable water is injected from the side surface of the evaporation wall reactor in two branches after being boosted to the same pressure as the fuel; the initial temperature of the evaporable water in the upper branch after being pre-heated is 400-600 DEG C; the evaporable water in the lower branch is at normal temperature. After the supercritical water oxidation in the reactor starts, the evaporable water in the upper branch declines to 250-370 DEG C. The fluid in the reactor flows out from the outlet of the reactor and then is injected to the oil well through an injection pipe after being regulated to 5-30 MPa by a pressure regulating valve; and the evaporable water with the same pressure is injected to the annular space between the injection pipe and a shaft. According to the injection production process, the multiple hot fluids produced when the fuel is processed by the supercritical water oxidation are injected to the oil well, so that the viscosity of the thickened oil is reduced, the oil productivity is increased and the application prospect is wide.

Owner:SHANDONG UNIV

CO2 drive oil-gas-water separate well injecting oil reservoir mixing drive development method

ActiveCN102777157AExpand the affected volumeAir channeling controlFluid removalSweep efficiencyProduct gas

The invention provides a CO2 drive oil-gas-water separate well injecting oil reservoir mixing drive development method, and belongs to the field for improving recovery ratio of an oil reservoir. The method comprises the following steps of: firstly, determining a development well pattern, well spacing and a development layer system of the oil reservoir; then, utilizing an overall process numerical simulation technique to determine advantage seepage direction and sweep efficiency of injection gas, designing an injection well in the advantage seepage direction of the injection gas as a water injection well, designing other injection wells as a gas injection well, forming water-gas mixed drive of partial water injected to well and partial gas injected into well; and finally determining the injection parameter of an injection production well and the development index forecast of a whole region. The method can form a water barrier in a gas channeling direction, thereby effectively controlling gas channeling, enlarging swept volume of the injected gas, and improving recovery efficiency; and the method provided by the invention has excellent guiding function on the gas injection drive oil well pattern, well type and injection and production parameter of a developed block and an undeveloped block, and the application prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

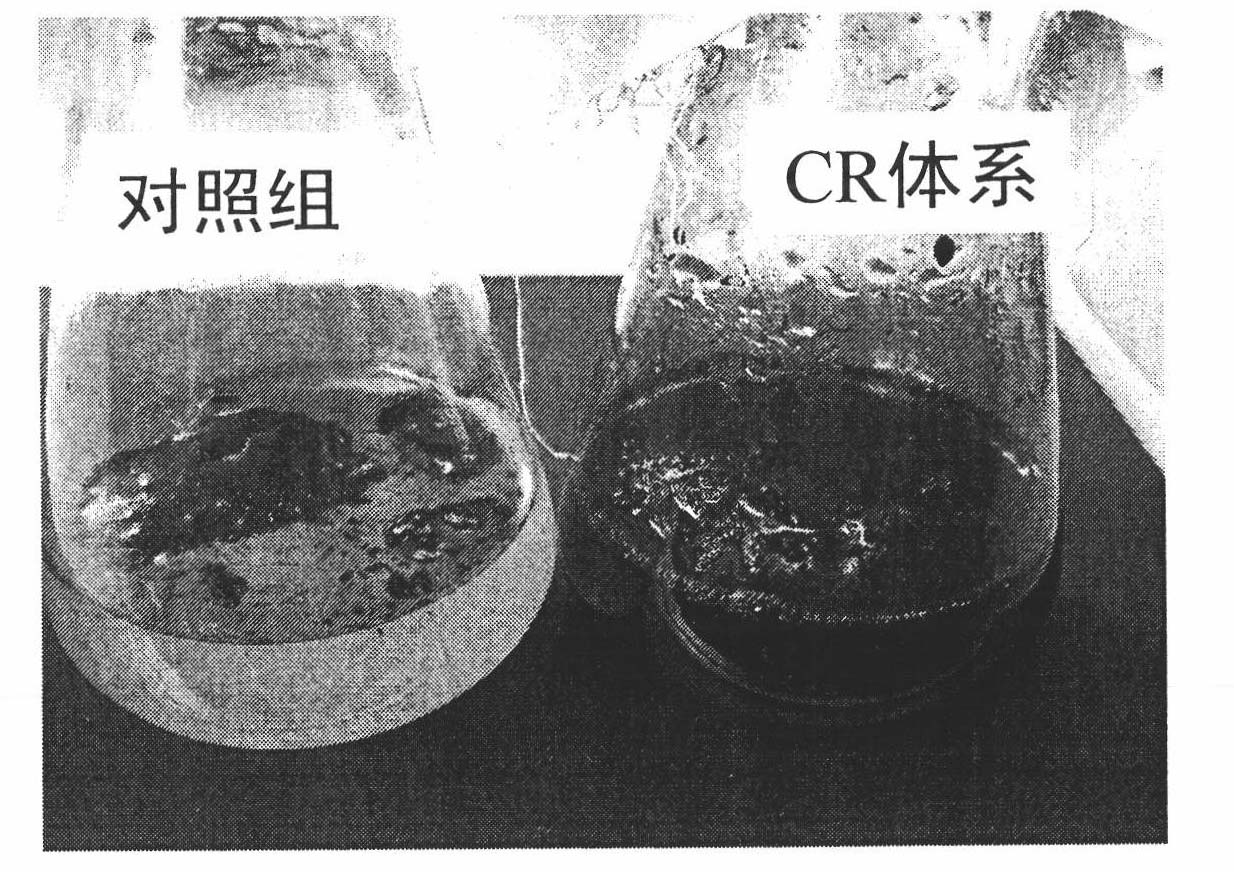

Method for increasing oil recovery ratio by utilizing symbiotic reproduction and complex metabolism and microbial preparation

The invention discloses a method for increasing the oil recovery ratio by utilizing symbiotic reproduction and complex metabolism and a microbial preparation, the CR-CM principle is mainly utilized for periodically injecting exogenous oil production microbes, an activating agent and air into a target oil layer, and an endogenous and exogenous oil production microbial new system (CR) is established in the oil layer by greatly activating endogenous oil production microbes. All the oil production microbes in the CR system are mutually linked through a biological chain through the technical control, and the complex metabolism (CM) which is conductive to oil production is further produced, thereby realizing the purposes of increasing the oil and increasing the recovery ratio under the dual-function of the oil production microbes and complex metabolites thereof. The method can not only increase the oil production, but also improve the oil reservoir conditions, increase the final recovery ratio by more than 4% and prolong the exploitation time by 3-5 years. For an oil field with high viscosity and high wax content, the method can reduce the viscosity of thick oil by more than 24%, reducea freezing point by 5-10 DEG C, increase the final recovery ratio by more than 5% and prolong the exploitation time by more than 5 years.

Owner:华汉生态修复新技术有限公司

Multilayer gas distribution full circulation carbonization furnace

ActiveCN101928582ASmall spray radiusHeating evenlyCoke oven safety devicesDirect heating destructive distillationHeat carrierSlag

The invention discloses a multilayer gas distribution full circulation carbonization furnace which comprises a furnace body, a discharge system and a slag discharge system, wherein the discharge system is arranged on the top of the furnace body, the slag discharge system is arranged at the bottom of the furnace body, the furnace body is divided into a carbonization section at the upper part and ageneration section at the lower part by an arched leg arranged at the middle part of the furnace body, a carbonization product outlet is arranged at the upper part of the carbonization section, an air supply system is arranged at the lower part of the generation section, a gas seal section which is communicated with a gas-seal gas inlet is arranged between the carbonization section and the generation section, and an annular gas distribution chamber which is communicated with an inner cavity of the carbonization section through a gas distribution hole and also communicated with a circulation gas inlet is arranged outside the carbonization section, a center gas collection cavity is arranged in the carbonization section, the upper end of the center gas collection cavity is closed, the lower end of the center gas collection cavity is communicated with the circulation gas inlet, a gas distribution hole is arranged at the middle part of the center gas collection cavity, and a generation gasoutlet is arranged at the upper part of the generation section. The invention has the advantages of small heat carrier jet radius, more uniform gas distribution and heating, high heating and oil production efficiency, and the like, can fundamentally avoid the oil firing phenomenon, makes up a blank of the kind of carbonization furnaces and is worthy of popularization and application.

Owner:中国寰球工程有限公司辽宁分公司 +1

Neutral blocking remover composition for oilfield oil extraction and preparation method thereof

ActiveCN104293333AImprove plugging efficiencyRestore permeabilityDrilling compositionButanedioic acidMethyl lactate

The invention relates to a neutral blocking remover composition for oilfield oil extraction, which is prepared from the following components in parts by weight: 30-35 parts of acrylic acid-methyl acrylate copolymer, 44-50 parts of diethylene triamine pentaacetic acid, 30-35 parts of sodium polyepoxysuccinate, 30-35 parts of amine malate, 10-14 parts of sodium alkyl sulfonate, 5-8 parts of amine hydroxy ethylidene diphosphate, 10-14 parts of hydrolyzed polyacrylamide, 12-17 parts of atlapulgite, 20-25 parts of sodium persulfate, 7-10 parts of sodium lignosulfonate, 5-8 parts of tannin, 12-16 parts of sodium malate, 5-8 parts of sodium sulfosuccinate, 5-8 parts of starch, 9-12 parts of methyl lactate, 0.2-0.3 part of vanadium pentoxide and 0.1-0.3 part of diisobutyl carbinol. The neutral blocking remover composition for oilfield oil extraction has the advantages of high blocking removal speed, no corrosivity due to neutrality and no dead area, can quickly dissolve the material scales, clean the oilfield stratum and remove blocking, and does not generate the phenomenon of precipitation or secondary blocking; and the cleaning waste liquid does not need to be subjected to sewage treatment after returning to the ground.

Owner:兰州熙瑞化工科技有限公司

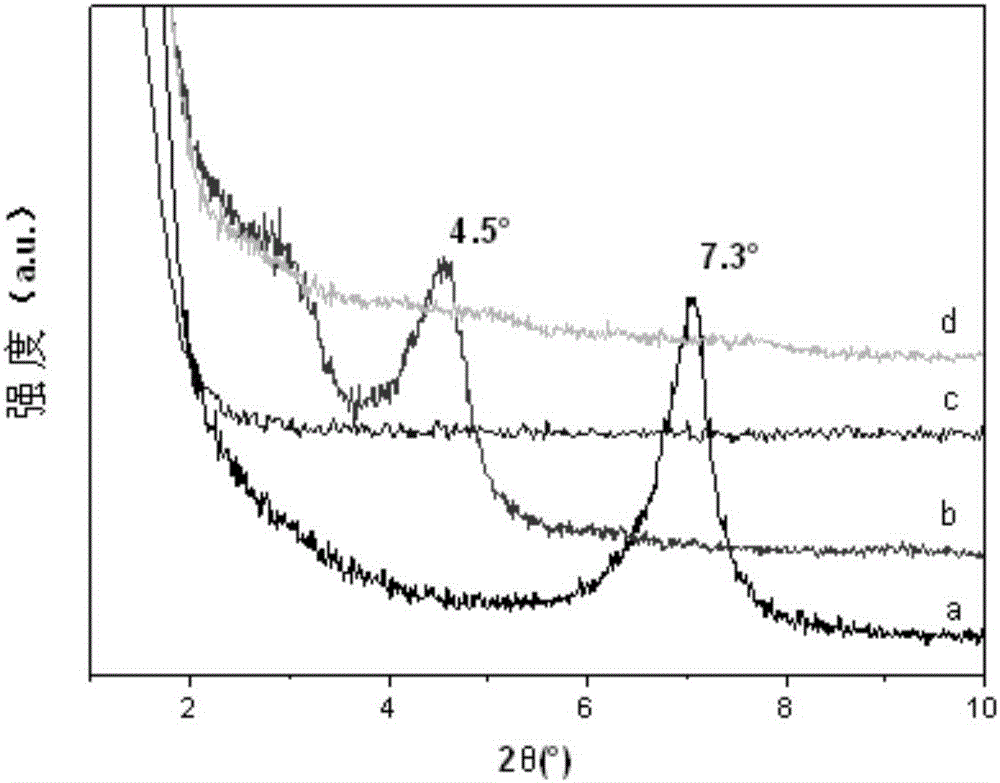

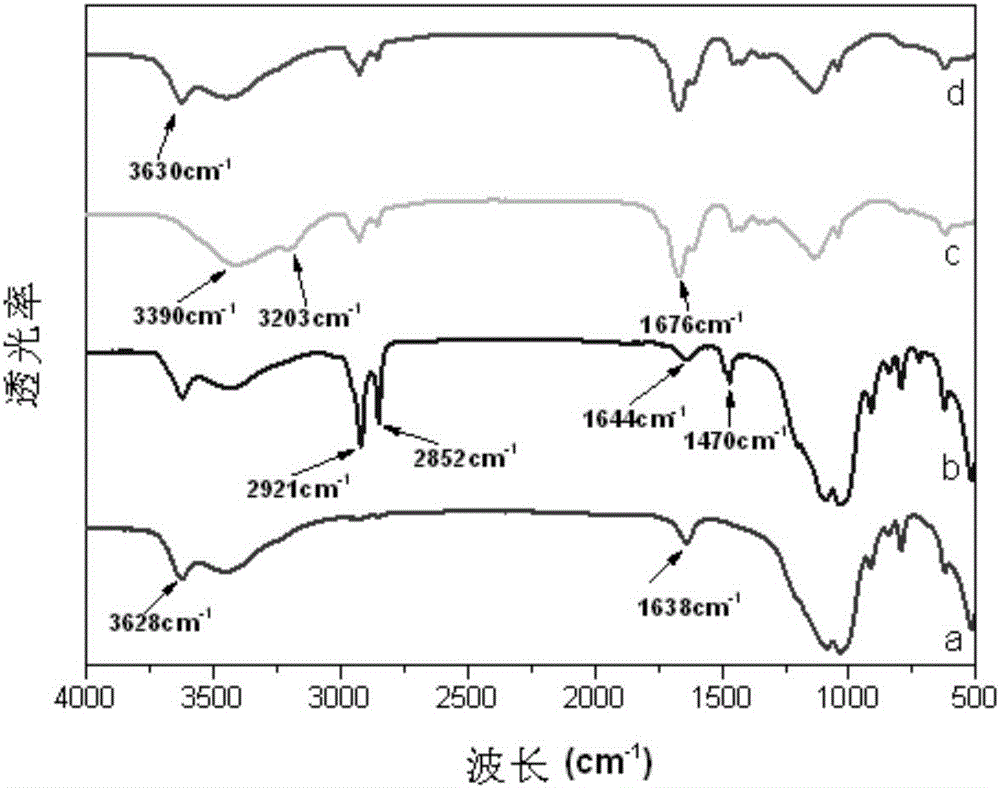

Viscoelastic weak gel profile control agent

ActiveCN101712865AAdjustable intensityGel forming time is adjustableDrilling compositionSulfite saltAmmonium chloride mixture

The invention discloses a viscoelastic weak gel profile control agent which is applied in oil field and oil well water injection operation. The viscoelastic weak gel profile control agent comprises the following components in parts by weight: 0.15-0.25 part of viscoelastic surface activity polymer, 0.05-0.15 part of cross-linking agent, 0.001-0.005 part of conditioning agent, and 99.8-99.6 parts of water. The viscoelastic surface activity polymer comprises the following components in parts by weight: 20-30 parts of acrylic amide, 1-2 parts of 3,3-dimethylacrylic acid, 1.5-3.5 parts of 2-acrylamido-2-dodecyl ethanesulfonic acid and / or 1-4 parts of N,N-dimethyl-allyl-hexadecyl ammonium chloride, 60-75 parts of deionized water and 0.3-1 part of initiating agent. The initiating agent comprises the following components in parts by weight: 2.5-3.5 parts of ammonium persulphate and 1 part of sodium sulfite. The viscoelastic weak gel profile control agent of the invention has a certain gel strength, capacity for lowering oil-water surface tensility and adjustable gel forming time, can improve water injection profile, lower oil-water surface tensility, wash away residual oil in a pore canal and improve water injection recovery ratio.

Owner:PETROCHINA CO LTD

Microbial oil recovery method

InactiveCN102213088APlay the role of growth metabolismHigh degree of degradationBacteriaMicroorganism based processesRecovery methodMicrobial oil

The invention discloses a microbial oil recovery method. By the method, the crude oil production rate of a field test is improved by 12.5 percent. The microbial oil recovery method provided by the invention comprises the following steps of: 1) carrying out pure oxygen aeration on a culture solution of petroleum hydrocarbon degrading bacteria to obtain an injection solution which is subjected to the pure oxygen aeration; 2) mixing the injection solution which is subjected to the pure oxygen aeration in the step 1) and a bacteria solution which contains the petroleum hydrocarbon degrading bacteria to obtain a mixed solution; and 3) injecting the mixed solution which is obtained in the step 2) into an oil reservoir by a production well for oil recovery to obtain crude oil. The content of dissolved oxygen in the injection solution is increased in a mode of carrying out pure oxygen aeration on the injection solution in a storage tank, so the activity of aerobic and / or facultative microbes can be effectively improved, life activity such as growth metabolism of the aerobic and / or facultative microbes is quickened, the degree of hydrocarbon degradation is improved, and the crude oil production can be improved.

Owner:PEKING UNIV

Green and environmentally friendly foam oil displacement system based on alkyl glycoside and preparation method and application thereof

ActiveCN106318358AGood dynamic stabilityGood blocking effectDrilling compositionChemistryPhysical model

The invention relates to a green and environmentally friendly foam oil displacement system based on alkyl glycoside and a preparation method and application thereof and belongs to the field of chemical oil displacement for improving oil field crude oil recovery rate. The foam oil displacement system is obtained by using the alkyl glycoside as a main surfactant and compounding the surfactant with an anionic surfactant and a cationic surfactant. The alkyl glycoside surfactant adopted by the oil displacement system is from a natural source, is green and environmentally friendly, the average polymerization degree of sugar moieties is 1.0-3.0, and hydrophobic carbon chain length is 8-12. Other surfactants are industrialized produced fine chemicals, raw materials are easy to obtain, and preparation is simple. The foam oil displacement system has the properties of good temperature resistance and oil resistance, good dynamic foam stability, strong plugging effect, good salt resistance, ultralow interfacial tension and the like, has good compatibility with other oil-displacing agents, the effect of improving crude oil recovery rate is obvious, and the recovery rate of an indoor physical model oil displacement test can be improved by about 20%-26% OOIP.

Owner:SHANDONG UNIV

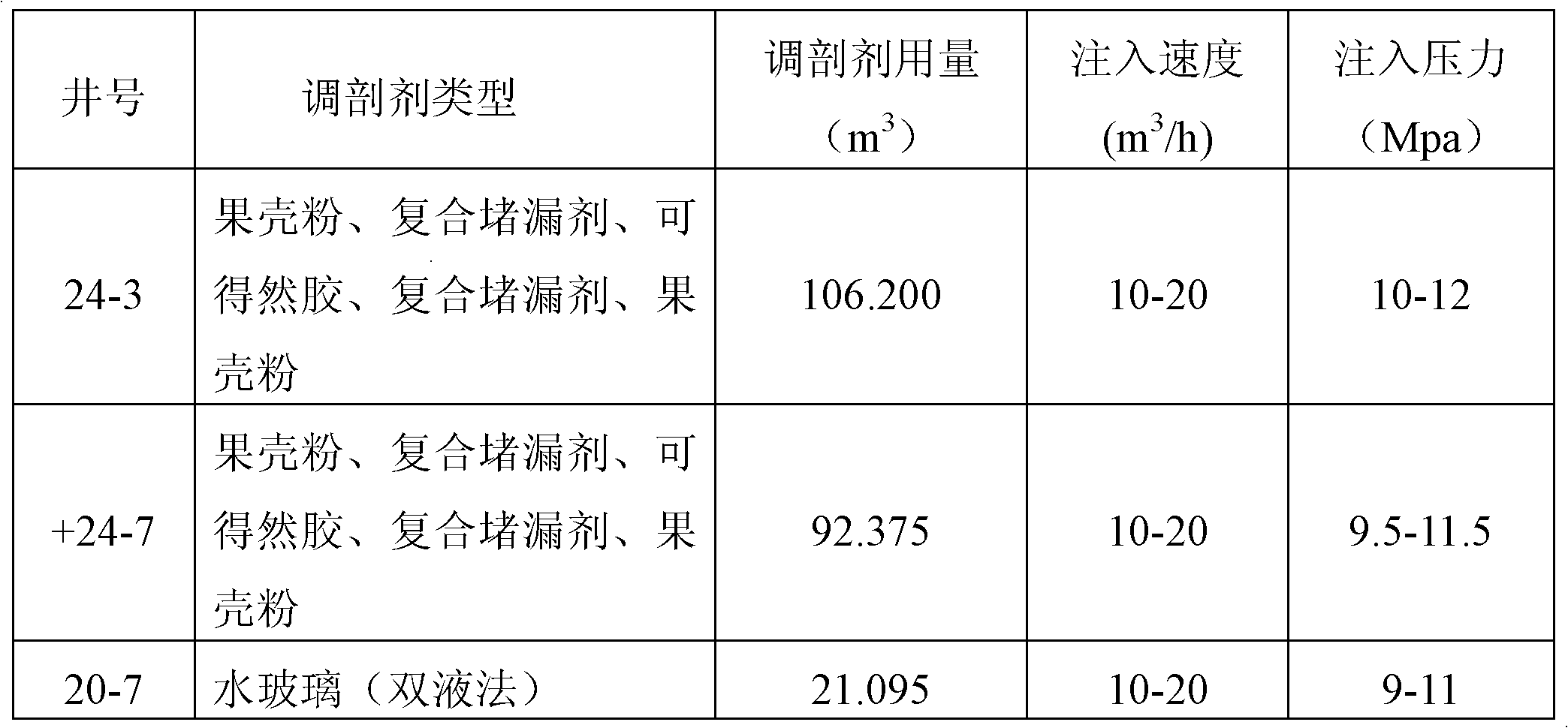

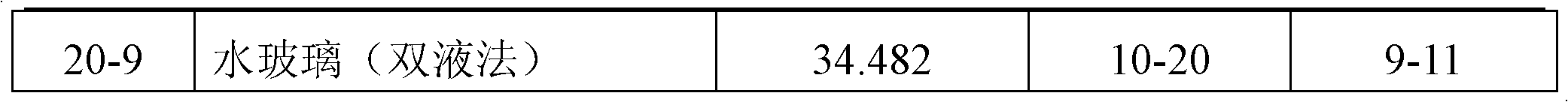

Application of curdlan as profile control agent in petroleum exploitation and application method

ActiveCN102627956AChange in permeabilityReduce penetrationDrilling compositionHigh intensityPetroleum

The invention discloses an application of curdlan as a profile control agent in petroleum exploitation and an application method. The application method comprises the following steps of: (1) cooling a water injection well pipeline which needs plugging to 20-30 DEG C; (2) uniformly stirring fruit shell powder with water, injecting the mixed solution into the water injection well pipeline while stirring, and stopping injection when pressure at the port of the water injection well is observed; and (3) according to the injection method in the step (2), respectively injecting a composite plugging agent, curdlan, the composite plugging agent and the fruit shell powder, continuously injecting steam into the water injection well pipeline after injection of all the raw materials, and carrying out oil extraction. Used as a profile control agent, curdlan has advantages of high intensity of a gelling system, good plugging performance, strong compatibleness with stratum water and strong stability, which can guarantee validity during its application process, and also can be used for well completion and well workover after drilling well, fracturing and tertiary oil recovery.

Owner:SHENGTAI BIOENG CO LTD OF JILIN WANTONG PHARMACY GRP CO

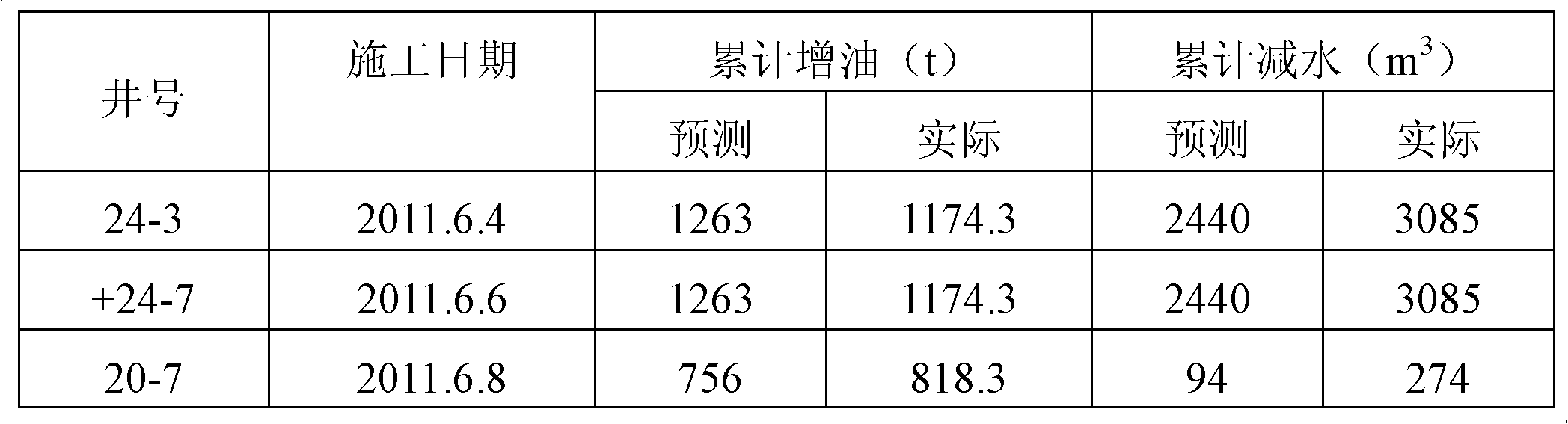

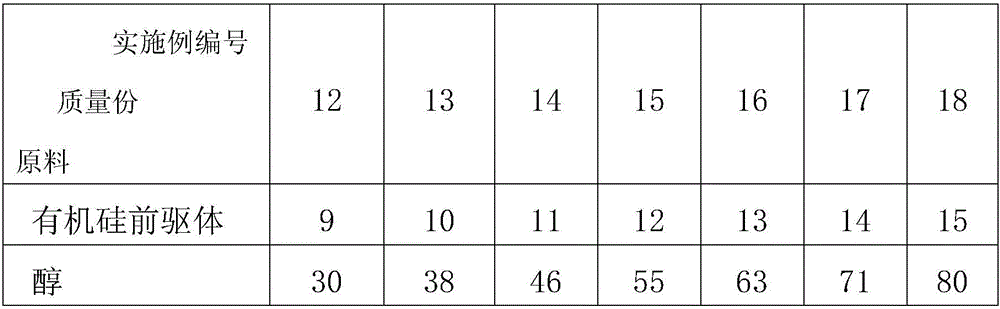

Preparation method of propping agent coated with superhydrophobic polymeric membrane

ActiveCN106147744AReduce contact areaAdhesionFluid removalDrilling compositionAlcoholShale oil and gas

The invention discloses a preparation method of a propping agent coated with a superhydrophobic polymeric membrane. The preparation method is characterized by comprising the steps that an organosilicone precursor and alcohol are mixed, the pH value is regulated to be 12-13 through alkali liquor, reacting is conducted for 0.5-5 h at the temperature of 30 DEG C to 70 DEG C, and then fluorosilane is added for reacting; liquor obtained after reacting and linear resin are mixed, and the temperature of the mixed liquor is increased to 70 DEG C to 100 DEG C; a curing agent is added, after the mixed liquor and a propping agent are mixed to be cured for 1-3 h at the temperature of 90 DEG C to 120 DEG C, curing is conducted for 1-3 h by increasing the temperature to 150 DEG C to 200 DEG C, and then the propping agent coated with the superhydrophobic polymeric membrane is prepared. According to the preparation method, the contact angle between the surface of the prepared polymeric membrane and water is larger than 150 degrees, the hydrophobicity of the surface of the propping agent can be greatly improved, the propping agent modified with the polymeric membrane serves as a key material of a hydrofracture technique, the exploitation quality of shale oil and gas can be improved, the exploitation yield of the shale oil and gas can be increased, and the practicability is high.

Owner:SOUTHWEAT UNIV OF SCI & TECH

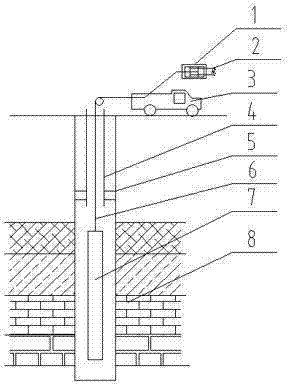

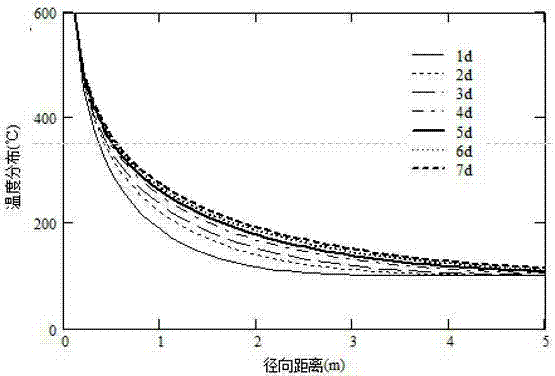

Method for relieving water blocking at high temperature in oil and gas exploitation process

The invention discloses a method for relieving water blocking at a high temperature in the oil and gas exploitation process. According to the method, an electrical heating rod is lowered into a reservoir stratum segment and is heated to a certain temperature, heat is transferred into a formation water blocking area through a casing pipe and a cement sheath, formation fluid in gaps is heated to evaporate and flow into a shaft, and then damages caused by water blocking can be avoided. The diameter of the electrical heating rod is 4 / 5 the inner diameter of the casing pipe of the reservoir stratum segment; the length of the electrical heating rod should be equal to the thickness of the reservoir stratum segment, and the electrical heating rod can be formed by connecting a plurality of fixed-length heating rods in series; the electrical heating rod should be parallel to the reservoir stratum segment when lowered into the reservoir stratum segment; the heating temperature of the electrical heating rod ranges from 300 DEG C to 600 DEG C, and the heating time is estimated. Principles are reliable, and the method is easy and convenient to implement, capable of effectively solving the problem of formation water blocking and suitable for barefoot well completion as well as cased hole completion and has broad application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

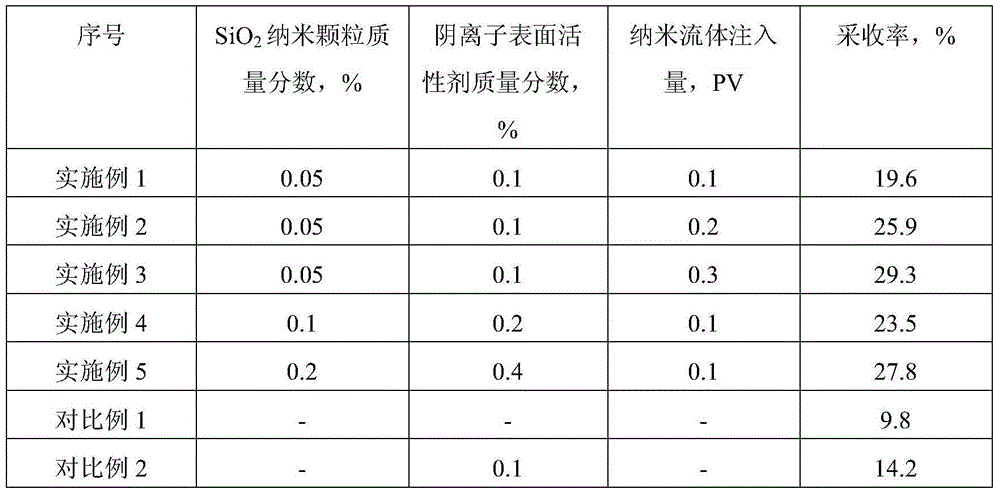

Method for mining tight oil reservoir by nanometer fluid

ActiveCN104594859AEOREnhanced overall recoveryFluid removalDrilling compositionOil productionPetrology

The invention relates to a method for mining a tight oil reservoir by nanometer fluid. The method comprises the following steps that a nanometer fluid segment plug is injected into the tight oil reservoir, then, water is injected into the oil reservoir through an injecting well, and the exploitation is carried out, and the water injecting speed needs to be smaller than 1.4m / d. According to the method provided by the invention, the nanometer fluid segment plug can invert the oil-wet tight oil reservoir into the water-wet reservoir, and the subsequently injected water can enter a substrate in a dialysis way under the effect of capillary force, so that rest oil in the substrate is used. The sudden water flooding due to fast fluid channeling of the injected water along the cracks can be avoided through low-speed water injection, and the stratum energy after the once oil production of the tight oil reservoir can be supplemented through the water injection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Primary explosive for reservoir gas power production increase

The invention discloses a primary explosive for reservoir gas power production increase. The primary explosive mainly comprises the following raw materials in percentage by weight: 28%-32% of potassium chlorate, 10%-14% potassium hyperchlorate, 24%-28% of barium nitrate, 3%-8% of ammonium nitrate, 8%-20% of aluminum powder, and 7%-18% of magnesium powder. The primary explosive also comprises 0.5%-1.5% of fluorous rubber as an adhesive. The primary explosive is not necessarily conveyed into rock gaps on the bottom of an oil well, so that the operation method is greatly simplified, the exposition effect is good, the ignition success rate reaches 100%, the oil production rate is effectively increased, and the primary explosive is safe and reliable, and has low cost.

Owner:XI'AN PETROLEUM UNIVERSITY

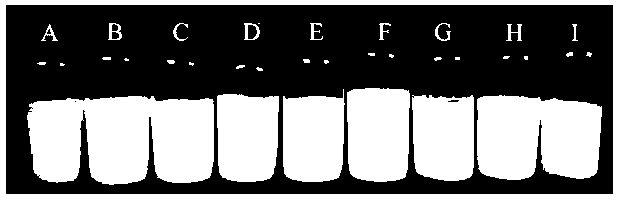

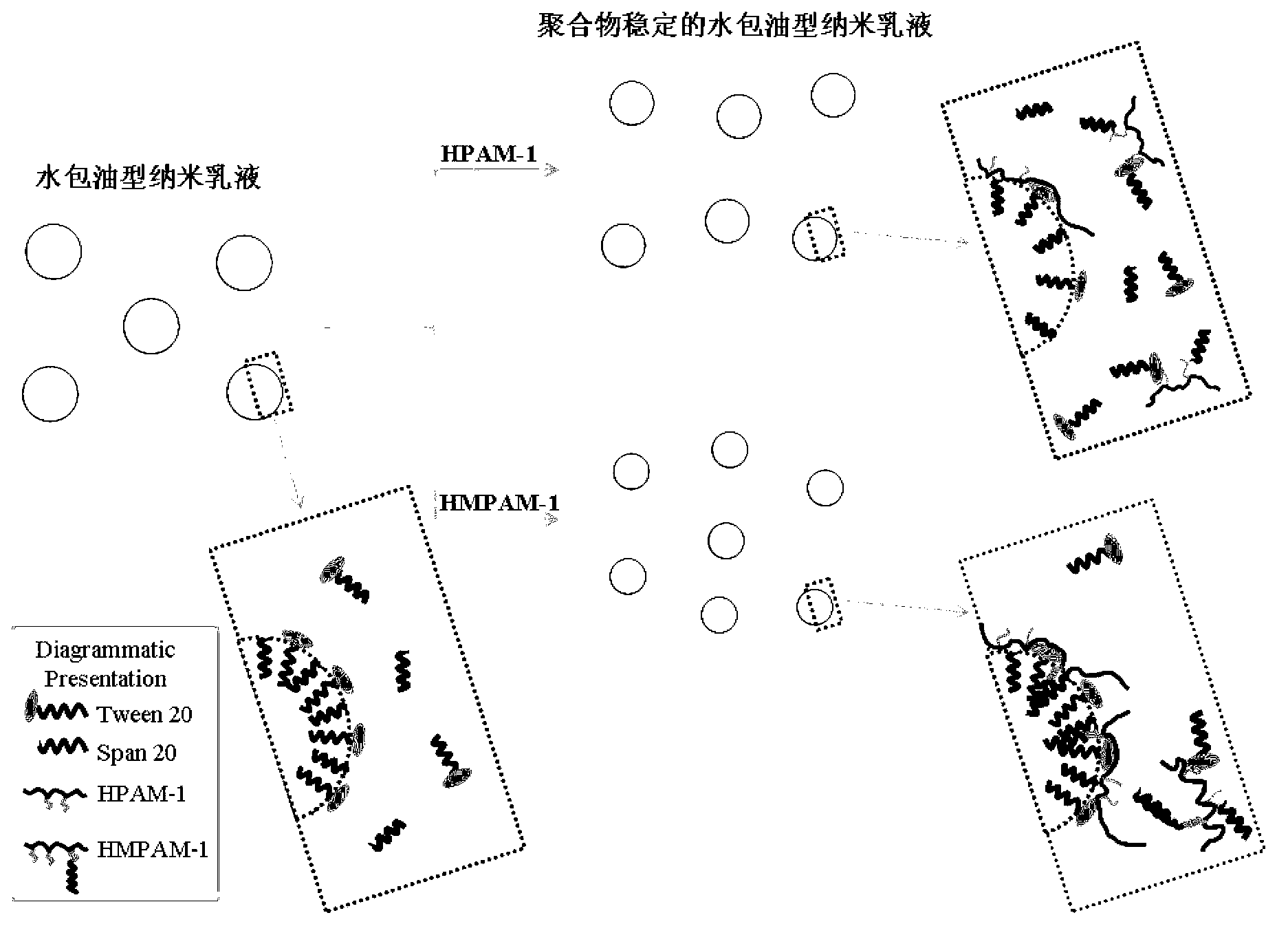

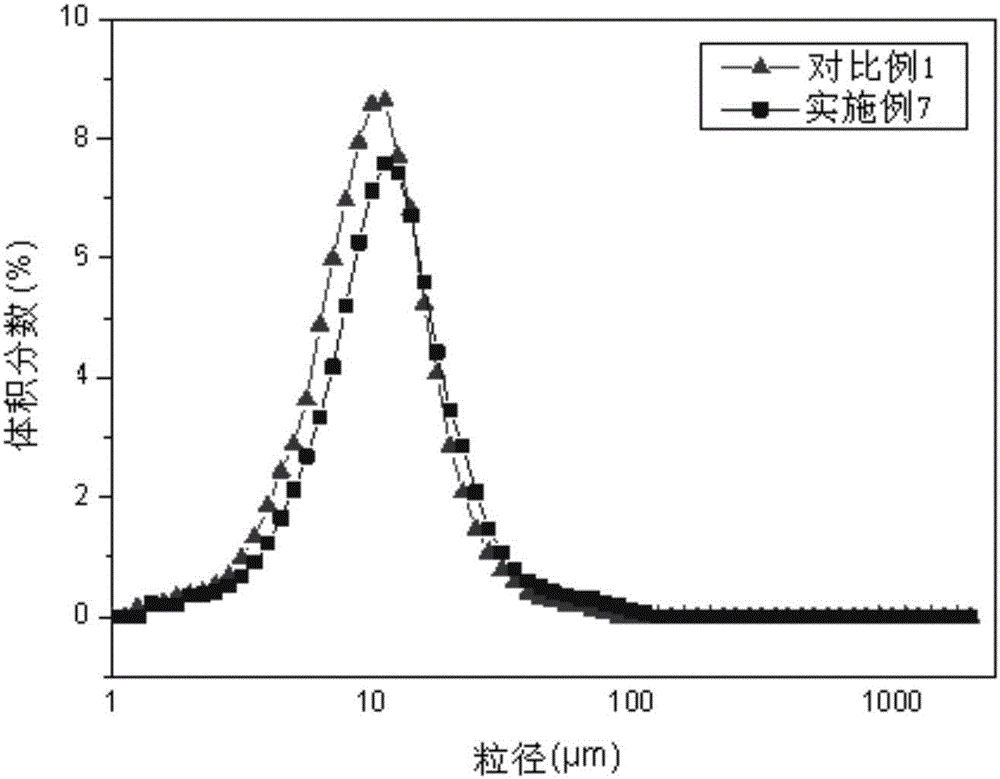

Preparation method for nano-emulsion with stable polymers

ActiveCN103191670ANarrow particle size distributionImprove long-term stabilityTransportation and packagingMixingOil phaseNanometre

The invention relates to a preparation method for nano-emulsion with stable polymers. The nano-emulsion comprises the following components in 100 parts by weight: 20-60 parts of oil phases, 5-10 parts of nonionic surfactants, 7*10<-5>-7*10<-2> parts of polymers and the balance of water. The preparation method comprises the following steps of: proportioning the nonionic surfactants into mixed emulgators by adopting a constant-temperature invert emulsion method, mixing the mixed emulgators with the oil phases, and dripping the mixture into aqueous phase containing the polymers under a high-speed stirring condition, so as to form the stable nano-emulsion. The preparation method has the characteristics that the components are simple, the operation is easy, the particle diameter of the prepared oil-in-water nano-emulsion is fine, the kinetic stability is durable, the energy consumption is small, and the cost is low.

Owner:SHANDONG UNIV

Surfactant as well as preparation method and application thereof

The invention provides a surfactant as well as a preparation method and an application thereof. The surfactant comprises the following components by mass percent: 45%-65% of aliphatic alcohol polyoxyethylene ether sulfonate, 20%-35% of a cationic surfactant and 10%-20% of a surfactant assistant, wherein a molecular formula of the aliphatic alcohol polyoxyethylene ether sulfonate is CnH[2n+1]-(CH2CH2O)m-SO3Na, n is an any integer ranging from 12 to 15, and m is an any integer ranging from 2 to 5. The invention further provides the preparation method for the surfactant and the application of the surfactant to tertiary oil recovery of a carbonate reservoir. The surfactant is independently used, does not need to be added with alkali, and is free of damage to a stratum and an oil well; an oil washing system prepared from the surfactant can effectively change the wettability of a rock surface and strip off crude oil adsorbed on the surface of a carbonate rock, and the oil washing efficiency reaches more than 60%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

New continuous production stabilization and efficient interactive blockage removal method for high water later oil reservoir of oil field

InactiveCN102230371AImprove the development effectEnhanced overall recoveryFluid removalDrilling compositionOil fieldTar

The invention provides a new continuous production stabilization and efficient interactive blockage removal method for the high water later oil reservoirs of an oil field. The method comprises the following steps of (1) backwashing a well for two days, and filling clear water in the wellhole; (2) calculating and preparing a corresponding amount of acid-resistant and oil soluble temporary plugging agent before the well is backwashed completely; (3) squeezing the temporary plugging agent from a sleeve, and replacing the temporary plugging agent by clear water until the temporary plugging agent enters the strata completely; (4) closing the well and waiting on cement for one day; and (5) continuously removing the blockages in an acidizing manner by adopting the conventional blockage removal technology. The problem that the tar productivity of high water oil well is not high by the conventional acidic blockage removal technology is solved; the temporary plugging agent is used for blocking a high-permeability layer; the pollution to a low permeability layer is relieved; the low permeability layer is released; and the high permeability layer is not polluted; the blockage removal is interacted, so that the aim of improving the tar productivity is finally fulfilled, and technical assurance is provided for stabilizing production of high water oil fields.

Owner:NORTHEAST GASOLINEEUM UNIV +1

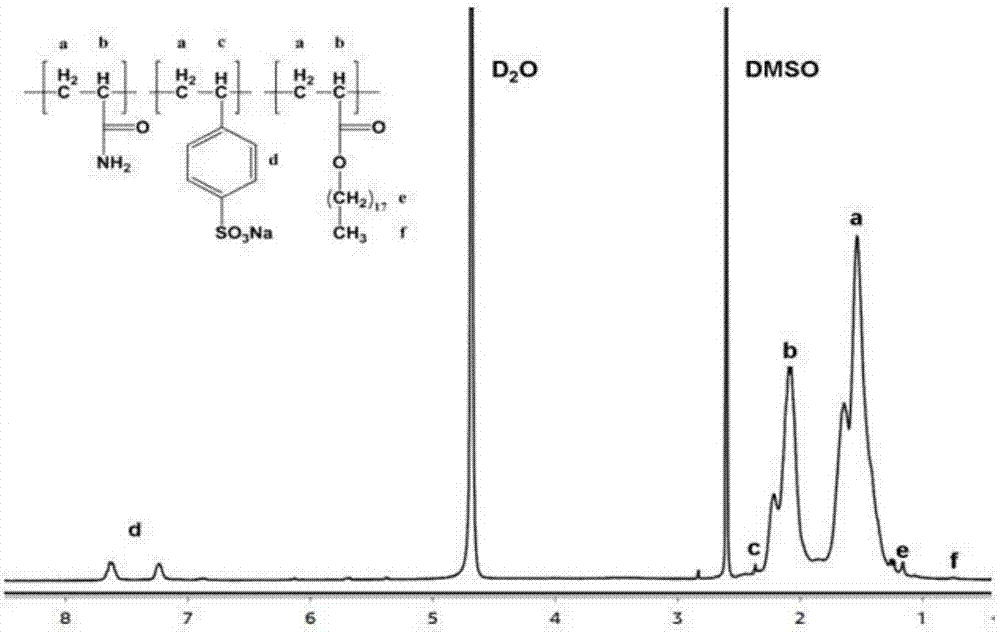

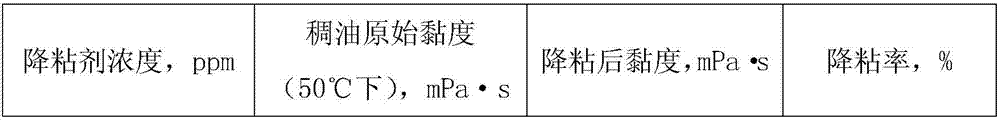

Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN107955592AImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityRaw material

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

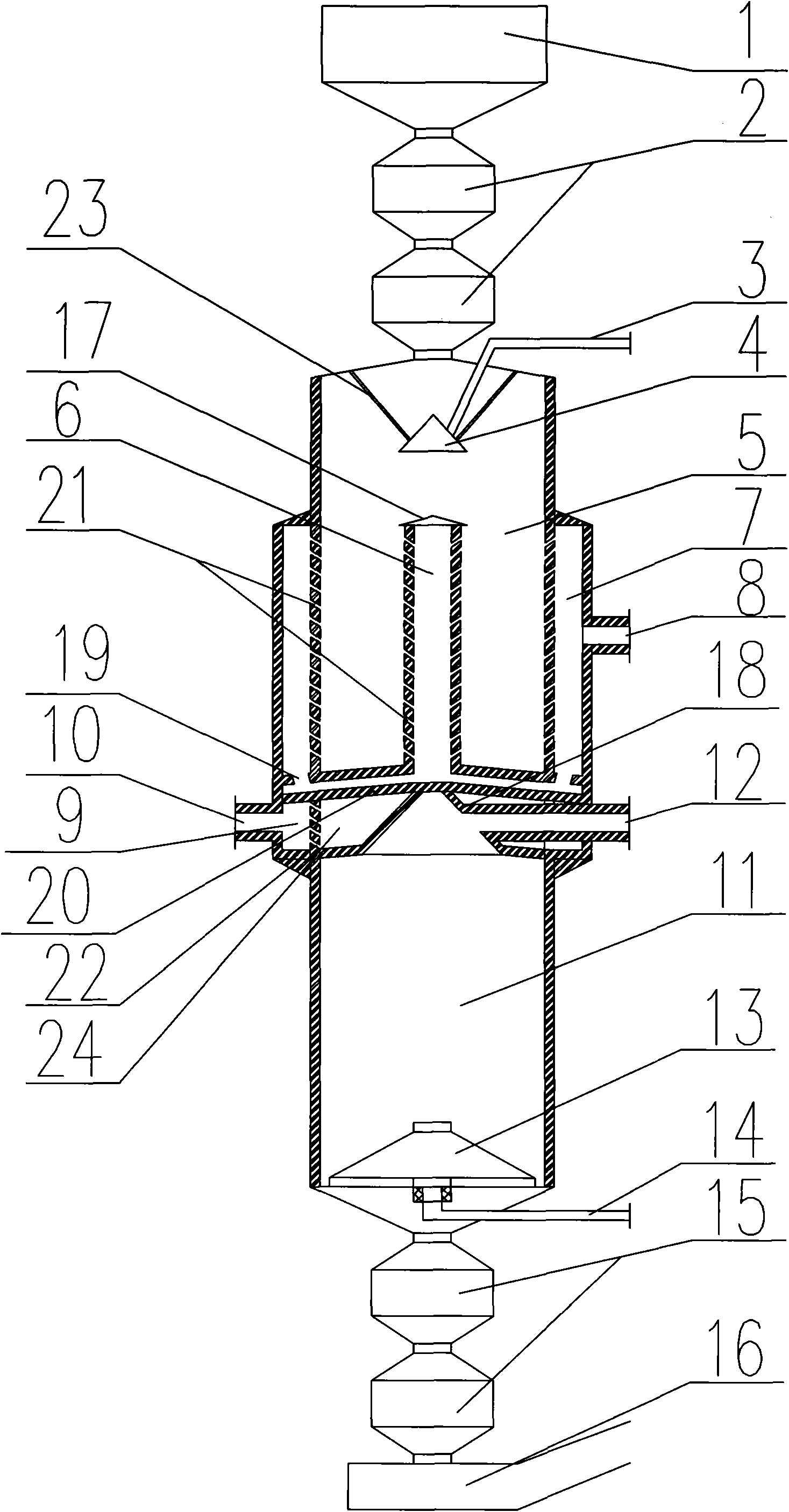

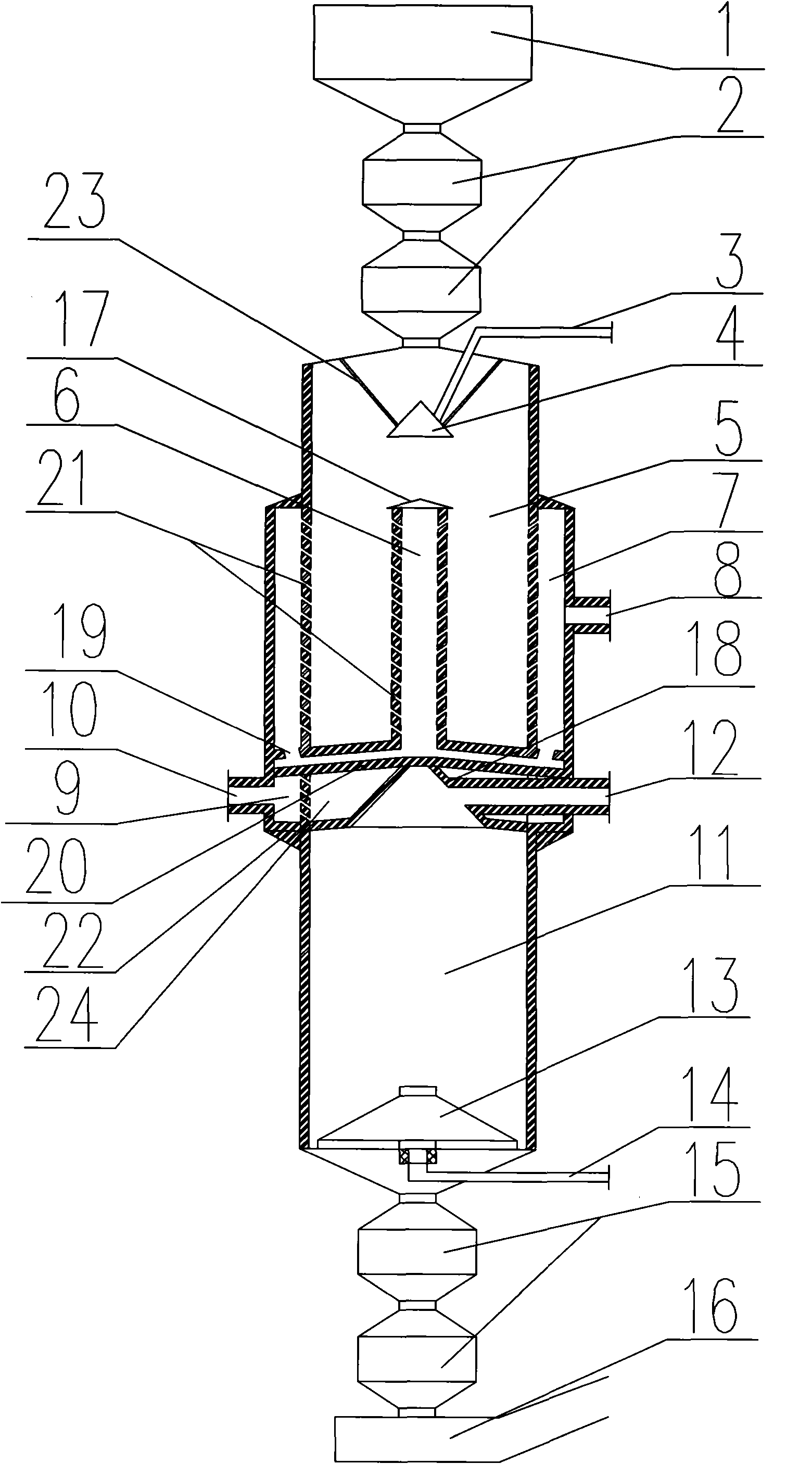

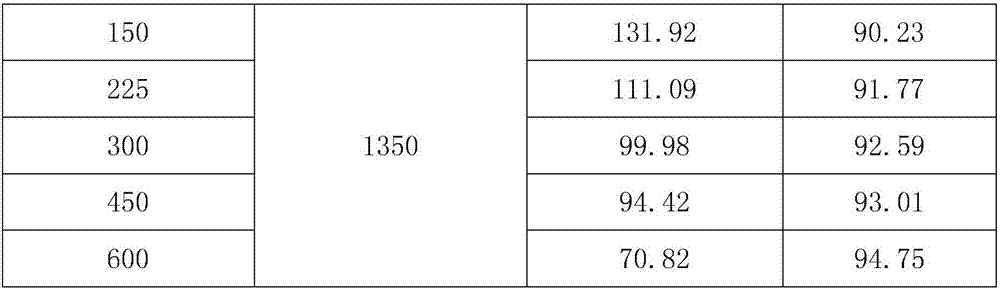

Supercritical water heat combustion reactor for thick oil injection production

InactiveCN103900094AStable combustionGood for burnoutFluid removalIncinerator apparatusCombustion chamberThermodynamics

The invention belongs to the field of energy and environments, and particularly relates to a supercritical water heat combustion reactor for thick oil injection production. The supercritical water heat combustion reactor for thick oil injection production comprises a reaction chamber, an upper top cover and a lower bottom cover, wherein the reaction chamber is hollow, openings are formed in the upper end and the lower end of the reaction chamber respectively, the upper top cover is connected with the opening formed in the upper end of the reaction chamber in a sealed mode, the lower bottom cover is connected with the opening formed in the lower end of the reaction chamber, and a closed space is formed by the reaction chamber, the upper top cover and the lower bottom cover; a cylindrical stepped hollow portion is formed in the center of the upper top cover, a stepped hollow portion on the lower portion of the cylindrical stepped hollow portion serves as a combustor, a stepped hollow portion on the upper portion of the cylindrical stepped hollow portion serves as a communicated fuel inlet, an annular groove is formed in the outer side of the lower end of the stepped hollow portion on the upper portion of the cylindrical stepped hollow portion, the lower portion of the annular groove is communicated with the combustor, and the annular groove is communicated with an oxidizing agent inlet formed in the side face of the upper top cover; a mixing chamber is arranged at the bottom of the combustor, an annular gap formed between the upper top cover and the reaction chamber is formed in the side of the combustor, and the annular gap is communicated with a supplementary water inlet formed in the side face of the reaction chamber.

Owner:TAIYUAN UNIV OF TECH

Nano composite core-shell particle oil-displacing agent and preparation method and application thereof

The invention provides a nano composite core-shell particle oil-displacing agent and a preparation method and an application thereof. The preparation method for the nano composite core-shell particle oil-displacing agent comprises the following steps: 1) mixing an acrylamide monomer with deionized water, then adding a crosslinking agent, and stirring, to obtain an acrylamide aqueous-phase system; 2) mixing the emulsifier with an organic solvent, then loading an oil-displacing surfactant layered silicate, and stirring to obtain an oil-phase system; and 3) under a protection atmosphere and stirring, slowly adding the oil-phase system to the acrylamide aqueous-phase system, then adding an initiator, carrying out a polymerization reaction, and after the completion of the reaction, demulsifying, filtering, and drying to obtain the nano composite core-shell particle oil-displacing agent. The nano composite core-shell particle oil-displacing agent can form ultra low interfacial tension with crude oil, and greatly improves the recovery ratio of petroleum; in addition, in the oil-displacing process, the oil-displacing agent is not easily adsorbed and eluted, the surfactant loss is low, and thus the oil production cost is facilitated to be reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

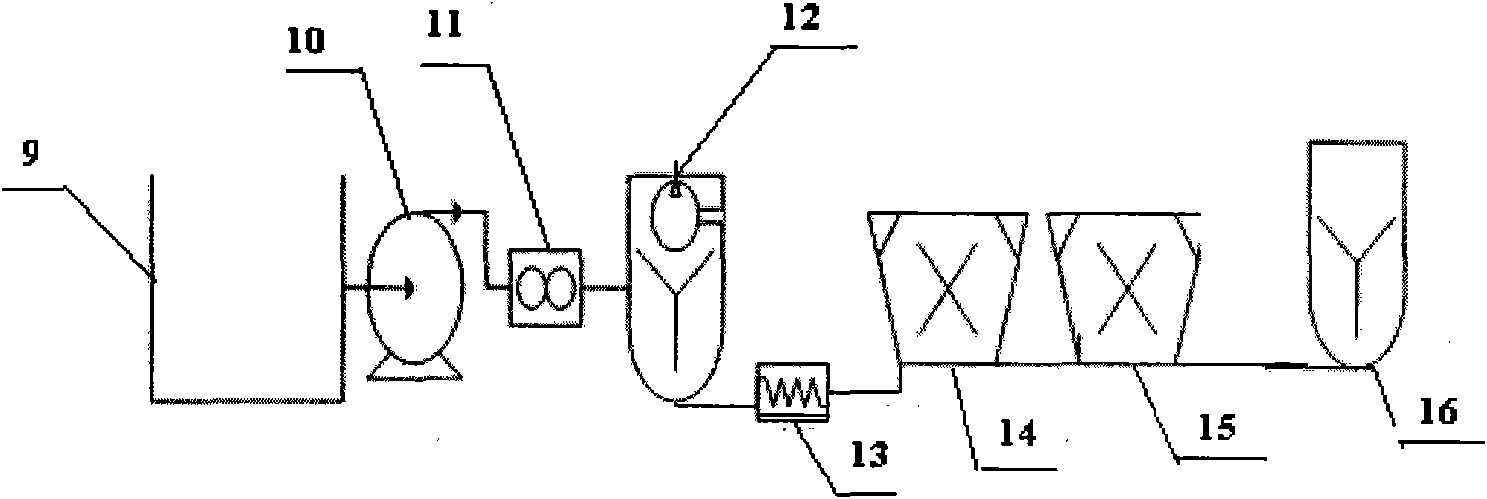

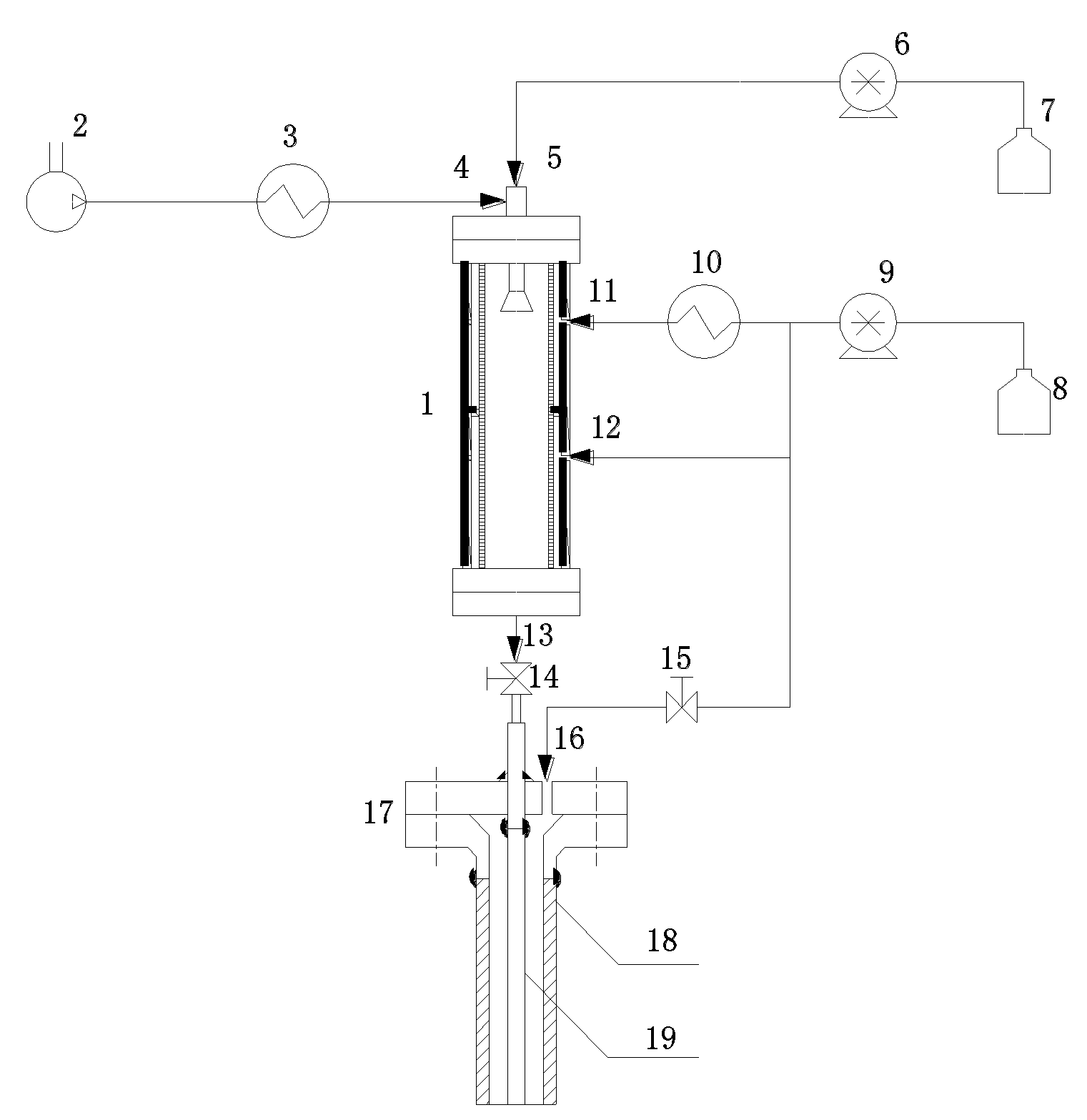

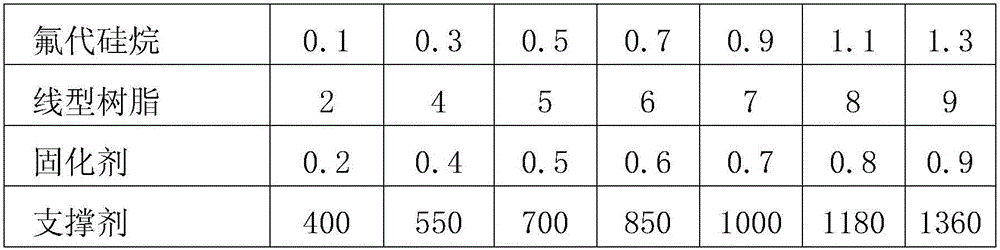

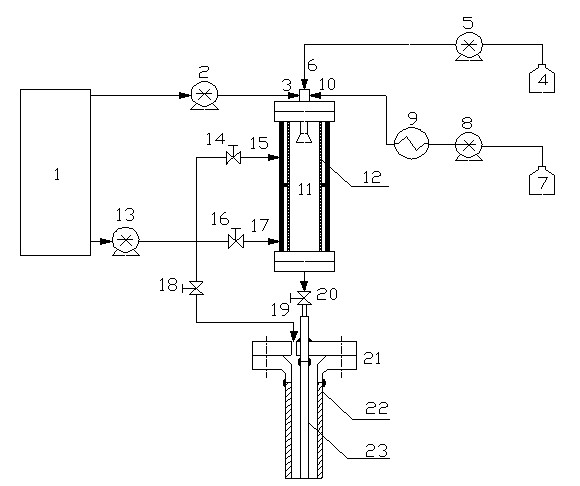

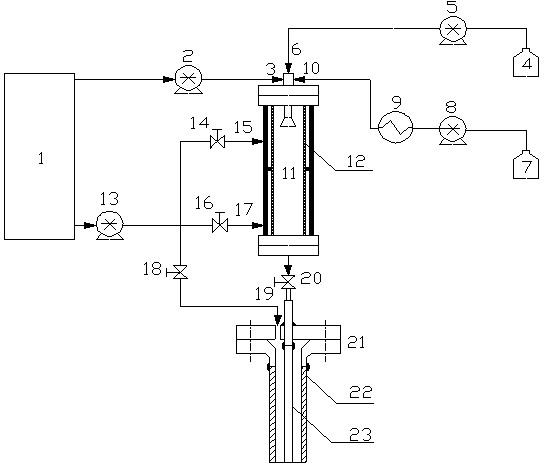

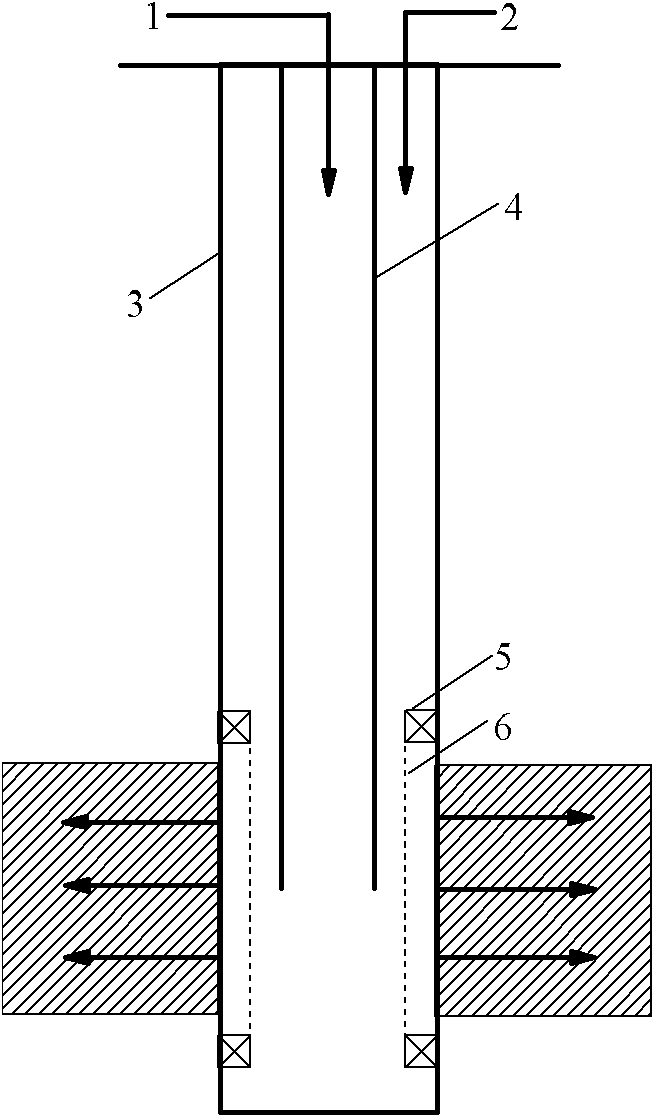

Supercritical water oxidation fluid injection production system using nitrogen as protective film and process using same

The invention discloses a supercritical water oxidation fluid injection production system using nitrogen as a protective film. The injection-production system comprises an air separation plant, an air film reactor, a shaft and an injection pipeline disposed in the shaft. An oxygen outlet of the air separation plant is communicated with an oxygen inlet at the upper end of the air film reactor through an oxygen booster pump. A nitrogen outlet of the air separation plant is communicated with an upper nitrogen inlet, a lower nitrogen inlet and a gap between the shaft and the injection pipeline through a nitrogen booster pump. The upper nitrogen inlet and the lower nitrogen inlet are reserved on one side of the air film reactor. A fuel inlet and a water inlet which are communicated with a fuel device and a water booster heating device respectively are reserved at the upper end of the air film reactor. An outlet which is communicated with the injection pipeline is reserved at the lower end of the air film reactor. The invention further discloses an injection-production process using the system. Oxygen is used as oxidant and the nitrogen is used as a protective film of the reactor and the shaft, fuel is oxidized through supercritical water, generated multiple thermal fluids are injected into an oil well, and accordingly, viscosity of thickened oil is lowered and oil recovery rate is enhanced.

Owner:SHANDONG UNIV

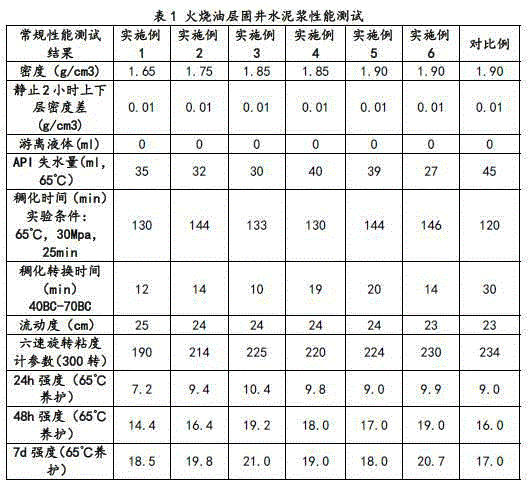

Well cementation cement system for in-situ combustion

ActiveCN105018056AReduce water lossThickening time controllableSolid waste managementDrilling compositionAluminatePolyvinyl alcohol

The invention discloses a well cementation cement system for in-situ combustion. The well cementation cement system for the in-situ combustion comprises, by weight, 50 parts of G-class oil well cement, 50 parts of aluminate cement, 20 parts of coal ash, 20 parts of quartz sand, 14 parts of micro silicon, 1.4 parts of sodium lignin sulfonate, 0-15 parts of iron ore powder, 0.6-1 part of retarder and 1.6-2 parts of fluid loss agents; the retarder adopts one of calcium hydrophosphate, sodium citrate and D-sodium gluconate or a composition of the calcium hydrophosphate, the sodium citrate and the D-sodium gluconate, and the fluid loss agents adopt one of polyvinyl alcohol, AM / AA / AMPS copolymers and sodium polystyrene sulfonate or a composition of the polyvinyl alcohol, the AM / AA / AMPS copolymers and the sodium polystyrene sulfonate. According to the well cementation cement system for the in-situ combustion, the requirements that the in-situ combustion reaches to temperature up to 600 DEG C to 700 DEG C in oil thermal recovery can be met, the advantages of being high in compression resistance strength, low in permeability and good in set cement stability and homogeneity at 600 DEG C to 700 DEG C are achieved, and the site construction requirements can be met.

Owner:四川凯尔油气田技术服务有限公司

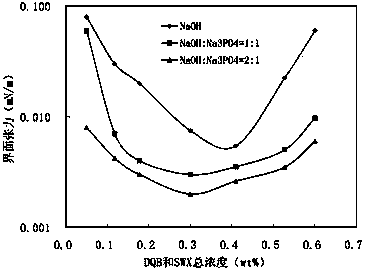

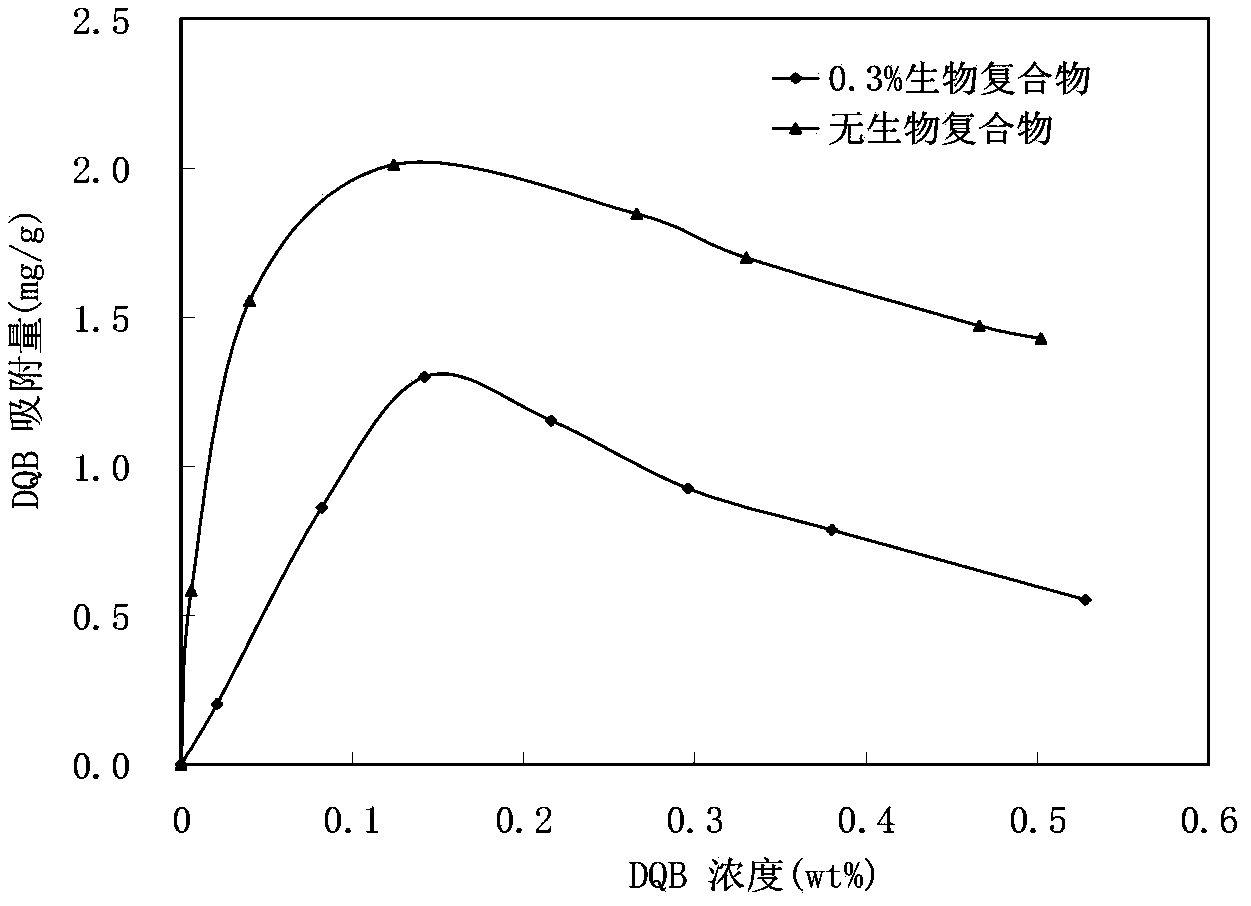

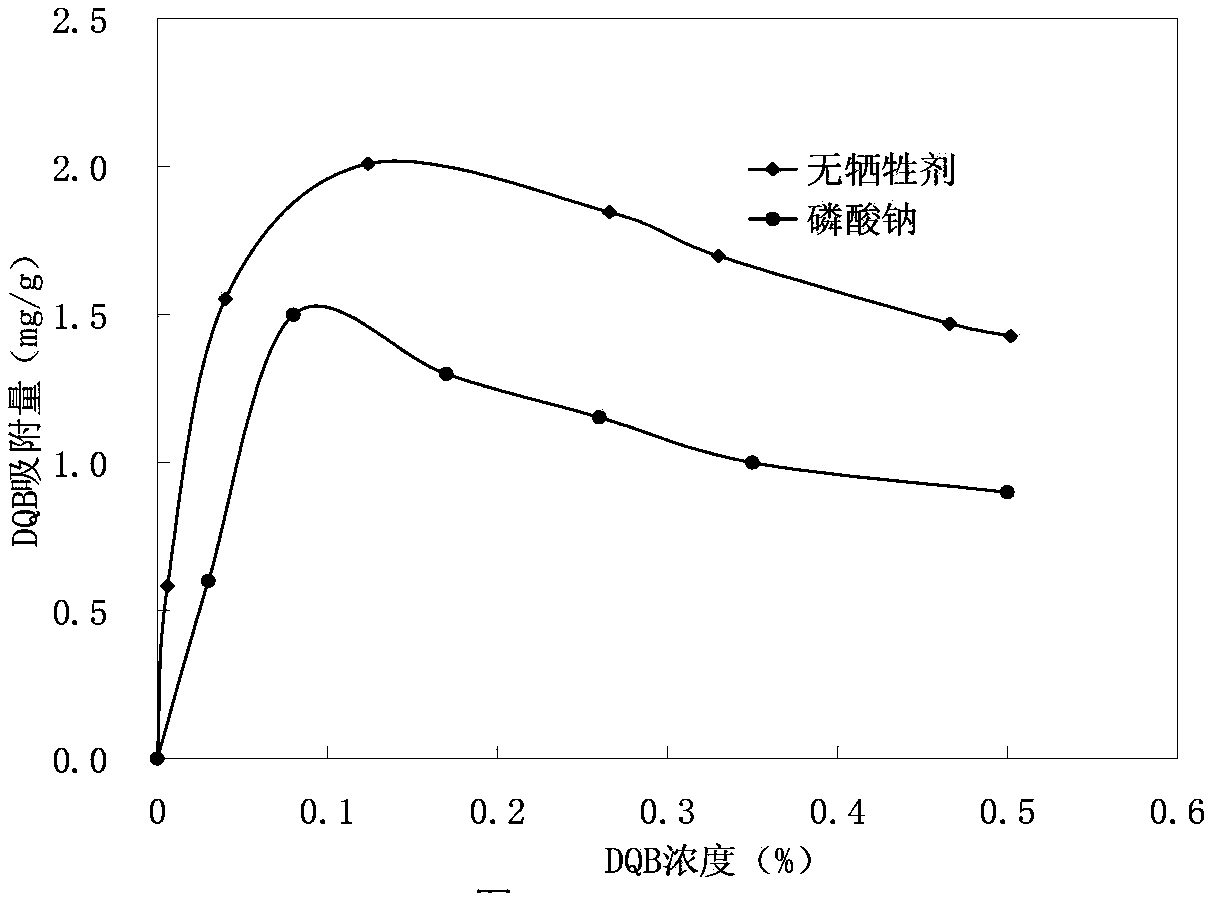

Composite oil displacing agent

ActiveCN104073231AProtective viscosityReduce the amount of adsorptionDrilling compositionDual effectSodium phosphates

The invention relates to a composite oil displacing agent, which is composed of sodium alkyl benzene sulfonate, a bio-compound, NaOH, Na3PO4, polymer and injected water. An organic bio-compound (a rhamnose ester mixture), which is cheaper than the surfactant, is added into the composite system to use as a sacrificial agent. The bio-compound will carry out competition adsorption against the surfactants on the rock surface, thus the adsorption of surfactants on the rock surface will be decreased, and the utilization rate of surfactants with a higher price is increased. At the same time, a synergetic effect is generated between the bio-compound and the surfactants, and the interface activity of the composite system is increased. The using amount of strong alkali (NaOH) is reduced by utilizing the dual effect of reducing the interface tensile of sodium phosphate after the interface adsorption of the sacrificial agent.

Owner:PETROCHINA CO LTD

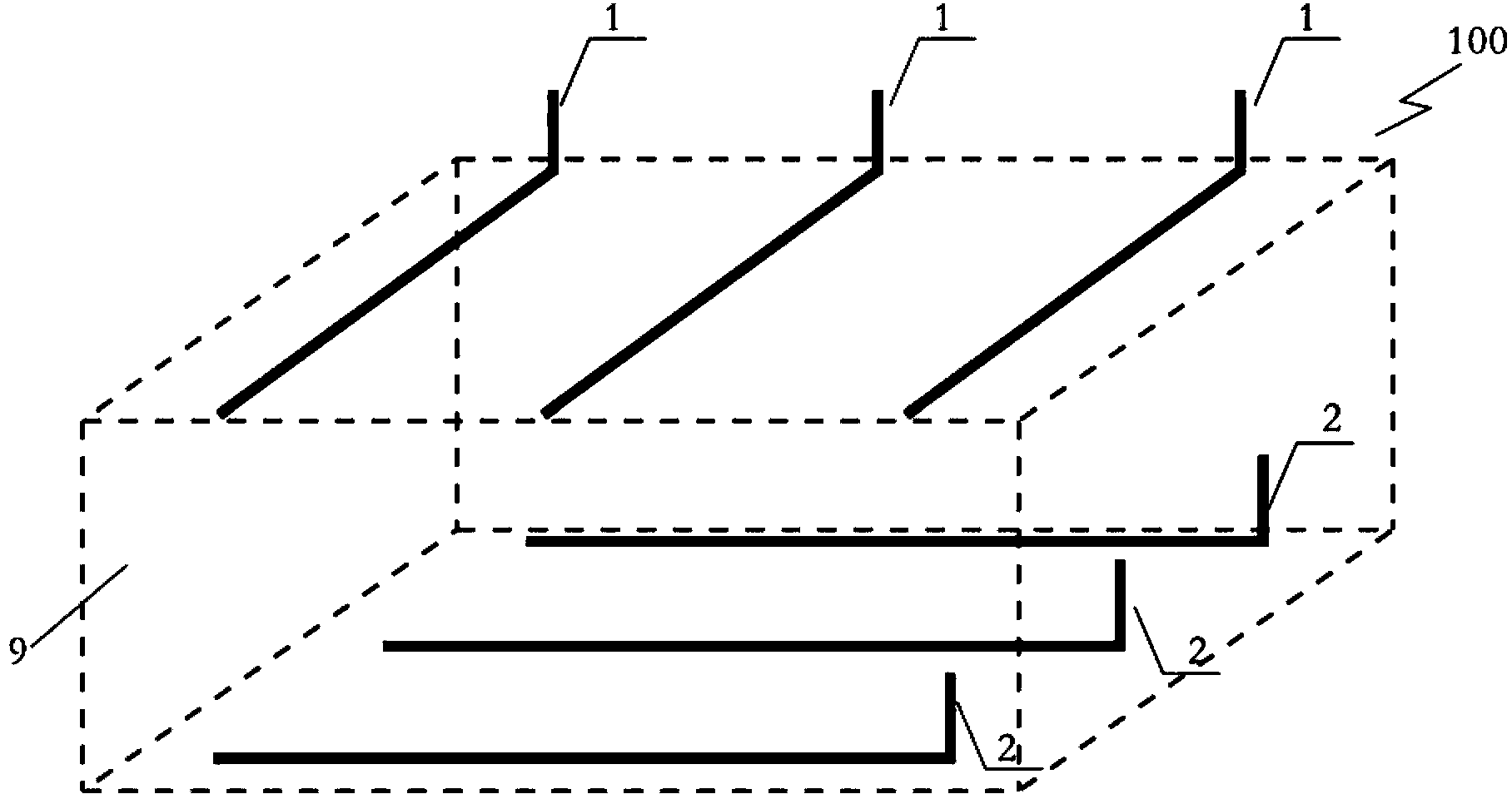

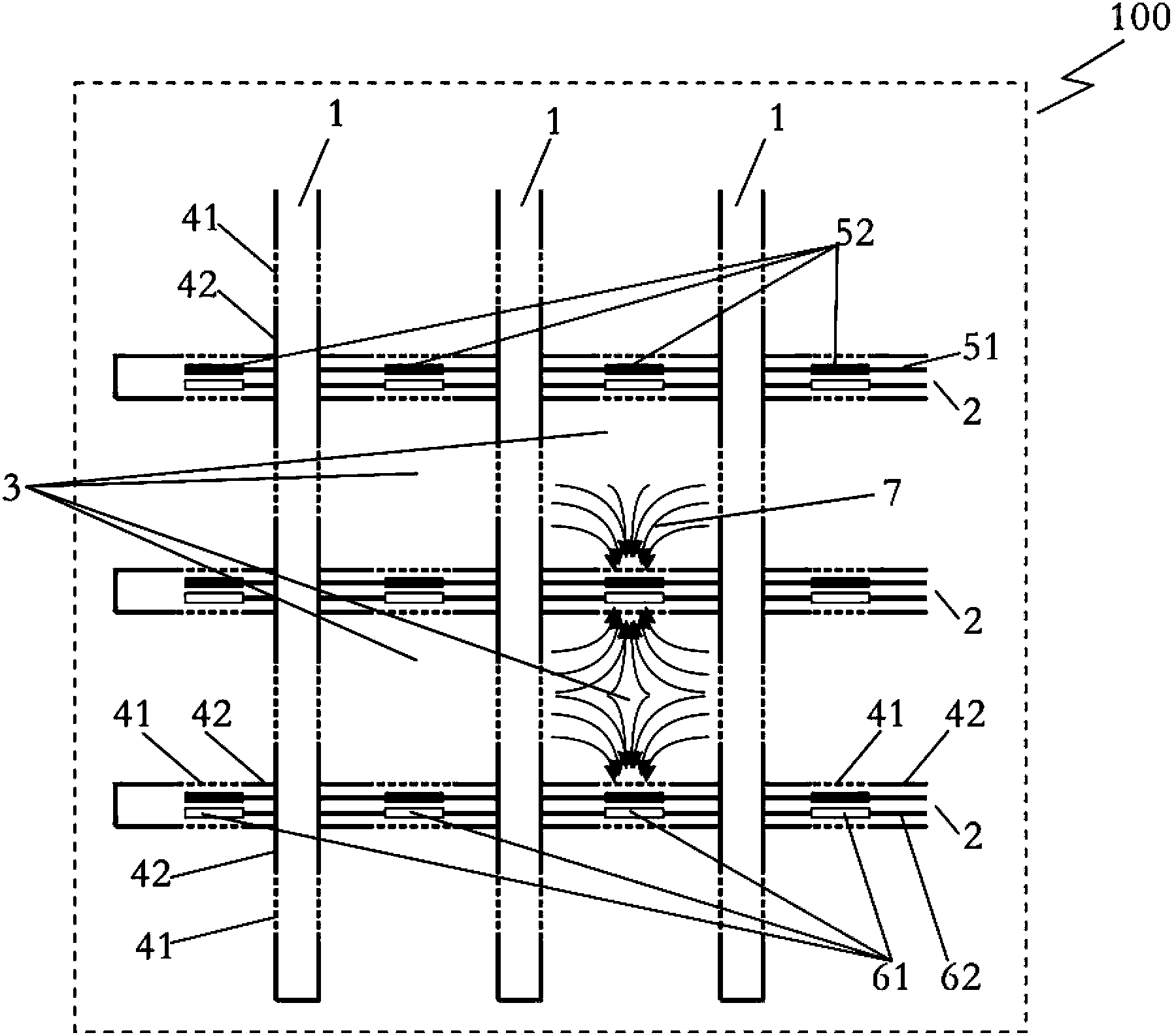

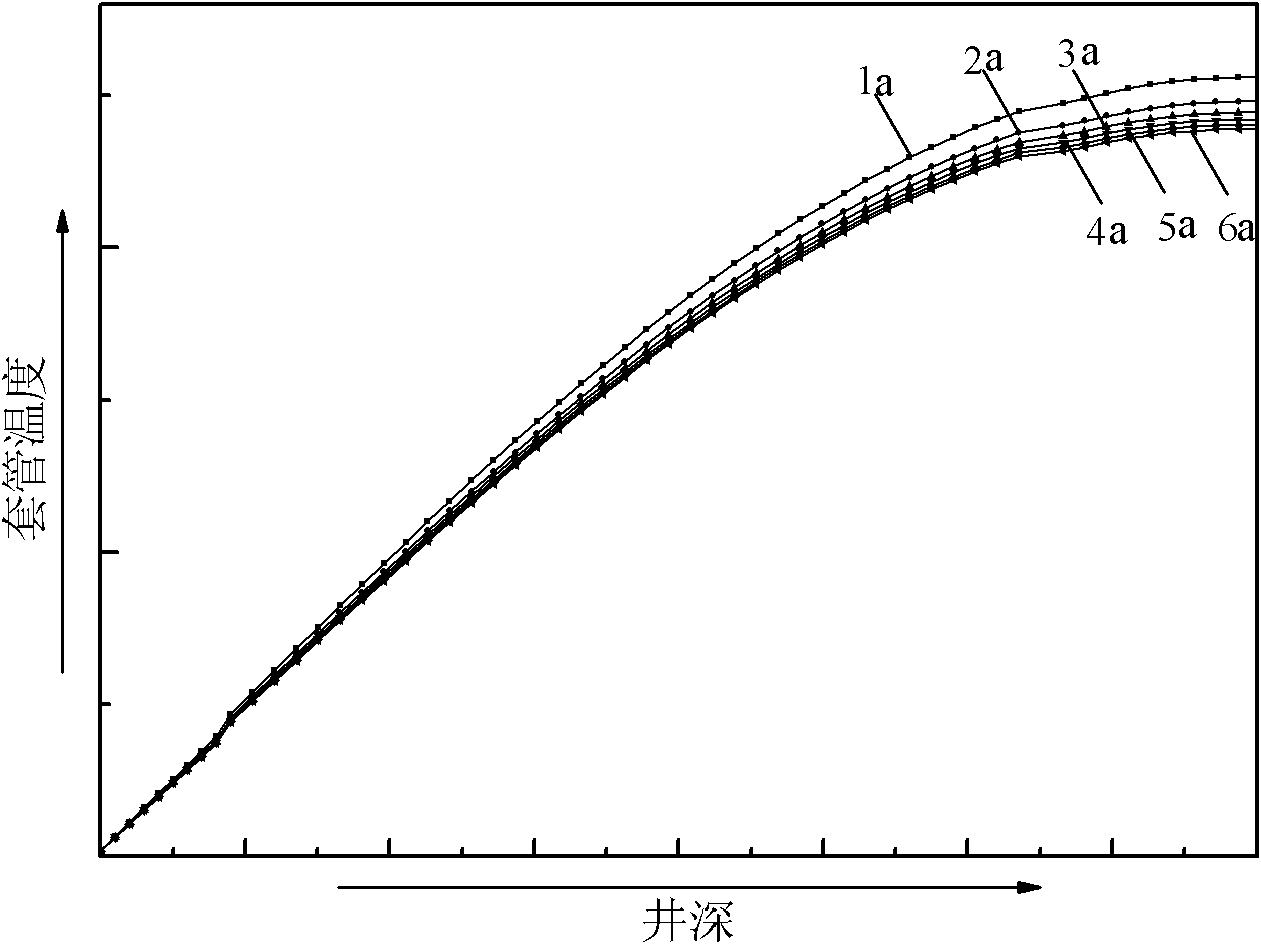

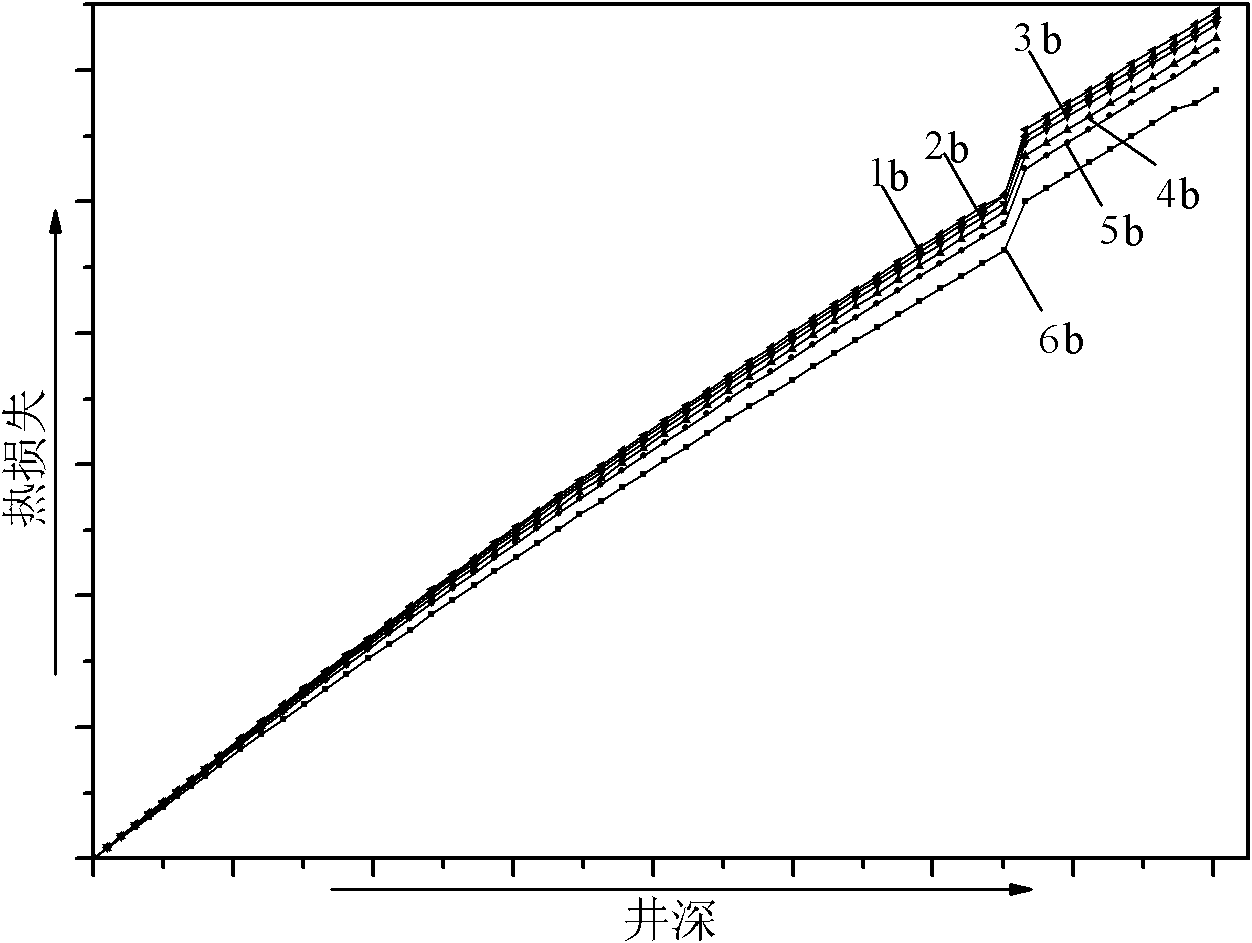

Method and well pattern structure for exploiting heavy oil reservoir through gravity assisted nano magnetofluid flooding

The invention relates to a method and a well pattern structure for exploiting a heavy oil reservoir through gravity assisted nano magnetofluid flooding. The method comprises the steps that a plurality of top horizontal wells and bottom horizontal wells are uniformly arranged at the top and the bottom of an oil layer to form a horizontal well space orthogonal well group, a slotted screen and blind pipe sectorial connecting manner is adopted at horizontal sections of the top horizontal wells and the bottom horizontal wells for well completion, high-energy electromagnets are placed in positions, corresponding to slotted screens, in shafts at the horizontal sections of the bottom horizontal wells respectively, surfactant wrapped hydrocarbon-based nano magnetofluid dispersion solutions are injected into the top horizontal wells at a certain speed, the electromagnets in the bottom horizontal wells are started, nano magnetofluid injected into the oil layer is magnetized, is diffused and moves from the top of the oil layer to positions nearby shafts at screen segments of the bottom horizontal wells of the oil layer by the action of attraction and self gravity, and displaces crude oil in the oil layer, and the crude oil is exploited to the ground by intermittent magnetism stop production of the bottom horizontal wells. The method can increase and improve the oil recovery rate and recovery efficiency of the heavy oil reservoir.

Owner:PETROCHINA CO LTD

Annular space continuous nitrogen injection auxiliary heat insulation method for offshore thermal recovery

The invention discloses an annular space continuous nitrogen injection auxiliary heat insulation method for offshore thermal recovery. The method comprises the following steps that: thermal fluid is injected into a heat-insulating oil pipe; nitrogen is continuously injected into an annular space which is formed between the heat-insulating oil pipe and a sleeve; the nitrogen is converged with the thermal fluid at an output end of the heat-insulating oil pipe; and the nitrogen and the thermal fluid are input to a stratum together. By the method, annular space heat insulation of a heat injection period can be realized, the sleeve is protected, the continuously injected nitrogen simultaneously enters the stratum, the energy of the stratum is increased, the energy increasing and pressure keeping effects are carried out, and meanwhile, the sweep range of the thermal fluid can be improved and the thermal recovery effect is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

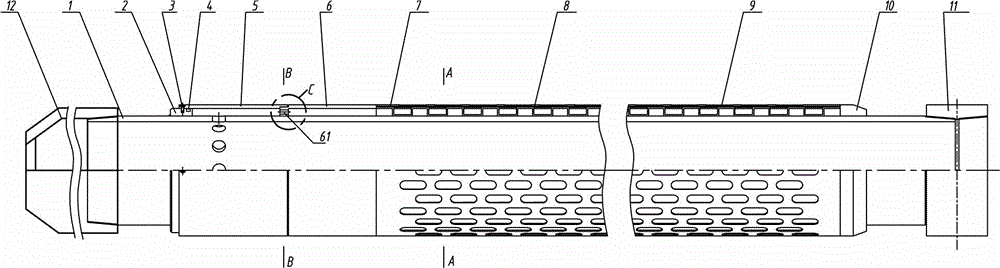

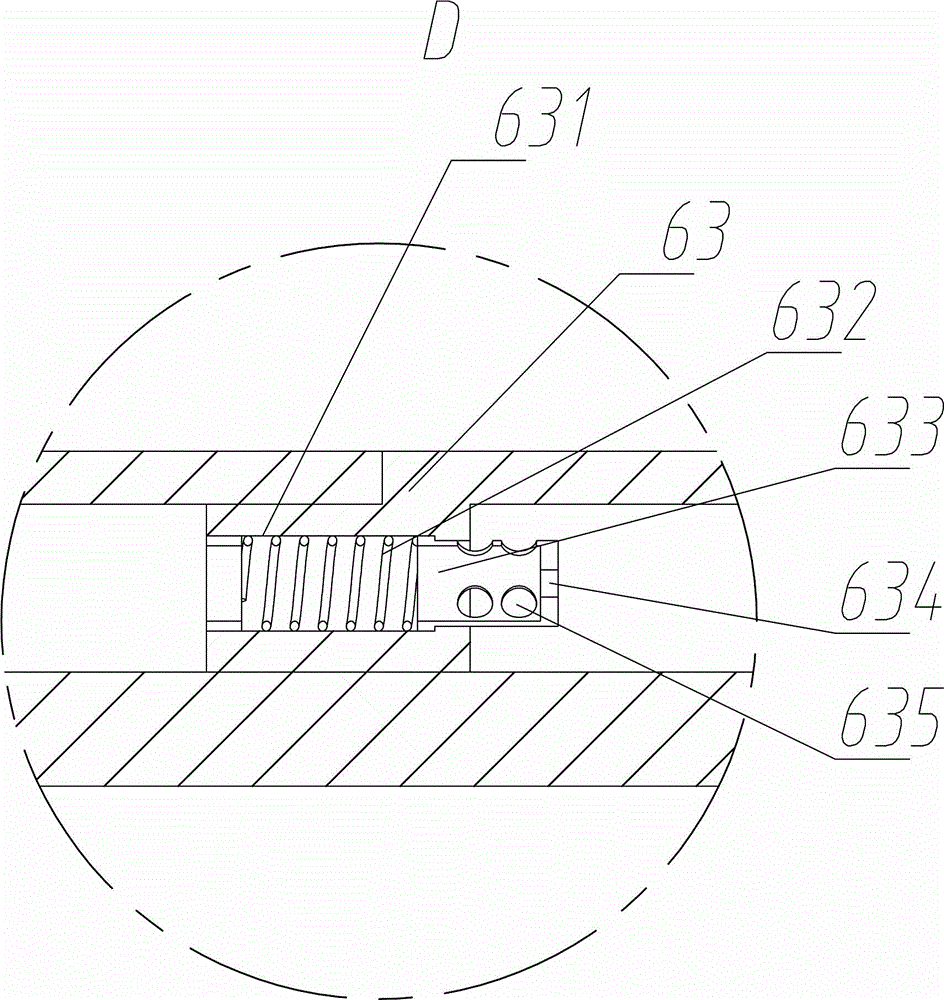

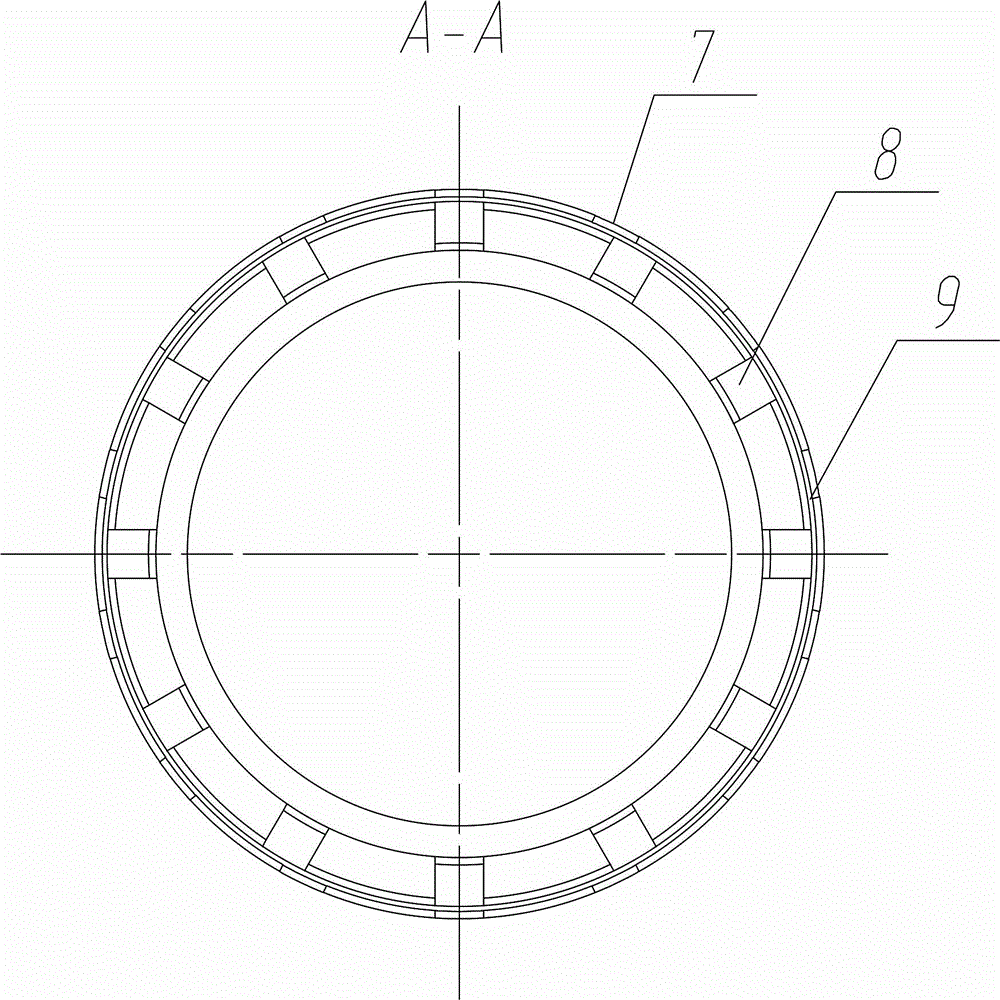

Horizontal well completion and sand control water controlling screen pipe

Disclosed is a horizontal well completion and sand control water controlling screen pipe. According to the horizontal well completion and sand control water controlling screen pipe, a screen and a throttle sleeve a base pipe, wherein the throttle is in a tubular shape; a throttle device is arranged between the inner wall of the throttle and the outer wall of the base pipe; one end of the throttle is connected with the base pipe through a first support disc, the other end of the throttle is communicated with one end of the screen, and the other end of the screen is connected with the base pipe through a second support disc; the outer wall of the base pipe between the first support disc and the throttle device is provided with at least one through hole so that a cavity formed between the inner wall of the throttle and the outer wall of the base pipe can be communicated with the inner cavity of the base pipe. The horizontal well completion and sand control water controlling screen pipe can delay the water breakthrough time during an oil recovery process and improve the recovery efficiency; the throttle device can reduce the occurrence of bottom water coning or cresting due to production pressure change.

Owner:YANGTZE UNIVERSITY

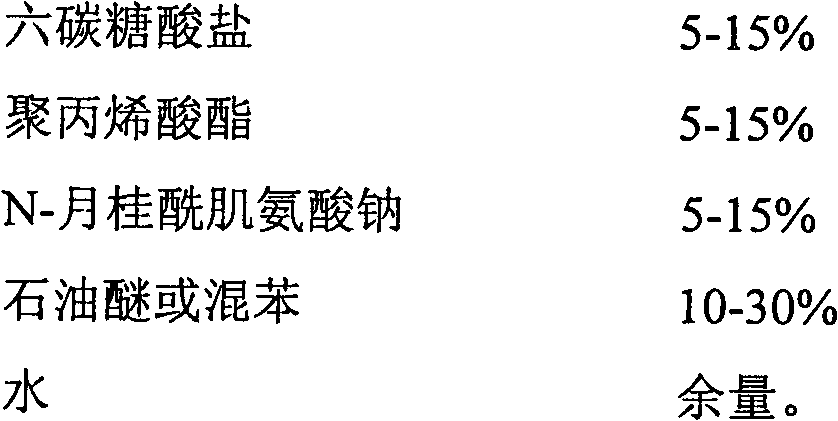

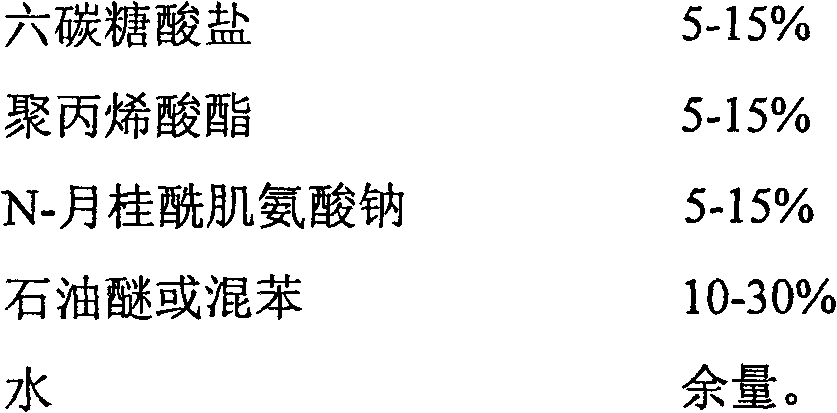

Multiple-effect viscosity depressant for exploiting thickened oil

The invention relates to a multiple-effect viscosity depressant for exploiting thickened oil. The multiple-effect viscosity depressant is prepared from the following raw materials in percentage by weight: 5-15 percent of hexose salt, 5-15 percent of polyacrylic ester, 5-15 percent of N-sodium lauroyl sarcosine, 10-30 percent of petroleum ether or mixed benzene and the balance of water. The product of the invention is a white emulsion at room temperature under normal pressure, has stable performance and can be stored for a long time. Before use, the product is diluted 20-30 times and added to an oil well to achieve the aim of reducing viscosity and increasing the yield of the thickened oil.

Owner:成都川大金钟科技有限公司

Mixed mining method capable of improving recovery ratio of thick oil in shallow oil reservoir

ActiveCN102268983AIncrease the extent of the stretchImprove thermal efficiencyFluid removalHorizontal wellsHigh pressure

The invention discloses a mixed mining method capable of improving the recovery ratio of thick oil in a shallow oil reservoir. The method comprises the following steps of: arranging three horizontal wells which are directly extended to the lower side of an oil bearing reservoir and are positioned on the same horizontal surface in a shallow oil reservoir area; injecting high-temperature high-pressure steam into the three horizontal wells by a steam stimulation method, and closing for several days; opening the oil wells to make the thick oil with reduced viscosity start to flow out, and recovering; discontinuously emitting hot steam diffused into the oil bearing reservoir upwards in the oil producing process of the three horizontal wells so as to form a steam cavity above the three horizontal wells; starting to inject the high-temperature high-pressure steam into a steam injection pipe of a middle horizontal well only at the moment so as to continuously heat the steam cavity, wherein the three horizontal wells continuously produces oil at the same time; and stopping injecting the high-temperature high-pressure steam into the steam injection pipe of the middle horizontal well when the oil yield of the oil bearing reservoir is continuously reduced and cannot reach anticipated oil yield so as to stop oil extraction. By the method, the extension range of the side surface of the steam cavity above the oil wells can be enlarged, and the using efficiency of heat can be improved, so that the oil yield, the ratio of oil to gas and the oil production ratio are improved.

Owner:李剑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com