Surfactant as well as preparation method and application thereof

A technology of surfactants and additives, which is applied in the field of surfactants and their preparation, can solve the problems of theoretical research lag and difficult implementation, and achieve the effects of promoting imbibition process, good biodegradation performance, and avoiding subsequent processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

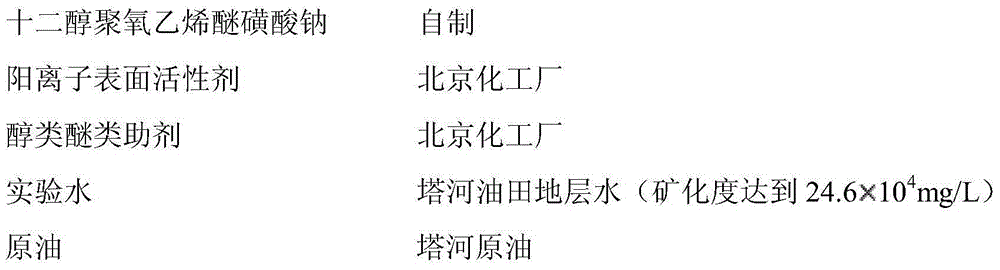

[0035] This embodiment provides a kind of fatty alcohol polyoxyethylene ether sulfonate, and the specific preparation steps are:

[0036] In a 250mL three-necked flask, add 12.89g (0.03mol) polyoxyethylene lauryl ether and 0.81g sodium metal, add 25mL toluene as a solvent, start stirring, and 2 Under the protection of , the temperature was raised rapidly to 115°C for reflux reaction for 4 hours to obtain sodium alkoxide;

[0037] Add sodium 2-chloroethylsulfonate (the molar ratio of sodium 2-chloroethylsulfonate to polyoxyethylene lauryl ether is 1:1.2), and react at 60°C for 7h;

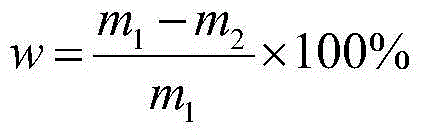

[0038] Remove toluene by rotary evaporation, add 120mL of absolute ethanol, reflux at 80°C for 30min, filter with suction, cool the filtrate, and crystallize the product sodium dodecyl alcohol polyoxyethylene ether sulfonate (AESO); recrystallize 3 times, dry at 80°C, Weighing, the yield is 80%.

Embodiment 2

[0040] This embodiment provides a surfactant and an oil washing system.

[0041] The preparation steps of this tensio-active agent are:

[0042] The sodium lauryl alcohol polyoxyethylene ether sulfonate, dodecyltrimethylammonium bromide, and hexanol that were synthesized in Example 1 were fully mixed in proportions of 60%, 30%, and 10% by mass fraction to obtain a surface active agent;

[0043] The preparation steps of this washing oil system are:

[0044] Add the above surfactant into an appropriate amount of water, heat and stir for 60 minutes to fully dissolve, then add formation water to prepare a solution with a concentration of 0.15 wt%, and stir for 30 minutes to obtain the oil washing system ①.

Embodiment 3

[0046] This embodiment provides a surfactant and an oil washing system.

[0047] The preparation steps of this tensio-active agent are:

[0048] The sodium dodecyl alcohol polyoxyethylene ether sulfonate, dodecyltrimethylammonium bromide, and hexanol synthesized in Example 1 are fully mixed in proportions of 55%, 30%, and 15% by mass fraction to obtain a surface active agent;

[0049] The preparation steps of this washing oil system are:

[0050] Add the above-mentioned surfactant into an appropriate amount of water, heat and stir for 60 minutes to fully dissolve it, continue to add formation water to prepare a solution with a concentration of 0.15 wt%, and stir for 30 minutes to obtain the oil washing system ②.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com