Patents

Literature

43results about How to "Effective start" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

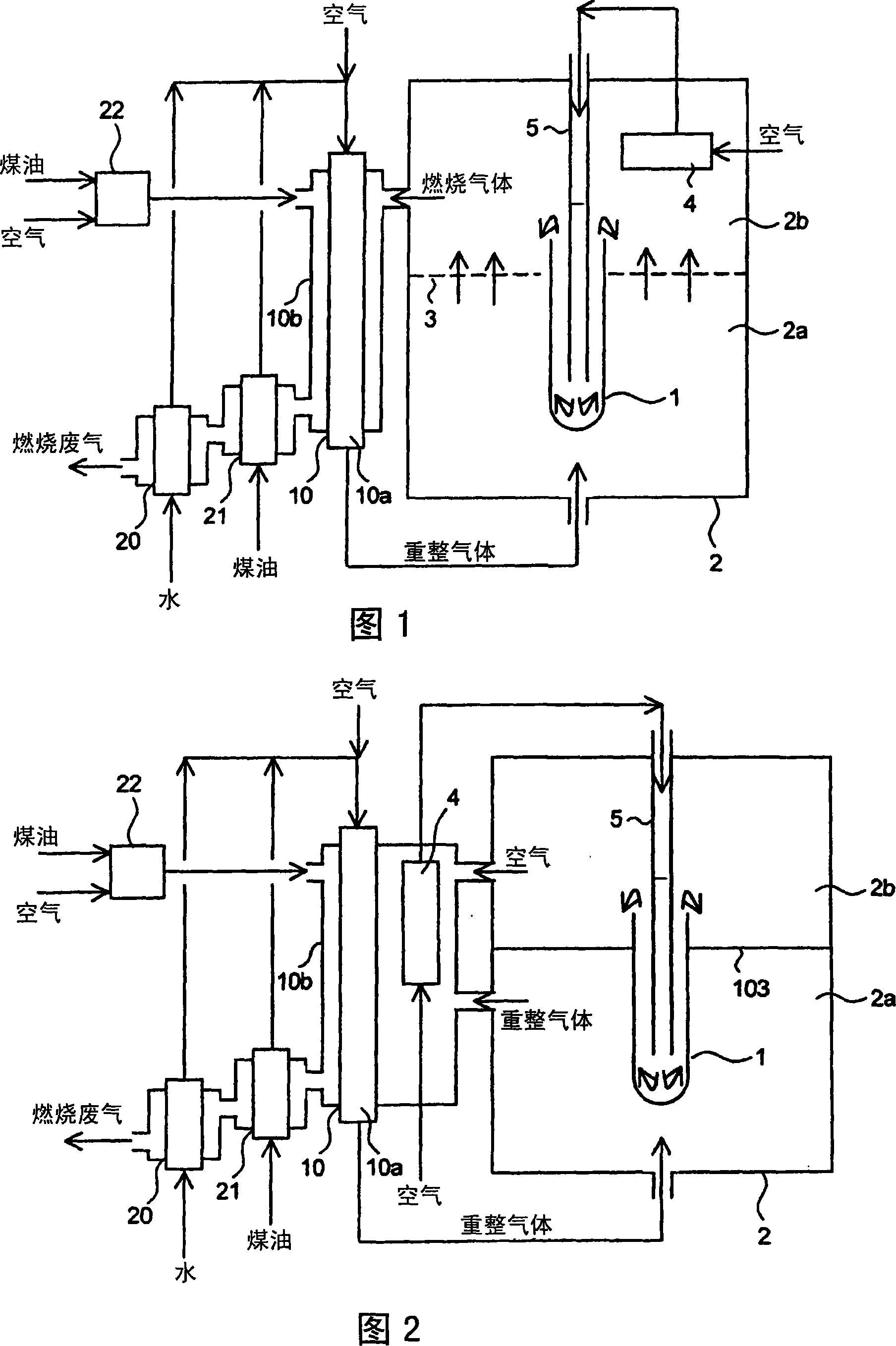

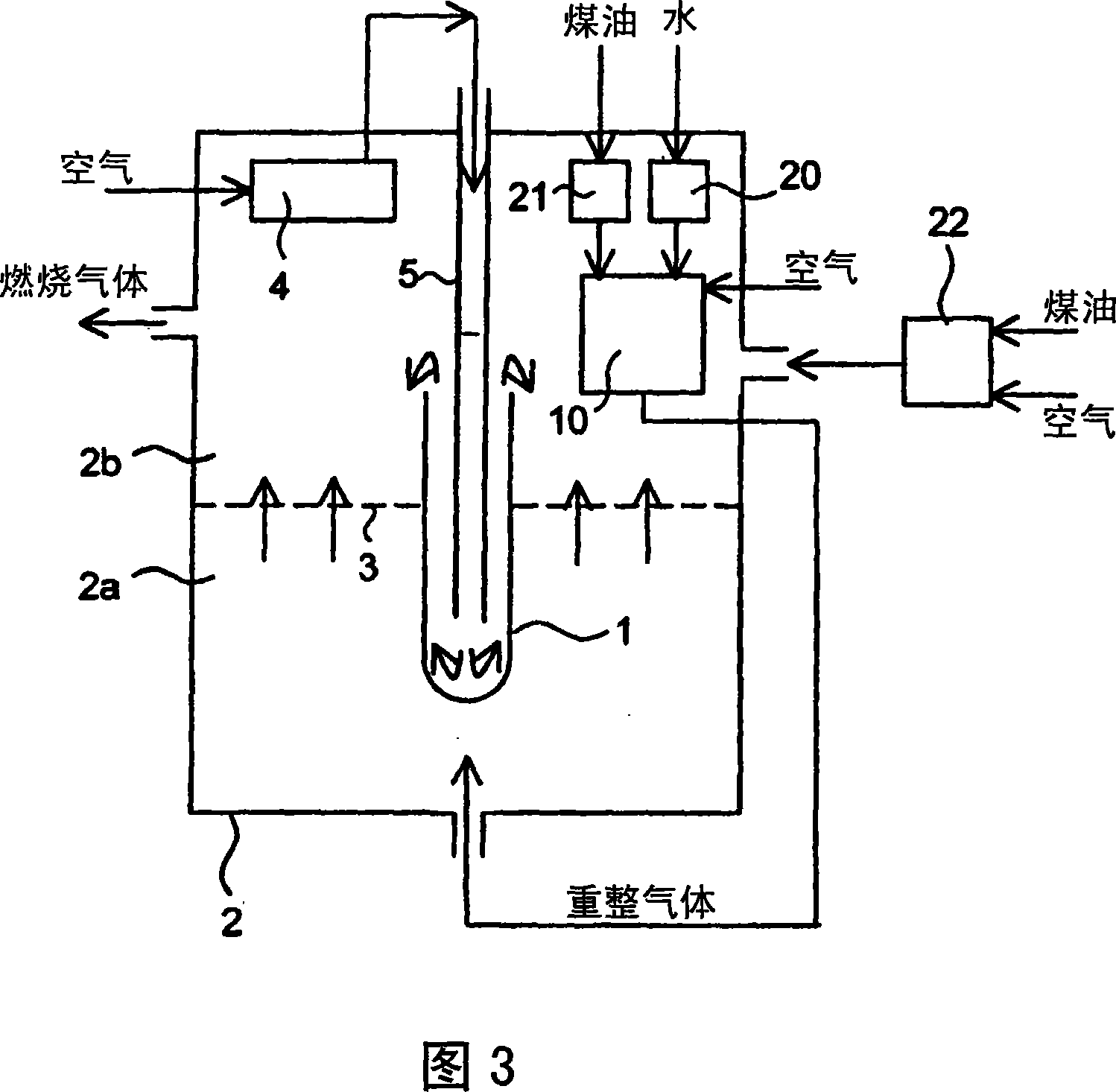

Method of starting solid oxide fuel cell system

InactiveCN101099256AIncrease the concentration of hydrogenEffective startHydrogenFuel cell auxillariesHydrogen concentrationElectricity

Owner:KYOCERA CORP

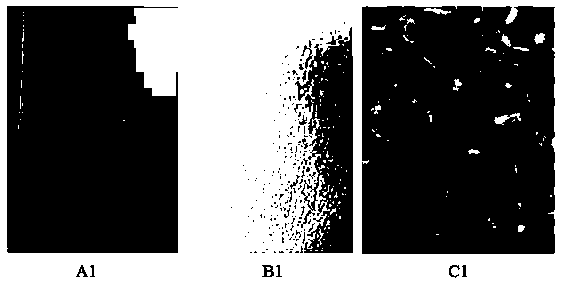

Hot-forging process for tantalum target material with high performance

The invention relates to a hot-forging process for tantalum target material with high performance. The process comprises the following steps of: firstly, forging a tantalum ingot by means of cold forging for the first time; performing acid washing and heat treatment on the tantalum ingot and forging the tantalum ingot by means of hot forging for the second time; and performing acid washing and heat treatment on the tantalum ingot again and forging the tantalum ingot by means of hot forging for the third time. By the hot-forging process, the tantalum ingot with large diameter (more than or equal to 160mm) applied to the tantalum target material with the high performance is forged by a combined process of cold forging and hot forging, and the process is matched with a proper heat treatment process so as to acquire grain sizes and texture components required by the product. By utilizing rolling blanks produced by the process, the tantalum target material with the high performance of which the texture proportion in the direction (100) of the thickness is more than 50 percent and is uniform and which meets a using requirement of high-end sputtering base platform can be obtained. Compared with the common tantalum target material, the tantalum target material with the high performance has the advantages that the texture components of which the texture proportion in the direction of the thickness of the target material is more than 50 percent is realized, and a high requirement on the texture uniformity is proposed, so that the consistency of sputtering velocity in a using process is ensured.

Owner:NINGXIA ORIENT TANTALUM IND

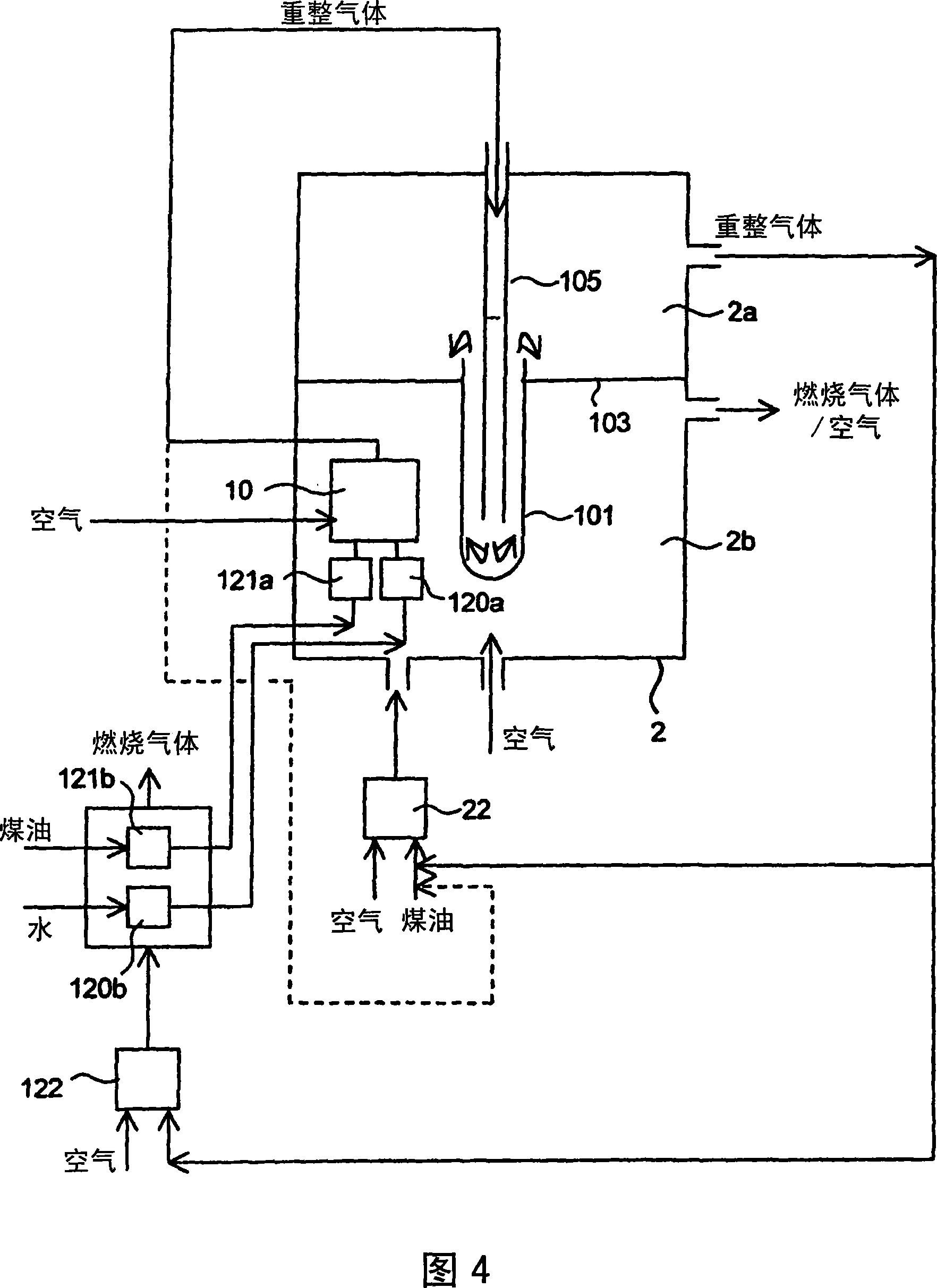

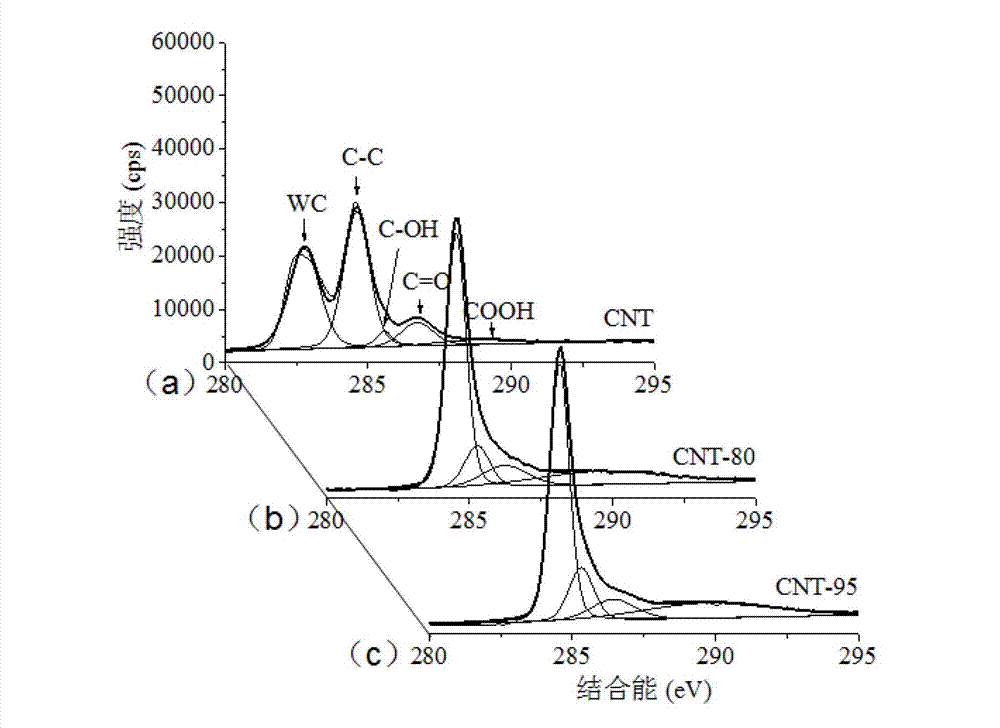

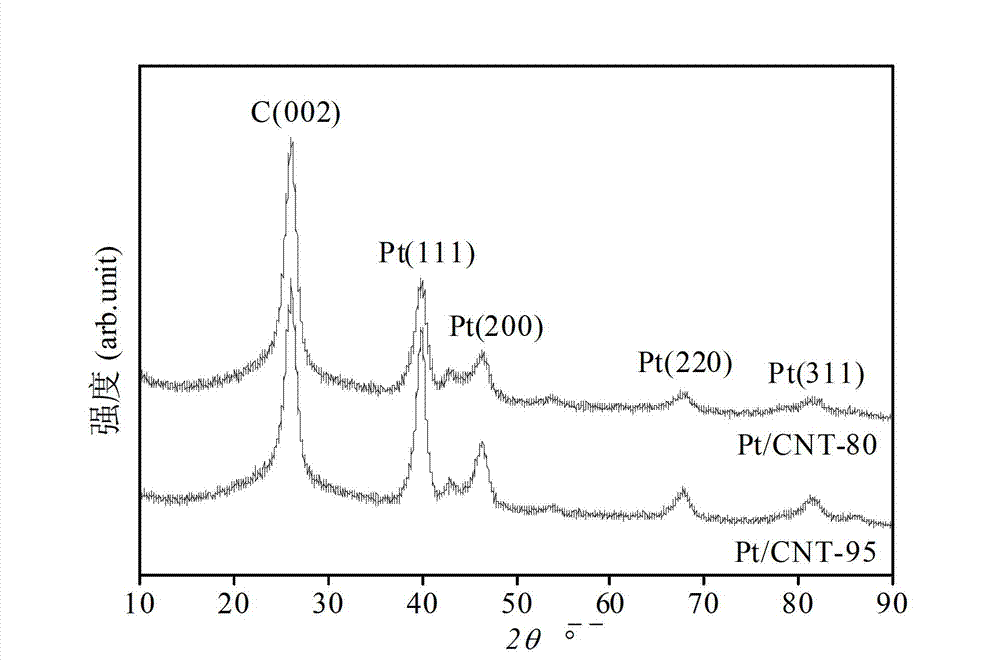

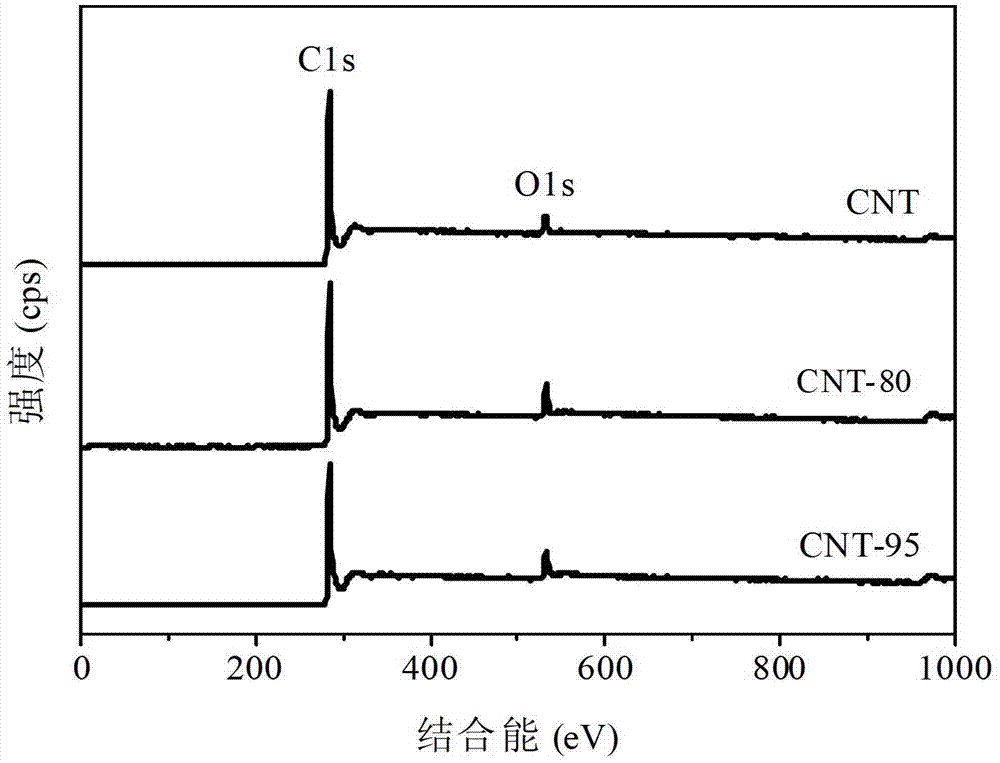

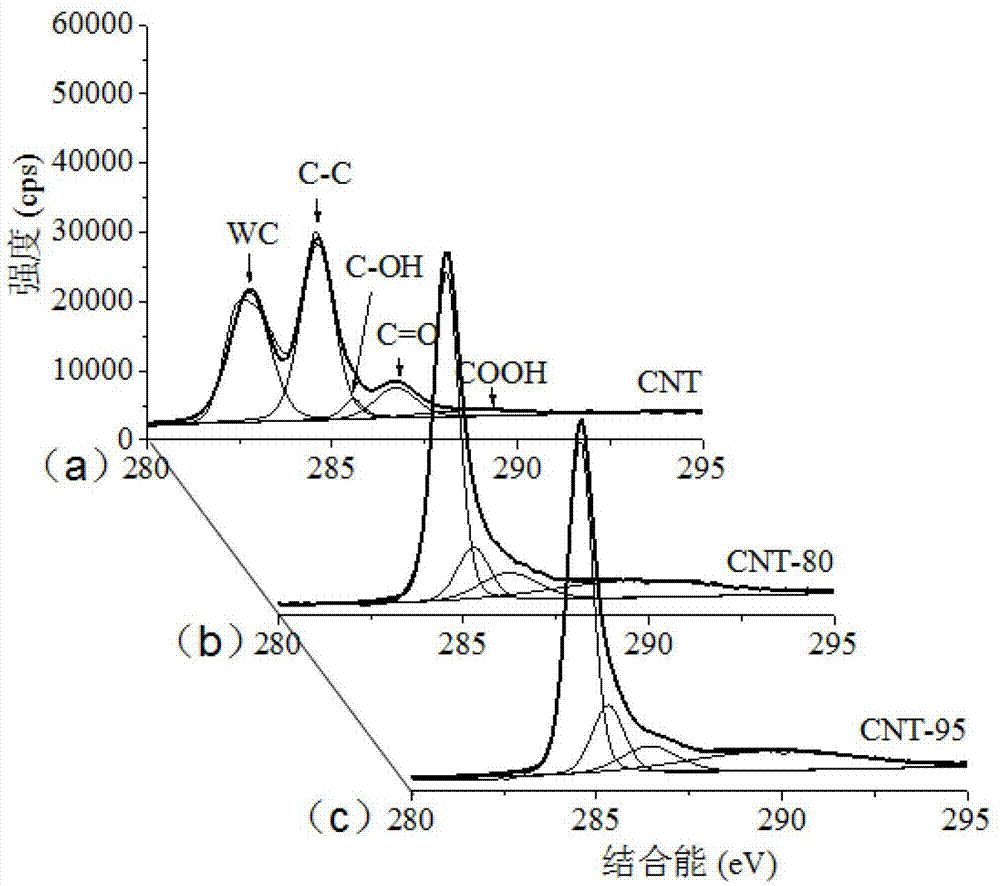

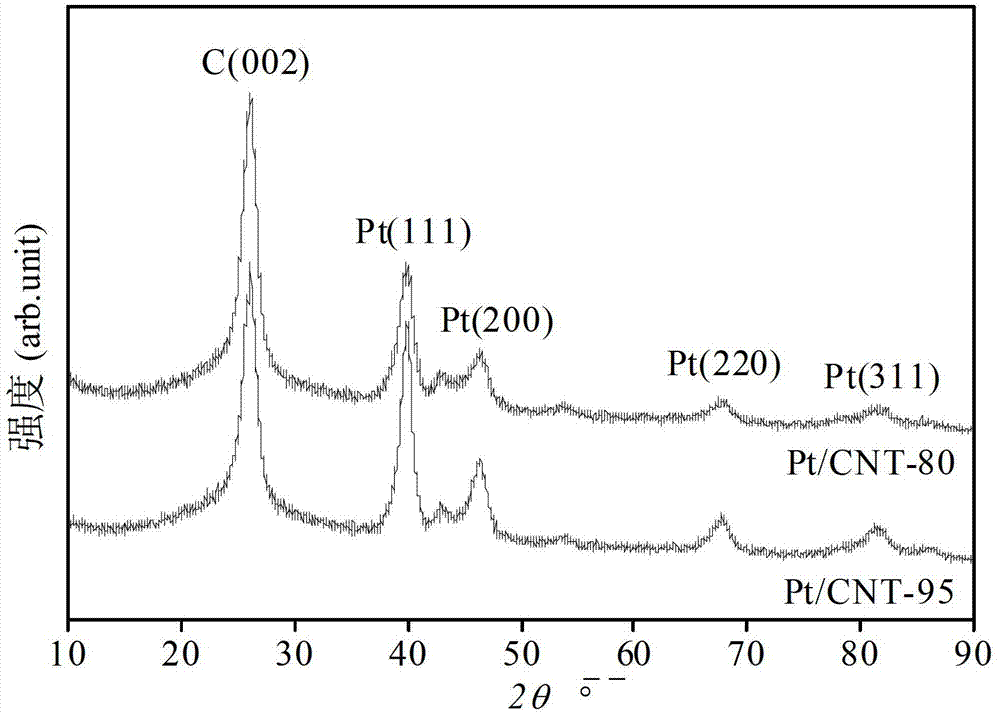

Carboxylated carbon nanotube catalyst carrier as well as preparation method and application thereof

ActiveCN103191787AIncrease inertiaImprove hydrophobicityCatalyst carriersCell electrodesFuel cellsInternal resistance

The invention discloses a carboxylated carbon nanotube catalyst carrier as well as a preparation method and application thereof. The preparation method of the carboxylated carbon nanotube catalyst carrier comprises the following steps of: putting carbon nanotubes in the mixed liquid of concentrated HNO3 and concentrated H2SO4 in a volume ratio of (1: 3)-(3: 2) and performing constant-temperature reflux treatment in the range of 80-95 DEG C for 100-120 minutes, and then washing and drying, thereby obtaining the carboxylic carbon nanotube catalyst carrier. The catalyst carrier is used for preparing Pt / CNT catalyst; the obtained Pt / CNT catalyst is used as an air cathode material for preparing a single-cavity membrane-free air cathode microbial fuel cell. The rich oxygen-containing groups are introduced on the surface of the catalyst carrier prepared by the method, so that the oxygen reduction effect of the catalyst is improved; and the Pt / CNT catalyst prepared from the catalyst carrier succeeds in starting MFC (Micro Function Circuit) so that the start period of MFC is shortened, the internal resistance of MFC can be reduced and the output voltage of MFC also can be greatly increased.

Owner:SOUTH CHINA UNIV OF TECH

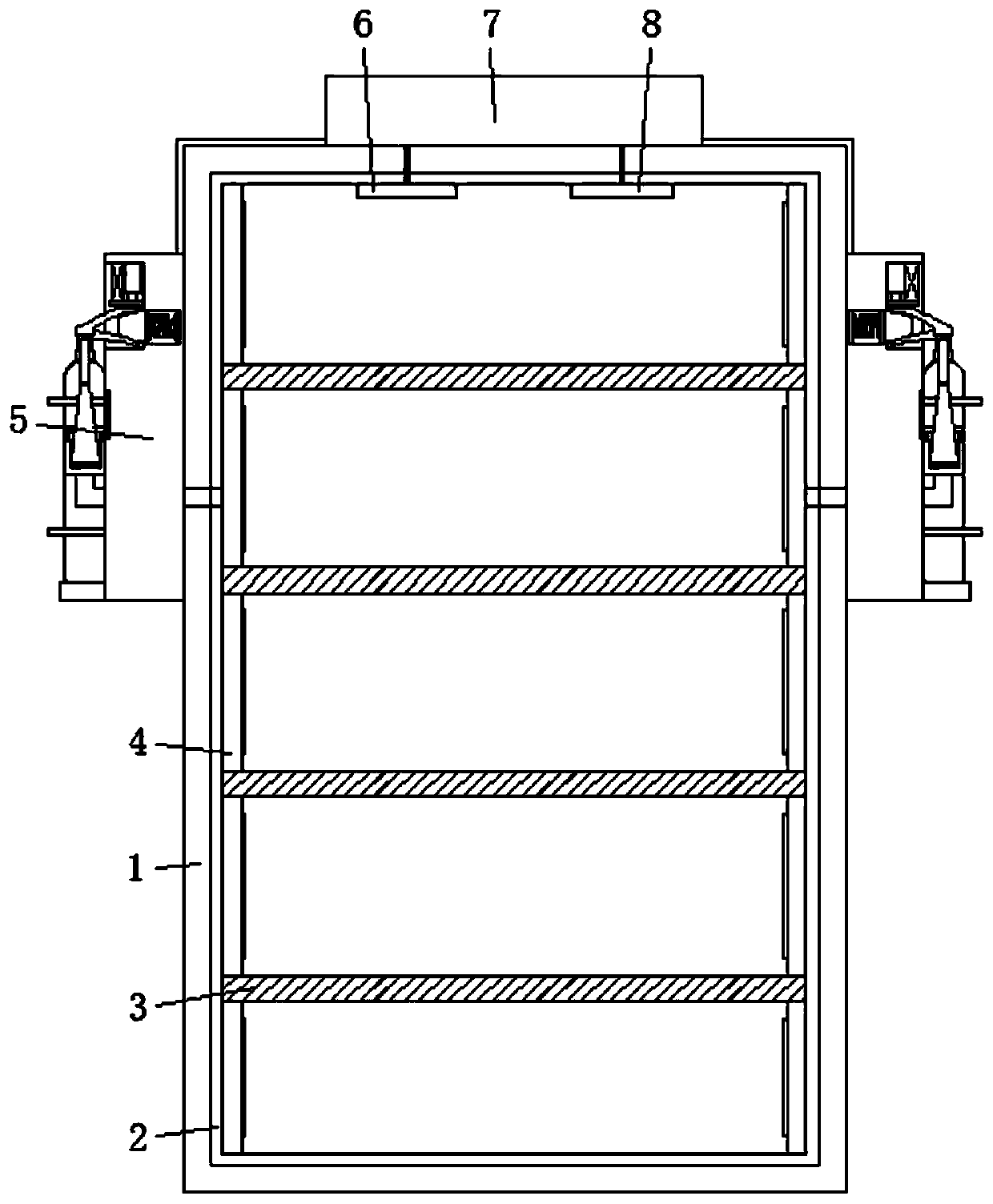

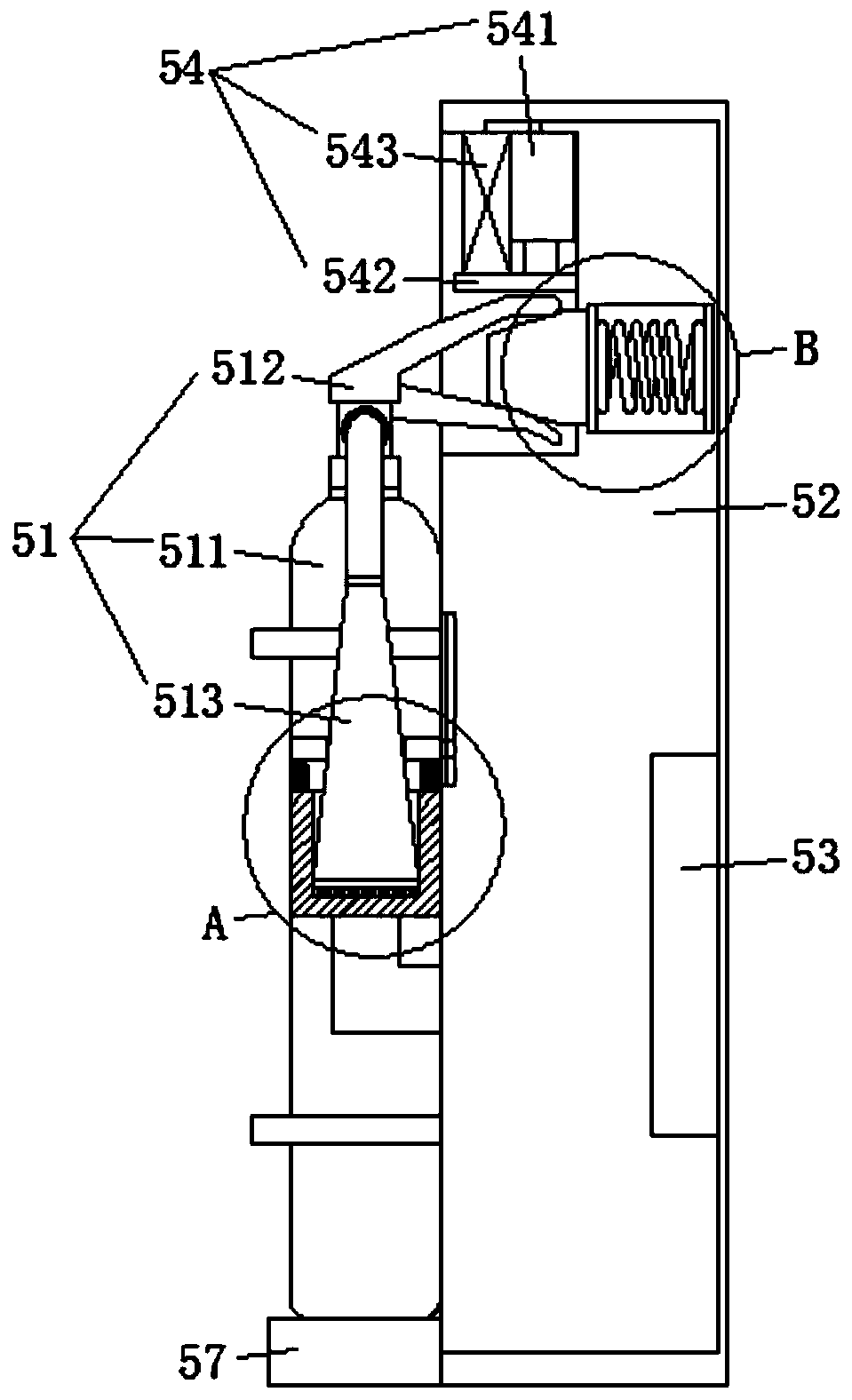

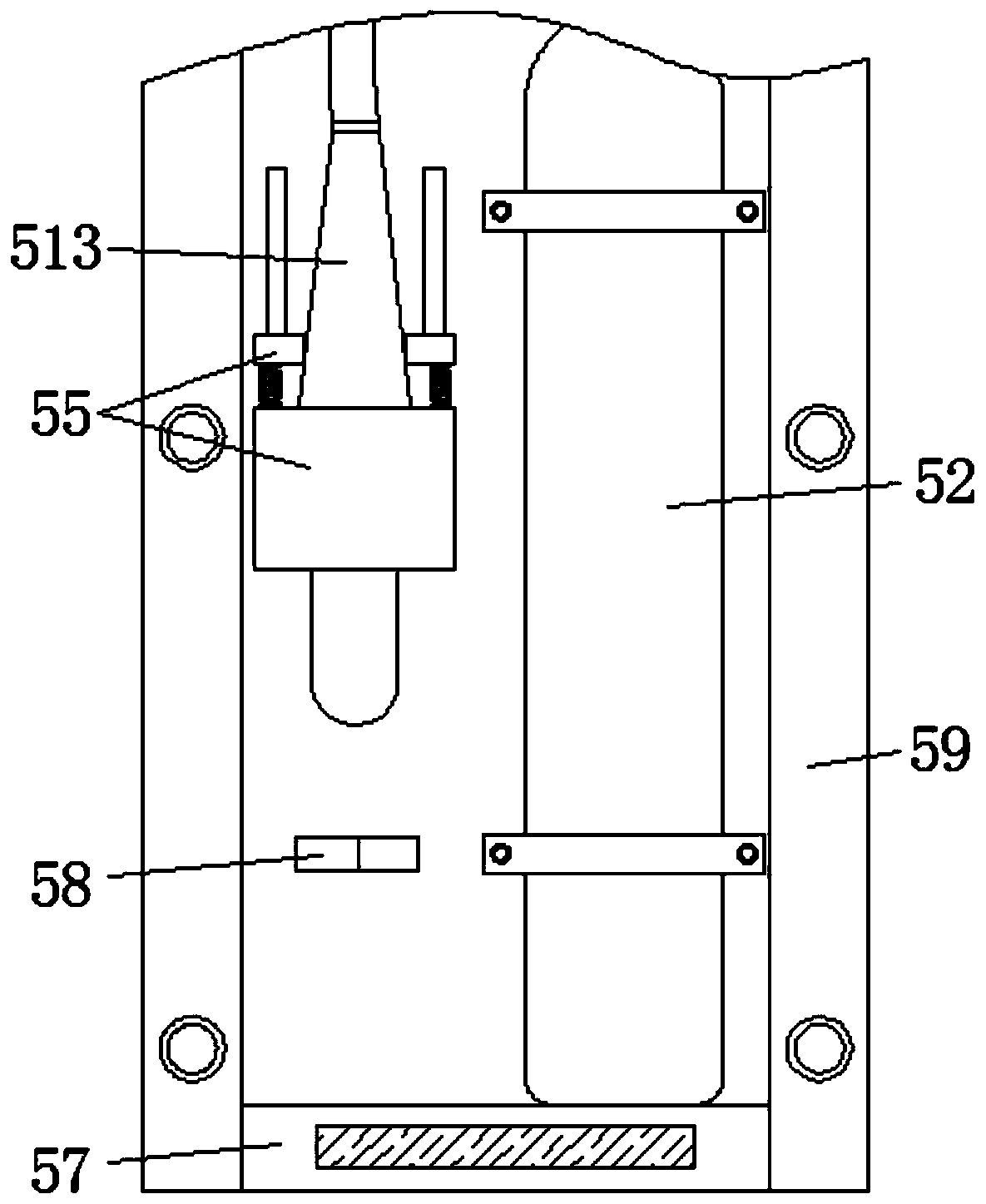

Cellular automatic electrical control cabinet with flame-retardant and fire-extinguishing functions

ActiveCN111010828AReduce lossesReduce manufacturing costCasings with display/control unitsCasings/cabinets/drawers detailsElectrical controlFire extinguisher

The invention belongs to the technical field of electrical control cabinets, and discloses a cellular automatic electrical control cabinet with flame-retardant and fire-extinguishing functions. The control cabinet comprises an outer cabinet, a fire-extinguishing pipeline, a temperature sensor, a smoke sensor, a fire-extinguishing assembly and a processing device, wherein the fire-extinguishing pipeline, the temperature sensor, the smoke sensor are arranged in the outer cabinet, and the fire-extinguishing assembly and the processing device are arranged outside the outer cabinet. At least one fire extinguishing pipeline and at least one fire extinguishing assembly are arranged; the fire extinguishing assembly comprises a fire extinguisher and a driving base, and the fire extinguisher is mounted on the driving base; the processing device comprises a PLC processor and is electrically connected with the driving base; real-time monitoring is performed by the temperature sensor and the smokesensor to determine whether a fire occurs in the control cabinet, and if yes, a fire extinguishing device is cooperated to realize timely fire extinguishing so as to effectively reduce losses of the control cabinet in case of fire; and the fire extinguishing device is composed of the fire extinguishing pipeline, the common fire extinguisher and the driving base, production cost is low, the fire extinguisher and the driving base can be detached and replaced, and use cost is low.

Owner:广东盛银新能源科技有限公司

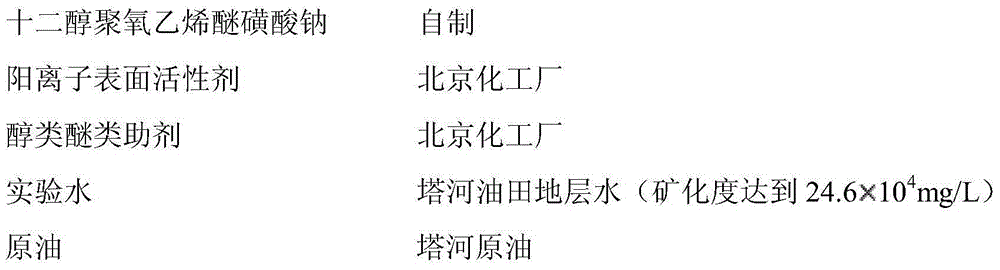

Surfactant as well as preparation method and application thereof

The invention provides a surfactant as well as a preparation method and an application thereof. The surfactant comprises the following components by mass percent: 45%-65% of aliphatic alcohol polyoxyethylene ether sulfonate, 20%-35% of a cationic surfactant and 10%-20% of a surfactant assistant, wherein a molecular formula of the aliphatic alcohol polyoxyethylene ether sulfonate is CnH[2n+1]-(CH2CH2O)m-SO3Na, n is an any integer ranging from 12 to 15, and m is an any integer ranging from 2 to 5. The invention further provides the preparation method for the surfactant and the application of the surfactant to tertiary oil recovery of a carbonate reservoir. The surfactant is independently used, does not need to be added with alkali, and is free of damage to a stratum and an oil well; an oil washing system prepared from the surfactant can effectively change the wettability of a rock surface and strip off crude oil adsorbed on the surface of a carbonate rock, and the oil washing efficiency reaches more than 60%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of large-sized magnesium alloy forged disc

ActiveCN103447433AReduce cumbersomeImprove plastic deformation abilityMetal-working apparatusIngotUltimate tensile strength

The invention relates to a preparation method of a large-sized magnesium alloy forged disc and belongs to the technical field of magnesium alloy materialmachining. The preparation method of the large-sized magnesium alloy forged disc comprises the following steps of heating a casting magnesium alloy ingot to 400-430 DEG C and preserving the heat, wherein the casting magnesium alloy ingot after homogenizing thermal treatment is 300-350mm in diameter and 1.5-1.85 in height-diameter ratio; upsetting and drawing out the heated casting magnesium alloy ingot at 400-430 DEG C to obtain a magnesium alloy forged disc; repeating processes of heating, preserving the heat, upsetting and drawing out till the diameter of the magnesium alloy forged disc is larger than or equal to 670mm to obtain the large-sized magnesium alloy forged disc, wherein the temperature when repeating the procedures of preserving the heat and upsetting every time is 10-20 DEG C lower than the temperature when previously repeating the procedures of preserving the heat and upsetting, the forging ratio in each upsetting procedure is 1.5-2, the forging ratio in each drawing-out procedure is 1.02-1.05, and the deformation speeds in the upsetting and drawing-out procedures both are 12-16mm / s. According to the preparation method of the large-sized magnesium alloy forged disc, which is disclosed by the invention, the large-sized magnesium alloy forged disc with the diameter of 670-720mm, the thickness of 80-120mm, the tensile strength of larger than or equal to 300MPa, the yield strength of larger than or equal to 180Mpa and the elongation percentage of larger than or equal to 10% can be manufactured, and the manufactured large-sized magnesium alloy forged disc can completely meet the requirements on the preparation of a large-sized magnesium alloy die forged piece.

Owner:CENT SOUTH UNIV

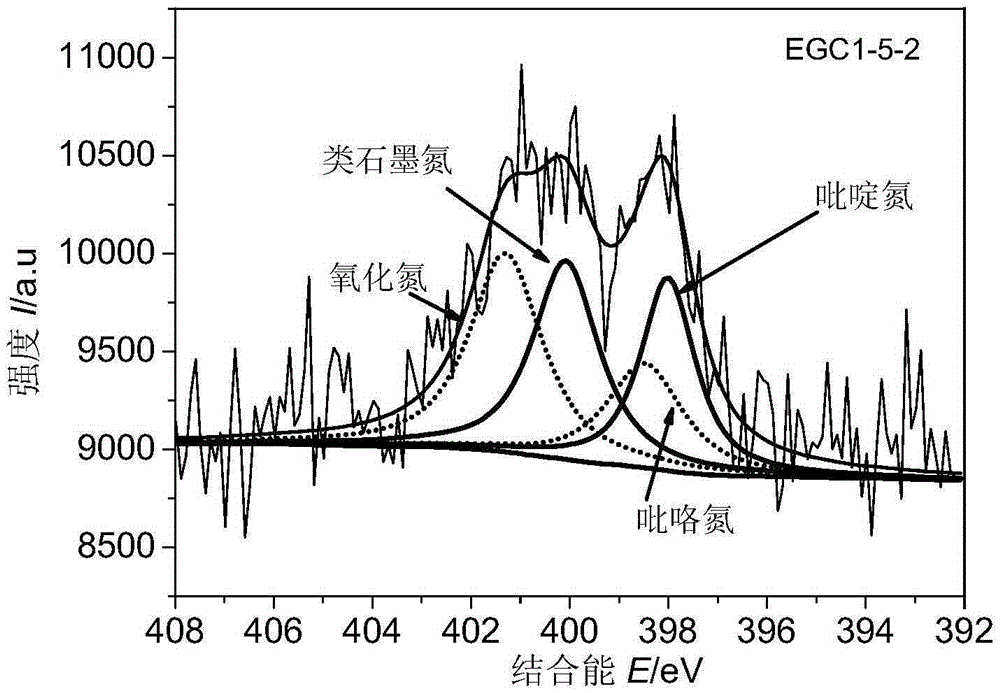

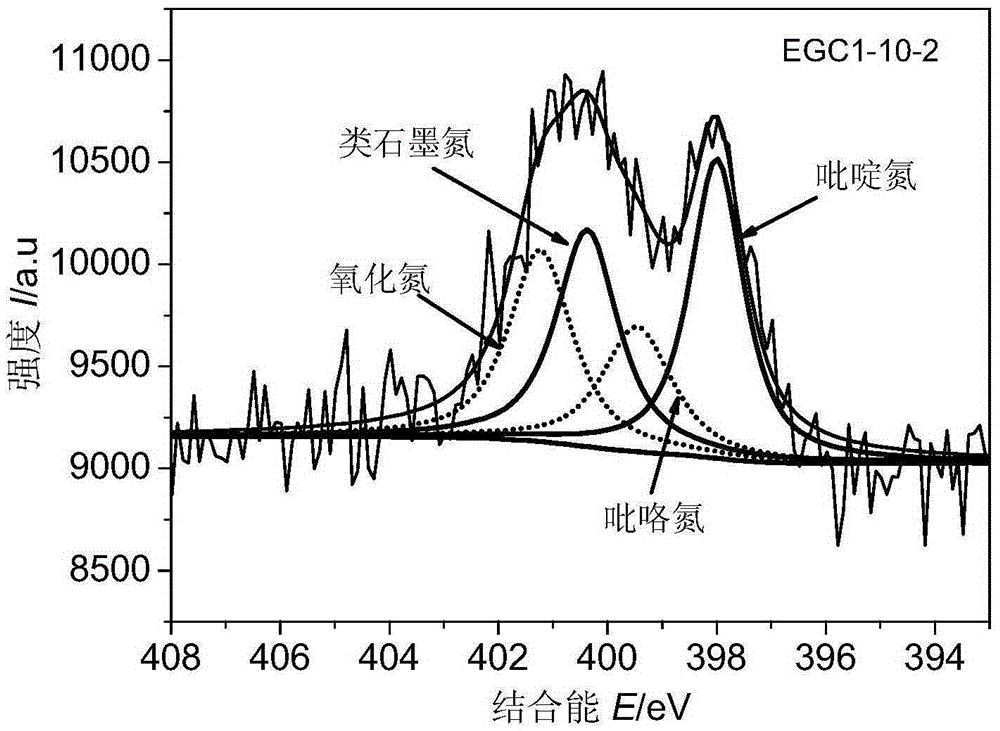

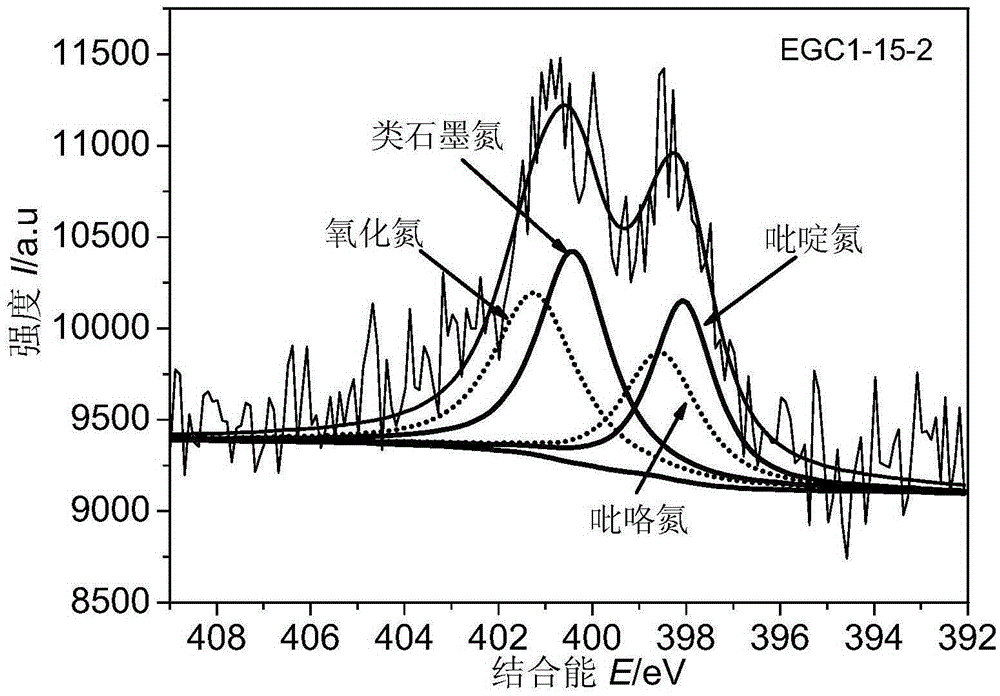

Carbon-doped nano-catalyst as well as preparation method and application thereof

ActiveCN105413731AHigh catalytic activity for oxygen reductionSimple methodPhysical/chemical process catalystsCell electrodesNano catalystTube furnace

The invention discloses a carbon-doped nano-catalyst as well as a preparation method and an application thereof. The preparation method comprises steps as follows: a whole boiled egg is ground, dehydrated and mixed with g-C3N4, the mass ratio of the dehydrated egg to g-C3N4 is 0.5-2, the mixture is ground uniformly and put in a tube furnace, nitrogen is introduced for protection, the mixture is calcined at the temperature of 800-1,000 DEG C for 1-3 h at the heating speed of 5-15 DEG C / min, and the carbon-doped nano-catalyst is obtained. Raw materials required for the carbon-doped nano-catalyst are cheap, the method is simple, the yield is high, the carbon-doped nano-catalyst with the best catalysis effect is obtained by changing the proportion of raw materials and the heating speed, and the carbon-doped nano-catalyst can replace expensive Pt / C (20%) to a certain extent in the aspect of oxygen reduction effect under the neutrality condition.

Owner:SOUTH CHINA UNIV OF TECH

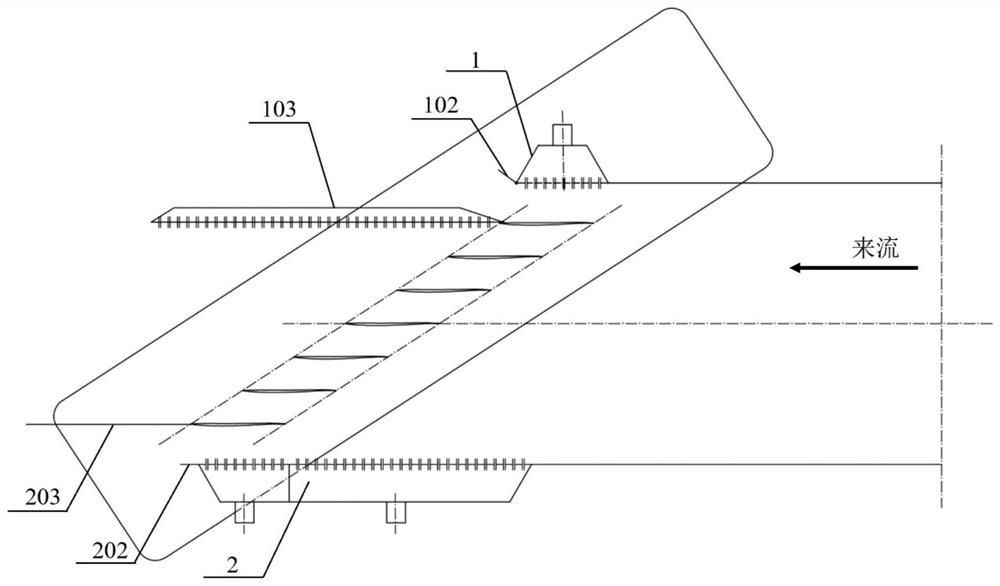

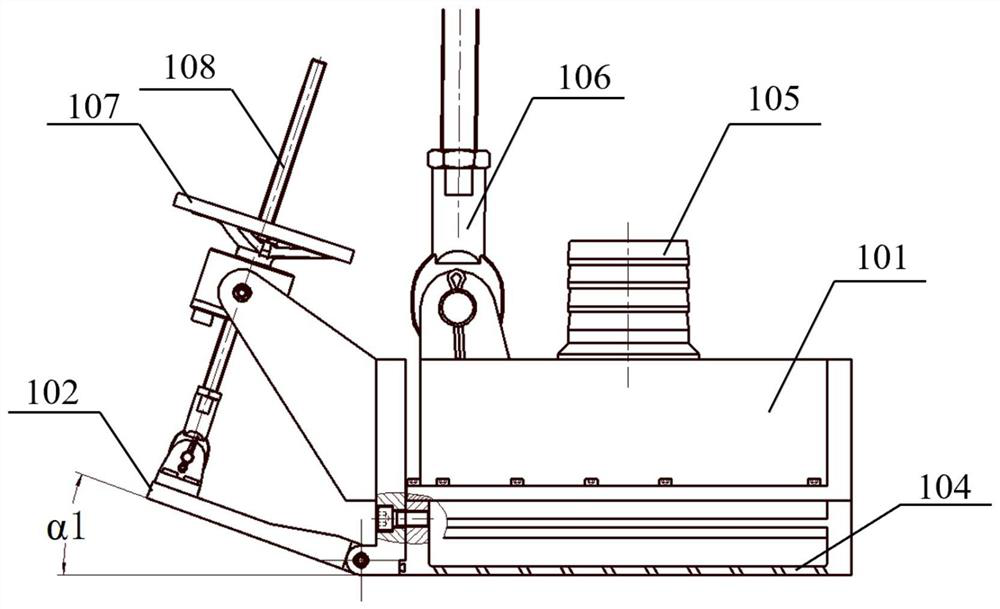

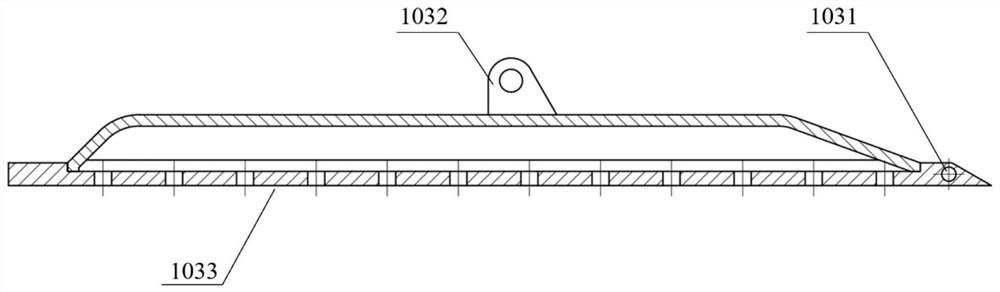

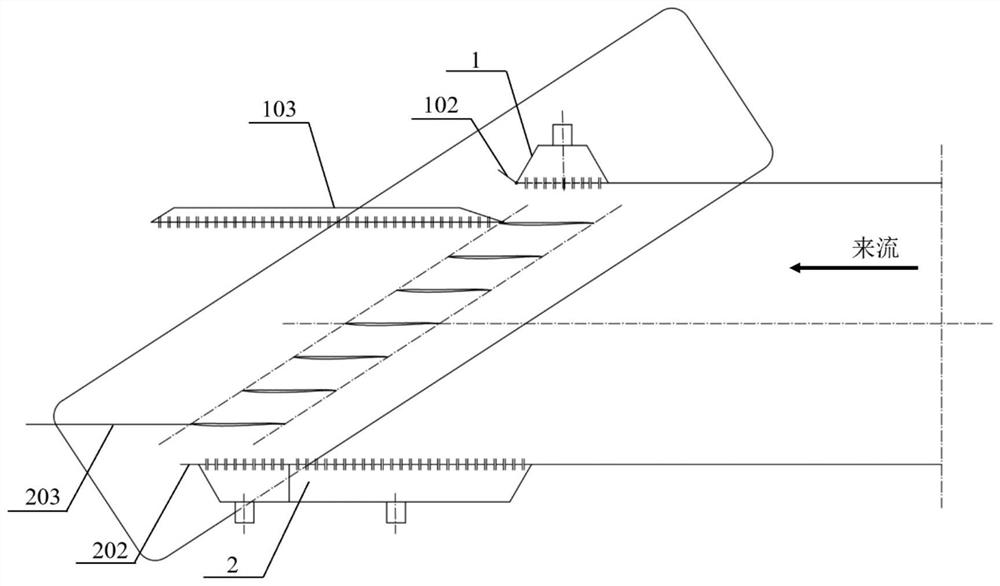

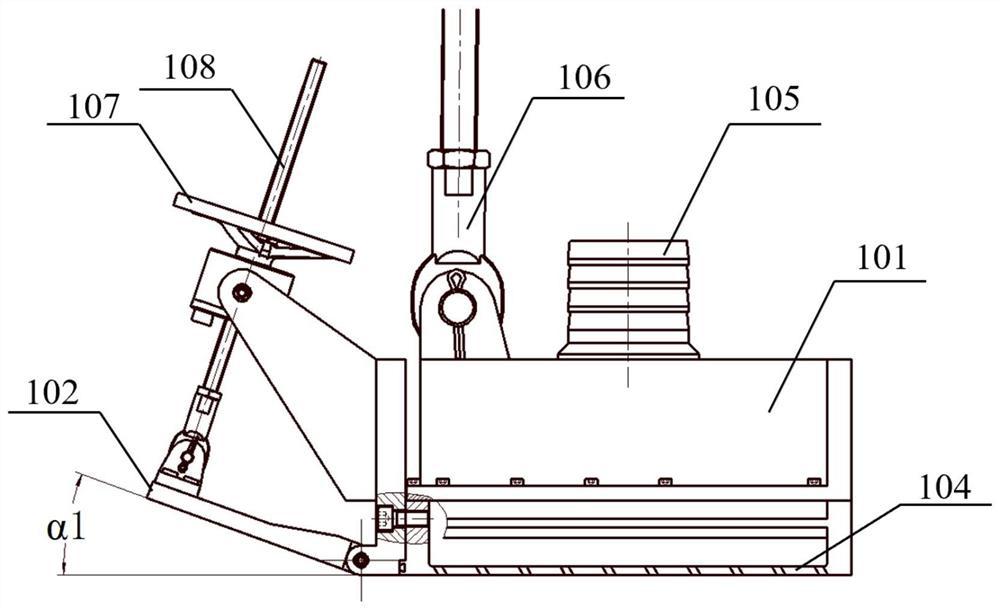

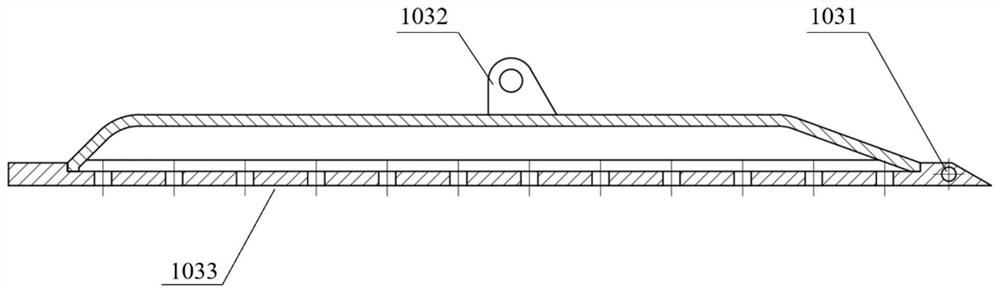

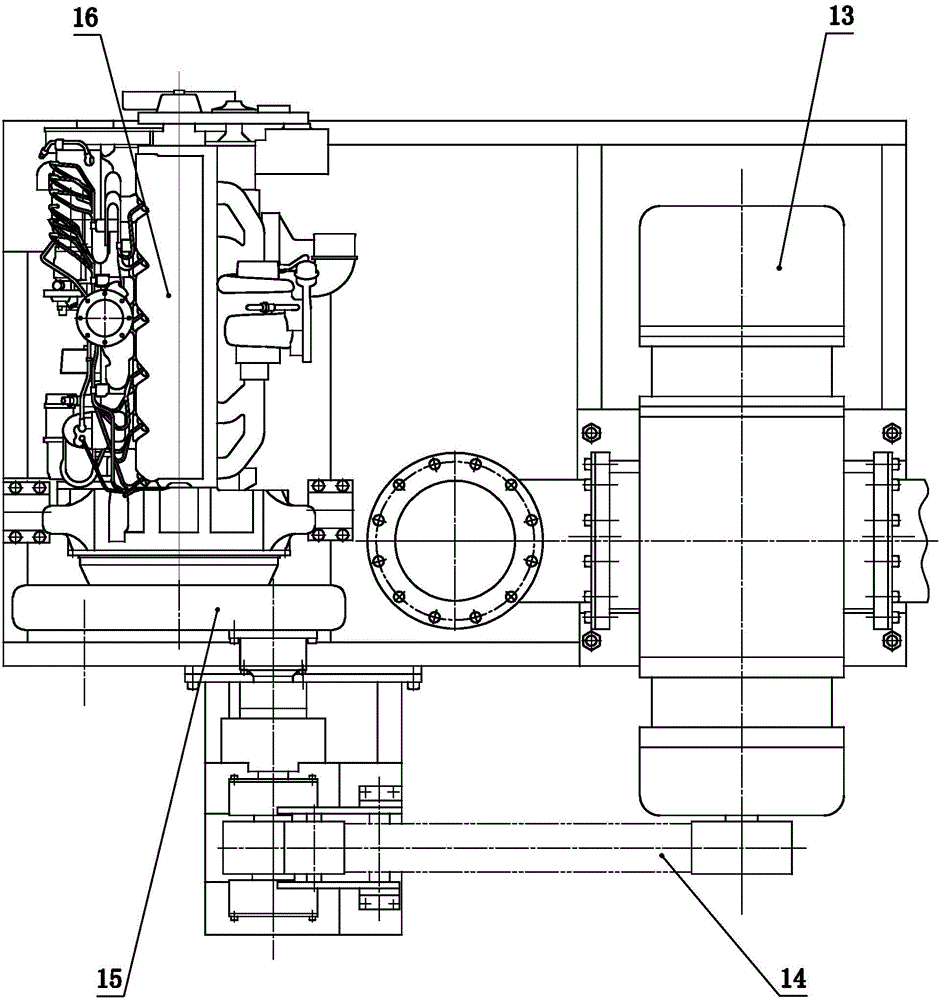

Supersonic plane cascade flow field starting and uniformity adjusting device

ActiveCN113188748AAdjustable positionRegulating pressureGas-turbine engine testingAerodynamic testingShock waveEngineering

The invention discloses a supersonic plane cascade flow field starting and uniformity adjusting device. The adjusting device takes the incoming flow of a cascade wind tunnel as the front and comprises an upper suction assembly arranged above a first blade of a cascade test model, an upper tail plate with a fixed front end and a suspended rear end is arranged behind the upper suction assembly, and an upper baffle with a fixed front end and a suspended rear end is arranged behind the first blade; the device further comprises a lower suction assembly installed below a tail blade of the cascade test model, a lower tail plate with a fixed front end and a suspended rear end is installed behind the lower suction assembly, and a lower baffle with a fixed front end and a suspended rear end is installed behind the tail blade. The adjusting device can stabilize the mass flow of the drainage channel in the suction test section, provide a stable drainage channel shock wave structure in a local low-pressure environment, regulate and control the pressure distribution condition in front of the grid, and achieve starting and uniformity adjustment of a supersonic flow field.

Owner:中国空气动力研究与发展中心空天技术研究所

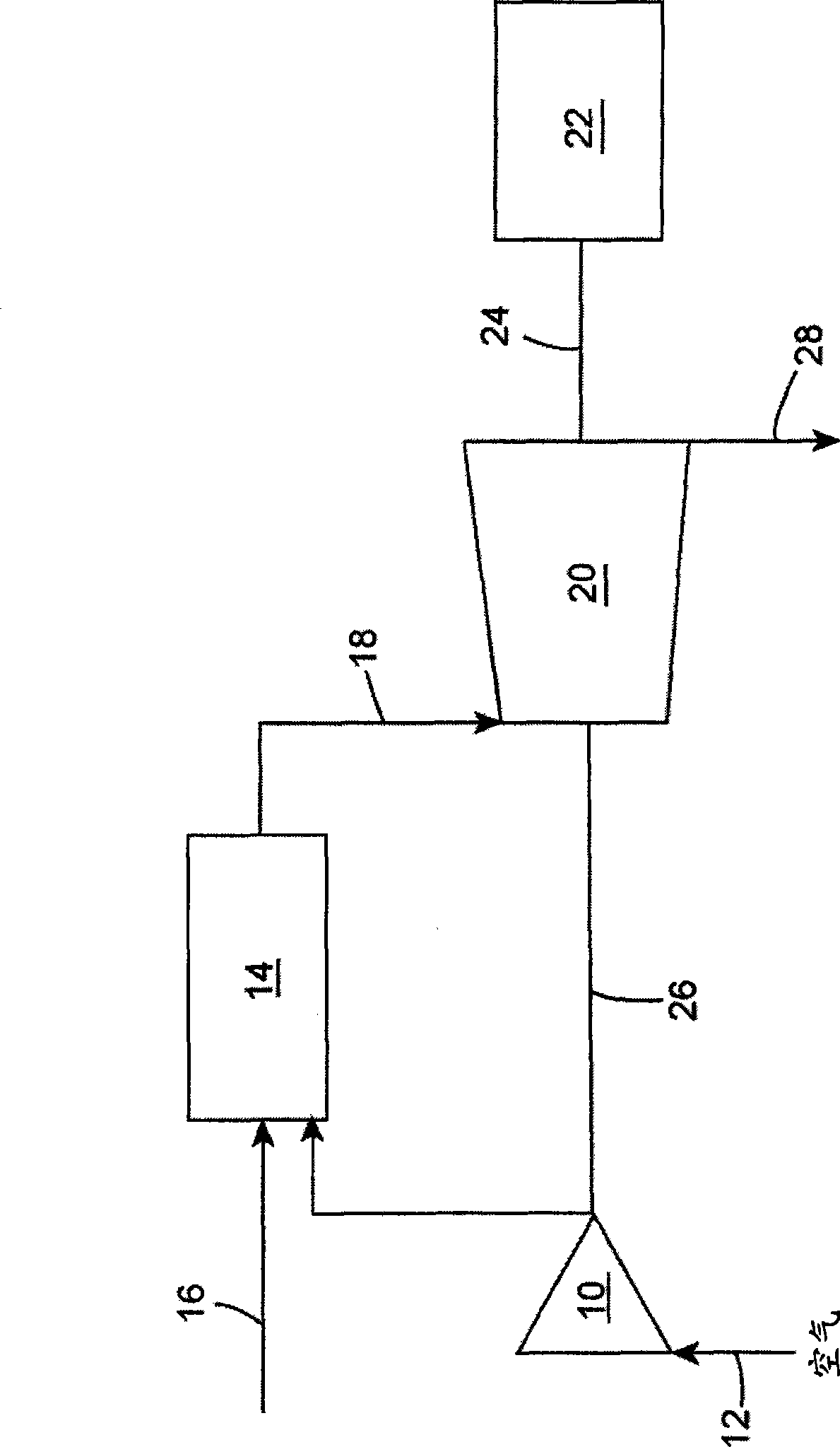

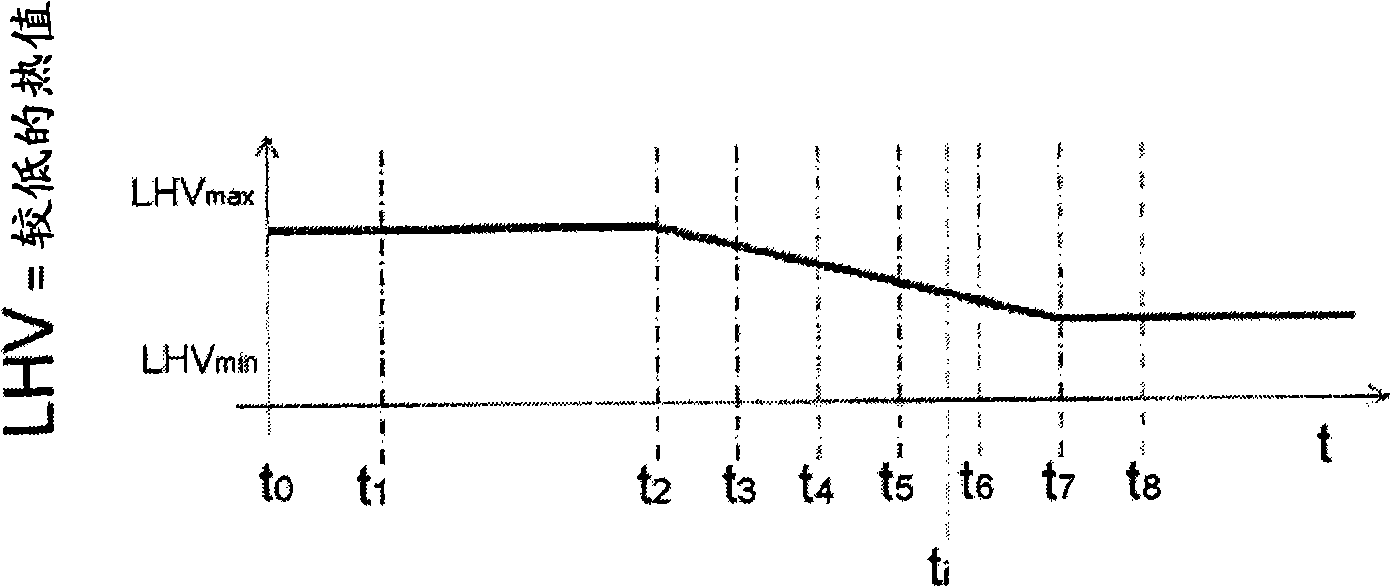

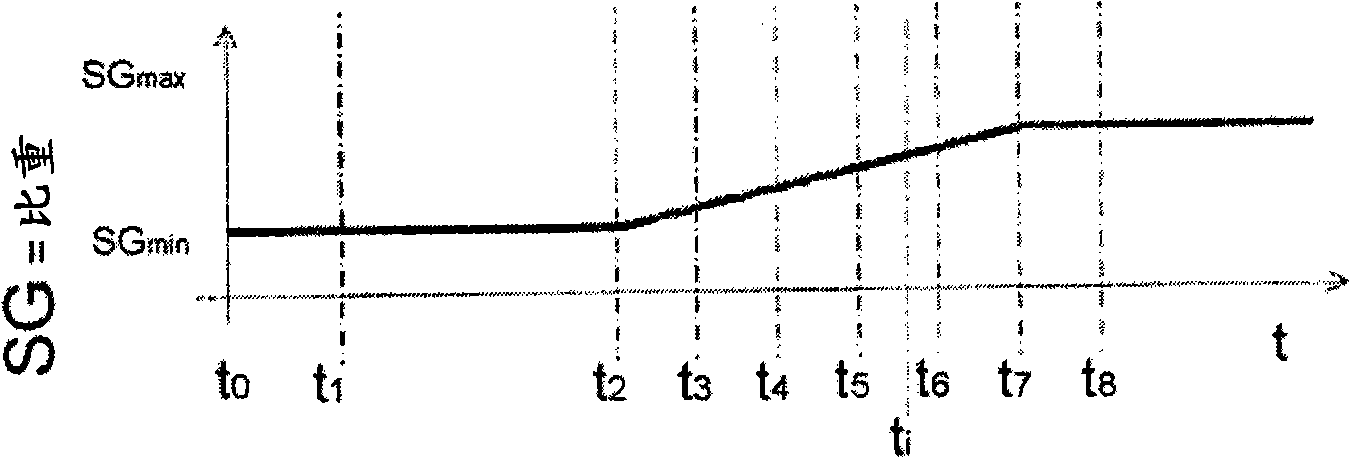

Method for the start-up of a gas turbine

InactiveCN101503977AEffective startSecure bootTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustorCombustion chamber

A method is described for the start-up of a gas turbine comprising the phases of effecting a preliminary purging cycle of the discharge duct (28) of the turbine (20), establishing a predetermined minimum value (FSR 1 ) for the flow of gaseous fuel entering the combustor (14) for a period of time which is adequate for effecting a first attempt at ignition and effecting a first attempt at ignition, effecting an intermediate purging cycle of the discharge duct (28), interrupting the flow of gaseous fuel to the combustor (14), and progressively increasing the value (FSR n ) of the flow of gaseous fuel entering the combustor (14), effecting further attempts at ignition until the mixture of air / gaseous fuel has been ignited and the consequent start-up of the turbine (20), or until a predetermined maximum value (FSR max ) of the flow of gaseous fuel has been reached.

Owner:NUOVO PIGNONE SPA

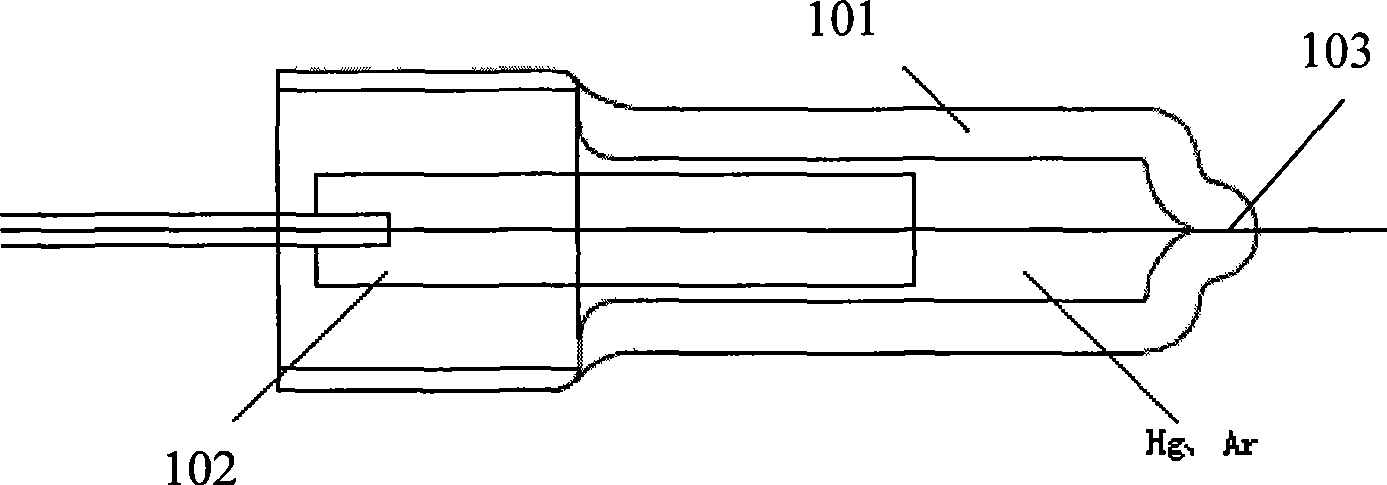

Metal halide lamp and UV bubble structure thereof

InactiveCN101436515AReduce volumeSmall Hg contentGas discharge lamp detailsMetal-halide lampMetal sheet

The invention discloses a UV bulb structure, which comprises a quartz glass shell, a molybdenum sheet and mixed gas of Hg and Ar packed in the shell. The shell is in a cylindrical shape, and the bottom of the shell is provided with a protrusion, wherein the content of the Hg is less than 0.5 milligram. As the content of the packed Hg is small, the structure is not easy to burst under heat, and possibly caused pollution is effectively reduced at the same time. The invention also discloses a metal halide lamp, which comprises a UV bulb, two electrodes and an electric arc tube, wherein the molybdenum sheet of the UV bulb is connected with one electrode; the shell of the UV bulb is connected with the other electrode through a metal sheet or a metal wire; and the metal sheet or the metal wire is wound around the outside of the UV bulb shell. The metal halide lamp has the advantages of no radioactivity and small volume. The gas between the molybdenum sheet and the quartz glass shell discharges electricity so as to emit rays to irradiate the electric arc tube, which can effectively help to start the metal halide lamp.

Owner:SHANGHAI YAMING LIGHTING

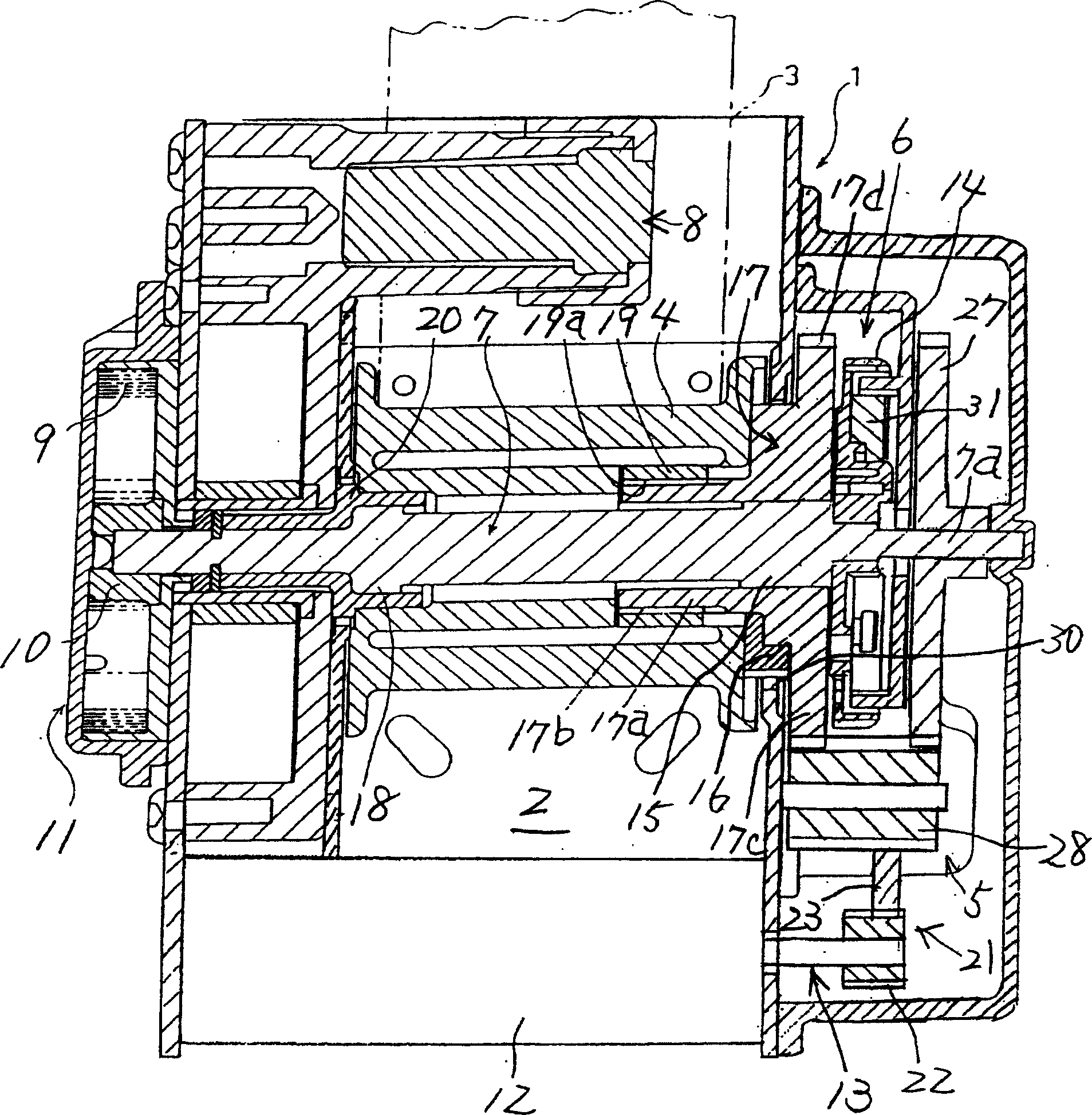

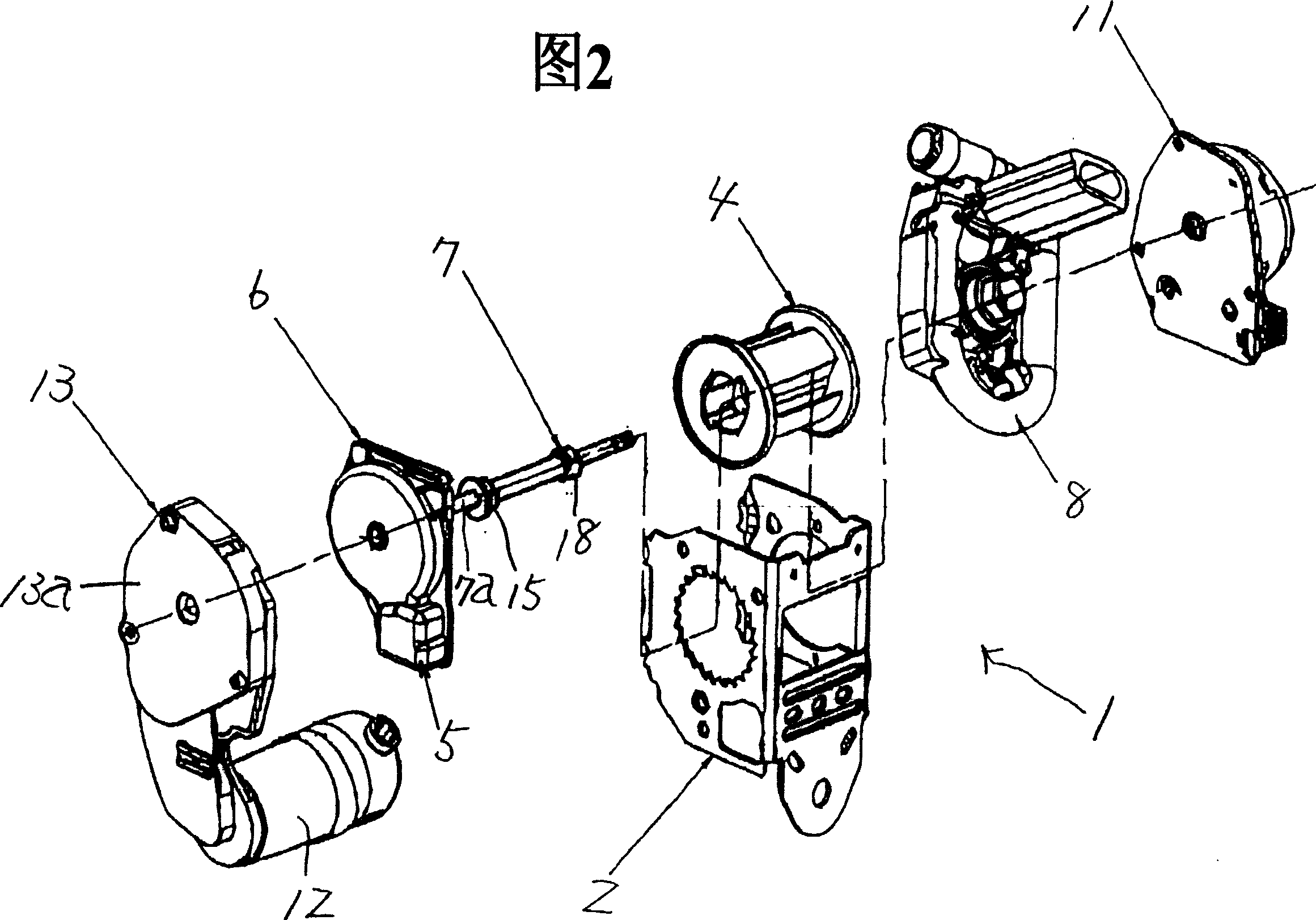

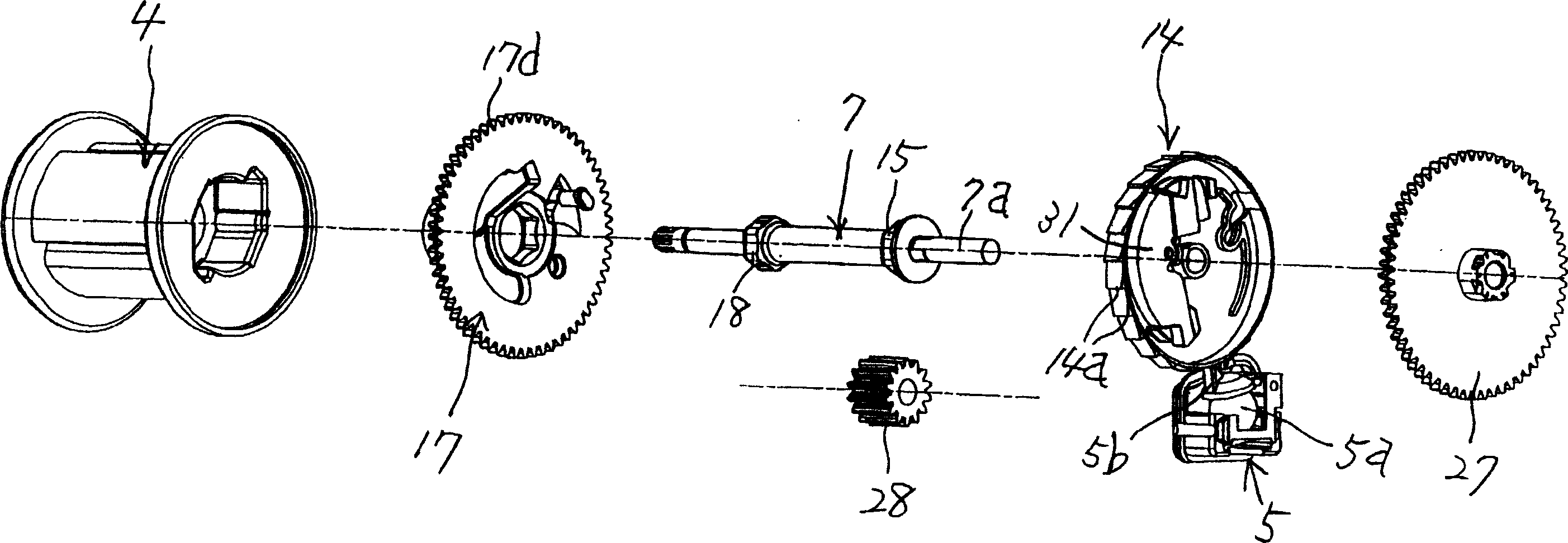

Seatbelt retractor

InactiveCN1597398AEfficient deliveryEasy to passBelt retractorsBelt control systemsMotor driveLocking mechanism

In order to more effectively absorb shock energy by a torsion bar included in a motor-driven emergency locking retractor, the power of a motor (12) is transmitted to a spool (4) through a connecting gear (27) of a power transmission mechanism (21), a pinion gear (28), a locking base (17), the torsion bar (7), and a bushing (20), and the spool (4) rotates so as to control the tension of a belt (3). Also, activation of deceleration-sensing means (5) causes a pawl (16) to rotate and to engage with internal teeth (30) formed on the sidewall of a frame (2), thereby preventing rotation of the locking base (17). Thus, the torsion bar (7) is twisted, and only the spool (4) rotates. In this state, a motor-driving unit (13) is disposed close to a locking mechanism (6) of the torsion bar (7), and the spool (4) rotates without receiving a resistance from the motor-driving unit (13), whereby shock energy is easily transmitted to the torsion bar (7).

Owner:TAKATA CORPORATION

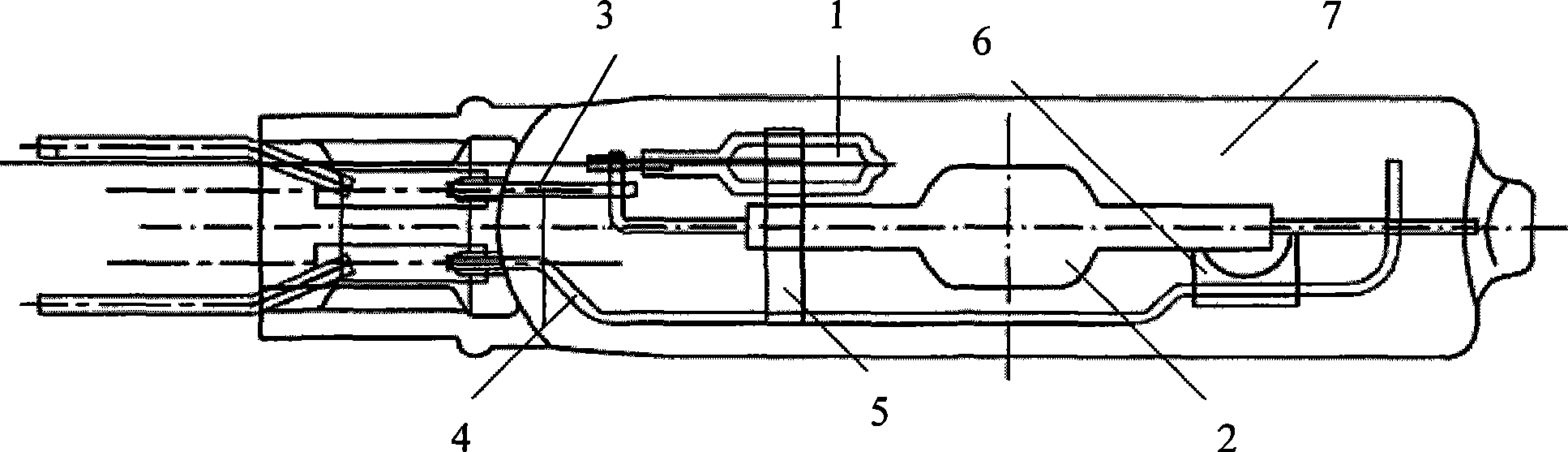

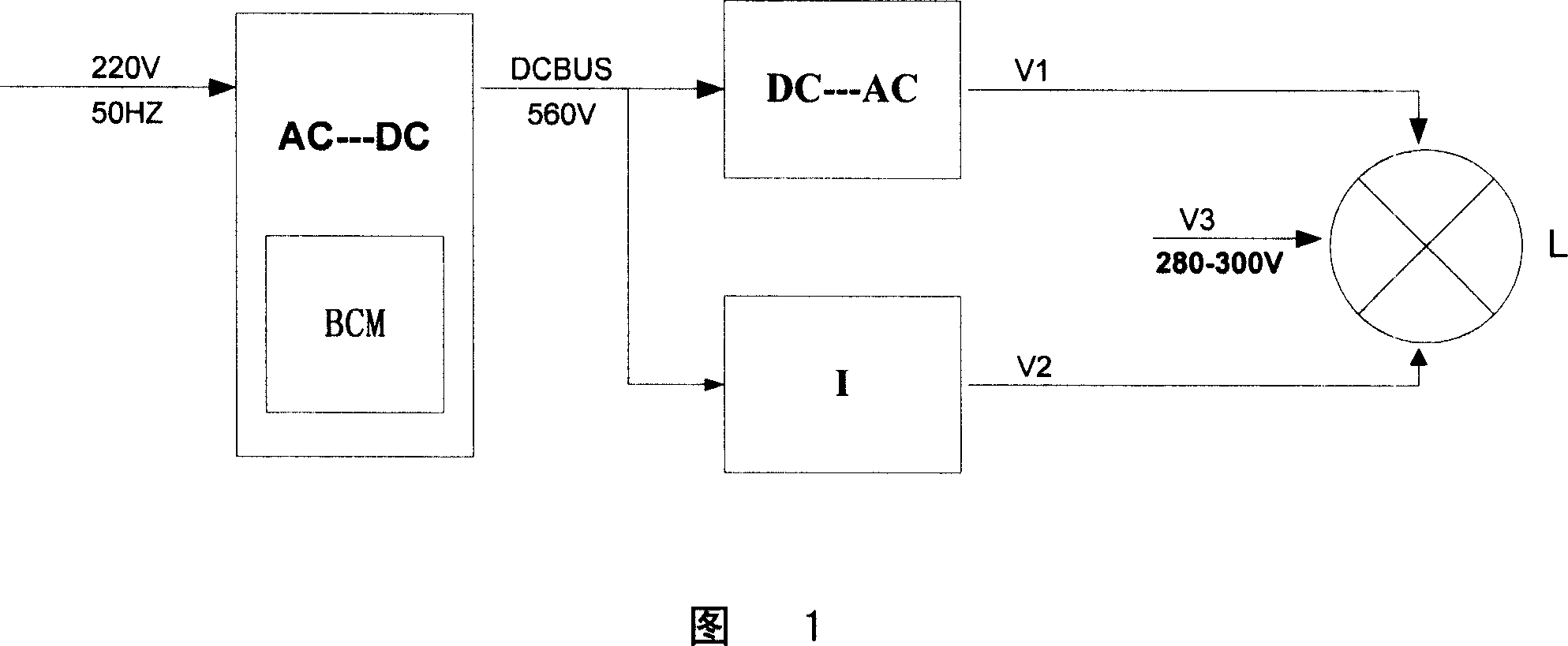

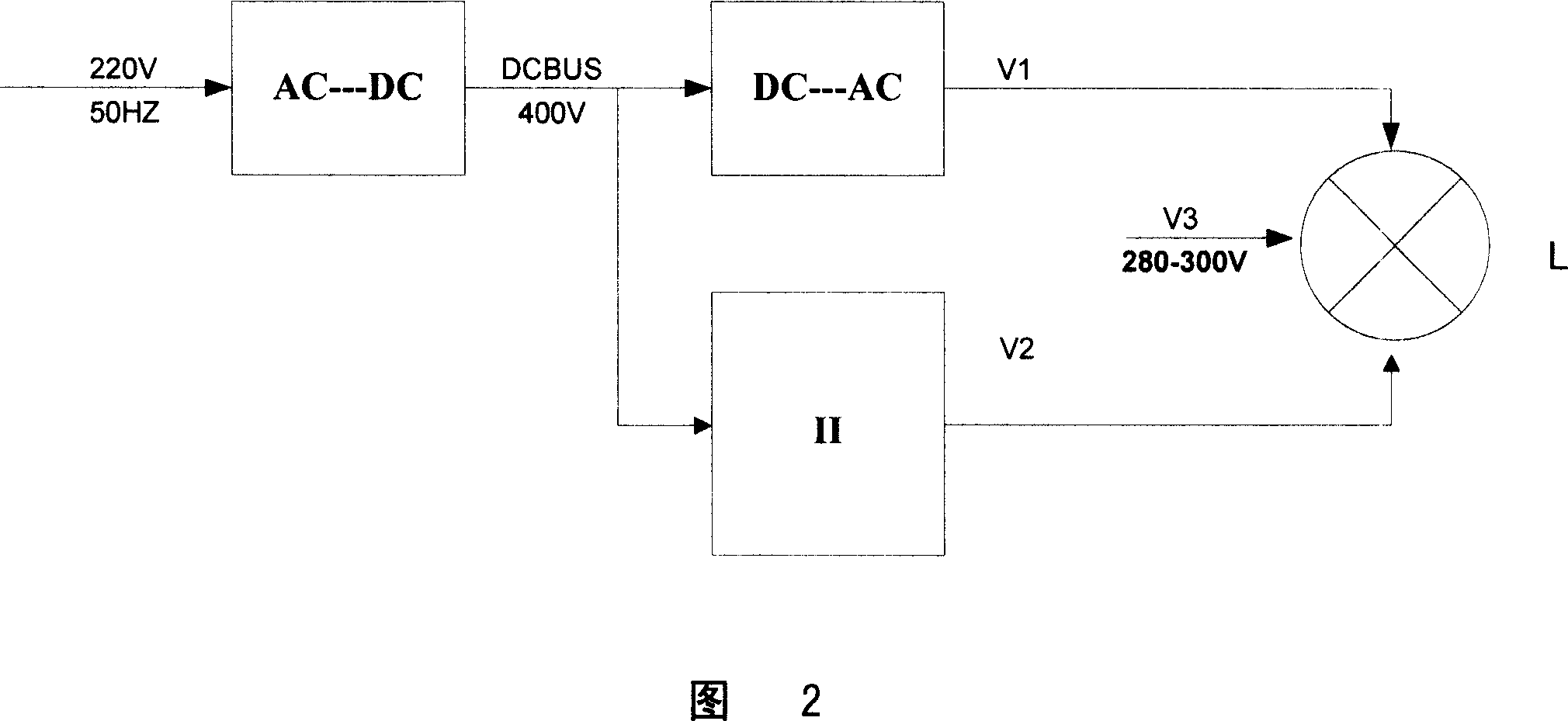

Starting device for gaseous discharging lamp

InactiveCN1960594AEffective startLow costElectrical apparatusElectric lighting sourcesHigh intensityPulse voltage

The invention is designed to be used in the ballast of high intensity gas-discharge lamp and comprises: a first module for generating first group of pulse voltage according to a low frequency driving signal; a second module for generating second group of pulse voltage according to a high frequency driving signal; a stacking and boosting module for stacking and boosting the first group of pulse voltage and second group of pulse voltage in order to generate a group of outputting voltage for breaking down the discharge lamp.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Application of carboxylated carbon nanotube catalyst carrier

ActiveCN103191787BHigh degree of carboxylationHigh degree of baseCatalyst carriersCell electrodesRefluxFuel cells

The invention discloses a carboxylated carbon nanotube catalyst carrier as well as a preparation method and application thereof. The preparation method of the carboxylated carbon nanotube catalyst carrier comprises the following steps of: putting carbon nanotubes in the mixed liquid of concentrated HNO3 and concentrated H2SO4 in a volume ratio of (1: 3)-(3: 2) and performing constant-temperature reflux treatment in the range of 80-95 DEG C for 100-120 minutes, and then washing and drying, thereby obtaining the carboxylic carbon nanotube catalyst carrier. The catalyst carrier is used for preparing Pt / CNT catalyst; the obtained Pt / CNT catalyst is used as an air cathode material for preparing a single-cavity membrane-free air cathode microbial fuel cell. The rich oxygen-containing groups are introduced on the surface of the catalyst carrier prepared by the method, so that the oxygen reduction effect of the catalyst is improved; and the Pt / CNT catalyst prepared from the catalyst carrier succeeds in starting MFC (Micro Function Circuit) so that the start period of MFC is shortened, the internal resistance of MFC can be reduced and the output voltage of MFC also can be greatly increased.

Owner:SOUTH CHINA UNIV OF TECH

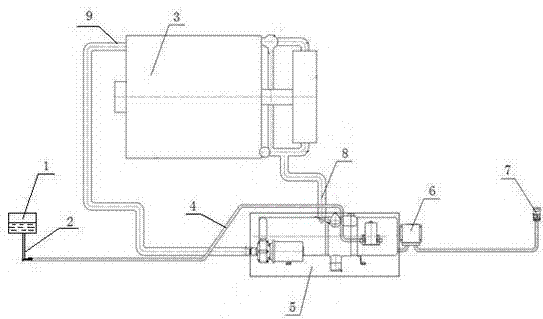

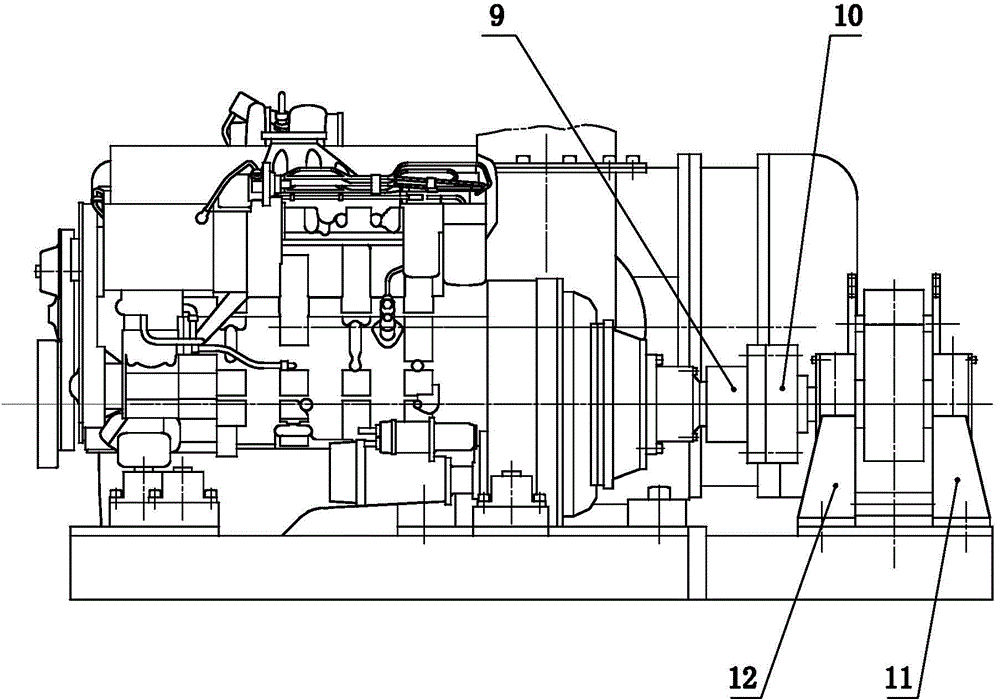

Low-temperature starting system of loader-digger

InactiveCN103541851AEffective startImprove adaptability to the natural environmentSoil-shifting machines/dredgersMachines/enginesElectricityFuel tank

The invention discloses a low-temperature starting system of a loader-digger. The low-temperature starting system of the loader-digger comprises a fuel tank and an engine and further comprises a liquid fuel heater, a controller and a switch. The fuel tank and the liquid fuel heater are connected through a fuel absorbing rod and a fuel conveying pipe. One end of the fuel absorbing rod is connected with the fuel tank, and the other end of the fuel absorbing rod is connected with one end of the fuel conveying pipe. The other end of the fuel conveying pipe is connected with the liquid fuel heater. The liquid fuel heater is fixed outside a shell of the engine, and an engine water inlet pipe and an engine water outlet pipe are connected with the liquid fuel heater. The controller is electrically connected with the switch and the liquid fuel heater through a wire harness. Fuel in the fuel tank is burned through the liquid fuel heater, cooling water in short circulation in the engine is preheated to 60 DEG C to 80 DEG C, and the purpose of preheating a body of the engine is achieved. Thus, the engine can be effectively started, and the natural environment suitability of the whole loader-digger is improved.

Owner:XUZHOU XUGONG SPECIAL CONSTR MASCH CO LTD

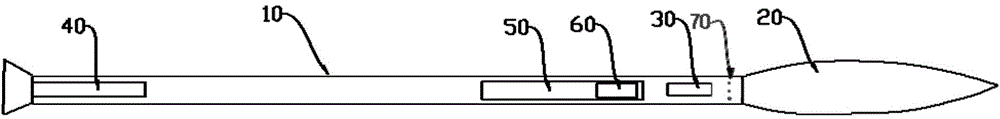

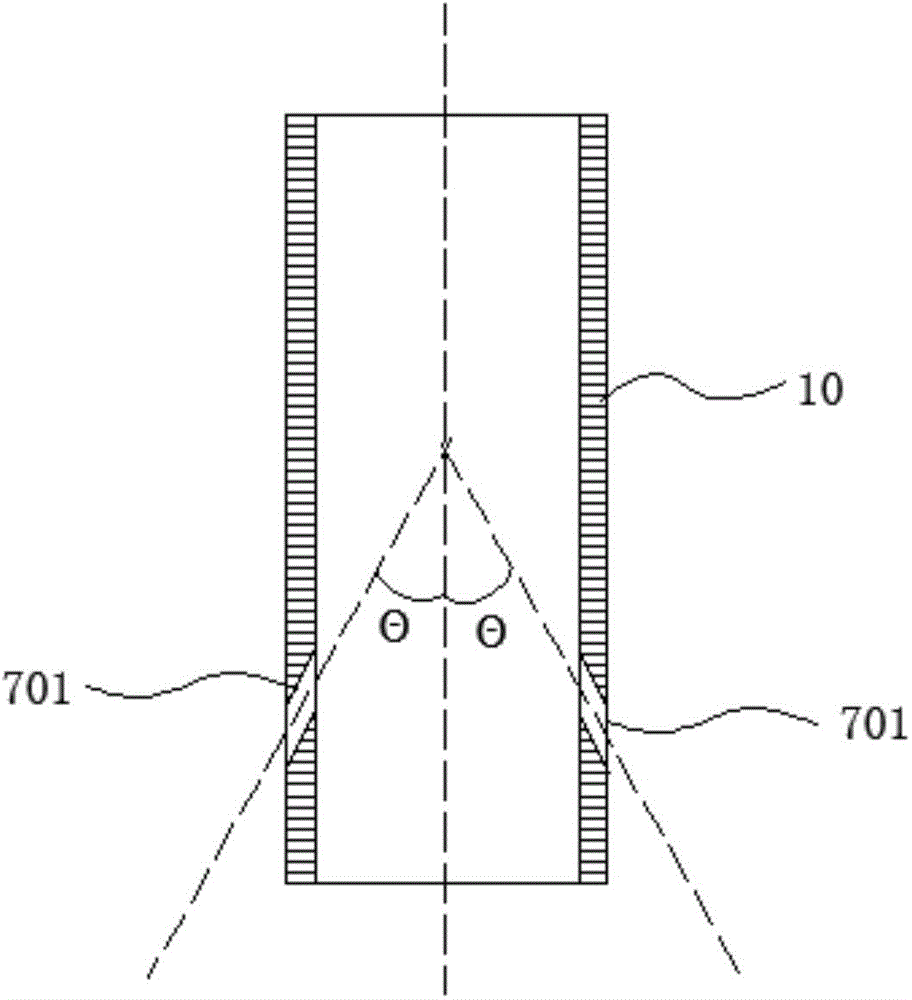

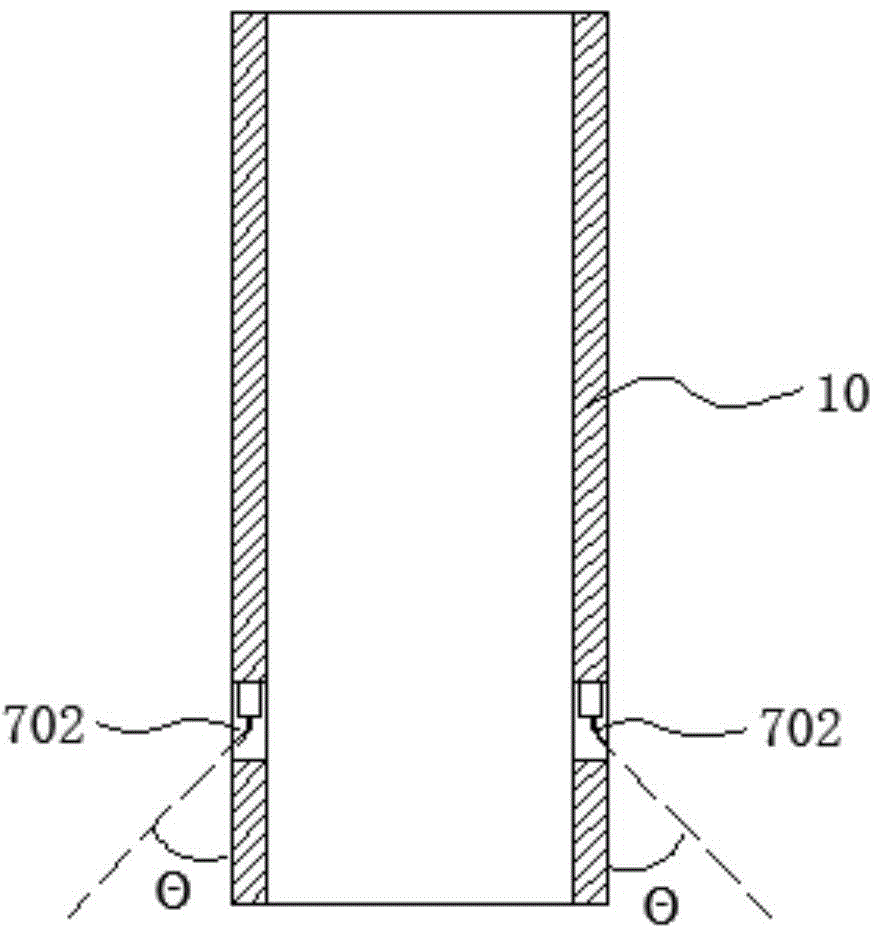

Positionable infrared paintbrush and positioning method thereof

ActiveCN104635960AEffective startEffective receiptInput/output processes for data processingAcute anglePaintbrush

The invention discloses a positionable infrared paintbrush and a positioning method thereof. The paintbrush comprises a paintbrush body (10), an infrared light source component (30) and a nib (20), the infrared light source component (30) is accommodated in the paintbrush body (10), the nib (20) is arranged at one end of the paintbrush body (10) and used for transmitting infrared light emitted by the infrared light source component (30) out of the paintbrush body (10), a plurality of infrared light emitting mechanisms (70) used for emitting the infrared light are arranged at one end, close to the nib (20), of the paintbrush body (10) so as to position the spatial position of the infrared paintbrush, the infrared light emitting mechanisms (70) are evenly distributed along the circumferential outer wall of the paintbrush body (10), the direction of the infrared light emitted by each infrared light emitting mechanism (70) on one side, facing the nib (20) is identical to that of the included angle of the axis of the paintbrush body (10), and the included angles are acute angles, so that the spatial position of the infrared paintbrush can be positioned according to incident points projected on a painting board by the infrared light emitting mechanisms, inclination of the paintbrush and distance between the tip of the nip and the painting board are judged, and first strokes and last strokes are effectively simulated.

Owner:INLIFE HANDNET CO LTD

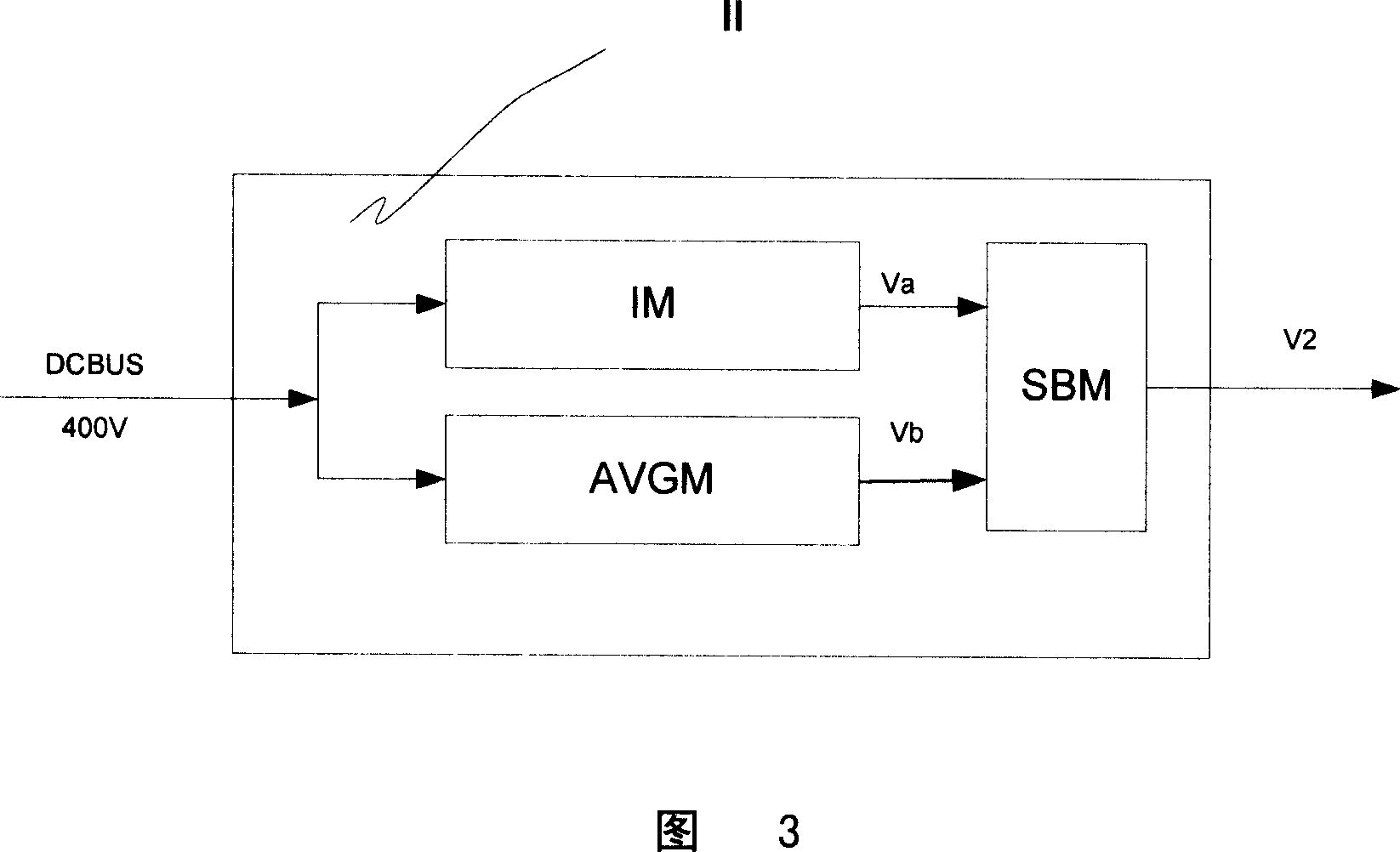

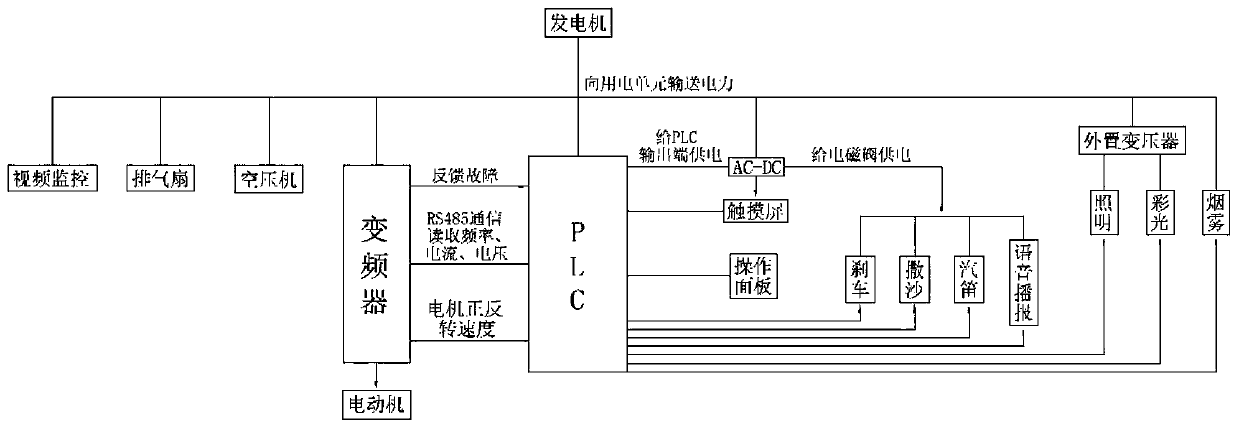

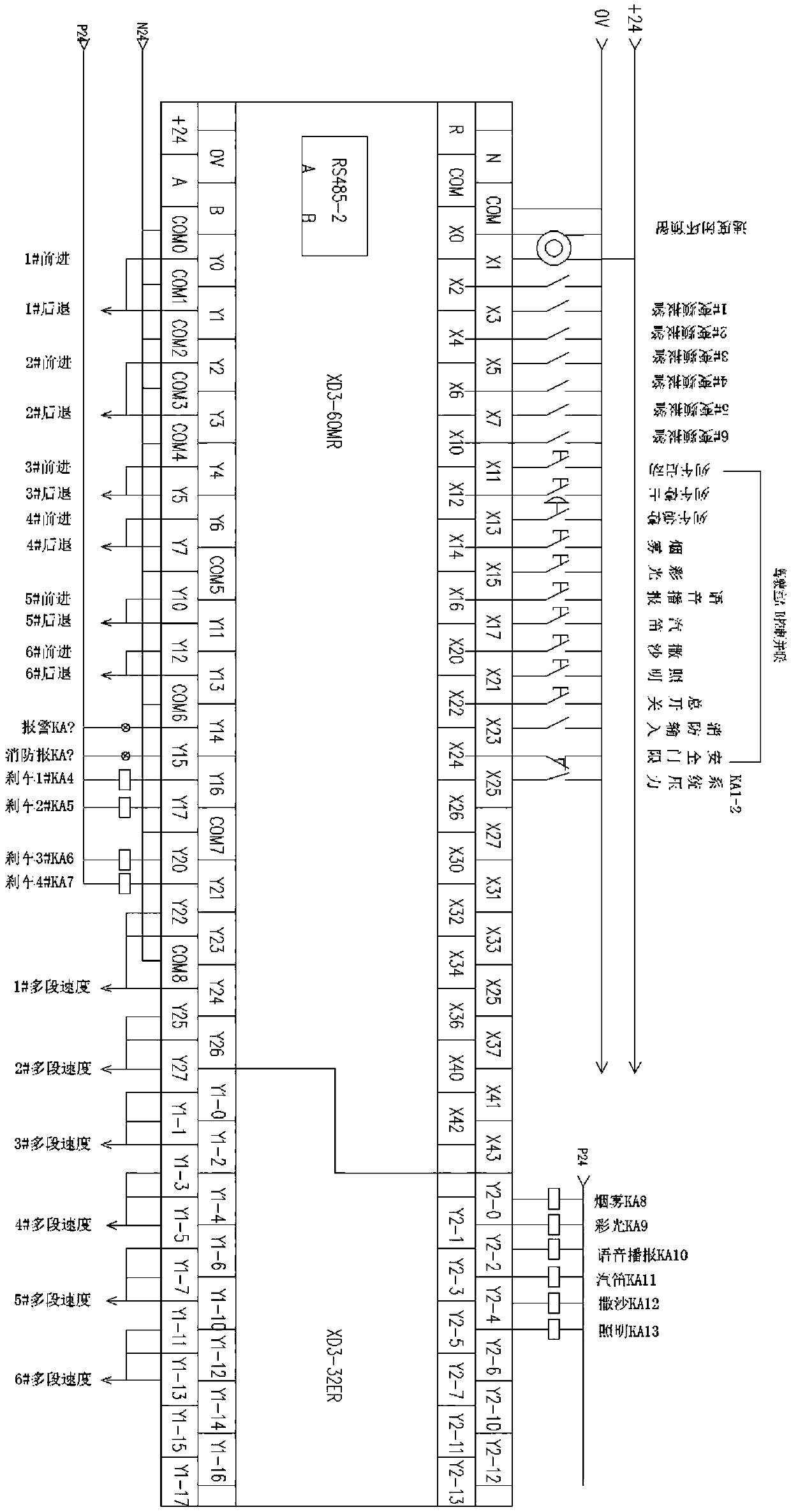

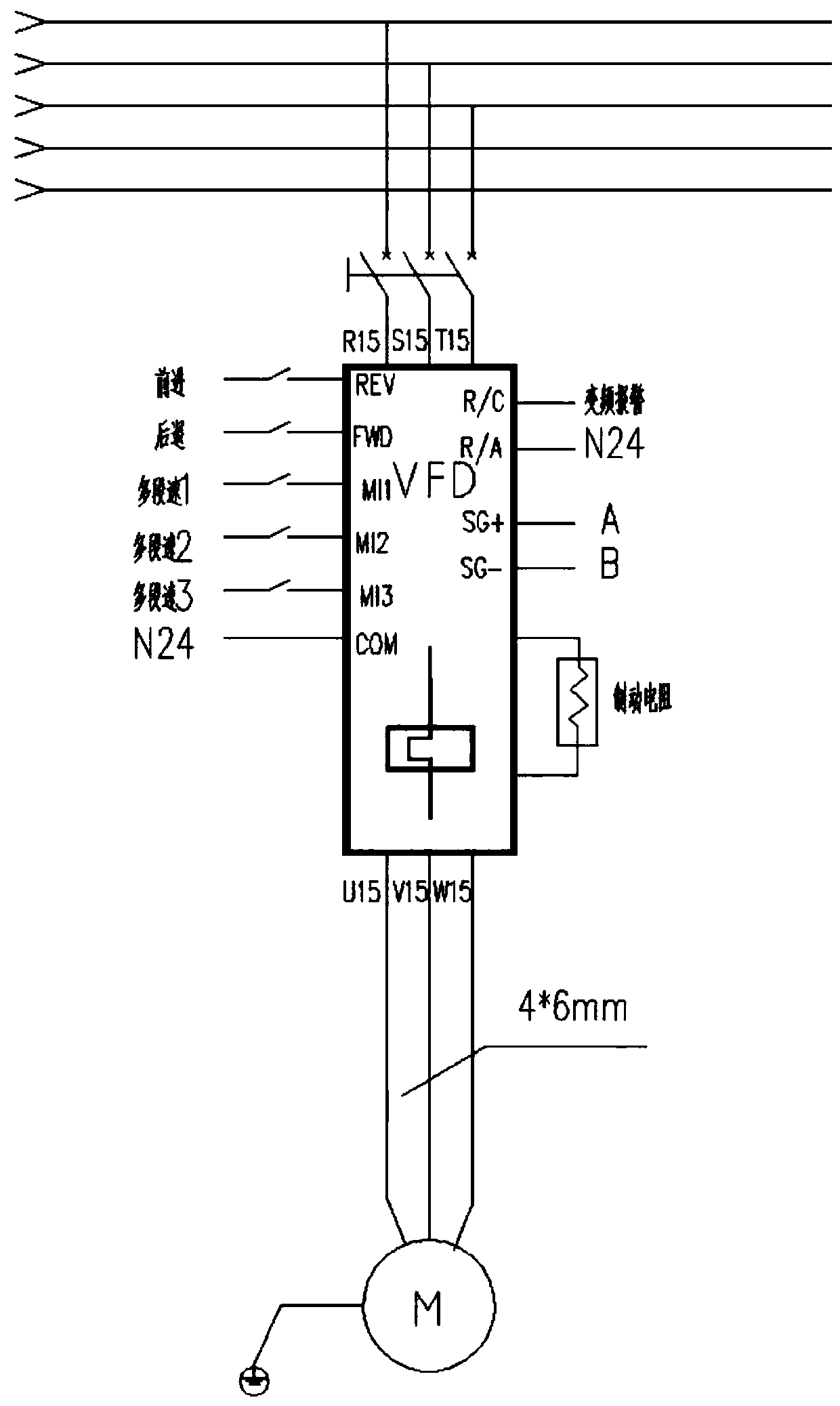

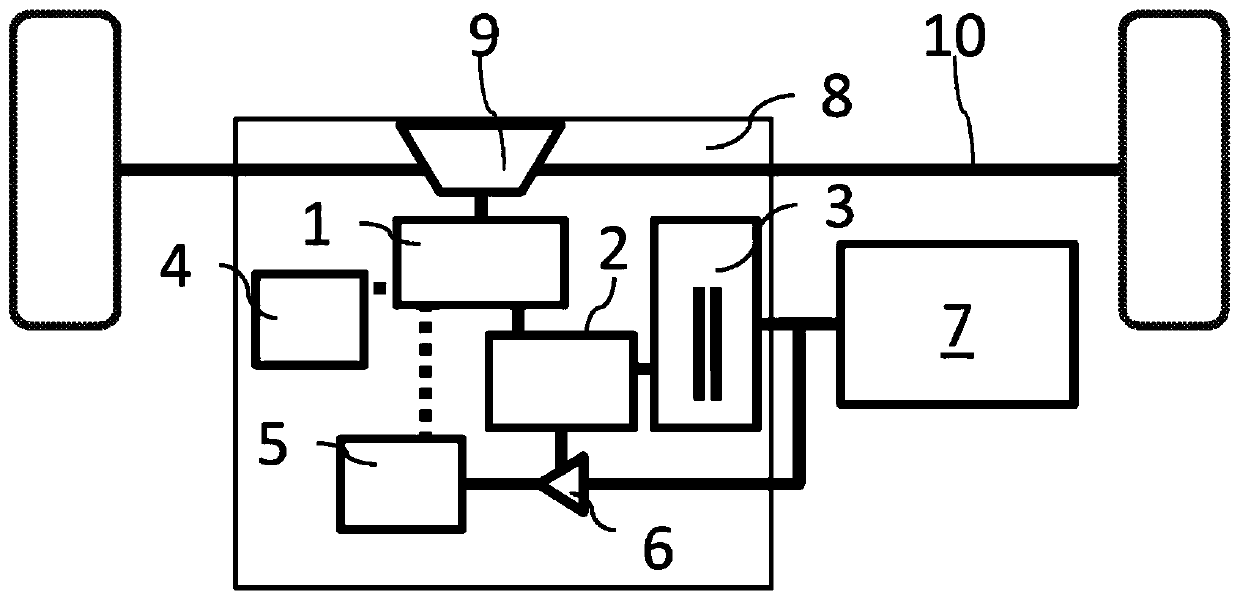

Sightseeing train control system

InactiveCN109814479AEffective startEffective stopProgramme control in sequence/logic controllersFrequency changerControl system

The invention discloses a sightseeing train control system which comprises a programmable logic controller (PLC), a frequency converter, a brake system, an operation panel and a touch screen. The PLCis connected with the frequency converter, the brake system, the operation panel and the touch screen through circuits, instructions are issued to the frequency converter and the brake system throughthe operation panel and the touch screen, and a power system of a sightseeing train is composed of a plurality of motors; each motor is connected with the frequency converter, and advancing, backing and stopping of the sightseeing train and control over the speed of the sightseeing train are realized by the PLC through the frequency converter. According to the sightseeing train control system, based on the PLC, control is accurate, the interface is user-friendly, operation is simple and convenient, running is stable, and the starting, stopping, running speed and running direction of the sightseeing train can be safely, effectively and reasonably controlled.

Owner:重庆艾博瑞威轨道交通设备有限公司

A kind of surfactant and its preparation method and application

The invention provides a surfactant as well as a preparation method and an application thereof. The surfactant comprises the following components by mass percent: 45%-65% of aliphatic alcohol polyoxyethylene ether sulfonate, 20%-35% of a cationic surfactant and 10%-20% of a surfactant assistant, wherein a molecular formula of the aliphatic alcohol polyoxyethylene ether sulfonate is CnH[2n+1]-(CH2CH2O)m-SO3Na, n is an any integer ranging from 12 to 15, and m is an any integer ranging from 2 to 5. The invention further provides the preparation method for the surfactant and the application of the surfactant to tertiary oil recovery of a carbonate reservoir. The surfactant is independently used, does not need to be added with alkali, and is free of damage to a stratum and an oil well; an oil washing system prepared from the surfactant can effectively change the wettability of a rock surface and strip off crude oil adsorbed on the surface of a carbonate rock, and the oil washing efficiency reaches more than 60%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

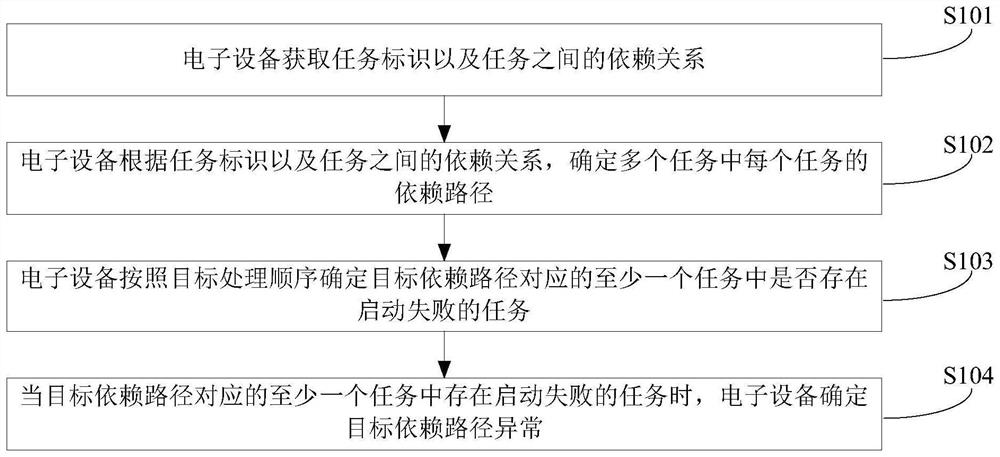

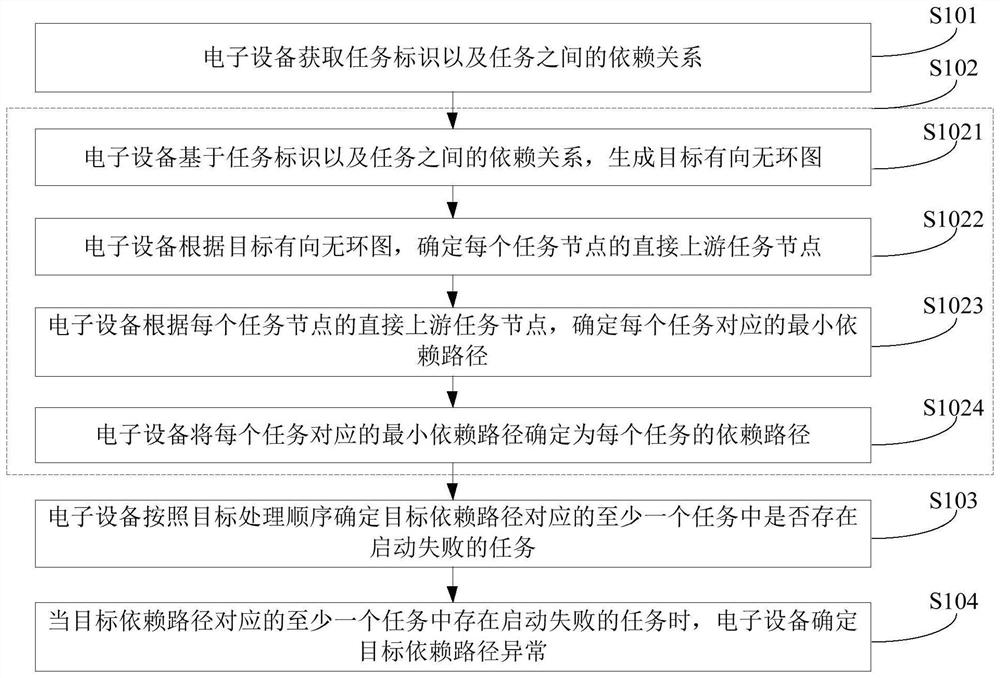

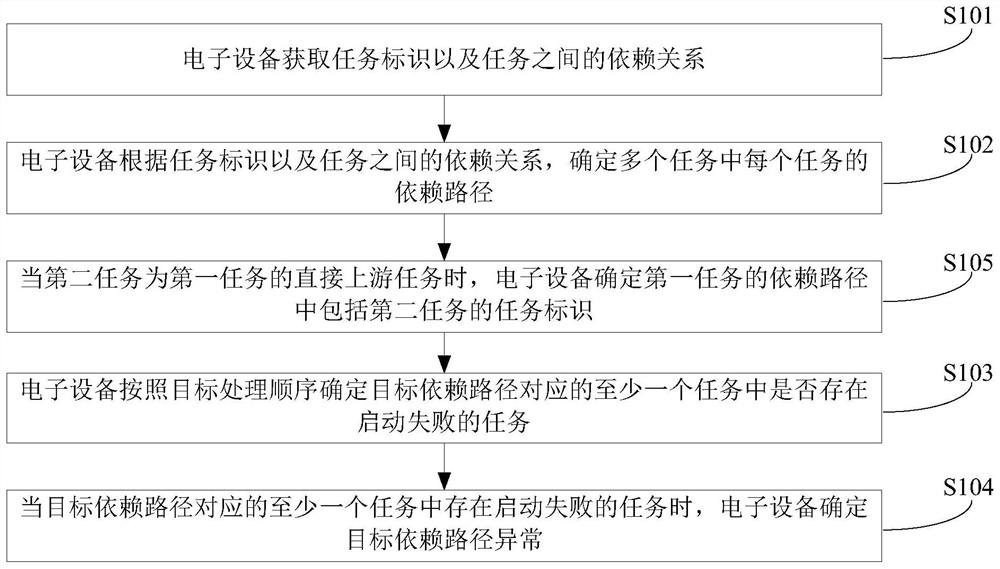

Task starting method and device, electronic equipment and storage medium

PendingCN114327673ASure reasonableEfficient determinationProgram loading/initiatingPathPingApplication procedure

The invention relates to a task starting method and device, electronic equipment and a storage medium, and relates to the technical field of computers. The method comprises the steps of obtaining a dependency relationship between task identifiers and tasks; determining a dependency path of each task in a plurality of tasks according to the task identifier and a dependency relationship between the tasks; determining whether a task failed to start exists in at least one task corresponding to the target dependency path according to the target processing sequence; and when the task failed to start exists in the at least one task, determining that the target dependency path is abnormal. According to the method and the device, the electronic equipment can reasonably and effectively determine the abnormal condition in the task processing process, so that the abnormal determination efficiency is improved, and effective starting of each task can be ensured. Furthermore, by processing the abnormal condition, the abnormal condition can be repaired, so that the target application program can be normally started.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

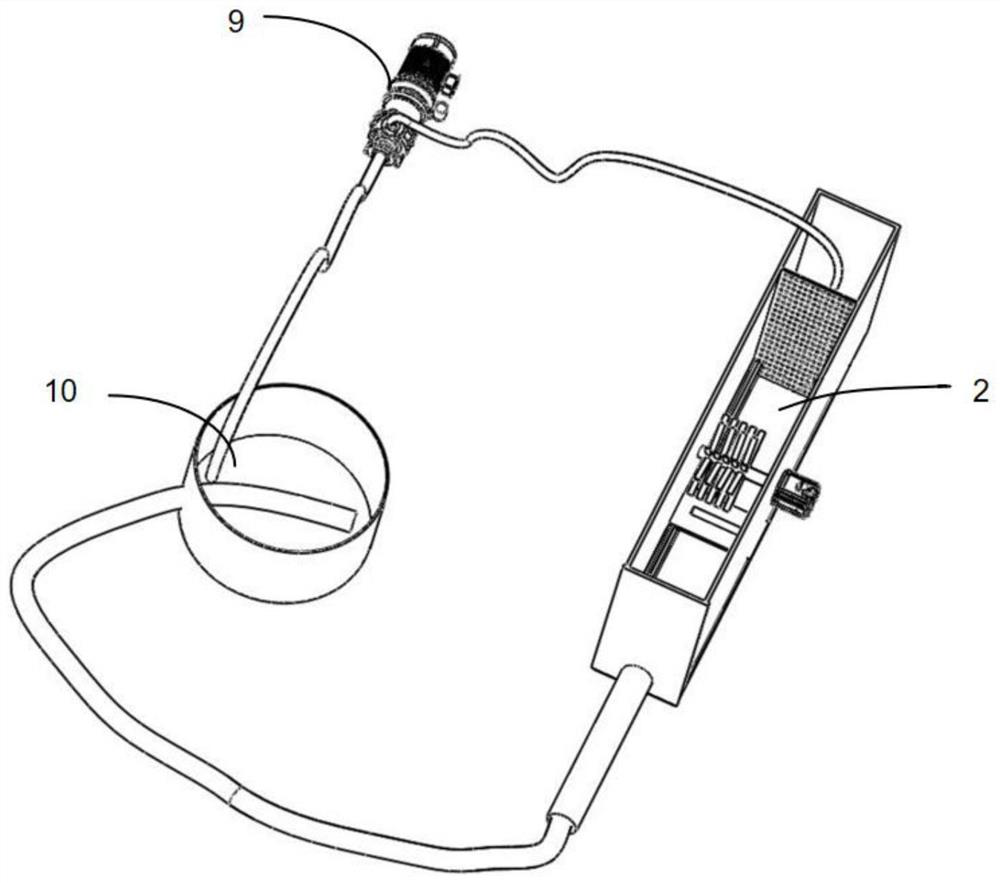

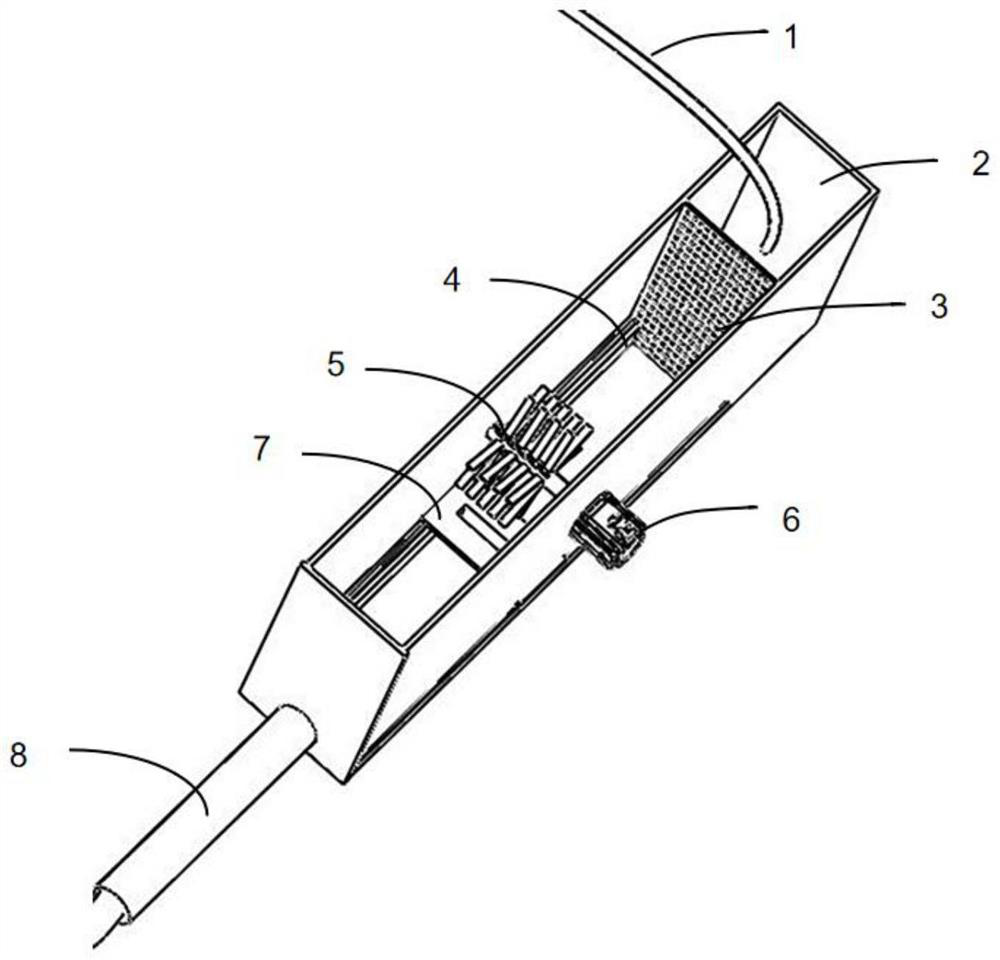

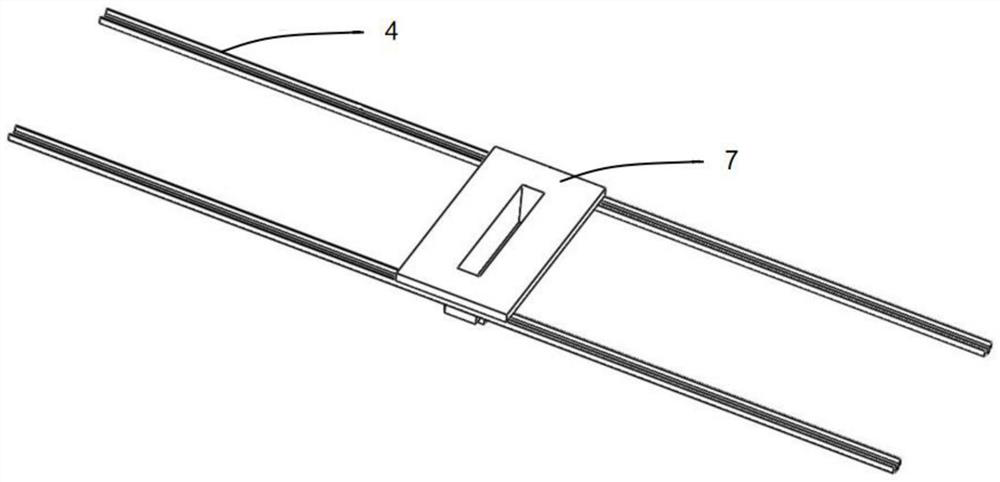

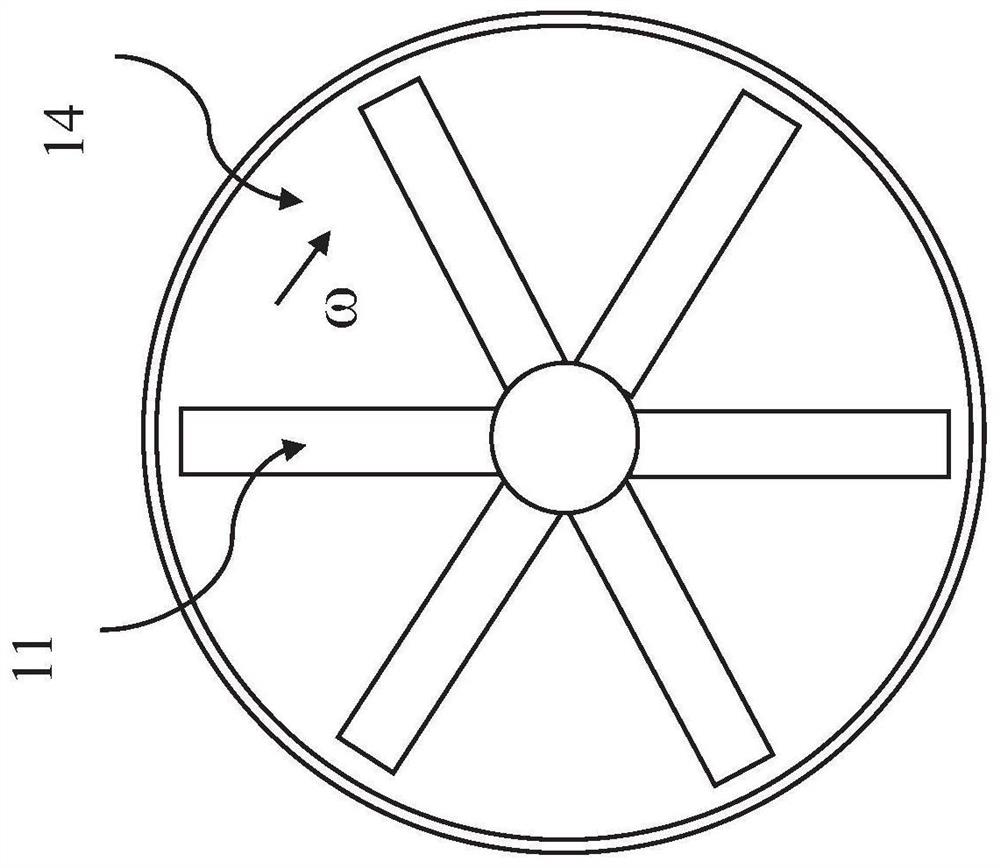

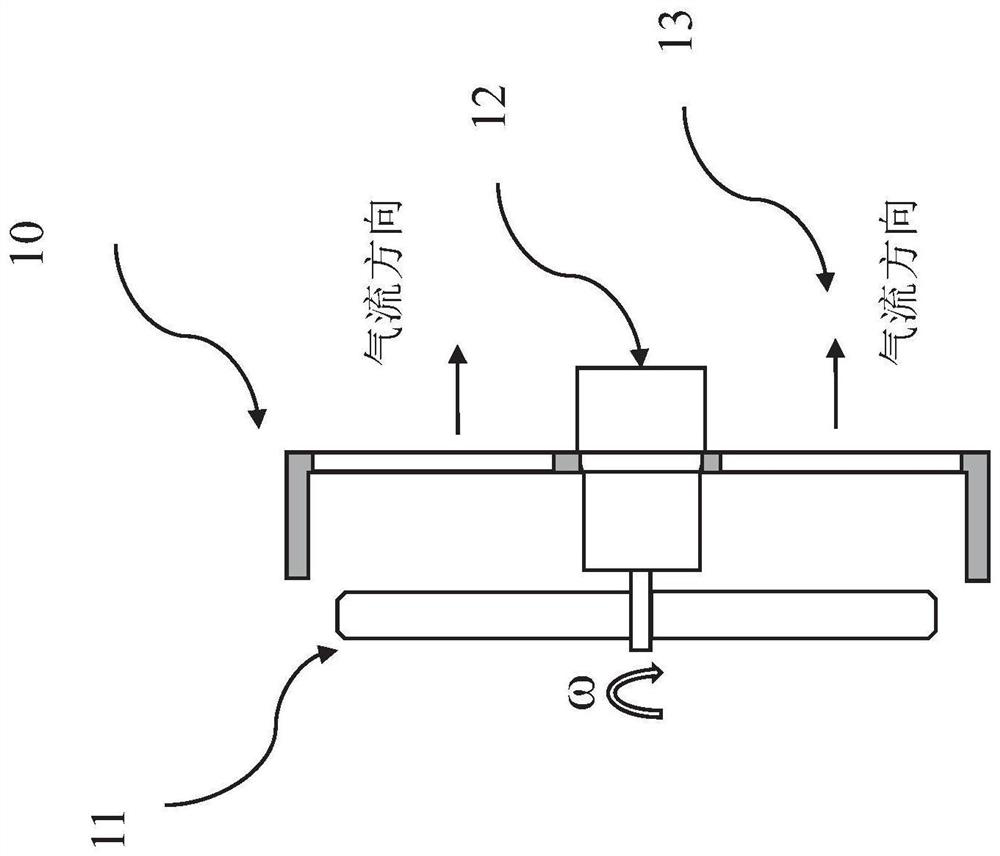

Experimental device for researching starting and washing rate of urban sewage sediment

ActiveCN114675003AEffective startEffective flushingHydrodynamic testingEarth material testingWater flowMunicipal sewage

The invention provides an experimental device for researching the starting and washing rate of urban sewage sediment, which comprises a circulating pump, an experimental water pool filled with experimental water and a circulating water tank communicated with one end of the experimental water pool, and the two ends of the circulating pump are respectively communicated with the other end of the experimental water pool and the circulating water tank. The driving device is used for driving the experimental water to circularly flow among the circulating pump, the experimental water pool and the circulating water tank; a sand box for accommodating a municipal sewage sediment sample and a rotating device for adjusting the water flow rate are arranged in the experimental water tank, so that the municipal sewage sediment sample in the sand box is started and washed under the action of the rotating device. By means of the mode, the starting rate and the washing rate of the urban sewage sediment sample under the effect of different uniform flow speeds at the same time can be obtained, and the good research effect on sedimentation of urban sewage pipelines is achieved.

Owner:CHINA CONSTR THIRD BUREAU GREEN IND INVESTMENT CO LTD

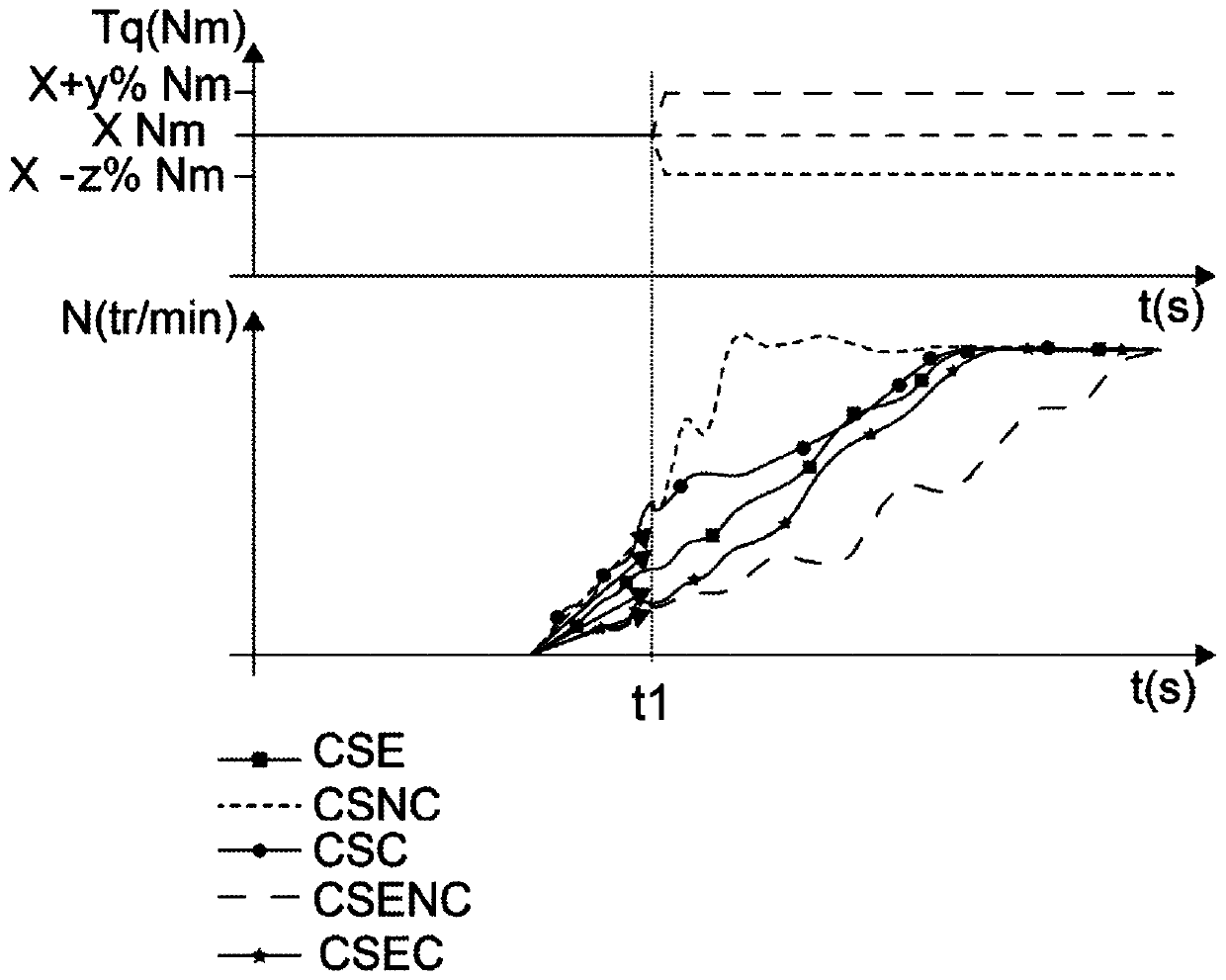

Method for controlling a clutch connected to an electric machine when a combustion engine starts

ActiveCN110382901AVibration and sound performance optimizationConvenient timeHybrid vehiclesClutchesFriction lossClutch

The invention relates to a method for controlling, when a combustion engine (7) starts, a clutch (3) that couples a high-performance electric machine (2) to the engine (7), the clutch (3) being controlled according to a reference maximum torque that can be transmitted to the engine (7) that is predetermined according to an estimate of the friction losses of the engine (7), so as to obtain a givenengine (7) speed gradient. A step of measuring or estimating an acceleration of the engine speed during the transmission of the reference torque is performed and when this measured or estimated acceleration returns a difference, in relation to the given speed gradient, of more than 6.66 revolutions per second squared, at least one step of correcting the reference maximum torque on the basis of themeasured or detected acceleration is performed so that the acceleration actually obtained during the start-up phase tends towards the given speed gradient.

Owner:PEZHO SITROEN AUTOMOBILS SA

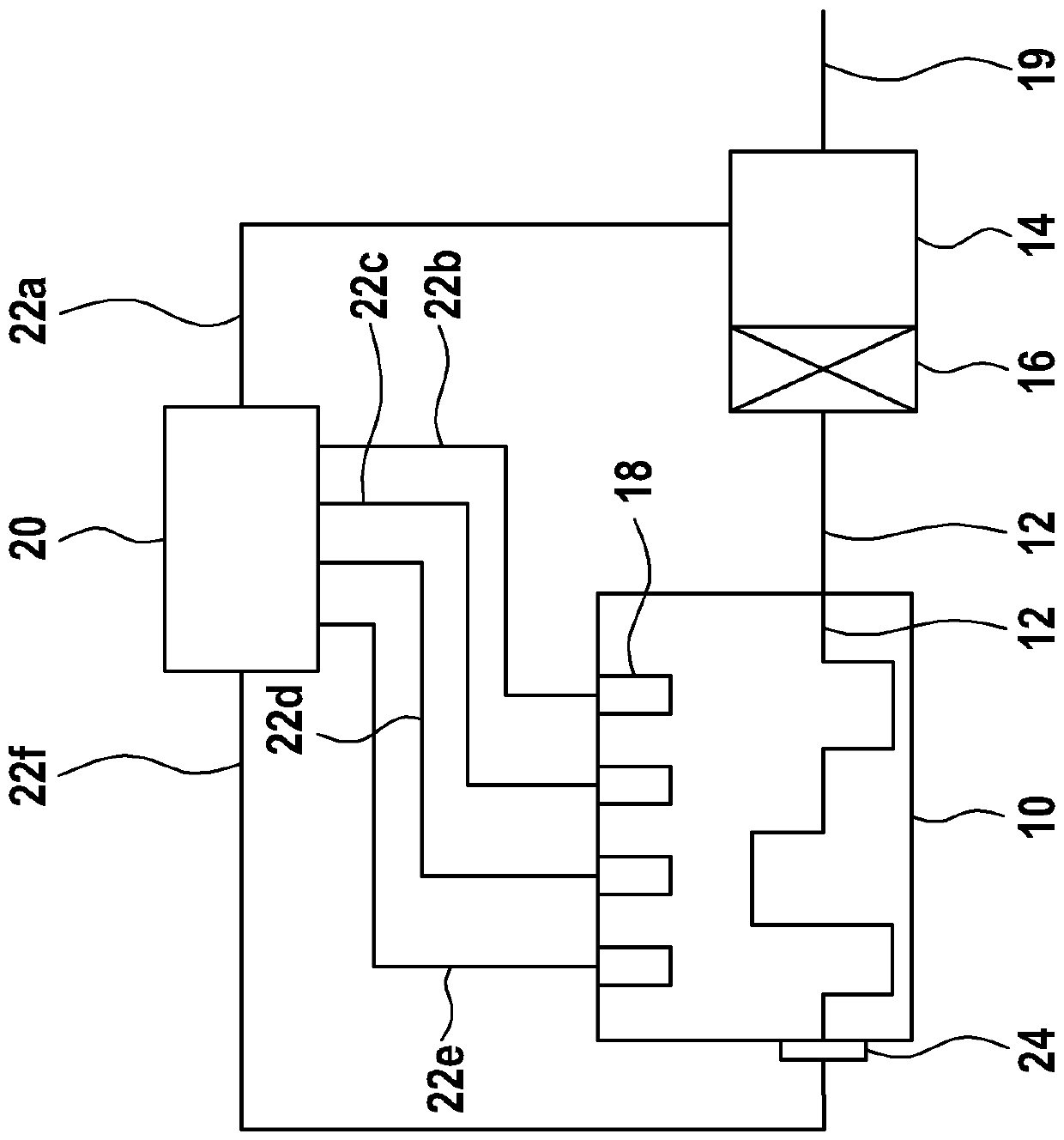

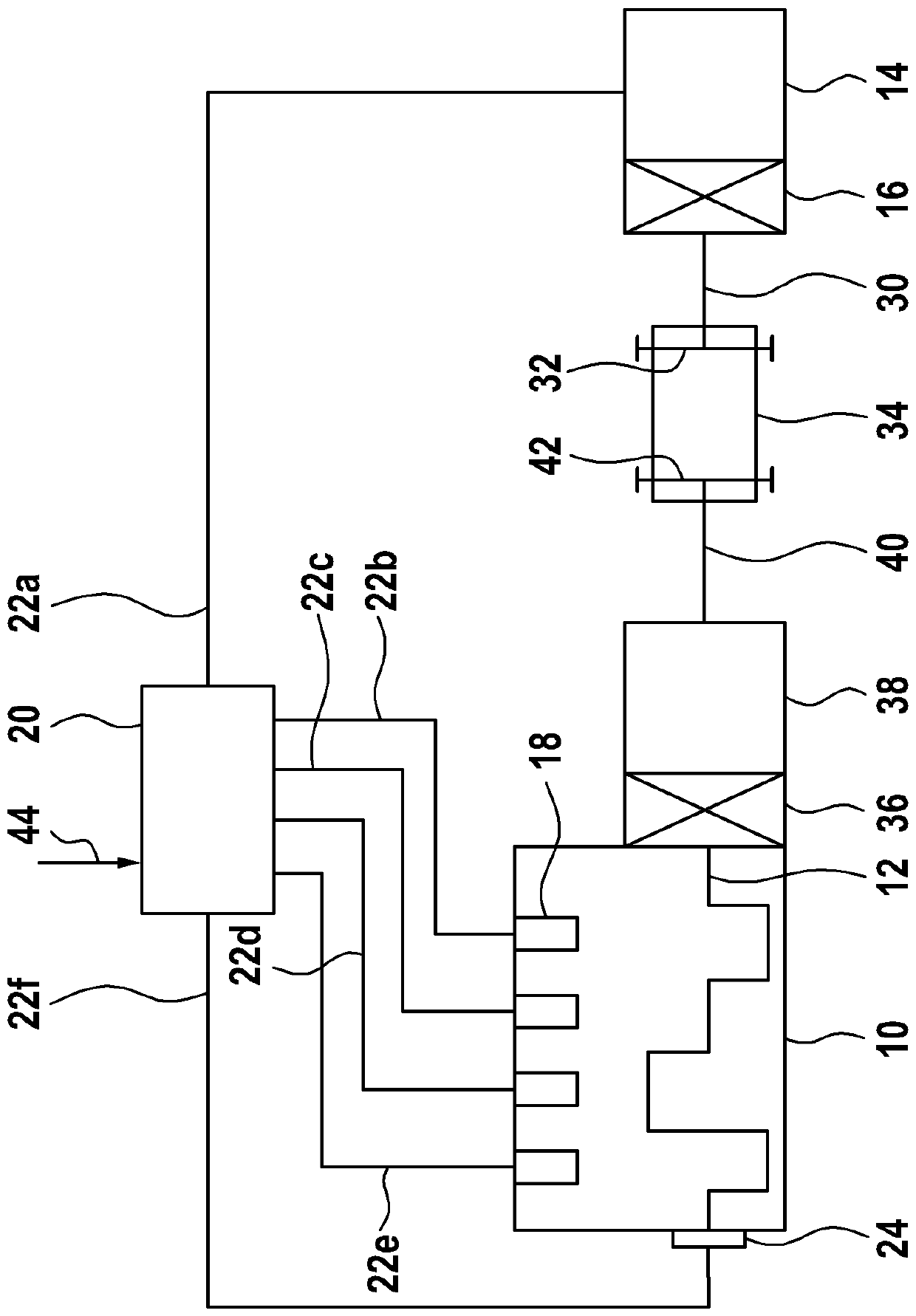

Method for operating hybrid drive system of hybrid vehicle and control device

InactiveCN110792544AComfort startEffective startHybrid vehiclesElectrical controlIgnition coilElectric machinery

The invention relates to a method for operating the hybrid drive system of a hybrid vehicle and a control device (20). According to at least one signal provided by one part of a hybrid vehicle (34), the start of the hybrid vehicle (34), which is static before the identification or prediction. During the operation period of the driving motor (14) of the hybrid drive system, through the rotation orlinkage of a crankshaft (12), the crankshaft (12) of the burning motor (10) of the hybrid drive system rotates to an initial position of the crankshaft (12) relative to the burning motor (10); from the moment when the crankshaft (12) exists on the initial position, the ejection valve an the ignition coil of the burning motor (10) can be controlled by the electronic device of the hybrid drive system to burn the burning motor (10); and after the hybrid vehicle (34) is started, the crankshaft (12) is rotated to the initial position.

Owner:ROBERT BOSCH GMBH

A supersonic plane cascade flow field start-up and uniformity adjustment device

ActiveCN113188748BAdjustable positionRegulating pressureGas-turbine engine testingAerodynamic testingShock waveEngineering

The invention discloses a supersonic plane blade cascade flow field starting and uniformity adjusting device. The adjusting device takes the flow from the cascade wind tunnel as the front, and includes an upper suction assembly installed above the leading blade of the cascade test model. Behind the upper suction assembly is an upper tail plate with a fixed front end and a suspended An upper baffle with a fixed front end and a suspended rear end is installed at the rear; it also includes a lower suction assembly installed under the tail blade of the cascade test model, and a lower tail plate with a fixed front end and a suspended rear end is installed behind the lower suction assembly. A lower baffle with a fixed front end and a suspended rear end is installed behind the tail blade. The adjusting device can stabilize the mass flow of the discharge channel in the suction test section, provide a local low-pressure environment to stabilize the shock wave structure of the discharge channel, regulate the pressure distribution in front of the grid, and realize the start-up and uniformity adjustment of the supersonic flow field.

Owner:中国空气动力研究与发展中心空天技术研究所

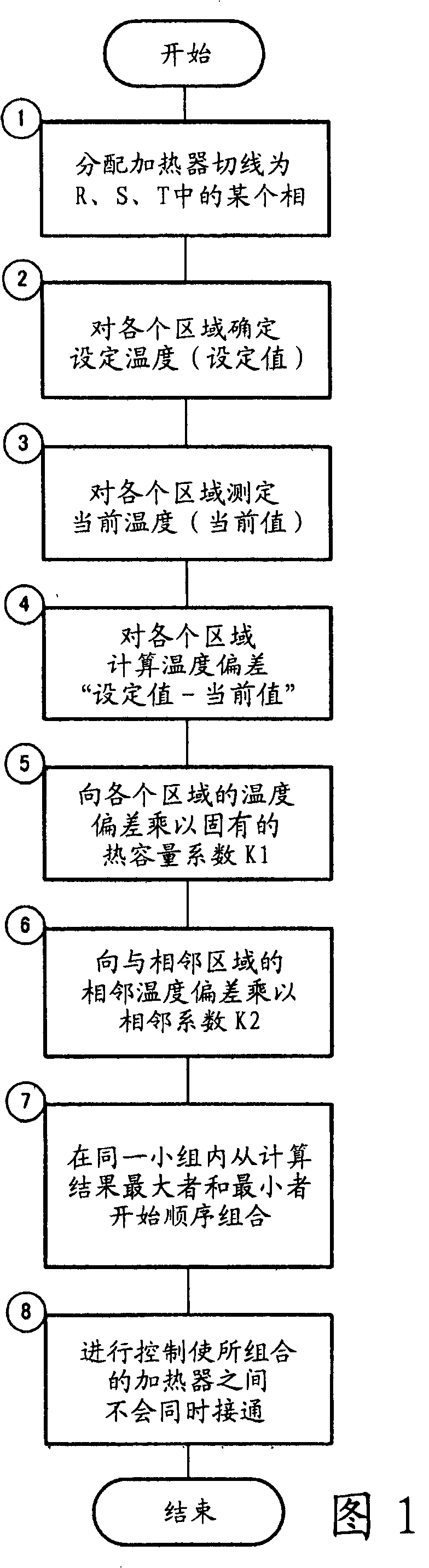

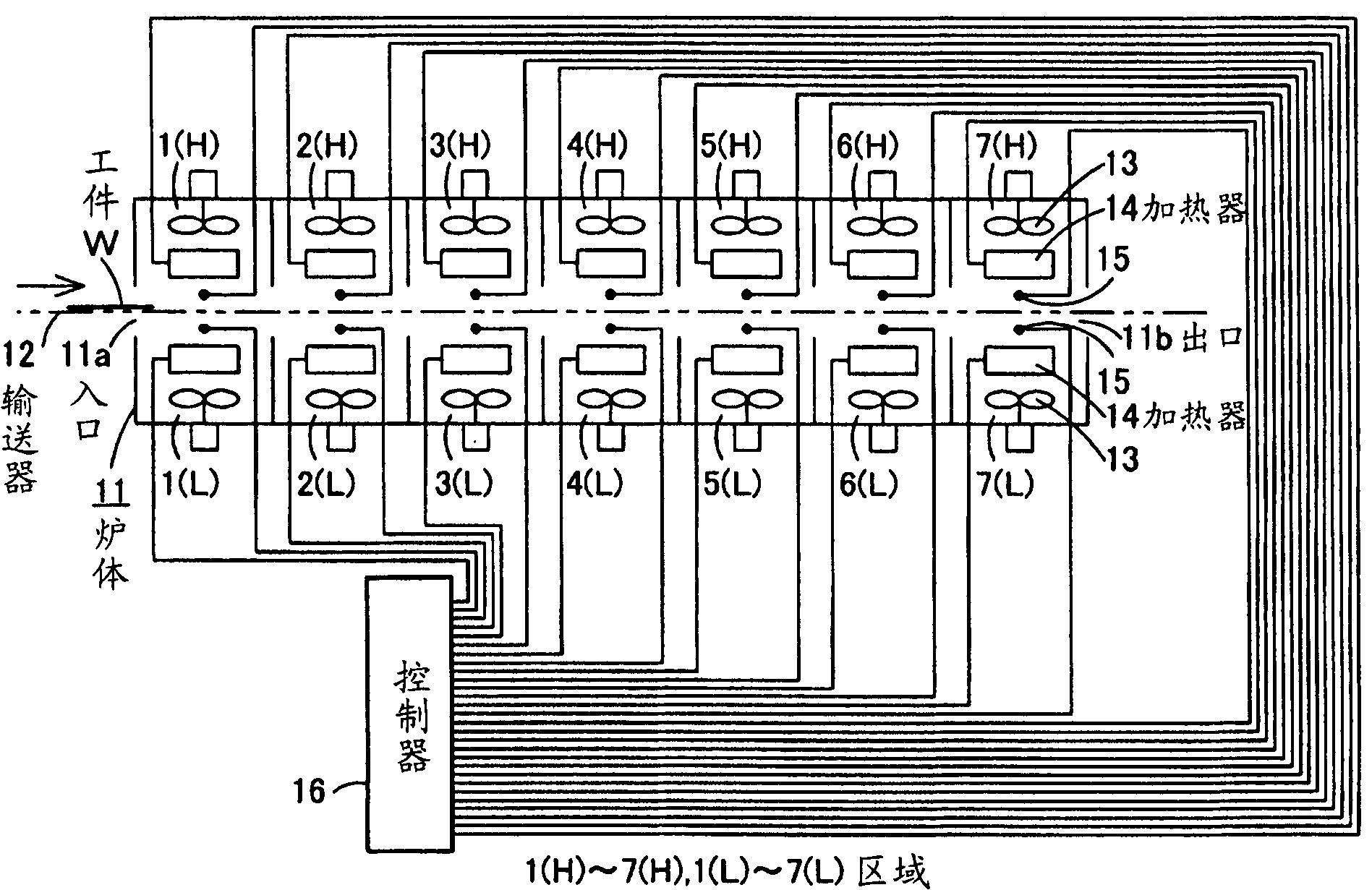

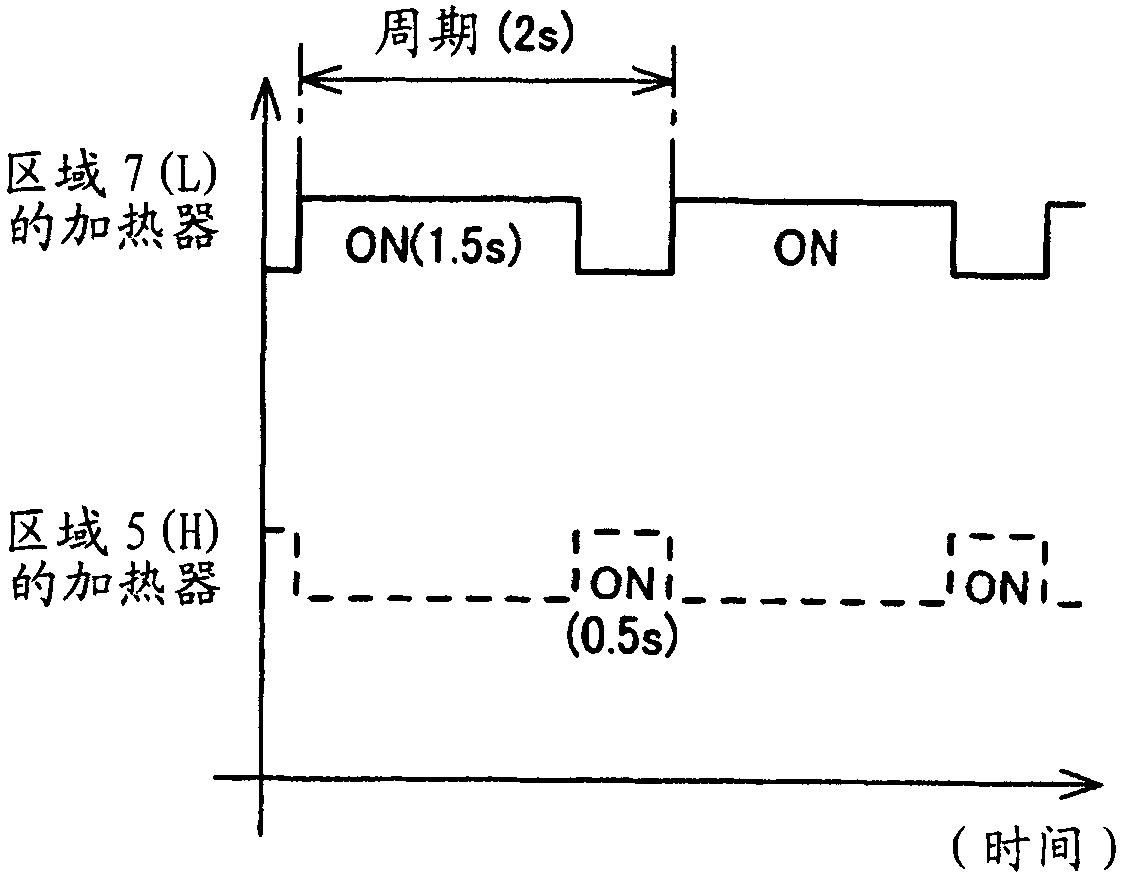

Method for controlling heating apparatus

InactiveCN1932704BControl power consumptionEffective startDrying gas arrangementsElectric programme controlEngineeringMechanical engineering

To provide a control method for a heating device capable of effectively starting the heating device by limited electric power consumption. (step 5) Heating priority is determined by a calculation of multiplying a temperature deviation of each zone by an inherent heat capacity coefficient K1 set per each zone. (step 6) Heating priority of a zone is subsidiarily determined by a calculation of multiplying an adjacent temperature deviation with an adjacent zone by an adjacent coefficient K2 set based upon an adjacent relationship. (step 7) An order from a zone with the maximum heating priority toa zone with the minimum heating priority is determined, one group is created by combining a plurality of zones including the zone with the maximum heating priority and the zone with the minimum heating priority, and groups are sequentially created by combining a plurality of zones in the same way from remaining zones. (step 8) Heater electric power consumption is limited in each group.

Owner:TAMURA KK +1

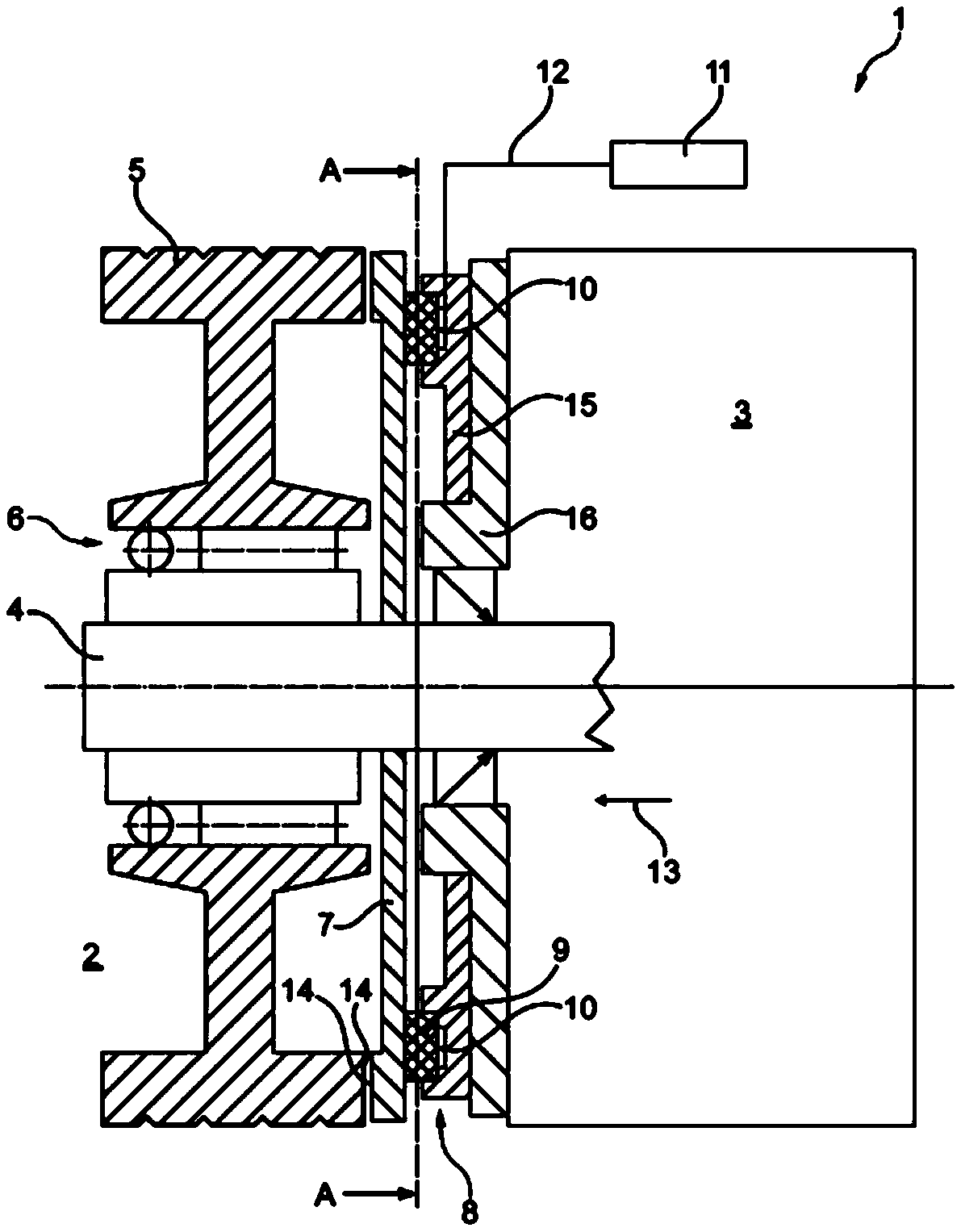

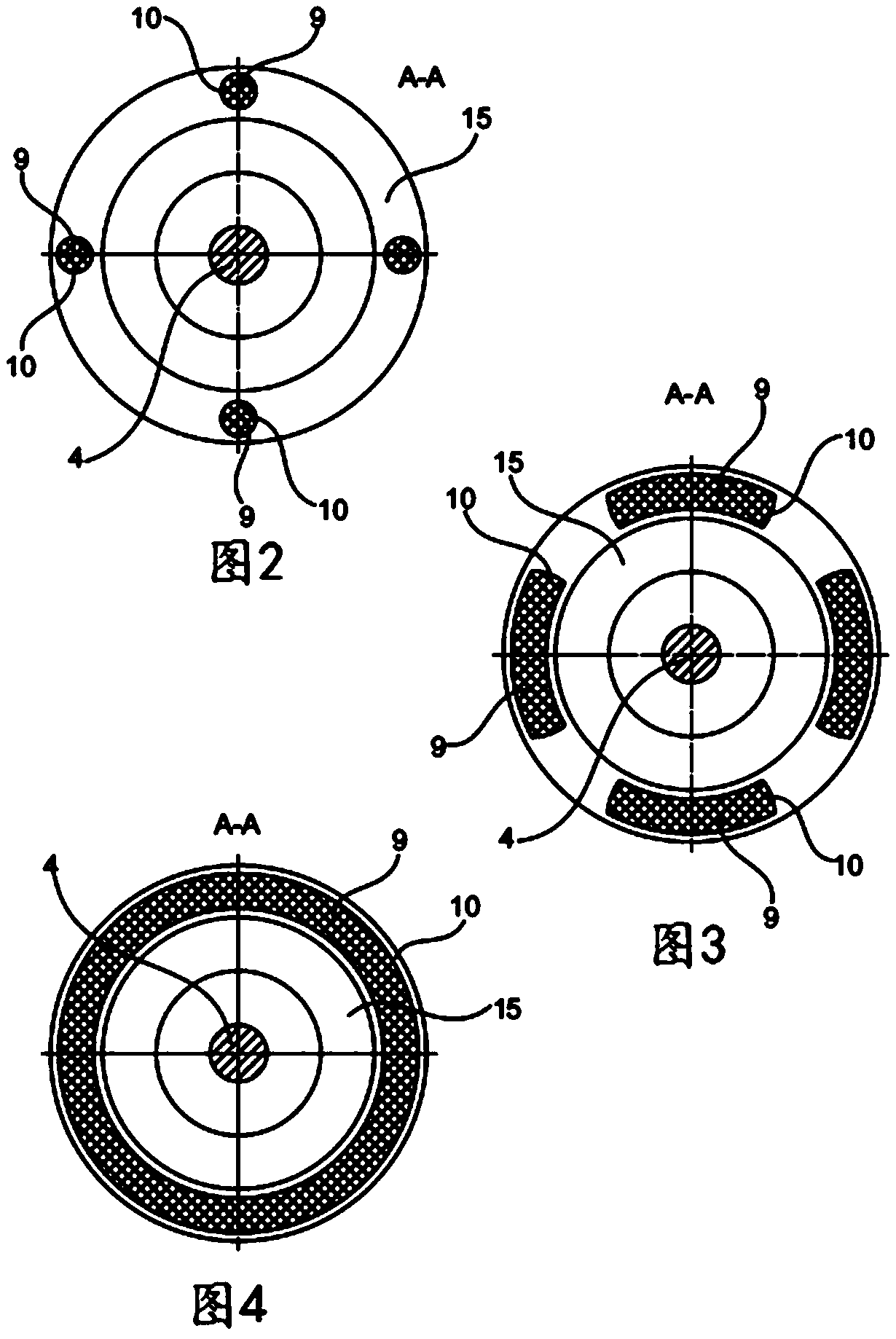

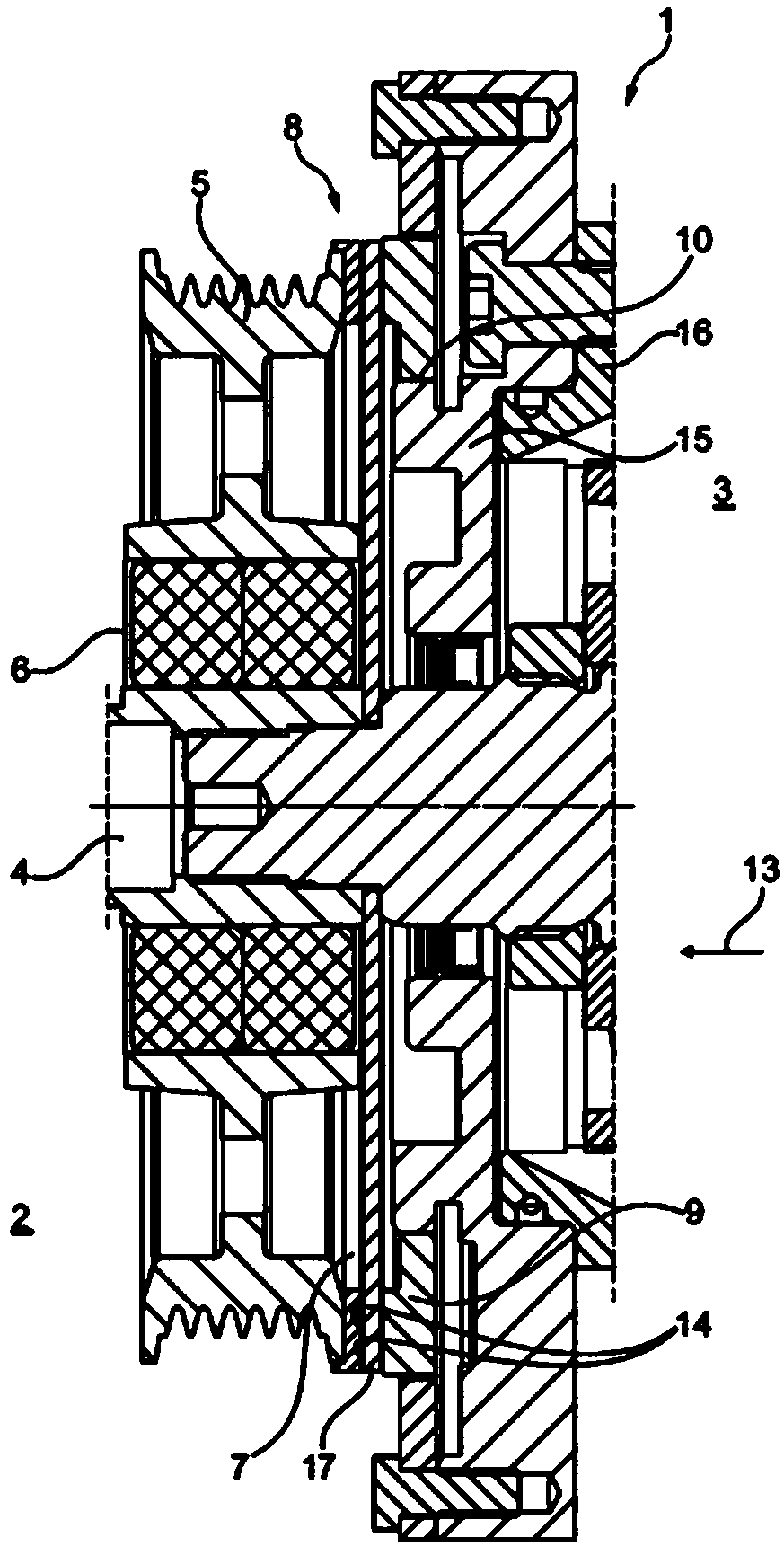

Engine assembly

InactiveCN108999893ASimple structure setupReliable startInternal combustion piston enginesFluid actuated clutchesInternal combustion enginePulley

An engine assembly (1). The engine assembly (1) may include an internal combustion engine (2), an expander (3) coupled to the engine, a pulley (5) rotatably arranged on a shaft (4) of the expander (3)and coupled to the engine (2), a drive disk (7) arranged on the shaft (4) of the expander (3) and disposed between the pulley (5) and at least one operating element (9), a coupling device (8) including at least one elastic operating element (9) arranged within an operating element accommodation (10) in an axially deformable manner, and a pressure device (11) connected to the operating element accommodation (10) via a fluid line (12) and configured to apply pressure to the operating element accommodation (10). The at least one operating element (9) may be deformable in an axial direction (13)such that the at least one operating element (9) adjusts the drive disk (7) into force-transferring contact with the pulley (5) when the at least one operating element (9) is deformed by a pressure applied to the operating element accommodation (10) by the pressure device (11).

Owner:MAHLE INT GMBH

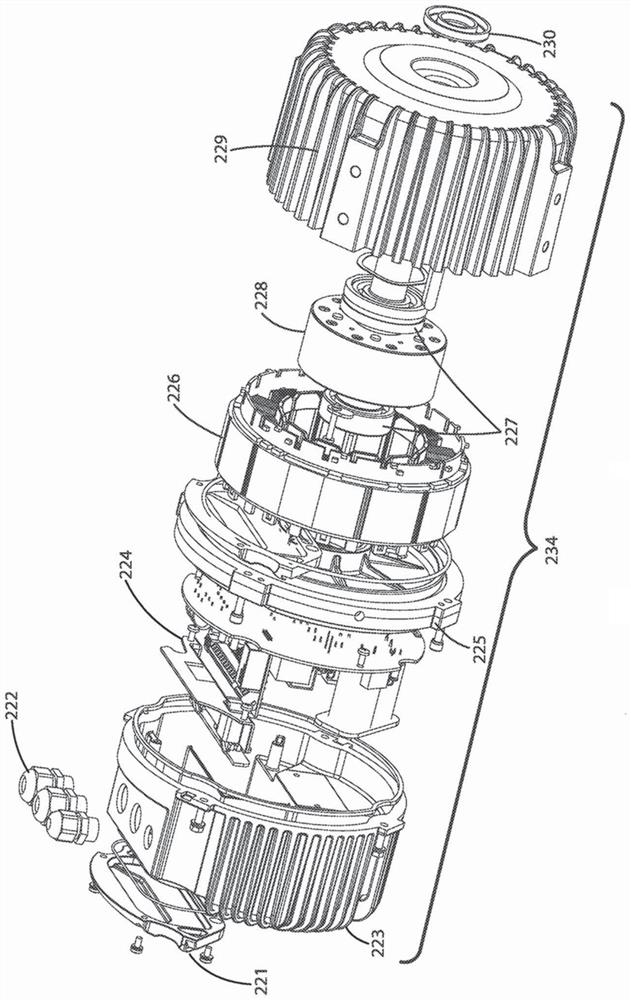

Sensorless salient pole permanent magnet synchronous motor and starting motor control method

ActiveCN113497530AEffective startAvoid excessive influenceElectronic commutation motor controlAssociation with control/drive circuitsMotor speedLoop control

The invention discloses a sensorless salient pole permanent magnet synchronous motor and a starting motor control method, and relates to the field of motors. Closed-loop control of start-to-operation of sensorless motors requires a more robust and advanced method. The system comprises a controller which detects rotor motion during a starting period so as to obtain a motor rotating speed estimation value at a starting moment; selecting one of a plurality of different motor rotating speed estimation methods as an initial starting motor rotating speed estimation method based on starting motor rotating speed estimation; estimating the rotating speed of the motor according to the selected initial starting motor rotating speed estimation method. A drive command is generated during motor startup using closed-loop control according to feedback provided to the controller, and a motor speed estimate is obtained according to the selected initial startup motor speed estimate. According to the technical scheme, a dynamic high-frequency injection speed estimation method is adopted and can be used even when the rotor rotates at a non-negligible speed, so that stable and efficient starting of the motor is achieved.

Owner:WOLONG ELECTRIC GRP CO LTD

A kind of preparation method of large size magnesium alloy forged cake

ActiveCN103447433BReduce cumbersomeImprove plastic deformation abilityMetal-working apparatusDiameter ratioIngot

The invention relates to a preparation method of a large-sized magnesium alloy forged disc and belongs to the technical field of magnesium alloy materialmachining. The preparation method of the large-sized magnesium alloy forged disc comprises the following steps of heating a casting magnesium alloy ingot to 400-430 DEG C and preserving the heat, wherein the casting magnesium alloy ingot after homogenizing thermal treatment is 300-350mm in diameter and 1.5-1.85 in height-diameter ratio; upsetting and drawing out the heated casting magnesium alloy ingot at 400-430 DEG C to obtain a magnesium alloy forged disc; repeating processes of heating, preserving the heat, upsetting and drawing out till the diameter of the magnesium alloy forged disc is larger than or equal to 670mm to obtain the large-sized magnesium alloy forged disc, wherein the temperature when repeating the procedures of preserving the heat and upsetting every time is 10-20 DEG C lower than the temperature when previously repeating the procedures of preserving the heat and upsetting, the forging ratio in each upsetting procedure is 1.5-2, the forging ratio in each drawing-out procedure is 1.02-1.05, and the deformation speeds in the upsetting and drawing-out procedures both are 12-16mm / s. According to the preparation method of the large-sized magnesium alloy forged disc, which is disclosed by the invention, the large-sized magnesium alloy forged disc with the diameter of 670-720mm, the thickness of 80-120mm, the tensile strength of larger than or equal to 300MPa, the yield strength of larger than or equal to 180Mpa and the elongation percentage of larger than or equal to 10% can be manufactured, and the manufactured large-sized magnesium alloy forged disc can completely meet the requirements on the preparation of a large-sized magnesium alloy die forged piece.

Owner:CENT SOUTH UNIV

A kind of medical hemostatic sponge and preparation method thereof

ActiveCN106075552BQuick and powerful hemostasisNon-irritatingSurgical adhesivesBiomedical engineeringCarboxymethyl-chitosan

The invention relates to medical hemostatic sponge and a preparation method thereof. The hemostatic sponge is formed by bonding freeze-dried chitosan sponge and carboxymethyl chitosan sponge, and tertiary butanol is added to freeze-dried chitosan sponge and carboxymethyl chitosan sponge in the preparation process. The hemostatic sponge prepared through the process is good in crystal type, short in in-vivo degradation cycle, capable of continuously and effectively adhering to wounds, strong in dissolution resistance, good in hemostatic effect, high in production efficiency, free of toxic and side effects and free of irritation.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

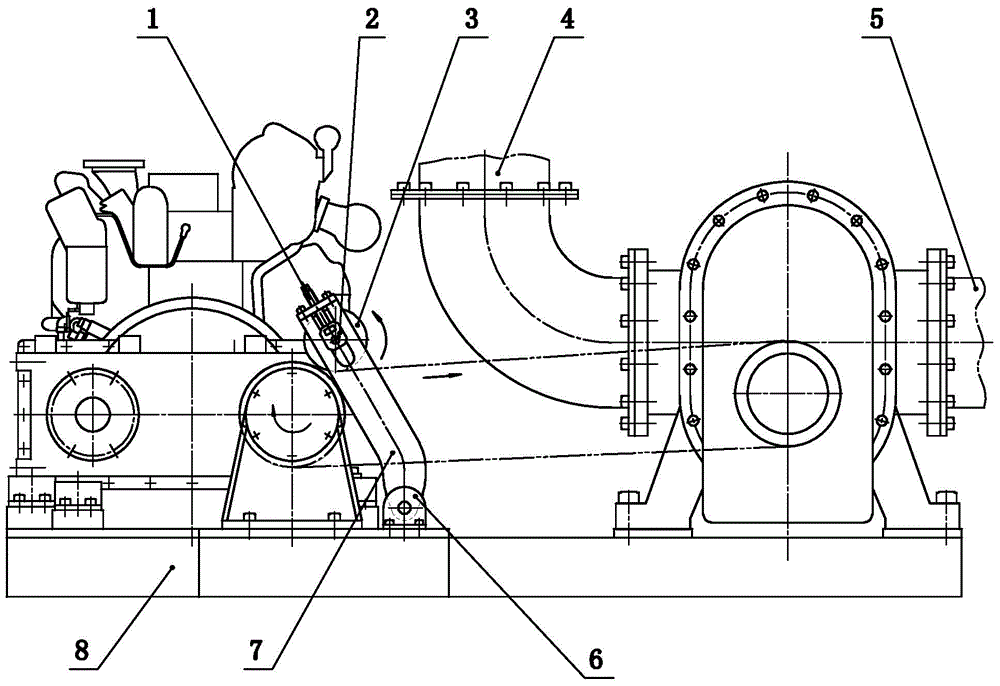

Driving device of blower for drainage asphalt pavement functional recovery vehicle

ActiveCN104005326ASolve the load problemSolve the problem that the engine is easy to stallRoads maintainenceElectromagnetic clutchCoupling

The invention relates to a driving device of a blower for a drainage asphalt pavement functional recovery vehicle. A base is provided with an engine, the blower, a left bearing seat and a right bearing seat; a power output shaft of the engine is provided with a power distribution box; one power output shaft of the power distribution box is coupled with an electromagnetic clutch; the electromagnetic clutch is coupled with a driving belt wheel of a belt transmission mechanism through an elastic shaft coupler; the driving belt wheel of the belt transmission mechanism is arranged on the left bearing seat and the right bearing seat through a coupling shaft; a driven belt wheel is coupled with a power input shaft of the blower; the base is also provided with a double-rocker hinged support; the double-rocker hinged support is provided with a belt tensioning mechanism. The driving device is reasonable in structural design, effectively and quickly realizes starting and driving of the large-power and high-pressure blower, and solves the problems in the prior art that the blower has large starting load and the engine is easily shut down.

Owner:HENAN GAOYUAN ROAD MAINTENANCE EQUIP

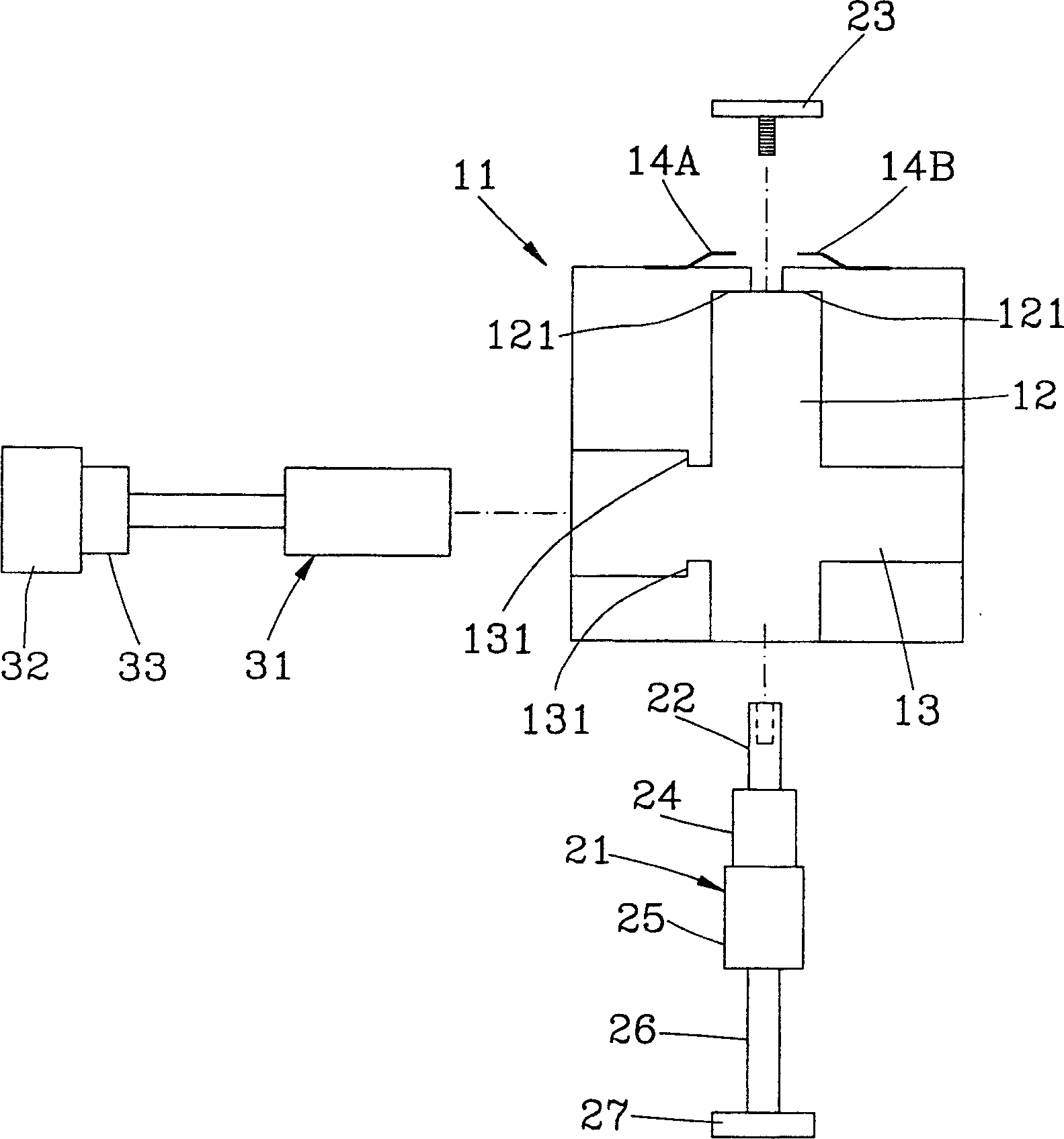

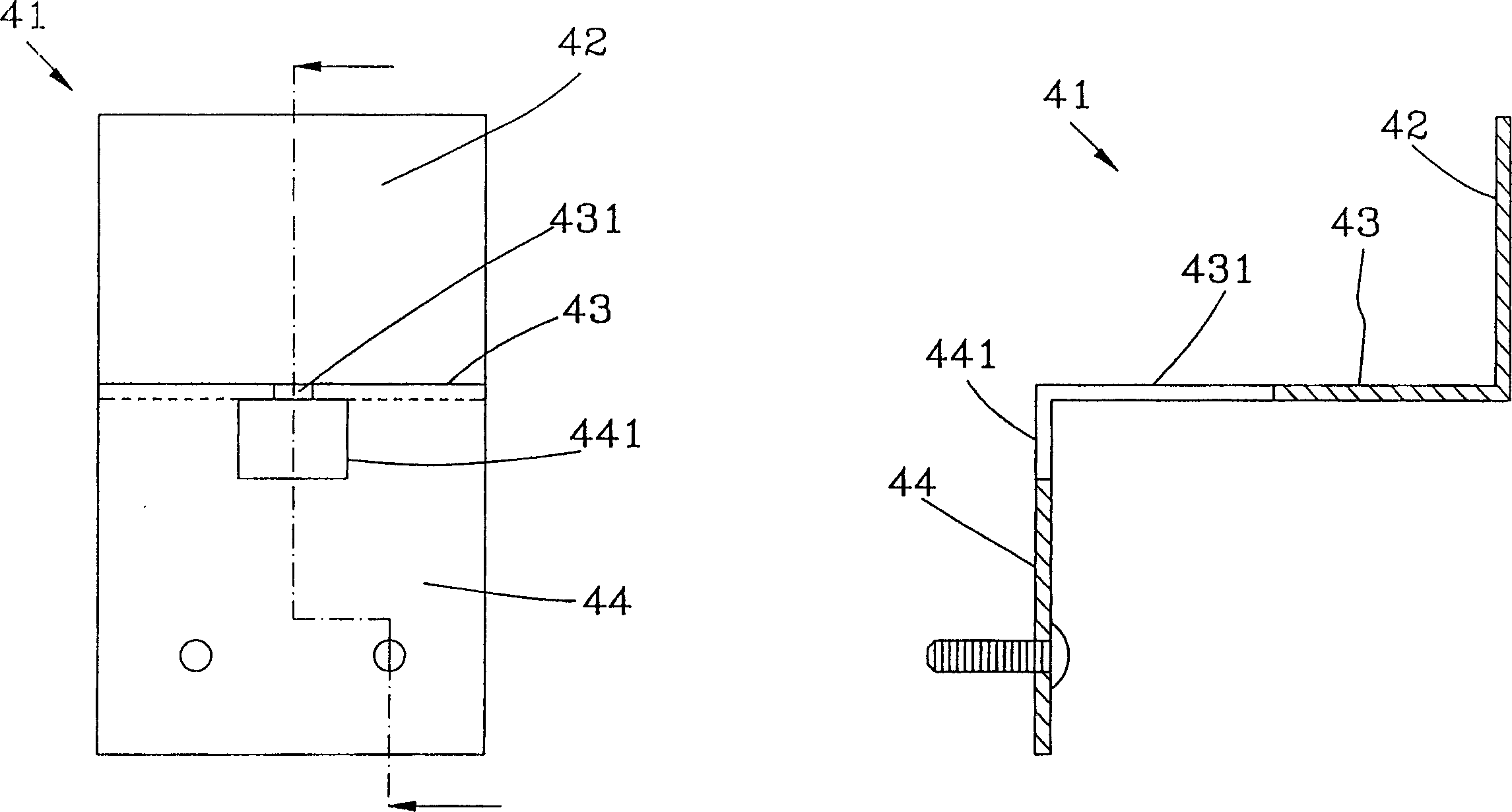

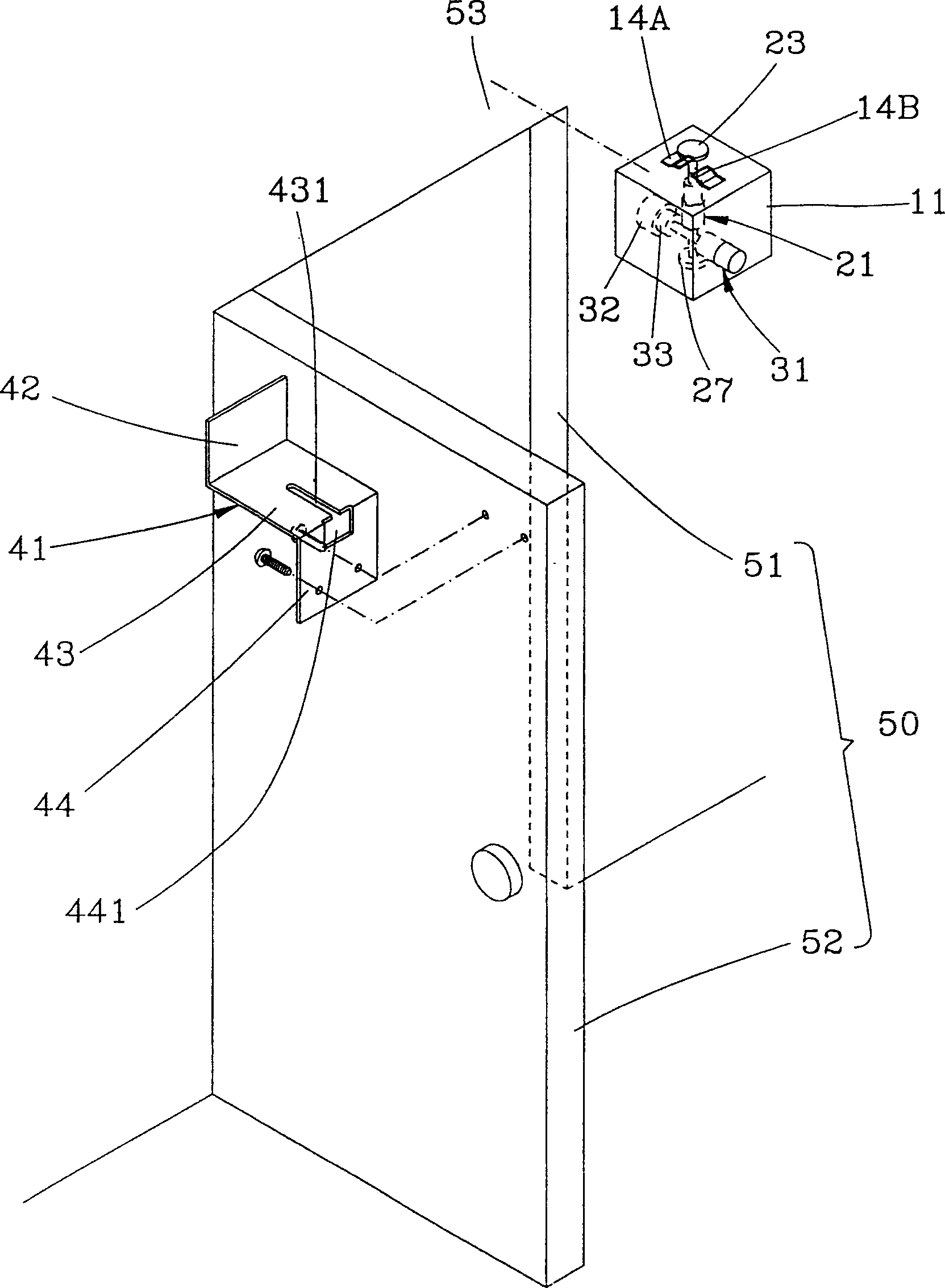

Mechanical linkage device for conducting valve

InactiveCN1508822ASimple structureEffective startBurglar alarm by openingContact operating partsFree fallingEngineering

A main body comprises a longitudinal room and a transverse room. There is a counteract part in each room. Two rooms are connected to each other through the side. Two not connected electric elastic pieces faced to each other are setup at outer port of the counteract part in the longitudinal room. An actuator passing through the longitudinal room does action in mode of free falling body. A conducting piece on top end of the actuator contacts to electric elastic pieces making them communicate electrically. A stopper passing through the transverse room can be moved horizontally to lock the actuator or to be locked by the actuator. A pushing piece possesses a pushing face, a token up face and a faxing face. The pushing face can touch the stopper, pushing it transverse moving.

Owner:翁锡光

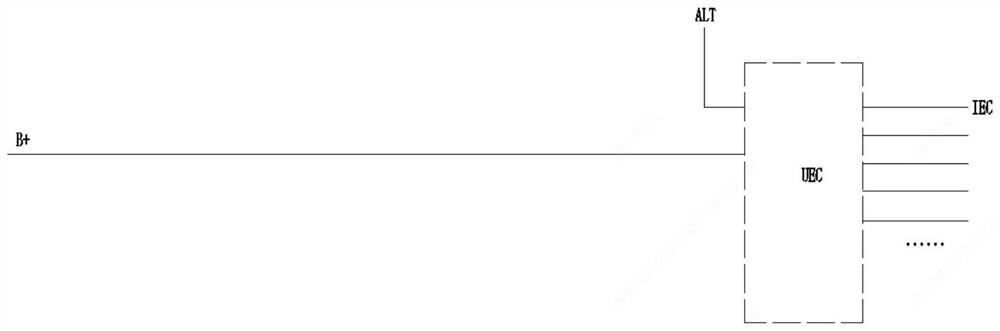

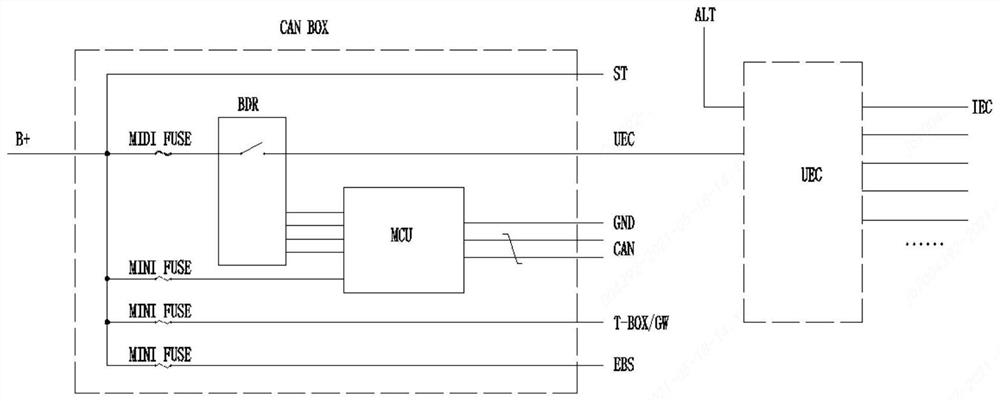

Power management system and method for preventing vehicle feed

ActiveCN113922461AGuaranteed operabilitySafe and reliable powerCircuit monitoring/indicationElectric powerEngineeringPower management system

The invention discloses a voltage management system and method for preventing vehicle feed. The system comprises a storage battery and a forecabin electric appliance box, and the forecabin electric appliance box is used for distributing power for a forecabin electric load. The system further comprises an upper CAN electric appliance box, the input end of the upper CAN electric appliance box is connected with the storage battery, the output end of the upper CAN electric appliance box is connected with the power input end of the forecabin electric appliance box, and the upper CAN electric appliance box is used for stopping distributing power to the power input end of the forecabin electric appliance box when the electric quantity of the storage battery is low. The advantages of the present invention are that the power supply of all electric appliances powered by the forecabin electric appliance box can be automatically cut off when the electric quantity is low; the safety and reliability of the electric quantity of the storage battery are guaranteed; the feed of the storage battery caused by the power distribution and power supply of the forecabin electric appliance box is avoided; and the electric quantity of the vehicle storage battery is guaranteed, so that an automobile can be effectively started.

Owner:CHERY COMML VEHICLE ANHUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com