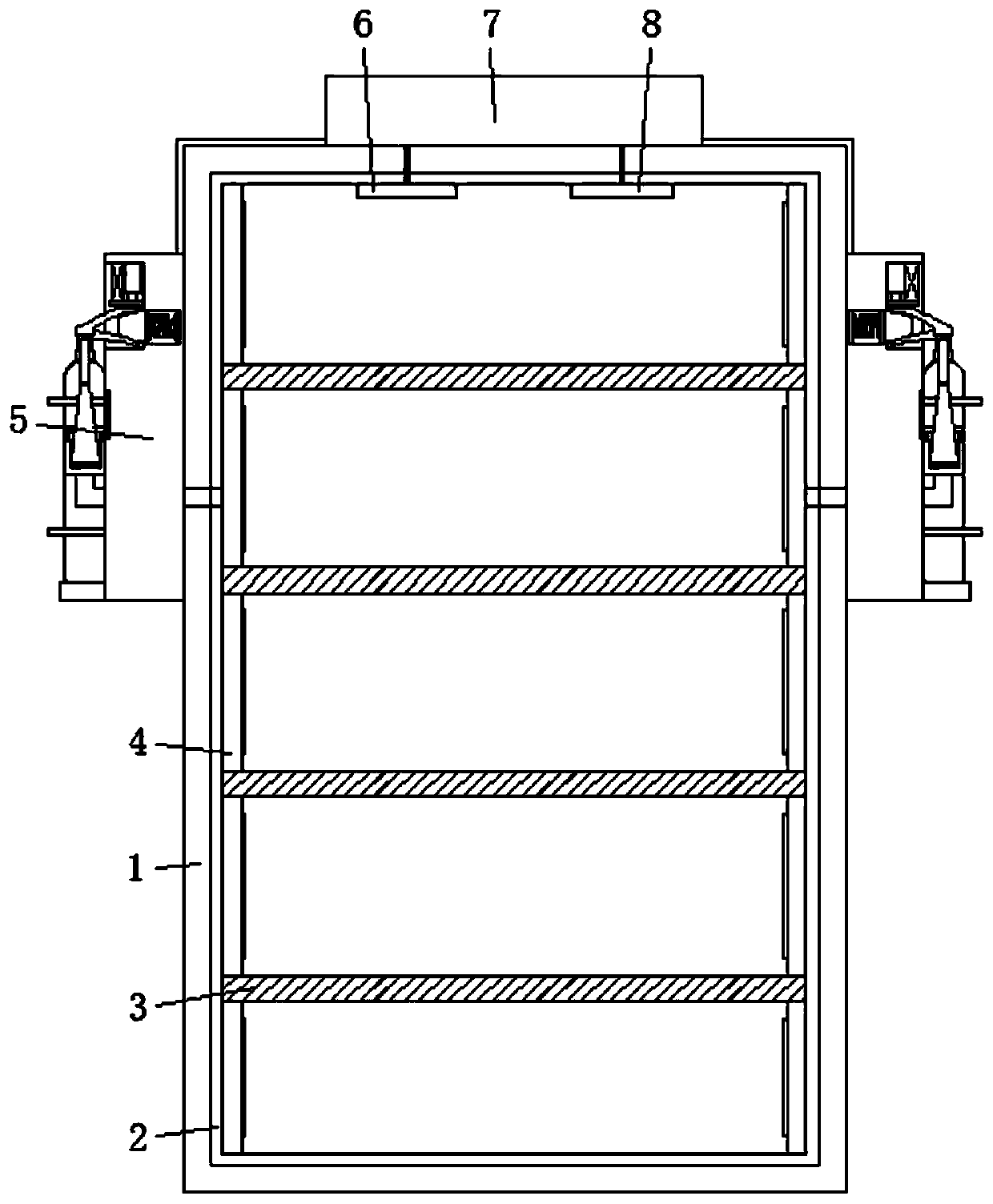

Cellular automatic electrical control cabinet with flame-retardant and fire-extinguishing functions

An electrical control cabinet and format technology, which is applied to the casing with display/control unit, electrical equipment casing/cabinet/drawer, electrical components, etc. Good flame retardant effect, low cost of use, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

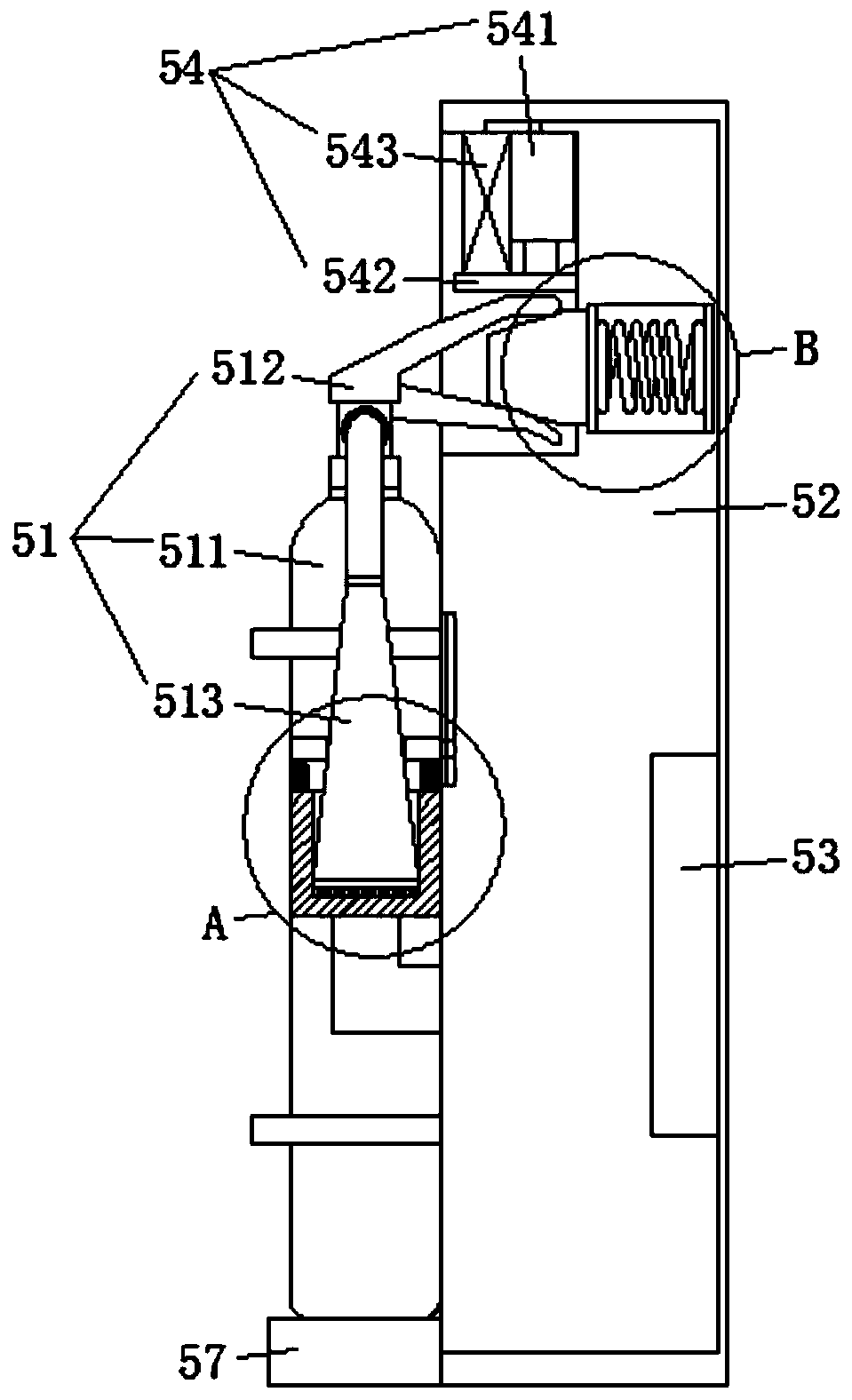

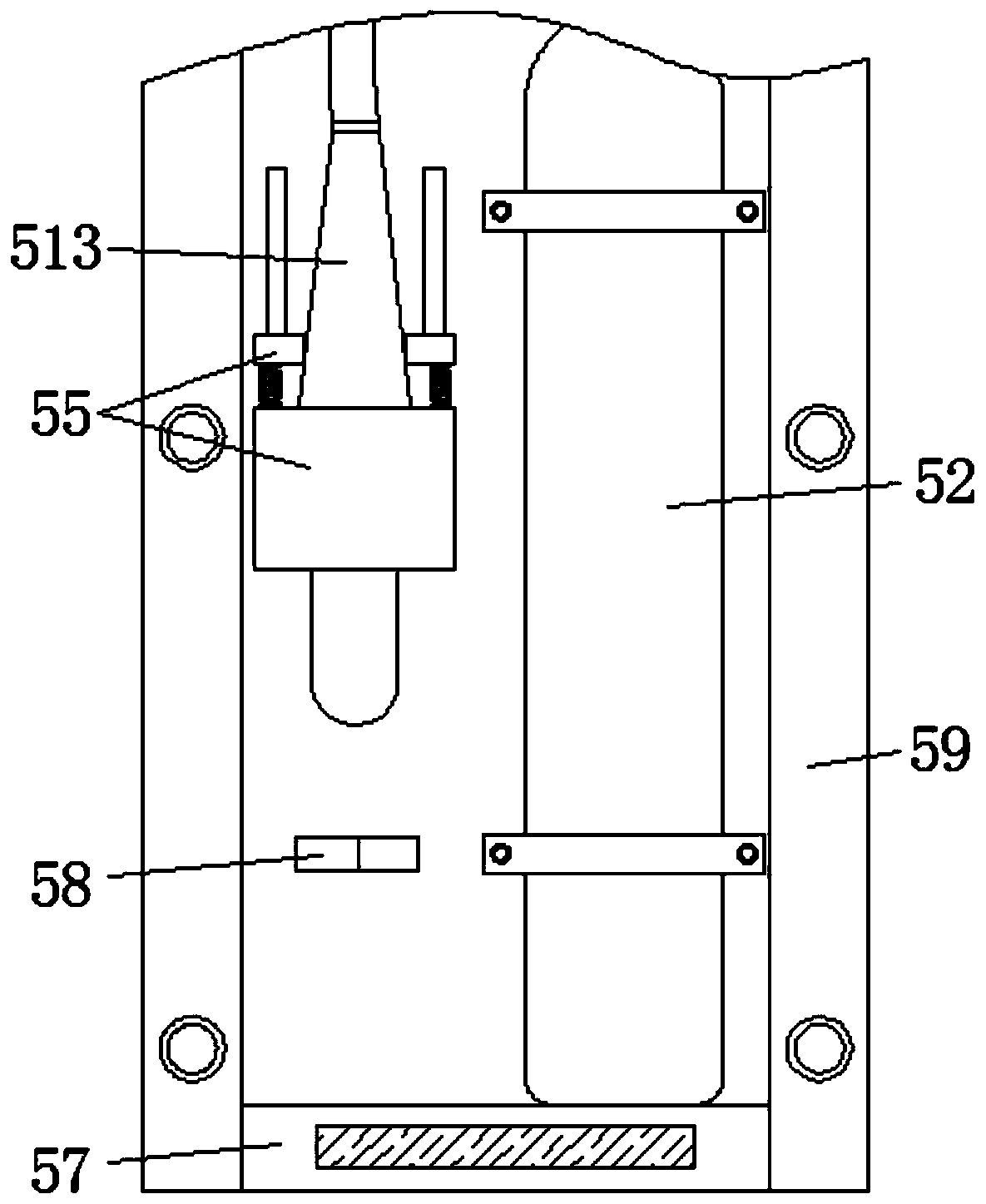

[0043] As an embodiment, the sealing connection mechanism 55 includes a movable pressure ring 551 and a fixed sealing sleeve 553, and the pressure ring 551 is a U-shaped structure, and an elastic connector 552 is connected with the sealing sleeve 553, and the nozzle pipe 513 is in the shape of One end is large and the other end is small. The end with a large diameter is inserted into the sealing sleeve 553, and the U-shaped groove of the pressure ring 551 is smaller than the maximum diameter of the nozzle 513. A conduit 554 is connected between the sealing sleeve 553 and the fire extinguishing pipe 4. Based on this, the connection principle of the sealing connection mechanism 55 is as follows: the pressure ring 551 is pulled apart, and the elastic connecting member 552 is stretched, so that the distance between the pressure ring 551 and the sealing sleeve 553 increases, and the nozzle 513 is snapped into the pressure ring 551. In the U-shaped groove, align the end of the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com