Carbon-doped nano-catalyst as well as preparation method and application thereof

A catalyst and carbon nanotechnology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex preparation methods and difficult to control, and achieve strong catalytic performance, simple methods, and large yields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Biomass Doped Carbon Nanocatalysts

[0038] The preparation process of EGC1-10-2 is as follows: the whole urea and eggs are steamed and ground, then placed in an 80°C drying oven to dry for 24 hours, and the urea is put into a crucible with a cover and calcined at 550°C for 3 hours to prepare g-C 3 N 4 , and the dried eggs are ground evenly, take the dried eggs and g-C 3 N 4 1:1, after uniform grinding, calcined at 900°C for 2h at a heating rate of 10°C / min in a tube furnace.

[0039] (EGCx-y-z, where X is dry egg and g-C 3 N 4 The mass ratio, Y is the heating rate of the tube furnace, Z is the heating time, EC is the preparation of pure eggs)

[0040] Wherein EGC0.5-5-2, EGC1-5-2, EGC1-10-1, EGC1-10-3, EGC2-5-2, EGC1-10-2, EGC1-15-2 were prepared according to the above method.

[0041] Through the doped carbon nanocatalysts under different conditions in this example, seven different doped carbon nanocatalysts were obtained.

Embodiment 2

[0043] XPS Characterization of Biomass Doped Carbon Nanocatalysts

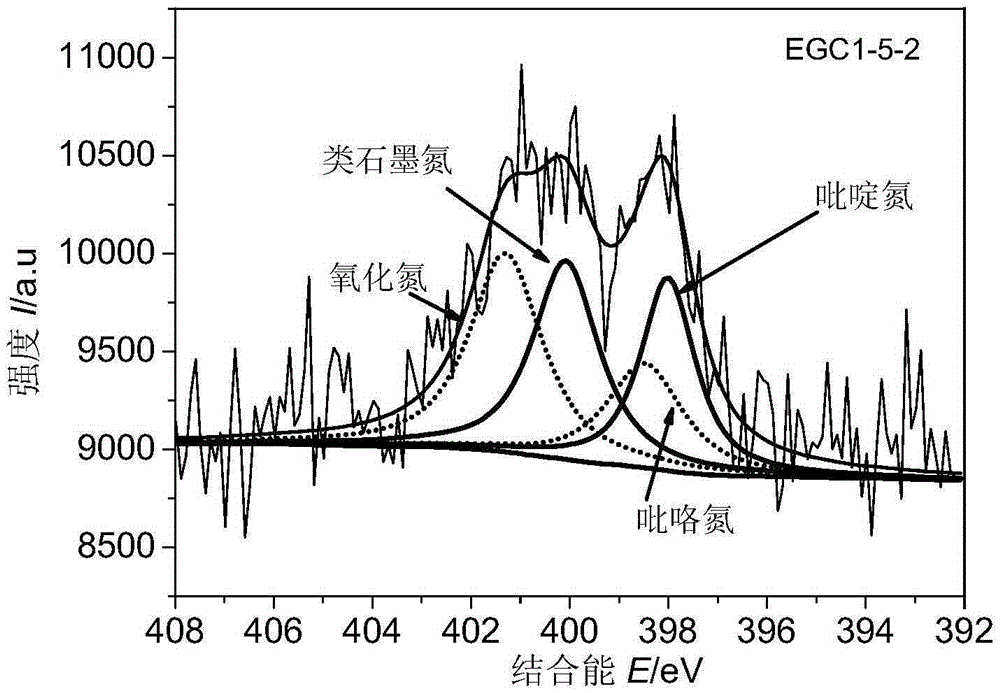

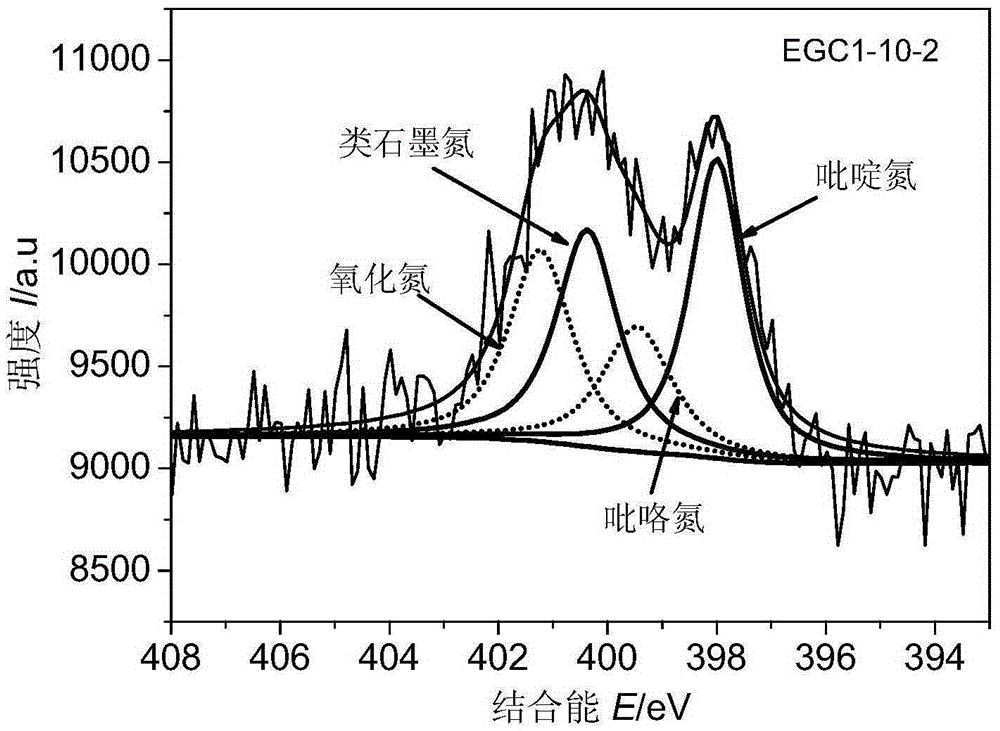

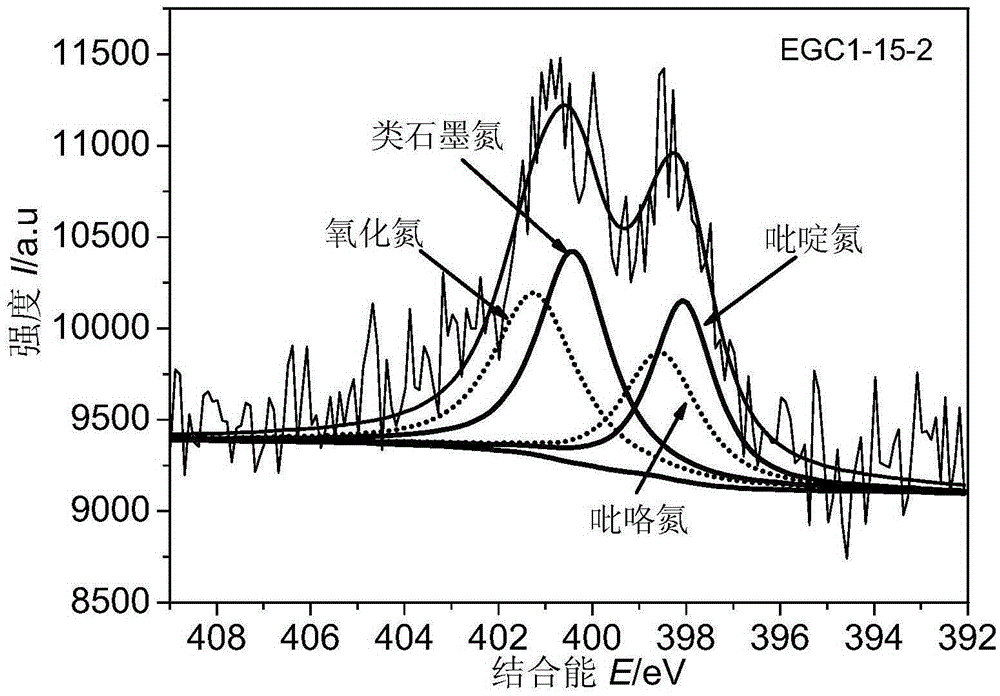

[0044] The XPS tests of EGC1-5-2, EGC1-10-2, and EGC1-15-2 three kinds of doped carbon nanocatalysts were realized on a multifunctional X-ray photoelectron spectrometer (model AxisUltraDLD), and the analysis room worked When the vacuum degree is about 5×10 -9 torr, the X light source used is a monochromatic AlKα source (MonoAlKα), the energy is 1486.6eV, 10mA×15KV, and the beam spot size is 700×300μm; the pass energy of full spectrum scanning is 160eV, and the pass energy of narrow spectrum scanning is 40eV, the number of scans is 1 time. Before the result analysis, the C1s and N1s of each sample were first divided into peaks, and then the binding energy of C1s at the lowest energy end was calibrated to 284.6eV, and the N1s element was corrected according to the shift of the C1s peak position.

[0045] Through the XPS analysis of the three materials EGC1-5-2, EGC1-10-2, and EGC1-15-2 in this example, nitroge...

Embodiment 3

[0051] XRD Characterization of Biomass Doped Carbon Nanocatalysts

[0052] XRD analysis: used to analyze the crystal structure of EGCx-y-z catalyst, the test process is realized on the D8ADVANCE instrument, the test conditions are copper target, incident ray λ=0.15418nm, Ni filter, tube pressure 40KV, tube flow 40mA; The scanning step length is 0.02 degrees, and the scanning speed is 0.1 seconds / step; the slit DS0.5°RS8mm (corresponding to the LynxExe array detector).

[0053] Through the XRD analysis of the three catalysts and EC in this example, the existence of a strong diffraction peak around 2θ=26° is a characteristic peak of the graphite structure. Among them, the C(002) peak of EGC1-10-2 shifts to the left by up to 23.6°, indicating that the interlayer spacing of this material is larger than that of other materials, and it is much larger than that of graphite microcrystals. It shows that the structure of this material is the most open, and the most condition has more a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com