Core shell carbon nano-structure electrocatalyst with high catalytic performance and preparation method thereof

A carbon nanostructure and catalytic performance technology, applied in nanotechnology, structural parts, nanotechnology and other directions for materials and surface science, can solve the problem of poor cycle stability, restrict the process of industrialization, and the battery performance cannot be well exerted and other problems to achieve the effect of improving utilization rate, improving cycle stability performance, and high oxygen reduction catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

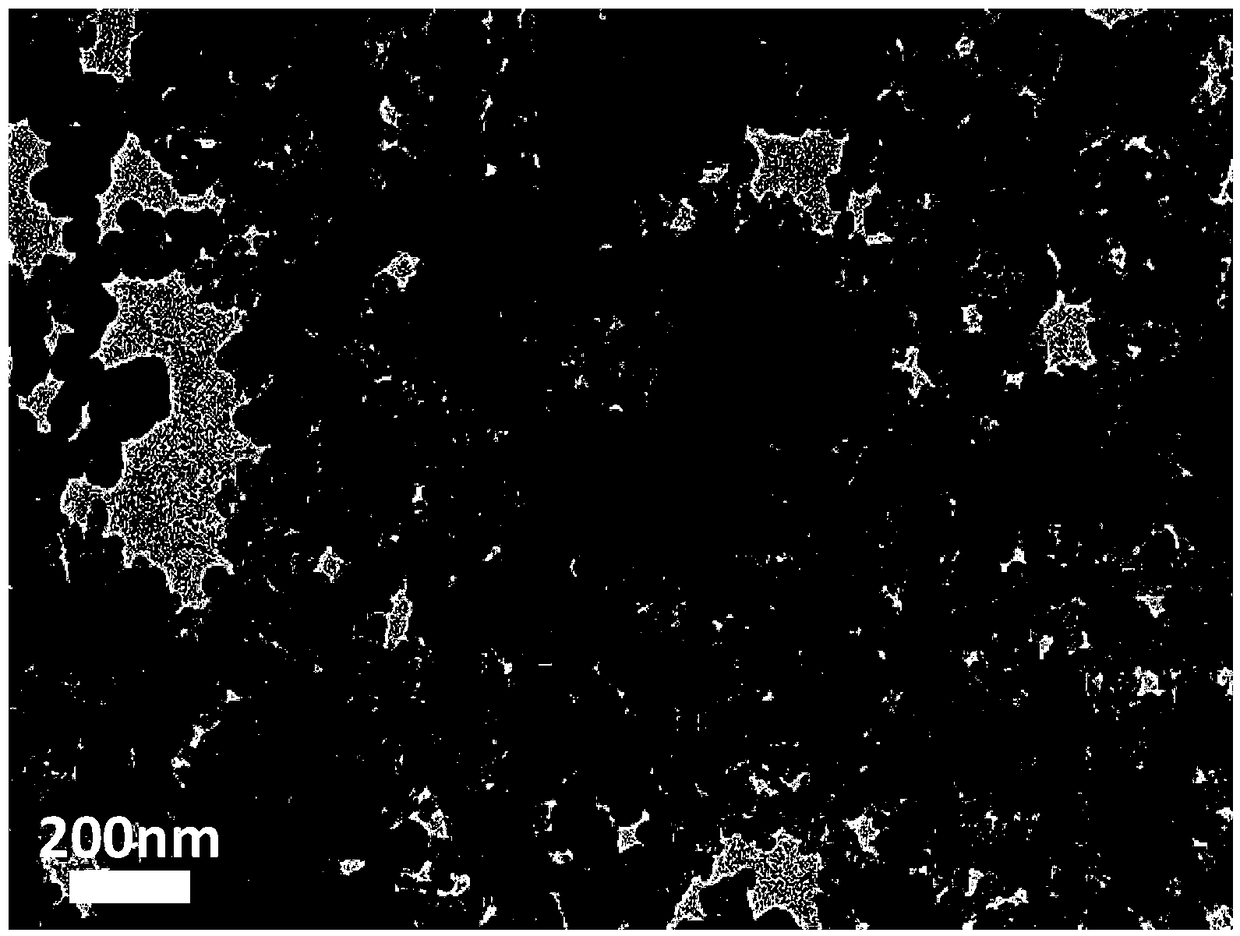

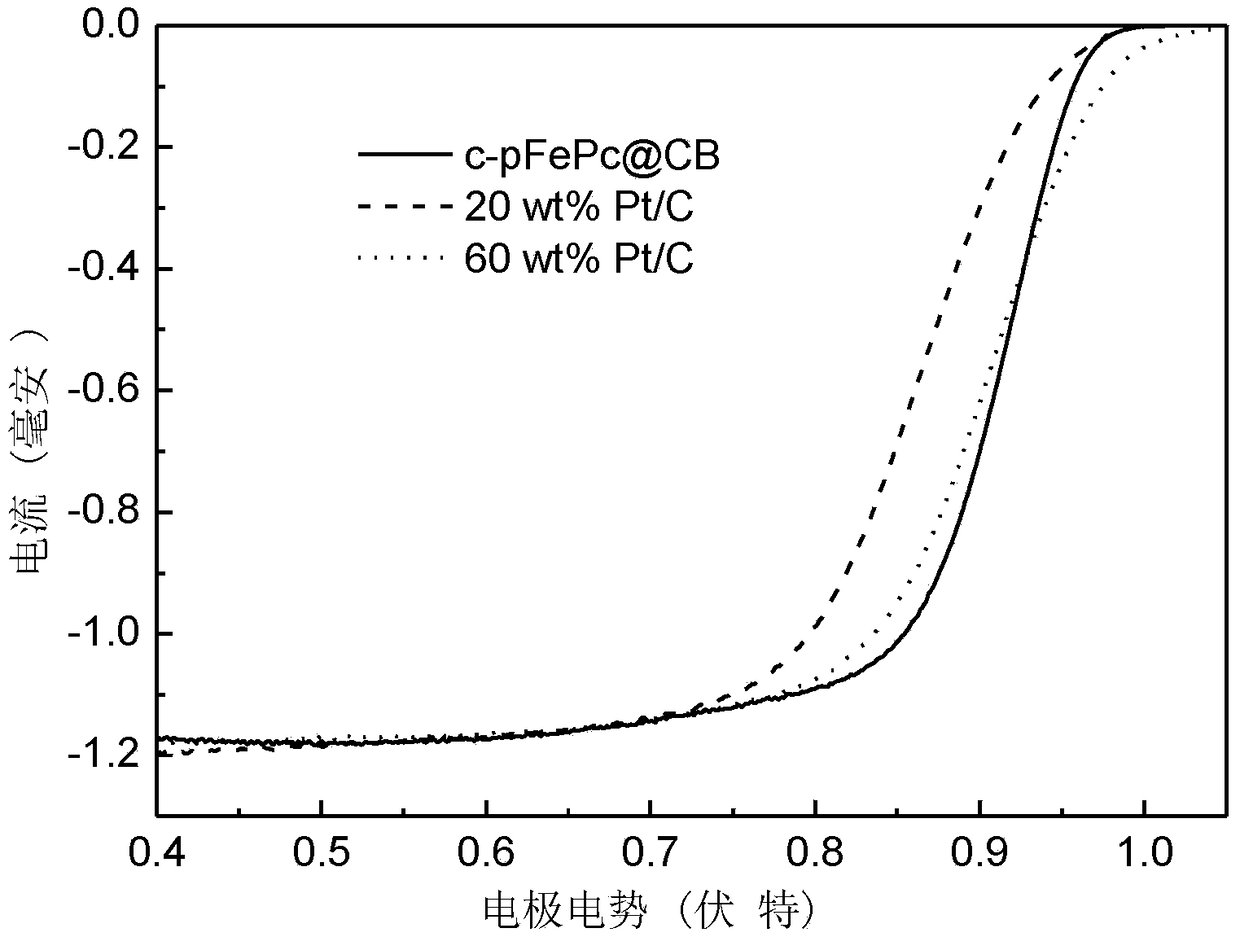

[0037] 1) Preparation of c-pFePc@CB core-shell carbon nanostructure electrocatalyst

[0038] Weigh the solid powders of pyromellitic dianhydride and phthalic anhydride respectively, and dissolve them in acetone solvent, add a certain mass of EC300J conductive carbon, ultrasonically disperse to obtain a uniformly mixed suspension, and dry to obtain a precursor powder . Further, the precursor powder is uniformly mixed with ferrous sulfate, ammonium molybdate, and urea, and heated to form a molten liquid, and the molten liquid is quickly transferred to a microwave reactor for in-situ polymerization, and polymerized around the conductive carbon A polyphthalocyanine iron shell with a closed edge structure is formed, and the c-pFePc@CB core-shell carbon nanostructure electrocatalyst is obtained.

[0039] Among them, the mass ratio of pyromellitic dianhydride to conductive carbon is 0.01-1:1; the mass ratio of phthalic anhydride to conductive carbon is 0.2-2:1; the mass ratio of iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com