Nitrogen-sulfur-iron triple-doped carbon black catalyst and preparation method and application thereof

A three-doping, catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of expensive oxygen reduction catalysts, poor selectivity and stability, and low catalytic activity, achieving good selectivity and stability, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

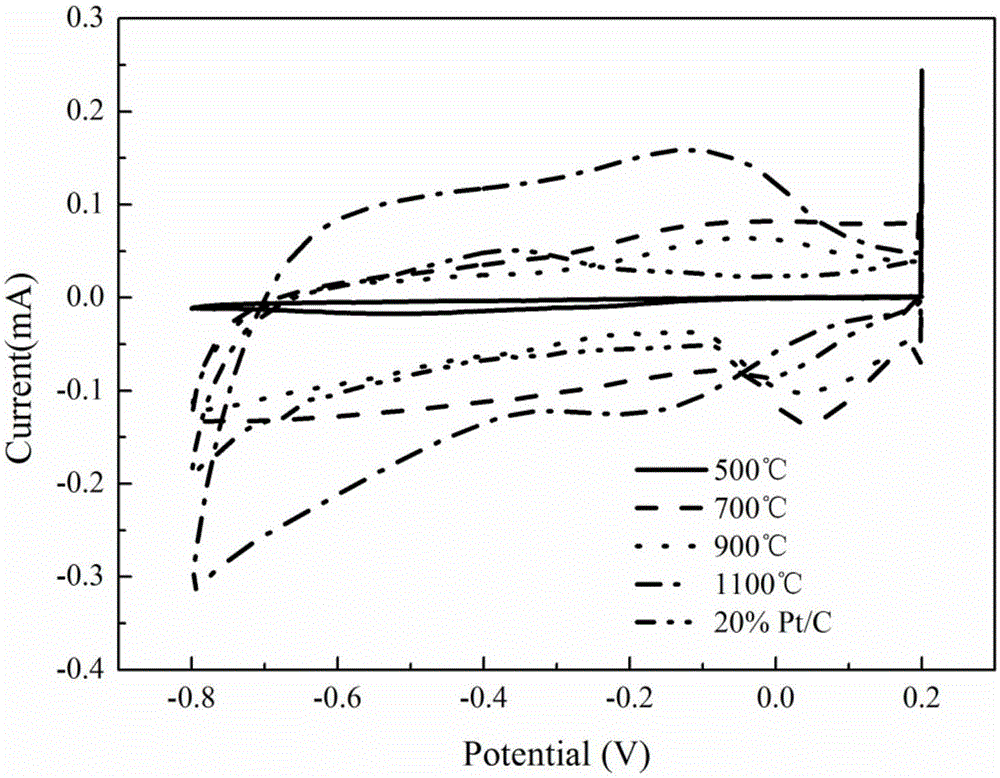

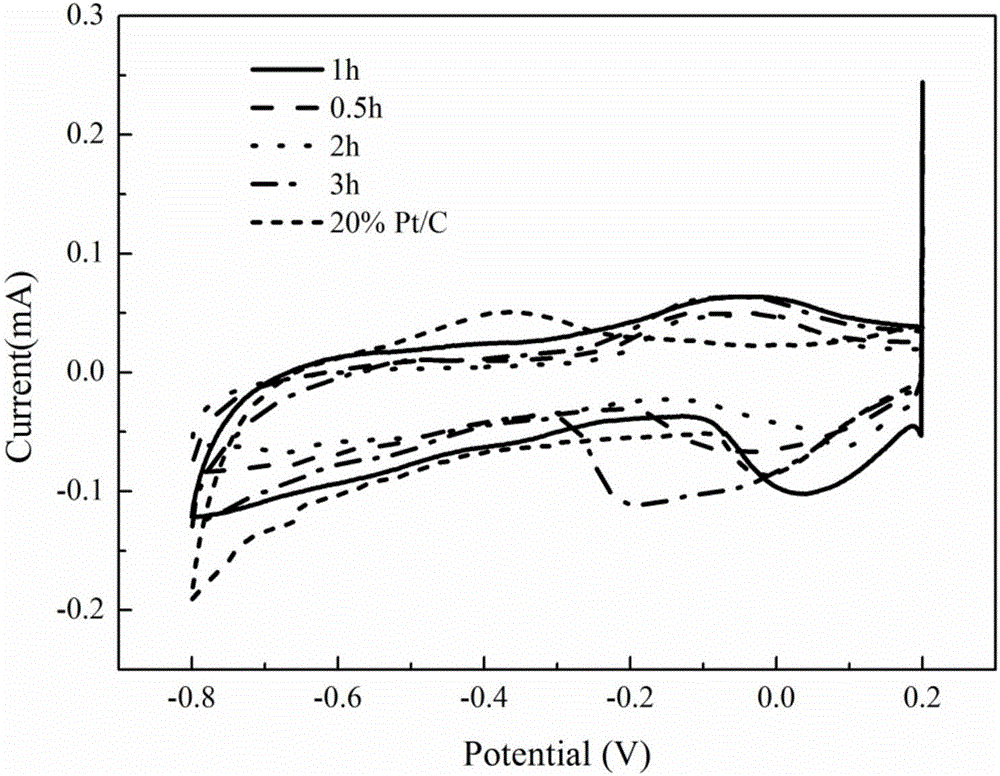

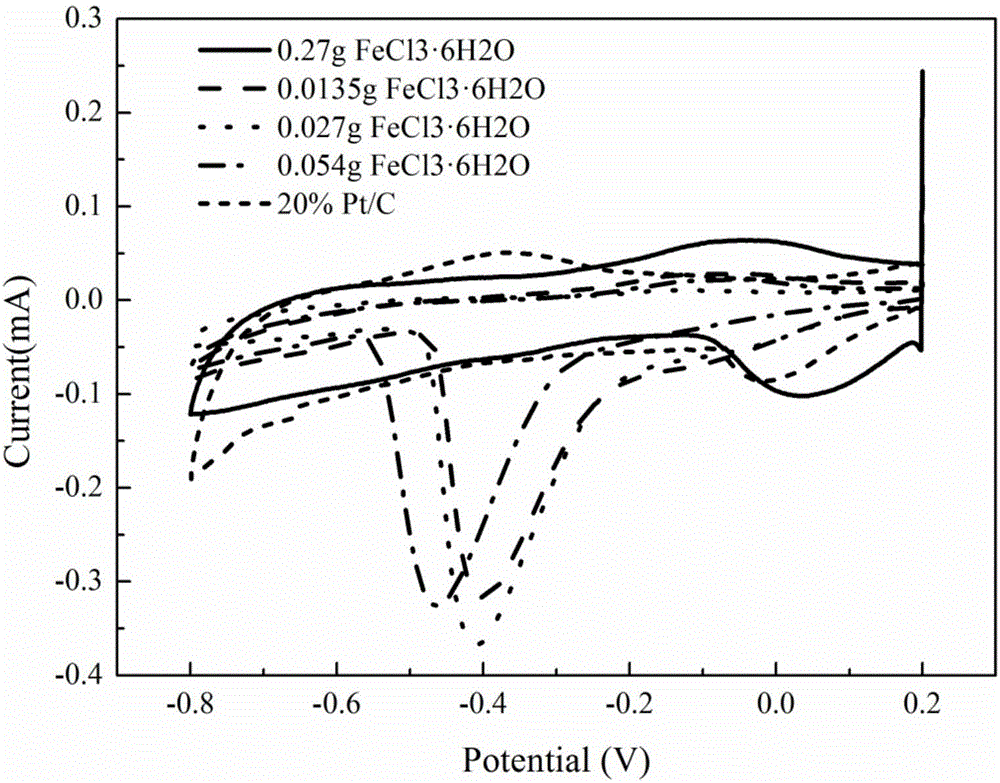

[0040] Embodiment 1: the FeCl of 0.27g 3 ·6H 2 Dissolve O completely in 2ml of distilled water, add 0.1g of carbon black, mix evenly, place in a blast electric drying oven, and dry at 40°C; transfer the dried powder to an agate mortar, and add 1g of thiourea , ground for 2 h; the ground powder was transferred to an ash dish, and calcined at 500° C. for 1 h under the protection of argon to obtain the target catalyst.

Embodiment 2

[0041] Embodiment 2: the FeCl of 0.27g 3 ·6H 2 Dissolve O completely in 2ml of distilled water, add 0.1g of carbon black, mix evenly, place in a blast electric drying oven, and dry at 60°C; transfer the dried powder to an agate mortar, and add 1g of thiourea , ground for 2 h; the ground powder was transferred to an ash dish, and calcined at 700° C. for 1 h under the protection of argon to obtain the target catalyst.

Embodiment 3

[0042] Embodiment 3: the FeCl of 0.27g 3 ·6H 2 Dissolve O completely in 2ml of distilled water, add 0.1g of carbon black, mix evenly, place in a blast electric drying oven, and dry at 50°C; transfer the dried powder to an agate mortar, and add 1g of thiourea , ground for 2 h; the ground powder was transferred to an ash dish, and calcined at 900° C. for 1 h under the protection of argon to obtain the target catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com