Catalyst prepared by in-situ growth of carbon nanotubes on ordered mesoporous carbon, and preparation method and application of catalyst

A carbon nanotube and carbon nanotube composite technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as differences in catalytic activity, and achieve the effects of low cost, high activity specific surface area, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of phenolic resin prepolymer:

[0042] Melt 2g of phenol at 50°C, add 0.5g of 20wt.% NaOH aqueous solution and stir for 10min, drop in 3.5g of 37wt.% formaldehyde aqueous solution and continue stirring for 10min, slowly raise the temperature to 60°C for 30min, cool down to room temperature, and use dilute HCl solution Adjust the pH value of the solution to 7.0, dry in a vacuum oven at 60°C for 6-12 hours to minimize the water content in the viscous liquid, dissolve the obtained soluble phenolic resin prepolymer in ethanol and stir for 12 hours, and dissolve the precipitated chlorinated Sodium was removed by centrifugation, and finally an ethanol solution of soluble phenolic resin prepolymer with a mass fraction of 25 wt.% was prepared for use.

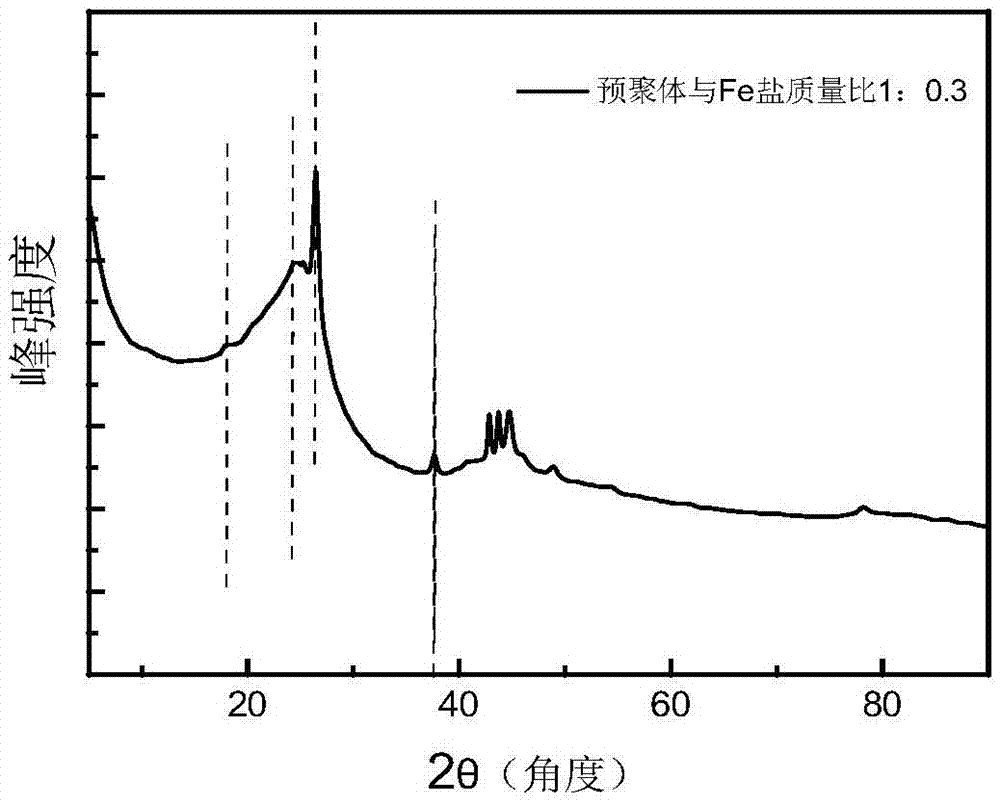

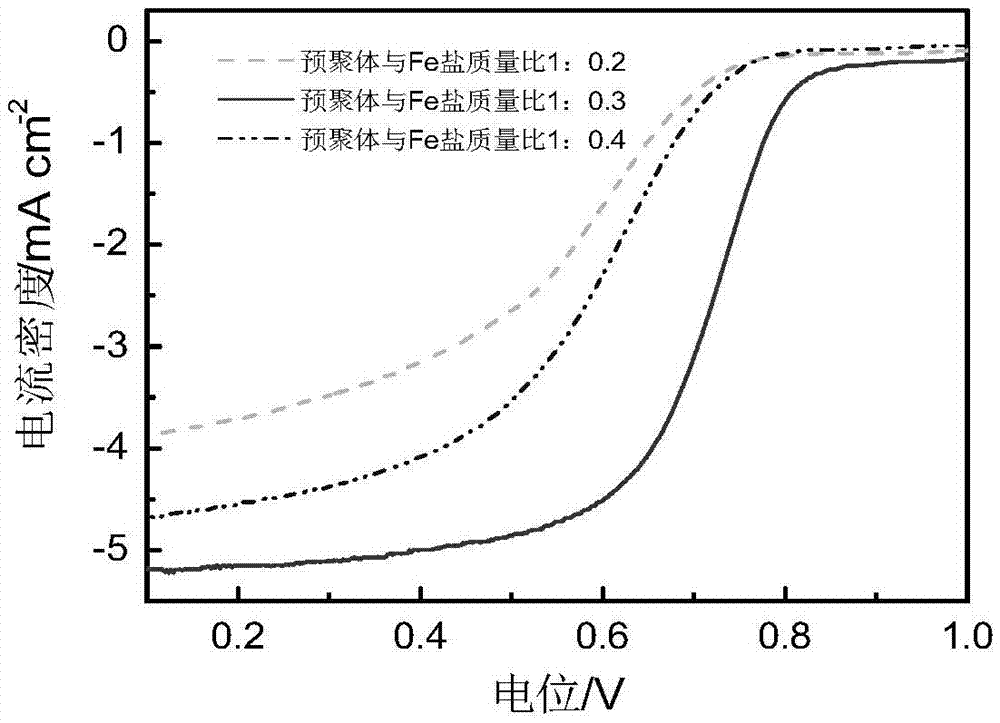

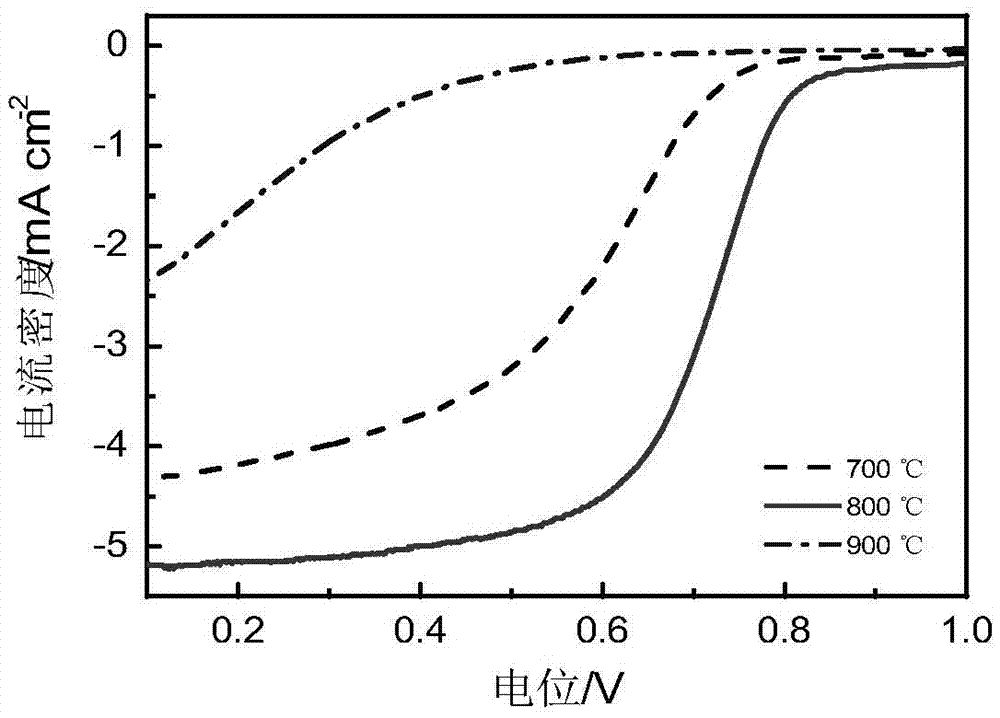

[0043] (2) Preparation of ordered mesoporous carbon in situ growth carbon nanotube composite catalyst

[0044] Dissolve 0.8g of F127 in 20g of ethanol, stir until clear and transparent, then add 4g of phenolic r...

Embodiment 2

[0048] (1) Preparation of phenolic resin prepolymer:

[0049] Melt 2g of phenol at 50°C, add 0.5g of 20wt.% NaOH aqueous solution and stir for 10min, drop in 3.5g of 37wt.% formaldehyde aqueous solution and continue stirring for 10min, slowly raise the temperature to 70°C for 30min, cool down to room temperature, and use dilute HCl solution Adjust the pH value of the solution to 7.0, dry in a vacuum oven at 60°C for 6-12 hours to reduce the water content in the viscous liquid as much as possible, dissolve the obtained soluble phenolic resin prepolymer in ethanol and stir for 12 hours, and the precipitated chlorinated Sodium was removed by centrifugation, and finally an ethanol solution of soluble phenolic resin prepolymer with a mass fraction of 25 wt.% was prepared for use.

[0050] (2) Preparation of ordered mesoporous carbon in situ growth carbon nanotube composite catalyst

[0051] Dissolve 1.6g of F127 in 20g of ethanol, stir until clear and transparent, then add 4g of p...

Embodiment 3

[0054] (1) Preparation of phenolic resin prepolymer:

[0055] Melt 2.2g resorcinol at 50°C, add 0.5g 20wt.% NaOH aqueous solution and stir for 10min, drop in 3.5g 37wt.% formaldehyde aqueous solution and continue stirring for 10min, slowly heat up to 80°C for 30min, cool to room temperature, Use dilute HCl solution to adjust the pH value of the solution to 7.0, dry it in a vacuum oven at 60°C for 6-12 hours to minimize the water content in the viscous liquid, dissolve the obtained phenolic resin prepolymer in ethanol and stir for 12 hours, and The precipitated sodium chloride is removed by centrifugation, and finally the soluble phenolic resin prepolymer ethanol solution is prepared for use.

[0056] (2) Preparation of ordered mesoporous carbon in situ growth carbon nanotube composite catalyst

[0057] Dissolve 2.1g of P123 in 20g of ethanol, stir until clear and transparent, then add 4g of phenolic resin prepolymer ethanol solution (the content of the prepolymer is 1g), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com