A supersonic plane cascade flow field start-up and uniformity adjustment device

A technology for regulating devices and cascade flow, which is applied in measuring devices, engine tests, jet engine tests, etc., can solve the problems of great difference in model blockage, great difference in flow conditions between head and tail blades, and limitations, etc. Achieve the effect of eliminating reflection problems, eliminating shock wave reflection problems, and achieving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

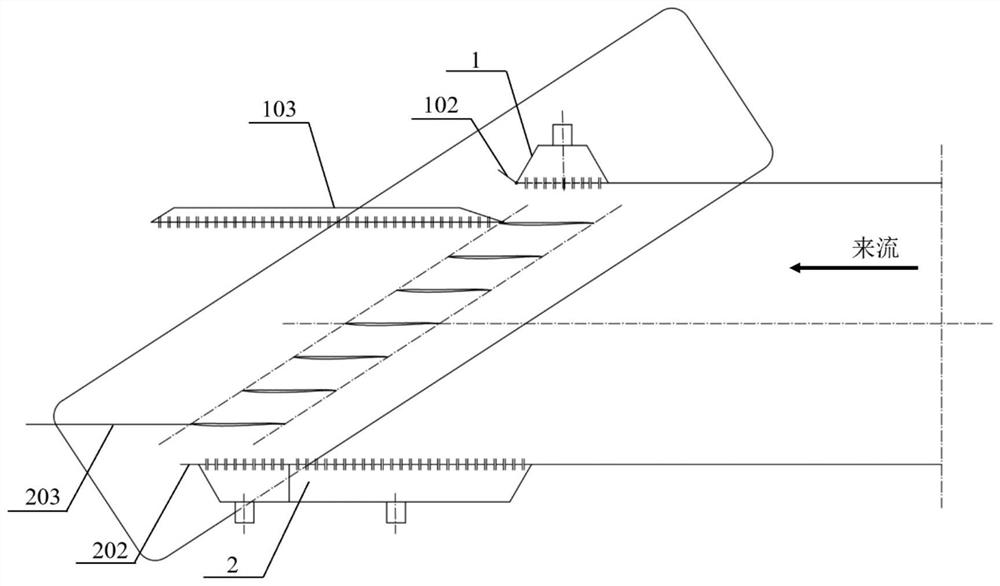

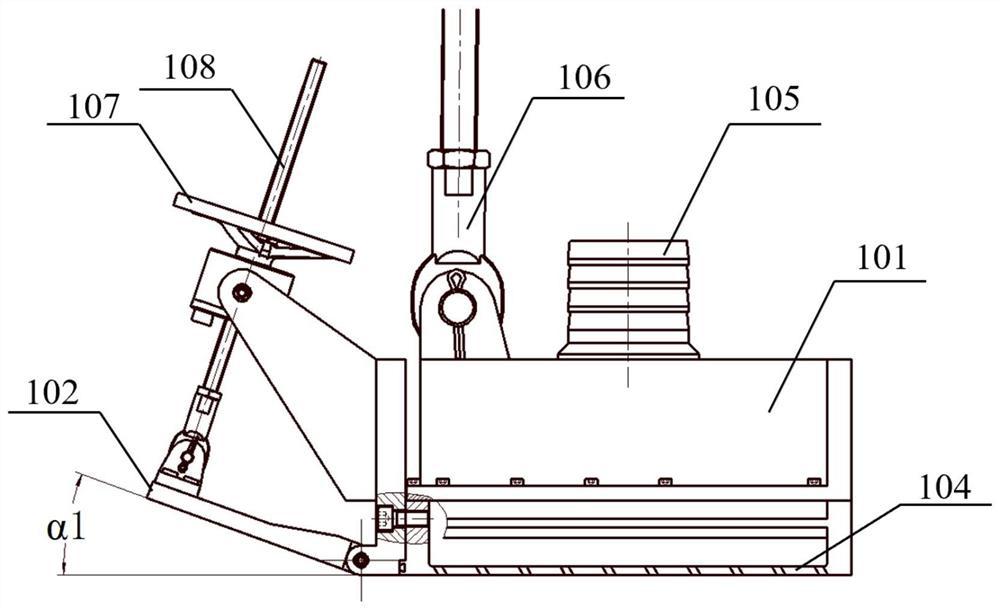

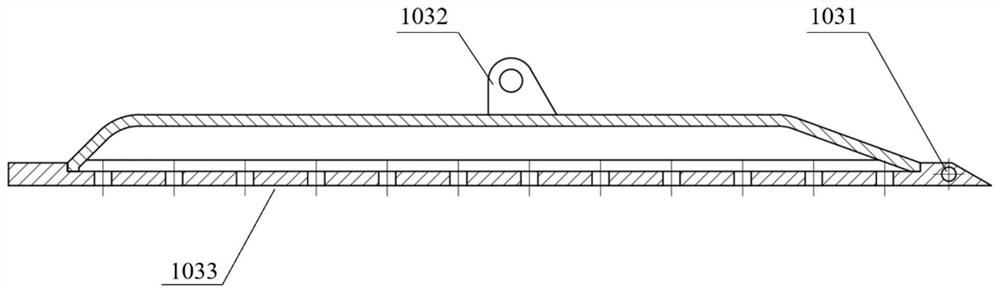

[0046] like figure 1 As shown, with the flow from the cascade wind tunnel as the front, the supersonic plane cascade flow field start-up and uniformity adjustment device of the present invention includes an upper suction assembly 1 installed above the first blade of the cascade test model, an upper suction assembly 1 An upper tail plate 102 with a fixed front end and a suspended rear end is installed at the rear of the blade, and an upper baffle 103 with a fixed front end and a suspended rear end is installed behind the bow blade; it also includes a lower suction assembly 2 installed under the tail blade of the cascade test model. , a lower tail plate 202 with a fixed front end and a suspended rear end is installed behind the lower suction assembly 2, and a lower baffle 203 with a fixed front end and a suspended rear end is installed behind the tail bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com