Patents

Literature

240results about How to "Stable suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

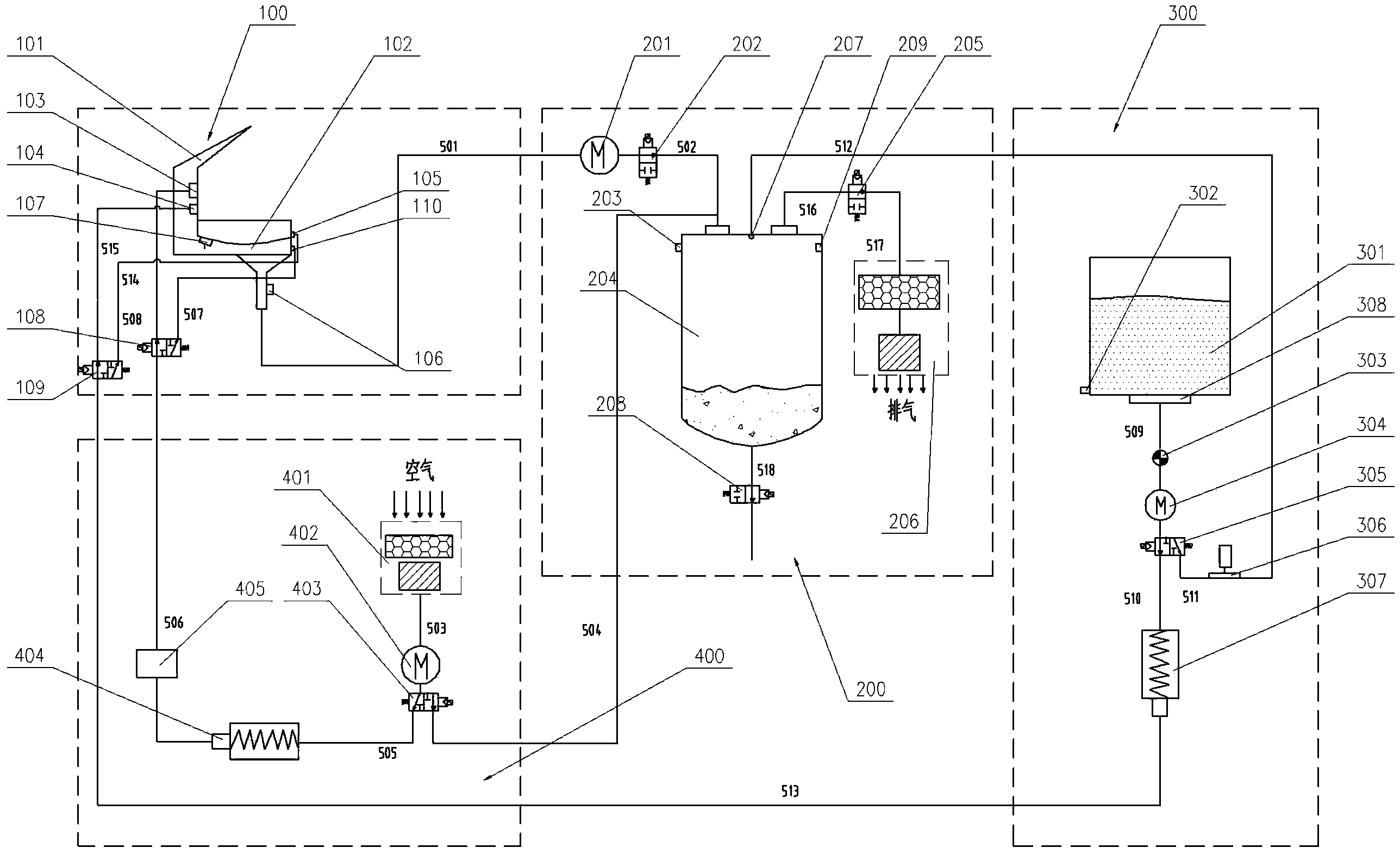

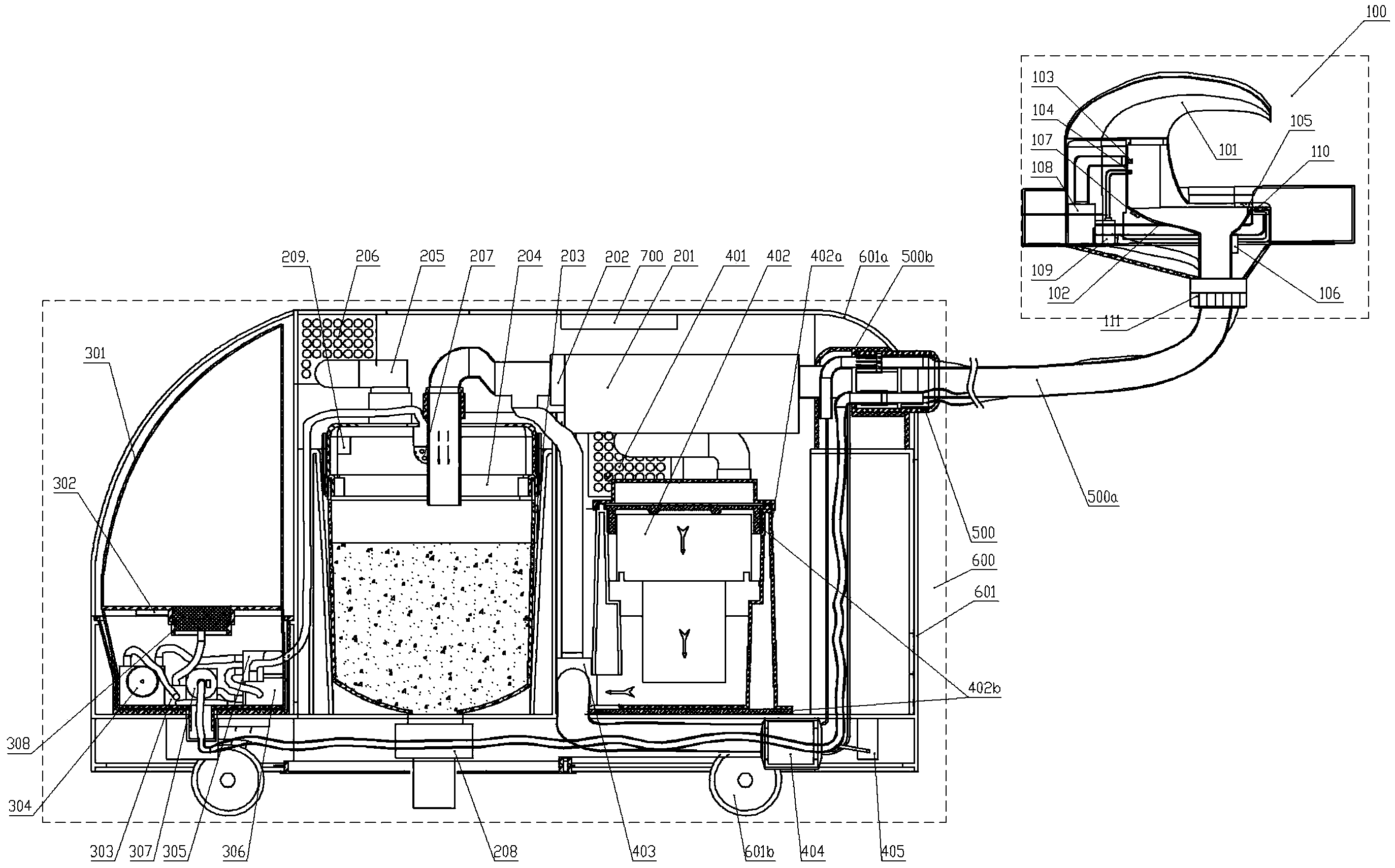

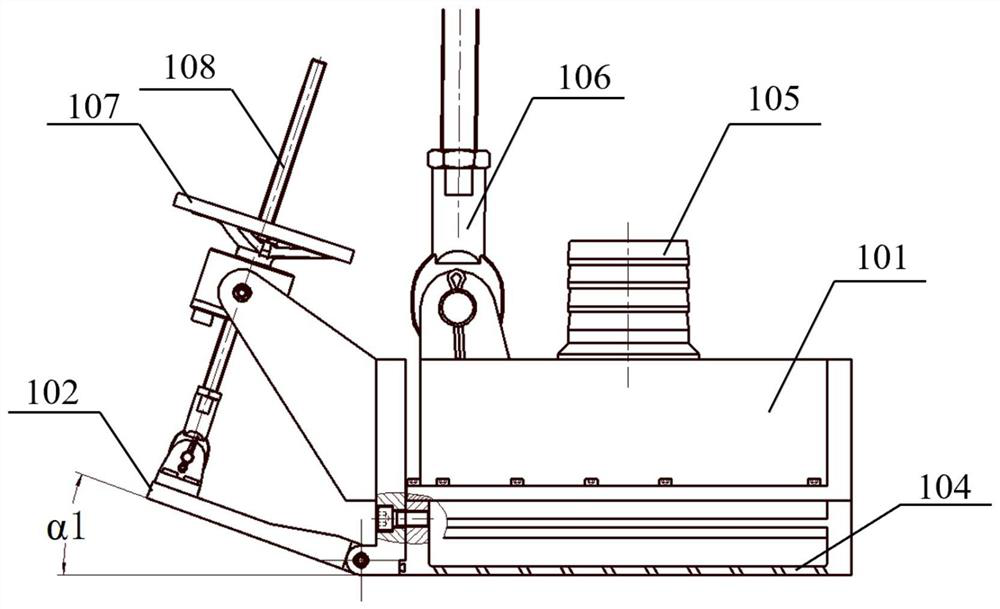

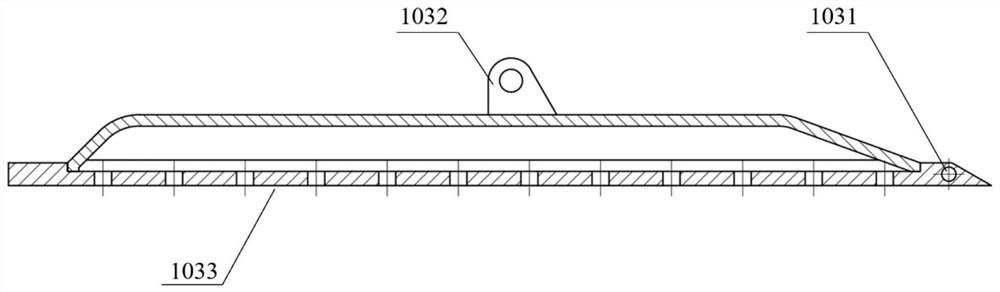

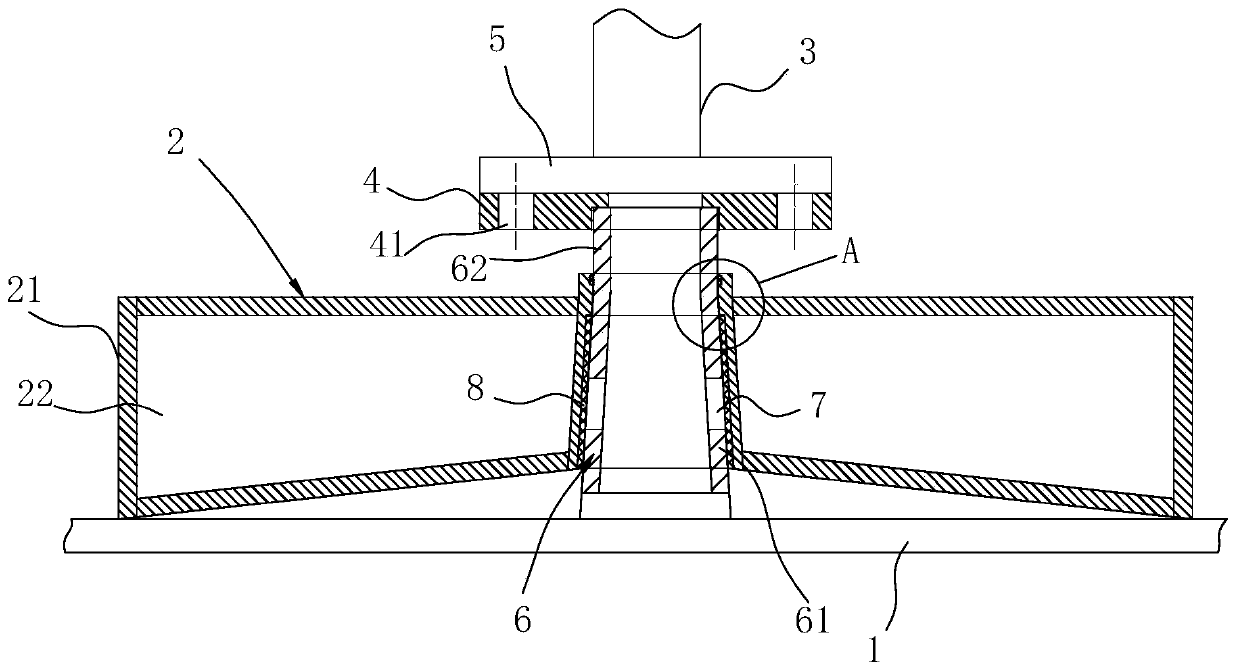

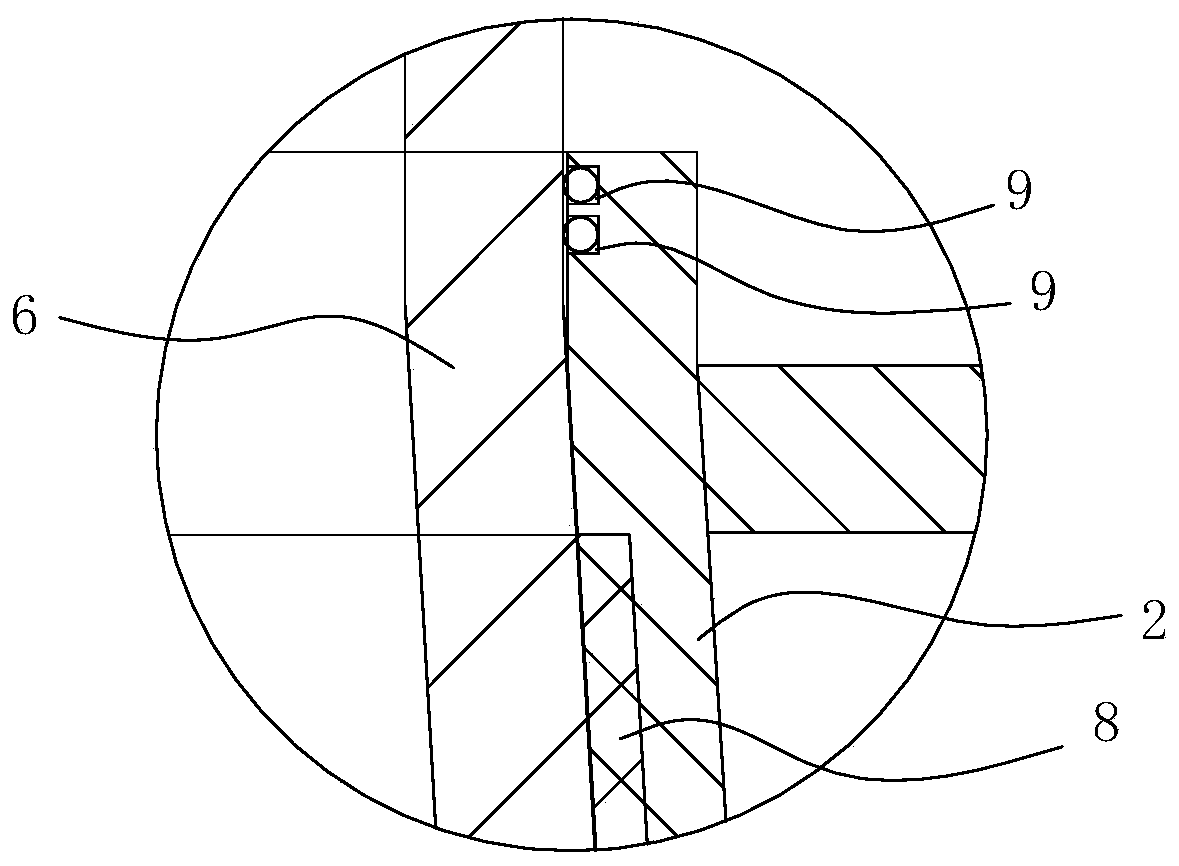

Automatic toilet nursing system

ActiveCN103655094AAchieve energy saving and water saving effectIncrease flushing functionMedical transportAtmosphereSewerage

The invention discloses an automatic toilet nursing system which comprises an excrement receiving assembly, a toilet host assembly and connecting pipelines. The excrement receiving assembly comprises a drying device, a flushing device, an excrement receiving device and a detection device. The drying device and the flushing device are arranged at the upper side of the excrement receiving assembly. The detection device is arranged in the excrement receiving assembly. The toilet host assembly comprises a host machine body, a collecting and evacuating unit, a washing unit, a drying positive-pressure unit and a control unit. The flushing device is connected with the washing unit through the washing pipeline. The excrement receiving assembly is connected with the collecting and evacuating unit through the sewage inlet pipeline. The drying device is connected with the drying positive-pressure unit through the drying pipeline. The collecting and evacuating unit is connected with the drying positive-pressure unit through the positive-pressure pipeline. The collecting and evacuating unit is communicated with the external environment through the sewage discharging pipeline and communicated with a toilet or a sewer. The collecting and evacuating unit is connected with the external atmosphere through the exhausting pipeline. The detection device, the washing unit and the drying positive-pressure unit are respectively connected with the control unit through circuits.

Owner:CRRC SHANDONG CO LTD

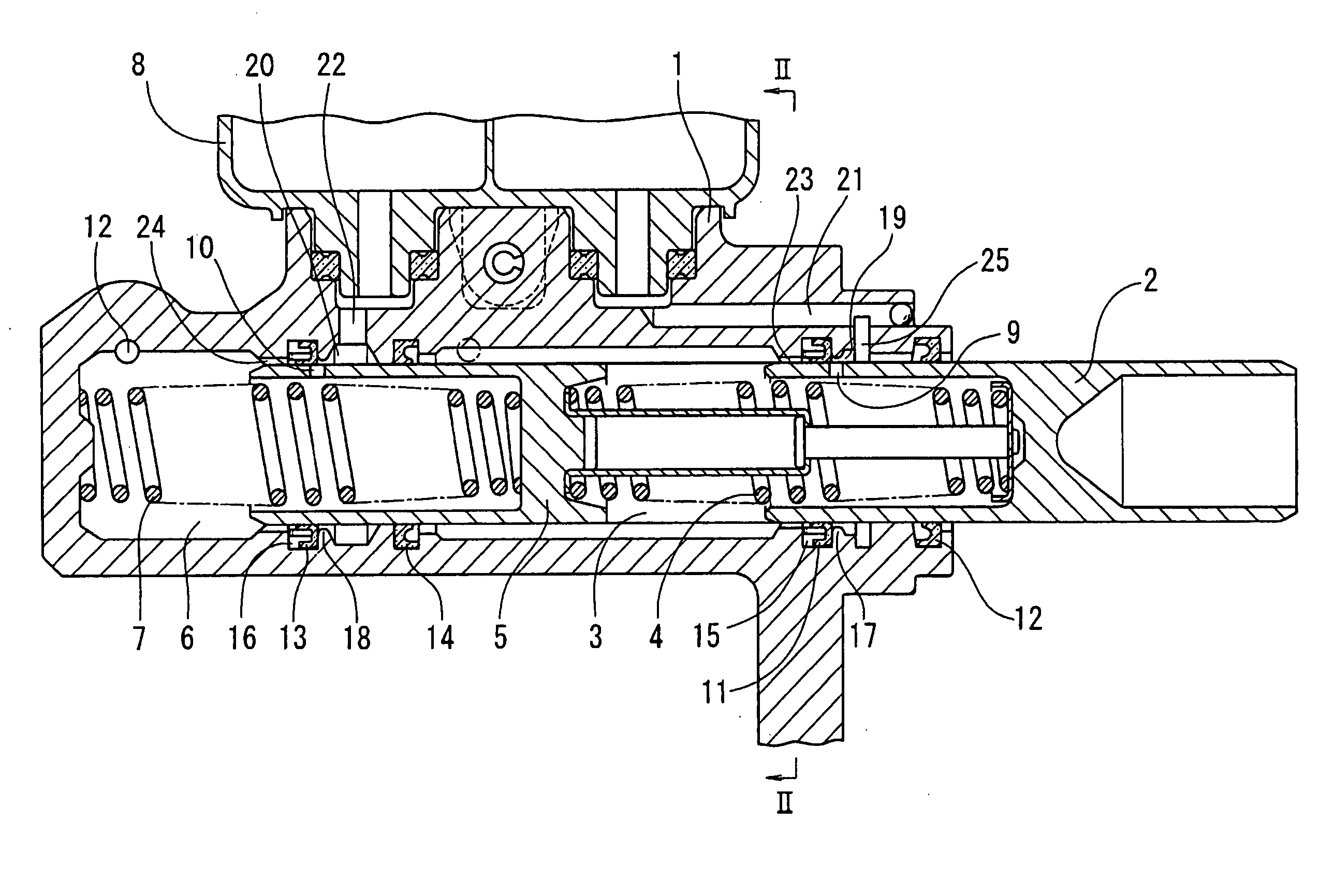

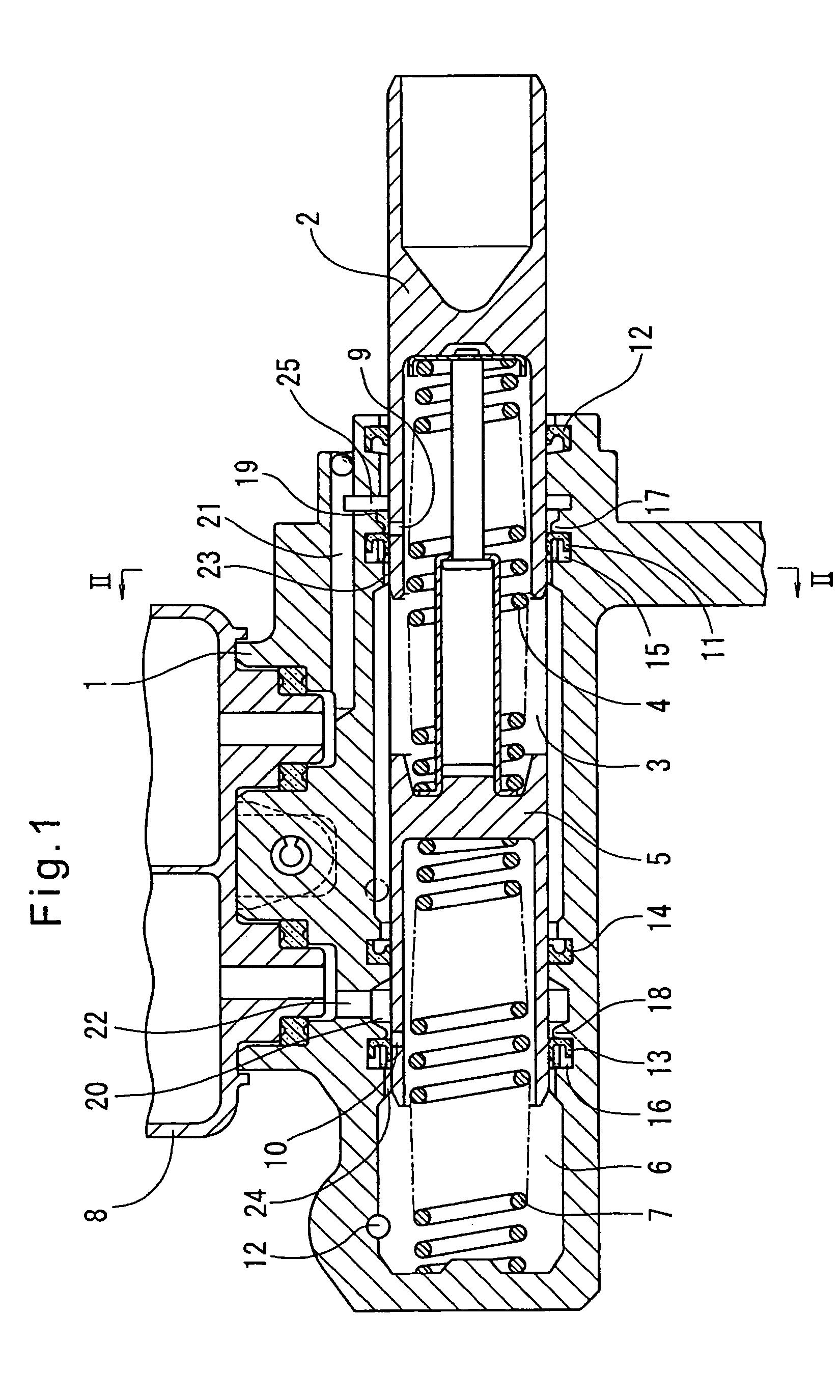

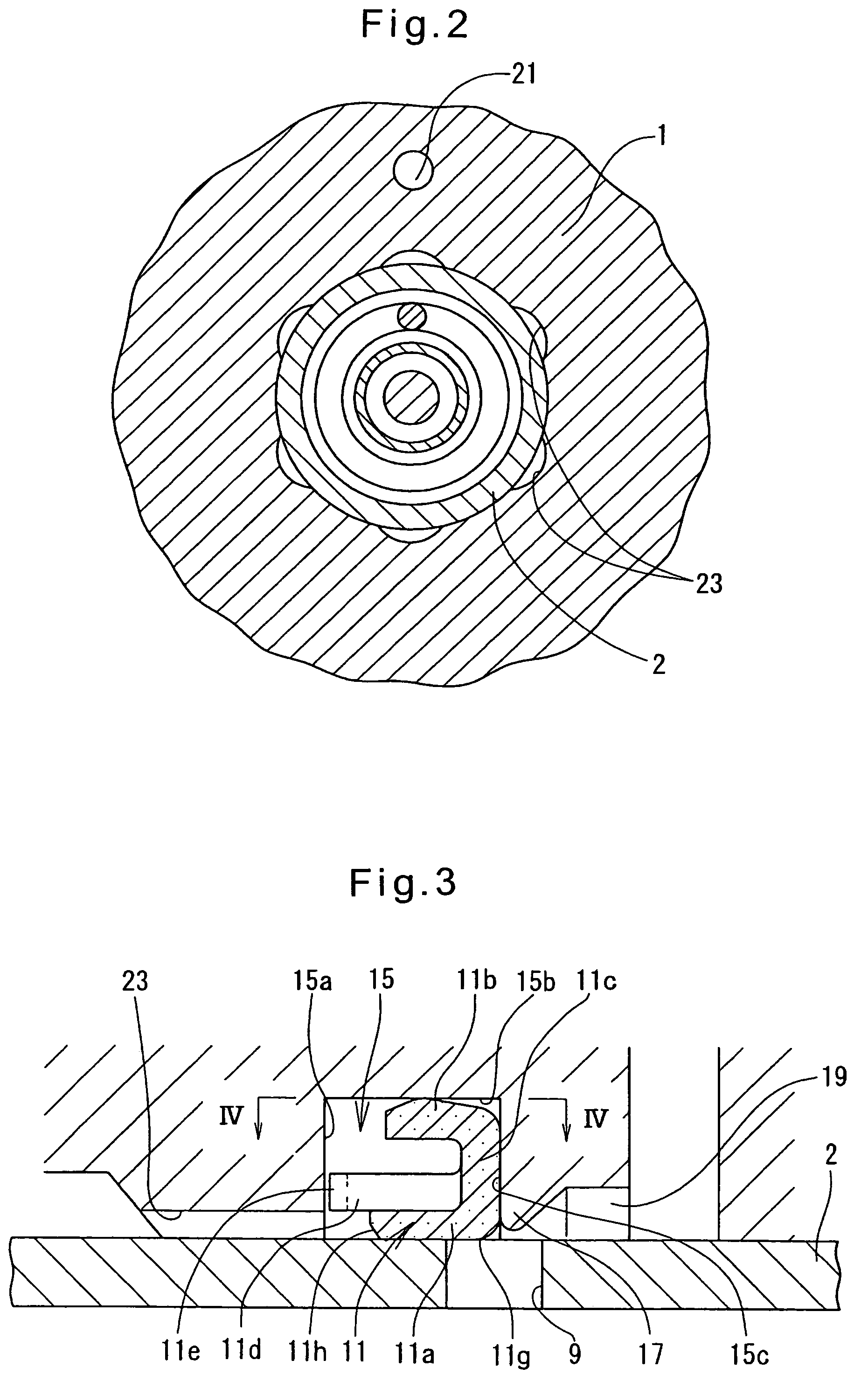

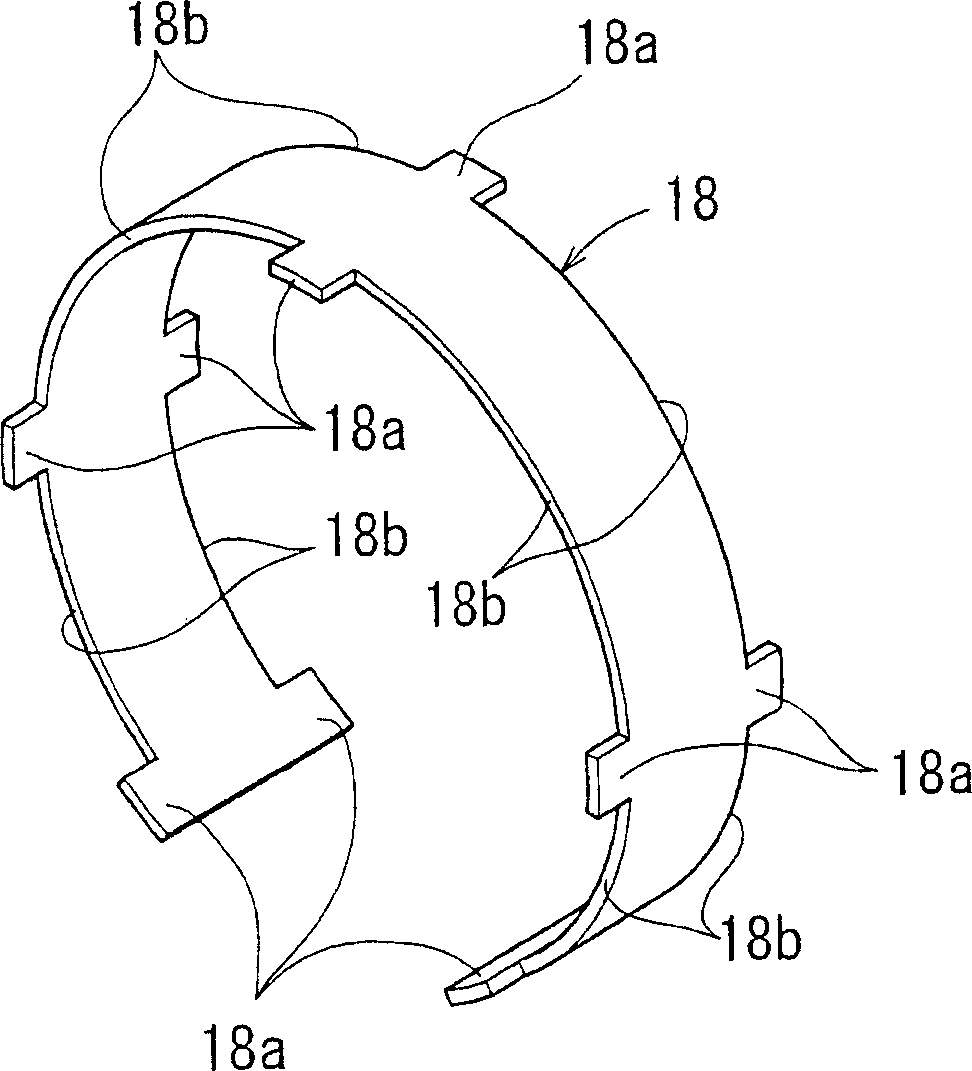

Master cylinder

ActiveUS20050115237A1Inhibition formationSpeed up the flowPiston ringsRotary clutchesMaster cylinderEngineering

A master cylinder includes a primary cup received in a groove formed in the inner wall of the cylinder body. Projections are formed on a radially inner portion of the cup so as to protrude forwardly from the front end of the radially inner portion. The projections are adapted to be pressed against the front end wall of the cup-receiving groove and elastically deformed under a pressure difference produced between the front and rear ends of the cup when the piston is returned quickly, allowing the cup to advance in the cup-receiving groove. When the cup advances in the groove, a fluid passage is defined between a base portion of the cup and the rear end wall of the groove. Brake fluid from the reservoir flows through this fluid passage, through a gap formed between a radially outer portion of the cup and the radially outer wall of the groove when the radially outer portion of the cup is deformed by the fluid flow, and through a fluid passage defined between the cup and the front end wall of the groove by the projections.

Owner:ADVICS CO LTD

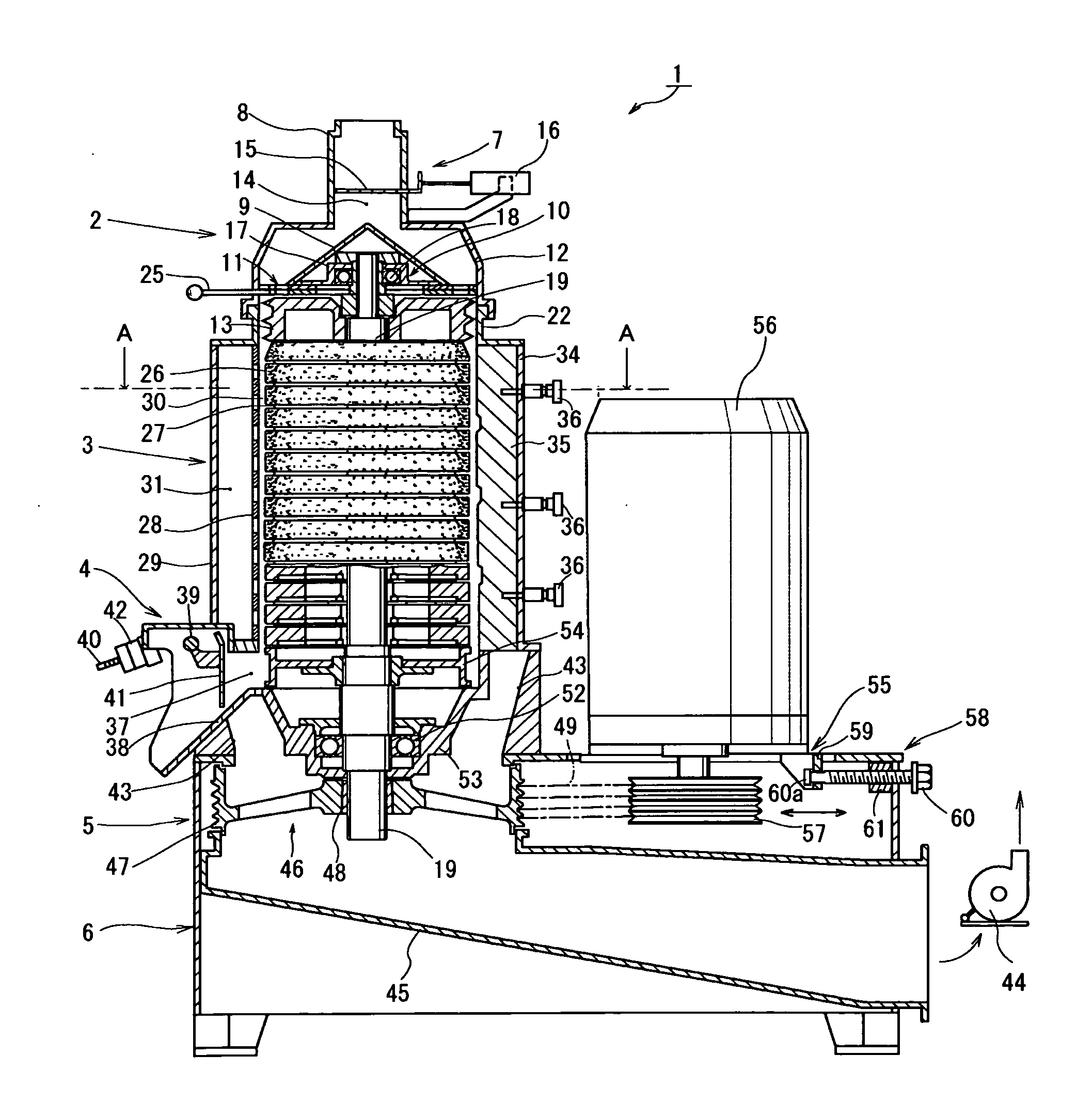

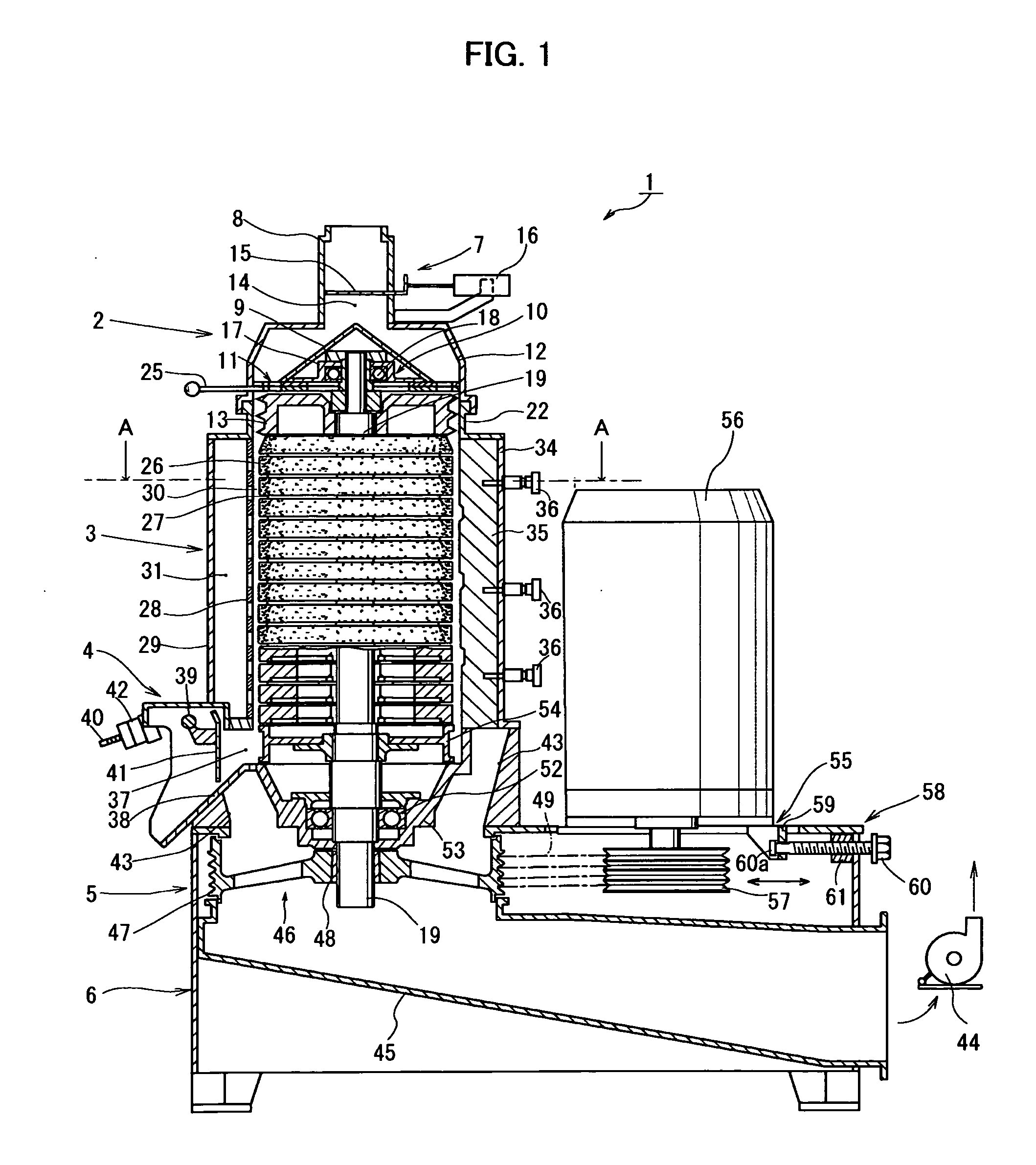

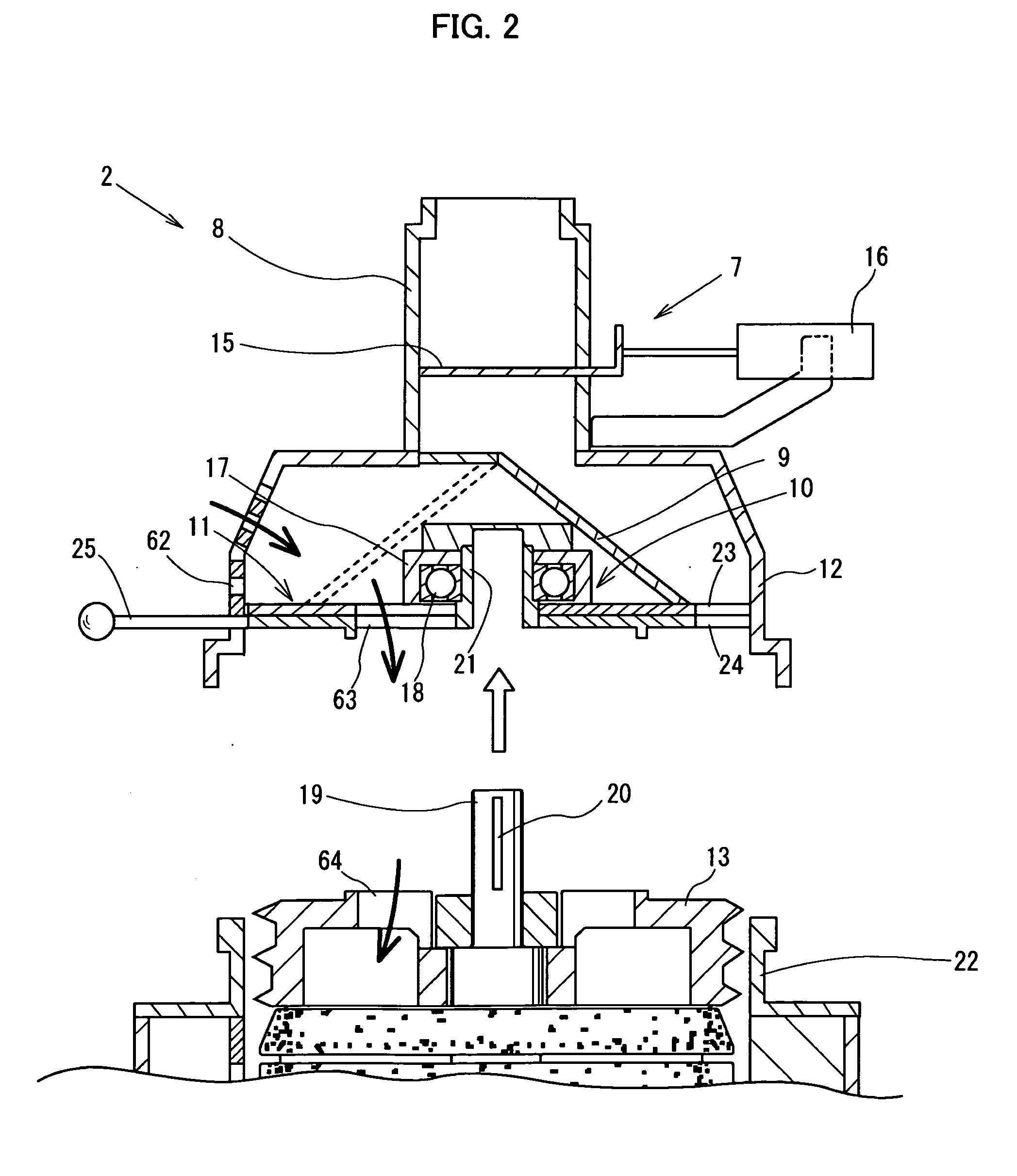

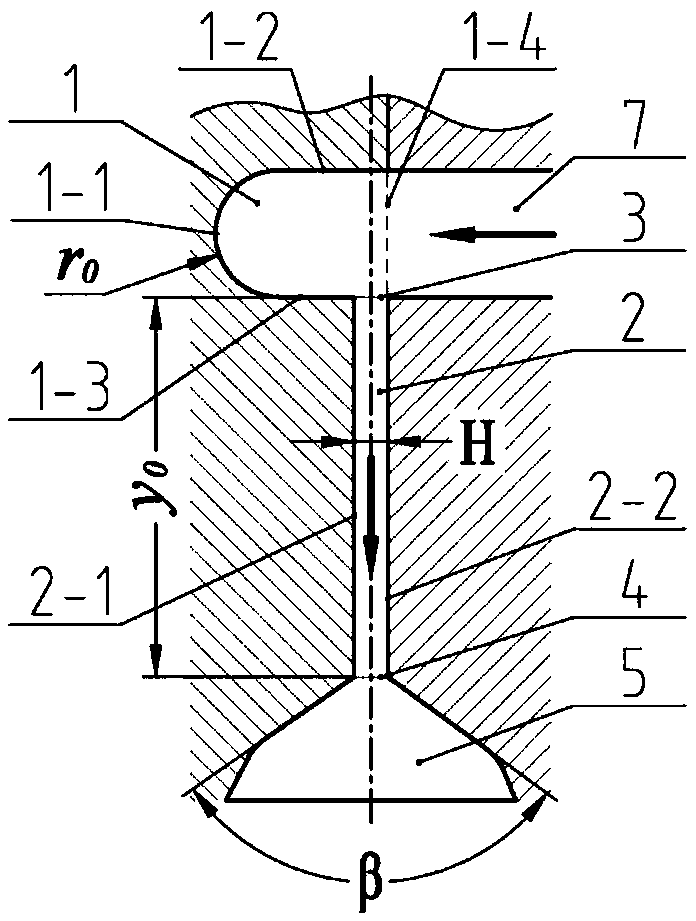

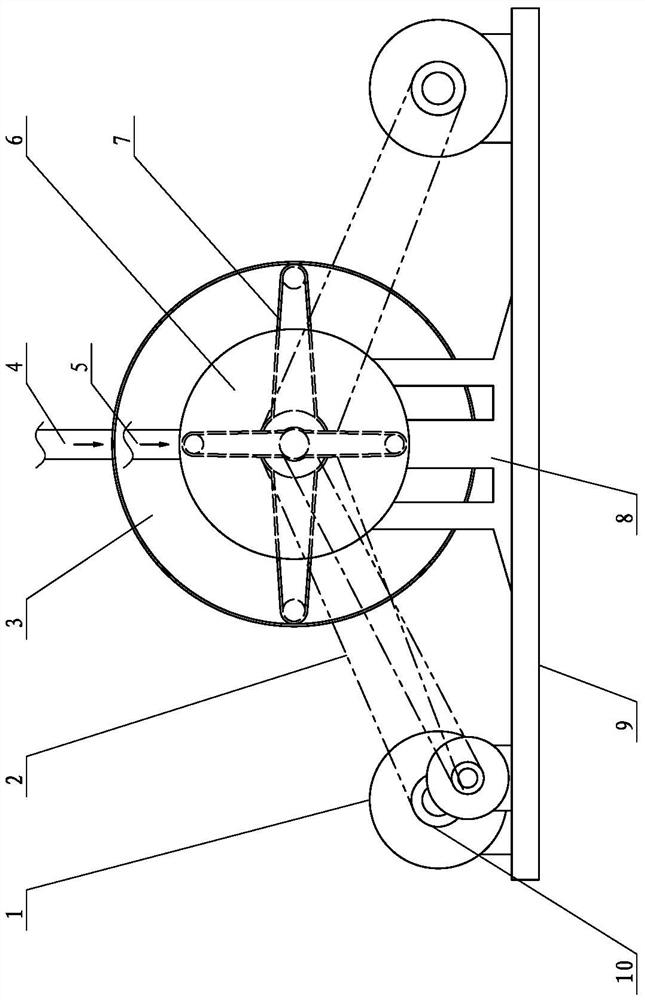

Grinding type vertical grain milling machine

A grinding type vertical grain milling machine is capable of shortening a dimension of a machine body in the vertical direction and removing bran by evenly suctioning an entire bran removing chamber. The grinding type vertical grain milling machine includes a bran removing metallic mesh cylinder with a main shaft, an integral grinding type grain milling roll body, a bran removing chamber, and a bran discharge pipe that discharges bran to the outside of the machine. A fan-pulley is provided between the bran removing chamber and the bran discharge pipe. The fan-pulley rotationally drives the main shaft to which the grinding type grain milling roll is axially attached and generates a bran removing wind to convey bran produced by the grain milling action of the grinding type grain milling roll from the bran removing chamber toward the bran discharge pipe.

Owner:SATAKE CORP

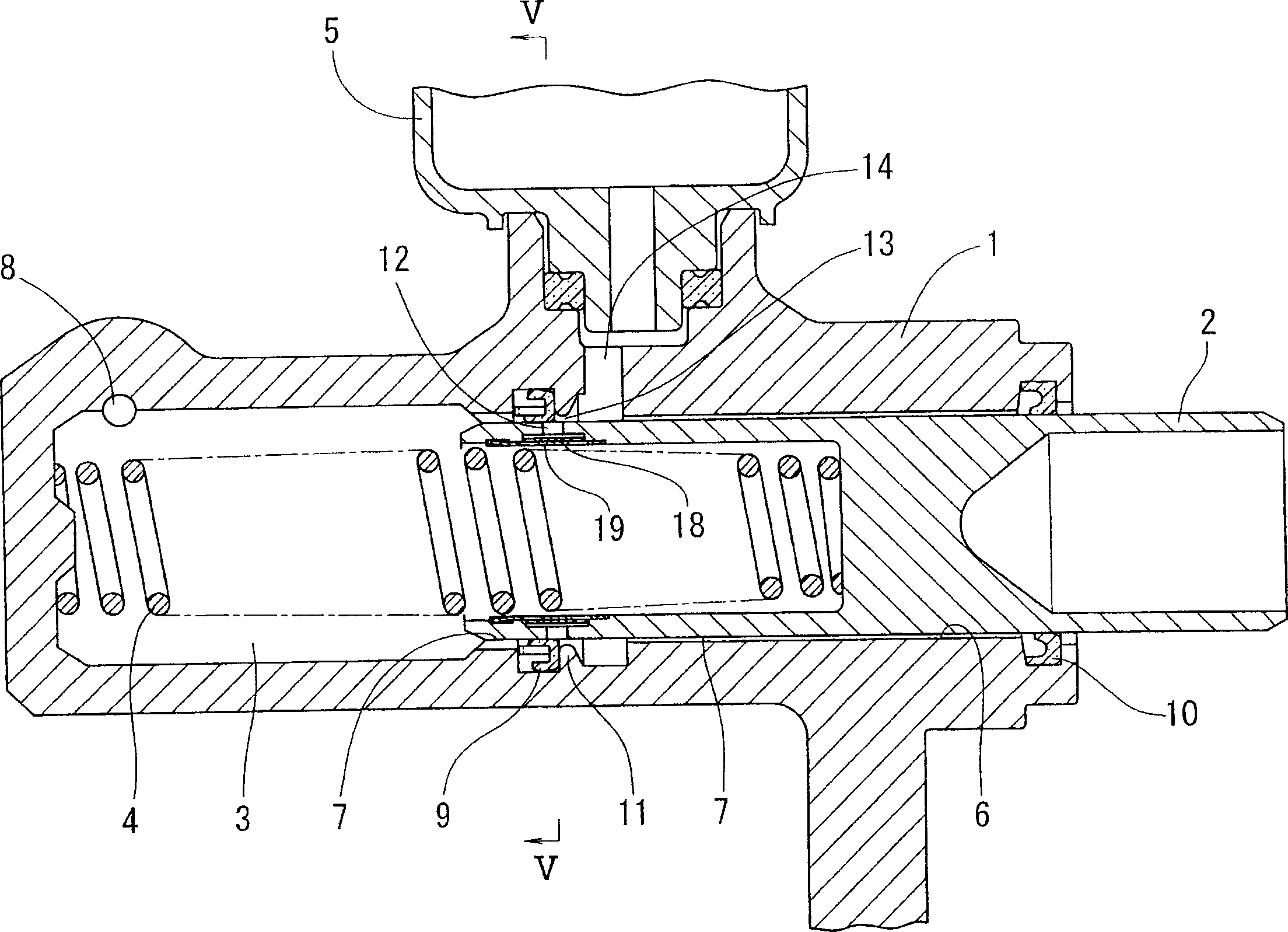

Master cylinder

ActiveUS7104059B2Speed up the flowShorten driving distancePiston ringsRotary clutchesMaster cylinderEngineering

A master cylinder includes a primary cup received in a groove formed in the inner wall of the cylinder body. Projections are formed on a radially inner portion of the cup so as to protrude forwardly from the front end of the radially inner portion. The projections are adapted to be pressed against the front end wall of the cup-receiving groove and elastically deformed under a pressure difference produced between the front and rear ends of the cup when the piston is returned quickly, allowing the cup to advance in the cup-receiving groove. When the cup advances in the groove, a fluid passage is defined between a base portion of the cup and the rear end wall of the groove. Brake fluid from the reservoir flows through this fluid passage, through a gap formed between a radially outer portion of the cup and the radially outer wall of the groove when the radially outer portion of the cup is deformed by the fluid flow, and through a fluid passage defined between the cup and the front end wall of the groove by the projections.

Owner:ADVICS CO LTD

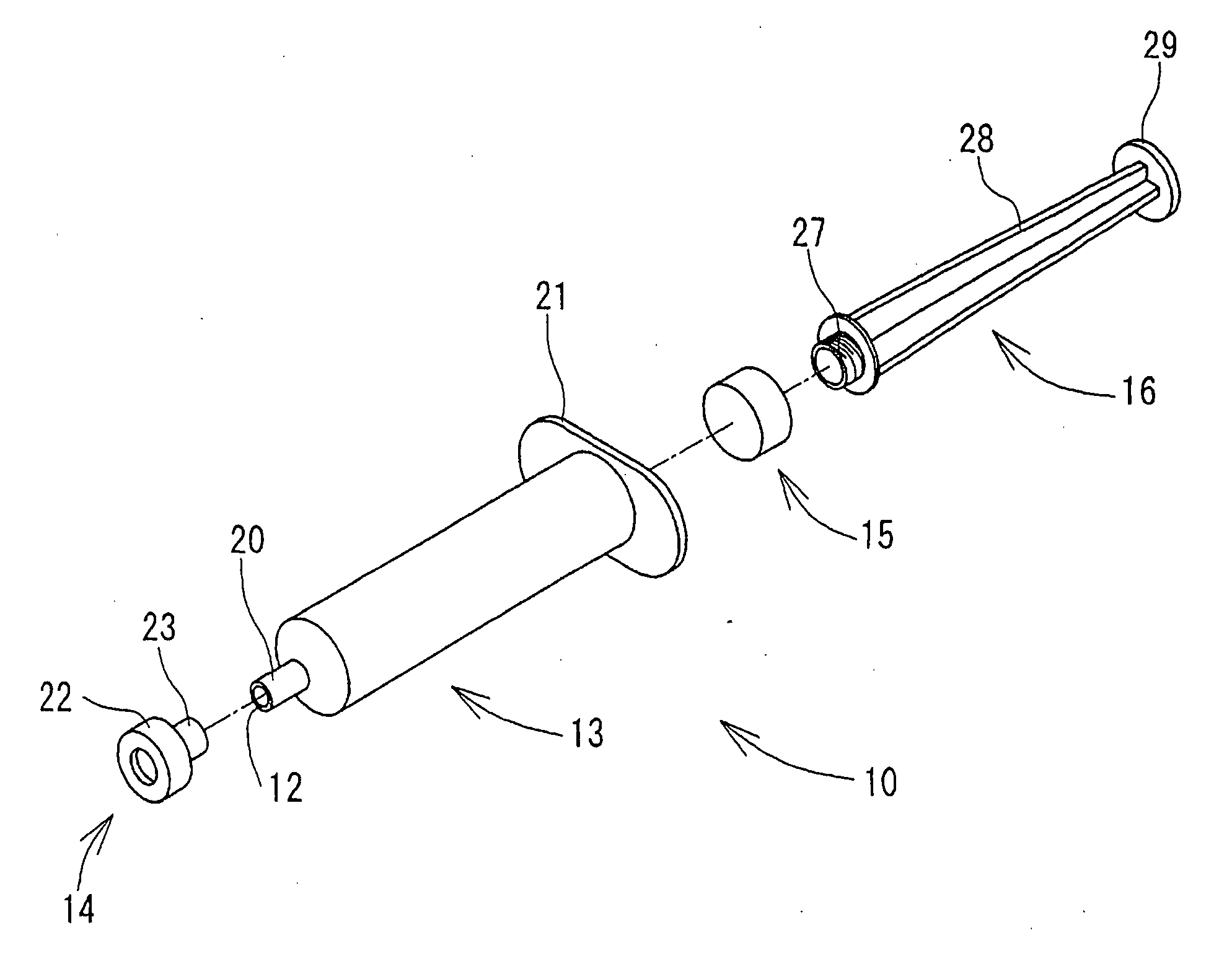

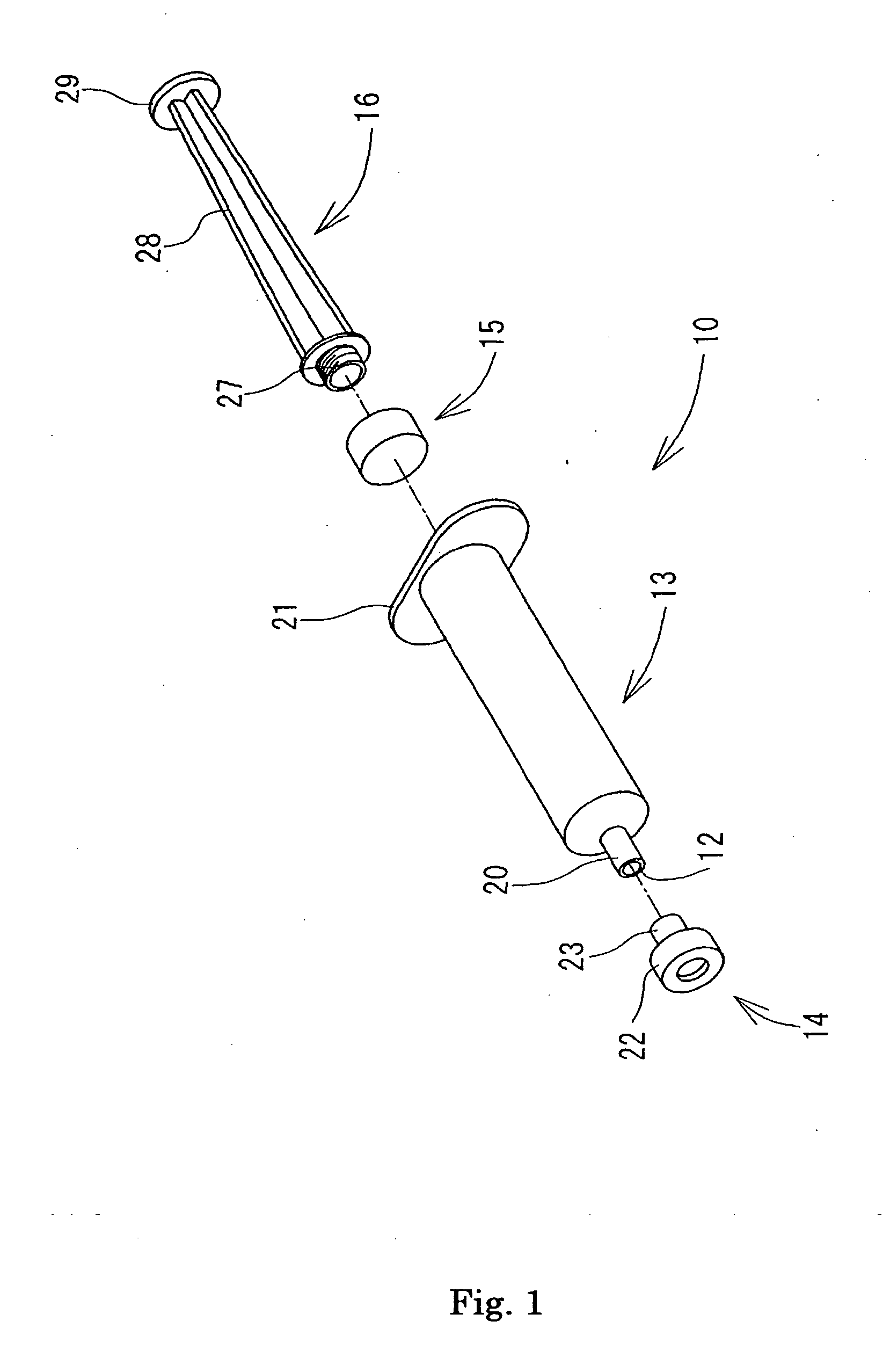

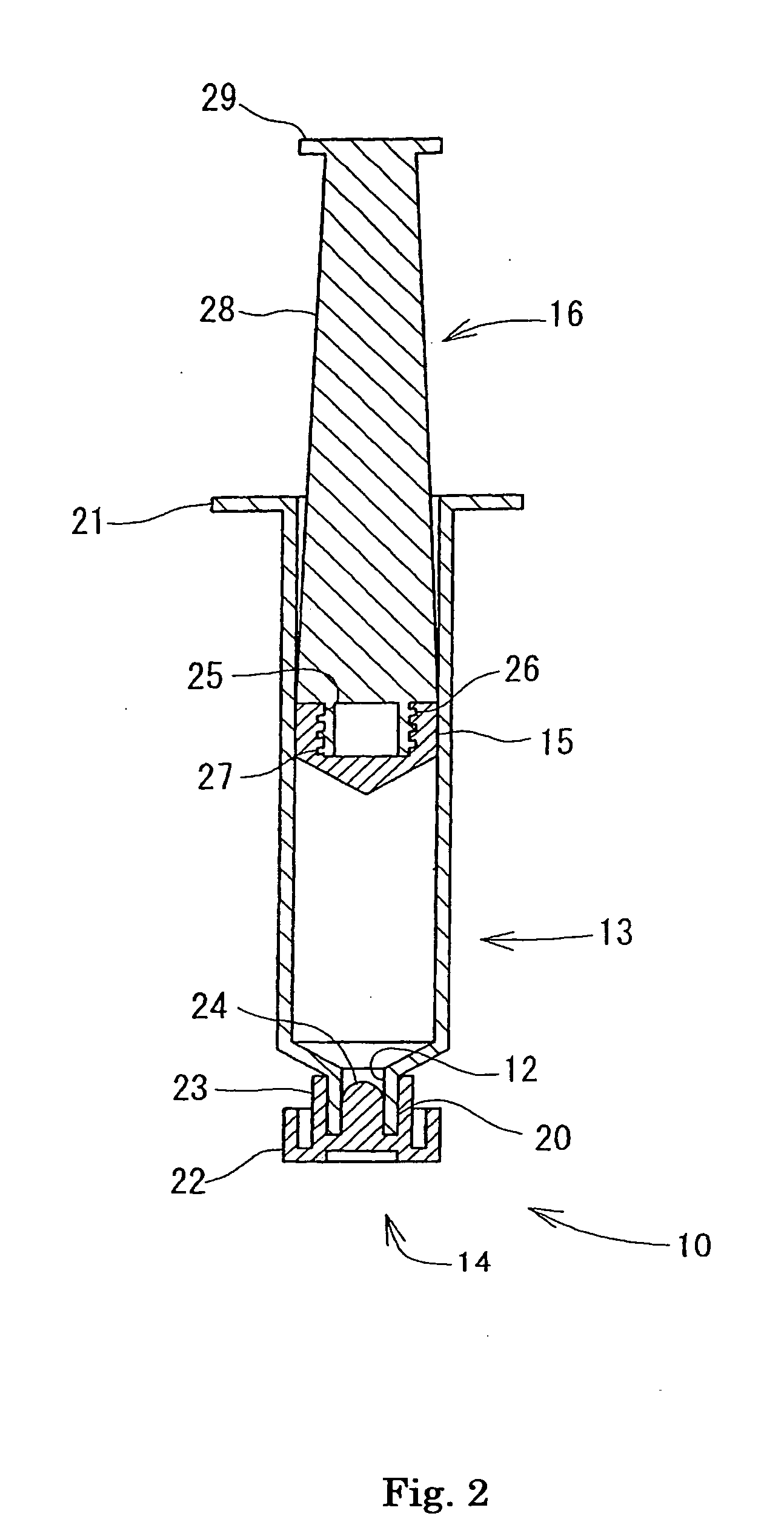

Platelet-rich plasma separator and platelet-rich plasma separation method

ActiveUS20100025342A1Reliable separationStable suctionMedical devicesMammal material medical ingredientsSyringePlatelet-rich plasma

Provided is a platelet-rich plasma separator which can carry out the separation of a platelet-rich plasma with a small number of gamma radiation sterilized instruments and a platelet-rich plasma separation method. The platelet-rich plasma separator comprises a first syringe and a second syringe. The first syringe comprises a first syringe cylinder provided with a first port on which a blood collection needle can be mounted, a first cap detachable from the first port, a first gasket for sealing the first syringe cylinder fluid-tightly, which first gasket is reciprocated within the first syringe cylinder, and a first plunger provided detachably on the first gasket. The second syringe comprises a first hollow needle, which can be passed through the first gasket, a second syringe cylinder having a second port on which the first hollow needle can be mounted, a second cap detachable from the second port, a second gasket for sealing the second syringe cylinder liquid-tightly, which second gasket is reciprocated within the second syringe cylinder, and a second plunger provided detachable on the second gasket.

Owner:NIPRO CORP

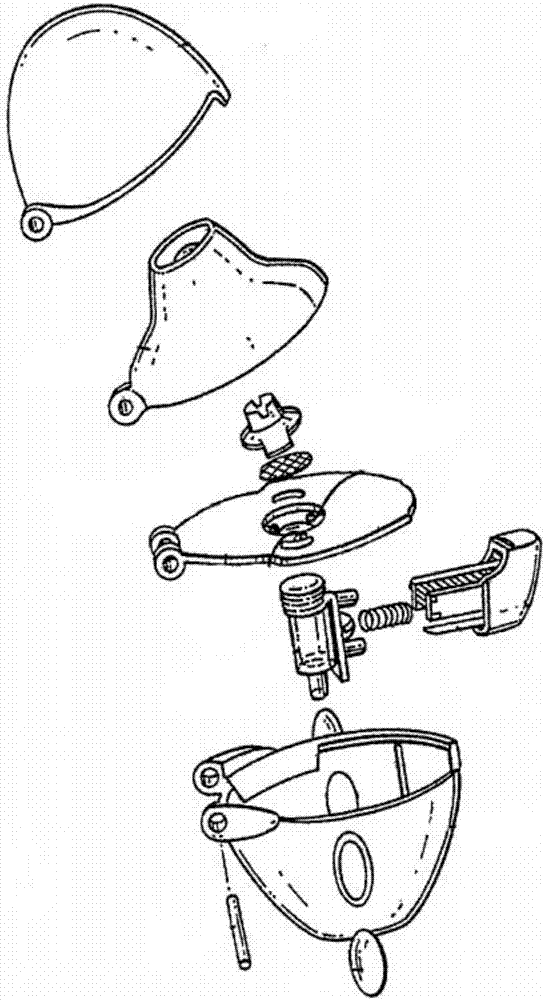

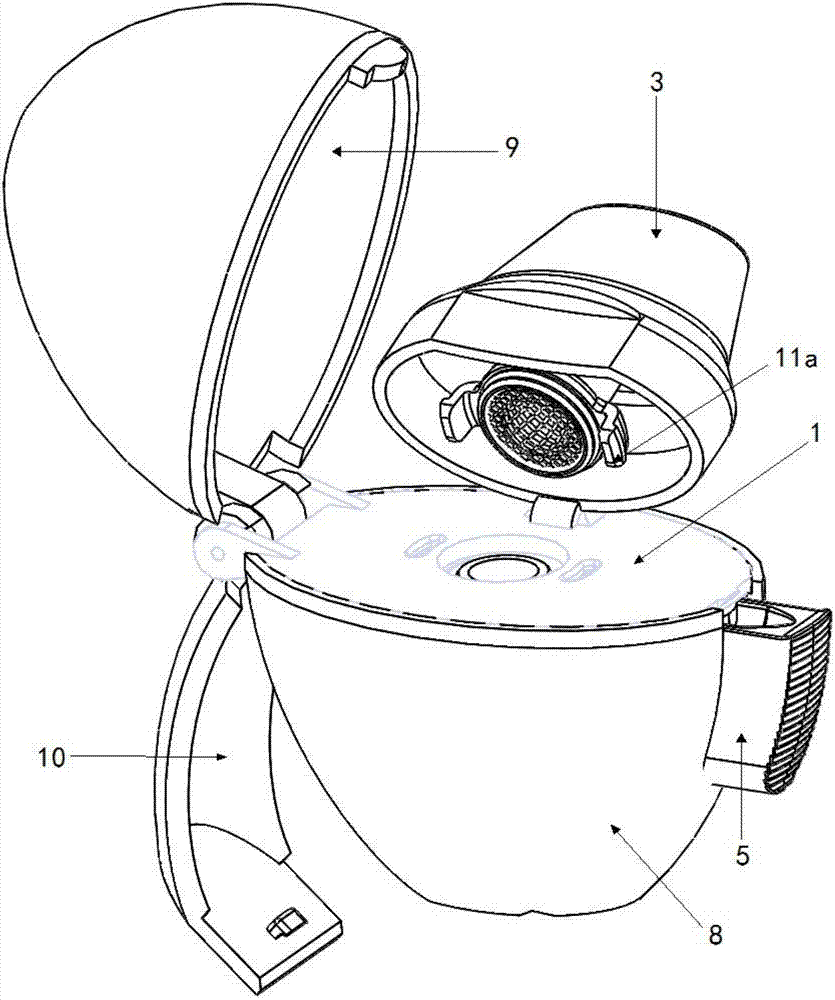

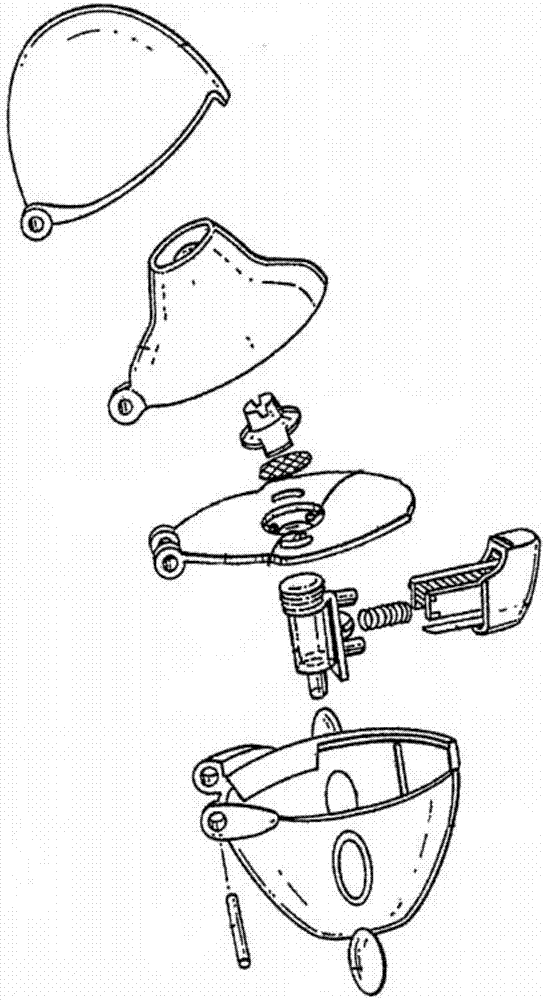

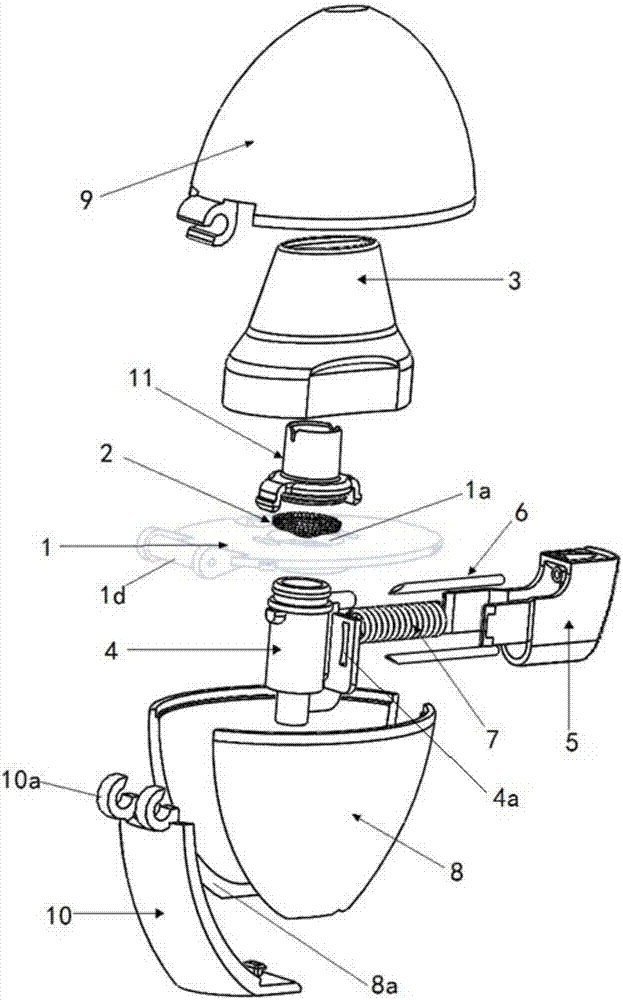

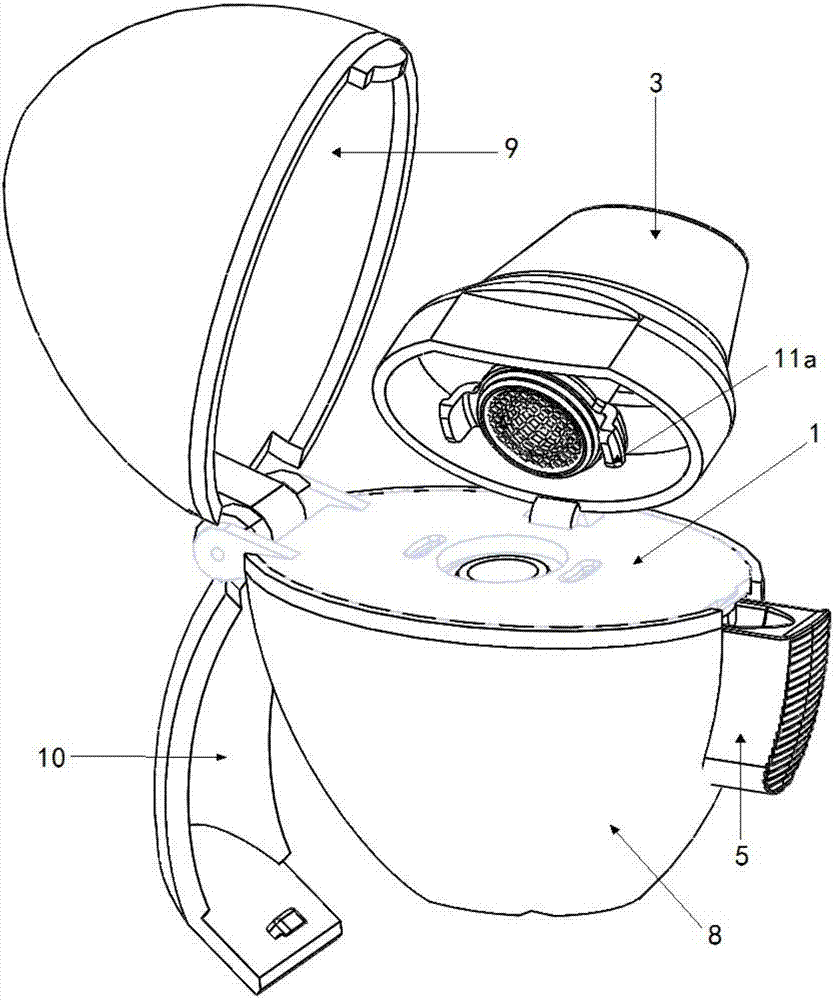

Dry powder inhaler

PendingCN106924845AEasy to assembleReduce manufacturing costMedical devicesInhalatorsBiomedical engineeringDry-powder inhaler

The invention discloses a dry powder inhaler, which comprises a bearing plate, a suction nozzle, a capsule chamber, a button, a spring and a lower shell, wherein through holes are formed in the bearing plate in a going-through mode; the suction nozzle is connected to the upper side of the bearing plate and is arranged on the through holes; the capsule chamber is connected to the lower side of the bearing plate and is located on the through holes; tip pins, which are made from metal, are connected to the button, and the tip pins, through a pressing action of the button, can extend into the capsule chamber; the spring is clamped between the button and the capsule chamber, and by virtue of the spring, elasticity away from the direction of the capsule chamber is exerted; the upper side of the lower shell is of an opening structure; the bearing plate is connected to an opening of the upper side of the lower shell, and meanwhile, the capsule chamber is accommodated within the lower shell; the tip pins are fixedly connected to the button by virtue of a plastic tip pin seat; the tip pins and the tip pin seat are fixed in an injection-molding mode; and the tip pin seat and the button are fixed in a clamping mode. According to the dry powder inhaler, the tip pins, when used, are prevented from getting fallen or displaced easily; and moreover, the capsule chamber can be cleaned by a user more conveniently.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

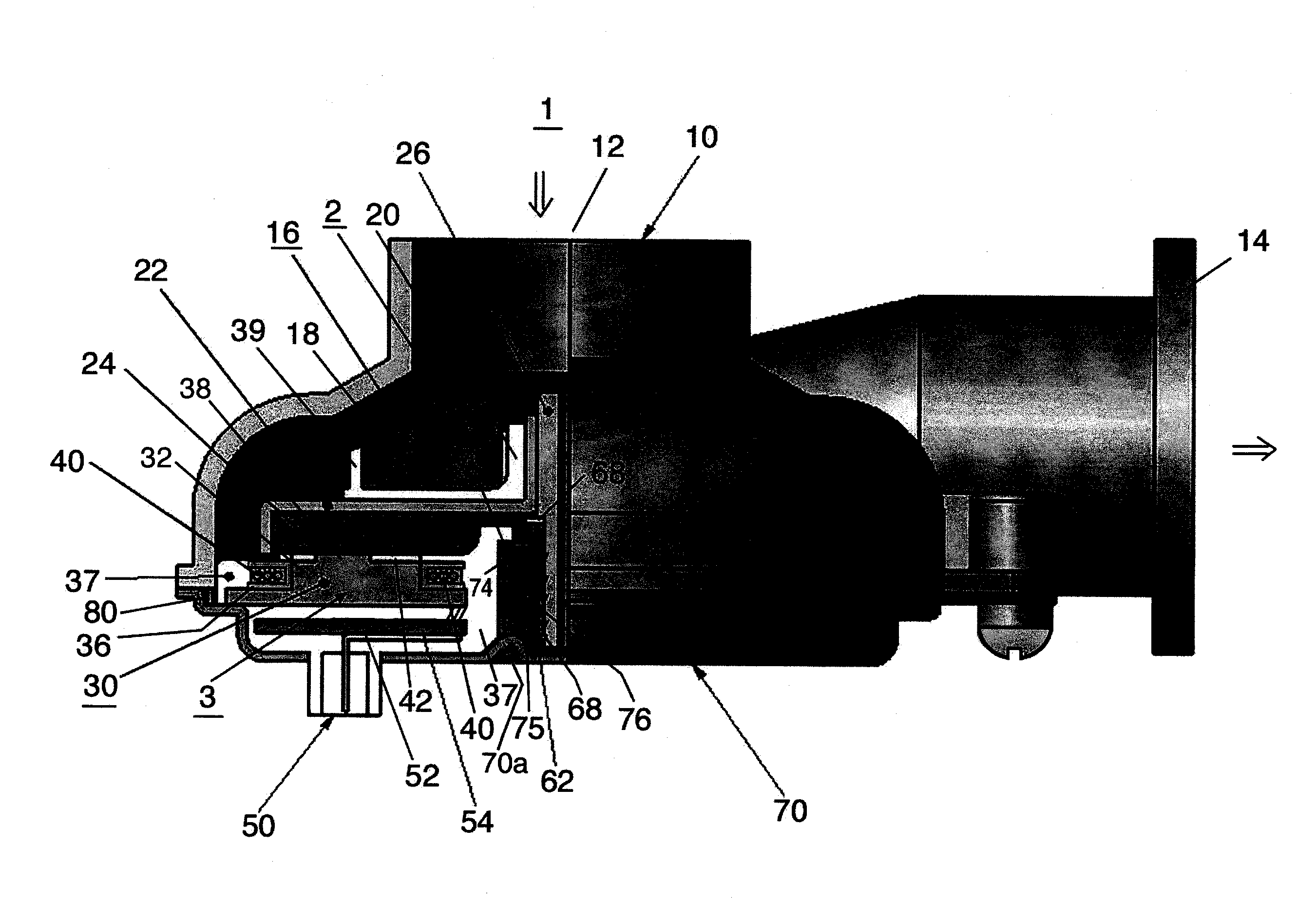

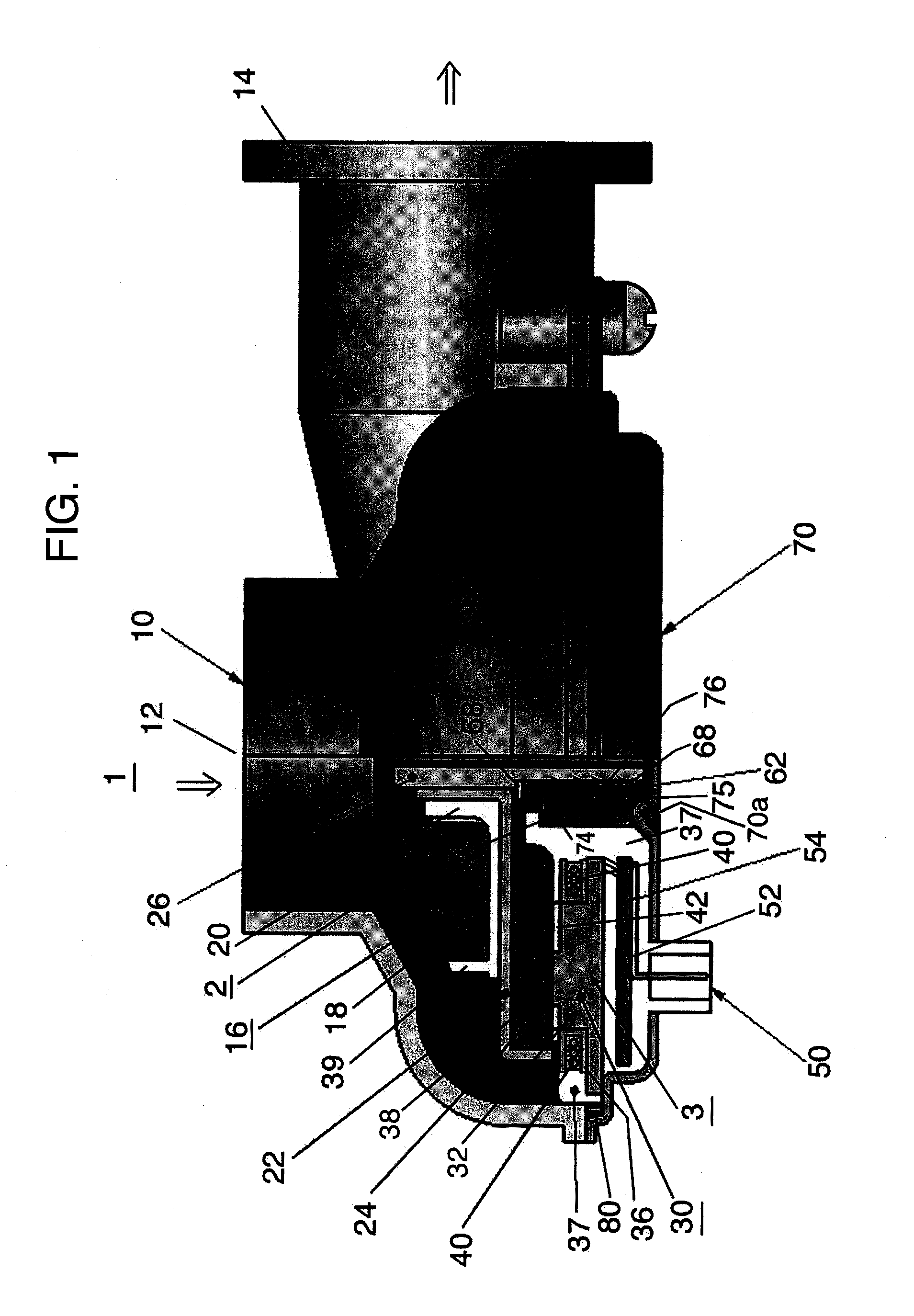

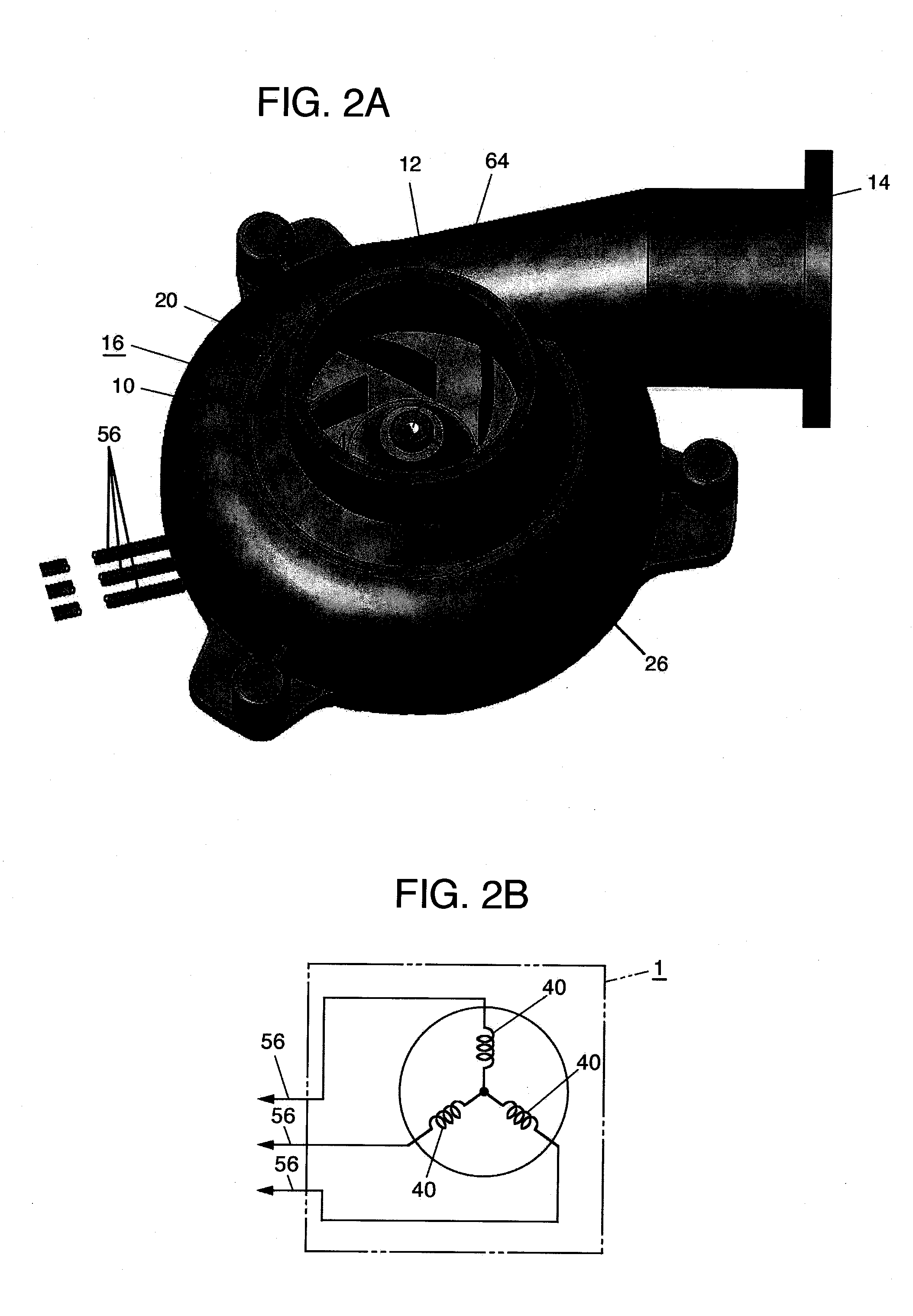

Flattened Brushless Motor Pump and Vehicle Electric Pump Unit Using Flattened Brushless Motor Pump

InactiveUS20080226474A1Simple configurationImprove featuresPositive displacement pump componentsBlade accessoriesBrushless motorsEngineering

The flattened brushless motor pump sucks liquid from suction port and discharges liquid from discharge port by rotating rotary shaft of flattened brushless motor flattened brushless motor has a stator unit having cores around which a plurality of armature coils are wound and terminals electrically connected to the armature coils, and being formed by molding the cores and the terminals with resin in a watertight manner a rotor unit having magnets disposed facing the cores via a gap, rotary shaft and a yoke fixed to the rotary shaft and holding the magnets, wherein an in-water bearing for sliding the rotary shaft by a water film.

Owner:YAMAMOTO ELECTRIC

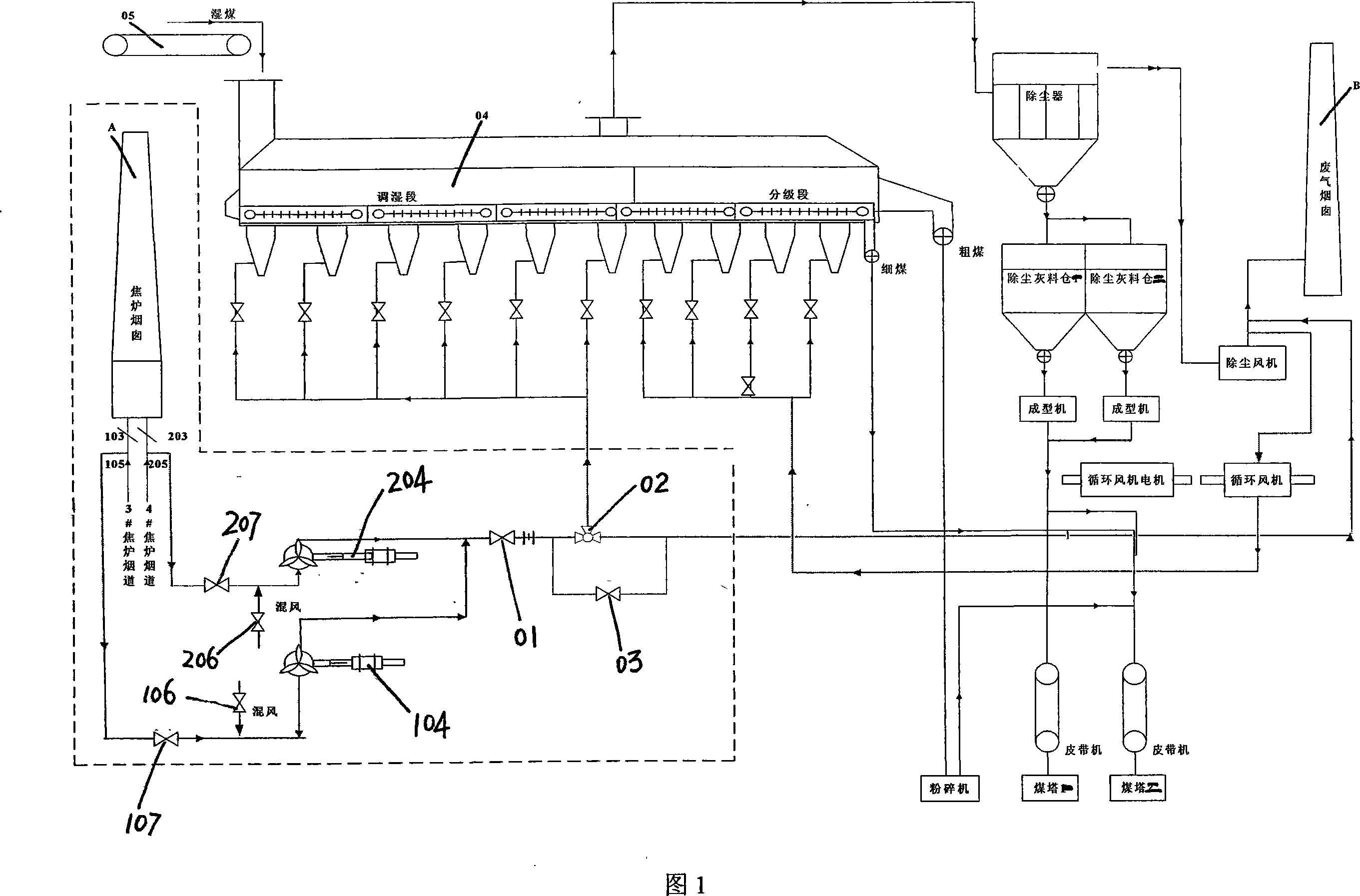

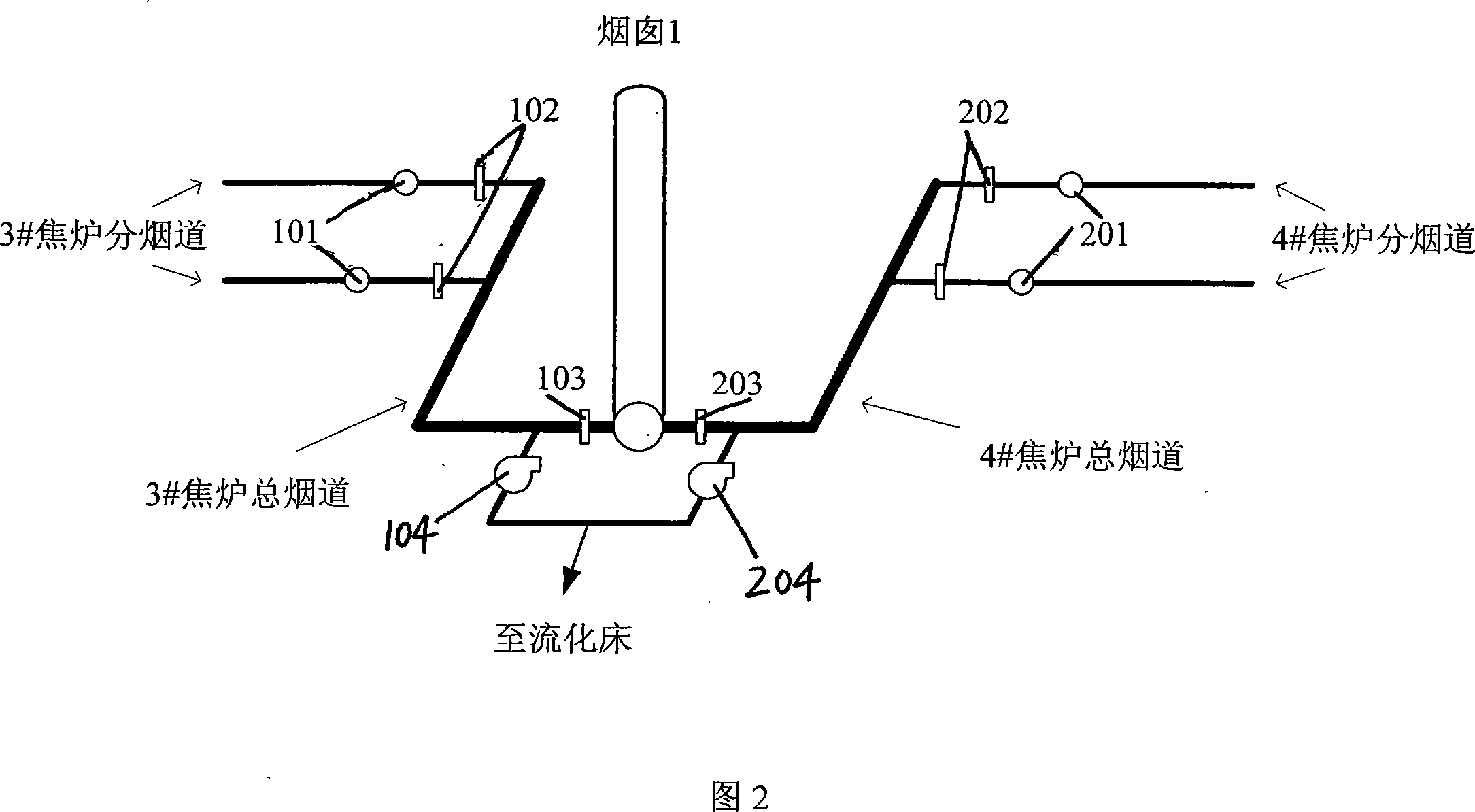

Method for grading and conditioning coal by stable obtained coke oven smoke

The invention discloses a method of steadily obtaining coke oven smoke for coal classification and moisture control, and is characterized in that: a waste gas extraction point of a coke oven flue is selected, frequency conversion control of a draught fan is done to obtain the waste gas in the coke oven flue for realizing the airflow classification and moisture control of the coking coal, the high temperature waste gas is maximally obtained under the premise of assuring the stability of the suction of the coke oven flue. The method steadily obtains the coke oven smoke as the gas medium of classification and moisture control in the pre-treatment of the coking coal while the production of the coke oven is not affected, and is applied in the waste energy utilization of the coke oven waste gas in the coking industry.

Owner:SHANDONG IRON & STEEL CO LTD

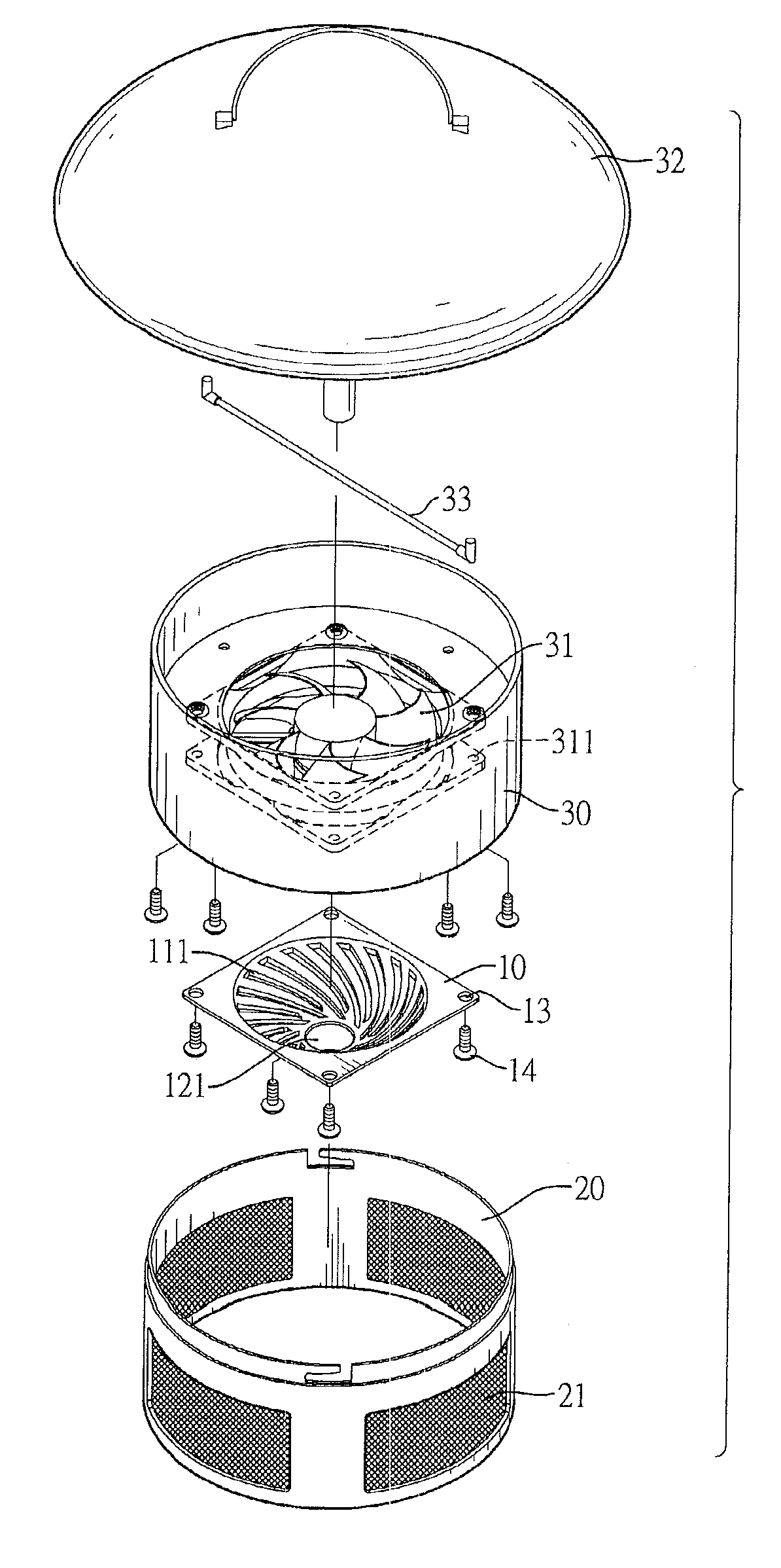

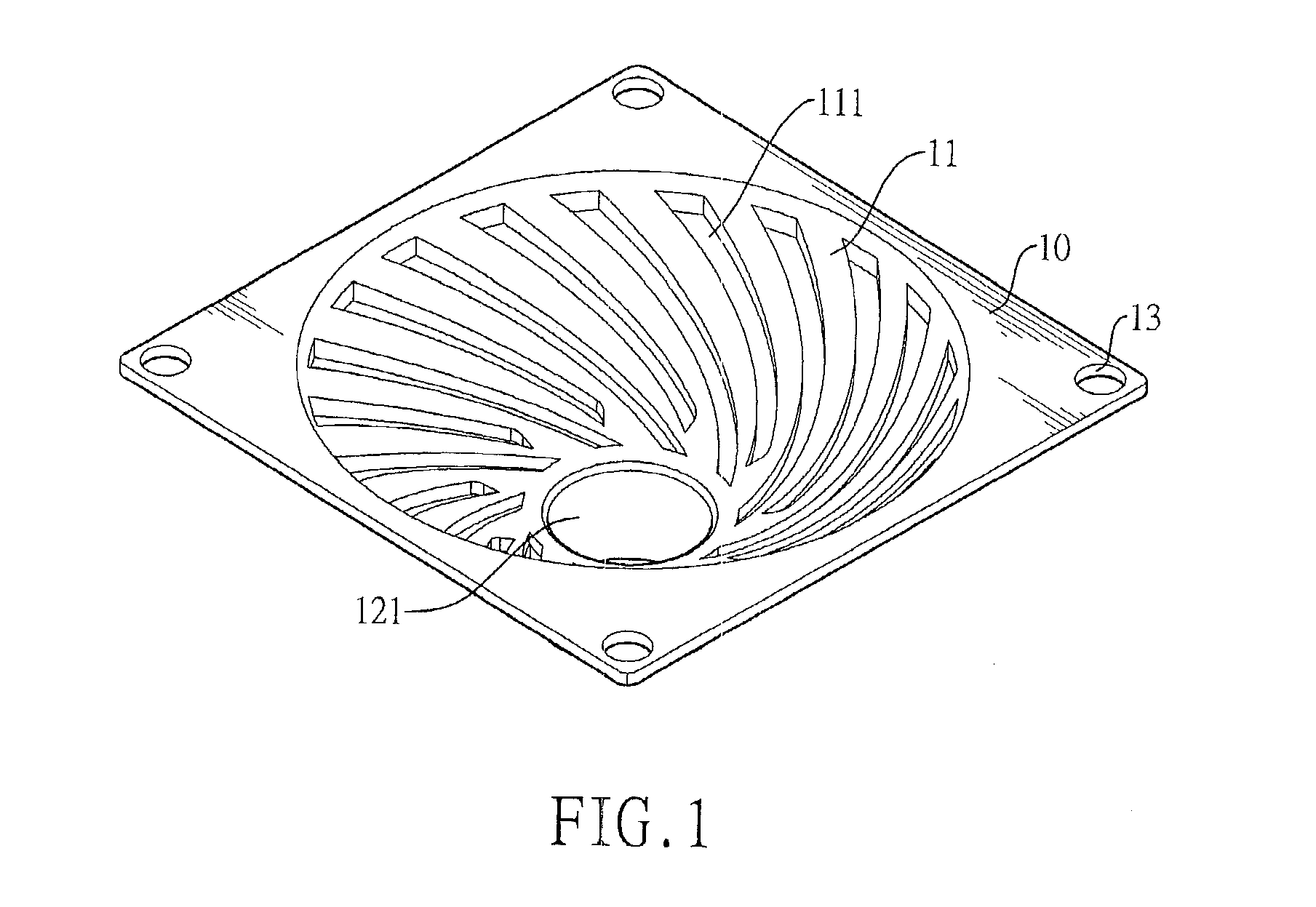

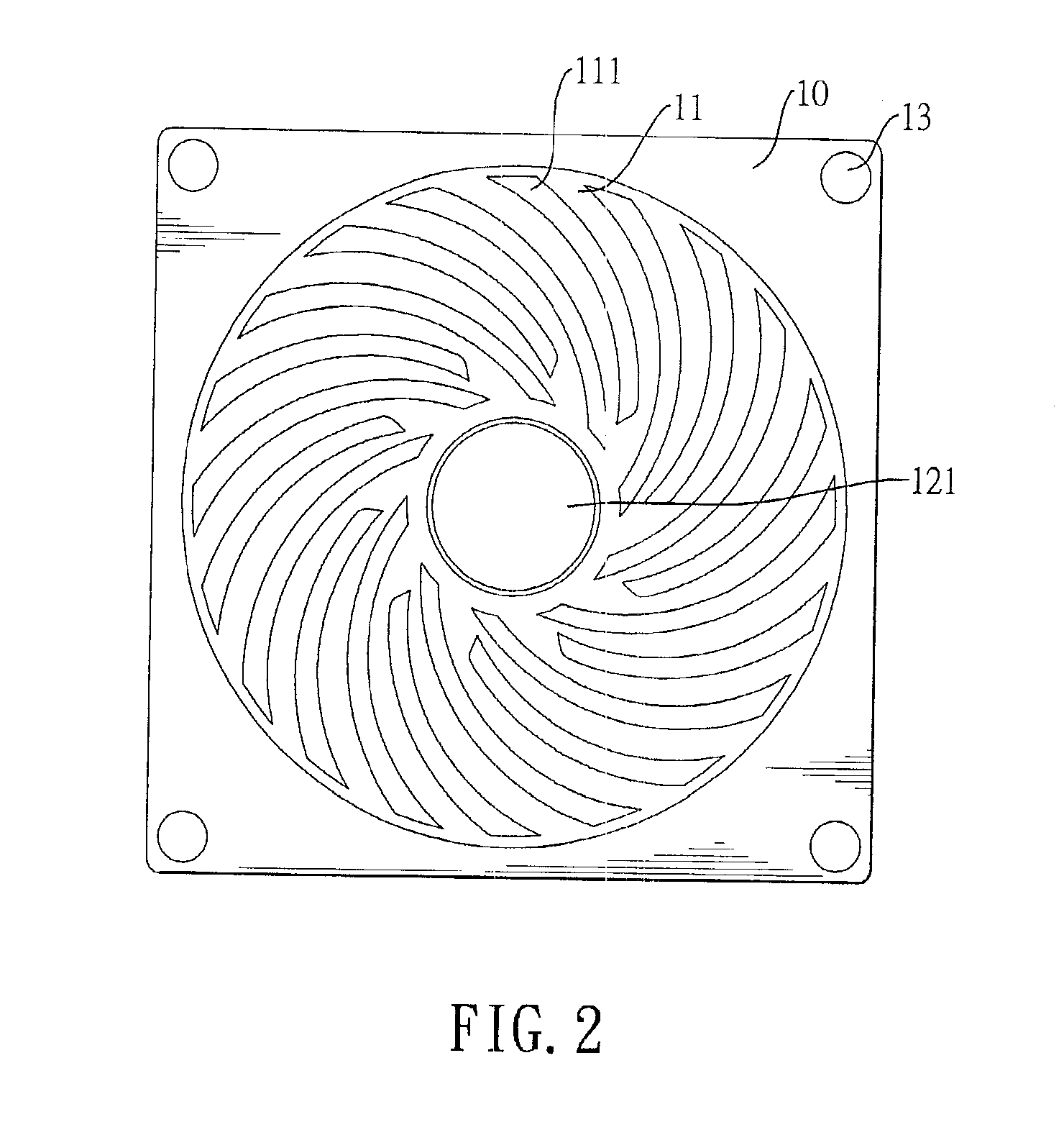

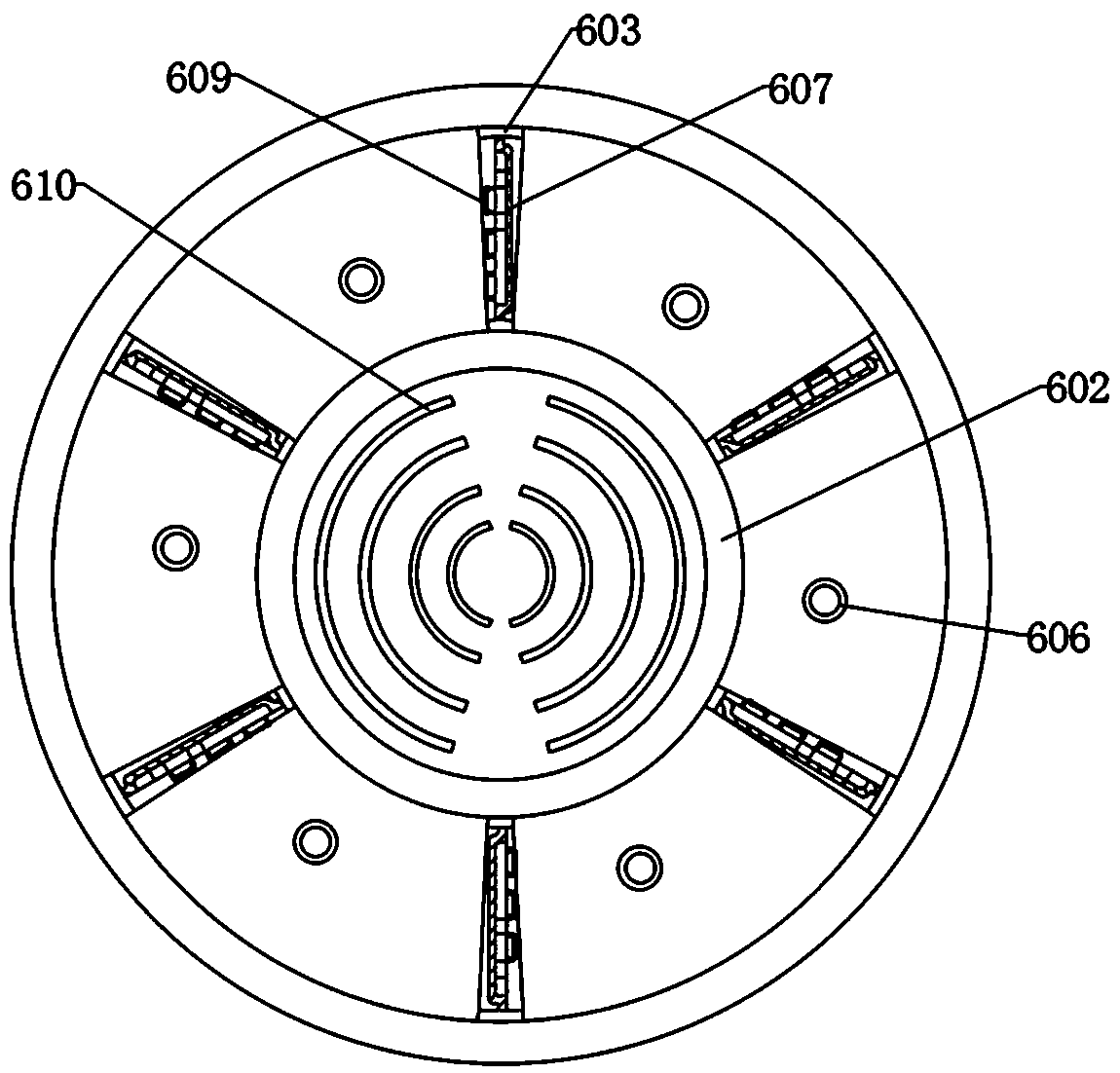

Fan grill for a mosquito trap

A fan grill for a mosquito trap is a board and has a center, a funnel-shaped shell, multiple air holes and a through hole. The shell is formed downward in the center and is tapered off to a bottom. The air holes are respectively formed through the shell and are arranged radially and spirally. The through hole is formed on the bottom of the shell. The radial and spiral air holes are designed according to direction of airflow created by a fan so allow the airflow to pass smoothly therethrough and to generate steady suction forces. Besides, hole diameters of the air holes are less than sizes of mosquitoes so trapped mosquitoes are prevented from escaping from between fan blades of the fan. Therefore, trapping efficiency is enhanced.

Owner:INVICTUS INT

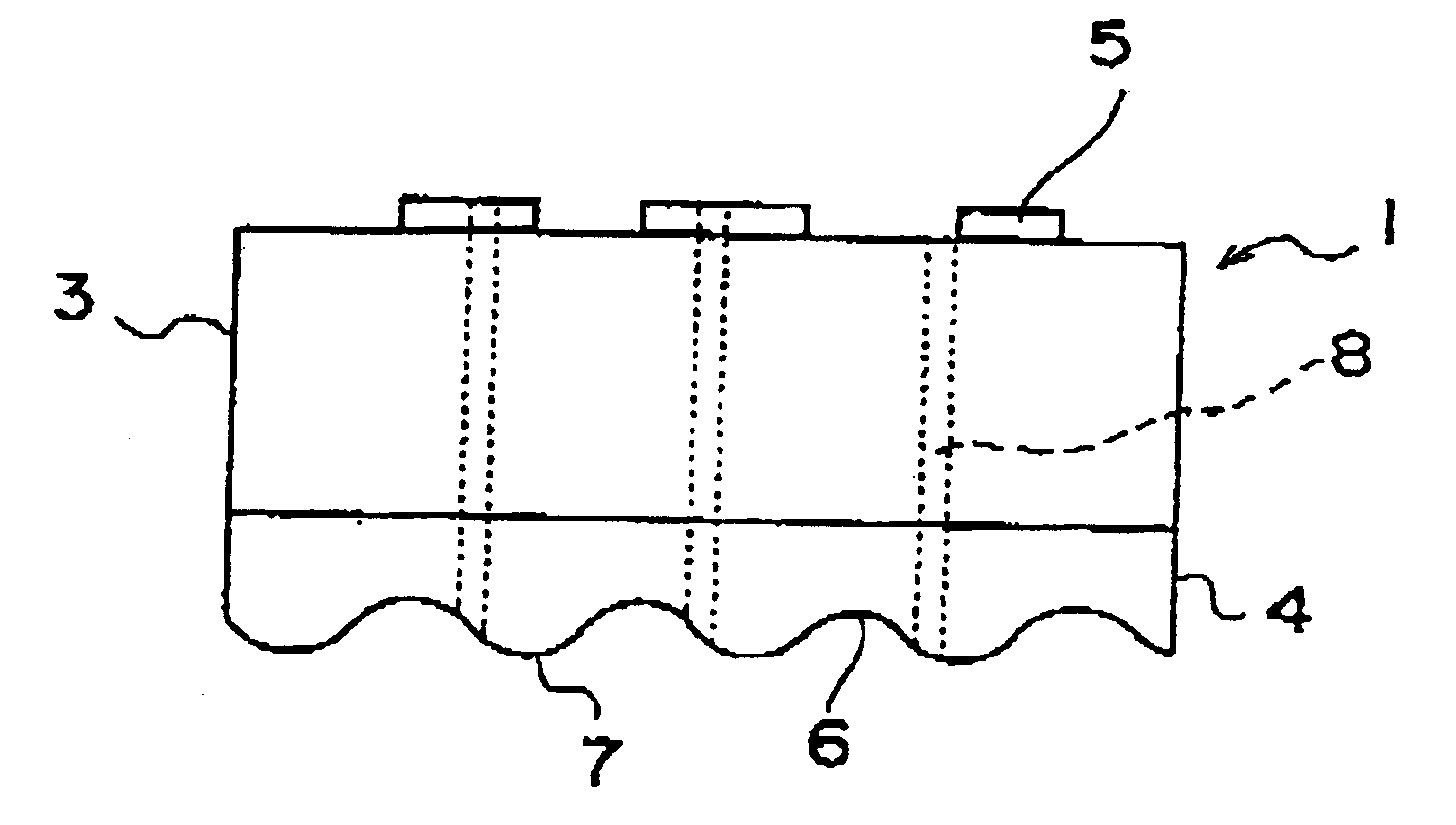

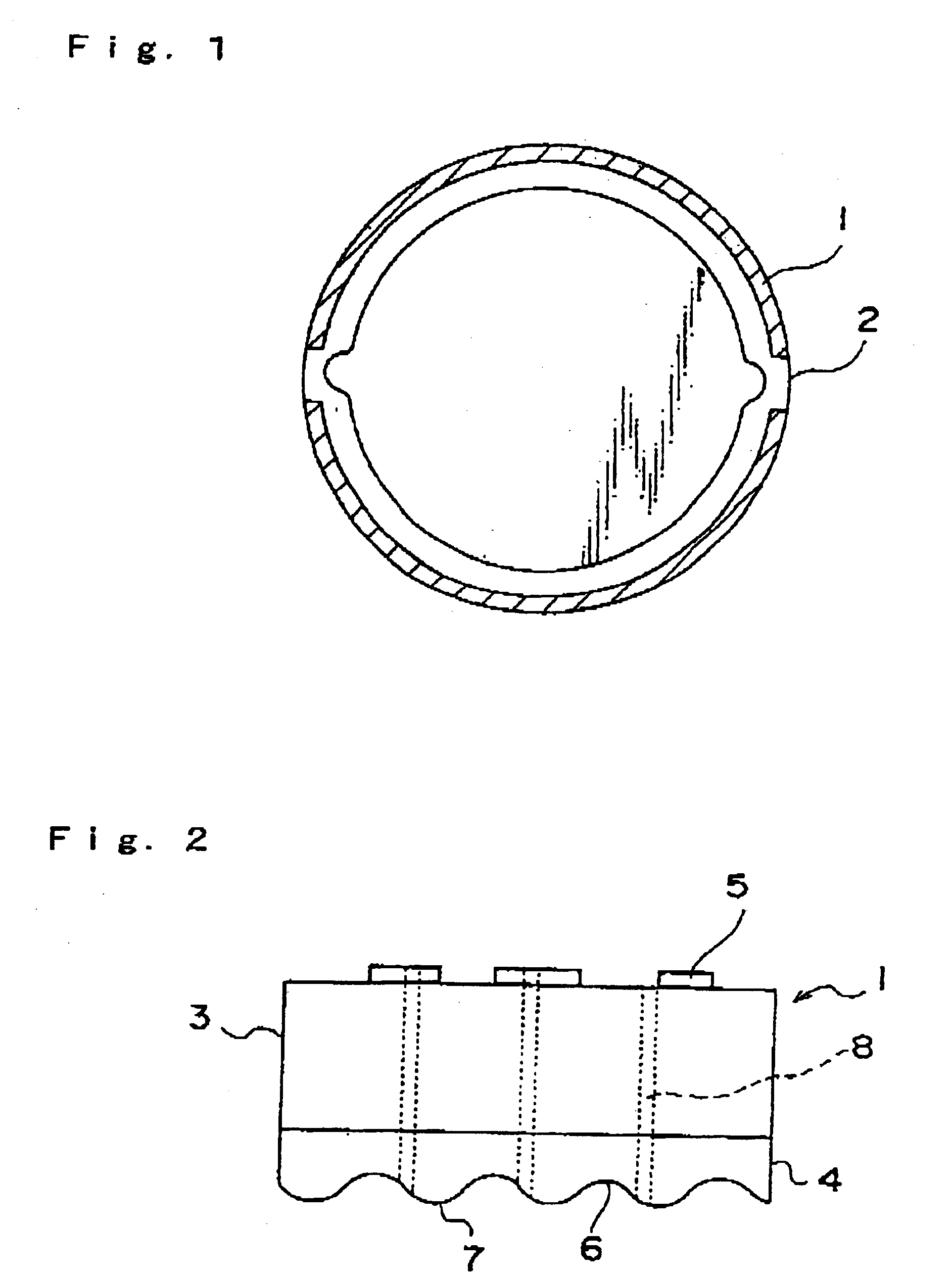

Labels for in-mold forming and molded resin products having the same

InactiveUS6858283B2Reliably securedSolve low manufacturing efficiencyStampsDecorative surface effectsMicrometerFilm base

Disclosed is a label for in-mold forming comprising a thermoplastic resin film base layer and a heat-seal resin layer, wherein a surface of the heat-seal resin layer has a centerline average roughness of 0.5 to 5 micrometers and the label has an air permeability of 10 to 20,000 seconds. When in-mold forming is conducted with the label of the present invention, labeled molded resin articles of various shapes can be manufactured while effectively inhibiting blistering.

Owner:YUPO CORP

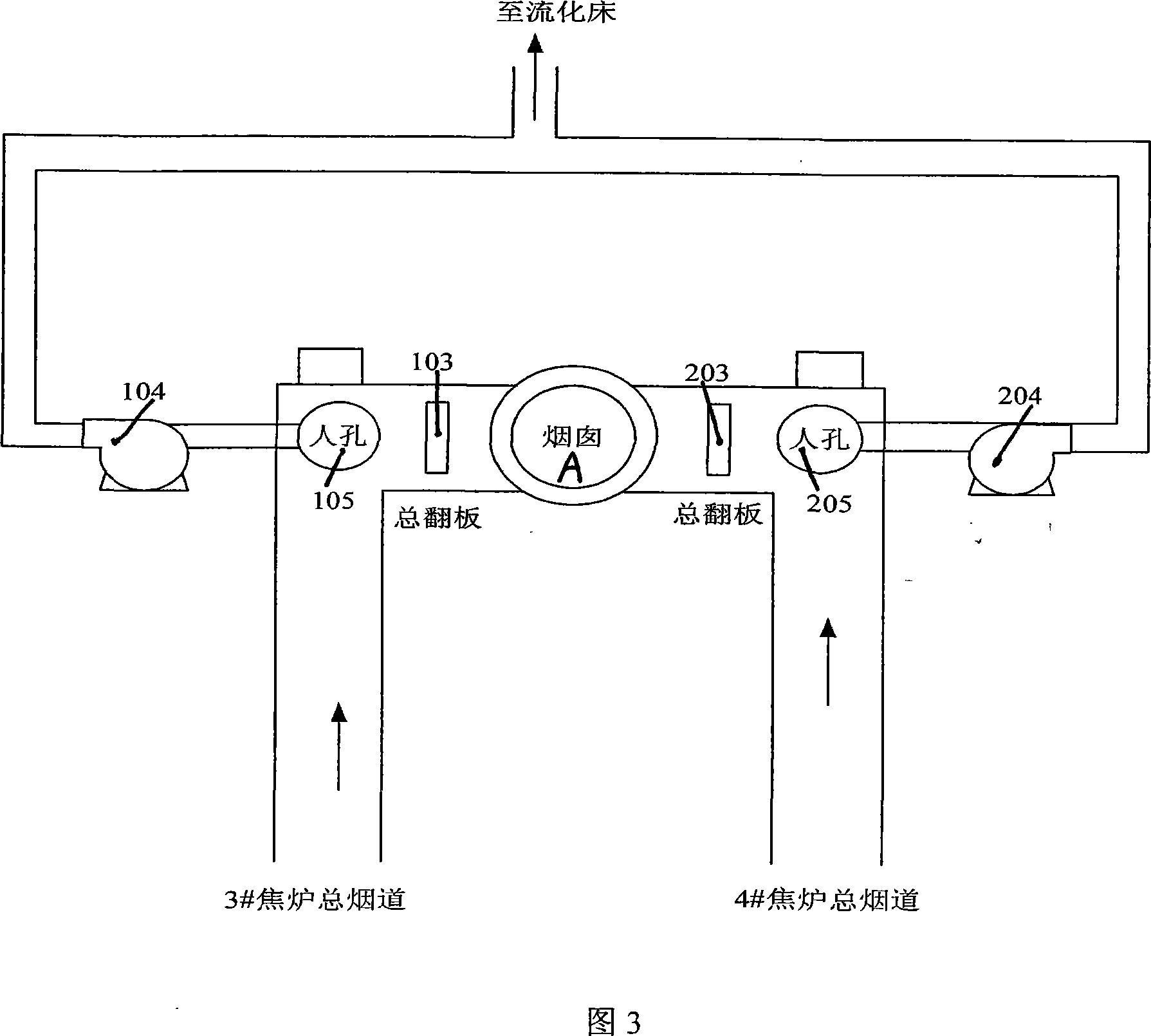

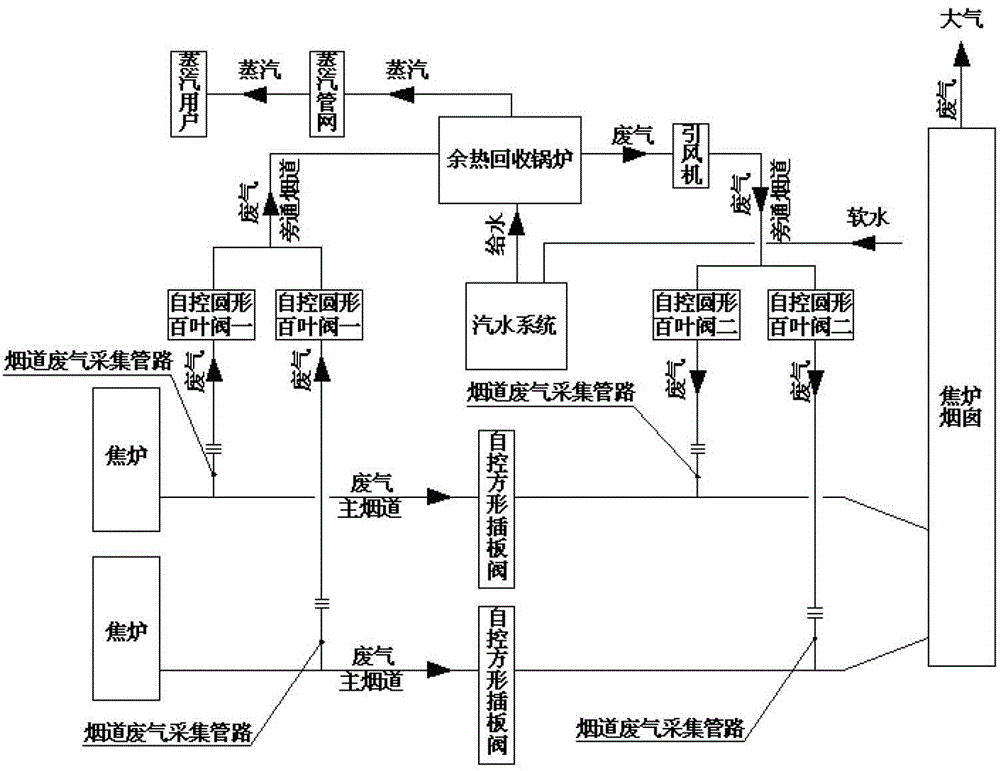

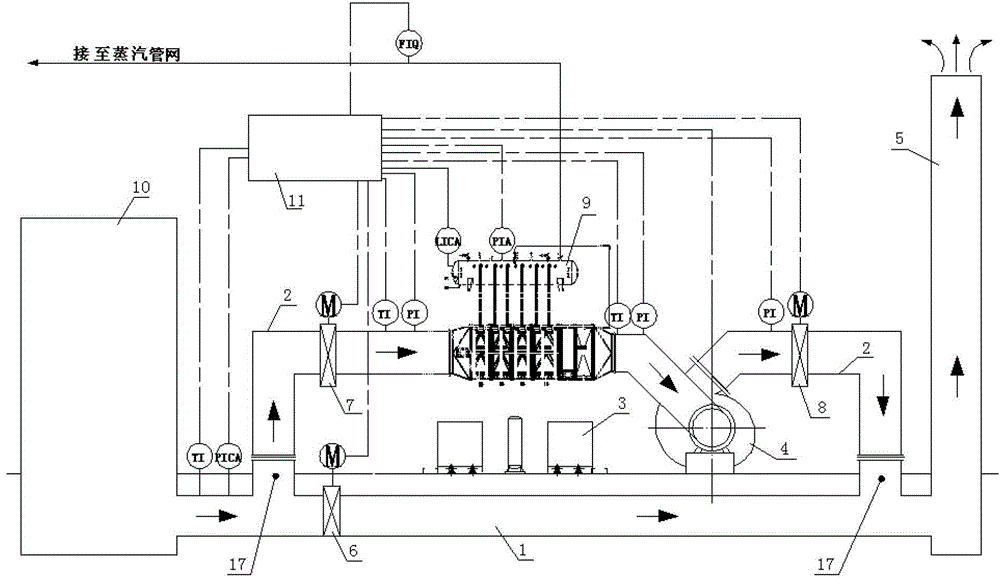

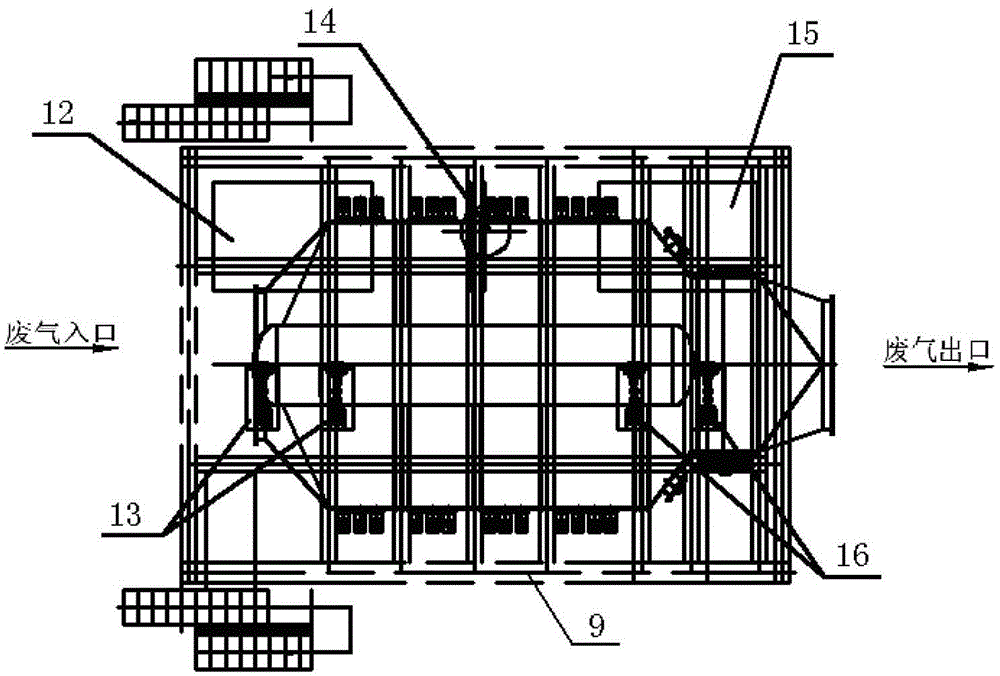

Coke oven flue gas waste heat recovery technology

ActiveCN103335530AGuaranteed uptimeSmall footprintIncreasing energy efficiencyWaste heat treatmentAutomatic controlChimney

The invention relates to the field of flue gas waste heat recovery in coke making enterprises and metallurgy enterprises, in particular to a coke oven flue gas waste heat recovery technology. A waste heat recovery device comprises a main flue, an auxiliary flue, a steam-water system, an induced draft fan and a coke oven chimney. The waste heat recovery device is characterized in that an automatic control square gate valve is arranged on the main flue, an automatic control round louver valve is arranged on the auxiliary flue, and the steam-water system is arranged under a waste heat recovery boiler. The induced draft fan is arranged on the side of an outlet of the waste heat recovery boiler and carries out frequency control to control the pressure of the main flue of a coke oven outlet to be within the range of negative 170-380Pa, and control the flow rate of flue gas in the auxiliary flue to be 10-15m / s. Compared with the prior art, the coke oven flue gas waste heat recovery technology has the advantages that through stabilizing of coke oven collecting flue suction, automatic switching control over a main flue system and an auxiliary flue system, and reasonable selection of valves and models and device arrangement for the waste heat recovery boiler, on the premise that land occupation is reduced and investments are saved, flue gas waste heat is effectively recovered, and stable, reliable and continuous operation of a coke oven is ensured.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

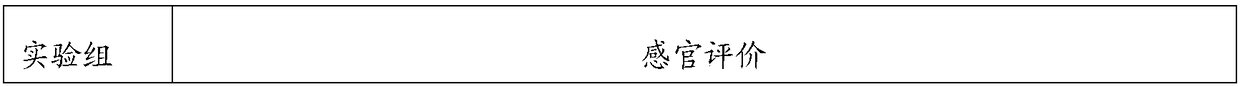

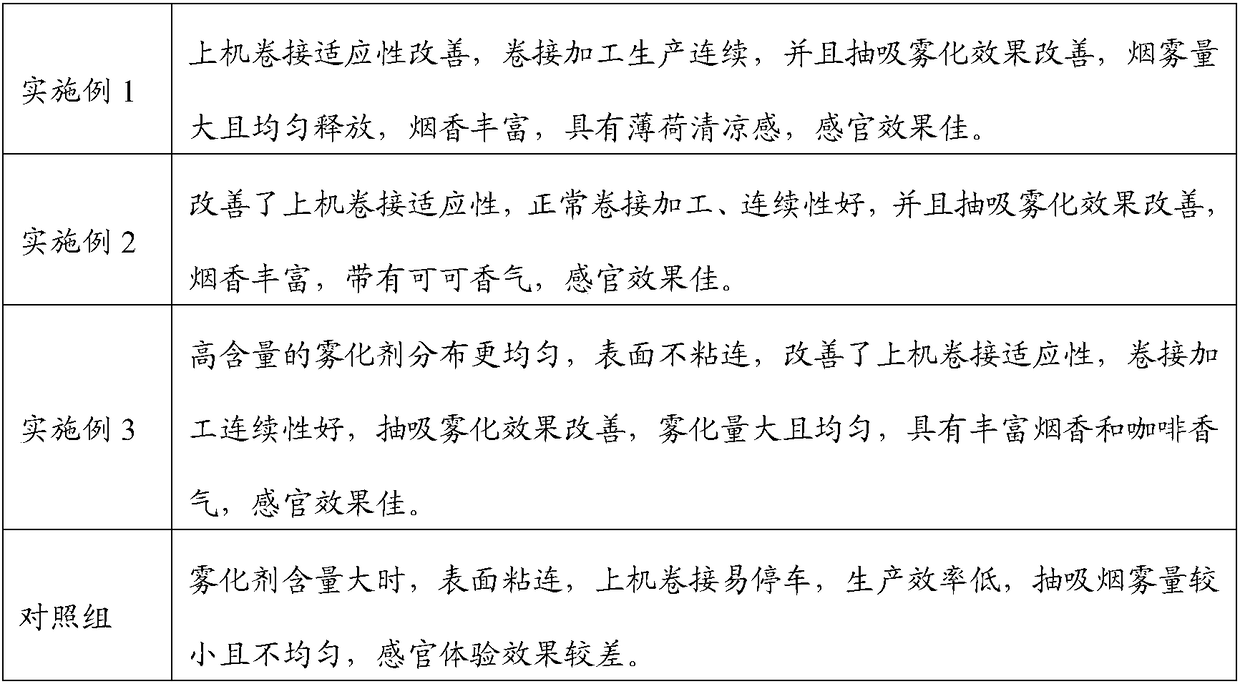

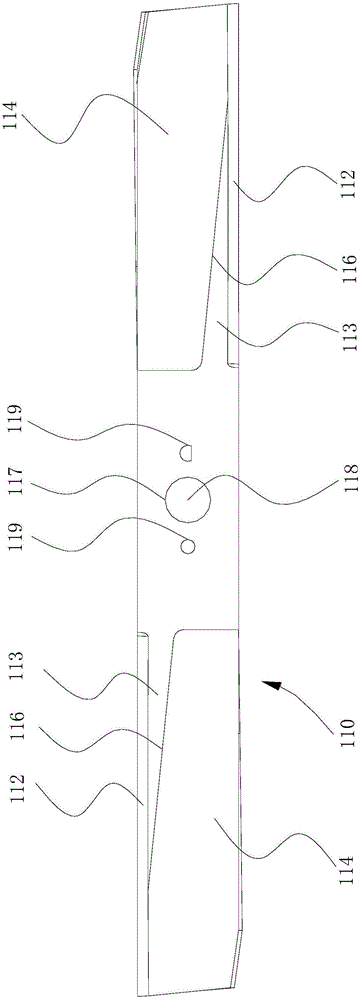

Atomized reconstituted tobacco processing method and application thereof

ActiveCN108208907AWith strengthReduce the broken rateTobacco preparationFood additiveChemical reaction

The invention provides an atomized reconstituted tobacco processing method and application thereof. On the basis of a rolling process, in a process of producing low-temperature reconstituted tobacco,food additives containing carbonate and bicarbonate radical and an acid pickling step are adopted, a chemical reaction is carried out, porous bubbles are produced therein, and the internal surface area is enlarged, so that the high-content atomizing agent is uniform in distribution, surface adhesion is avoided, the strength of the reconstituted tobacco is high, and on-board rolling adaptability ofthe atomized reconstituted tobacco is improved. Therefore, the conventional rolling unit is capable of realizing normal rolling, the production continuity is excellent, the production efficiency is high, and the reconstituted tobacco is improved in smoking and atomizing effect, rich in cigarette aroma and excellent in sensory effect.

Owner:HUBEI CHINA TOBACCO IND +1

Cutting blade of mower

Provided is a cutting blade of a mower. The cutting blade comprises a cutting blade body in the shape of a long strip. Two cutting edges, in proximity to the end portion of the cutting blade body, are arranged in a central symmetry manner. The end portions, opposite to end corners of side edges of the cutting edges, of the cutting blade body bend towards the direction away from the cutting blade body in order to from bending parts. Each bending part has an arc-shaped bending surface and is tangent to the cutting blade body in a transitional mode in order to form a tangent line. The connecting line for the center of the cutting blade body and pointed ends of the cutting edges runs parallel to the tangent line. When the cutting blade body of the mower rotatably works, the bending part drives the air to generate additional turbulent flow moving from the position below the cutting blade body to the upward part such that upper ends of grass mowed rapidly enter a cutting region of the mower under the suction effect of turbulent flow. As a result, the cutting blade of the mower performs cutting operation. Accordingly, grass needed to be cut can be rapidly sucked into the cutting region of the mower in order to finish pruning operation. The advance speed of the mower is improved. The cutting blade of the mower has advantages such as large turbulent flow for suction, smoother cutting and fine quality of broken grass.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

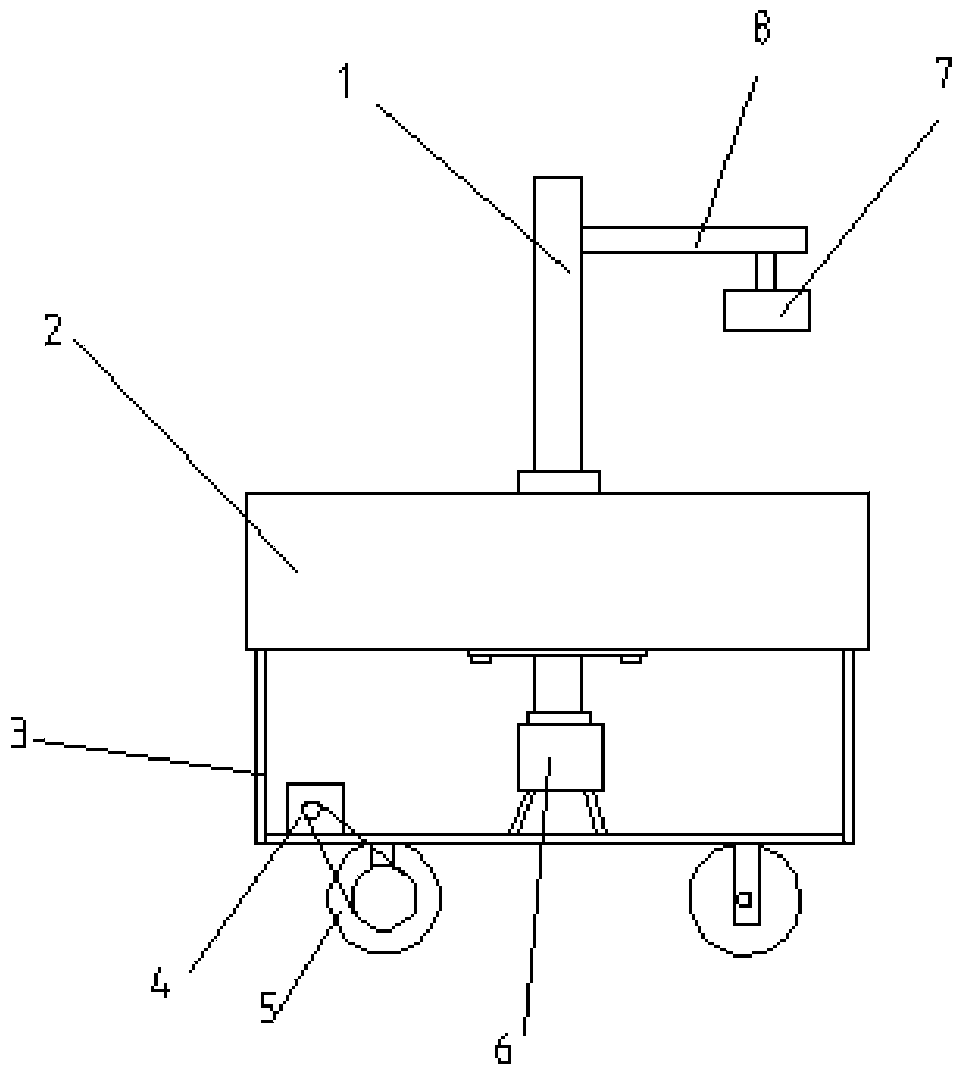

Conveying robot

The invention provides a conveying robot, which comprises a platform, wherein a frame is arranged below the platform; wheels are arranged at the bottom of the frame, and are connected with a first motor which is fixedly arranged on the frame. The robot is used for conveying a semi-finished product machined by a machine tool to a special inspection platform, and the semi-finished product is inspected by a special inspector, and is conveyed back to the procedure after being inspected to be qualified.

Owner:天津恒威先创科技发展有限公司

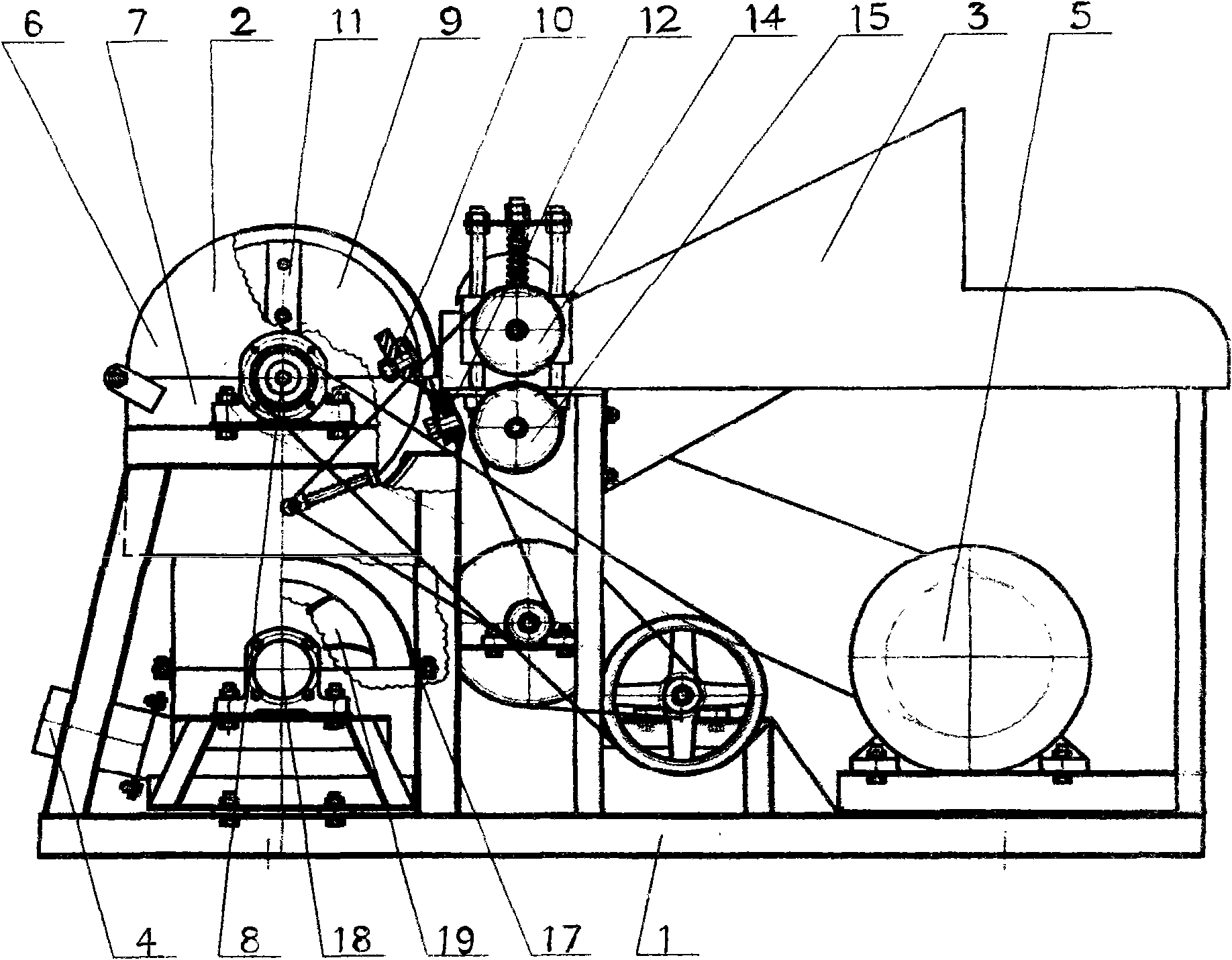

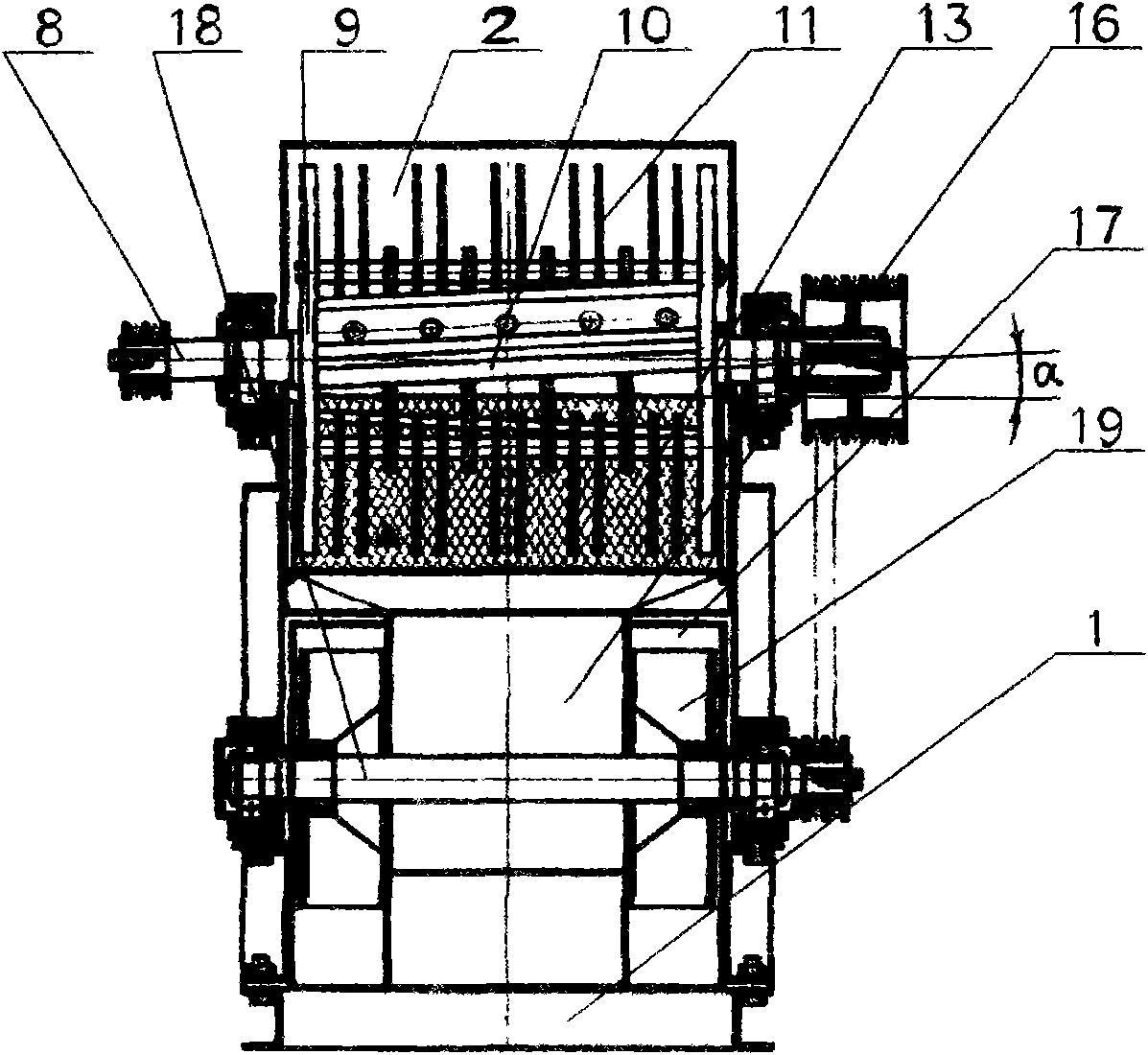

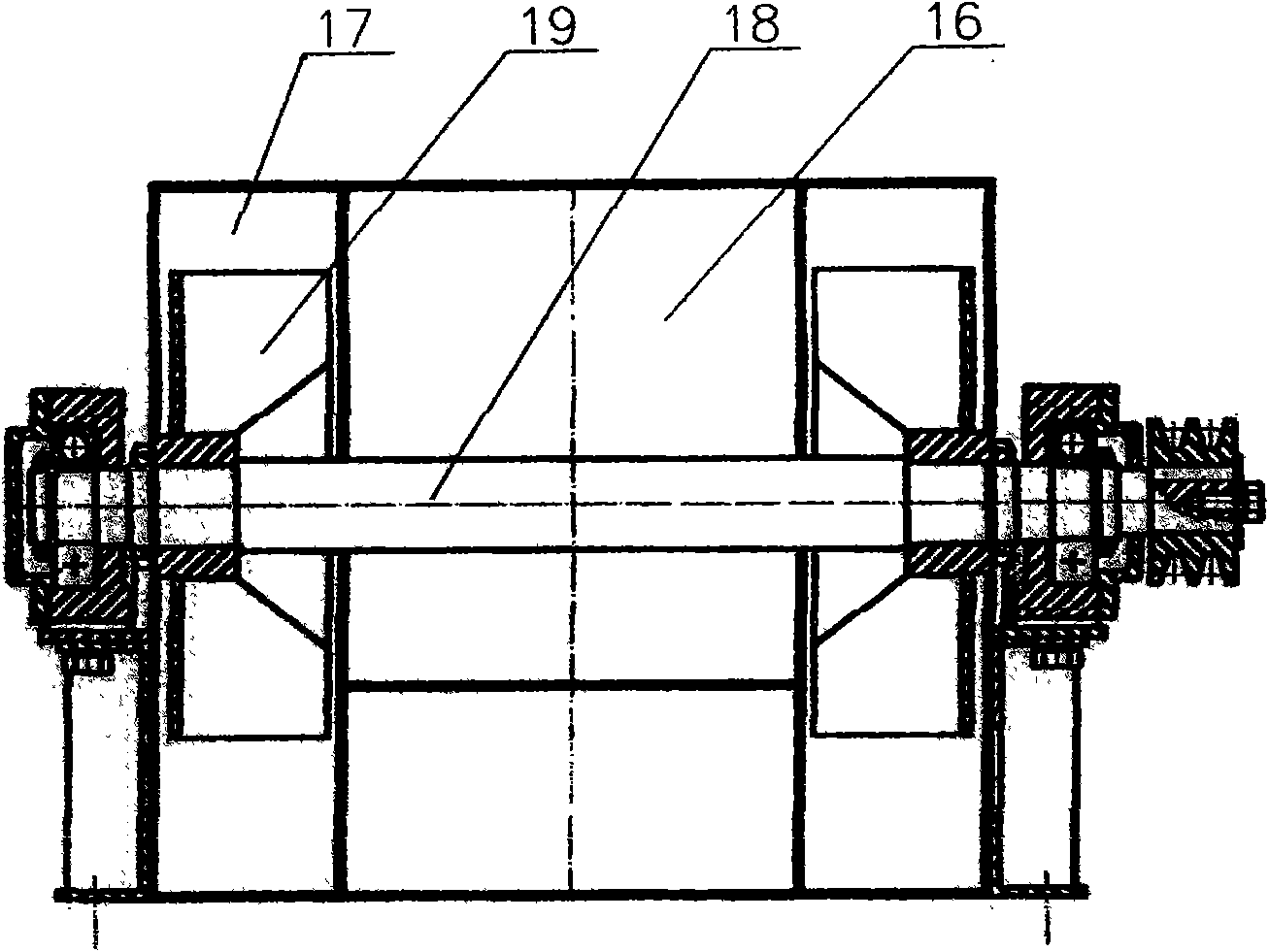

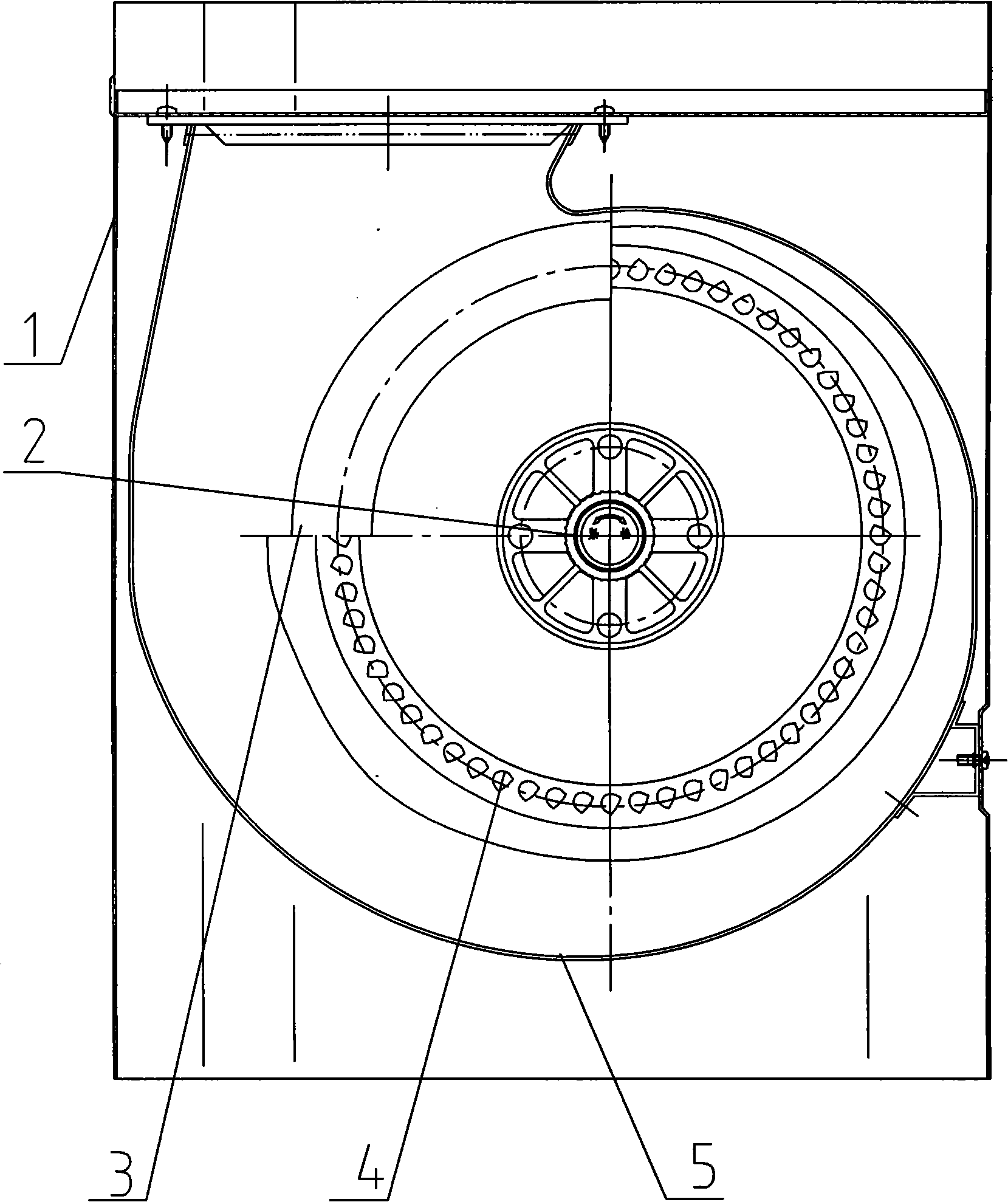

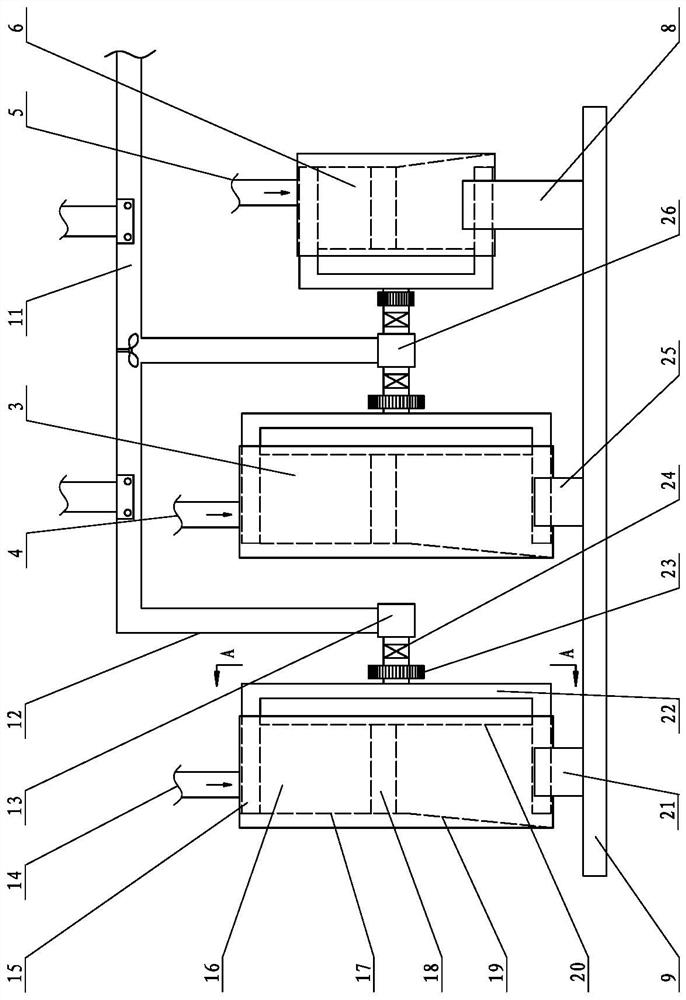

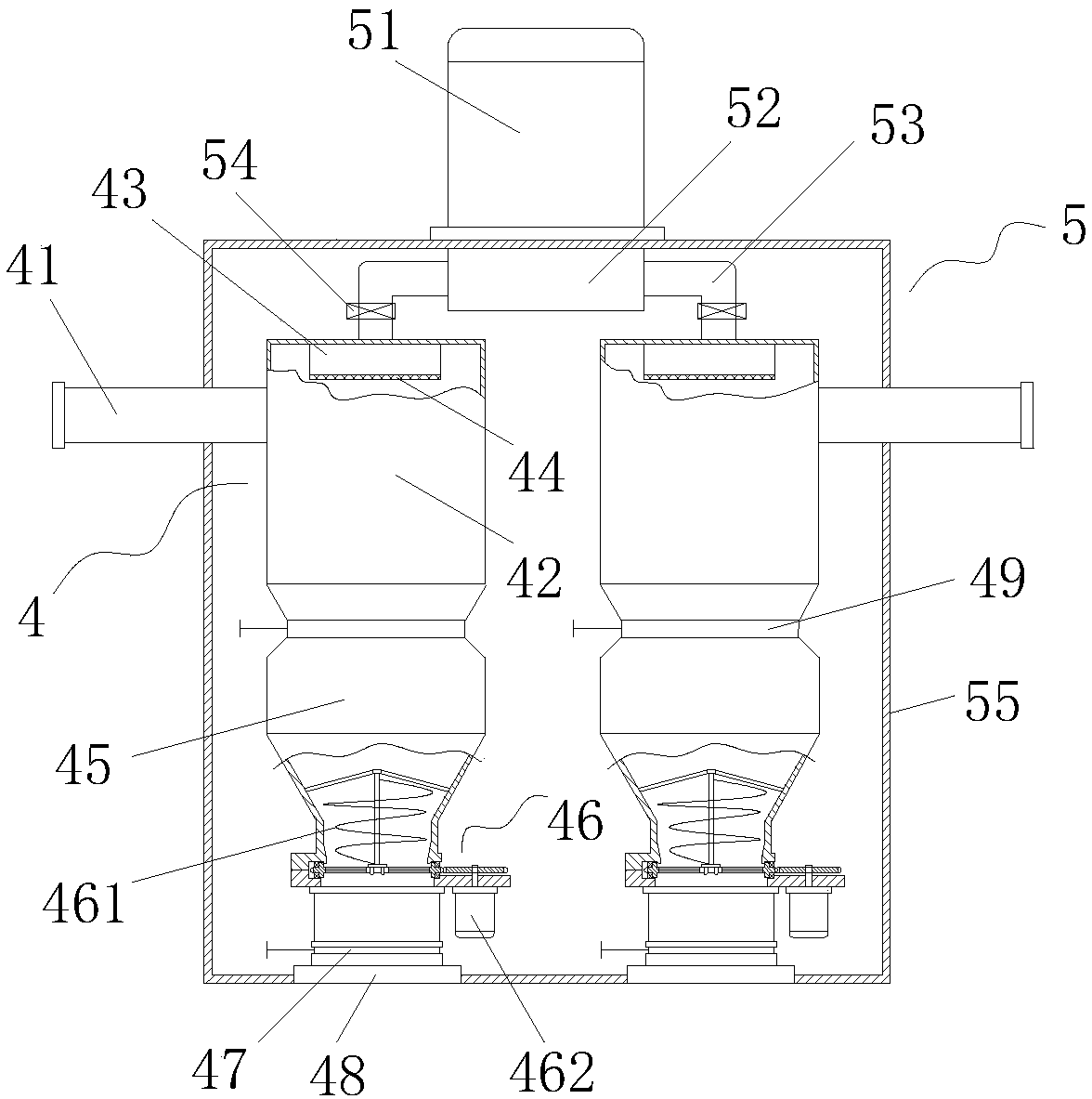

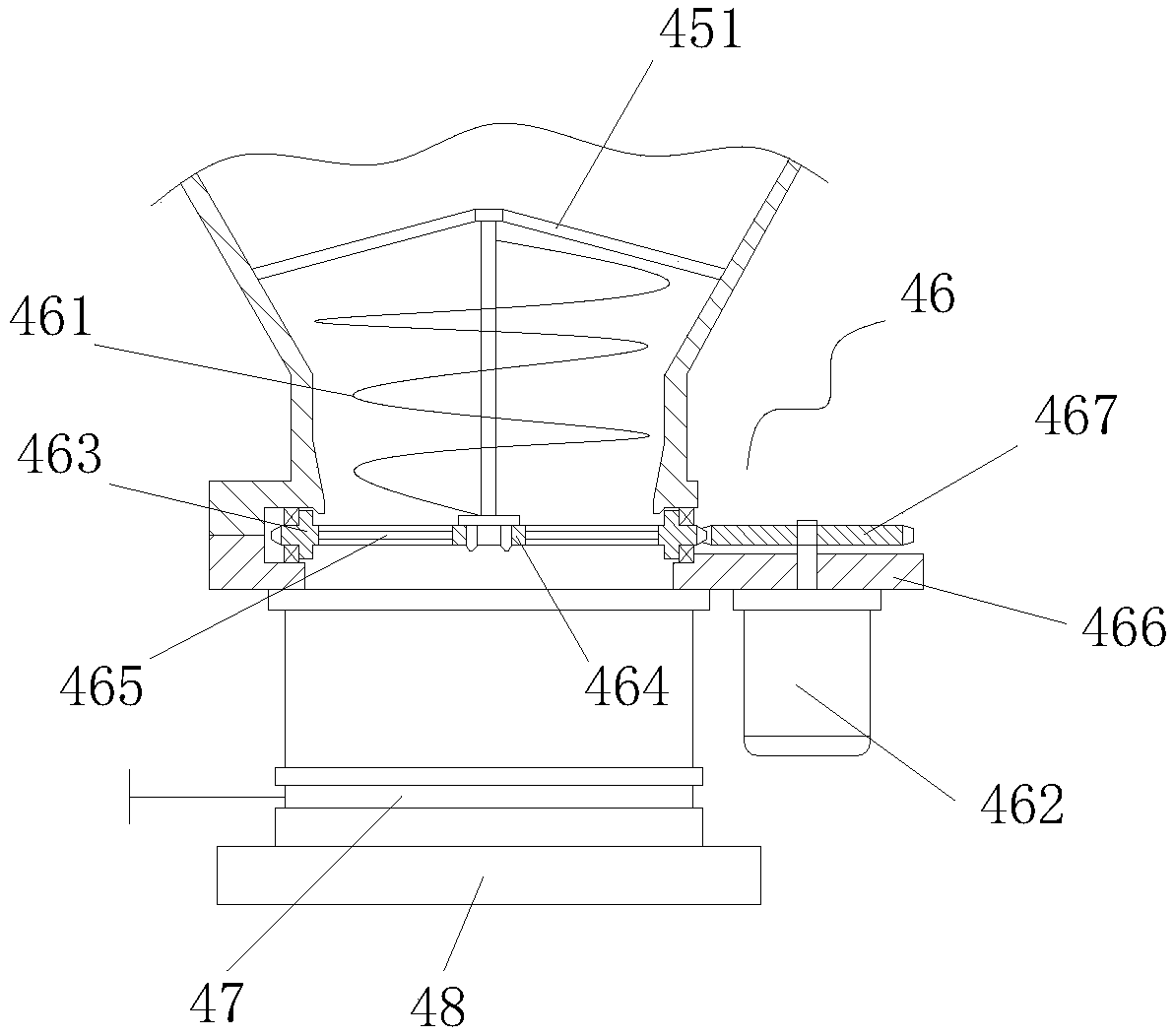

Double-use plant material cutting grinder

InactiveCN101786034AReduce energy consumptionStable suctionCuttersGrain treatmentsImpellerEngineering

The invention relates to processing machinery for producing edible fungi culture materials, in particular to a double-use plant material cutting grinder. The grinder comprises a frame, a cutting-grinding chamber arranged on the frame, a feeding hopper, a material outlet, a power device and a variable-speed transmission mechanism, wherein a public blanking hopper is directly arranged below the cutting-grinding chamber, namely at the bottom of a filter screen; a centrifugal material-sucking fan device is arranged in the public blanking hopper; the centrifugal material-sucking fan device consists of a pair of air impellers arranged on two sides of the same centrifugal fan main shaft ; and an air outlet of the centrifugal material-sucking fan device is communicated with the material outlet. The grinder can cut and grind straw of various plant materials, weeds, branches, woodwork shavings and other soft / hard raw materials, and helps to directly and smoothly suck out raw material particles even with high water content, thereby achieving the effects of reducing energy consumption, simplifying process and improving production efficiency.

Owner:翁赐和

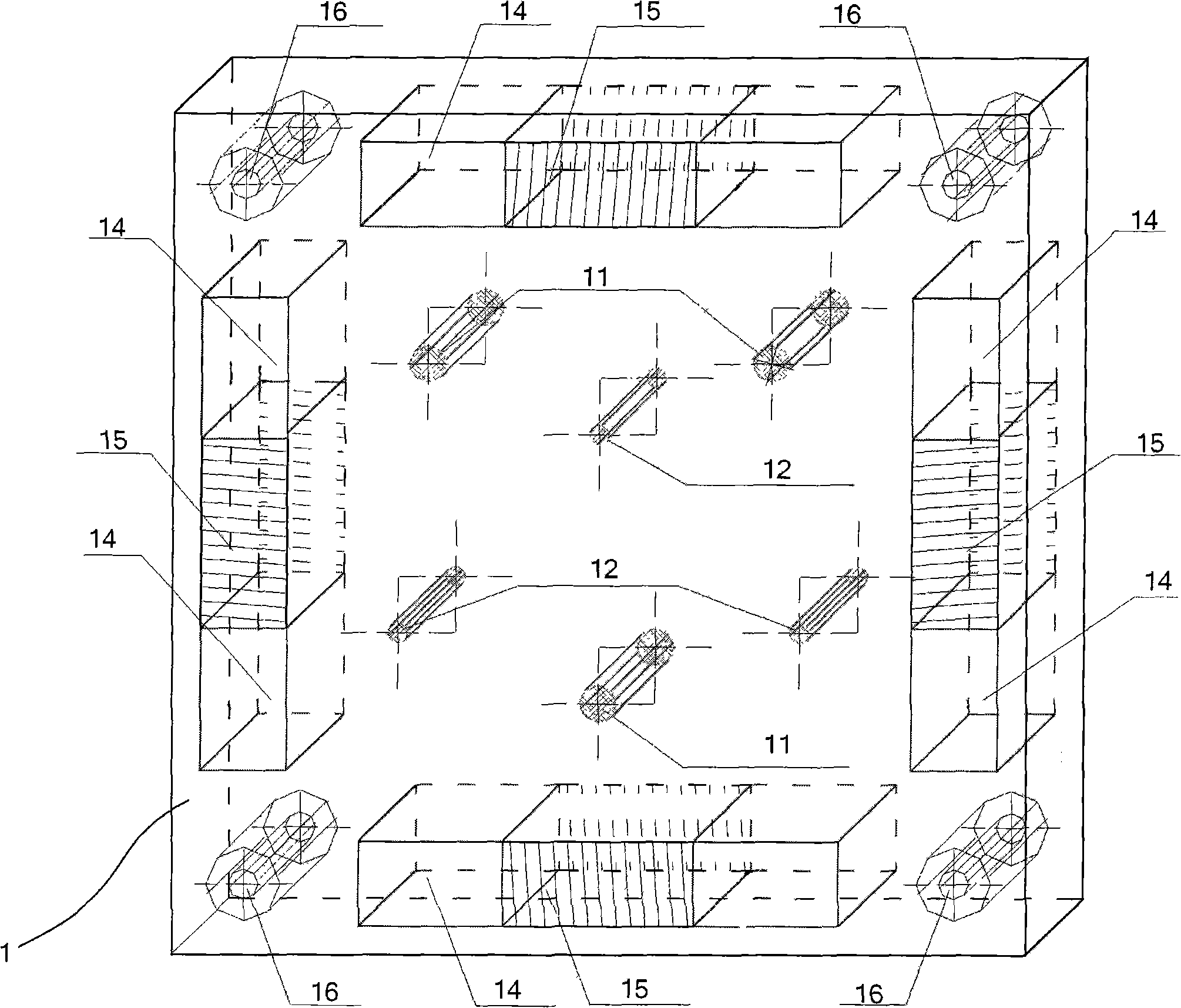

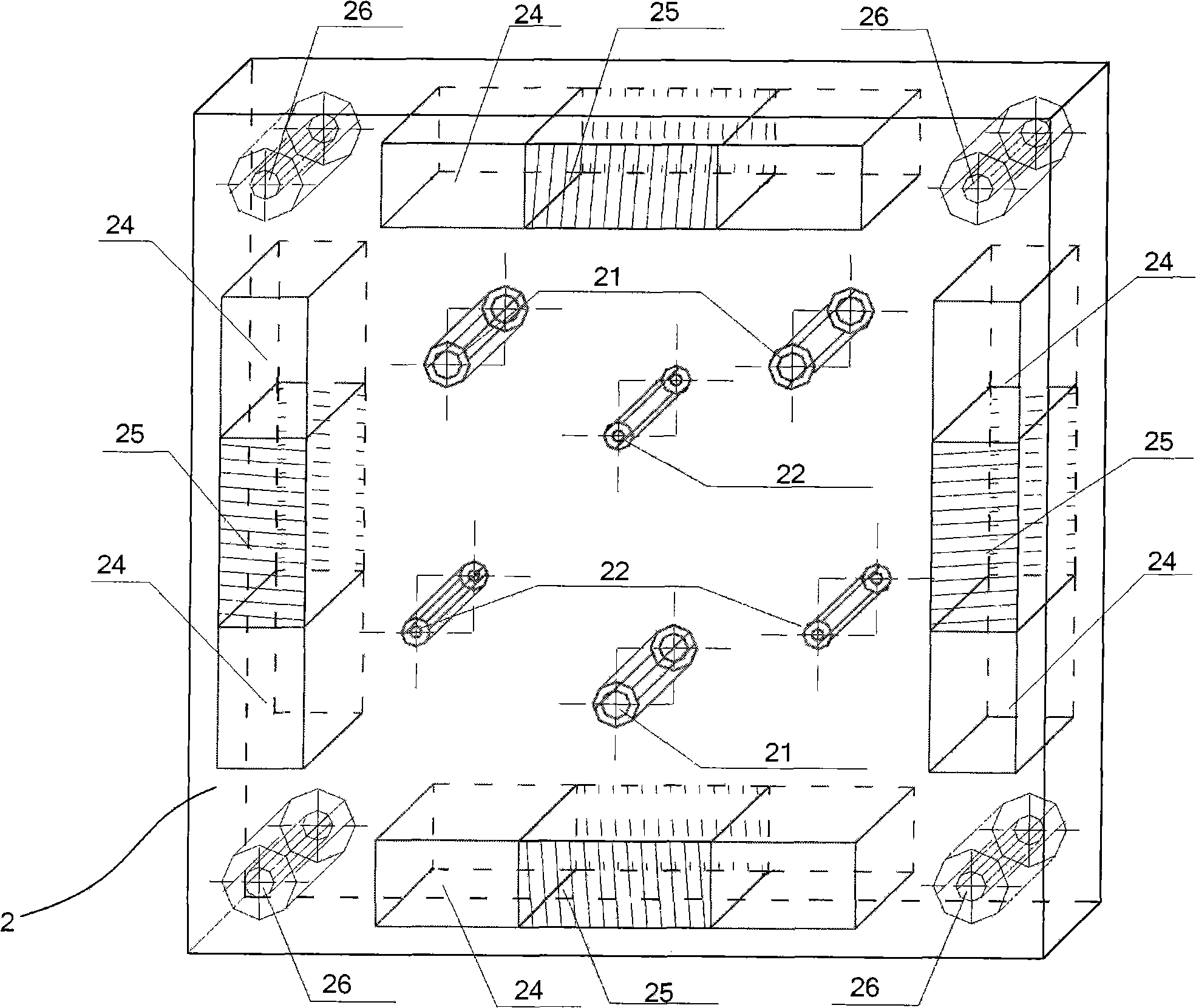

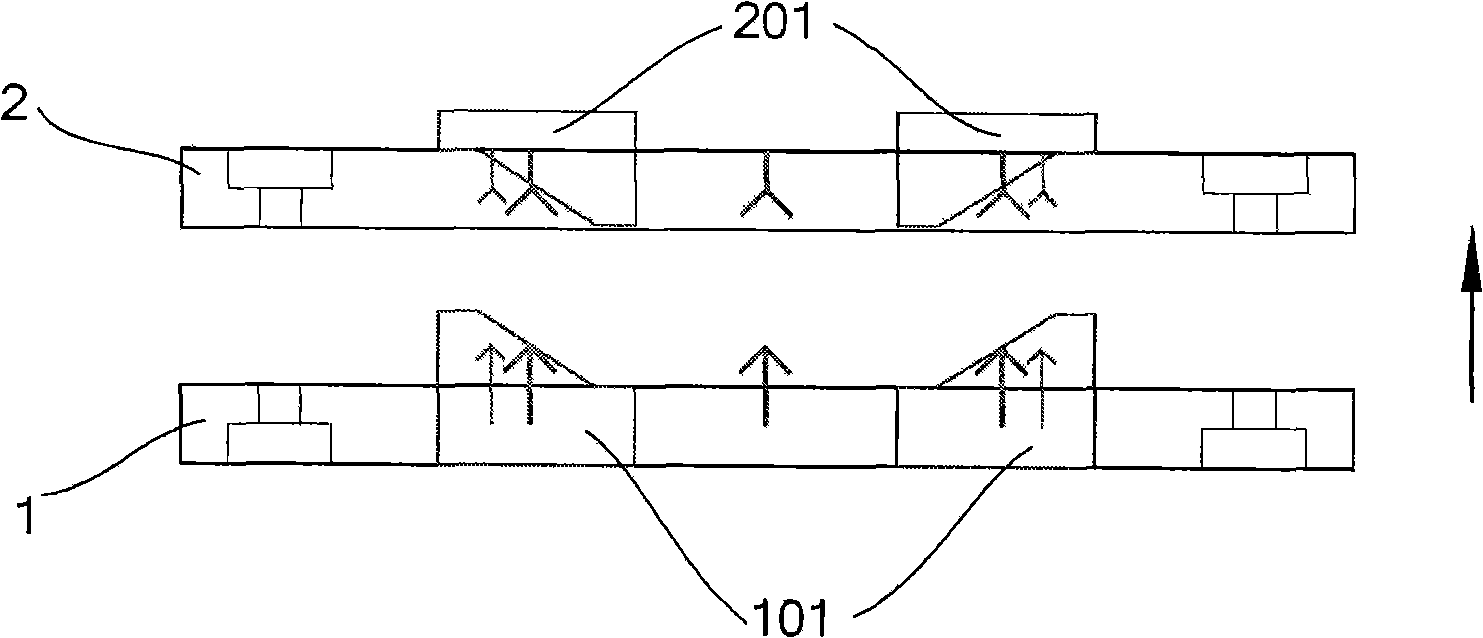

Electromagnetic clutch device of mobile equipment for automatic power taking

InactiveCN101794944AEasy to connect and disconnectOvercome power instabilityEngagement/disengagement of coupling partsMagnet coilElectricity

Owner:上海浦帮机电制造有限公司

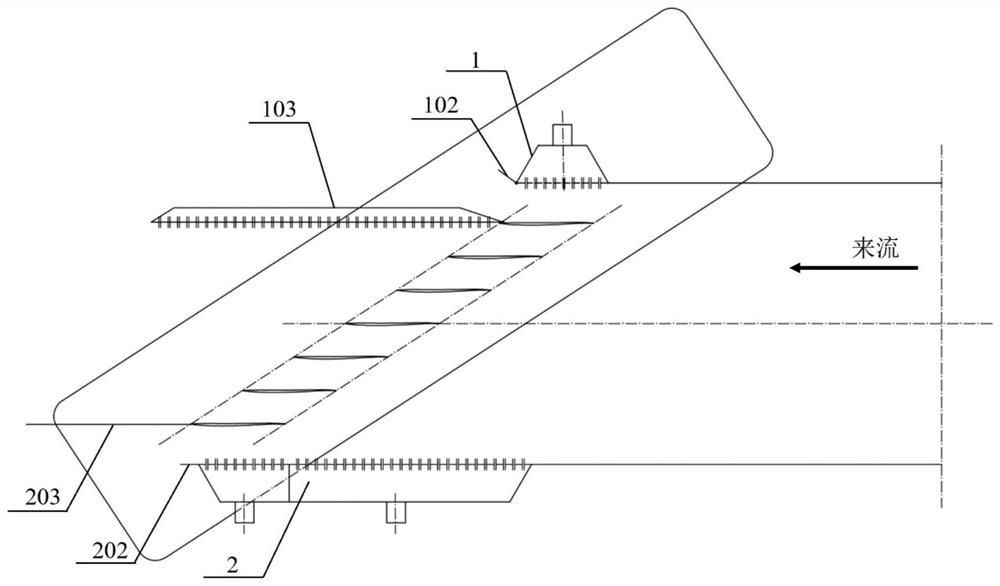

Supersonic plane cascade flow field starting and uniformity adjusting device

ActiveCN113188748AAdjustable positionRegulating pressureGas-turbine engine testingAerodynamic testingShock waveEngineering

The invention discloses a supersonic plane cascade flow field starting and uniformity adjusting device. The adjusting device takes the incoming flow of a cascade wind tunnel as the front and comprises an upper suction assembly arranged above a first blade of a cascade test model, an upper tail plate with a fixed front end and a suspended rear end is arranged behind the upper suction assembly, and an upper baffle with a fixed front end and a suspended rear end is arranged behind the first blade; the device further comprises a lower suction assembly installed below a tail blade of the cascade test model, a lower tail plate with a fixed front end and a suspended rear end is installed behind the lower suction assembly, and a lower baffle with a fixed front end and a suspended rear end is installed behind the tail blade. The adjusting device can stabilize the mass flow of the drainage channel in the suction test section, provide a stable drainage channel shock wave structure in a local low-pressure environment, regulate and control the pressure distribution condition in front of the grid, and achieve starting and uniformity adjustment of a supersonic flow field.

Owner:中国空气动力研究与发展中心空天技术研究所

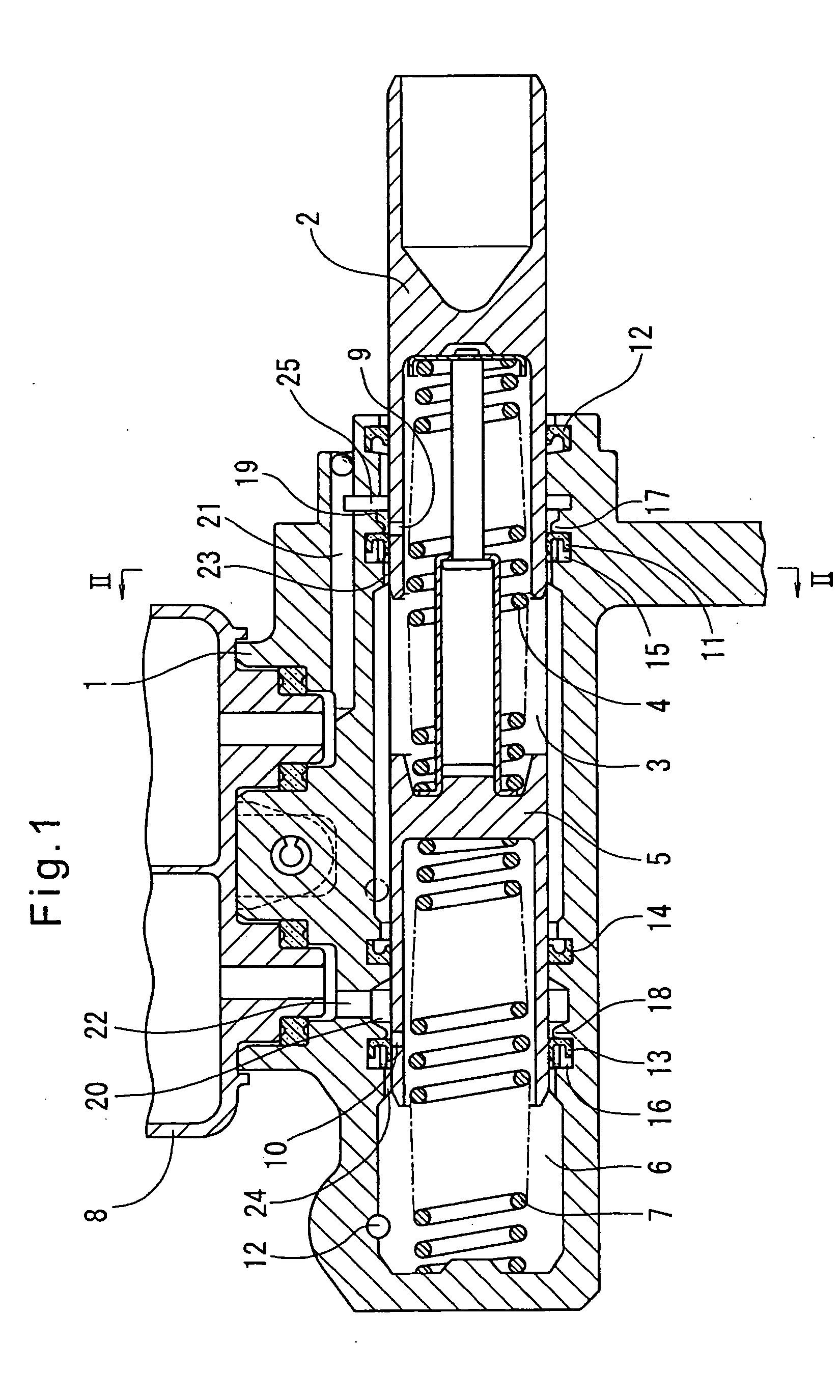

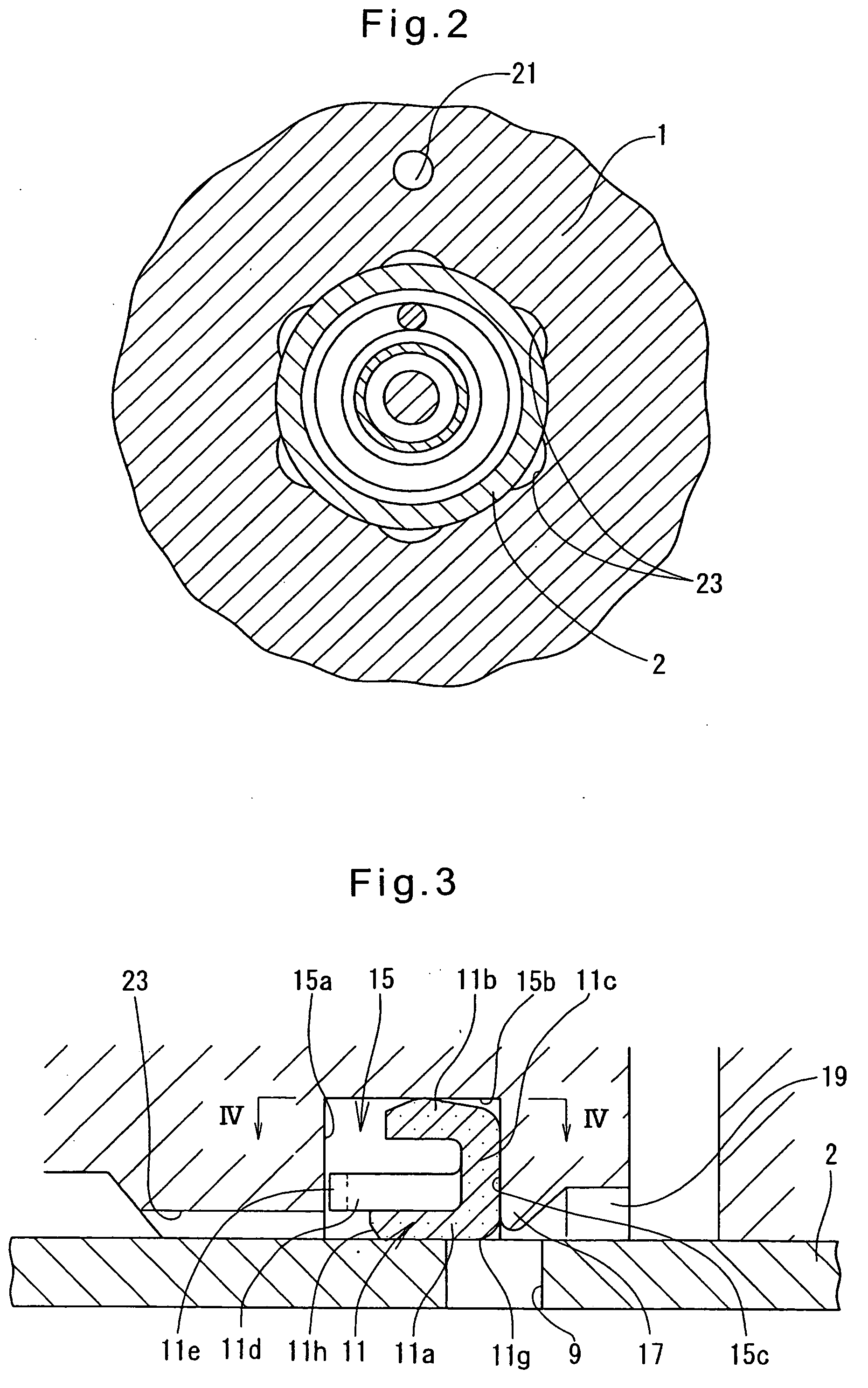

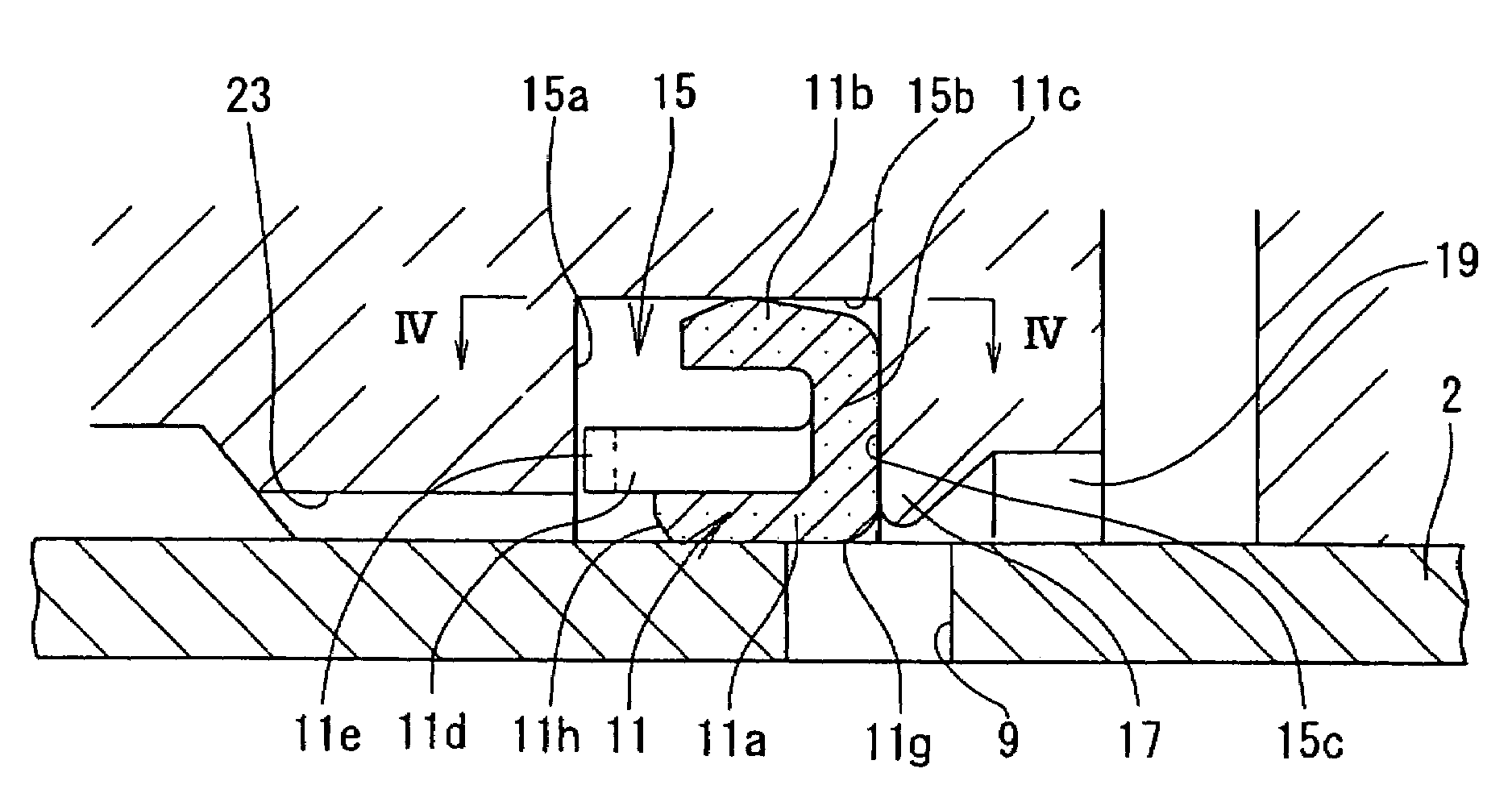

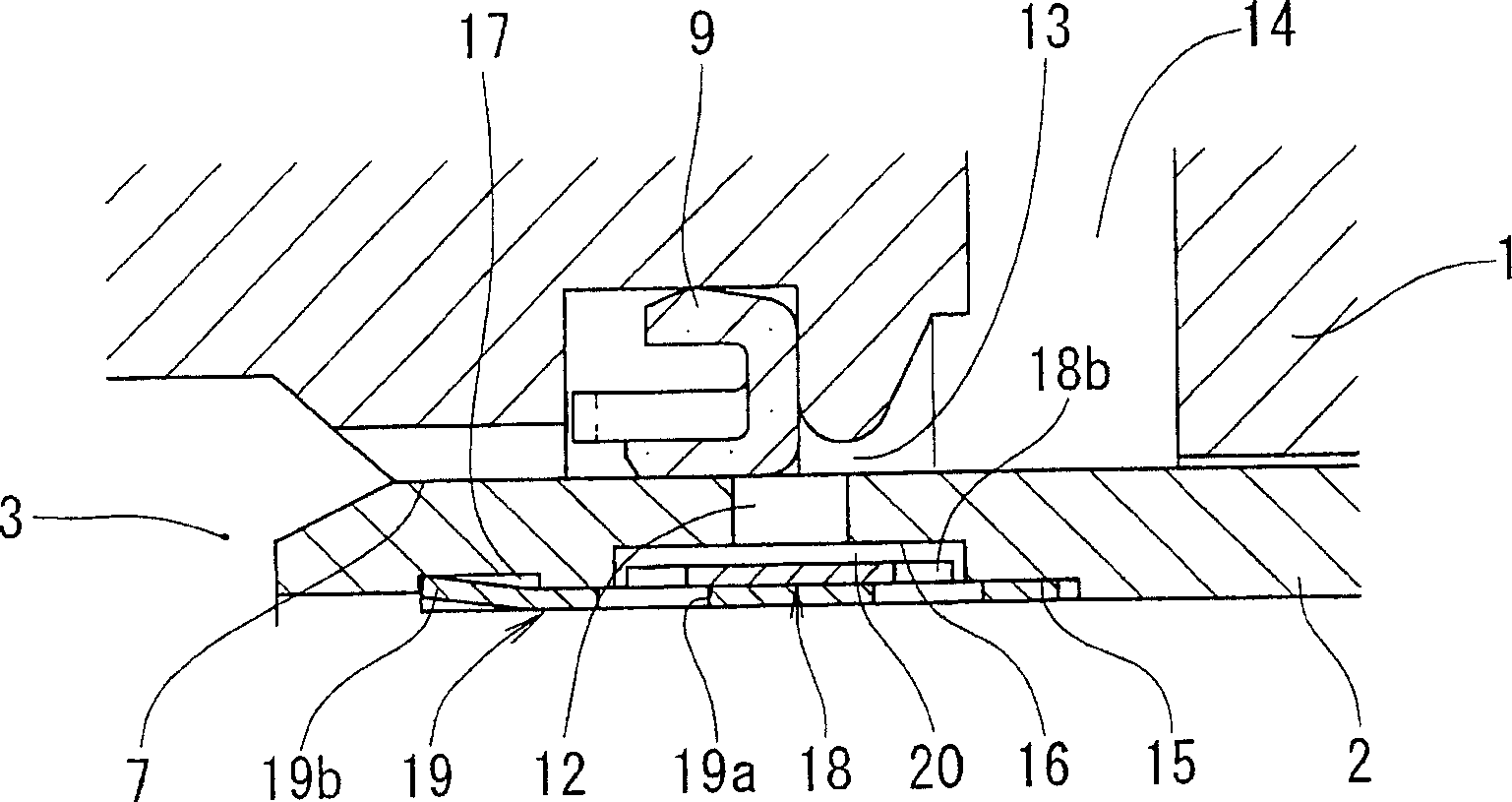

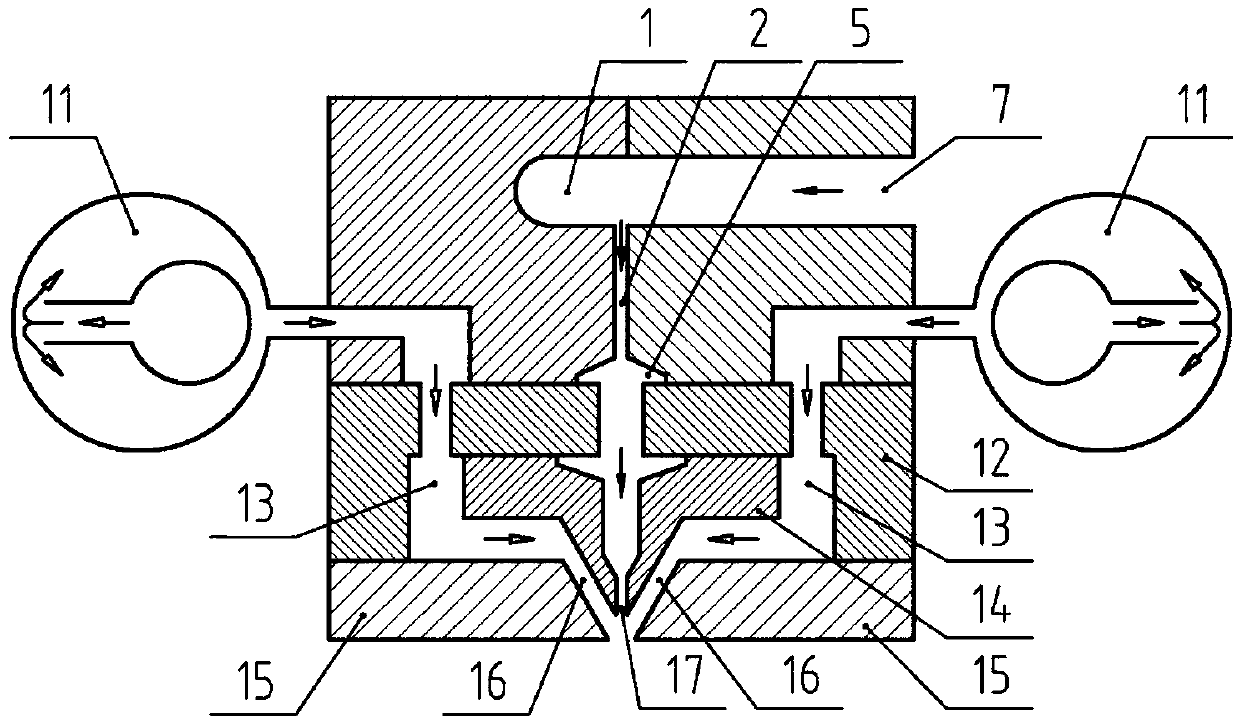

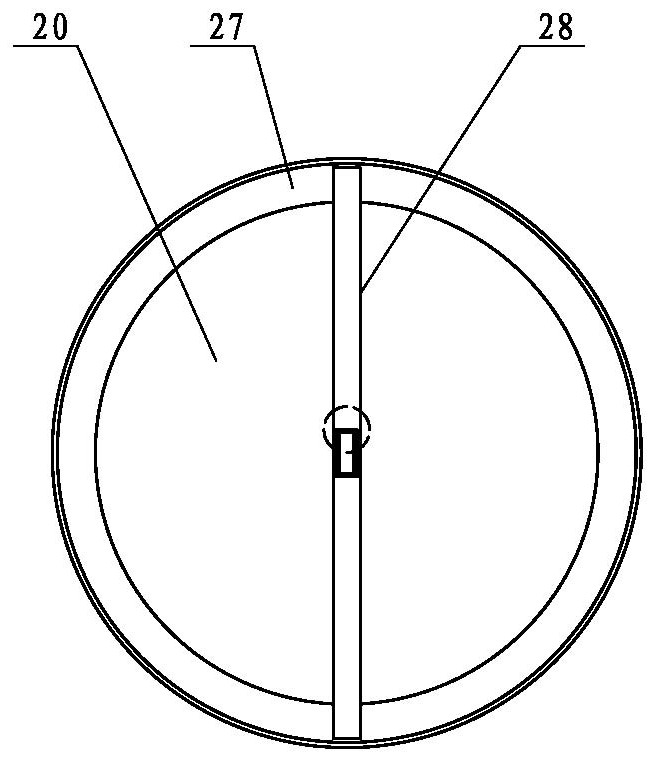

Plunger type master cylinder

InactiveCN1899896AMobility restrictionsStable suctionTelemotorsFluid braking transmissionMaster cylinderEngineering

A master cylinder includes a piston received in a cylinder body and formed with piston ports. An annular groove is formed in the inner periphery of the piston in its area where the piston ports are formed. An arcuate plate is received in the annular groove. A sleeve is inserted into the arcuate groove to retain the arcuate plate in the annular groove. A gap as a fluid passage is defined between the arcuate plate and the inner surface of the annular groove. A pressure chamber defined in the cylinder body communicates with a communication passage communicating with a reservoir through the above gap, cutouts of holes formed in the arcuate plate and holes formed in the sleeve. When hydraulic fluid flows rapidly from the pressure chamber toward the reservoir, the arcuate plate is adapted to elastically and radially expand, thus closing some of the piston ports.

Owner:ADVICS CO LTD

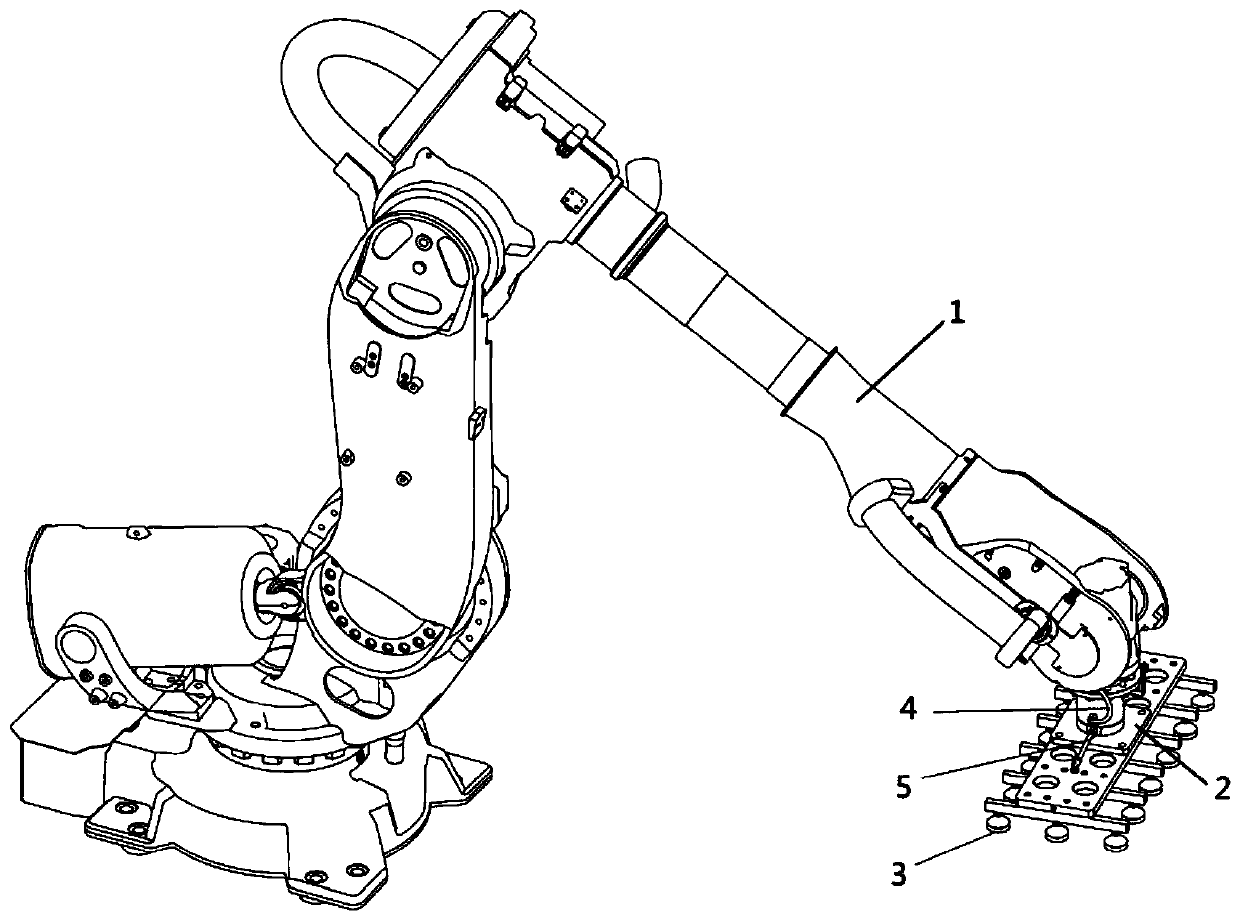

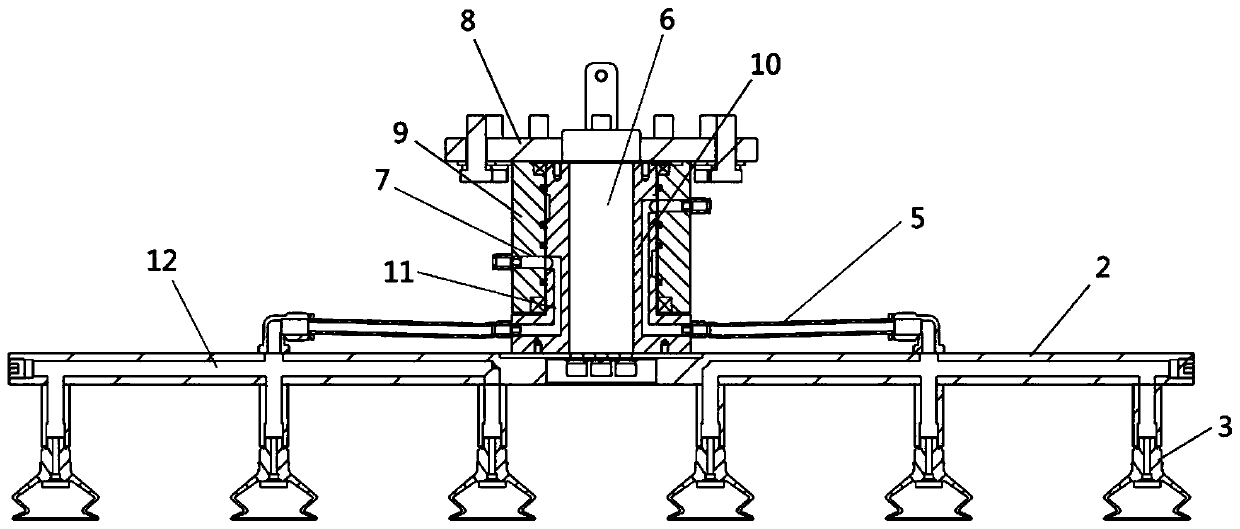

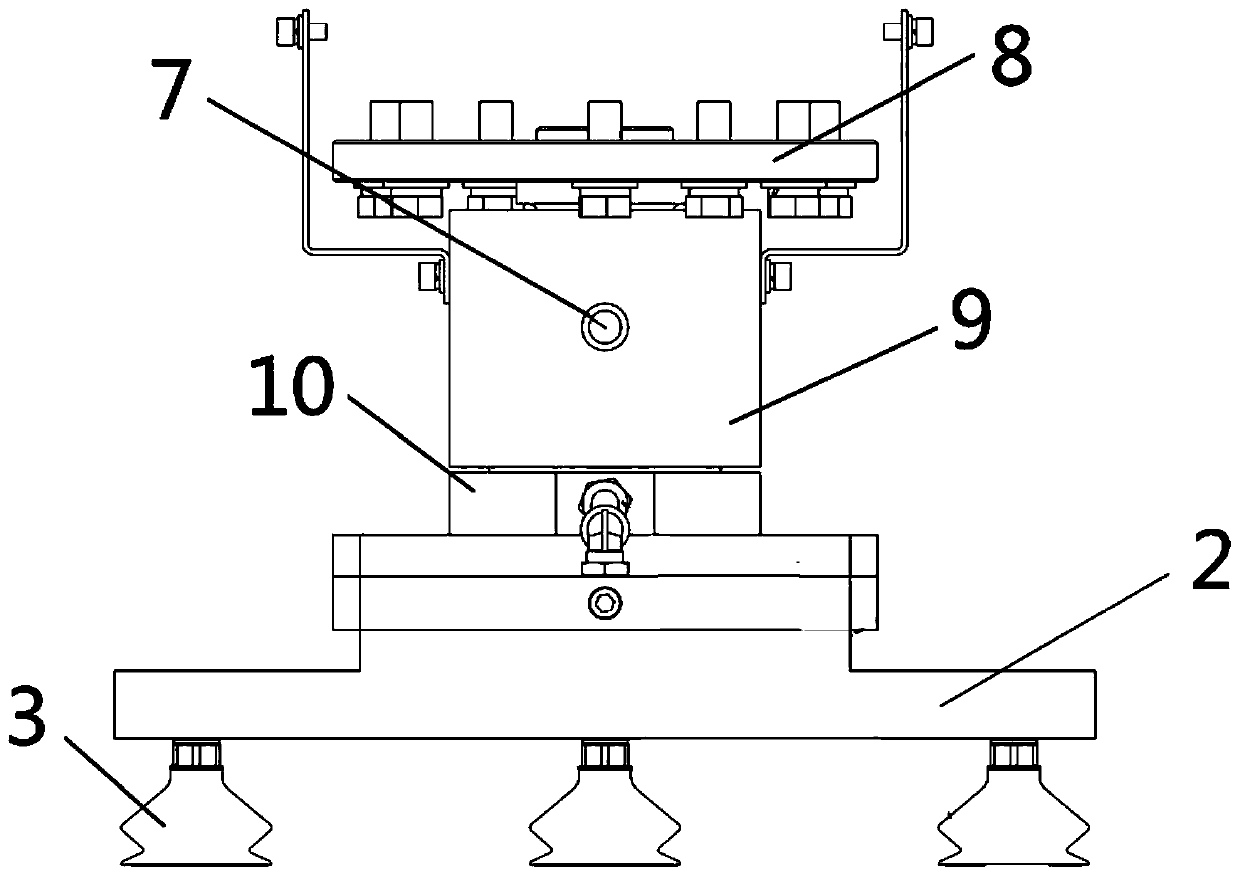

Mechanical arm rotating sucker conveying device

The invention relates to the technical field of conveying devices, in particular to a mechanical arm rotating sucker conveying device. The mechanical arm rotating sucker conveying device comprises a mechanical arm main body, a sucker assembly, an air pipeline assembly and a first air pipe, wherein the sucker assembly comprises a fixed component fixedly connected with the mechanical arm main body, a rotating component which is connected with the mechanical arm main body and rotates relative to the fixed component and a plurality of suckers which are connected with the rotating component and synchronously rotate with the rotating component; the air pipeline assembly comprises a plurality of first air pipeline structures arranged on the fixed component and a plurality of second air pipeline structures arranged on the rotating component, and the second air pipeline structures separately communicate with the suckers and an air path formed by the first air pipeline structures; and the first air pipe is connected with the first air pipeline structures of the fixed component. The service life of the mechanical arm rotating sucker conveying device is longer, economical losses can be reduced, and the production efficiency is increased.

Owner:CHINA TOBACCO GUANGXI IND

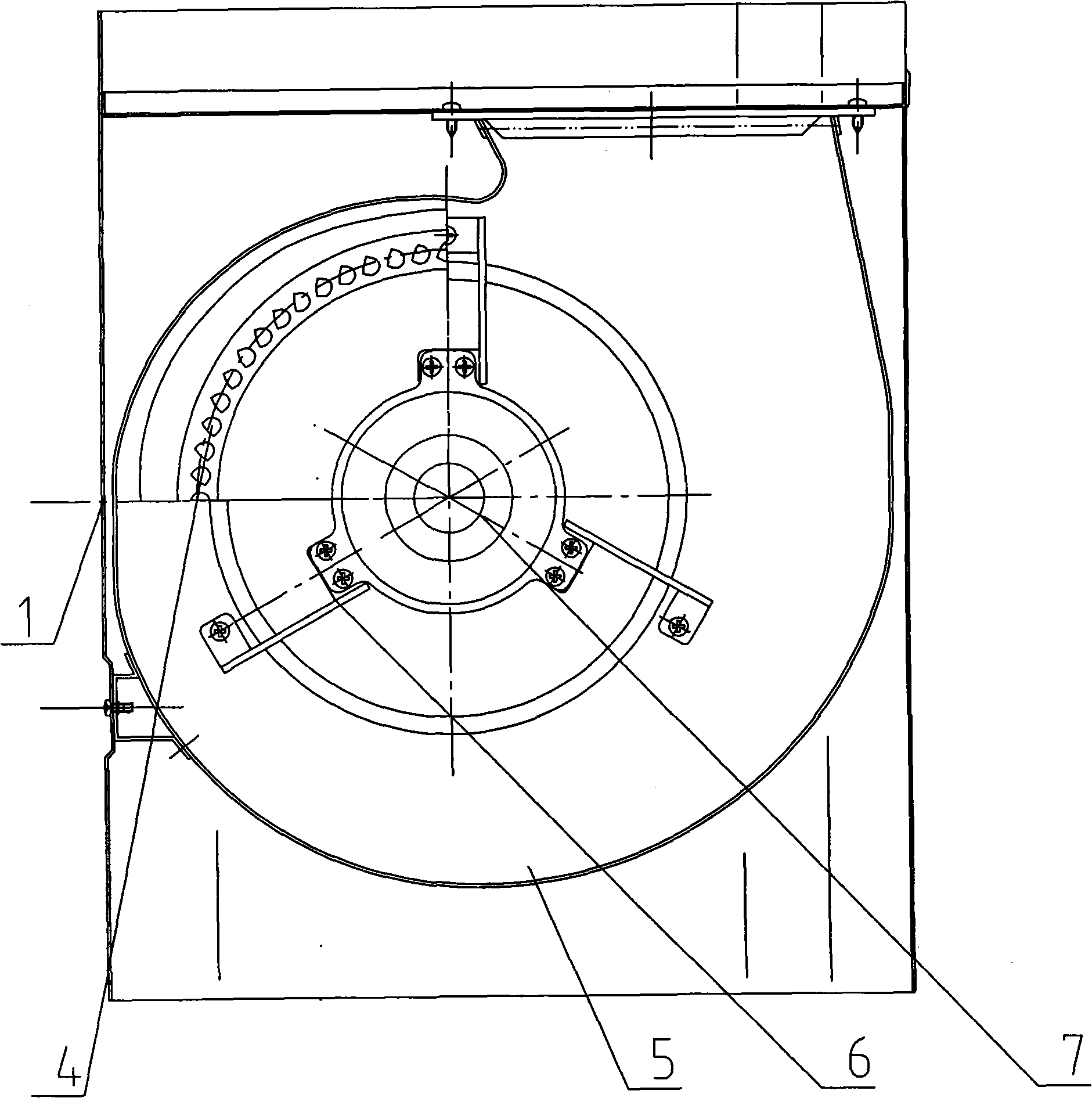

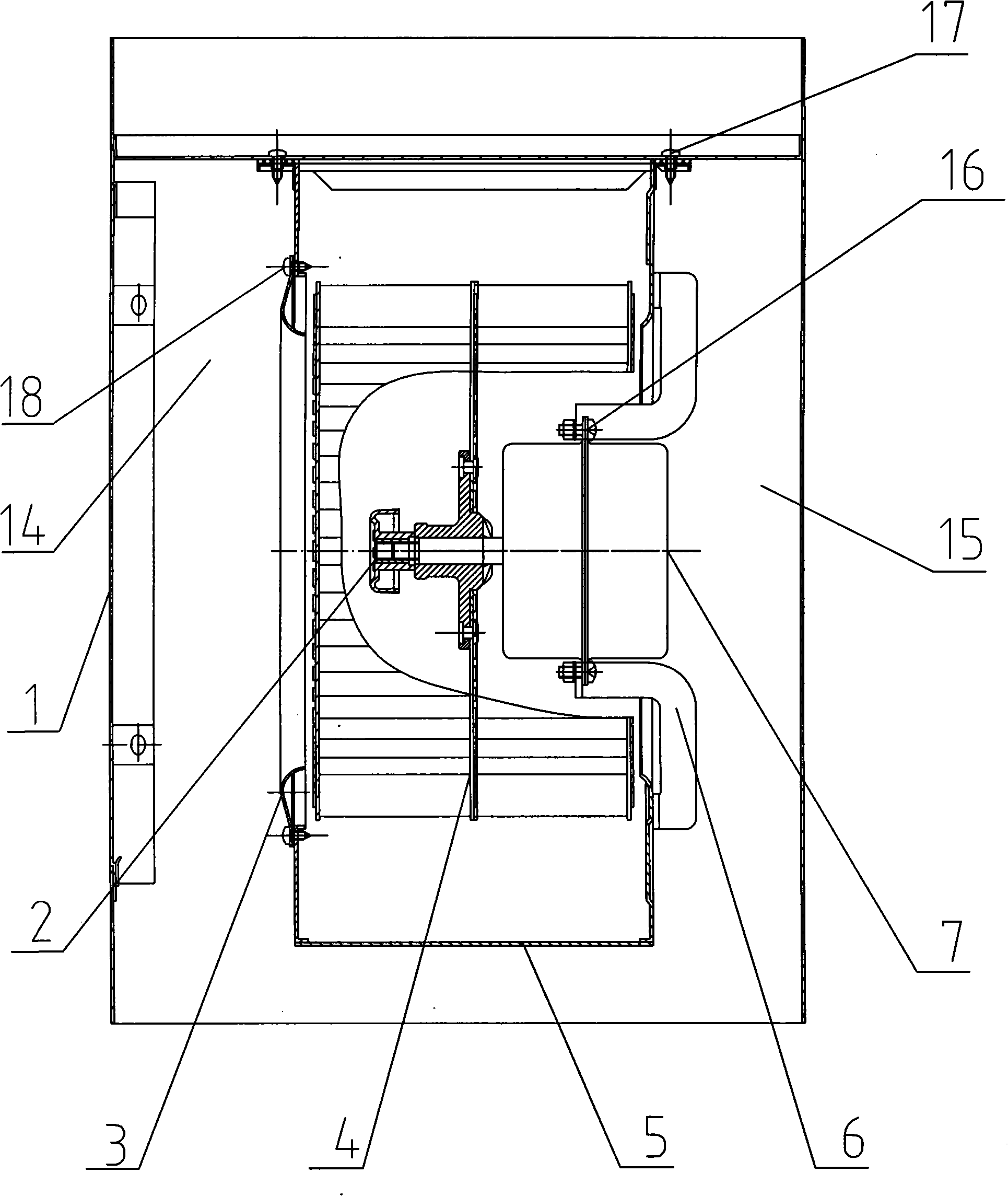

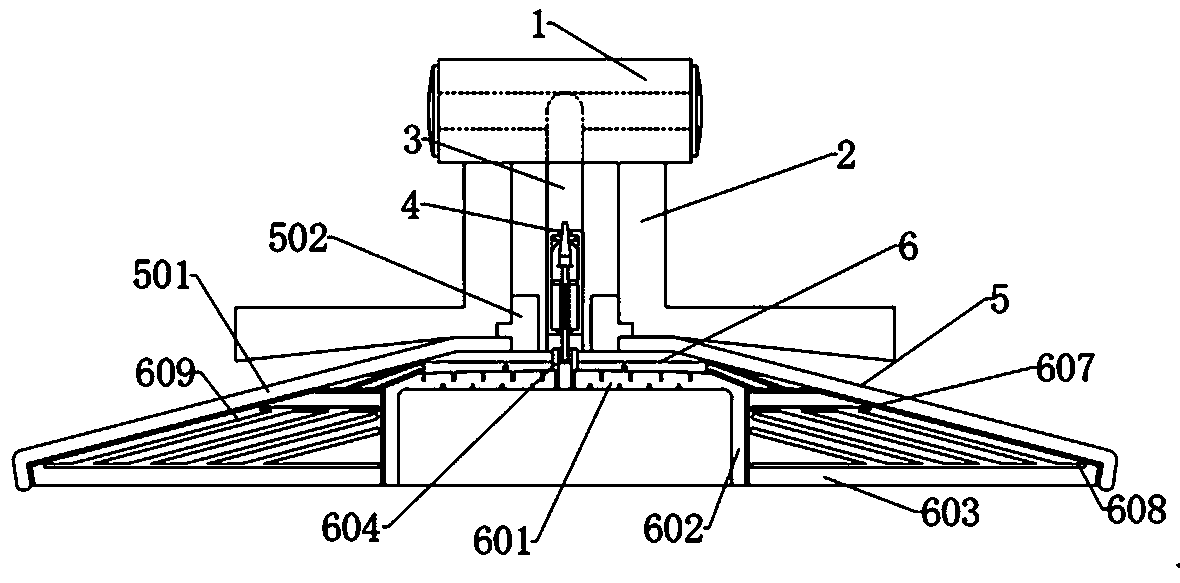

Two-sided uniform air intake blower fan system of fume exhauster

InactiveCN101280932AEfficient developmentFully developedDomestic stoves or rangesLighting and heating apparatusImpellerAir volume

The invention relates to a uniform air intake draught fan system on double-side of a fume exhaustor, comprising a main unit, impeller and draught fan, a set of motor support frames are fixedly connected onto the motor, the motor support frame is fixedly connected onto the draught fan, the draught fan is fixedly connected onto the internal wall of the main unit, the impeller is connected to the output shaft of the motor, a communicated left air intake cavity and right air intake cavity are formed inside the main unit cavity. The impeller includes an upper loop, a central loop, a bottom loop and an impeller vane, the central loop is arranged between the upper loop and the bottom loop, an impeller frame for connecting the motor output shaft is fixedly connected onto the central loop. The invention has useful effect of: 1 effectively developing right side space of the draught fan system such that uniform air intake on double-side is obtained, easily absorbing oil smoke generated by a left boiler or right boiler in cooking process; 2 sufficiently developing right side area of the draught fan system to resolve bottleneck of improving air capacity such that air capacity is improved greatly.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

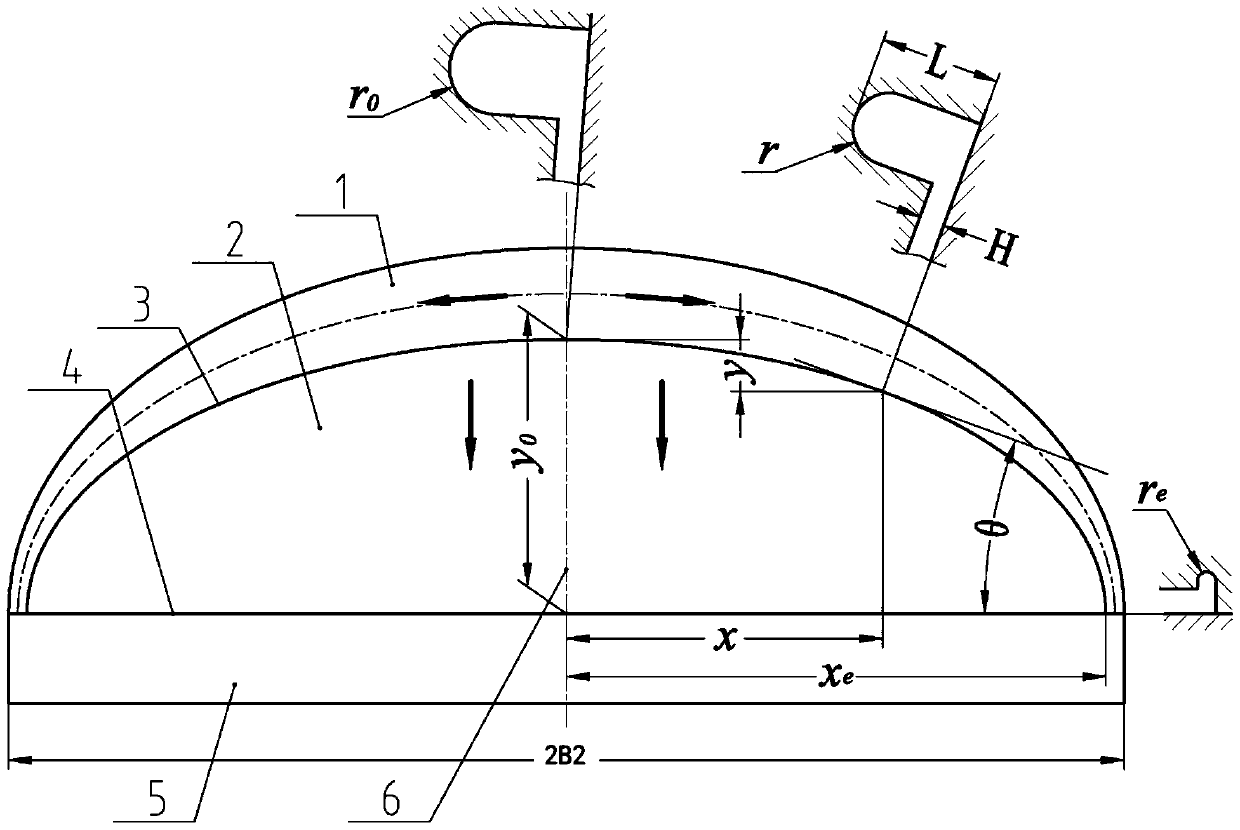

Clothes-hanger shaped spinning die head runner structure for uniform melt distribution

PendingCN110644062AReduce the amount of processingReduced processing performanceSpinnerette packsMelt spinning methodsFiberPolymer science

The invention provides a clothes-hanger shaped spinning die head runner structure for uniform melt distribution and a clothes-hanger shaped spinning die head with the die head runner structure. The structure is characterized in that firstly, the flow rate of high polymer melt in the breadth direction of a slit runner outlet is equal everywhere; secondly, the pressure drop of the high polymer meltflowing from a feeding port to the slit runner outlet is equal everywhere in the breadth direction; thirdly, the staying time of the high polymer melt in the whole spinning die head runner structure is short and equal everywhere at the slit runner outlet along the in the breadth direction. The equalities in three aspects have unique advantages in production of high polymers with poor thermal stability or with dependency of the rheological property on time. By adoption of the clothes-hanger shaped spinning die head runner structure, stable and uniform products can be prepared, such as ultrafinenanofibers and related products thereof. A wide application range is realized, and a great spinning performance aiming at high polymers which can be hardly processed and utilized by conventional spinning equipment is achieved.

Owner:北京钧毅微纳新材科技有限公司

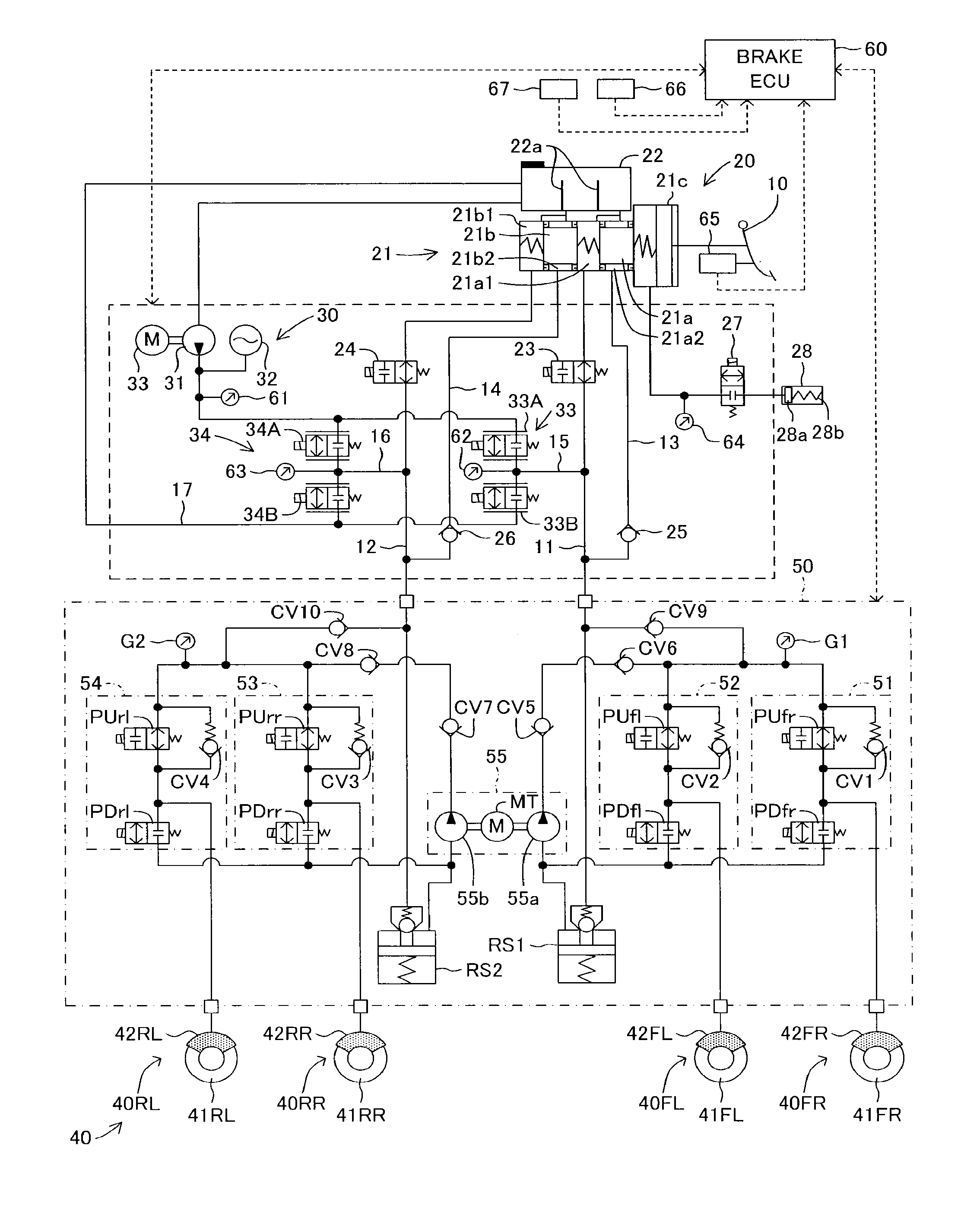

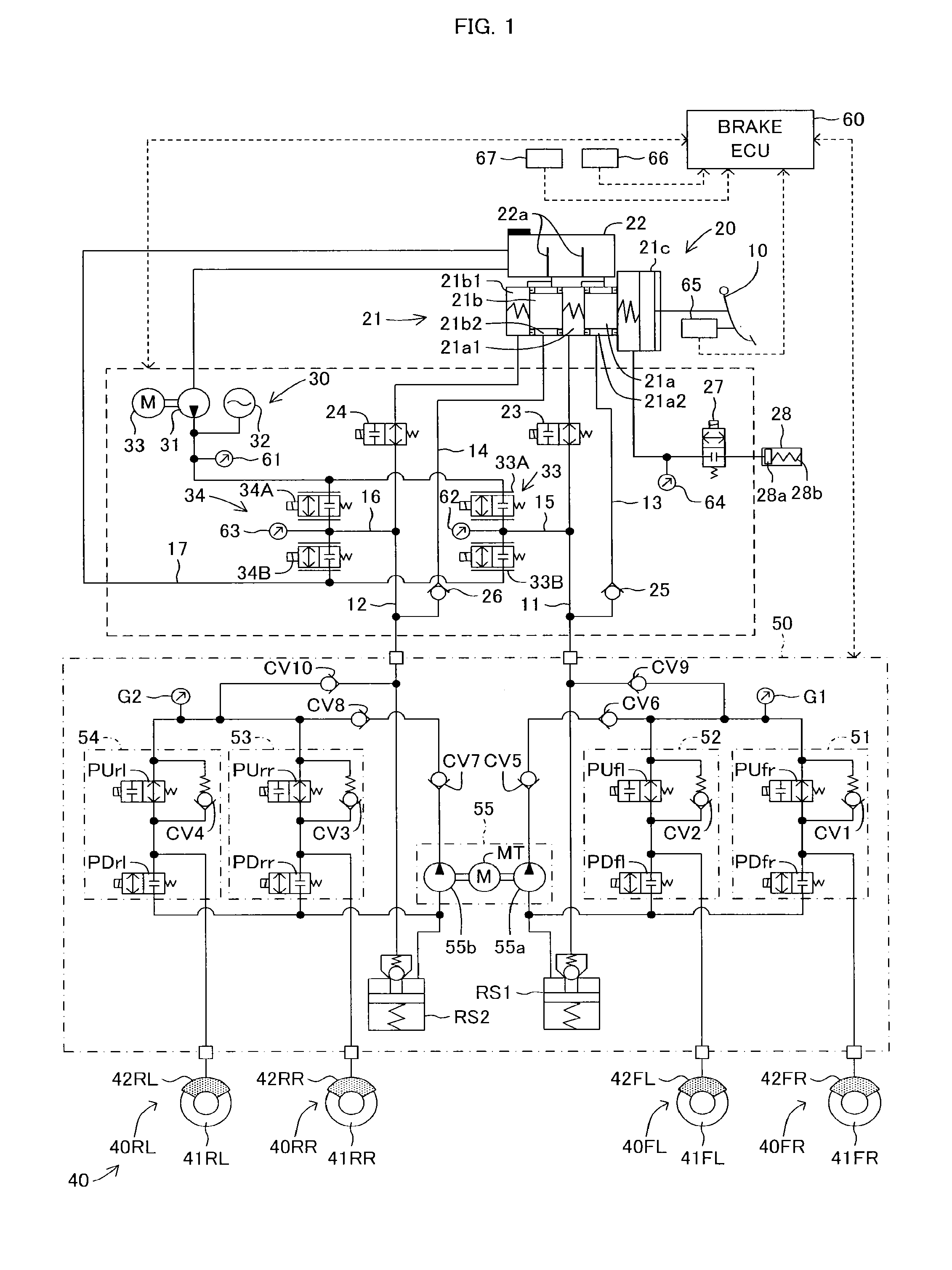

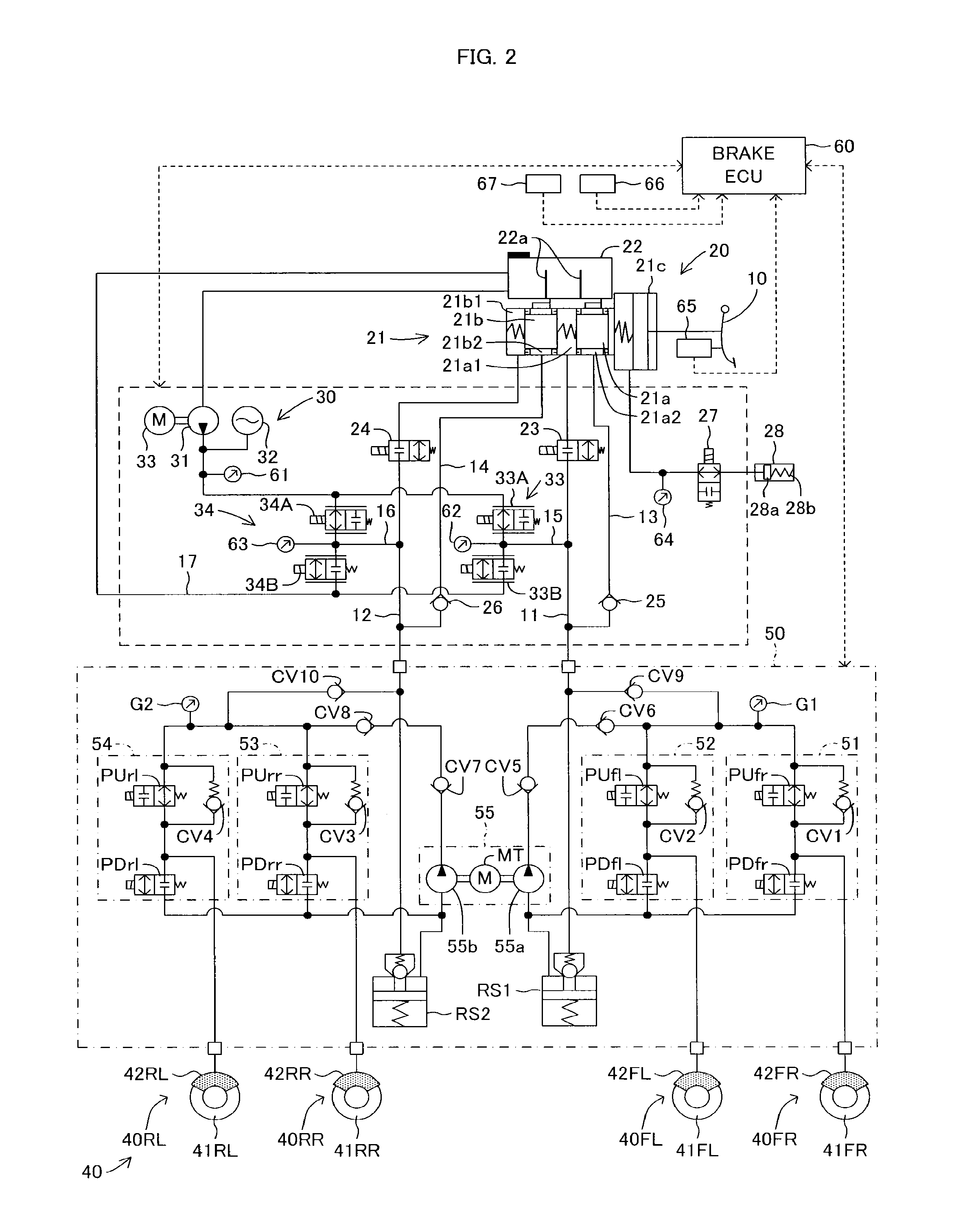

Brake device for vehicle

ActiveUS20160121868A1Low costWell formedBraking action transmissionBrake control systemsMaster cylinderEngineering

A master cylinder includes pressurizing chambers and atmospheric pressure chambers which are in communication with a reservoir provided upstream. The pressurizing chambers of the master cylinder are connected to a brake fluid pressure control valve device through master pressure pipes provided with master cut valves. The atmospheric pressure chambers of the master cylinder bypass the master cut valves and are connected to the brake fluid pressure control valve device through bypass pipes provided with check valves. A pump constituting a brake fluid pressurizing section of the brake hydraulic control valve device suctions the brake fluid from the reservoir preferentially through the bypass pipes provided with the check valves and pressurizes the brake fluid to supply a brake fluid pressure to brake fluid pressure adjust sections.

Owner:TOYOTA JIDOSHA KK

High-temperature-resistant precipitation antagonist

ActiveCN112481008AImprove thermal stabilityReduced chromaticity variationTransportation and packagingMixer accessoriesCresolUltraviolet lights

The invention discloses a high-temperature-resistant precipitation antagonist, which belongs to the technical field of lubricating oil preparation. The high-temperature-resistant precipitation antagonist is characterized by being prepared from the following raw materials in parts by weight: 3-5 parts of 2, 6-di-tert-butyl-p-cresol, 3-5 parts of zinc dialkyl dithiophosphate, 0.5-1 part of an anticoagulant, 0.5-1.5 parts of a dispersing agent, 5-10 parts of an ultraviolet light absorber, and the balance of base oil. The anticoagulant and the dispersing agent are added into the component A or thecomponent B or the component C in proportion; the component A, the component B and the component C are added into lubricating oil to be updated through online blending and filling equipment; and theaddition amount of the high-temperature-resistant precipitation antagonist is 0.1-0.2% of the lubricating oil to be updated. The quantitative premixing device, the nitrogen adding pulse blending device and the suction type replacement device are sequentially connected from front to back.

Owner:山东恒利热载体工程技术有限公司

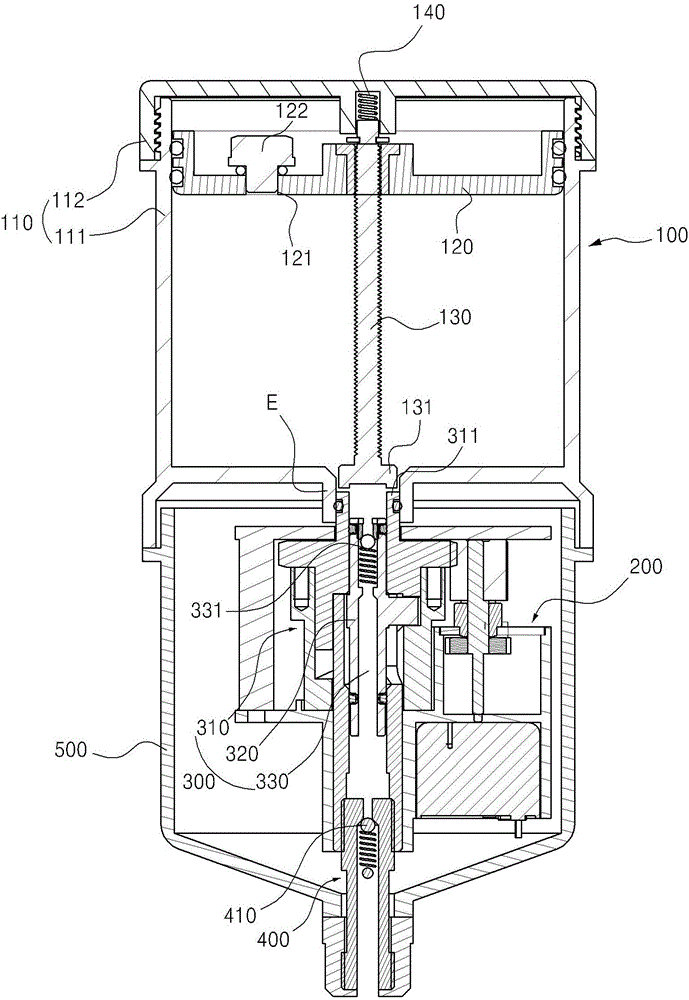

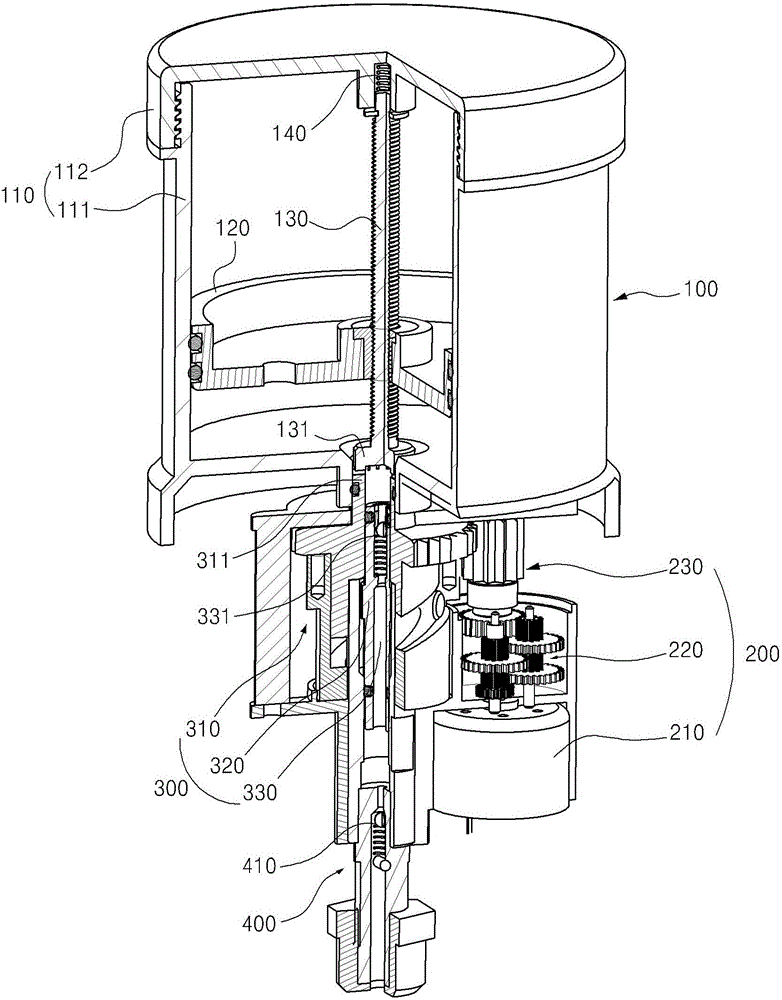

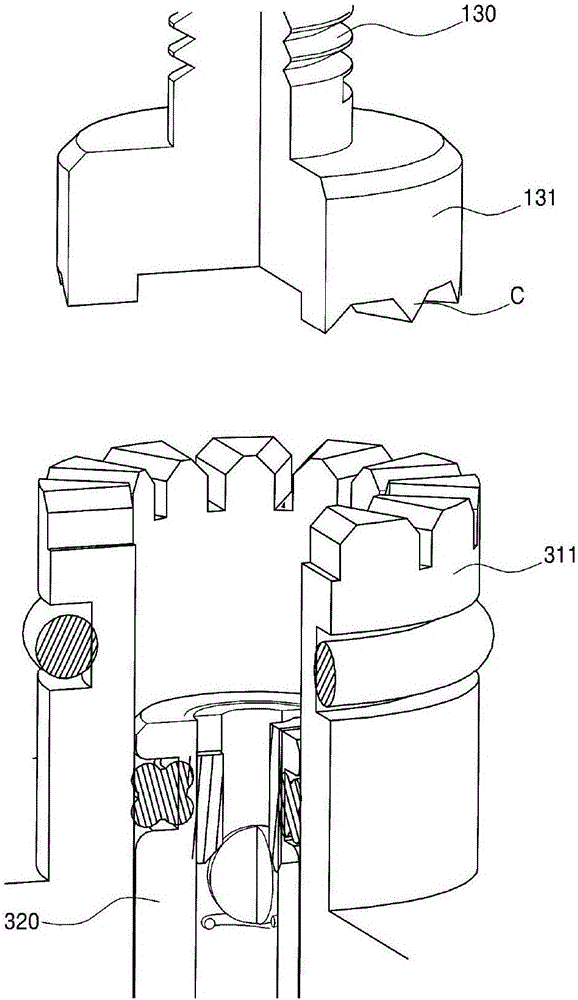

Lubricant injector

InactiveCN106030183AReduce oil separationOvercome the disadvantage of low discharge pressureContracting/expanding measuring chambersLubricating pumpsGear wheelCam

The purpose of the present invention is to provide a lubricant injector, which implements extrusion and pumping of a lubricant using a single power source, and which can intermittently perform extrusion of the lubricant, the lubricant injector comprising: a storage unit comprising a storage chamber filled with a lubricant, a piston provided inside the storage chamber, a screw shaft coupled to the piston so as to lift / lower the piston according to rotation, a following gear installed on the bottom portion of the screw shaft, and an elastic support member installed on one side of the screw shaft to elastically support the following gear; a power generation unit installed on one side of the lower portion of the storage unit to provide a rotation driving force; and an emission unit comprising a cylindrical cam which interworks with the power generation unit and thereby rotates, a driving gear which is formed on the top portion of the cylindrical cam and meshes with the following gear, thereby forming a space such that the lubricant is introduced into the cylindrical cam, a plunger which interworks with rotation of the cylindrical cam and moves up / down inside the cylindrical cam, thereby pumping the introduced lubricant, and an emission tube line formed inside the plunger such that the pumped lubricant can be emitted to target locations, wherein the following gear and the driving gear intermittently mesh with each other according to the change of pressure inside the storage chamber.

Owner:KLT CO LTD

Formulating method of felon herb aspiration product

InactiveCN1475171ARefreshingClear liver and improve eyesightTobacco treatmentChrysanthemum FlowerMugwort

A cigarette is prepared from argyi leaf, essence and one or more of lotus leaf, mulberry leaf, argyi stem, mint, chrysanthemum flower and honeysuckle flower through proportioning. Its advantages are health-care effect, high productivity and low cost.

Owner:大老板经贸有限责任公司

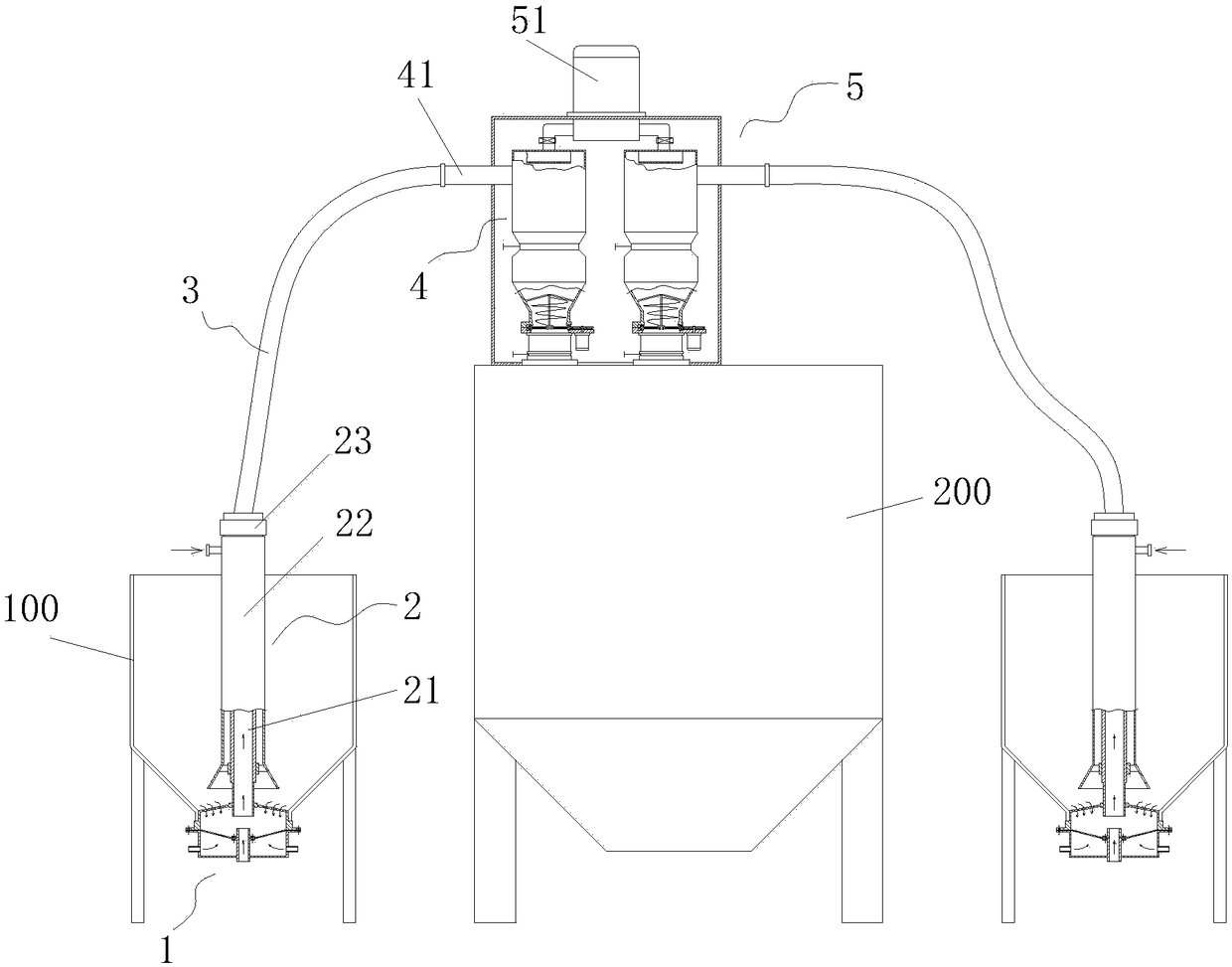

General multi-channel powder granule sucking device

The invention discloses a general multi-channel powder granule sucking device. The general multi-channel powder granule sucking device comprises at least two sets of sucking nozzle mechanisms, a conveying hose and a discharging mechanism installed on the top of a stirring barrel; each set of sucking nozzle mechanism is detachably installed at a discharging opening in the bottom of a correspondingcontaining barrel; the discharging end of each set of sucking nozzle mechanism communicates with the feeding end of the discharging mechanism through the conveying hose; and the discharging end of thedischarging mechanism communicates with the interior of the stirring barrel. The general multi-channel powder granule sucking device is reasonable in structural arrangement. During sucking and discharging, the powder granule conveying efficiency is improved, the mixing uniformity degree of later different materials is facilitated, the mixing efficiency is improved, deep materials are sucked moresmoothly, the deep materials are prevented from being too dense to form a vacuum cavity, and the sucking efficiency of the powder is prevented from being greatly reduced.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Ship water absorption device and ship

ActiveCN109795618AAvoid enteringStable suctionSelf-bailing equipments/scuppersVessel partsBilge pump

The invention discloses a ship water absorption device which comprises a water absorption pipe and a floating component which are positioned inside a cabin. One end of the water absorption pipe is connected with a bilge, the other end of the water absorption pipe is connected with a supporting pipe, a water inlet for entering of accumulated water in the cabin is formed in the side wall of the water absorption pipe, and the floating component sleeves the periphery of the water absorption pipe and can vertically float relative to the water absorption pipe to selectively plug the water inlet. Bythe design, the floating component can automatically close the water inlet along with change of the accumulated water in the cabin, air can be timely prevented from entering the water absorption pipefrom the water inlet, a bilge pump can smoothly pump accumulated water in other cabins, so that normal operation of a bilge water system is ensured, and safety of a ship is improved. The invention further provides the ship which is low in manufacturing cost and good in safety.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

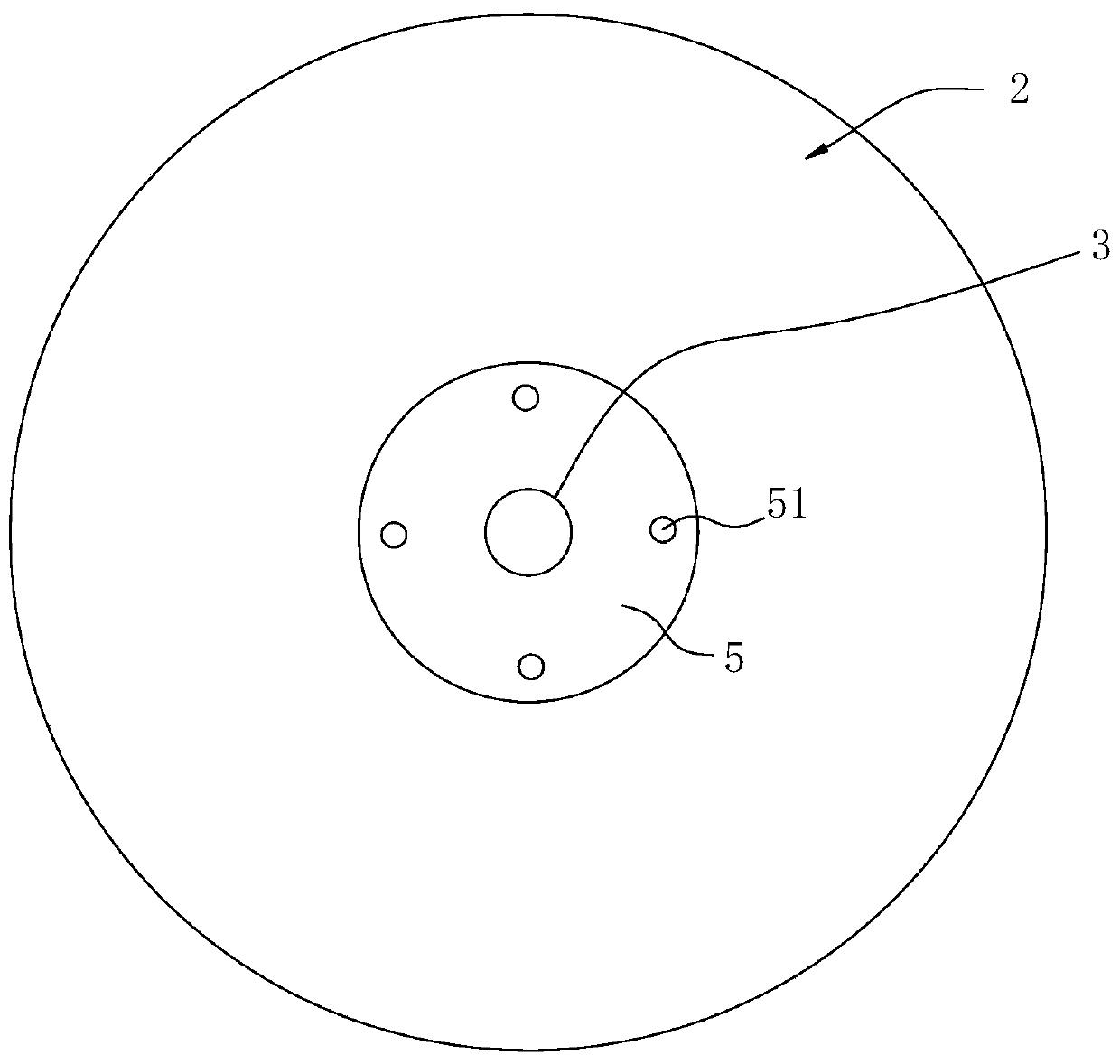

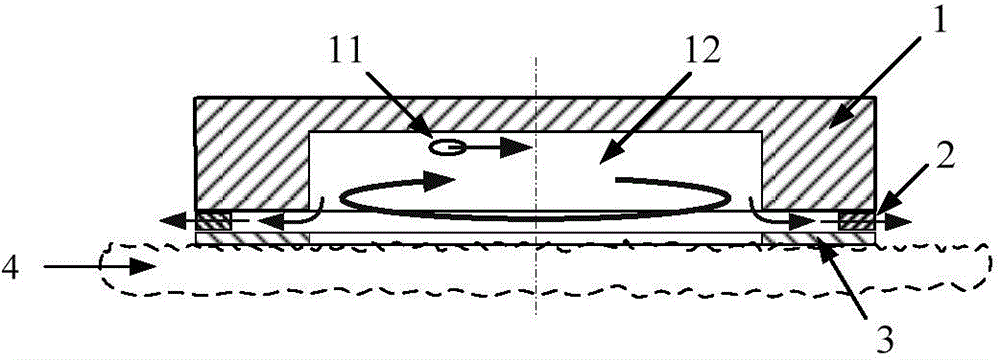

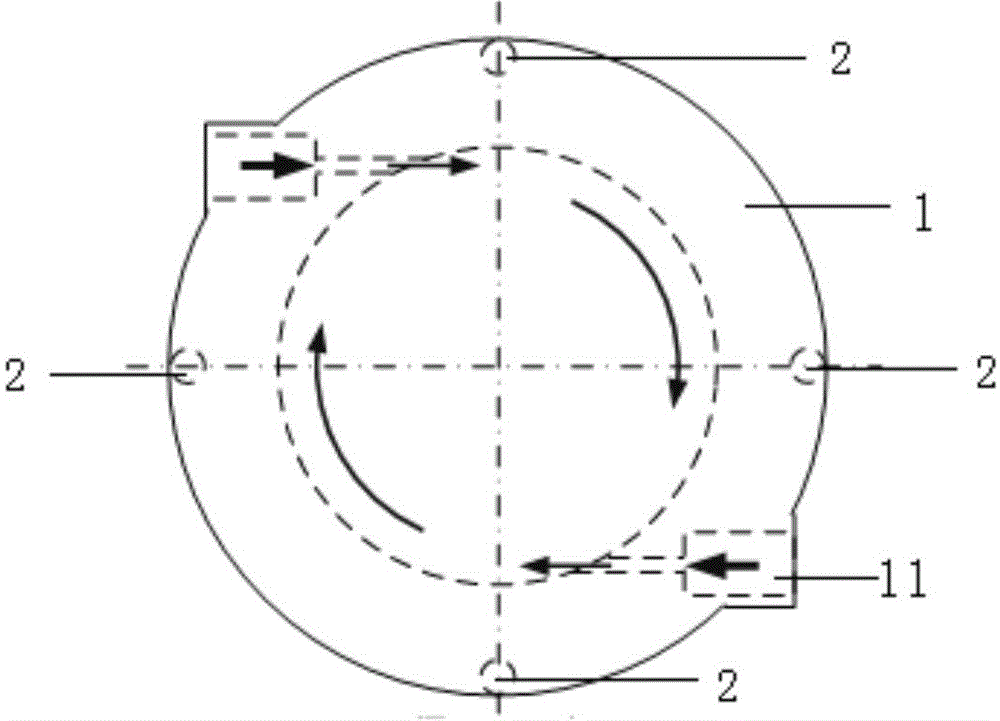

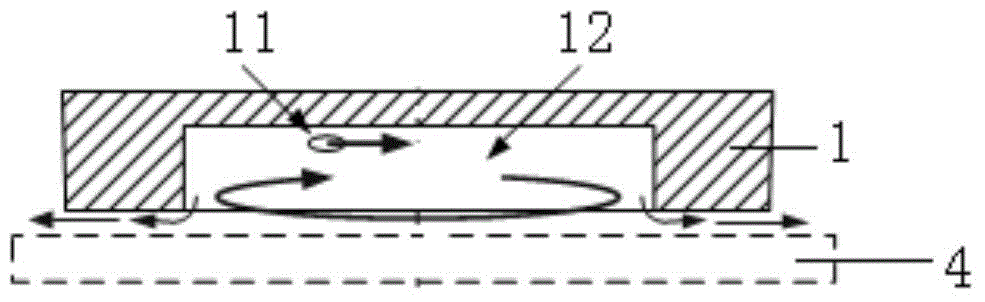

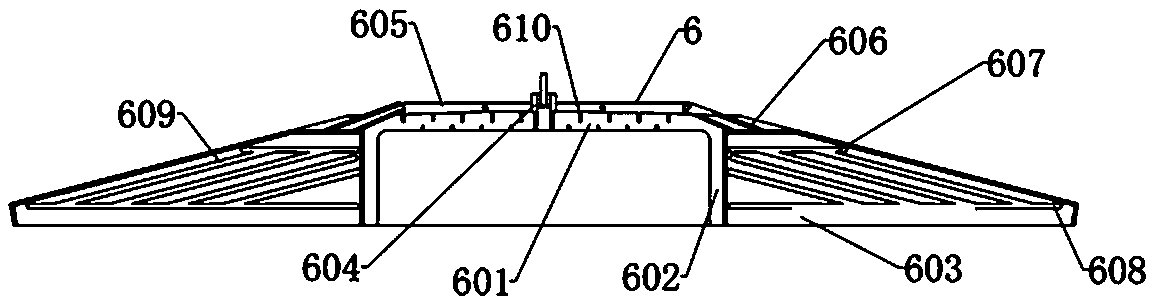

Suction cup

ActiveCN104626174AGood friction effectFully contactedGripping headsConveyor partsCushionRough surface

A sucking disc comprises a sucking disc body (1), an annular separation plate (3), and cushion blocks (2). The sucking disc body (1) is internally provided with a chamber body (12) of which a transverse cross section is circular. A tangential nozzle (11) is disposed on a wall surface of the chamber body (12). An upper surface of the annular separation plate (3) is fixedly connected to the edge of a bottom surface of the sucking disc body (1) by mans of the cushion blocks (2). The cushion blocks (2) are disposed on the edge of the bottom surface of the sucking disc body (1) in a spaced manner. The number of the cushion blocks (2) is four, and the four cushion blocks (2) cover part of the area of the annular separation plate (3). Space between the cushion blocks (2) forms a fixed flow channel between the edge of the bottom surface of the sucking disc body (1) and the annular separation plate (3), and the fixed flow channel is in communication with the chamber body (12) and the peripheral environment. The sucking disc can suck a soft object with a rough surface, and consumes a little gas.

Owner:ZHEJIANG UNIV

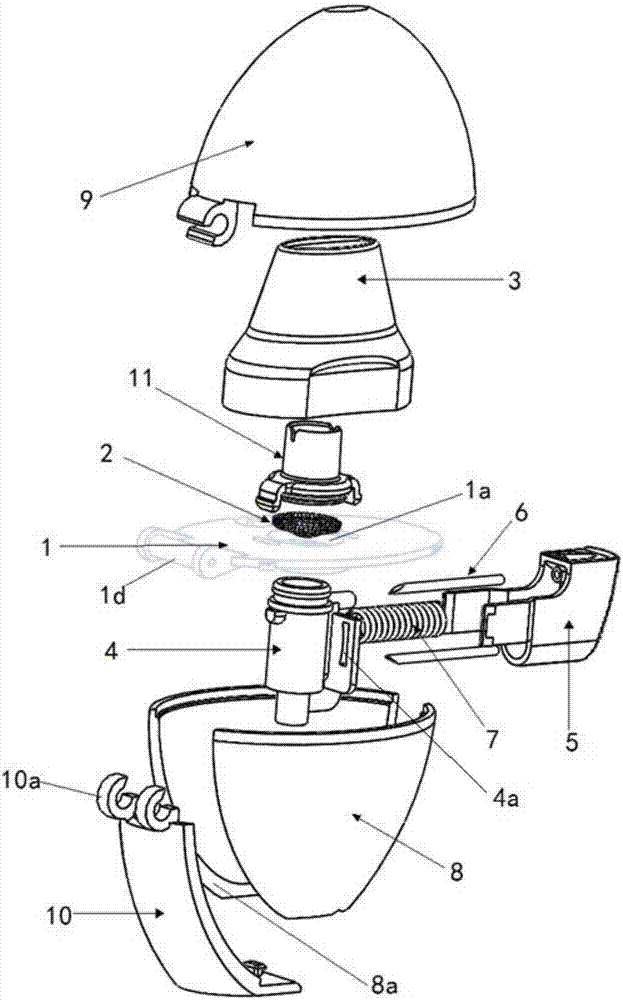

Powder medicine inhaler

InactiveCN107041986AEasy to assembleReduce manufacturing costMedical devicesInhalatorsEngineeringInhaler

The invention discloses a powder medicine inhaler comprising a bearing plate, a suction nozzle, a capsule chamber and an upper housing. Two spaced bearing plate lugs are integrally formed on the side part of the bearing plate; the inner sides of the two bearing plate lugs are close to each other and integrally form internal bosses; the deviated external sides integrally form external bosses; the side part of the suction nozzle integrally forms two suction nozzle lugs spaced to each other; the two suction nozzle lugs are provided with suction nozzle rotary holes matched with the internal bosses; the two suction nozzle rotary holes respectively cover the internal bosses in a rotary way; an upper housing lug is integrally formed on a lower part opening side of the upper housing; the left and right sides of the upper housing lug integrally form a left boss and a right boss; and the left boss and the right boss are respectively disposed in the two suction nozzle rotary holes of the suction nozzle in a rotary way. Pivotal connection between the upper housing, the suction nozzle, the bearing plate and the lower housing requires no specific rotating shaft component, so product production and management cost can be reduced and assembling of the powder medicine inhale can be simplified.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

Air suction end executor

ActiveCN110871454AAffect suctionAffect the inspiratory operationGripping headsSuction forceStructural engineering

The invention discloses an air suction end executor. The air suction end executor comprises a suction sucker frame, wherein a sucker fixing sleeve is mounted on the suction sucker frame, a suction hole is formed in the suction sucker frame, an air guiding mechanism is arranged in the suction hole, and a suction sucker connected with the air guiding mechanism is mounted at the end of the suction bole; and a multi-chamber separating mechanism is mounted on the inner wall of the suction sucker. According to the air suction end executor, a separation rubber block and separation sheets are arrangedin the sucker, and the sucker can be divided into a plurality of chambers by the separation sheets, so that the sucker is stable in attraction force when being used for tracing objects; and when thesucker sucks the objects, air bleeding columns can pump out air in the chambers, if the upwards traction operation is performed, even though air enters the sucker from score marks or split marks of the objects, the air can only enter the corresponding chamber, and the remaining chambers can also suck the objects. Therefore, the condition that the entire sucker is flabby to cause the attraction ofthe sucker to be rapidly reduced, so that traction of the objects is influenced, can be avoided.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com