Plunger type master cylinder

一种柱塞型、主缸的技术,应用在液压制动传动装置、流体压力致动装置、遥控马达等方向,能够解决插入、活塞跑到杯外、歪斜等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

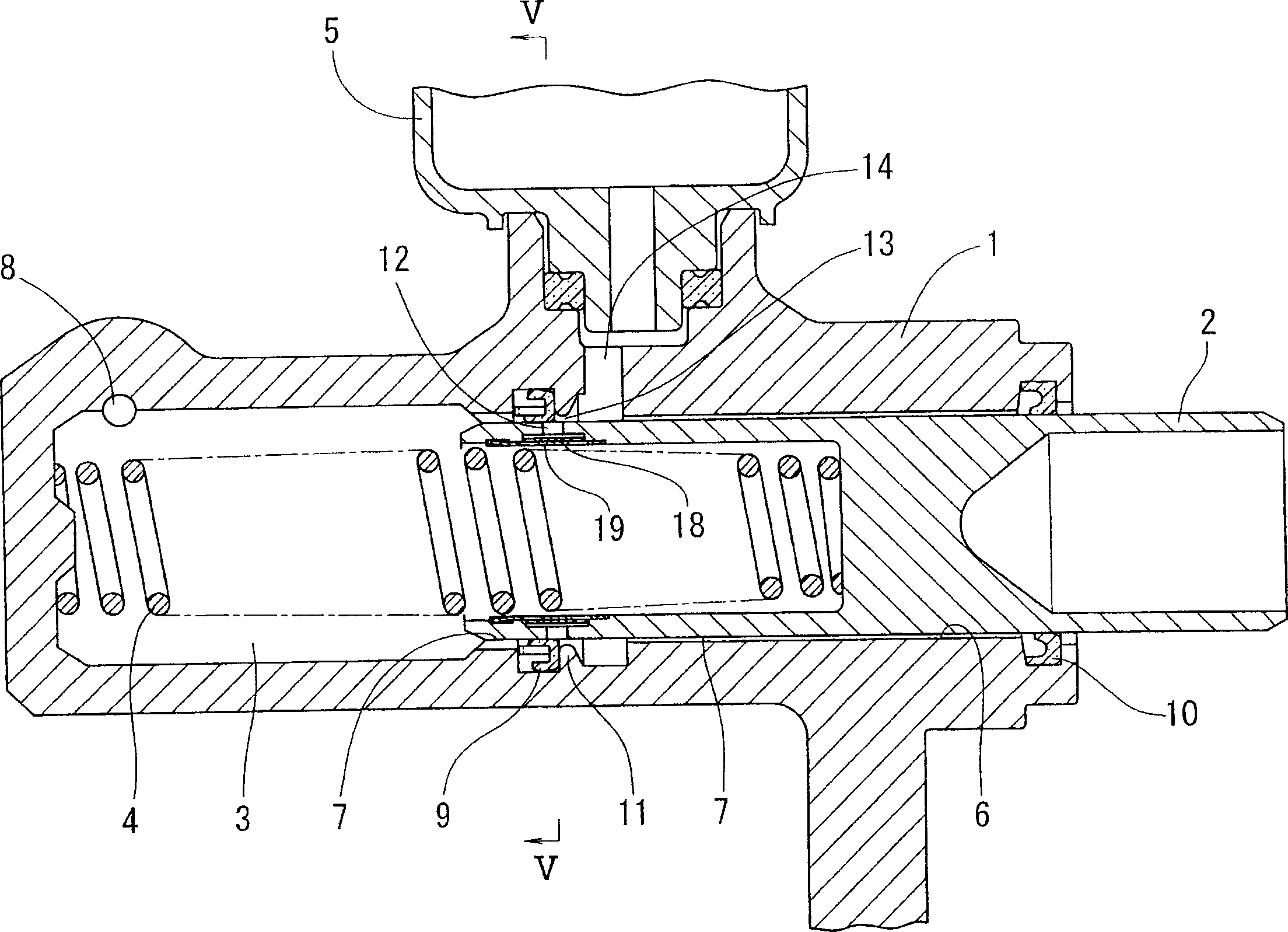

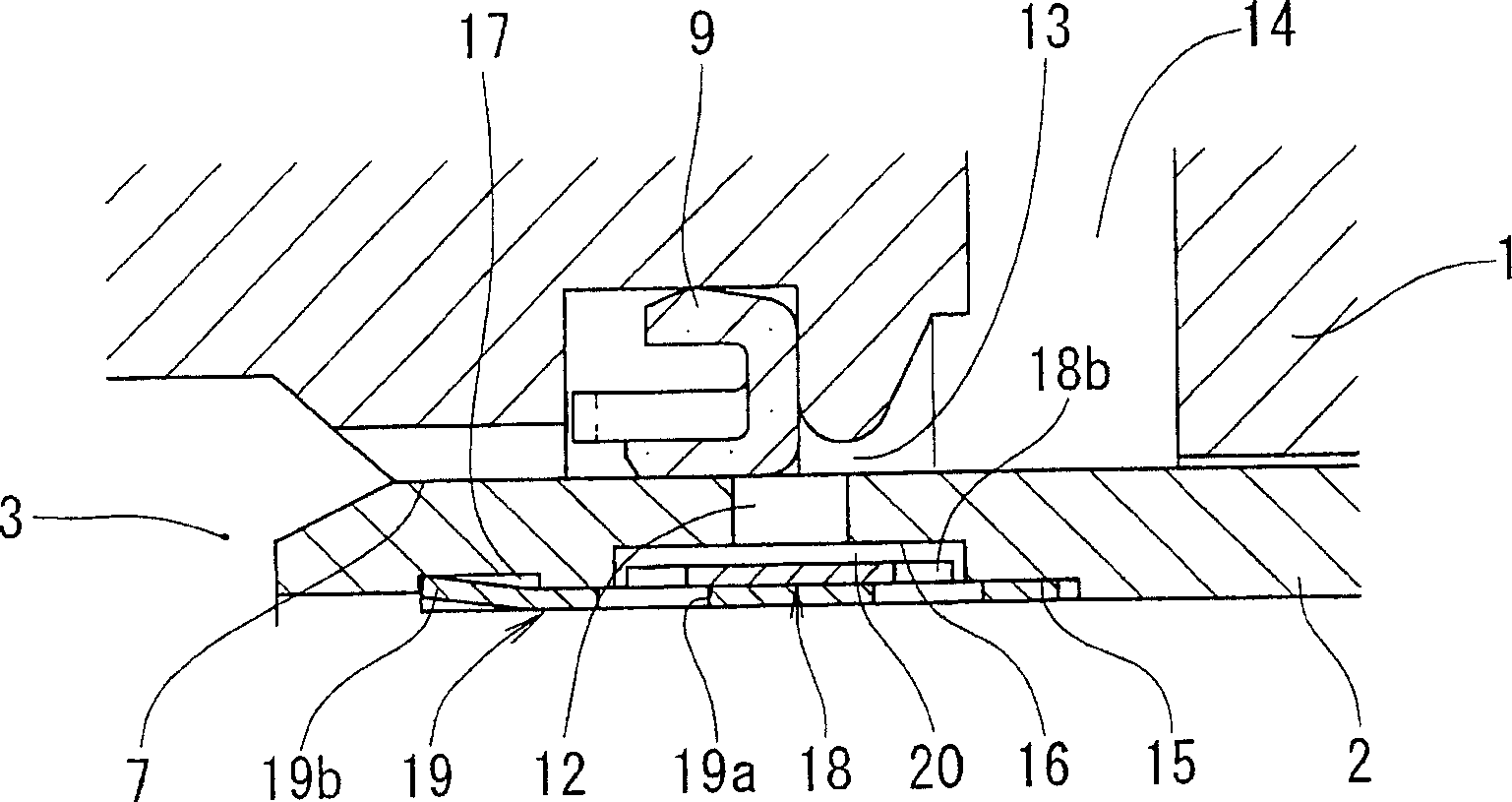

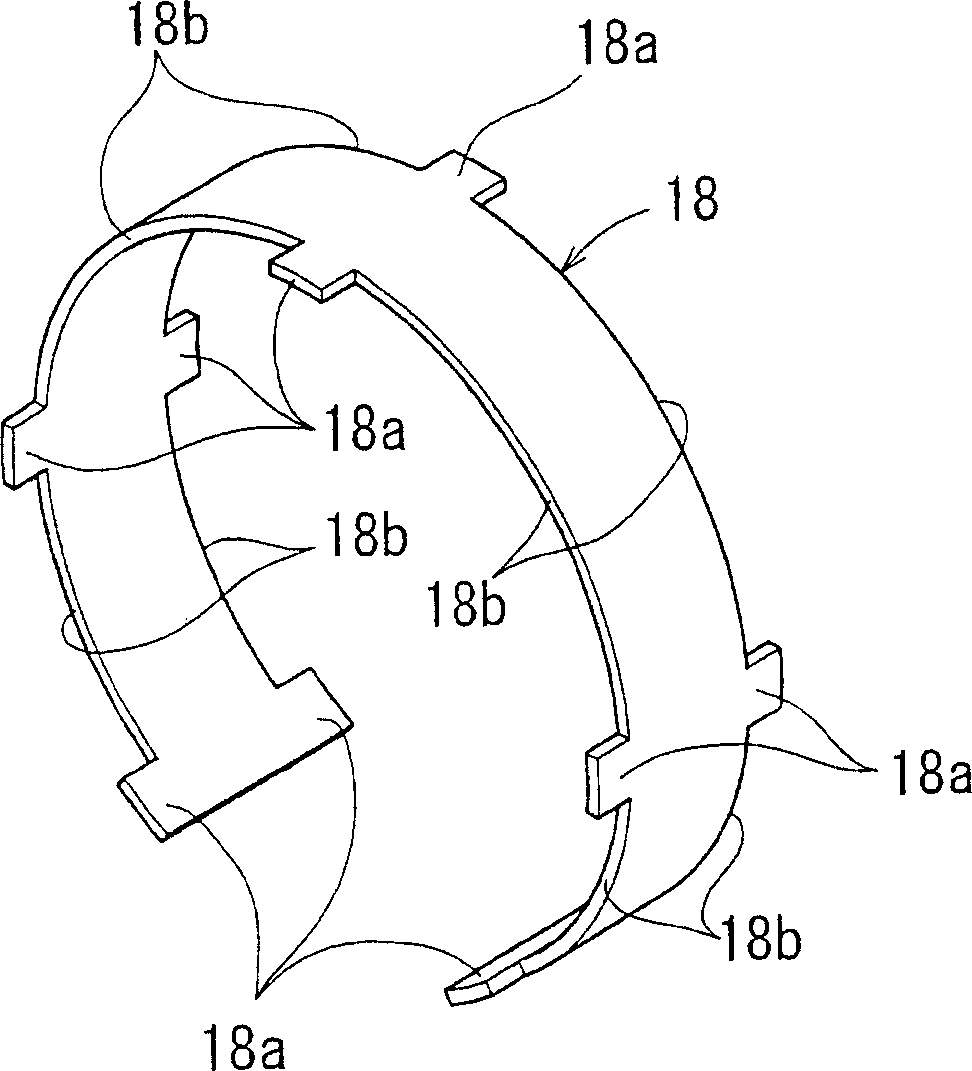

[0027] will now refer to Figure 1 to Figure 8 A master cylinder embodying the invention is described. figure 1 The basic structure of the master cylinder according to the invention is shown. The master cylinder includes a cylinder body 1 , a piston 2 installed in the cylinder body 1 , a return spring 4 for the piston 2 and a storage tank 5 . A pressure chamber 3 is defined in the cylinder body 1 in which a brake fluid pressure is generated by pressurizing a hydraulic fluid therein with a piston 2 . The pressure chamber 3 comprises an outlet orifice 8 through which the hydraulic pressure generated therein is discharged.

[0028] The primary cup 9 and the secondary cup 10 are housed in grooves formed in the inner circumference of the cylinder 1 and held in place by the cylinder 1 . The main cup 9 seals the outer circumference of the piston 2 . The secondary cup 10 is pressed against the outer periphery of the piston 2, thereby sealing the interior of the cylinder 1 from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com