Height adjusting assembly for electrical equipment overhaul

A technology of height adjustment and power equipment, applied in the direction of hoisting equipment safety devices, hoisting devices, etc., can solve the problems of unstable lifting of the maintenance platform, difficulty in carrying out work, and prone to accidents, so as to achieve high reliability, reduce danger, Flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

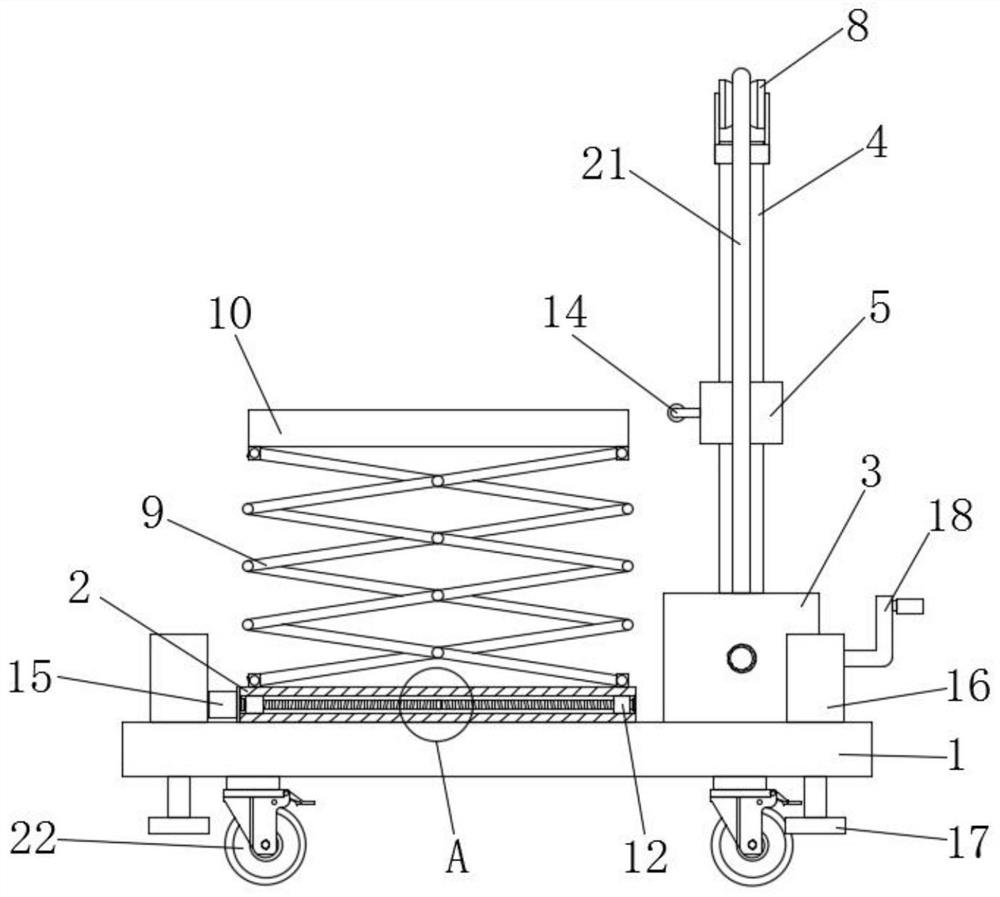

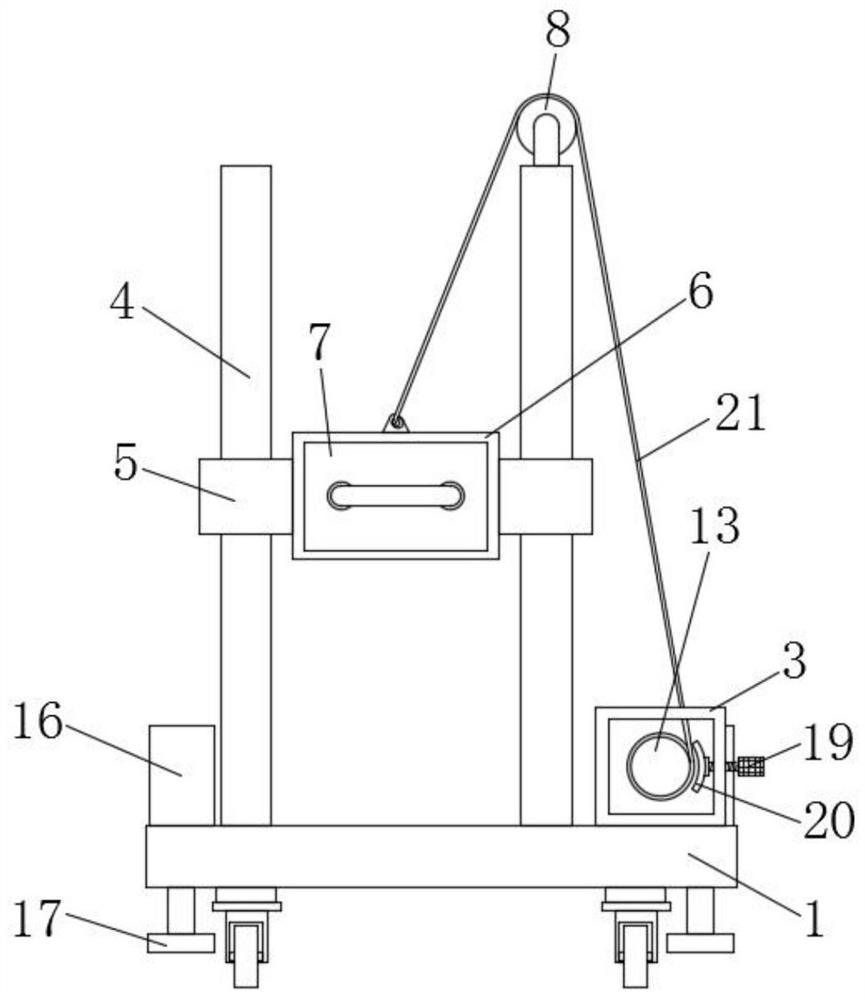

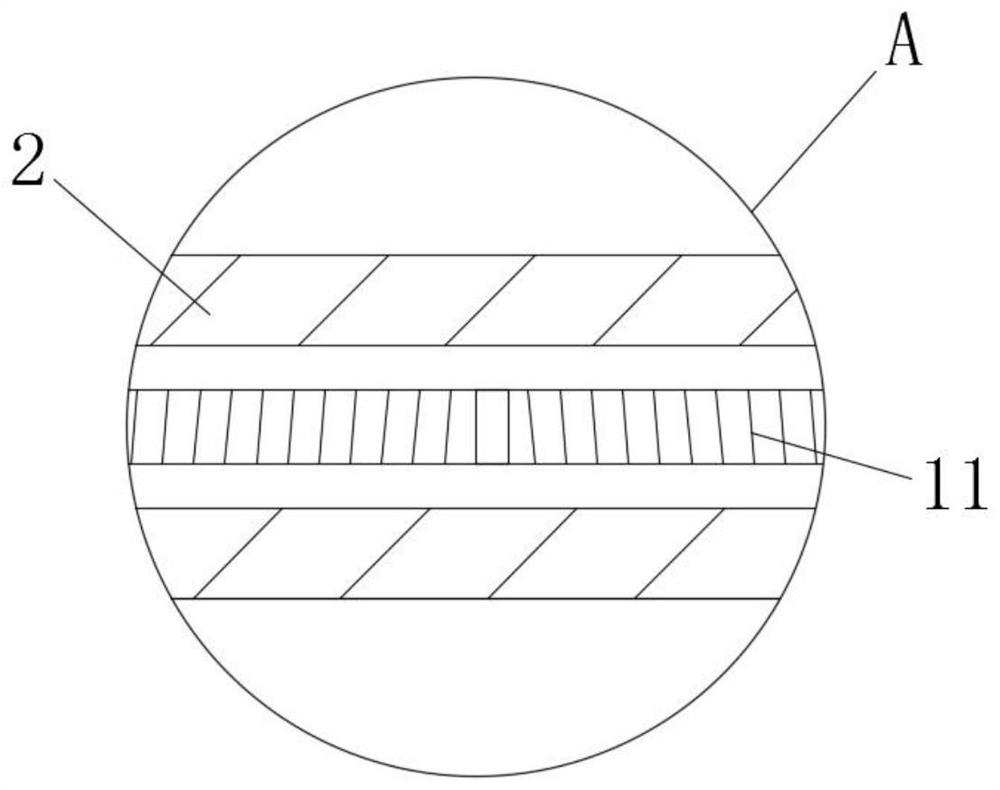

[0022] Embodiment 1: refer to Figure 1-3 , a height adjustment assembly for power equipment maintenance, including a vehicle board 1, a base 2, a fixed box 3 and a column 4, the upper surface of the vehicle panel 1 is provided with a base 2, and one side of the base 2 is also provided with two sets of columns 4 One side of the column 4 is provided with a fixed box 3, the fixed box 3 is provided with a wire roller 13, the upper surface of the base 2 is provided with a folding frame 9, and the top of the folding frame 9 is fixedly connected with a top seat 10 by bolts, sliding on the column 4 Be connected with moving block 5, be welded with tool box 6 between moving block 5, tool box 6 is also provided with drawer 7 near the side of top base 10, and pulley 8 is installed on the top of column 4 wherein near fixed box 3 side, base 2 is provided with a chute, and a slide bar 11 is horizontally arranged in the chute, and two groups of sliders 12 are symmetrically arranged at the le...

Embodiment 2

[0024] Embodiment 2: In this embodiment, the limiting plate 20 is designed as an arc structure.

Embodiment 3

[0025] Embodiment 3: In this embodiment, the support block 17 is designed as an inverted tapered structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com