Two-sided uniform air intake blower fan system of fume exhauster

A range hood and blower technology, which is applied in the field of double-sided uniform air intake fan system, can solve the problems of uneven air intake, inability to increase air volume, and large occupied volume, and achieve the effect of solving the bottleneck of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

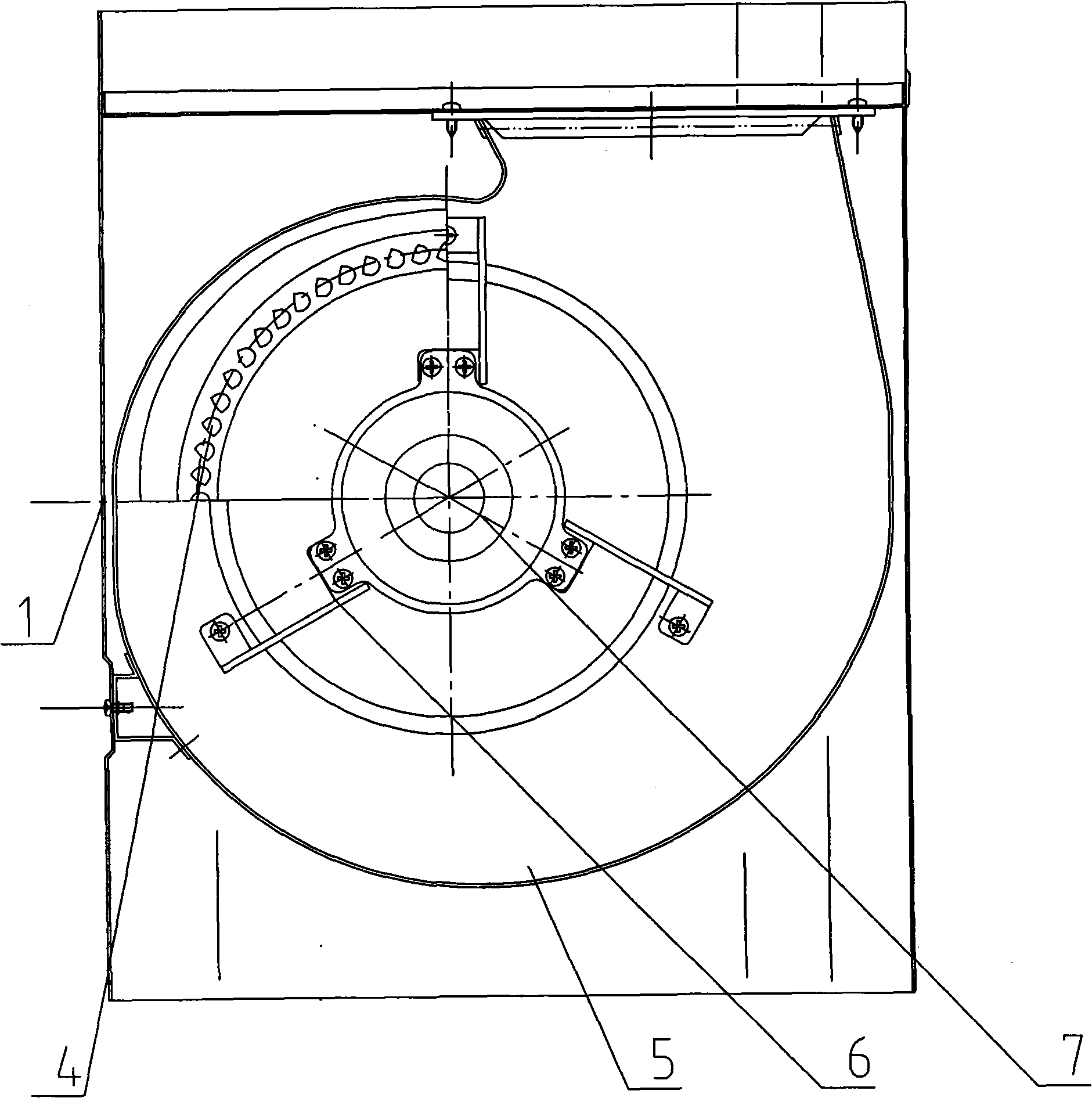

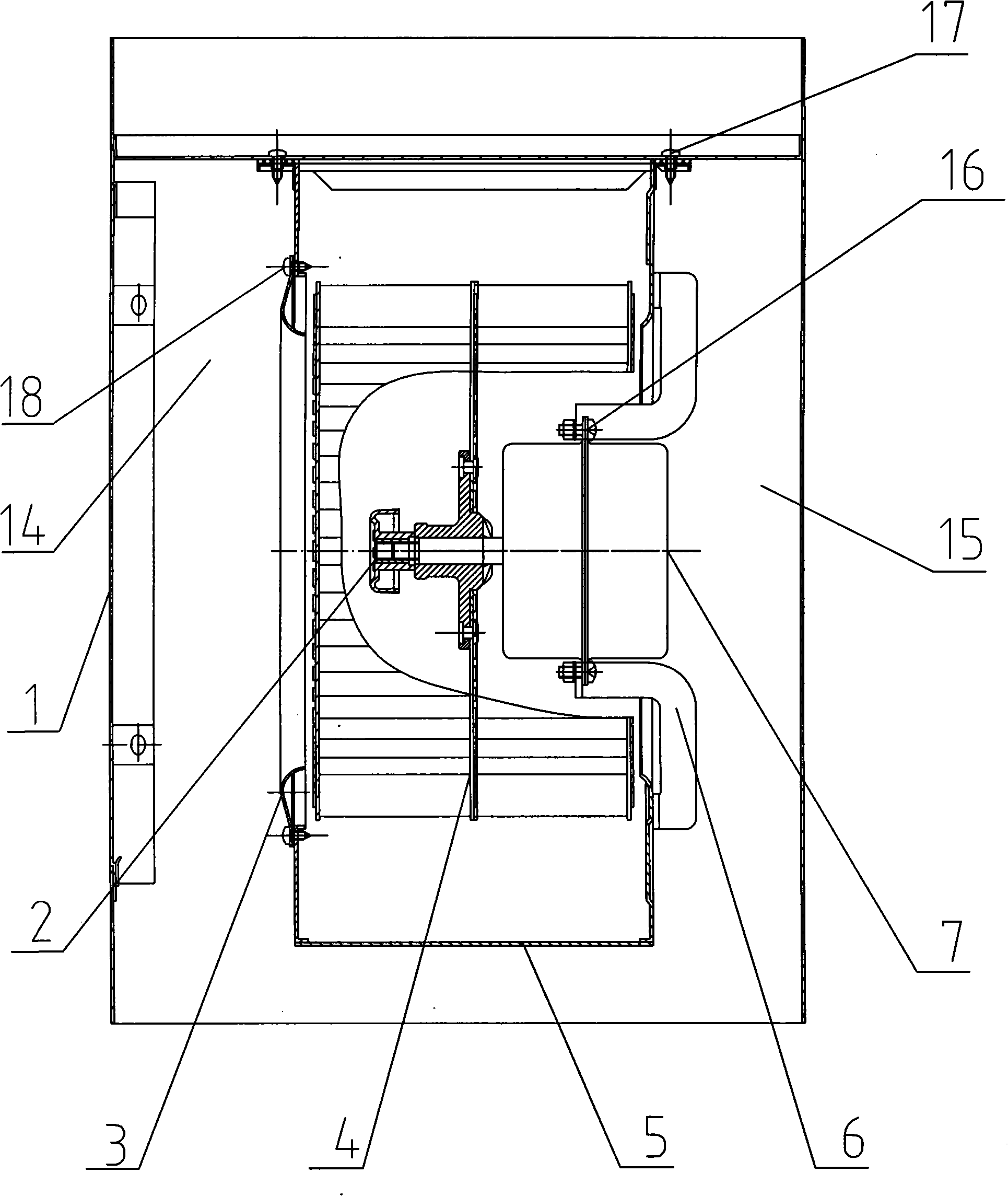

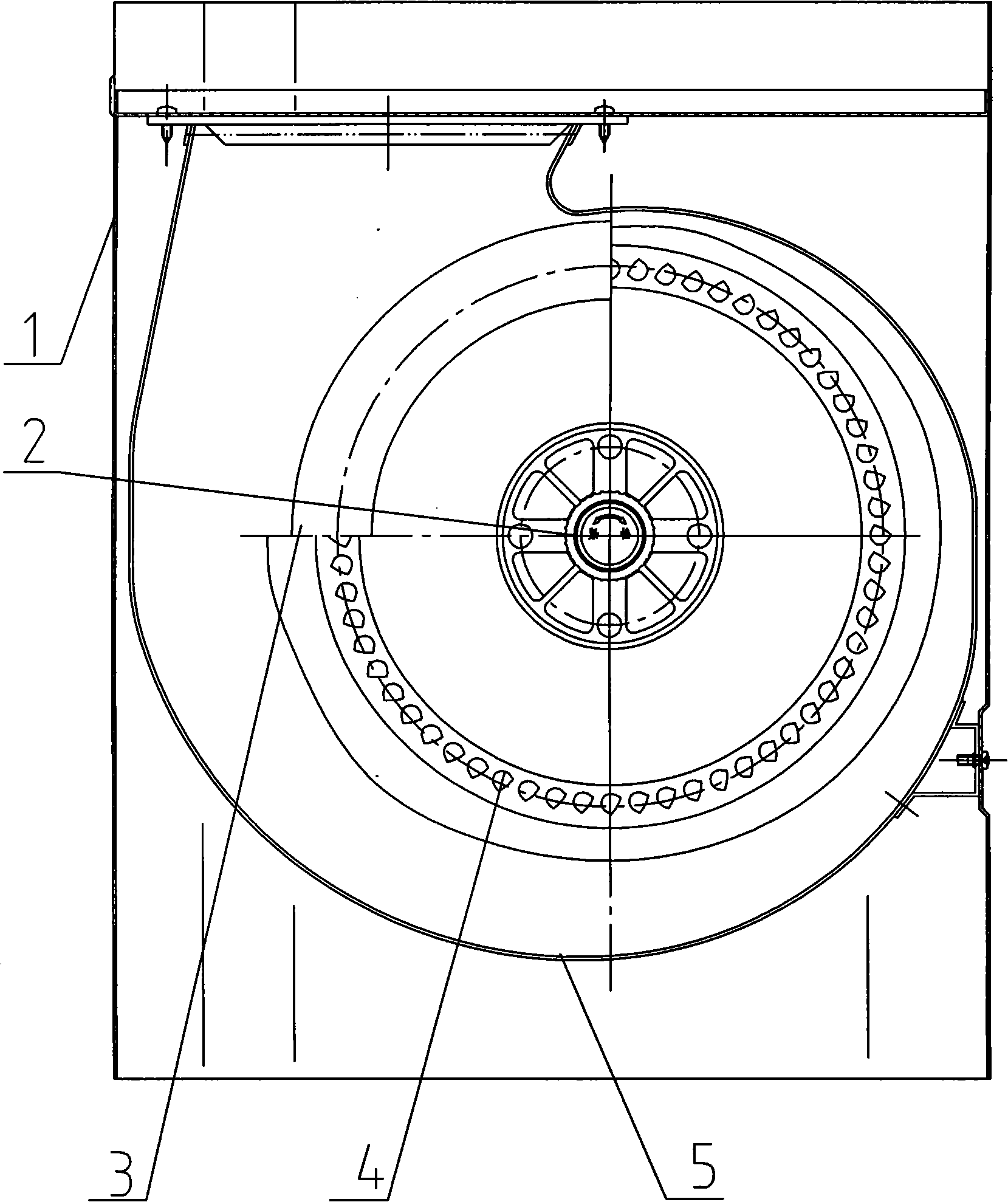

[0015] As shown in the figure, the double-sided uniform air intake fan system of this range hood includes a main engine 1, an impeller 4 and a fan 5, and the motor 7 is fixedly connected with three motor brackets 6 through first bolts 16. The motor bracket 6 Fixedly connected to the fan 5, the fan 5 is fixedly connected to the inner wall of the main engine 1 through the first screw 17, the impeller 4 is connected to the output shaft of the motor 7, and a left air inlet chamber 14 and a right inlet chamber connected to each other are formed in the main engine 1 cavity. Wind cavity15.

[0016] Concrete structure and principle are: at first motor support 6 is installed on the motor 7, then is fixed on the blower fan 5, then impeller 4 is contained on the motor 7, fixes with block cap 2 then. The fan retaining ring 3 is fixedly installed on the fan 5 by the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com