Patents

Literature

93results about How to "Good job continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Straightening device for eliminating bending and distortion of aluminum profile

ActiveCN111790775AThe force of the roller pressure increasesReduce curvatureMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

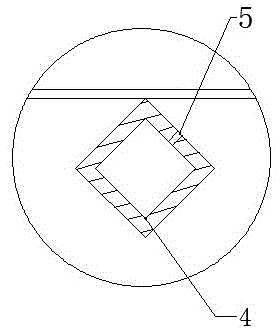

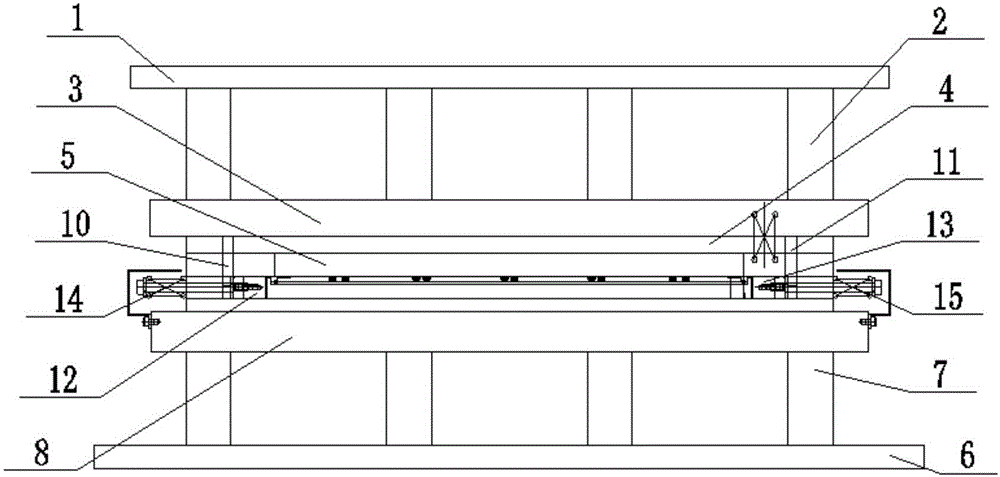

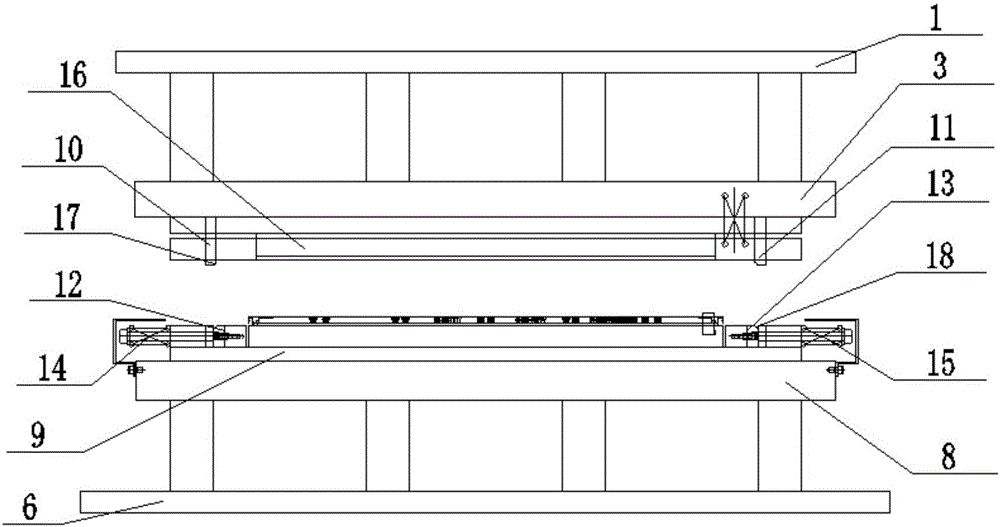

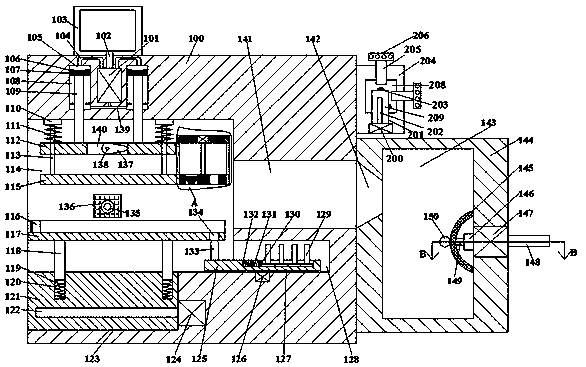

The invention discloses a straightening device for eliminating bending and distortion of an aluminum profile, relates to the related field of aluminum profile straightening, and aims to solve the problems that for an aluminum profile with large bending degree, the feeding position slips and the bending position is stressed to be prone to generating breaking cracks in an existing straightening device. A worktable top is arranged at the upper end of a worktable; a first supporting vertical plate is fixedly connected to the rear end of one side of the upper end of the worktable top; a first rectangular long groove is formed in the first supporting vertical plate; an overturning unit is arranged on one side of the front end of the first supporting vertical plate and comprises a sliding motor,a rotating screw rod and a sliding block; a rotating motor and a speed reducer are installed on one side of the middle of the sliding block, and a turntable is installed on the other side of the middle of the sliding block; an inner driving box is arranged on one side, away from the sliding block, of the turntable; rotating connecting rods are arranged at the upper end and lower end of the front end and rear end of the inner driving box; and rotating blocks are arranged on one sides, away from the inner driving box, of the rotating connecting rods.

Owner:大冶市华厦铝业有限公司

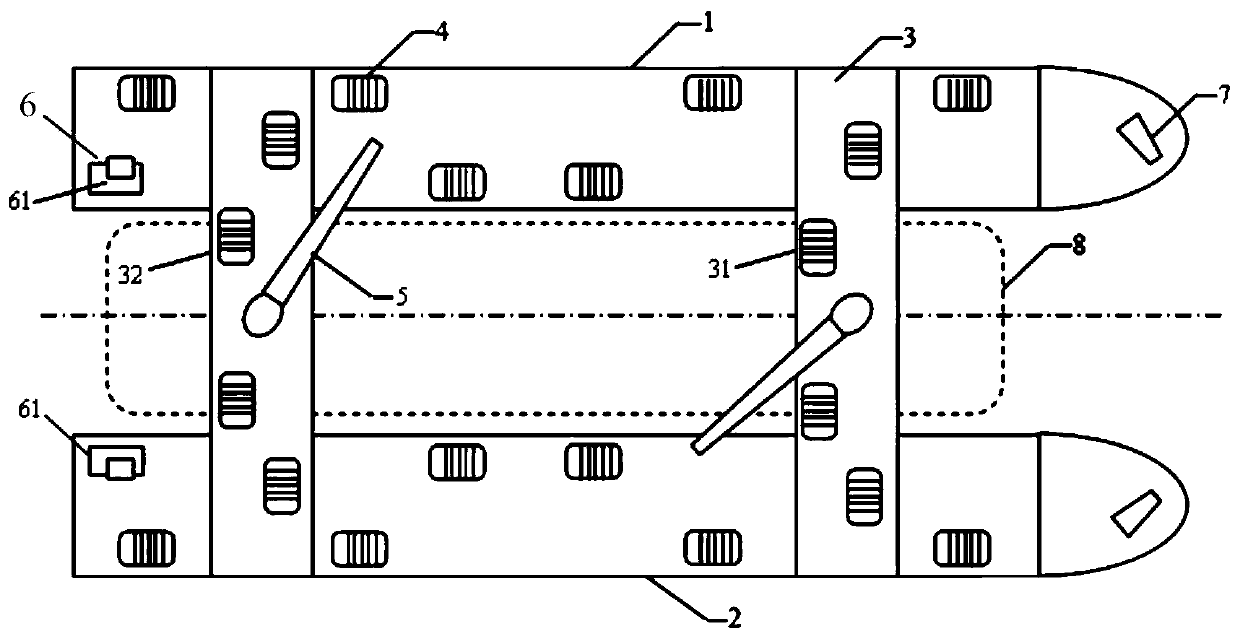

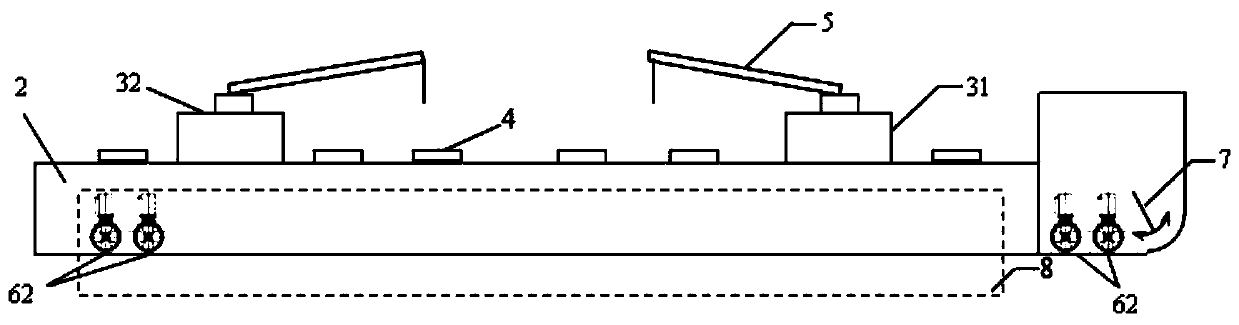

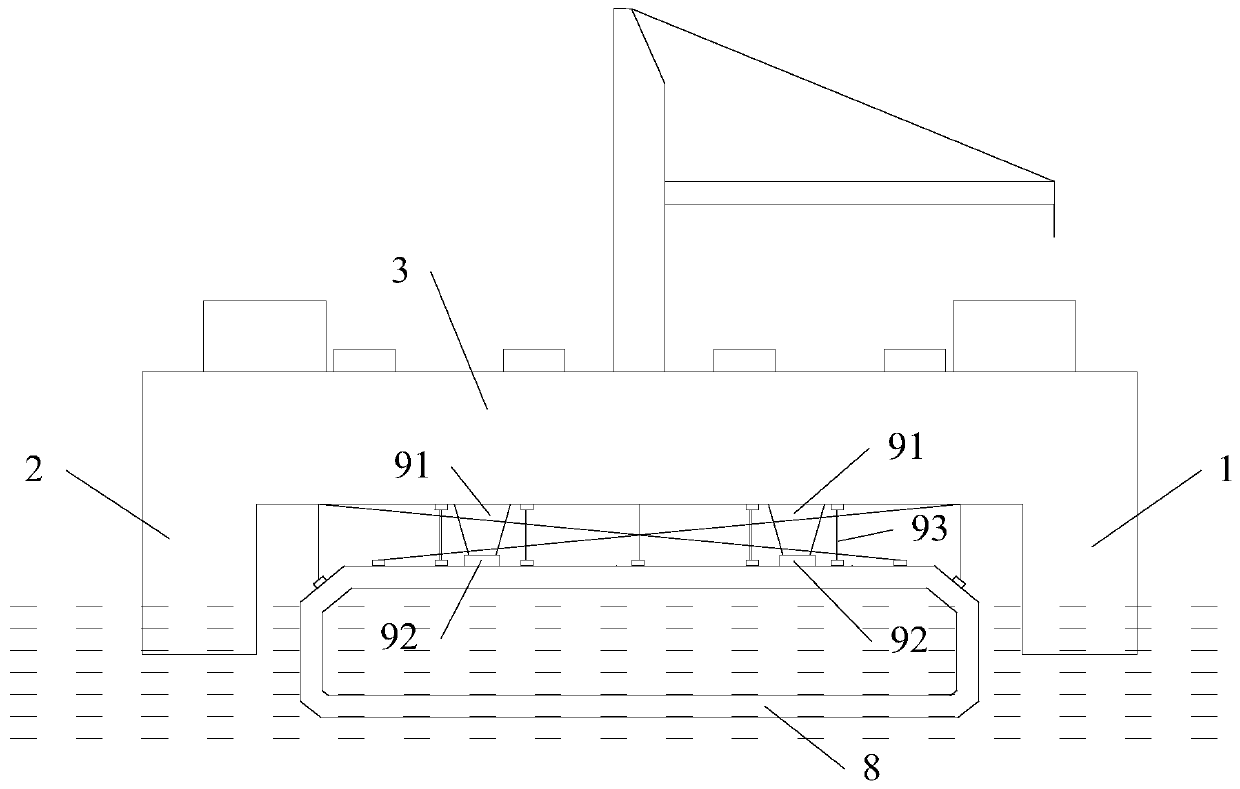

Self-propelled underwater tunnel immersed tube carrying and mounting integrated ship and construction process

InactiveCN110877666ADoes not affect trafficEasy to installArtificial islandsCargo handling apparatusBuoyant flowMechanical engineering

The invention discloses a self-propelled underwater tunnel immersed tube carrying and mounting integrated ship. The ship comprises a first ship body and a second ship body which are parallel, a connecting structure is arranged between the first ship body and the second ship body, and traction hoisting equipment arranged on the first ship body, the second ship body and the connecting structure. A carrying space is formed between the first ship body and the second ship body below the connecting structure, a component to be installed is arranged in the carrying space and connected with the ship bodies, and a propelling power device and a power positioning system are arranged on the first ship body and the second ship body. The lower portion of the integrated ship is provided with the carryingspace. Goods to be transported are placed in the carrying space and float in water. Most weight of goods is shared by buoyancy. The goods are transported to the designated position, and precise installation work is completed. Underwater tunnel immersed tubes or similar large components of various sizes can be independently transported and installed through one self-propelled ship body successfully, other ships do not need to be used for dragging, channels do not need to be sealed for other ships in the transportation process, and passing of other ships is not affected.

Owner:CCCC FIRST HARBOR ENG

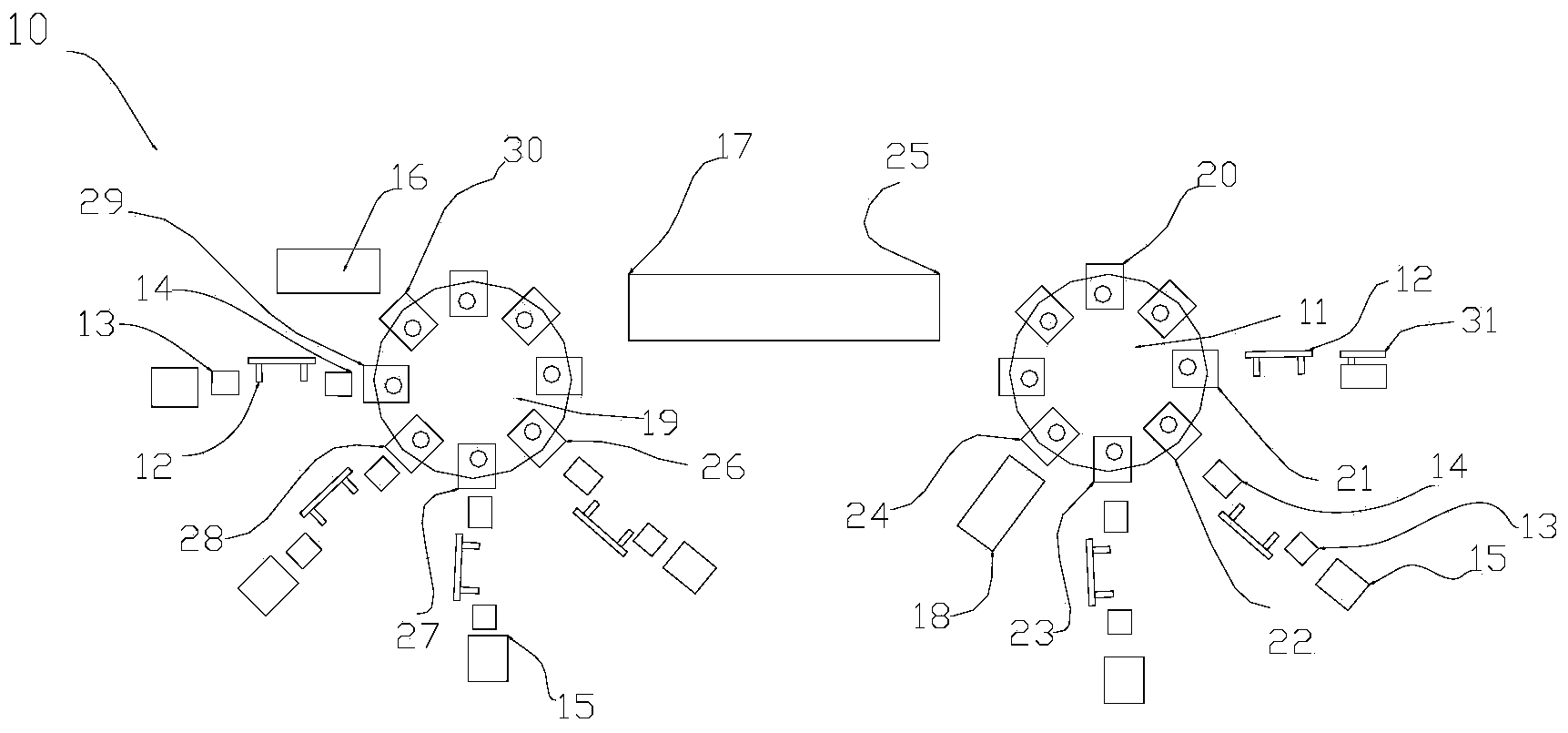

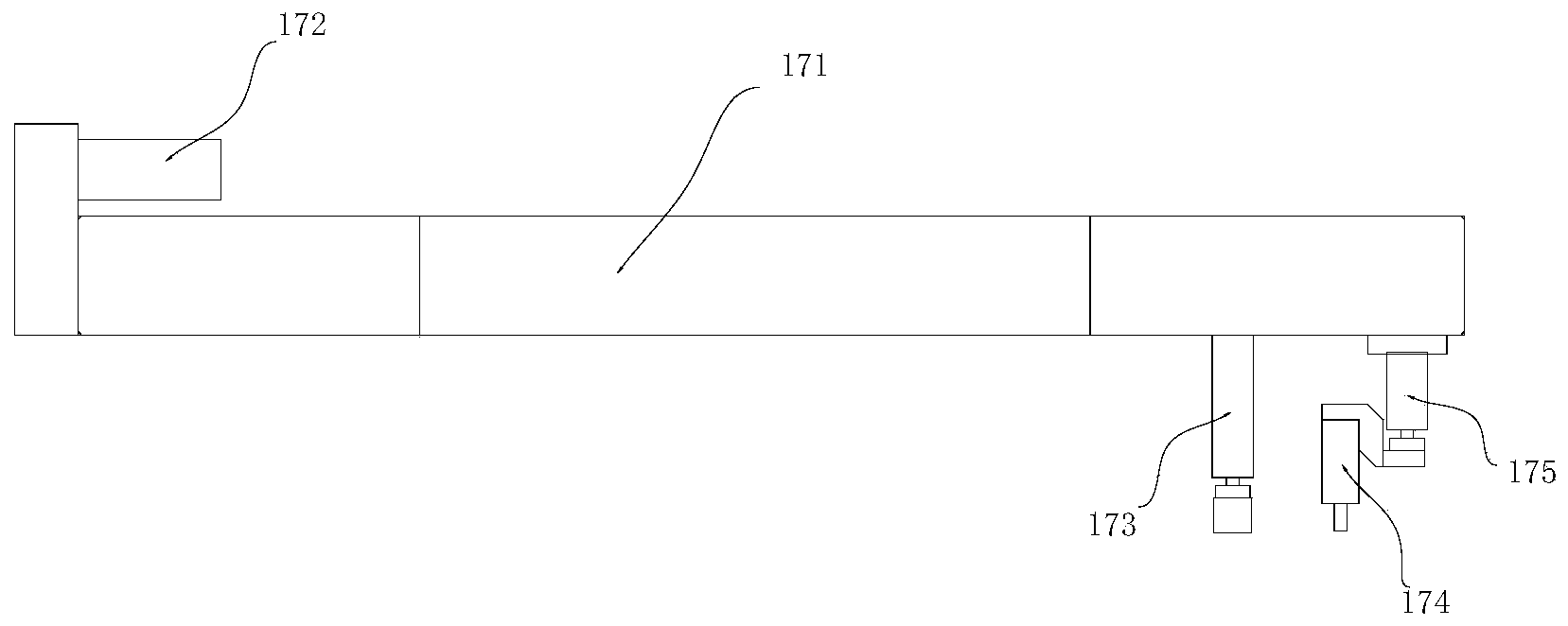

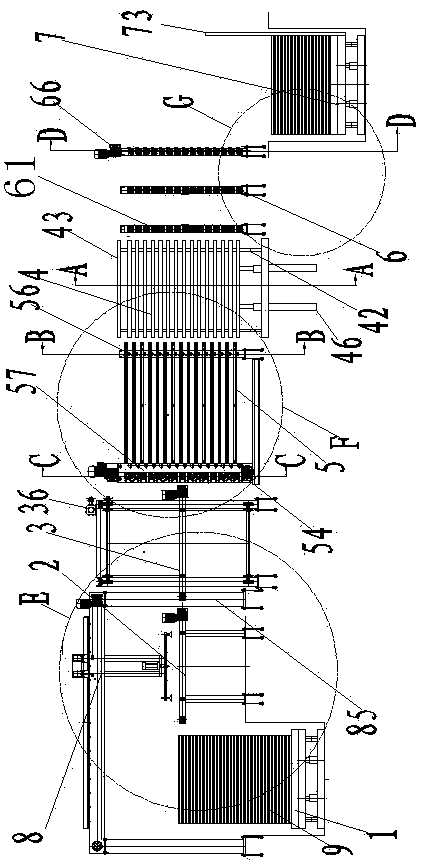

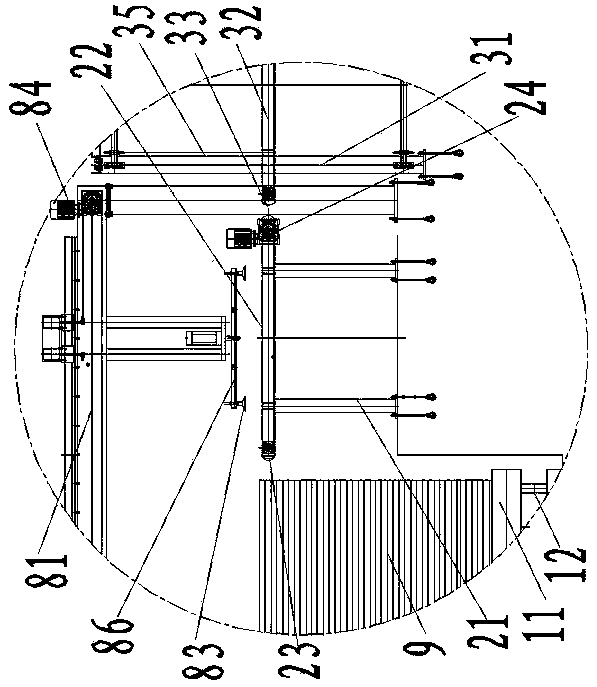

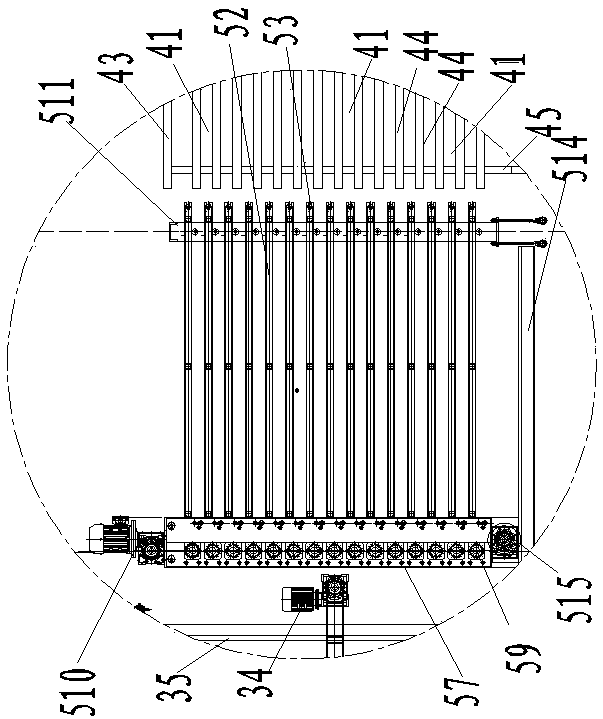

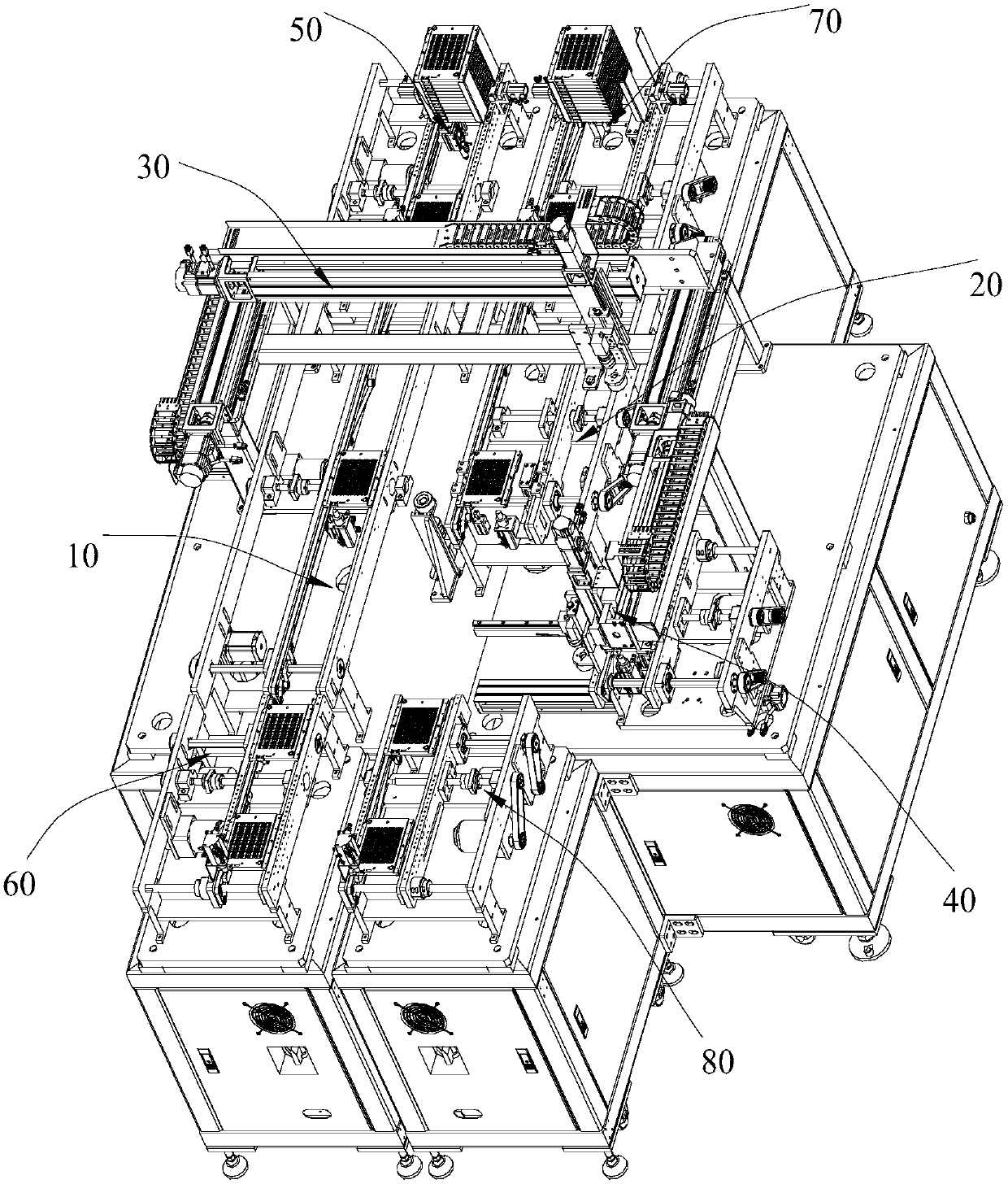

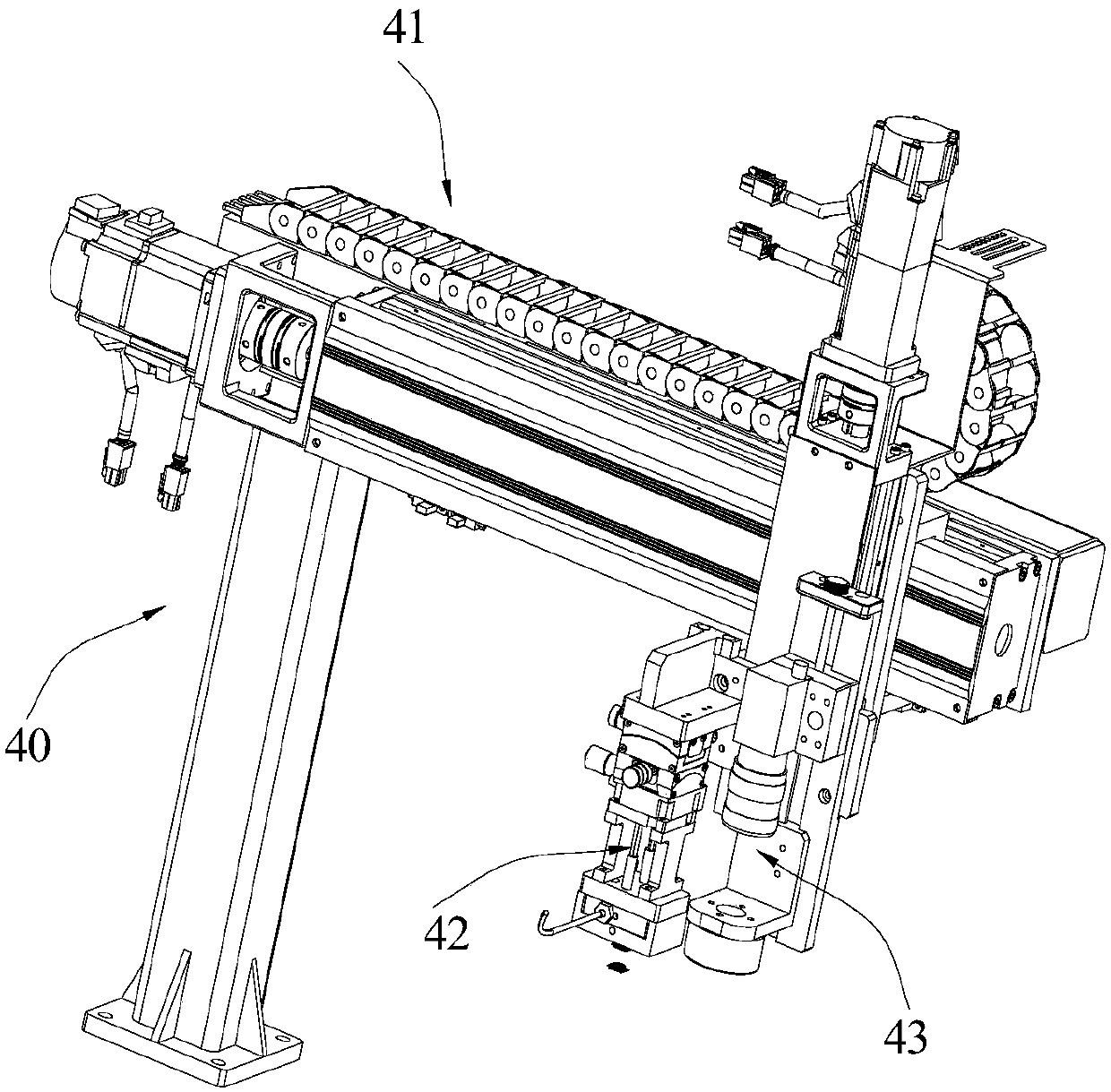

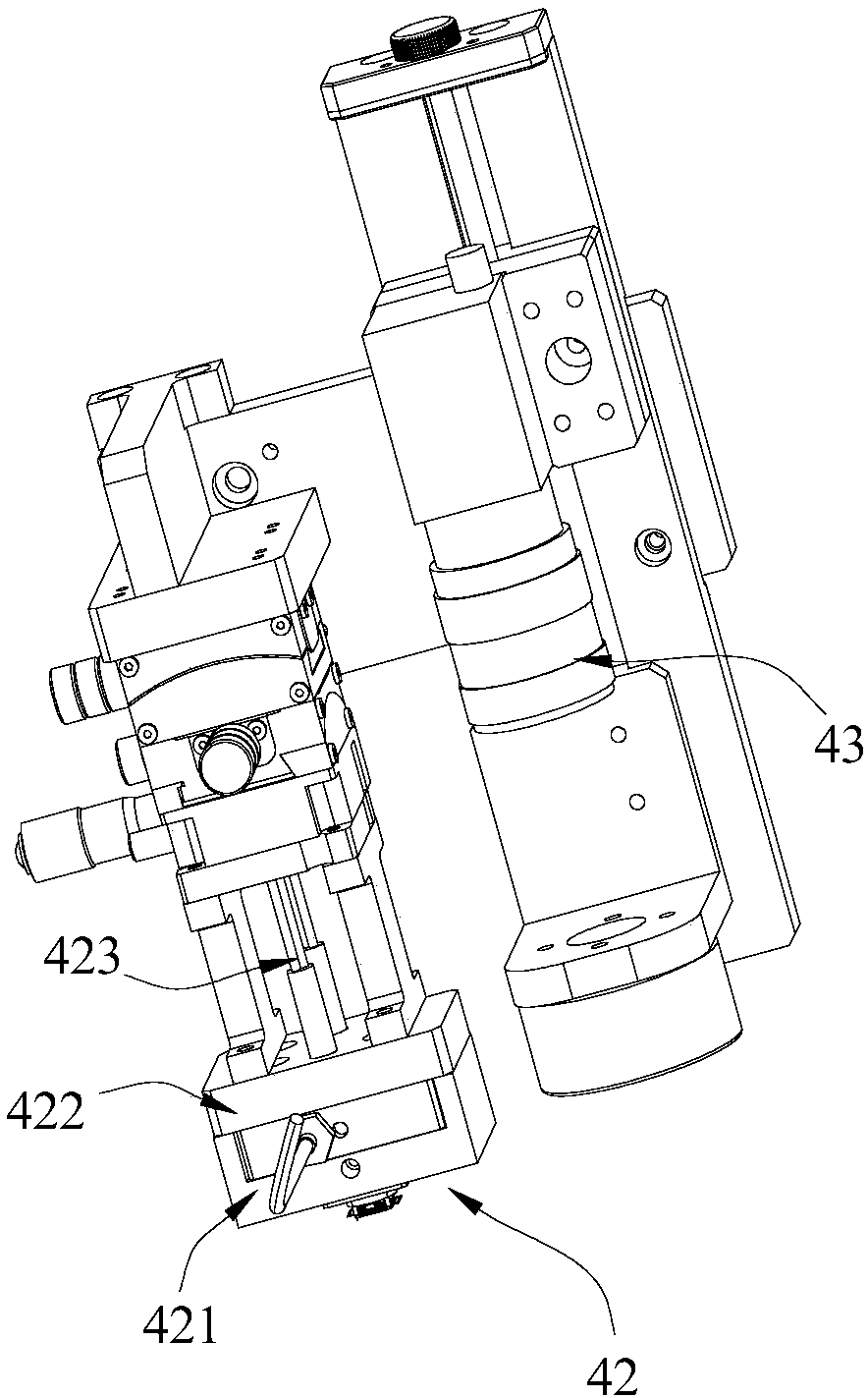

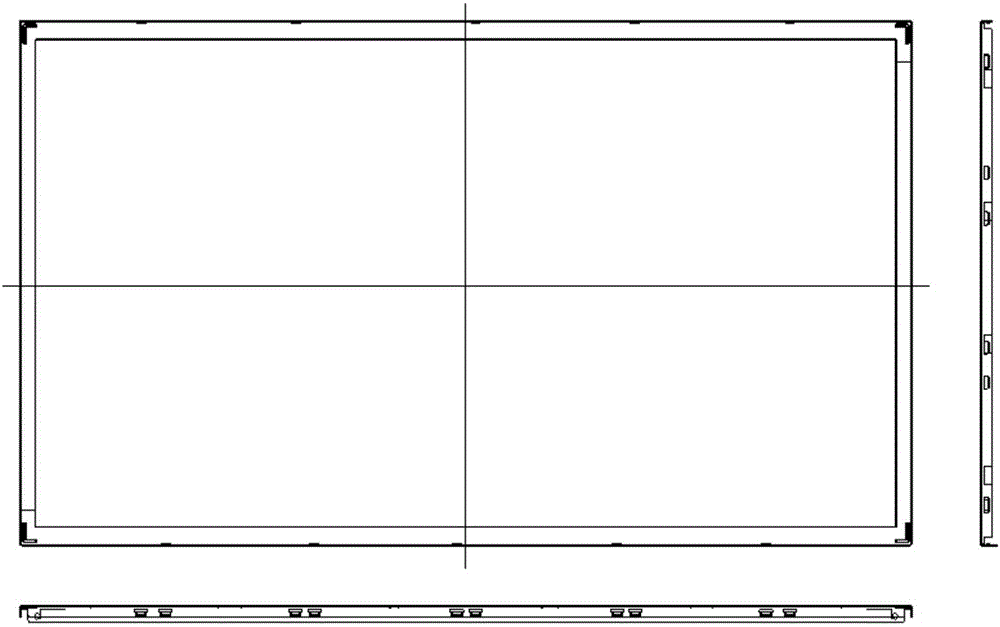

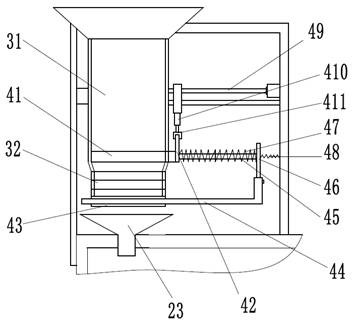

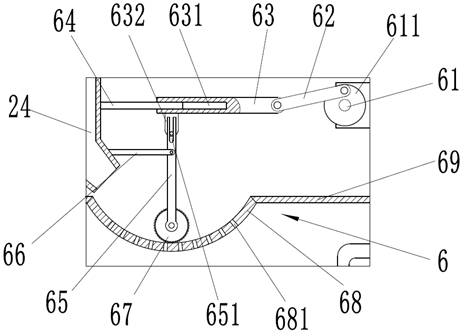

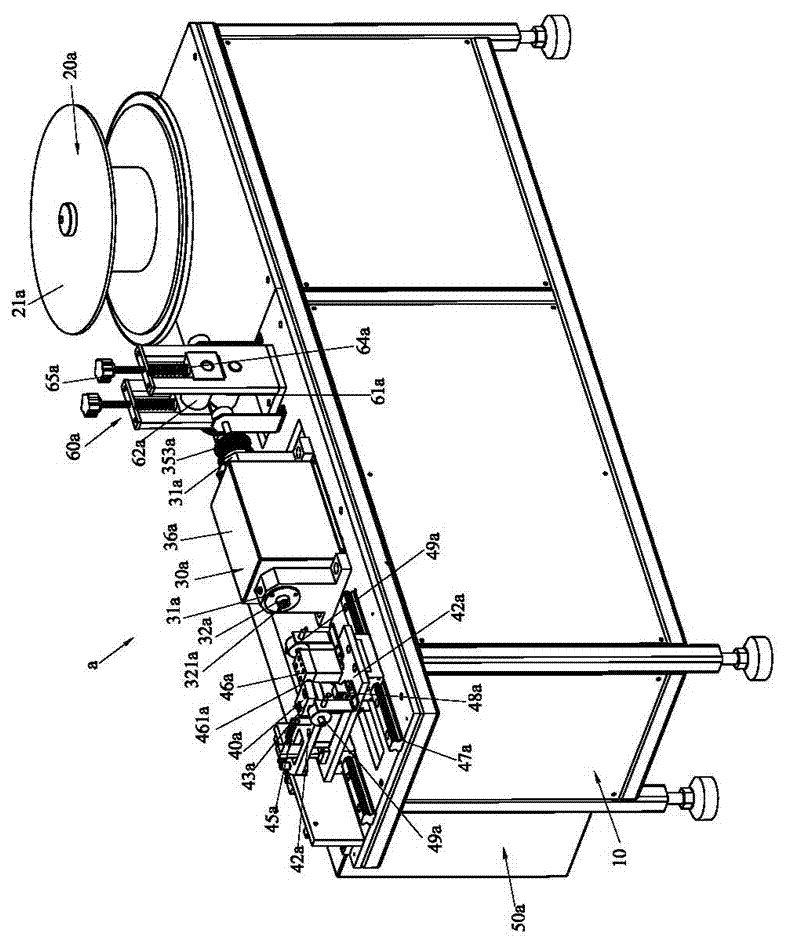

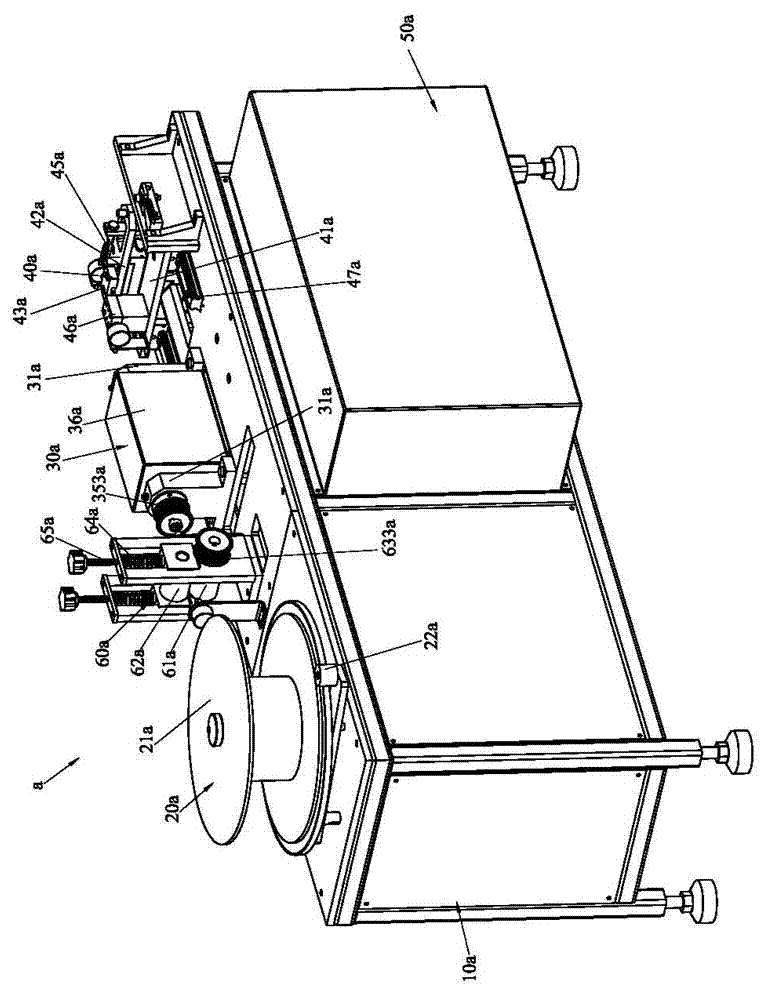

Backlight integrally assembled equipment

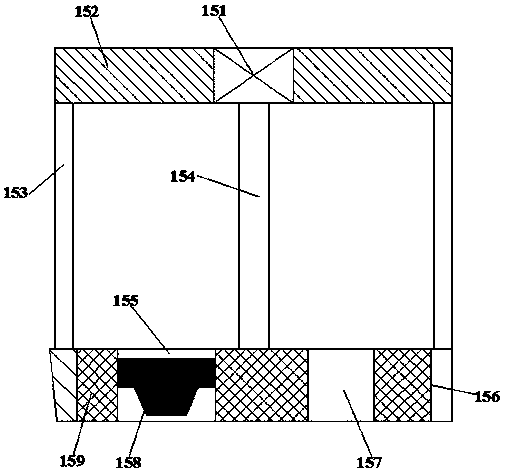

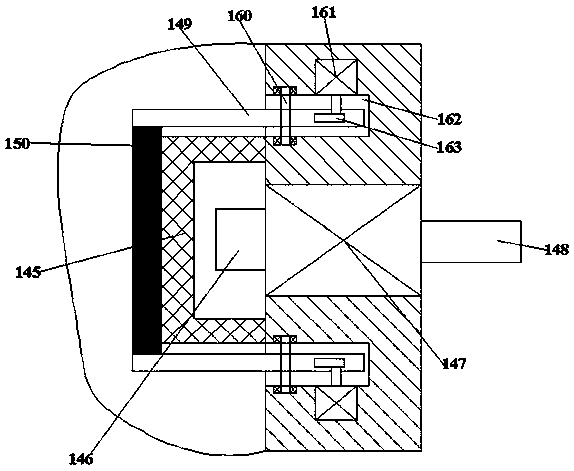

ActiveCN104354440AHigh precisionImprove the film effectLamination ancillary operationsLaminationLight guideEngineering

The invention discloses backlight integrally assembled equipment. The equipment comprises a first rotary work table, a second rotary work table, an FPC (flexible printed circuit) manual laying position, an automatic reversing glue frame position, a reflecting film pasting position, a light guide plate pasting position, an FPC assembly position, a diffusion barrier pasting position, a light enhancement film 1 pasting position, a light enhancement film 2 pasting position, a light shading film pasting position, a compressing discharge position and a connecting position, wherein the reflecting film pasting position, the light guide plate pasting position, the diffusion barrier pasting position, the light enhancement film 1 pasting position, the light enhancement film 2 pasting position and the light shading film pasting position respectively comprise a feeding mechanism, a stripping mechanism corresponding to the feeding mechanism, a pre-alignment mechanism, an alignment mechanism and a grabbing mechanism. The equipment is high in accuracy, saves material, has a good film pasting effect andhigh operating continuity, saves manpower and is fully automatically operated during backlight assembly, and positions of the two rotary work tables can be operated in a combined manner or the position of a single rotary work table can be operated.

Owner:SHENZHEN WEIHONGKE TECH

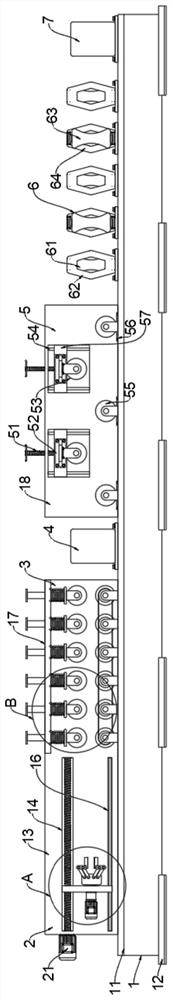

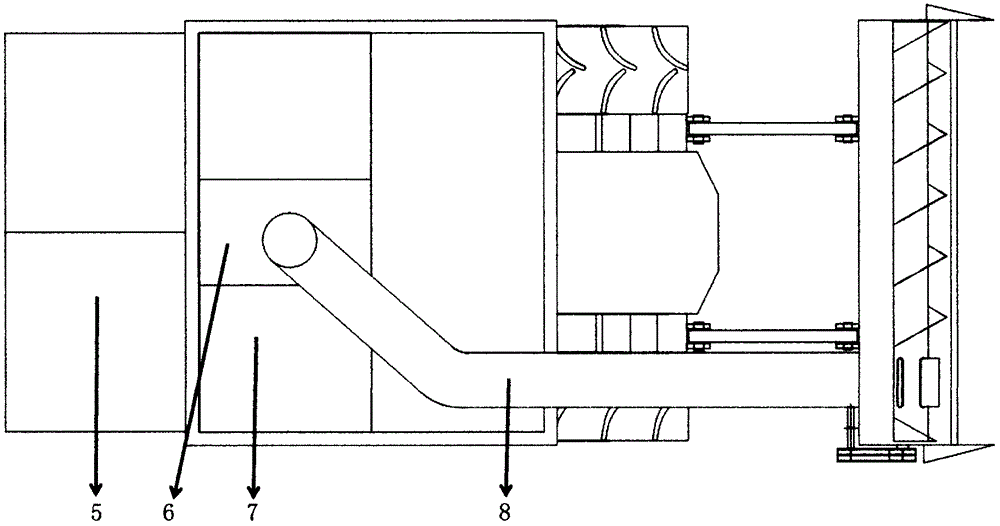

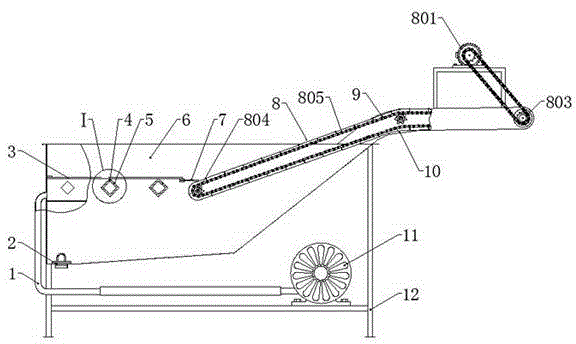

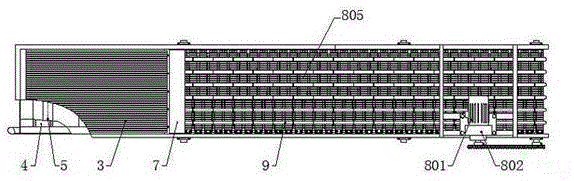

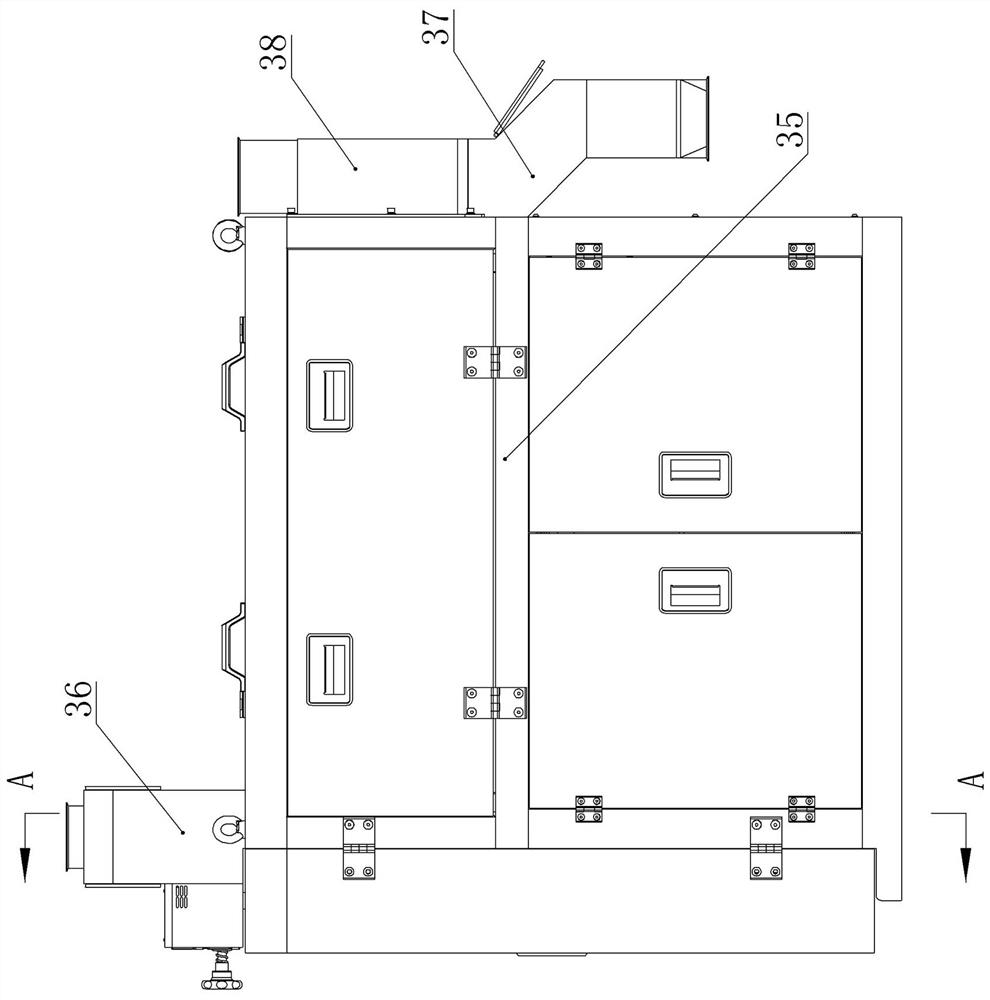

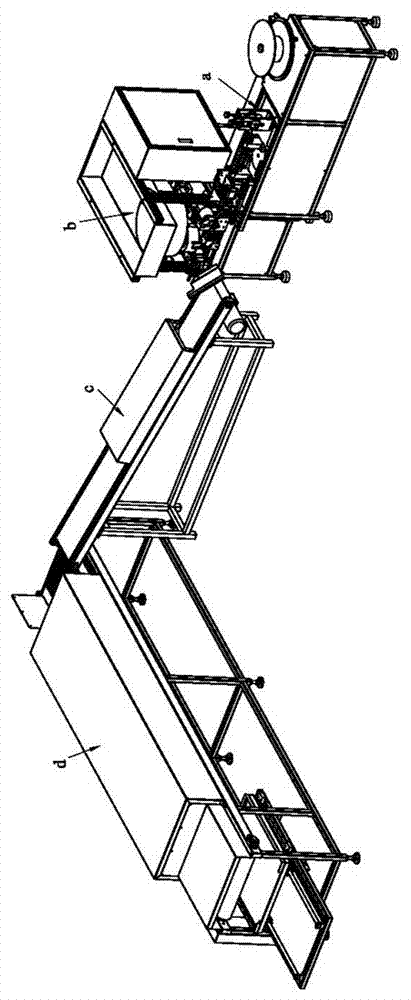

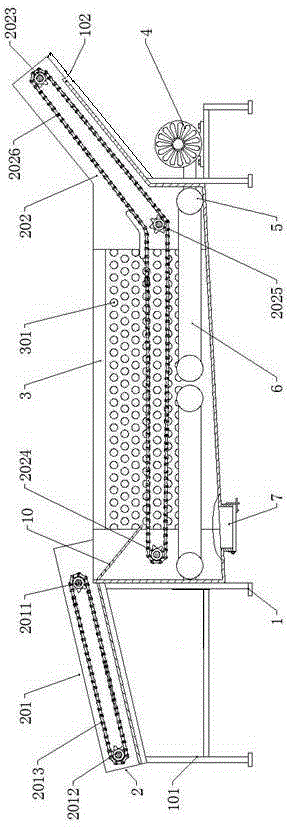

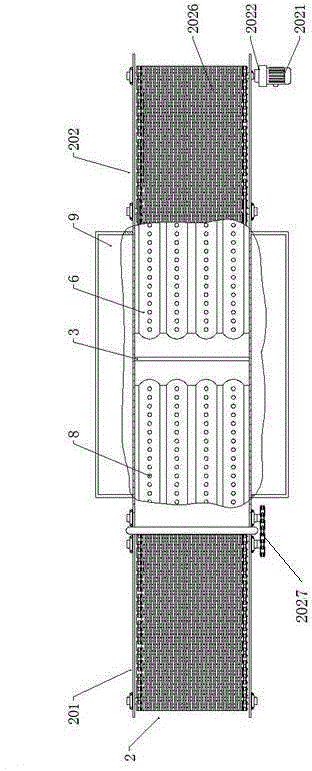

Full-automatic hot-pressing membrane laminating assembly line for plywood and hot-pressing membrane laminating method thereof

PendingCN110466163ANot easy to wrinkleEnsure safetyWood veneer joiningFlat articlesAssembly lineEngineering

The invention discloses a full-automatic hot-pressing membrane laminating assembly line for plywood and a hot-pressing membrane laminating method thereof. The full-automatic hot-pressing membrane laminating assembly line comprises a sticking membrane conveying device, a lifting conveyor, a plate loading machine, a hot pressing machine, a cooling stand and a plate receiving device which are arranged in sequence, and an adsorption device for feeding materials to the sticking membrane conveying device, wherein third plywood horizontal conveyor belt frames are vertically arranged on the plate loading machine, the number of the third plywood horizontal conveyor belt frames is the same as the number of hot pressing cavities of the hot pressing machine, and the positions of the third plywood horizontal conveyor belt frames correspond to the heights of the hot pressing cavities of the hot pressing machine; fourth plywood horizontal conveying devices are vertically arranged on the cooling stand, the number of the fourth plywood horizontal conveying devices is the same as the number of the hot pressing cavities of the hot pressing machine, and the positions of the top surfaces of the fourthplywood horizontal conveying devices correspond to the heights of the hot pressing cavities of the hot pressing machine; third conveyor belts are arranged on the third plywood horizontal conveyor beltframes; and the end, far away from the hot pressing machine, of each third plywood horizontal conveyor belt frame is connected to a horizontal travelling mechanism. The automatic hot-pressing membrane laminating assembly line for plywood has the advantages of good hot pressing membrane laminating effect and high automation degree.

Owner:山东金如意木业集团股份有限公司

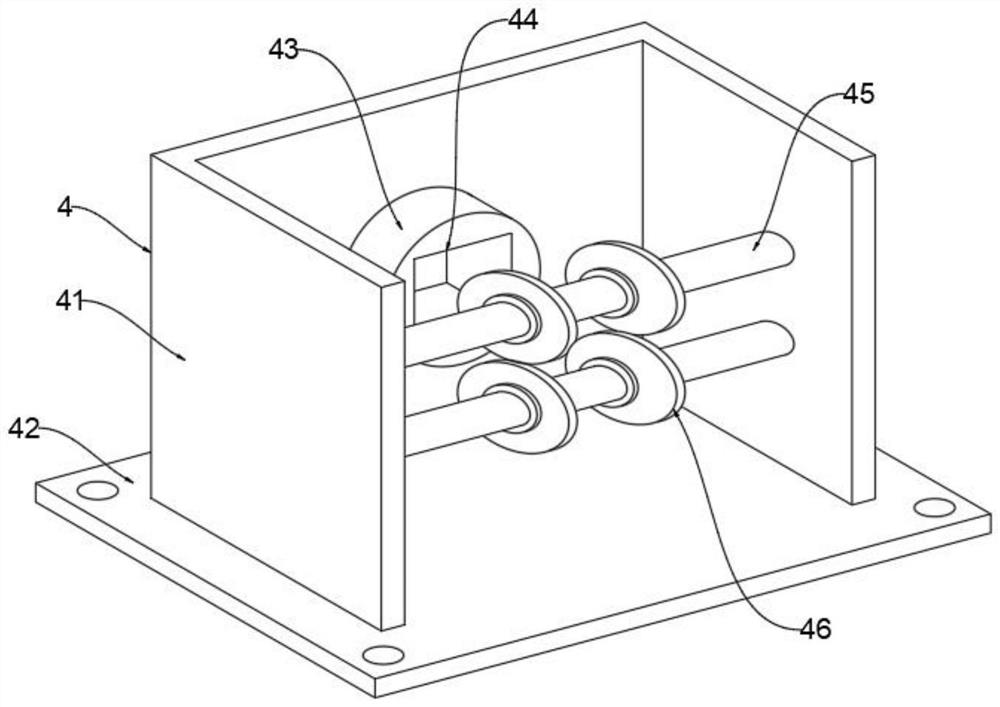

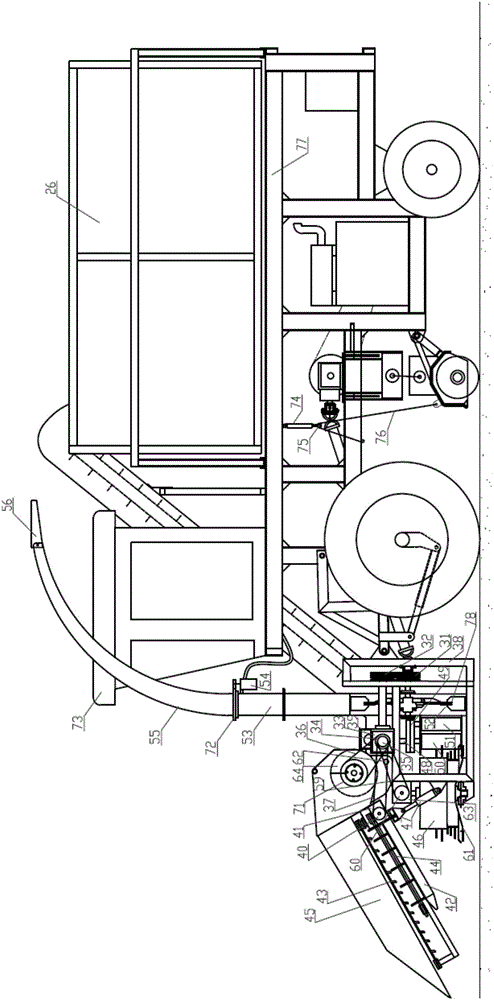

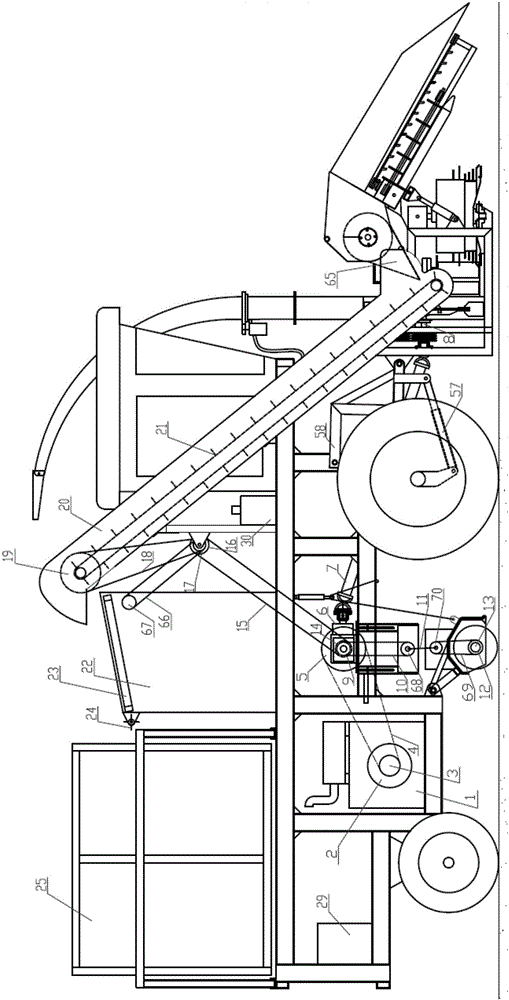

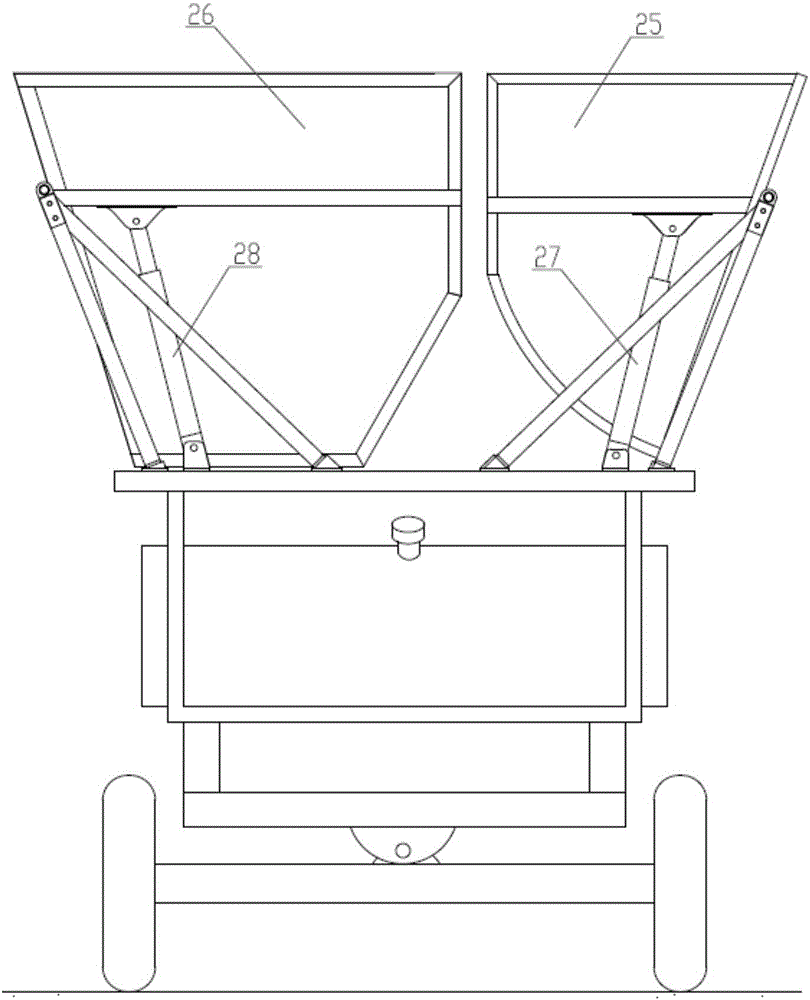

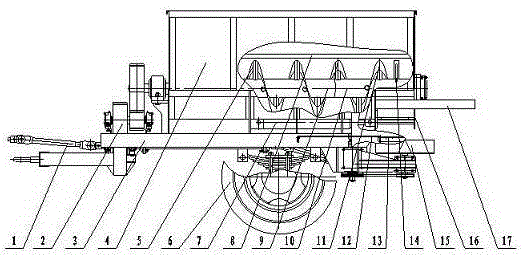

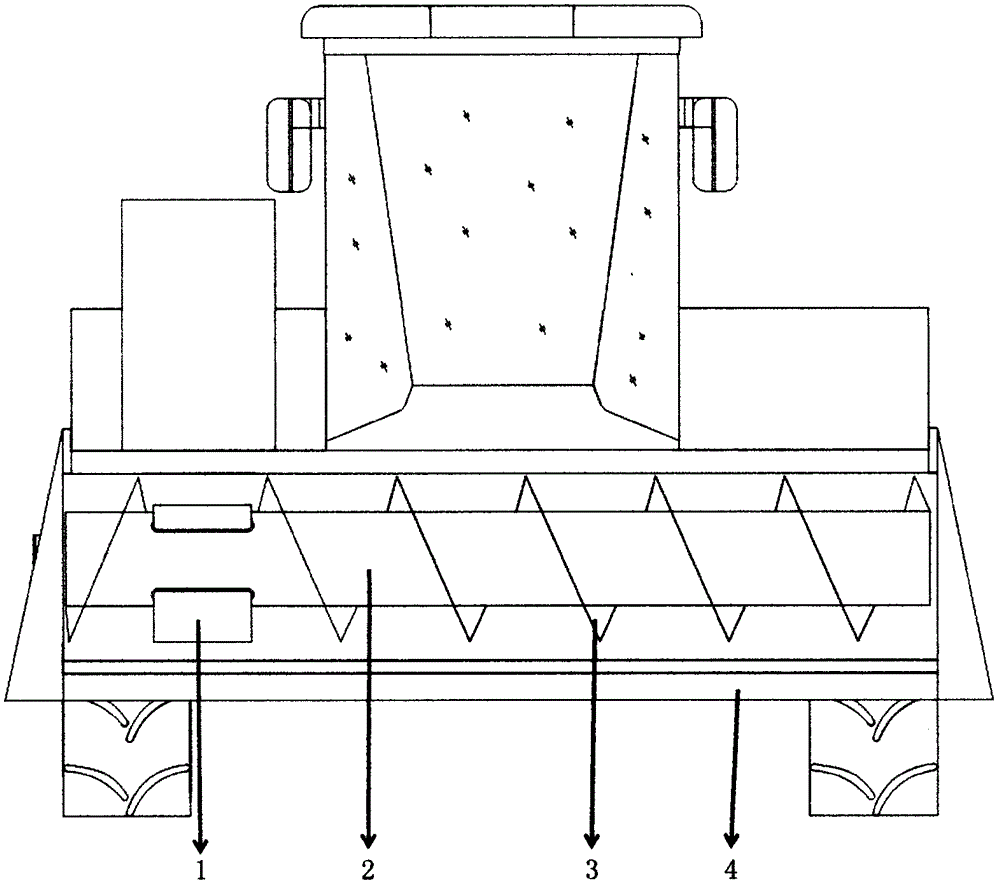

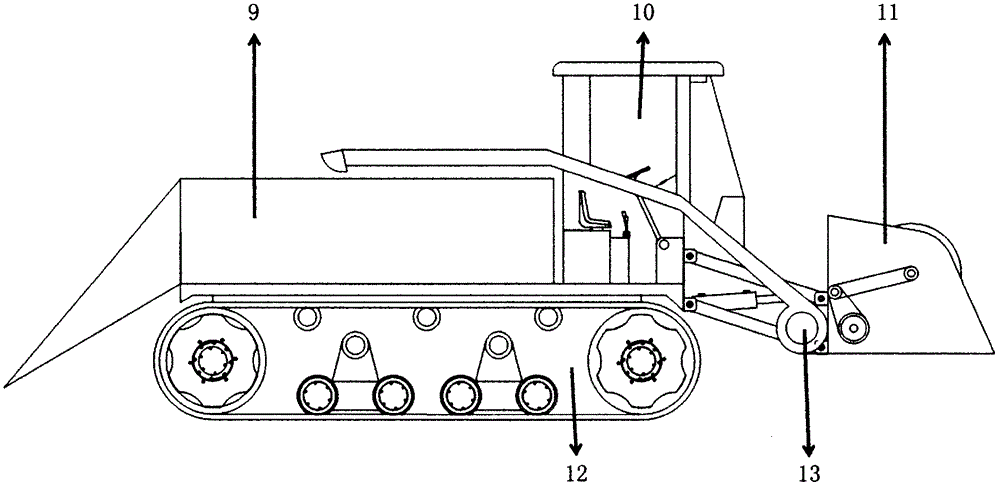

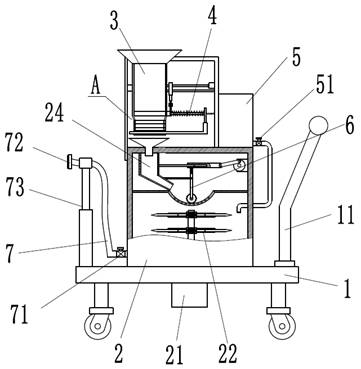

Silage whole-plant harvest and silage ear stem harvest inclusive type corn machine

The invention relates to core harvest, in particular to a silage whole-plant harvest and silage ear stem harvest inclusive type corn machine. A roller power gearbox is connected with two straw feeding rollers and a roller bottom cutter disc respectively, the bottom of a straw feeding system power gearbox is in power connection with a straw feeding system speed change gearbox, the system speed change gearbox is connected with plate-tooth rollers and prepressing rollers, the plate-tooth rollers are located in the rear of the straw feeding rollers, the prepressing rollers are located in the rear of the plate-tooth rollers, a cutting-table hay cutter is located in the rear of the plate-tooth rollers, a cutter disc impeller is located in the cutting-table hay cutter, the gap ranging from 300mm to 400mm is formed between the neighboring straw feeding rollers right above the cutting-table hay cutter of a tossing system, the gap ranging from 20mm to 30mm is formed between the two neighboring plate-tooth rollers, and the gap ranging from 15mm to 120mm is formed between the two neighboring preprocessing rollers. Silage whole-plant harvest and silage ear stem harvest are included into one harvester, fund for purchasing the harvester is saved for users, operating cycle can be greatly prolonged, and diversified harvest of corn is realized.

Owner:QINGDAO LONGSHUO FARMING MACHINERY MFG

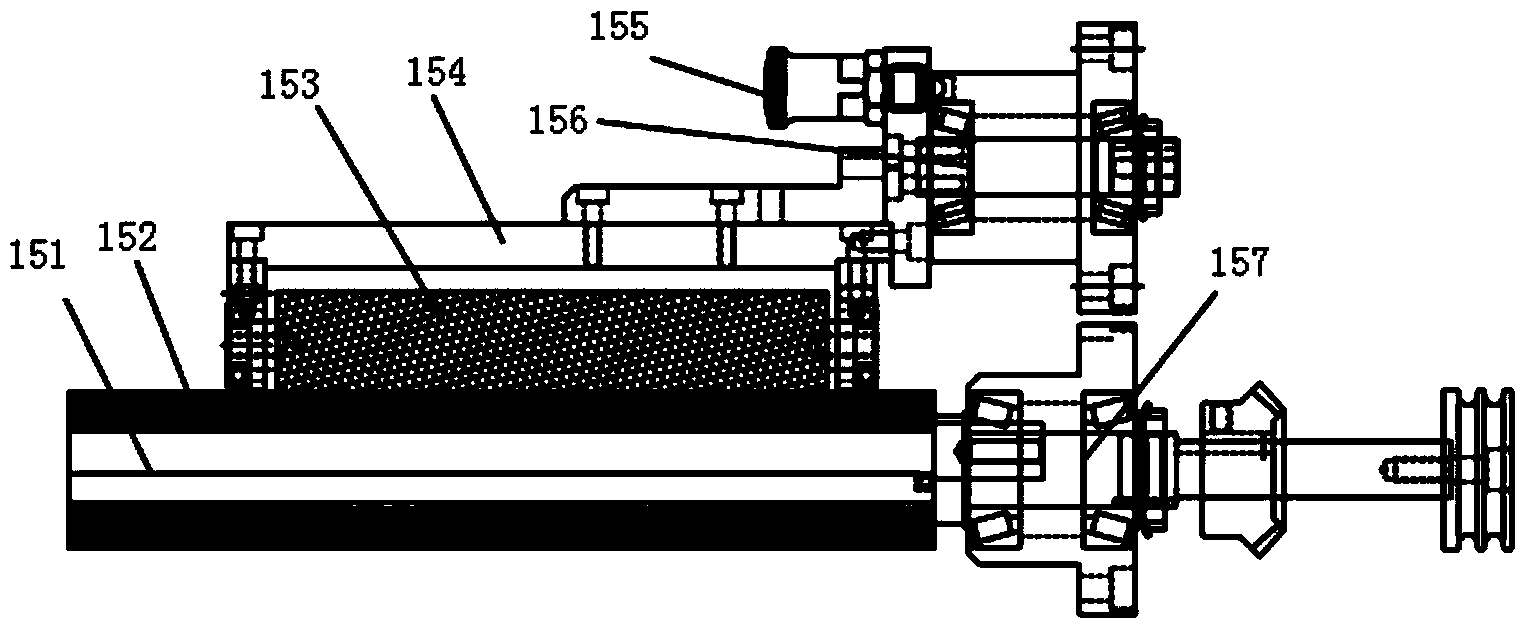

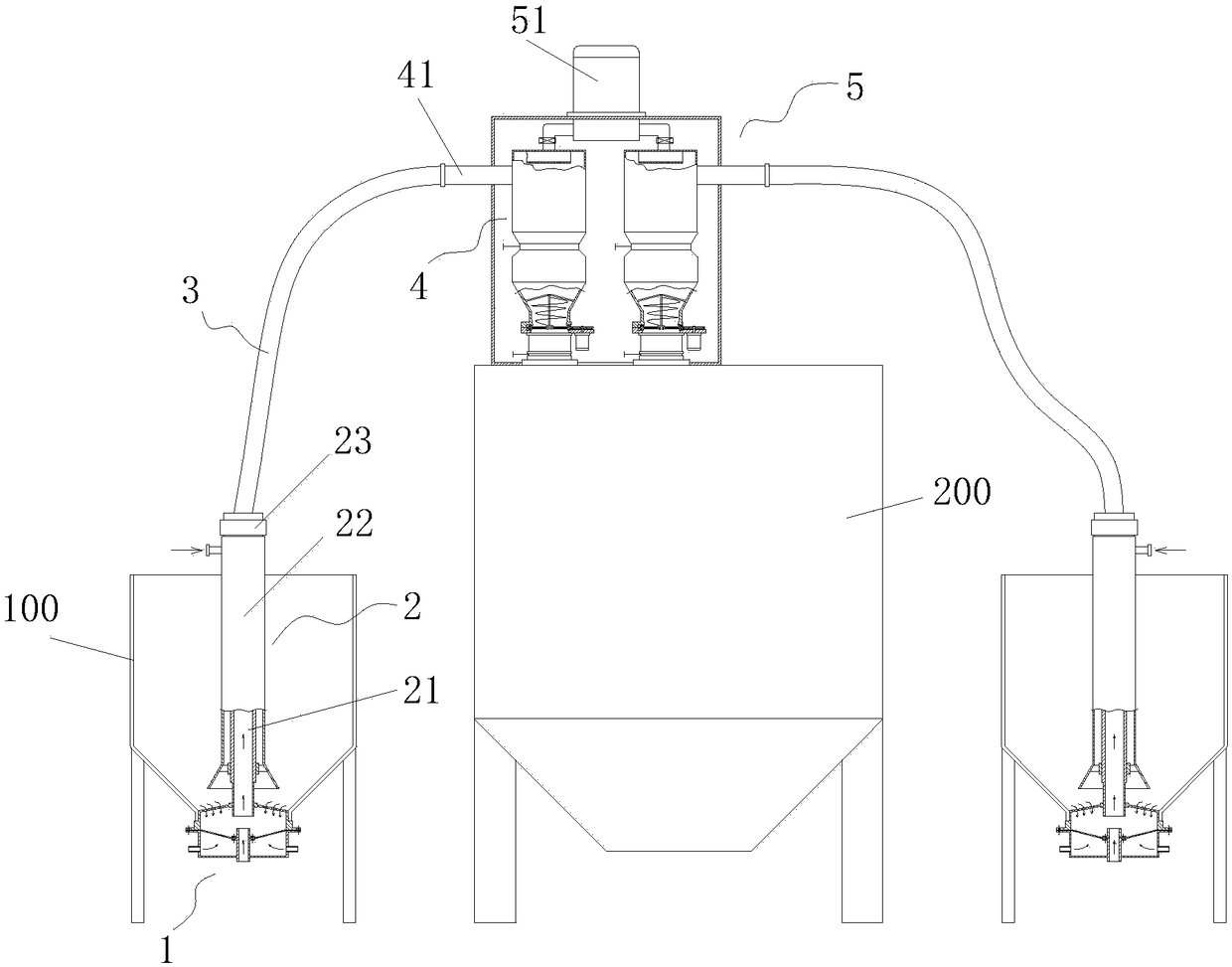

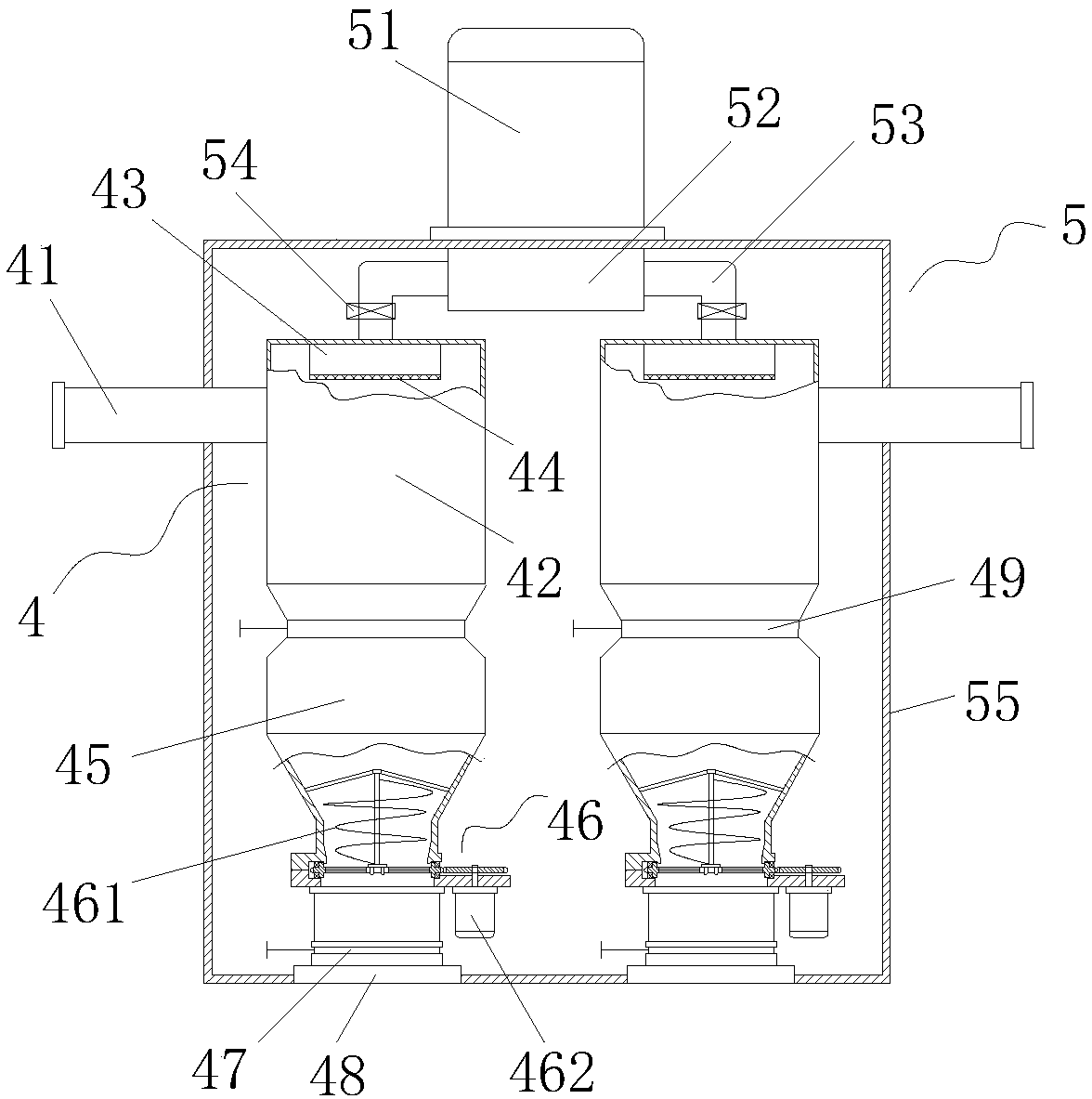

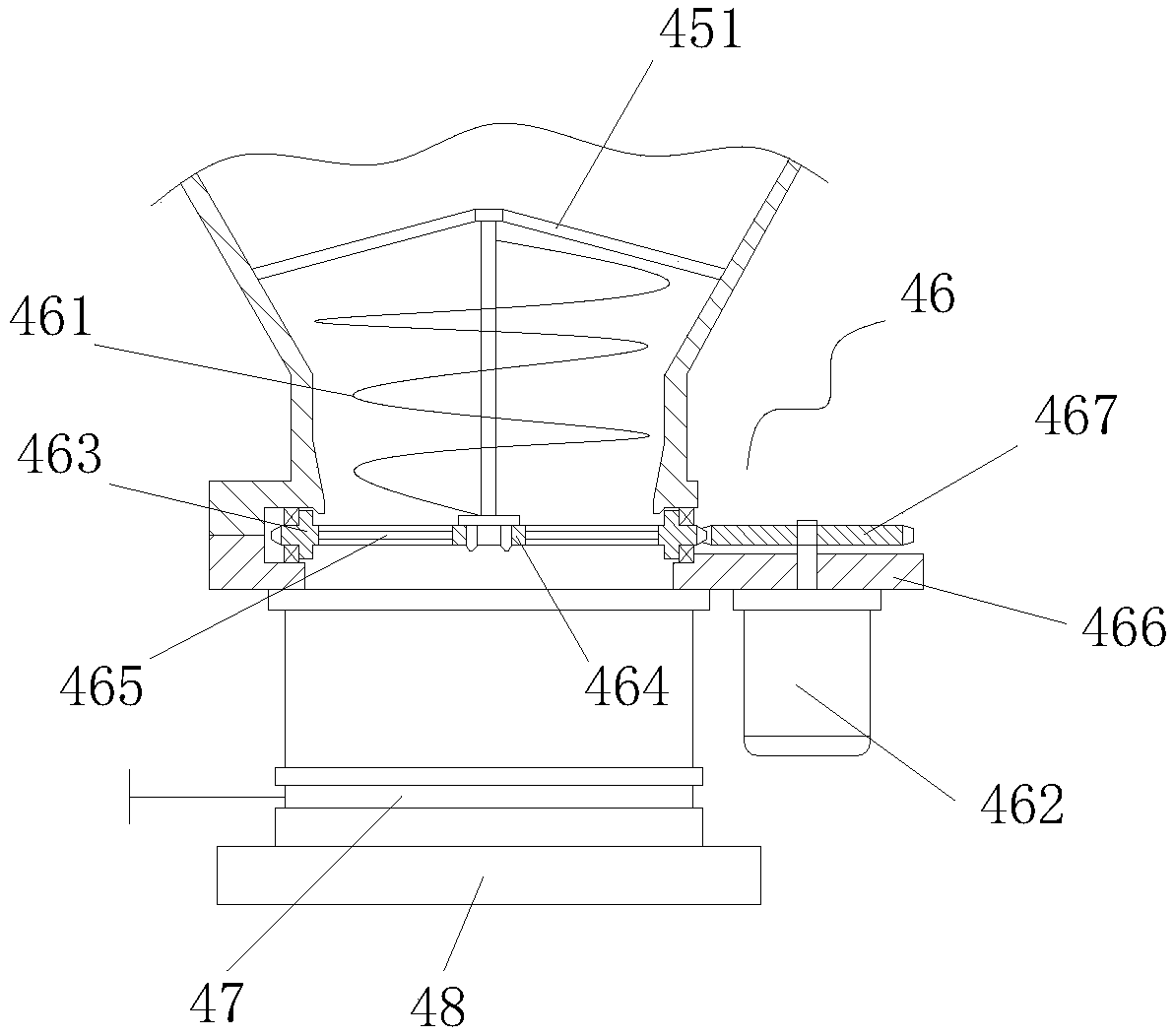

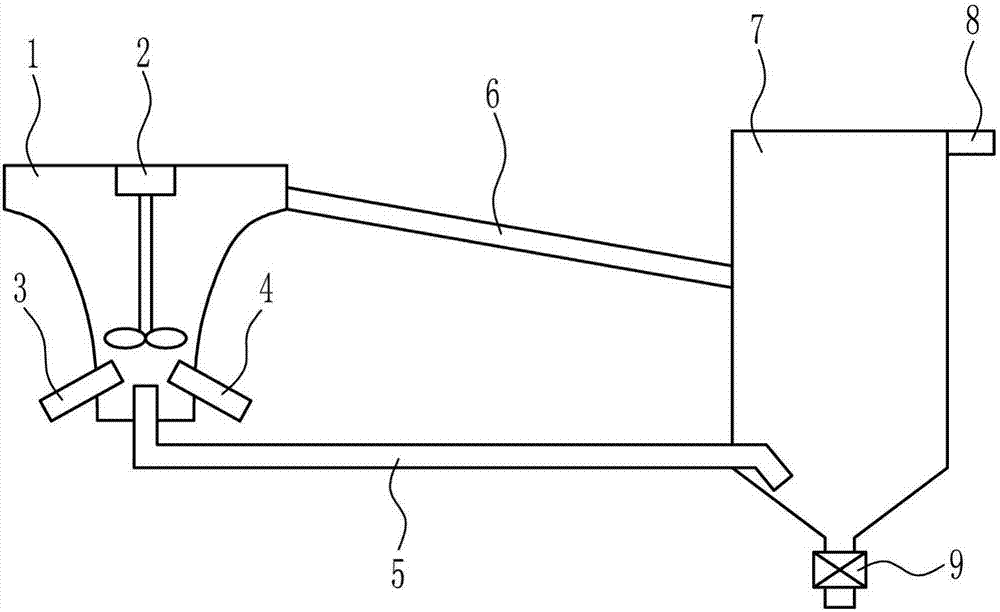

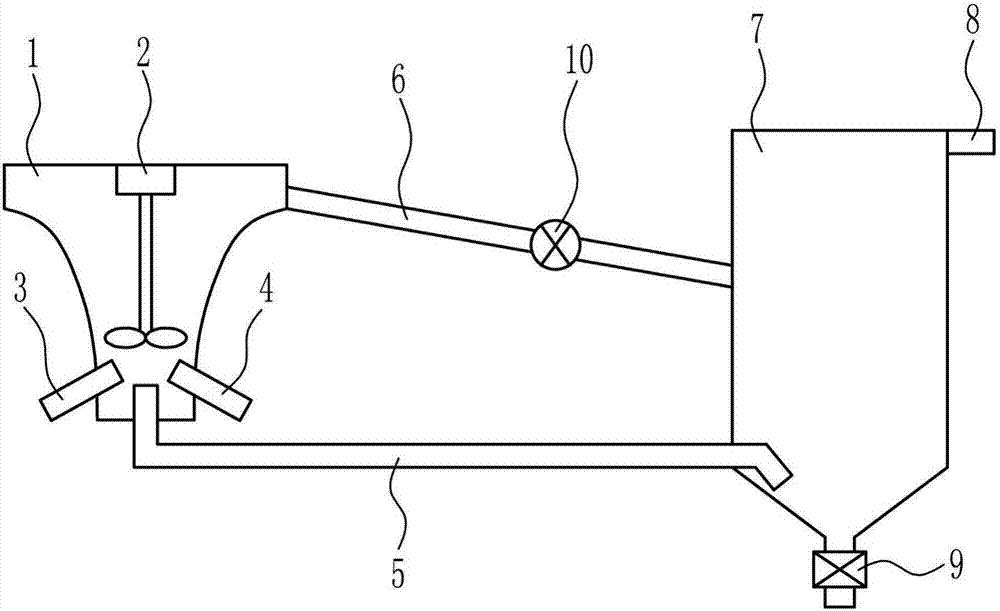

General multi-channel powder granule sucking device

The invention discloses a general multi-channel powder granule sucking device. The general multi-channel powder granule sucking device comprises at least two sets of sucking nozzle mechanisms, a conveying hose and a discharging mechanism installed on the top of a stirring barrel; each set of sucking nozzle mechanism is detachably installed at a discharging opening in the bottom of a correspondingcontaining barrel; the discharging end of each set of sucking nozzle mechanism communicates with the feeding end of the discharging mechanism through the conveying hose; and the discharging end of thedischarging mechanism communicates with the interior of the stirring barrel. The general multi-channel powder granule sucking device is reasonable in structural arrangement. During sucking and discharging, the powder granule conveying efficiency is improved, the mixing uniformity degree of later different materials is facilitated, the mixing efficiency is improved, deep materials are sucked moresmoothly, the deep materials are prevented from being too dense to form a vacuum cavity, and the sucking efficiency of the powder is prevented from being greatly reduced.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

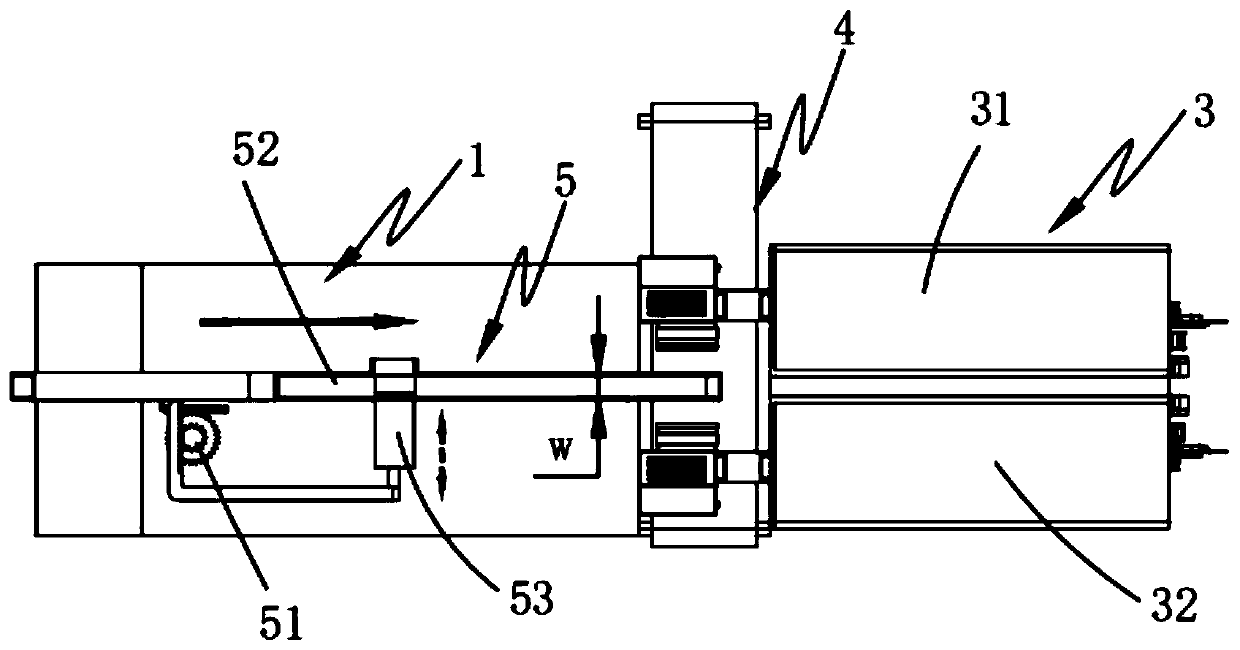

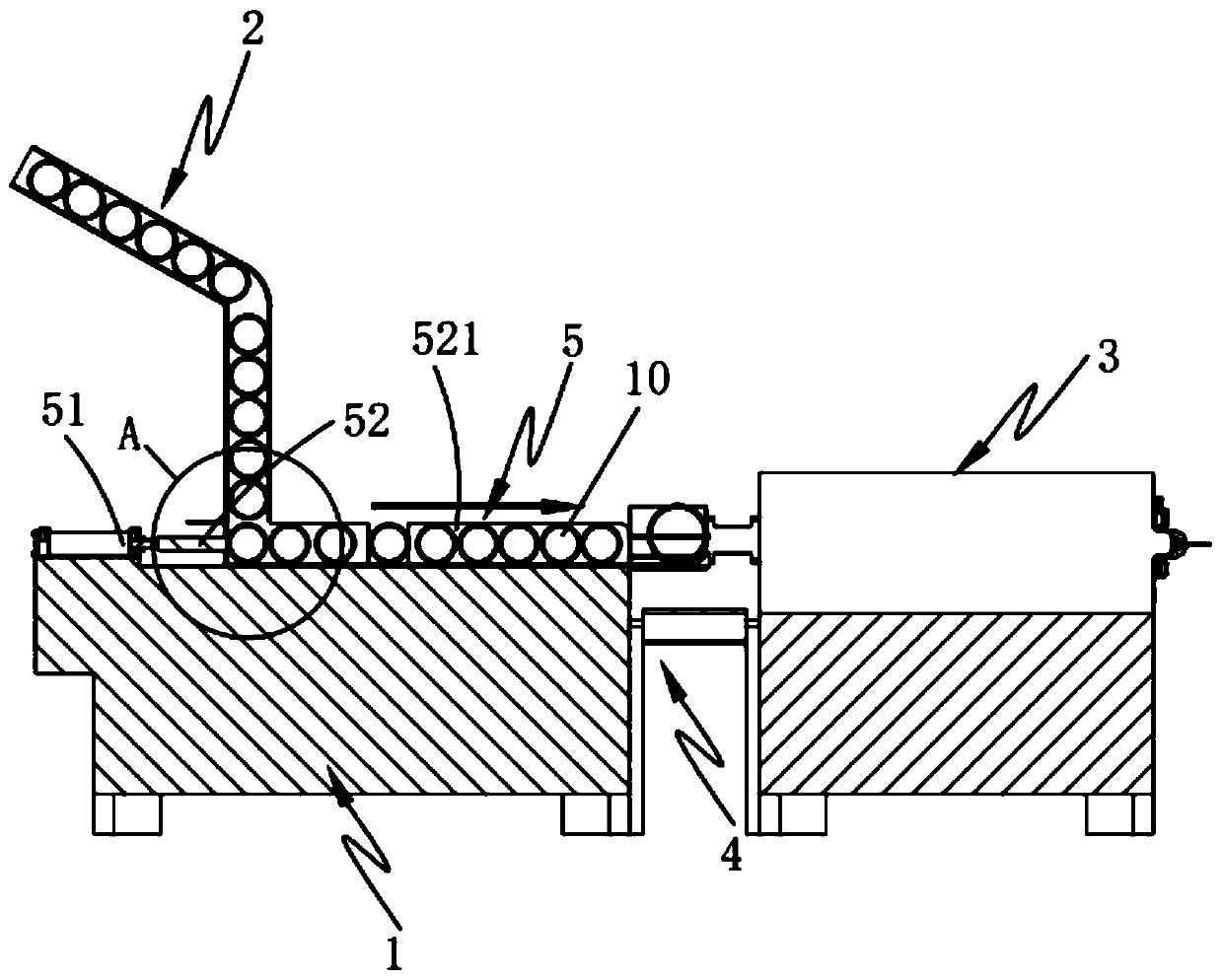

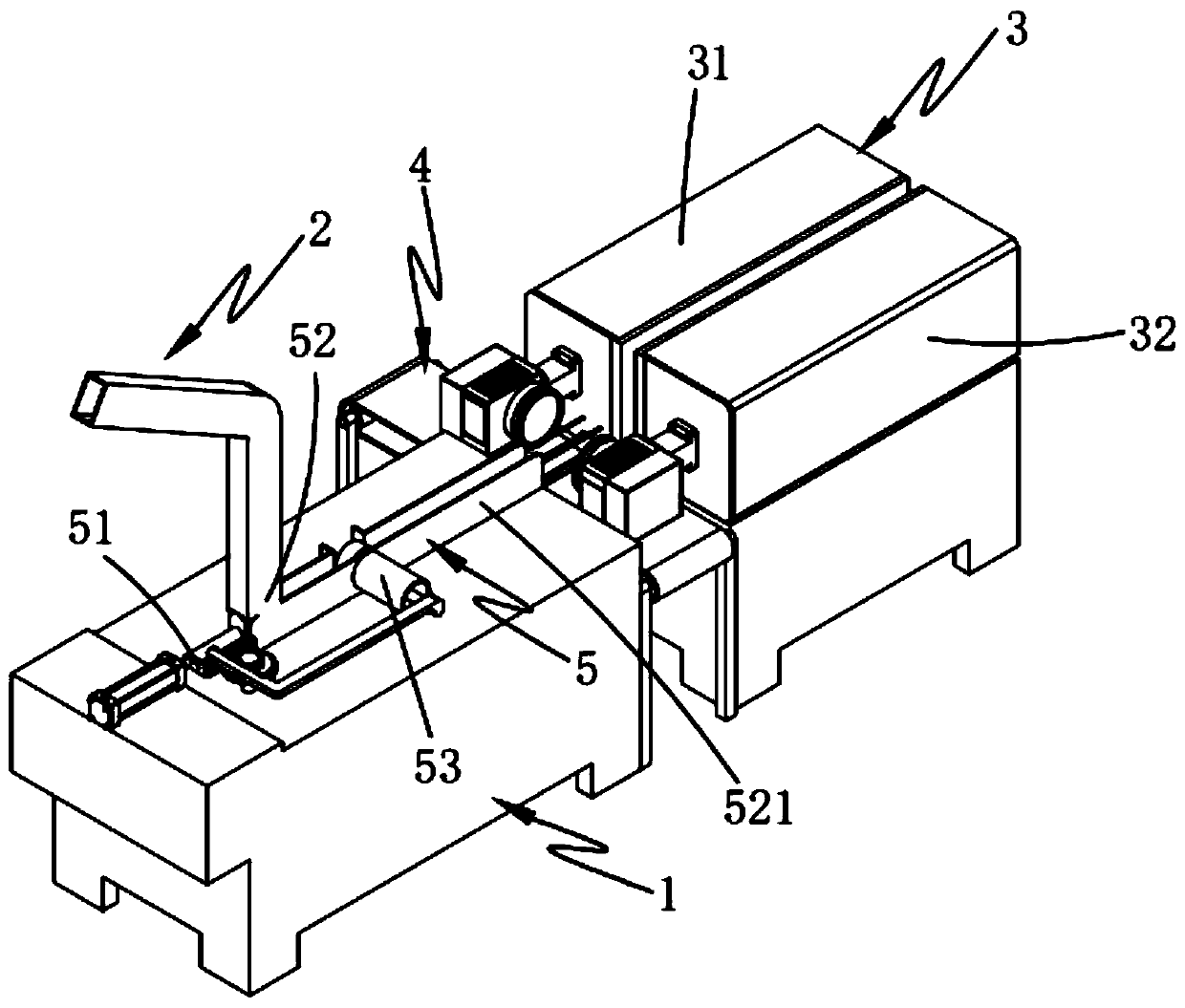

Automatic transmission type bottle cap laser coding equipment

The invention provides automatic transmission type bottle cap laser coding equipment. The automatic transmission type bottle cap laser coding equipment includes a supporting platform, a bottle cap feeding track, a coding device, a finished product output device and a feeding and sorting device, the feeding and sorting device includes a driving assembly, a feeding assembly and a sorting assembly, and the sorting assembly communicates with the feeding assembly in an angle mode; by arranging the feeding and sorting device, the bottle caps are transported by an external conveying device into the bottle cap feeding track, the intermittent forward feeding of the bottle caps in a feeding channel is achieved under the intermittent pushing of the feeding assembly, meanwhile, the sorting facing different bottle caps by the sorting assembly are conducted simultaneously in the battle cap feeding process, the battle caps with the consistent direction are transmitted to a coding section of the feeding channel for simultaneous coding processing of the front and back faces, the integration of bottle cap sorting, transmission, and coding is achieved, the production efficiency is greatly improved, and the technical problem of time and labor wasting of battle cap manual sorting in the prior art is achieved.

Owner:德玛克(浙江)精工科技有限公司

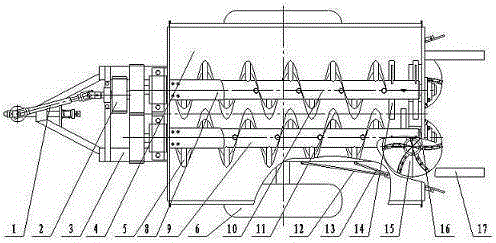

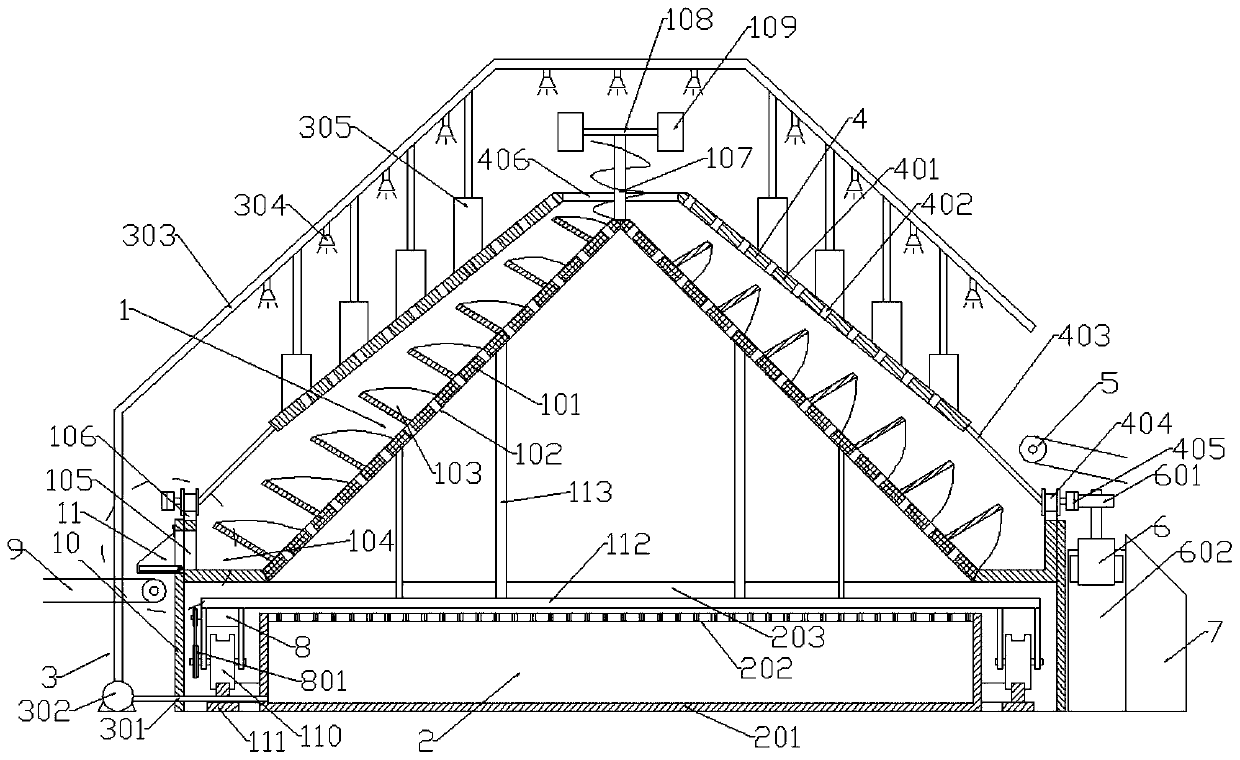

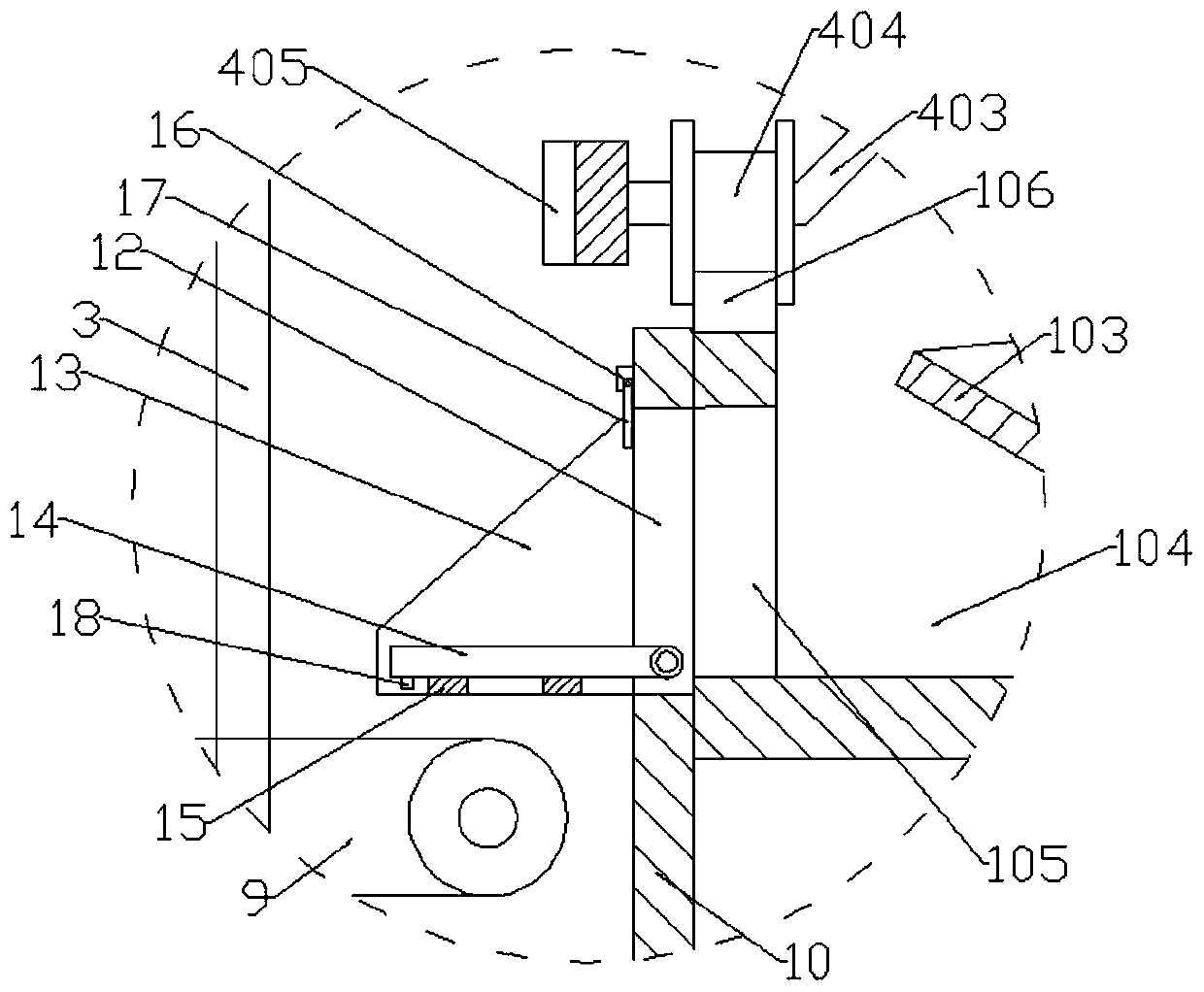

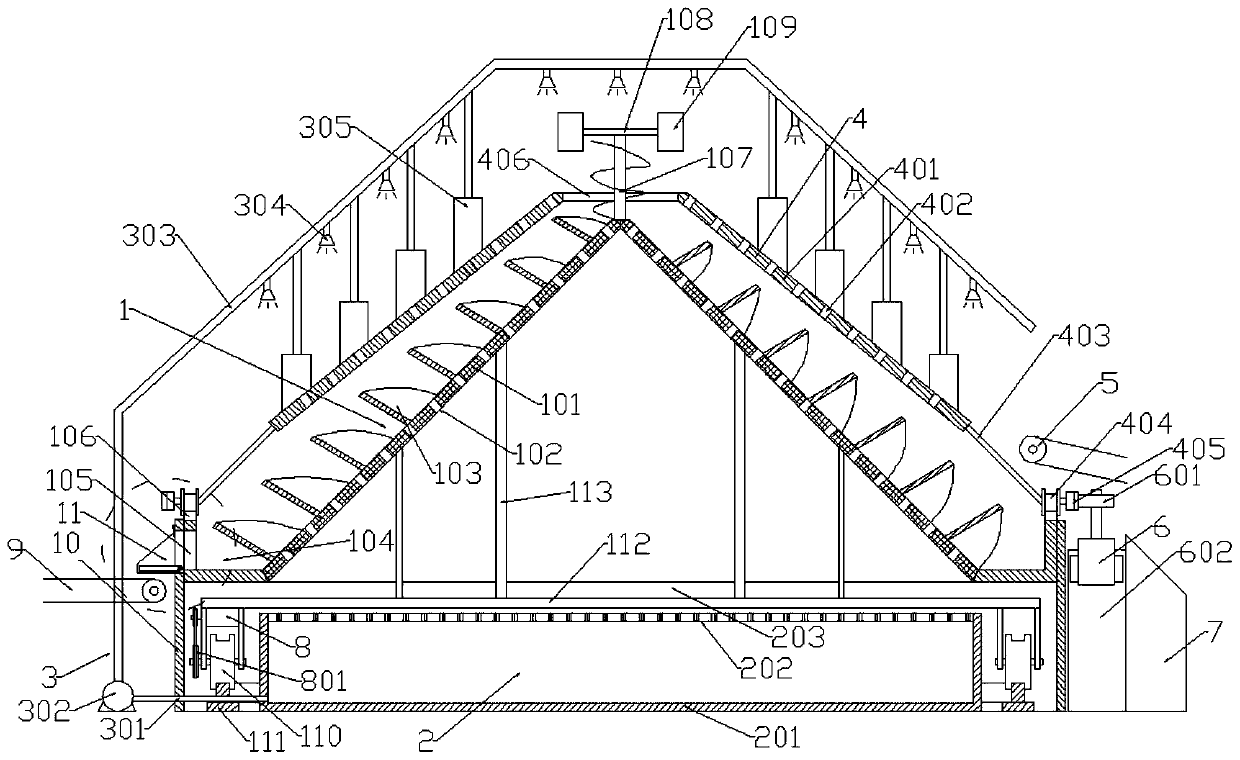

Spiral ring belt type barnyard manure crushing and scattering mechanism

ActiveCN105248026AOutput evenlySimple structureFertiliser distributersAgriculture gas emission reductionHydraulic cylinderDrive shaft

The invention provides a spiral ring belt type barnyard manure crushing and scattering mechanism and belongs to the technical field of agricultural machinery. The spiral ring belt type barnyard manure crushing and scattering mechanism comprises main parts including a rack, a manure box, spiral ring belts, crushing teeth, transmission shafts, a spiral support, a buffering beam, scattering discs, an unloading door, a hydraulic cylinder, a width adjusting plate, a hook and the like; the spiral ring belts and the crushing teeth are symmetrically mounted on the two parallel transmission shafts in the manure box in a staggered manner, and turning directions and rotary directions are opposite, so that the crushing and conveying of barnyard manure are guaranteed; the buffering beam is longitudinally distributed above the spiral ring belts so that shaft pressure is alleviated; the scattering discs are symmetrically mounted on the lower side of the unloading door; the transverse central lines of the two discs correspond to the central line of the unloading door; parabola-shaped throwing plates are mounted in the peripheral direction of the discs, and a conical flow guide cover is mounted in the middle of each disc, so that the manure can be uniformly and widely scattered; the width adjusting plate and the hook are hinged on the rack and the width can be adjusted; the manure box is in a reversed trapezoid shape, the bottom face of the manure box is W-shaped, and the central line of the manure box is overlapped with the central line of a corresponding shaft; materials are convenient to load and can be smoothly discharged, and no materials are remained; and the spiral ring belt type barnyard manure crushing and scattering mechanism has a simple structure, and high scattering efficiency and uniformity.

Owner:黑龙江省农业机械工程科学研究院齐齐哈尔分院

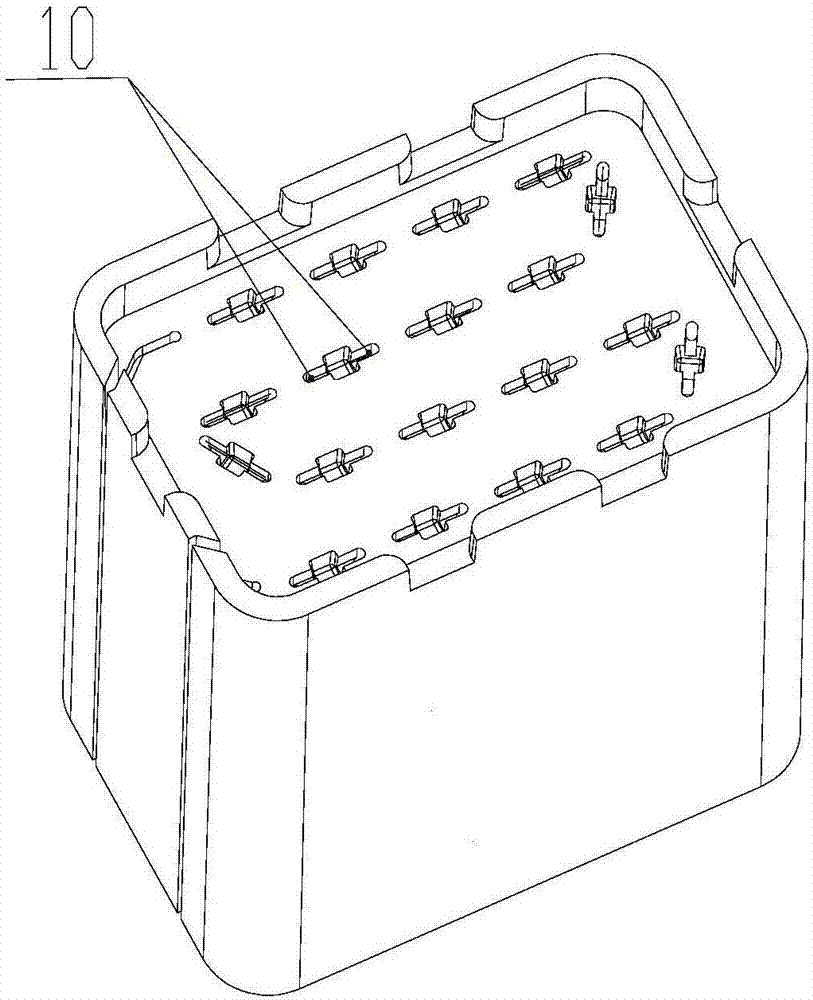

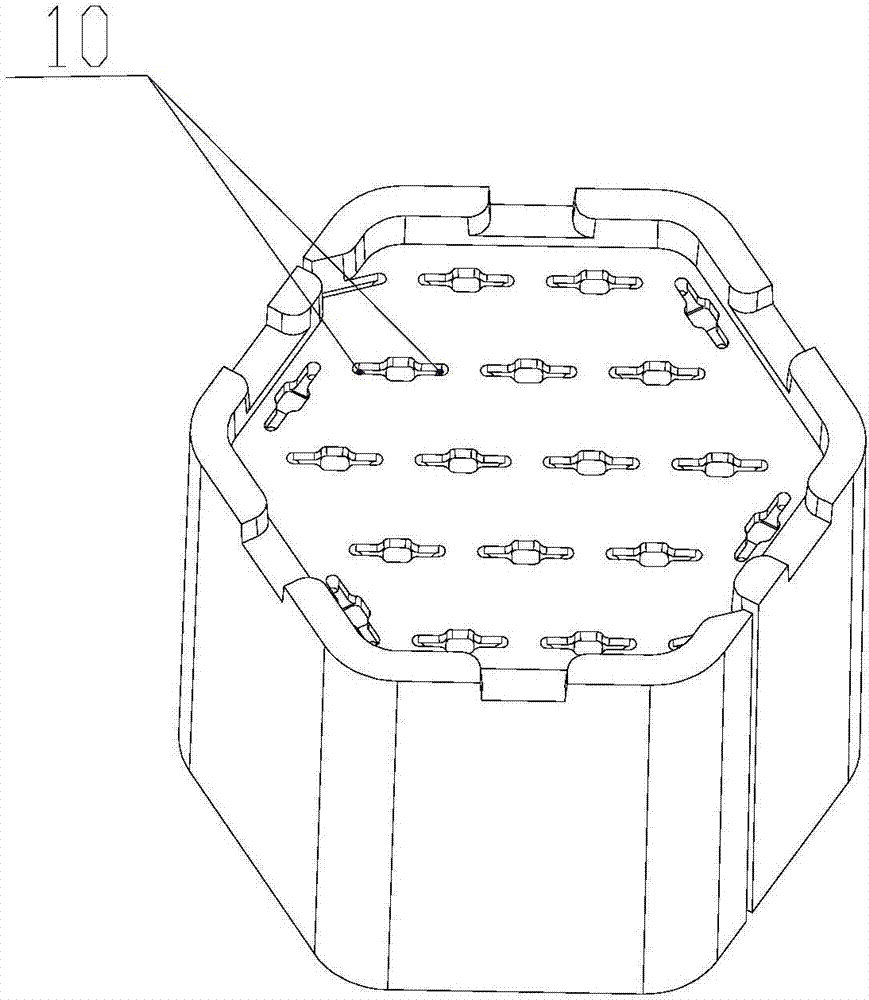

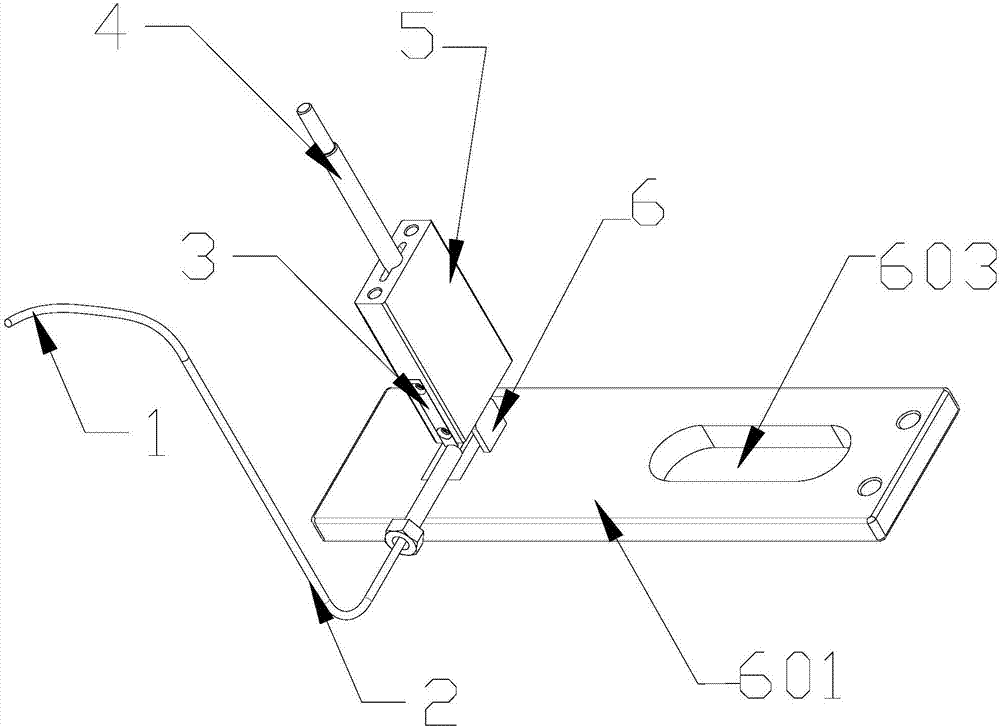

Automatic lead inserting device for mould pressing forming combined fireworks

ActiveCN106907961ABreak the production bottleneckInsert accurately and securelyFireworksMulti unitPunching

The invention discloses an automatic lead inserting device for mould pressing forming combined fireworks. The automatic lead inserting device is composed of a lead conveying mechanism, a lead cutter, a lead detaching sleeve, a lead detaching punching rod and a lead detaching plate. The automatic lead inserting device has the advantages that only 2.5 seconds are needed to complete lead inserting work once, and production efficiency is high; the automatic lead inserting device is delicate and simple in mechanism, small and compact in structure and suitable for multi-unit parallel simultaneous work; the automatic lead inserting device meets scaled production requirements, and production necks of existing mould pressing forming combined fireworks are broken through; work reliability is high, and work continuity is good; processing quality is good, the length standard of two feet of an inverted-U-shaped lead is consistent, and thus the fire cutoff phenomenon is eliminated; and the lead is inserted accurately and firmly.

Owner:浏阳市拓腾出口烟花有限公司

Snow removal and briquetting all-in-one machine

InactiveCN106638439AGood job continuitySimple and flexible operationSnow cleaningSnow removalWinding machine

The invention provides a snow removal and briquetting all-in-one machine. By means of the snow removal and briquetting all-in-one machine, while snow removal is achieved, snow can be recovered and briquetted according to actual requirements, formed snow blocks are effectively utilized, and waste is changed into wealth. To achieve the purposes, the snow removal and briquetting all-in-one machine is composed of a briquetting machine, a cab, a snow removal and winding machine, a traveling chassis and a snow scattering machine. The snow removal and briquetting all-in-one machine is scientific and reasonable in structure design, the modular structure is adopted by a vehicle body, and the vehicle body is high in strength, good in reliability, long in service life and easy to operate and maintain.

Owner:黑龙江省奕博连创科技发展有限公司

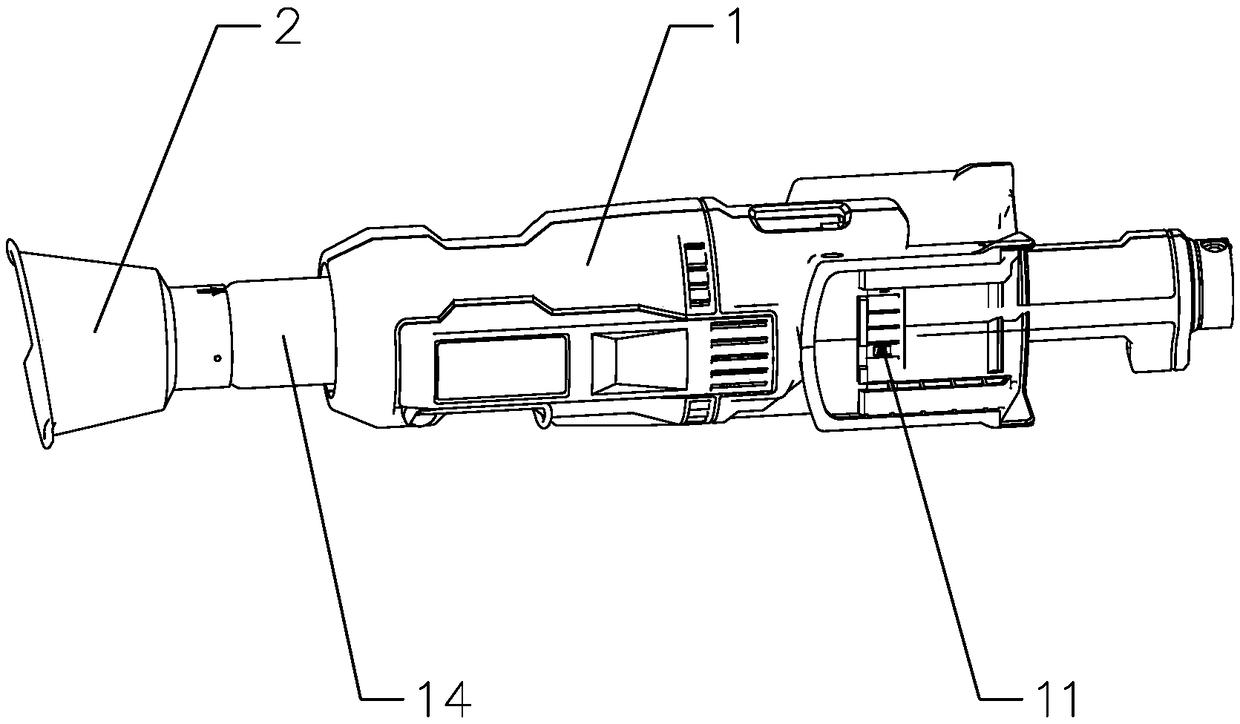

Seafloor discrete mineral particle explorer

ActiveCN106379504AReduce the impactImprove environmental adaptabilityUnderwater equipmentMineral particlesEngineering

The invention discloses a seafloor discrete mineral particle explorer. The seafloor discrete mineral particle explorer comprises a storage cabin and a detection cabin, wherein the bottom of the storage cabin is provided with an opening and an opening / closing device for opening or closing the opening; a lifting device for driving the detection cabin to stretch out of or retract into the opening is arranged on the storage cabin; the bottom of the detection cabin is provided with a material inlet / outlet and an openable / closable filter screen device for opening or closing the material inlet / outlet. The seafloor discrete mineral particle explorer also comprises an electronic scale for weighing the weight of the detection cabin. The seafloor discrete mineral particle explorer has the advantages of simple structure, good operation continuity, high efficiency, high pertinence, little influence on deep sea environments and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

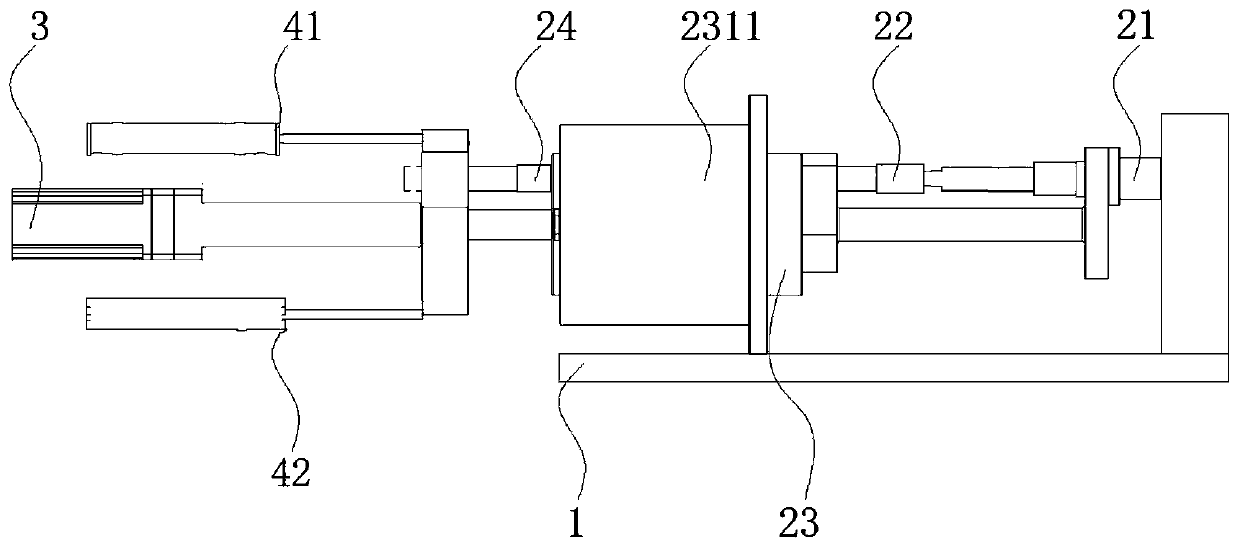

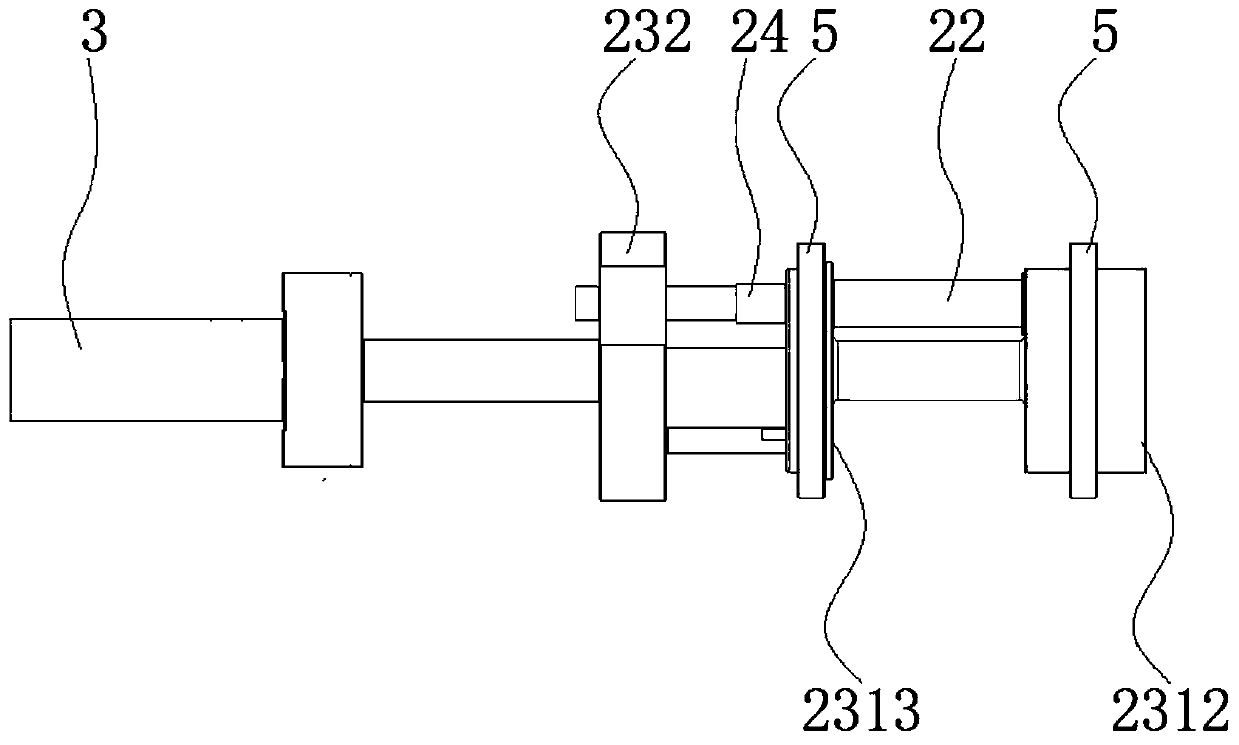

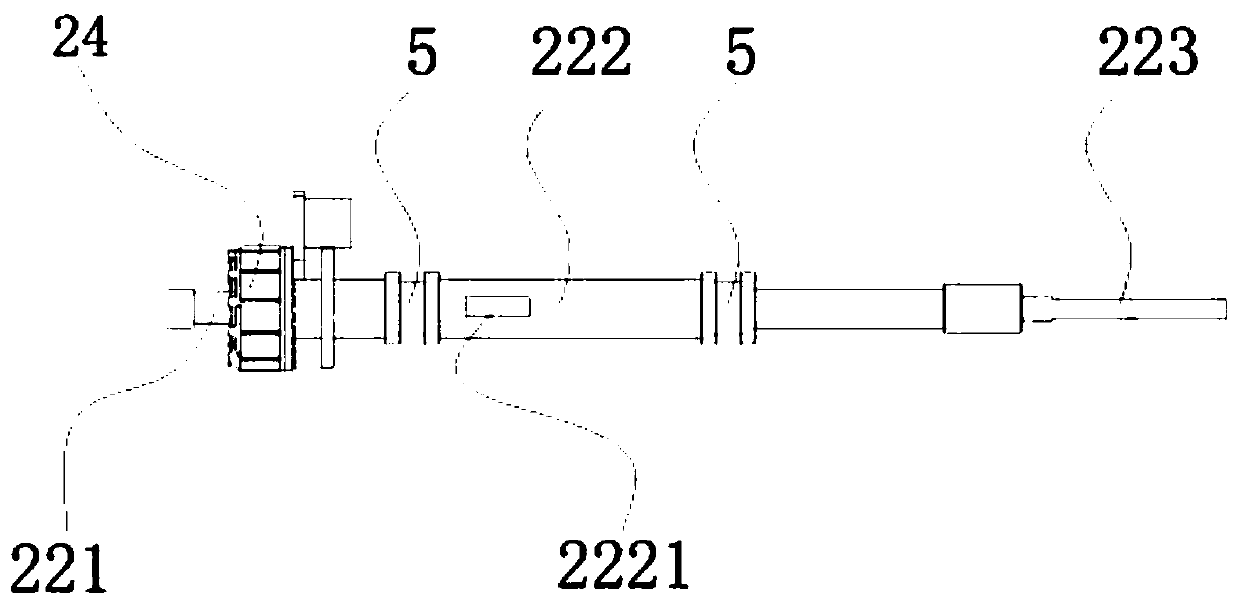

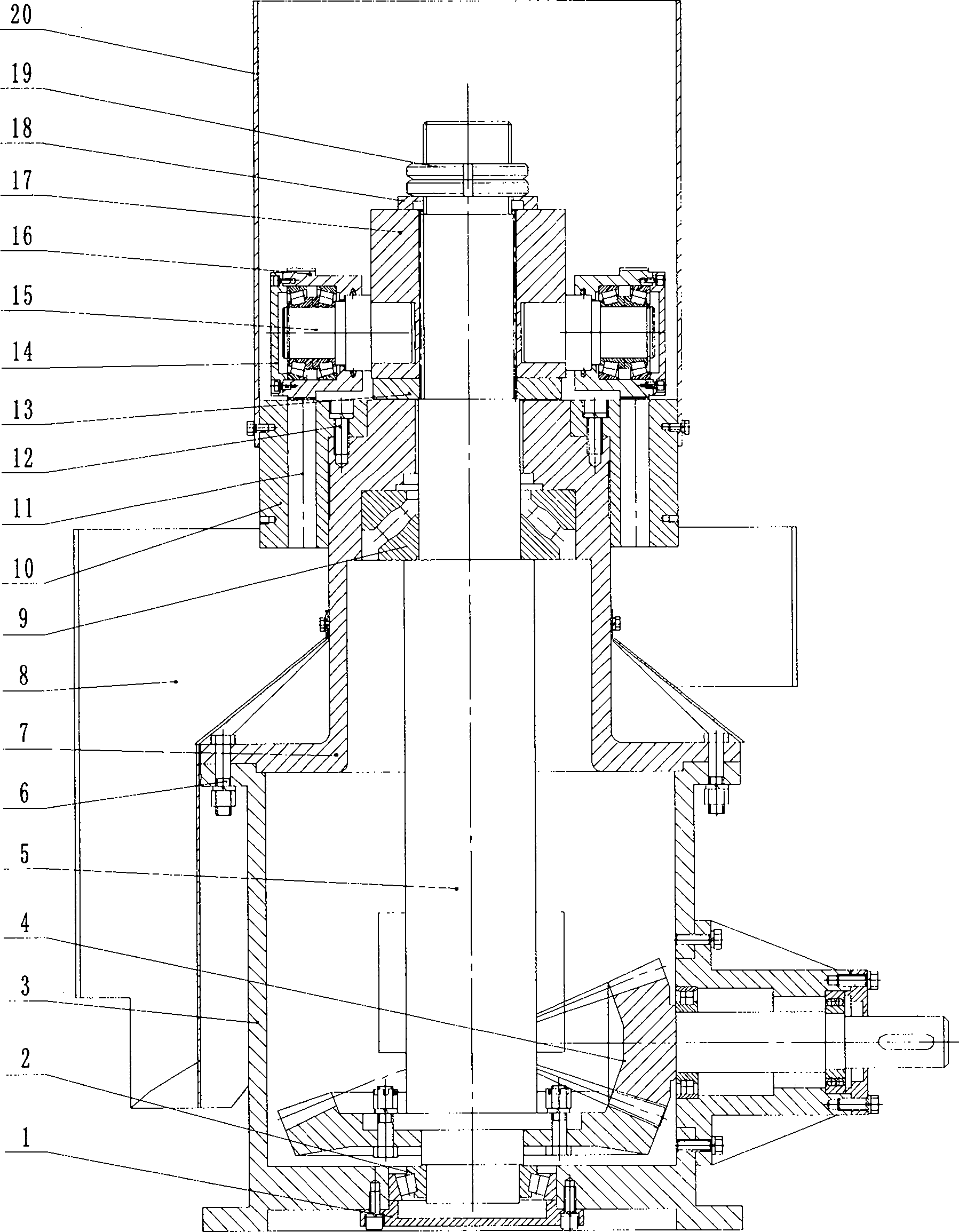

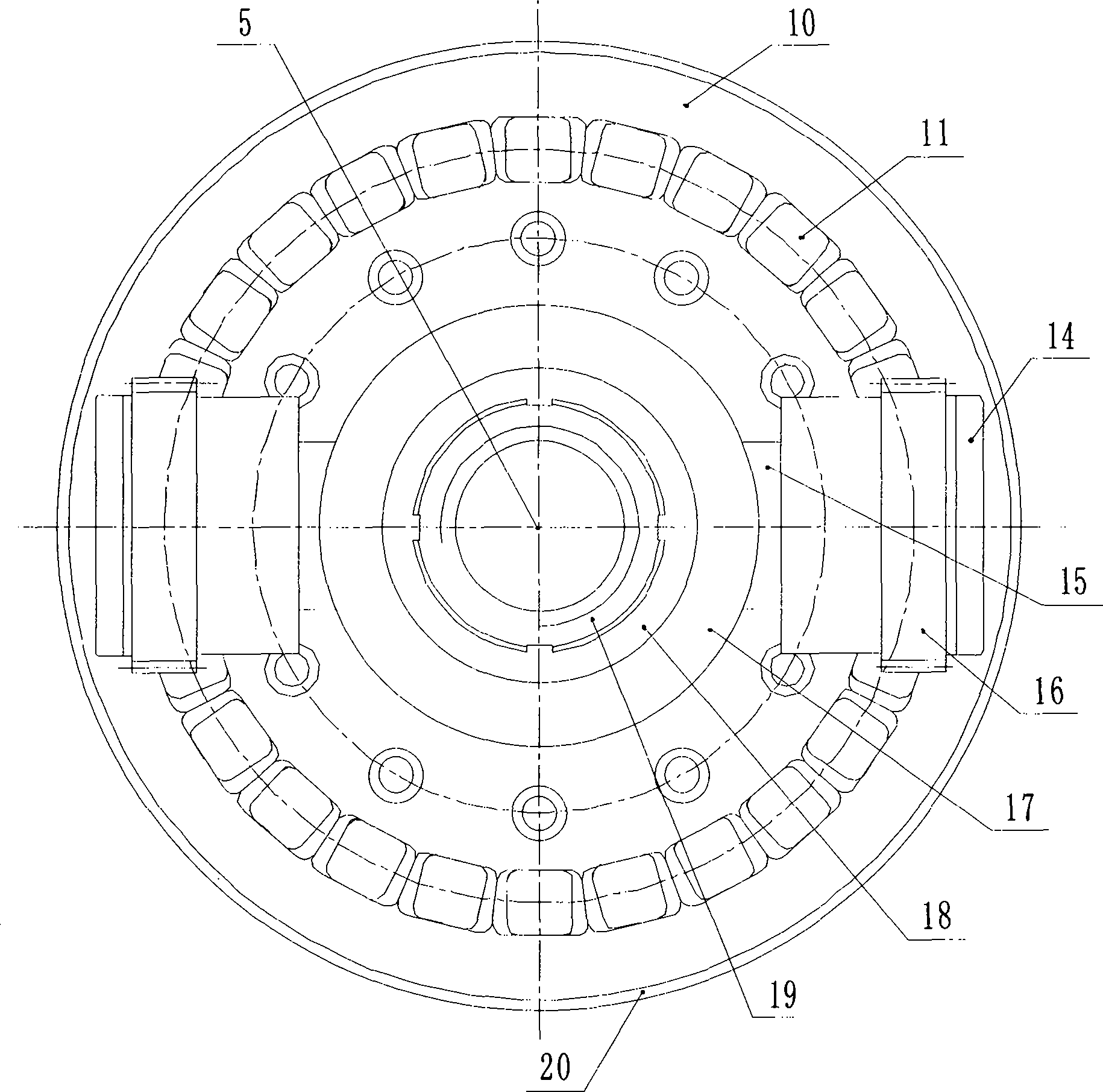

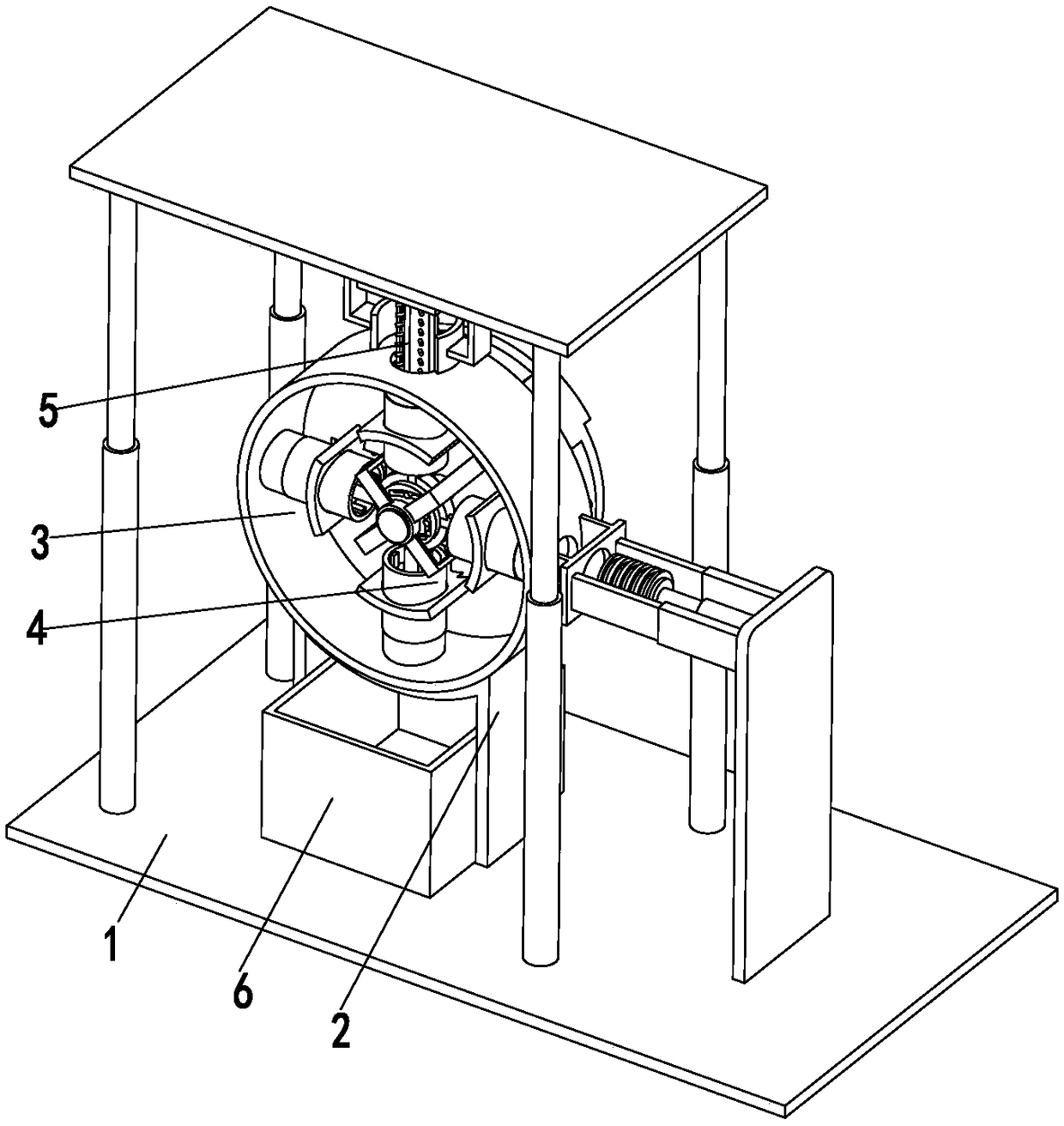

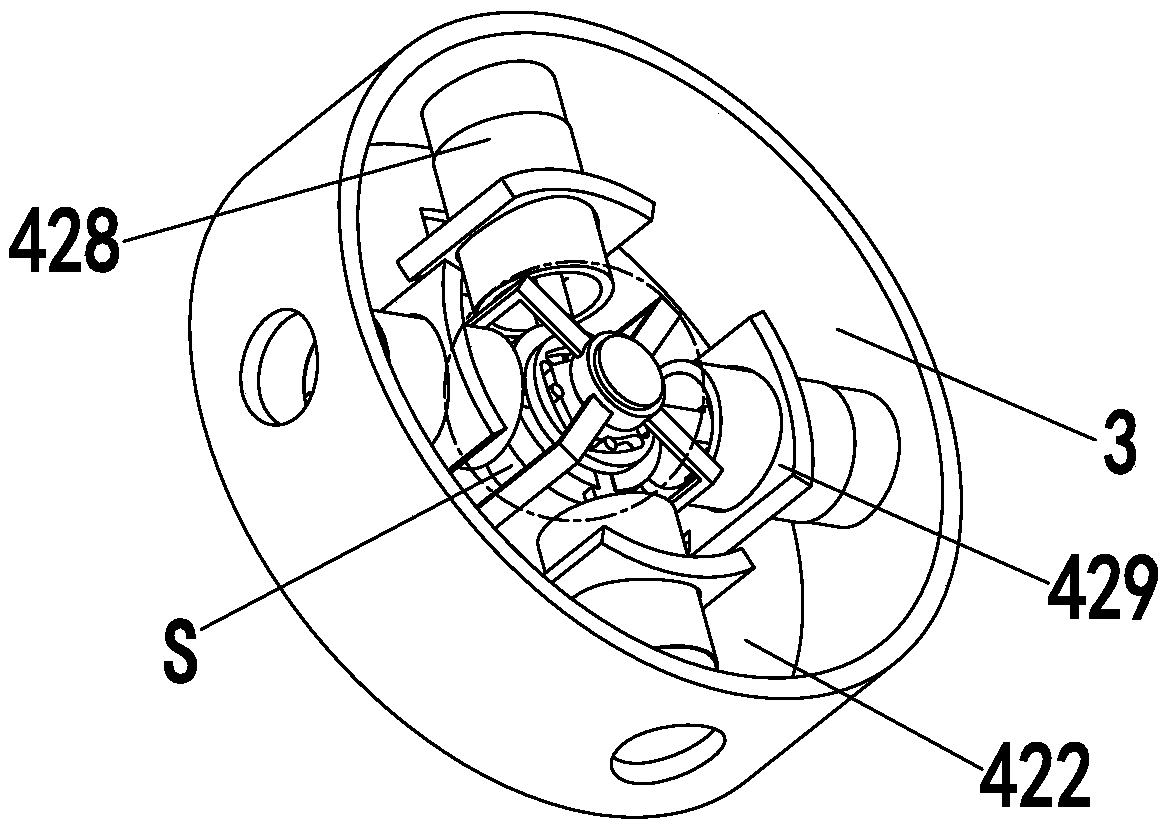

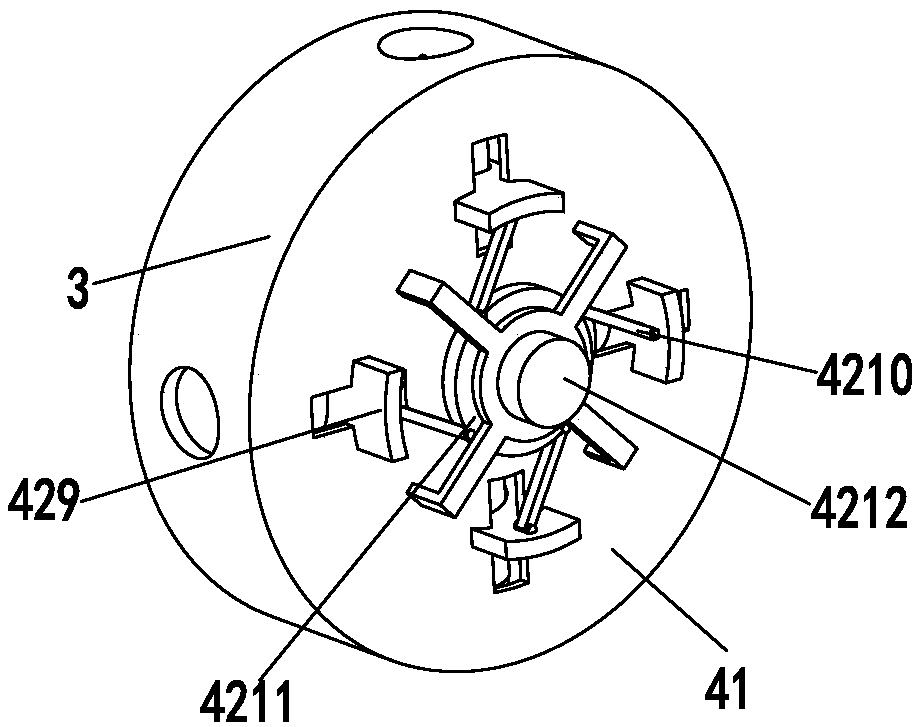

Multi-station winding device

ActiveCN111403823ANo indirect lossSimple structureAssembling battery machinesFinal product manufactureElectric machineryDrive motor

The invention discloses a multi-station winding device. The multi-station winding device comprises a base, the winding mechanism is in transmission connection with the transposition driving assembly and is driven by the transposition driving assembly to revolve; the winding mechanism comprises a front needle nozzle part, a plurality of groups of winding needle assemblies and a plurality of groupsof driving sources; the plurality of groups of driving sources correspondingly drive the plurality of groups of winding needle assemblies to rotate; each winding needle assembly comprises a winding needle, a winding needle handle and a shaft sleeve, the driving source is directly connected with the winding needle handle or the shaft sleeve to drive the winding needle to rotate, the winding needlehandle is arranged in the shaft sleeve in an axially movable mode, and the winding needle and the winding needle handle are driven by the needle penetrating and pulling mechanism to move axially alongthe shaft sleeve to move forwards or backwards. The device is simple in structure and small in size, the direct drive motor is directly connected with the winding needle handle or the shaft sleeve todirectly drive the winding needle to rotate, a complex transmission mechanism is omitted, indirect loss is avoided, concentricity can be guaranteed, the winding speed and winding tension of equipmentcan be effectively controlled, and the rotation stress point of the winding needle is converted to the shaft sleeve, so that the rotation stress point is centered, transmission is stable, and the whole machine operation continuity is good.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

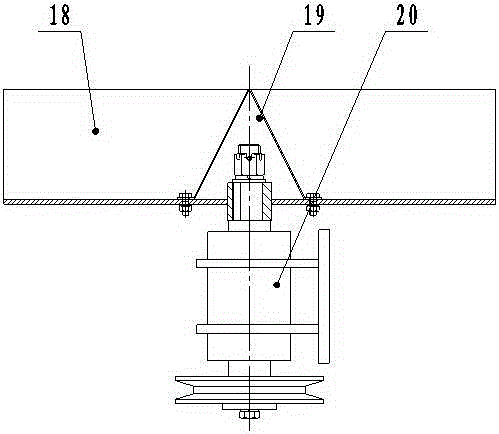

Straw briquetting mechanism with vertical shaft, flat die and straight roller

The invention provides a straw briquetting mechanism with a vertical shaft, a flat die and a straight roller, and belongs to the technical field of agricultural machinery. The straw briquetting mechanism mainly comprises a base, a transmission system, a collection hopper, a support, the main shaft, the flat die, a pressing roller frame, the pressing roller and a sleeve. The main shaft is vertically installed at the center position of the base and the center position of the support. The flat die is horizontally installed on the support. A pressing roller frame sleeve is vertically installed on the main shaft and fixed on the support. The pressing roller is horizontally installed at the radial shaft end of a pressing roller frame sleeve. The flat die is sleeved with the sleeve. The collection hopper is installed at the lower end of the flat die and fixed to the support. The flat die is provided with a plurality of square through holes within the circumference, and the center line of each hole coincides with the rotation center line of each pressing roller tooth, so that it is ensured that straws can be successfully pressed into the holes of the die. The pressing roller is in a straight gear shape, rotates along with the shaft under the driving of the pressing roller frame, and meanwhile rotates around the axis of the pressing roller to press the straws into the holes of the die continuously, so that straw blocks with the regular shape and high intensity are formed, and the production rate and the ratio of briquetting are high. The straw briquetting mechanism is simple and compact in structure, the holes of the flat die are not prone to being blocked, and working continuity is good.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

Full-automatic hot riveting machine

PendingCN107671184AGood job continuityImprove heat riveting efficiencyShaping toolsManufacturing dynamo-electric machinesProduction lineReciprocating motion

The invention discloses a full-automatic hot riveting machine, which comprises a first conveying mechanism, a second conveying mechanism, a capturing mechanism and a hot riveting mechanism. The firstconveying mechanism is used for conveying a first riveting workpiece; the second conveying mechanism is used for conveying a second riveting workpiece; an assembling station and a hot riveting stationare arranged on the second riveting workpiece, and are arranged along a conveying direction of the second conveying mechanism at an interval; the capturing mechanism is arranged on the assembling station, can move between the first conveying mechanism and the second conveying mechanism in a reciprocating way, and is used for capturing the first riveting workpiece to assemble on the second riveting workpiece; and the hot riveting mechanism is arranged on the riveting station, and is used for riveting the first riveting workpiece and the second riveting workpiece. According to the full-automatic hot riveting machine provided by the invention, the workpieces to be riveted can be combined and riveted on a production line, and the hot riveting efficiency is higher.

Owner:深圳双十科技股份有限公司

Cotton opening mechanism

InactiveCN101876098ASimplify the structure of the openerReduce the size of the openerFibre cleaning/opening machinesElectric machineryBarrel Shape

The invention provides a cotton opening mechanism which is applied to the cotton opening procedure of a blow room system. The cotton opening mechanism is characterized in that a shutter grate mechanism is made into a barrel shape; grid bars are arranged from one end to the other end of the barrel in a spiral shape from sparseness to denseness; a beater roller is in a long cylinder shape; the length of the beater roller is the same as that of the shutter grate of the barrel; beaters are arranged on the beater roller in the spiral shape; a brad-type roller beater, a porcupine beater and a card wire fin comprehensive beater are distributed from one end to the other end of the beater roller and are slightly staggered with the spiral of the shutter grate; the beater mechanism is vertically arranged in the cotton opening mechanism; when in work, a single motor is utilized to make the cylindrical roller beater rotate; cotton flow inflows from the lower end of the shutter grate; and along with that the beaters generate tear and impact actions with the grid bars in a shutter grate barrel and the spiral continuously flows from one end of the shutter grate barrel to the upper end, the whole procedure from coarse cotton opening to fine cotton opening is carried out in the middle of the procedure, thereby obtaining the cotton flow which is sufficiently opened and decontaminated. The cotton opening mechanism has skillful design. Compared with the traditional cotton opening mechanisms, the cotton opening mechanism of the invention integrates the coarse cotton opening procedure and the fine cotton opening procedure into a whole, occupies very small space and has very high cotton opening work continuity.

Owner:李钟平

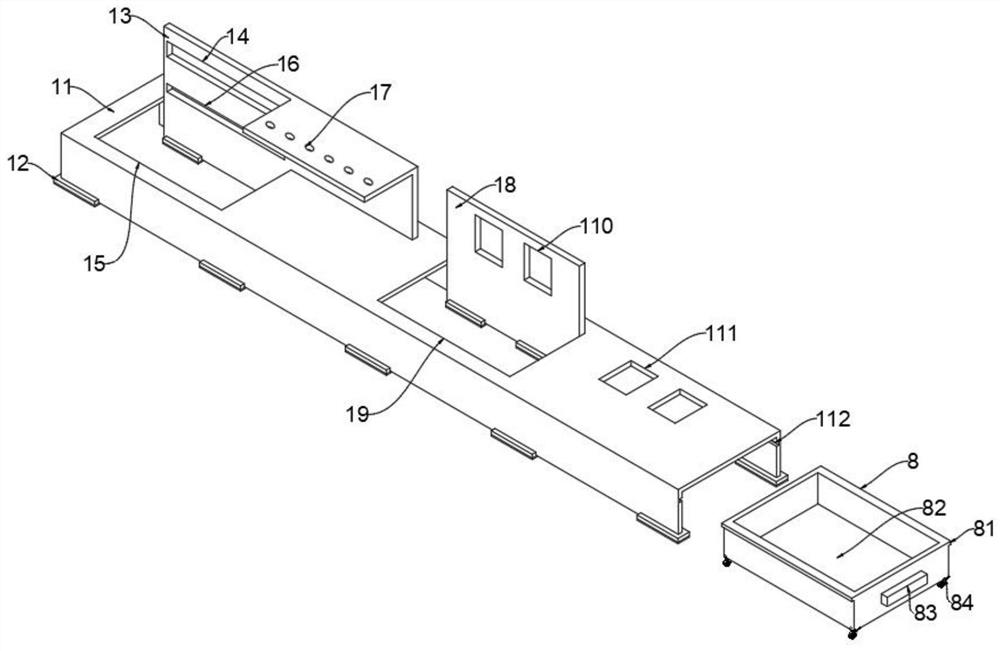

Automatic PVC tube recovery system and automatic PVC tube processing technique

ActiveCN109013582AImprove cleaning effectIncrease labor intensityHollow article cleaningAutomatic processingHigh intensity

The invention relates to an automatic PVC tube recovery system and an automatic PVC tube processing technique thereof. The automatic PVC tube recovery system comprises a base plate, a bearing base, alimiting ring, a conveying device, a cleaning device and a collection box. The bearing base is arranged on the base plate. The collection box is arranged at the lower end of the bearing base. The lower end of the collection box is closely attached to the base plate. The limiting ring is mounted on the bearing base. Round holes are evenly formed in the side wall of the limiting ring in the circumferential direction, and the number of the round holes is four. The conveying device is arranged in the limiting ring. The cleaning device is arranged at the upper end of the conveying device, and the conveying device and the cleaning device are mounted on the base plate. By adoption of the automatic PVC tube recovery system and the automatic PVC tube processing technique thereof, the problems of high labor cost, high labor intensity, low working efficiency, poor work continuity, cleaning dead angles and the like in an existing PVC tube recovery and cleaning process can be solved, and automaticrecovery and cleaning of PVC tubes can be achieved; and the automatic PVC tube recovery system and the automatic PVC tube processing technique thereof have the advantages of being high in labor cost,low in labor intensity, high in work efficiency, good in work continuity, good in cleaning effect and the like.

Owner:湖南晟塑管业有限公司

Cleaning, distribution and conveying machine of fishes

ActiveCN104472651AReduce labor intensityReasonable designFish washing/descalingBlowoff valveEngineering

The invention discloses a cleaning, distribution and conveying machine of fishes, which comprises a rack, an opened cleaning pool and a conveying device, wherein the cleaning pool is supported by the rack and placed horizontally; a blowoff valve is arranged at the bottom of the cleaning pool; and the conveying device is used for conveying the cleaned fishes out of the cleaning pool. The machine is characterized in that a fence is arranged in the cleaning pool; a plurality of air outlet pipes arranged in parallel and communicated with a fan are arranged in the cleaning pool located below the fence; a plurality of air outlet holes facing the conveying device are uniformly formed in each air outlet pipe; the distal end of the fence is close to the conveying device; and a fish distributor is arranged on the conveying device, puts the cleaned fishes together and distributes the fishes in lines. The machine is reasonable in design, good in cleaning effect, high in automation degree, good in operation continuity, low in labor intensity and high in production efficiency.

Owner:RONGCHENG JINDA STAINLESS STEEL EQUIP

Television front frame four-window hole deburring shaping die

InactiveCN105834301AGuaranteed appearanceGuaranteed accuracyShaping toolsEconomic benefitsEngineering

Owner:KUNSHAN JIXINCHENG PRECISION MOLD

Intelligent perforating binding machine for financial sheets

The invention discloses an intelligent perforating binding machine for financial sheets. A machine body and a work cavity arranged in the machine body and provided with a leftward opening are included; the bottom of the work cavity is provided with a first guiding slide groove with a leftward opening in a communicating manner; a scrap sucking port is formed in the right end of the work cavity in athrough manner; a first cavity with a leftward opening is formed in the inner wall of the right end of the work cavity in a communicating manner; a first guiding slider is connected in the first guiding slide groove in a sliding fit manner; round holes, with upwards openings, in left and right symmetry are formed in the top end face of the first guiding slider; a first threaded rod extending leftwards and rightwards is connected in the first guiding slider in a threaded fit manner; and the tail end of the right end of the first threaded rod is in power connection with a first electromotor.

Owner:朱榆洲

Quantitative fertilization device of vegetable planting water and fertilizer all-in-one machine

InactiveCN114467456ARealize quantitative cuttingGood job continuityRotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses a vegetable planting water and fertilizer all-in-one machine quantitative fertilization device which comprises a frame, a stirring treatment box, a liquid storage box arranged at the top of the stirring treatment box, a material storage barrel and a quantitative discharging control mechanism arranged on the material storage barrel. The quantitative discharging control mechanism comprises a lead screw nut piece located on one side of the storage material barrel, a drawing partition plate and a drawing door plate, the drawing partition plate and the drawing door plate are both arranged on the storage material barrel, the drawing partition plate is located above the drawing door plate in a spaced mode and provided with a driving end plate, a sliding frame penetrates through the driving end plate to be inserted into the drawing partition plate in a sliding mode, and the sliding frame is provided with a limiting end plate. The limiting end plate is connected with the drawing door plate through a connecting frame, a lifting driving mechanism is connected to a nut of the lead screw nut piece, the end of the lifting driving mechanism is connected with a clamping block, the clamping block is connected with the driving end plate or the limiting end plate in a clamped mode, and the drawing partition plate and the drawing door plate alternately act to achieve quantitative discharging. The water and fertilizer mixing ratio is high in precision and easy to adjust, and the mixing process is easy to control.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

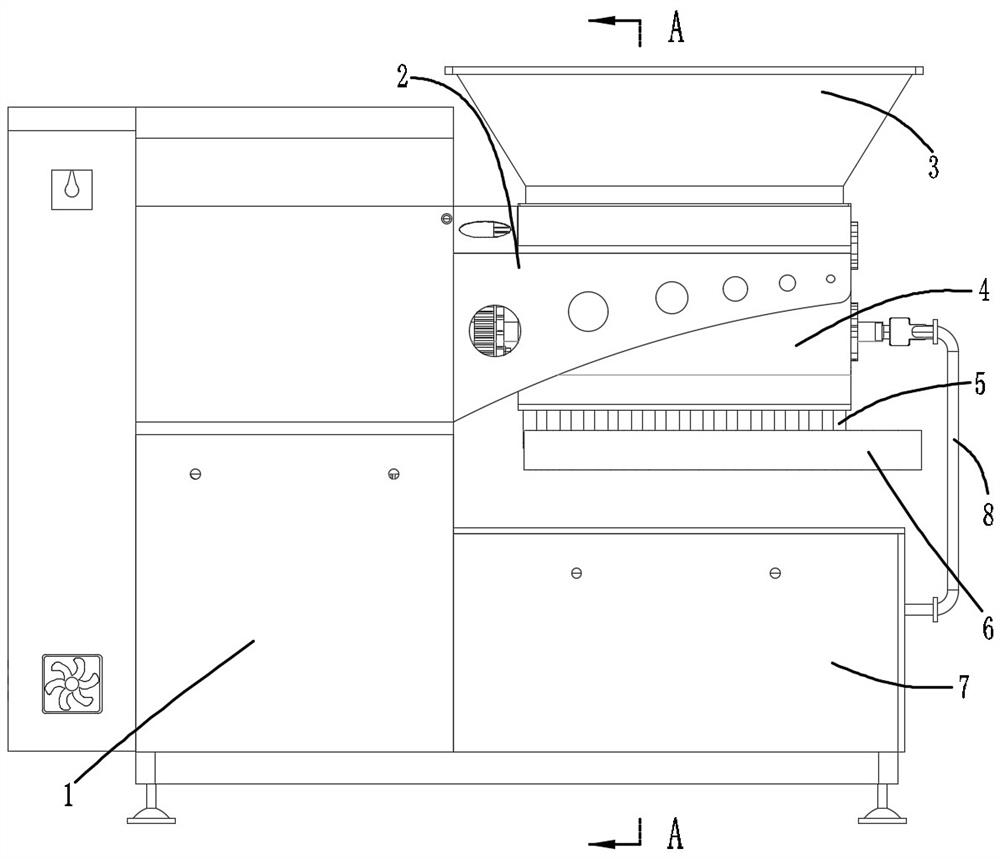

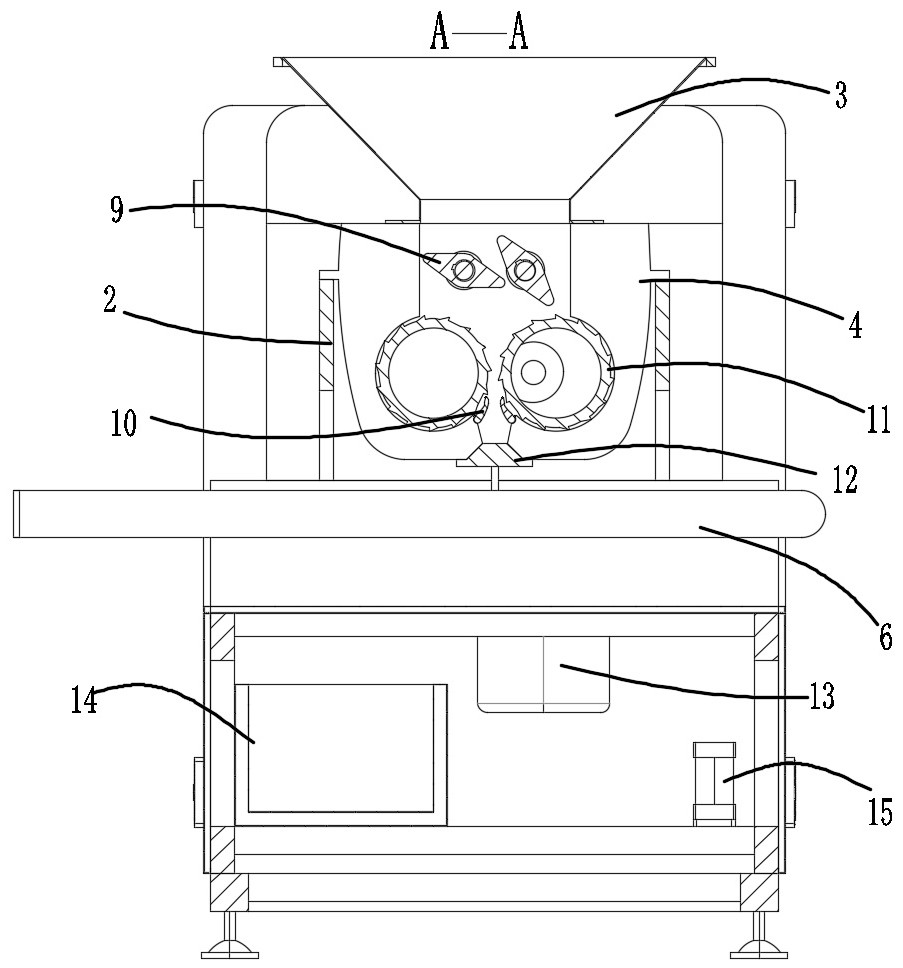

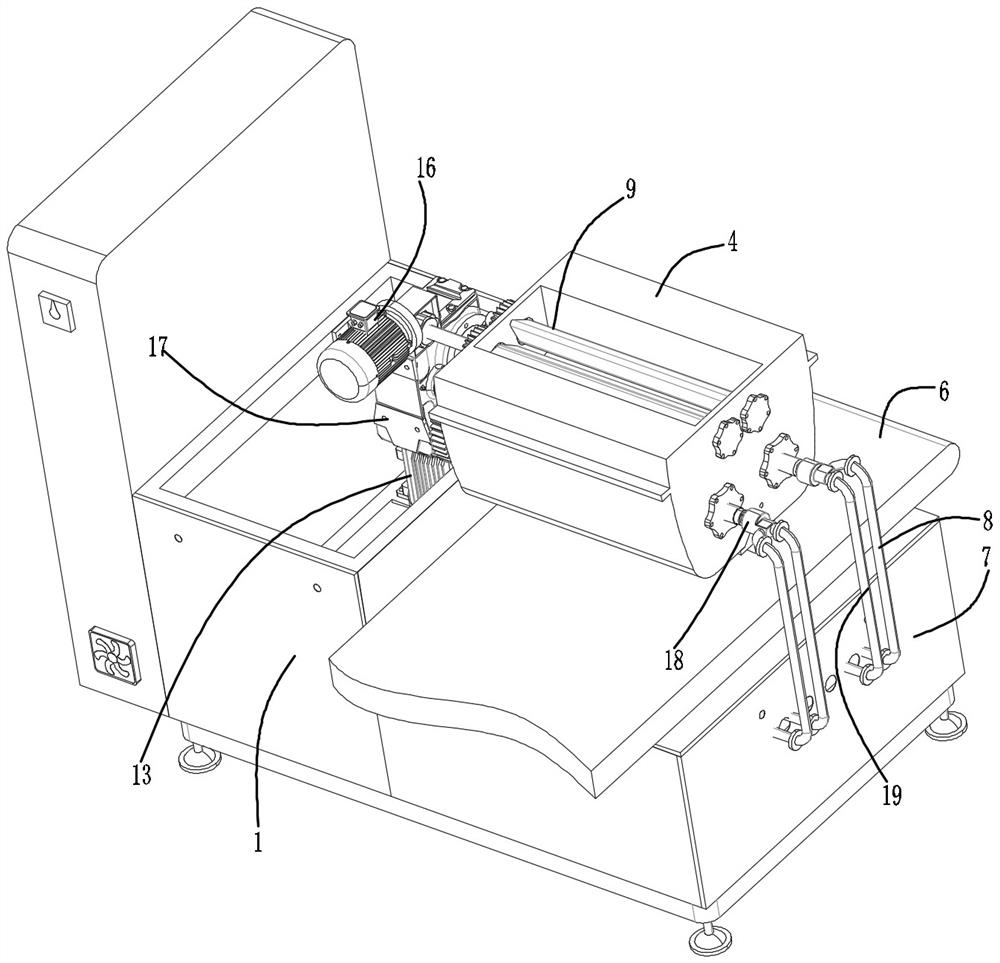

Flexible kinetic energy carborundum and net composite huller

PendingCN113842974AIncrease frictionImprove peeling efficiencyGrain huskingGrain polishingEngineeringBran

The invention relates to a flexible kinetic energy carborundum and net composite huller which comprises a rack, a feeding chamber installed on the rack, a discharging chamber, two flexible kinetic energy carborundum and net hulling devices and a bran collecting hopper located on the lower portions of the flexible kinetic energy carborundum and net hulling devices, wherein the two flexible kinetic energy carborundum and net hulling devices are arranged in parallel. Each flexible kinetic energy carborundum and net hulling device comprises a cylindrical roller body and a cylindrical screen arranged outside the roller body in a sleeving mode, flexible blade assemblies evenly distributed in the circumferential direction and a plurality of flow deflectors arranged in the spiral line direction are fixed to the circumferential face of the roller body, and each flexible blade assembly comprises a blade made of an elastic steel plate, and carborundum structure layers with uniform thickness are arranged on the outer surfaces of the working ends of the blades and the inner surface of the screen. The carborundum structure layers are arranged on the outer surfaces of the blades and the inner surfaces of the screens, so that the friction force to grain materials is increased, the grain hulling efficiency and hulling quality are improved under the condition that the rubbing force is not additionally increased, and the integrity of grain particles is kept.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +2

Soil remediation device

The invention discloses a soil remediation device. The device comprises a rotation accommodating portion; a liquid storage portion is arranged under the rotation accommodating portion, the liquid storage portion is connected with a conveying portion, the conveying portion is connected with a spray portion located above the rotation accommodating portion, and a rotation slide portion is arranged between the spray portion and the rotation accommodating portion; the rotation accommodating portion includes a central conical shell body and a peripheral annular groove body, and the conical shell body and the annular groove body are in fit rotation connection; the surface of the side wall of the conical shell body is provided with first mesh holes, the outer wall of the conical shell body is provided with spiral blades, and the bottom of the conical shell body is connected with supporting rods; and the supporting rods are connected with a circular chassis frame, a plurality of second casterswhich form a circle in a surrounding manner are arranged on the bottom lower edge of the chassis frame, and each second annular track is arranged under one corresponding second caster. The device provided by the invention has a water-saving effect and a large single-time soil remediation amount, a leaching liquid is not easy to splash during high-speed rotation work, and the soil remediation efficiency is high.

Owner:泰顺县王日飞家庭农场

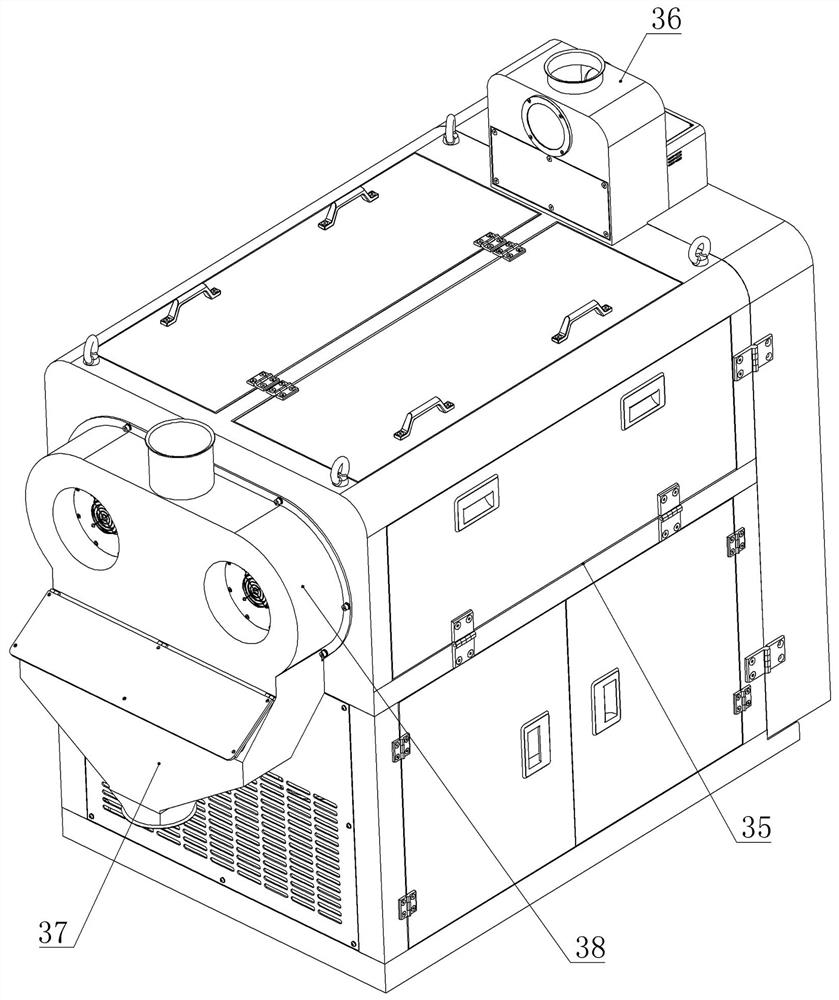

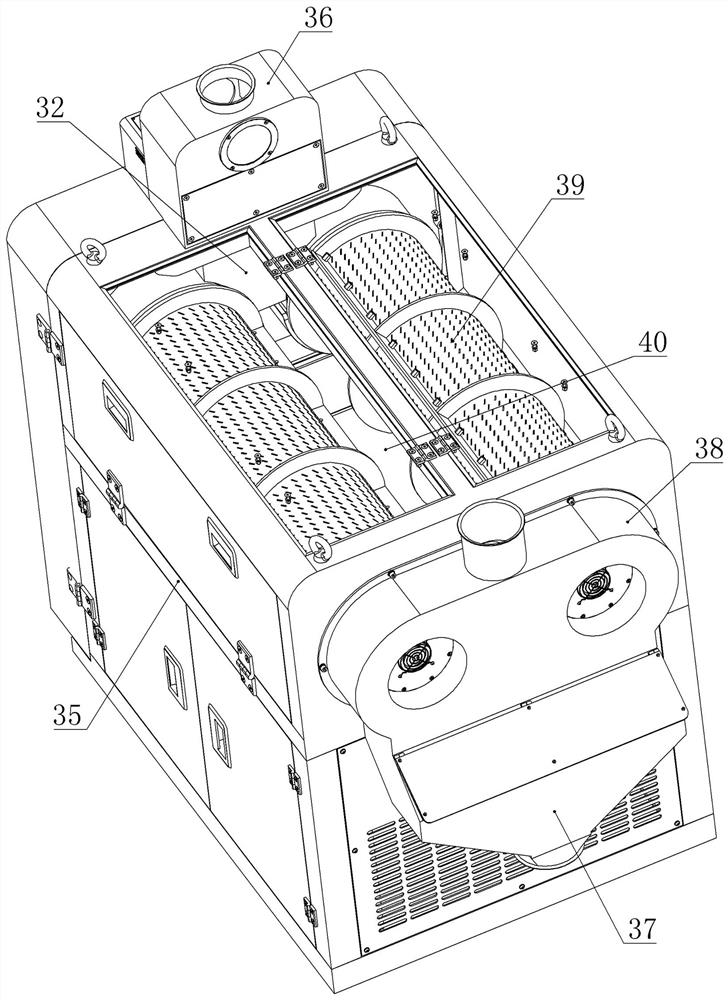

Full-automatic sparkler manufacturing device

The invention discloses a full-automatic sparkler manufacturing device. The full-automatic sparkler manufacturing device comprises a metal-wire straightening shearing machine, a gunpowder-jet-flow main machine, a magnetic-force material receiving machine, a drying machine and a control system. The metal-wire straightening shearing machine, the gunpowder-jet-flow main machine, the magnetic-force material receiving machine and the drying machine are sequentially arranged; the metal-wire straightening shearing machine comprises a first machine frame, an unwinding device, a straightening device, a dynamic shearing device and a control box; the gunpowder-jet-flow main machine comprises a second machine frame, a material hopper, a jet flow base, a wire pushing device, a shifting device, a pressing device and an extruding device. The metal-wire straightening shearing machine, the gunpowder-jet-flow main machine, the magnetic-force material receiving machine and the drying machine are controlled by the control system to work in a matched mode to automatically complete straightening and shearing of a metal wire, packaging of gunpowder and receiving and drying of a semi-finished product, and therefore a sparkler finished product is automatically prepared. The work continuity is good, the efficiency is effectively improved, and the yield is higher; meanwhile, artificial participation is not required in the whole process, labor consumption is greatly reduced, and the production cost is reduced.

Owner:东莞市力优机械设备有限公司

Shellfish ice glazing machine

InactiveCN104430805AReduce labor intensitySimple structureMeat/fish preservation by freezing/coolingIce storageEngineering

The invention discloses a shellfish ice glazing machine. The ice glazing machine comprises a frame, a horizontal open working pool supported by the frame and a conveying device; the conveying device comprises a material feeding device and a discharging unloading device; the material feeding device is used for conveying the shellfish material to the working pool; and the material discharging device is used for conveying the ice-glazed shellfish material to the working pool. The ice glazing machine is characterized in that two sides of the working pool are respectively provided with an ice storage tank, and the ice storage tank is communicated with the working pool through a working pool wall with holes; and the bottom of the working pool is uniformly distributed with a plurality of air discharging tubes, each air discharging tube is uniformly distributed with a plurality of air discharge holes in the discharging direction, and the air discharging tubes are communicated with a fan through a connecting tube. The shellfish ice glazing machine is simple in structure, high in degree of automation and high in transparency, and ice glazed clothes are smooth without burrs.

Owner:RONGCHENG JINDA STAINLESS STEEL EQUIP

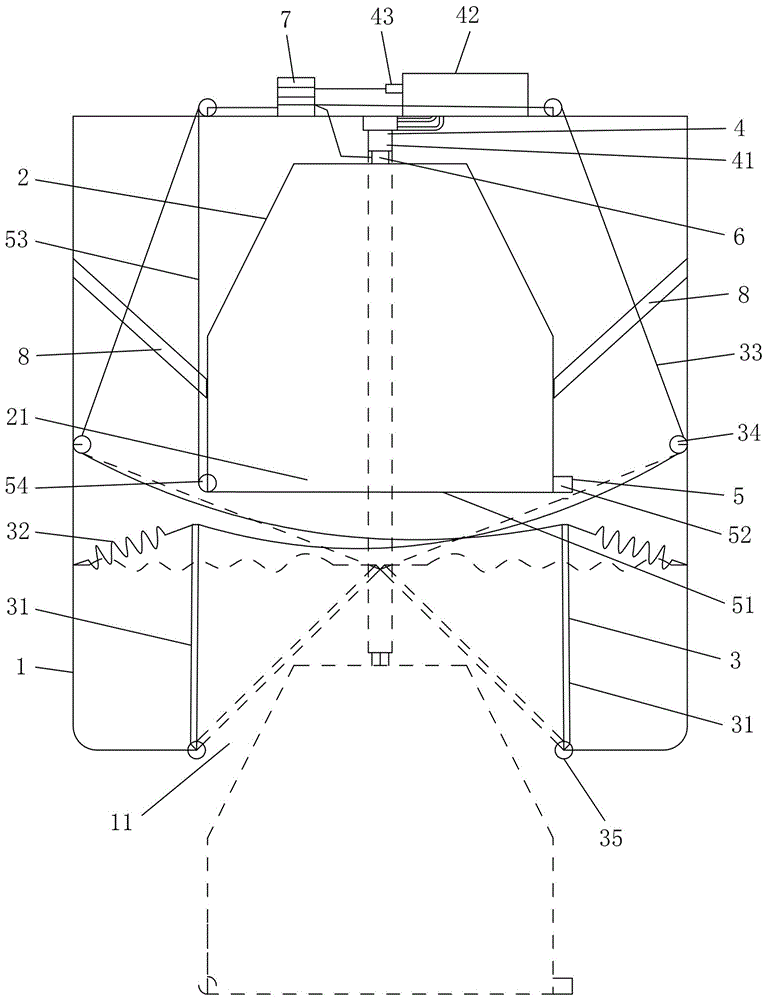

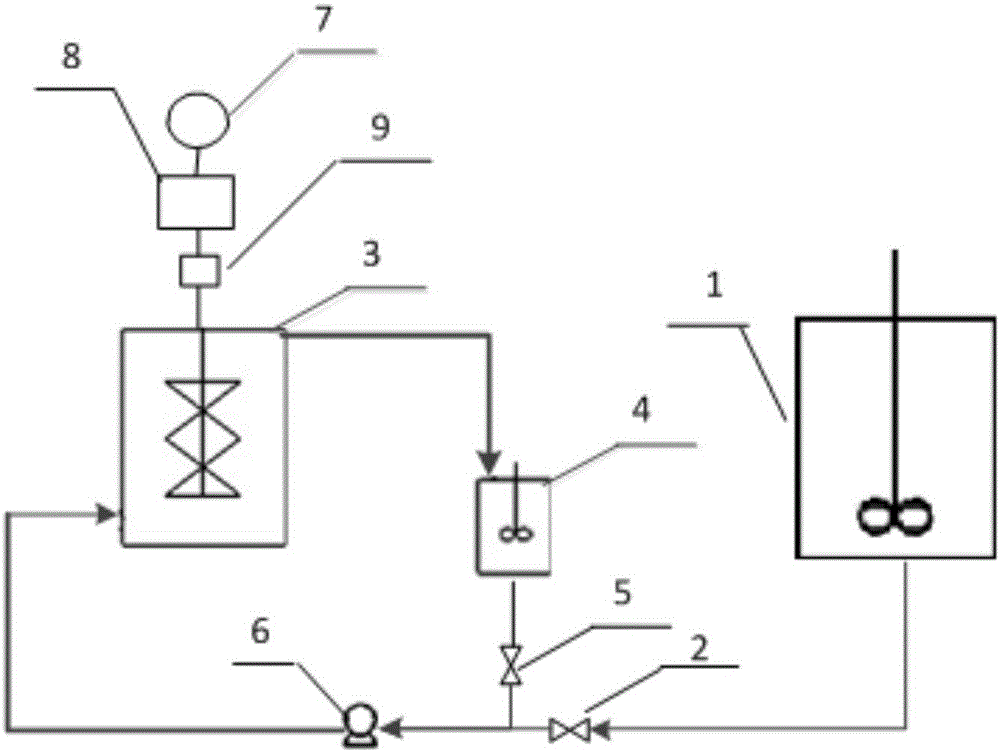

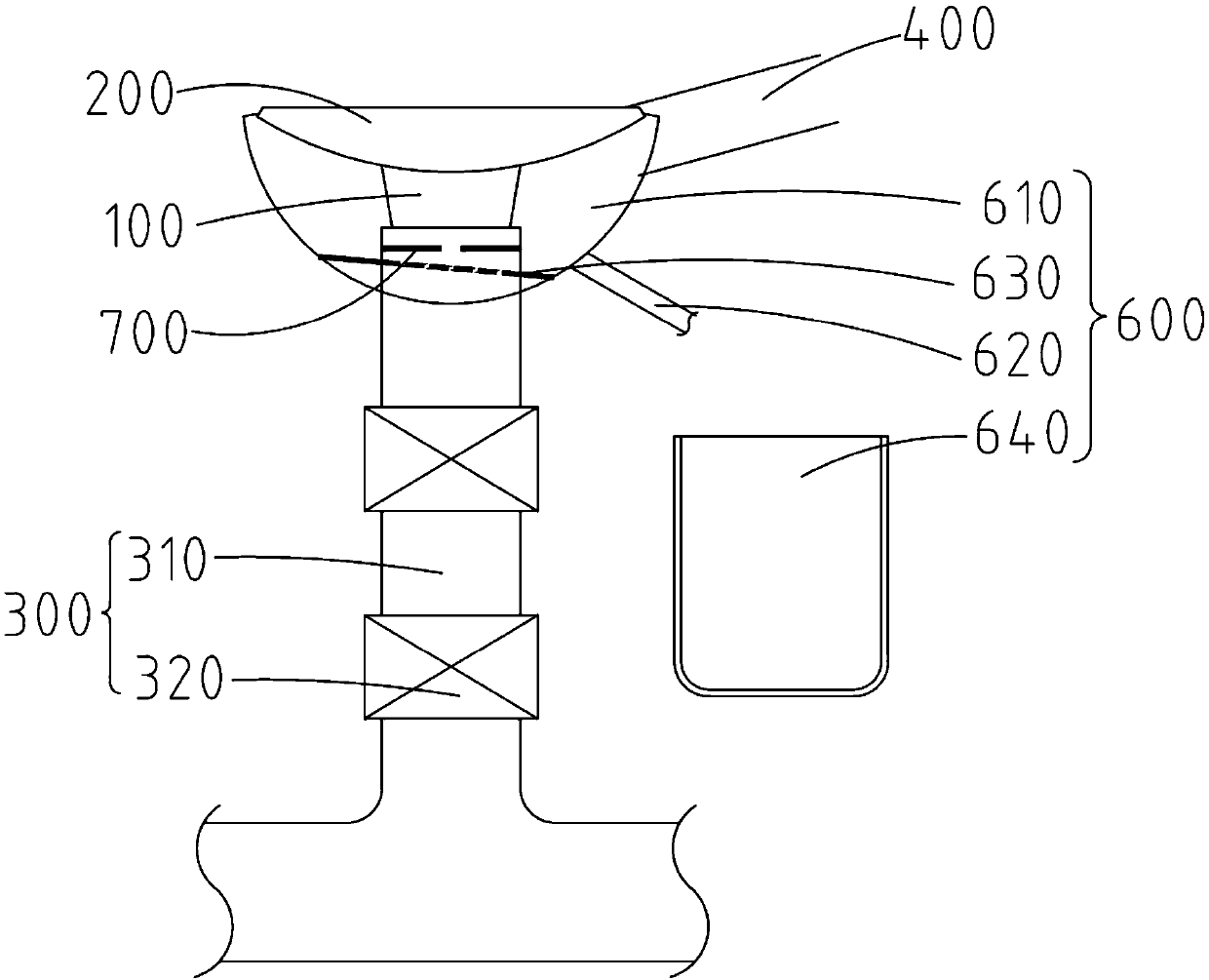

Continuous preparation device of rare earth compound precipitates

ActiveCN106947861AExtension of timeRealize continuous productionProcess efficiency improvementRefluxRare earth

The invention discloses a continuous preparation device of rare earth compound precipitates. The device comprises a horn-shaped reaction chamber, a self-suction stirring device, a feed pipe I, a feed pipe II, a reflux pipe, a purifying pipe, a clearing chamber, an overflow pipe and a pump I; the self-suction stirring device is fixedly mounted at the top in the horn-shaped reaction chamber; the lower part in the horn-shaped reaction chamber is connected with the feed pipe I and the feed pipe II; the clearing chamber is arranged on one side of the horn-shaped reaction chamber; the lower part of the clearing chamber is conical; the pump I is fixedly mounted at the conical bottom of the clearing chamber; the upper part of the clearing chamber is connected with the overflow pipe; the middle part of the clearing chamber is connected with the purifying pipe; the other end of the purifying pipe is connected to the upper part of the horn-shaped reaction chamber; the lower part of the clearing chamber is connected with the reflux pipe; and the other end of the reflux pipe is connected to the bottom of the horn-shaped reaction chamber. The device can realize continuous preparation of the rare earth compound precipitates, and is excellent in operation continuity, high in productivity, low in energy consumption and high in consistency of produced products.

Owner:カン州晨光希土新材料有限公司

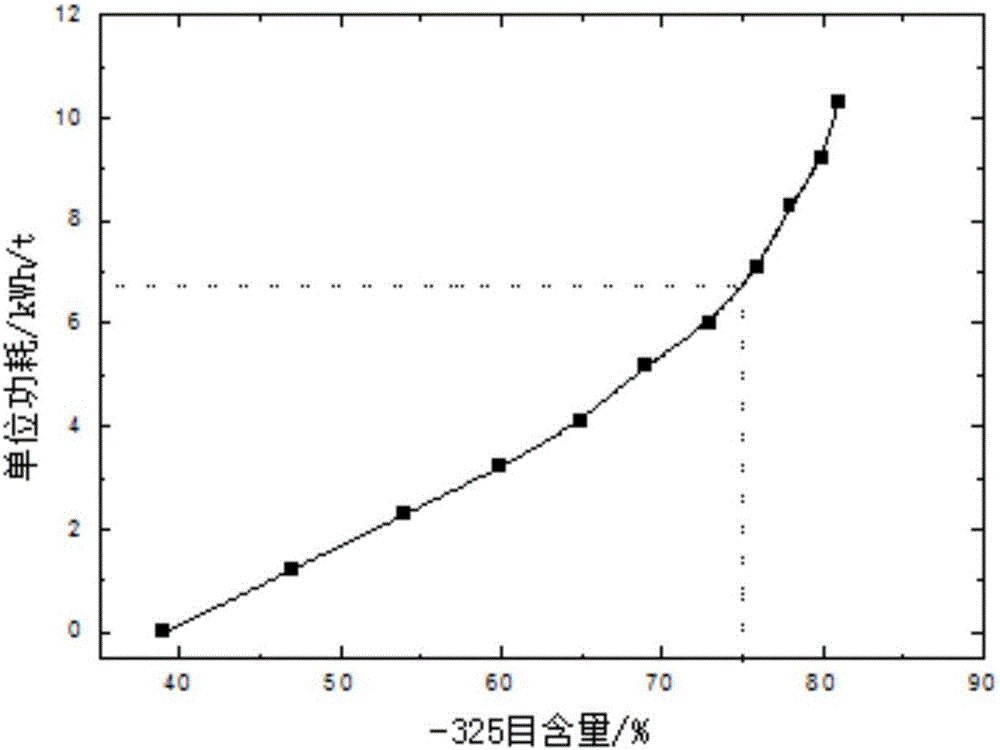

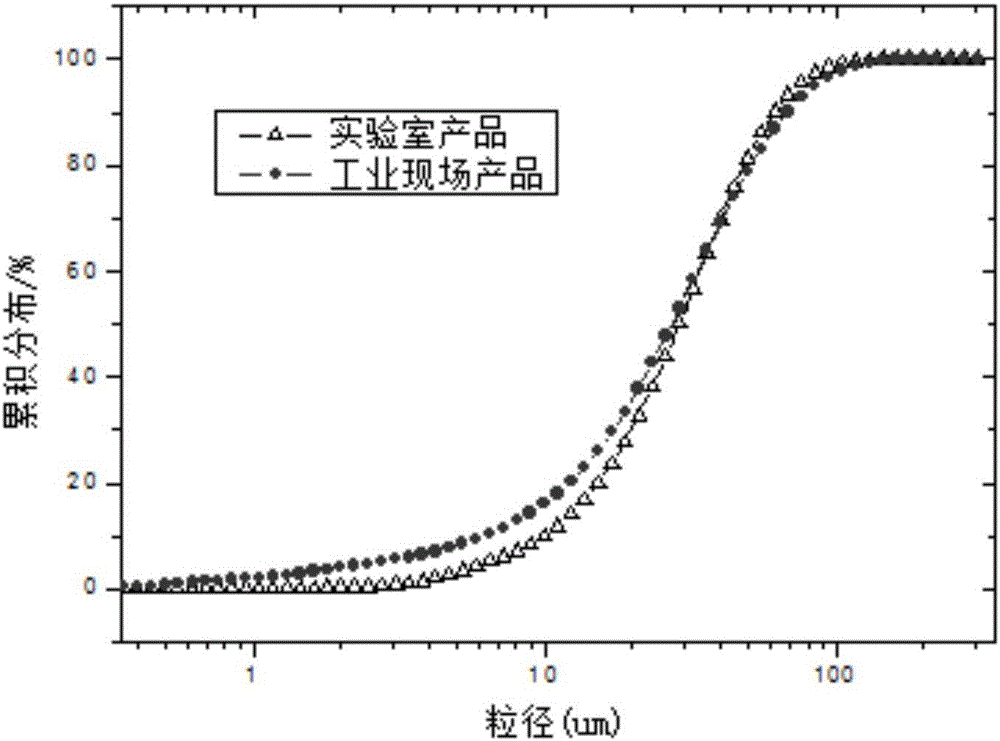

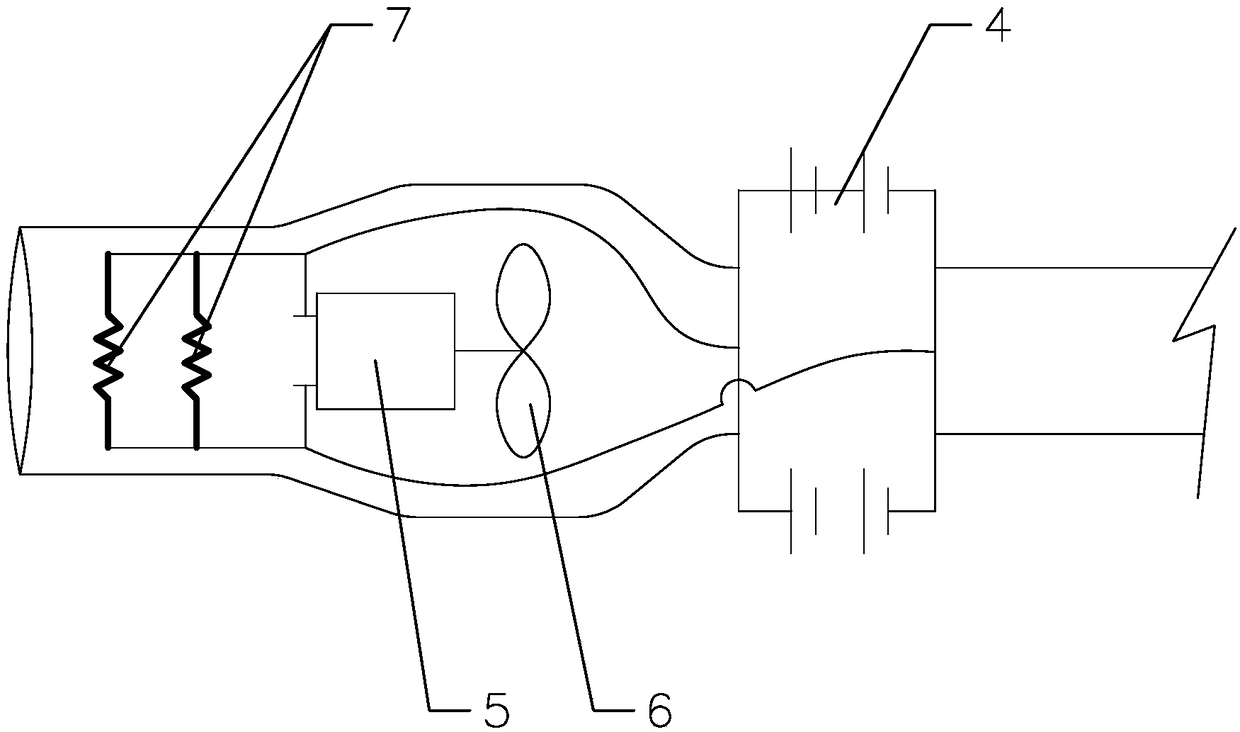

Model selection method for industrial type vertical stirring mill and model selection test closed-circuit fine milling system

ActiveCN106644639AAccurate and reliable power measurementCompact structurePreparing sample for investigationGrain treatmentsModel selectionEngineering

The invention discloses a model selection method for an industrial type vertical stirring mill and a model selection test closed-circuit fine milling system. The model selection method comprises the following steps: preparing a model selection test closed-circuit fine milling system, mixing ore slurry, feeding the slurry, performing an ore milling test, repeatedly sampling, calculating according to the content of minerals of the target particle size in the samples and the fine milling consumed power, drawing a unit energy consumption curve, and calculating the required power of an industrial vertical stirring mill of a model to be selected. The model selection test closed-circuit fine milling system comprises a test type vertical stirring mill and a circulating device which are connected to form a closed-circuit circulation ore milling system, and the model selection test closed-circuit fine milling system is provided with a power determination device for determining the power of a stirring shaft of the test type vertical stirring mill. The invention is applicable to model selection of industrial type vertical stirring mills for iron ores, molybdenum ores, copper ores, lead-zinc ores, gold ores and other metal minerals, and has the advantages of simple and convenient operation, small error and the like.

Owner:湖南金磨科技有限责任公司

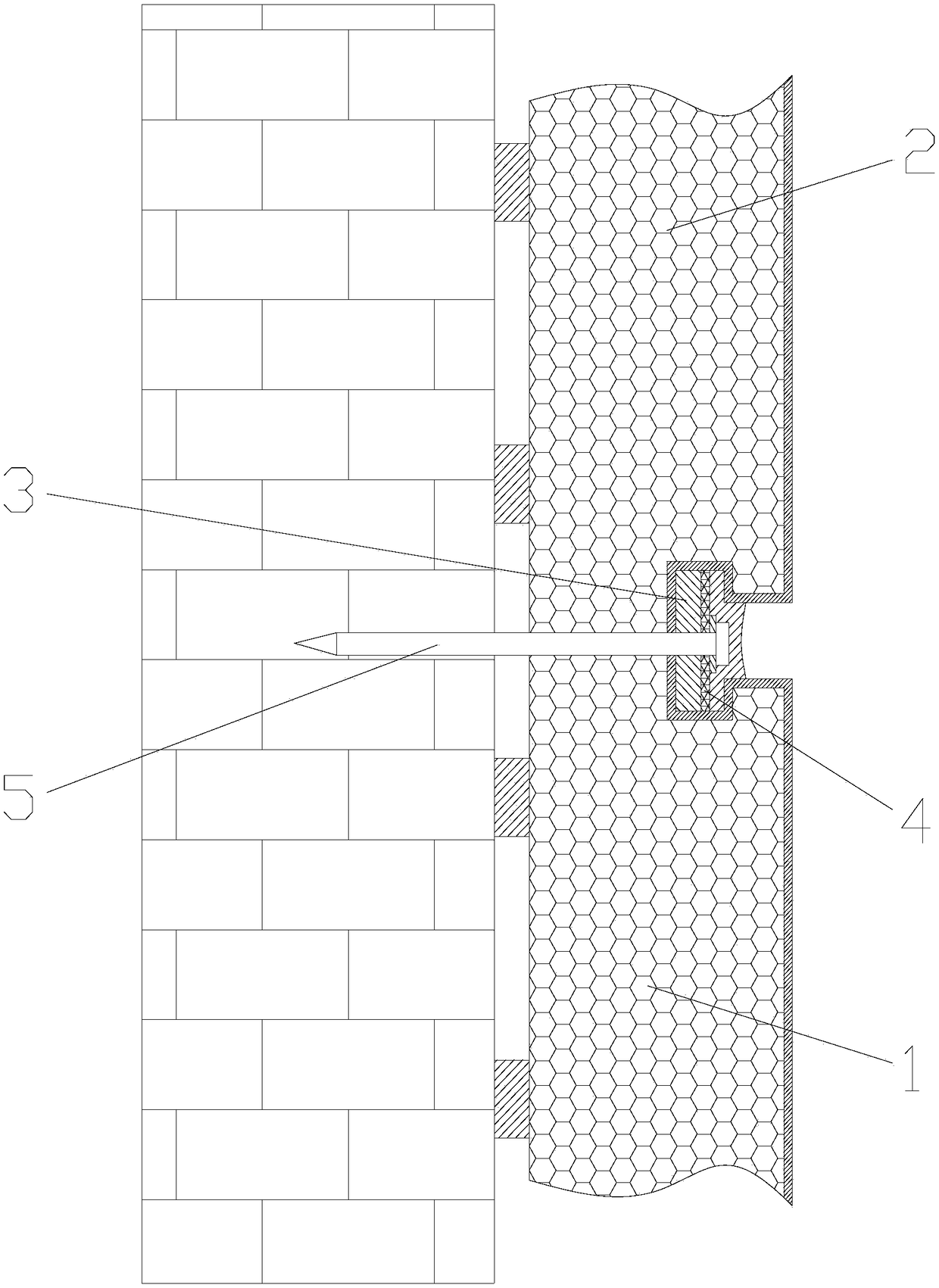

Method for anchoring building decorative boards

ActiveCN109113350AGood job continuityImprove anchoring efficiencyBuilding material handlingFiberAnchor bolt

The invention discloses a method for anchoring building decorative boards. The method comprises the following steps: (1) mounting a row of decorative boards on the surface of a building and correspondingly mounting another row of decorative boards above the row of decorative boards; (2) smearing mortar into a horizontal groove between the adjacent upper and lower rows of decorative boards; (3) placing a fiber sheet into the horizontal groove and allowing the fiber sheet to smoothly adhere to the mortar; (4) hitting anchor bolts along the horizontal groove so that the anchor bolts are anchoredinto the building after sequentially penetrating through the fiber sheet and the mortar. Compared with a traditional method of performing the anchoring operation while mounting each decorative board,the method for anchoring the building decorative boards is higher in operation continuity, higher in anchoring efficiency and higher in overall construction efficiency. Moreover, according to the method disclosed by the invention, the anchor bolts can be directly anchored into the fiber sheet so as to avoid the problem that anchor holes need to be opened on a locking board in advance when the locking board is used for anchoring, facilitate the improvement of the construction efficiency and reduce the mounting cost.

Owner:蔡启中

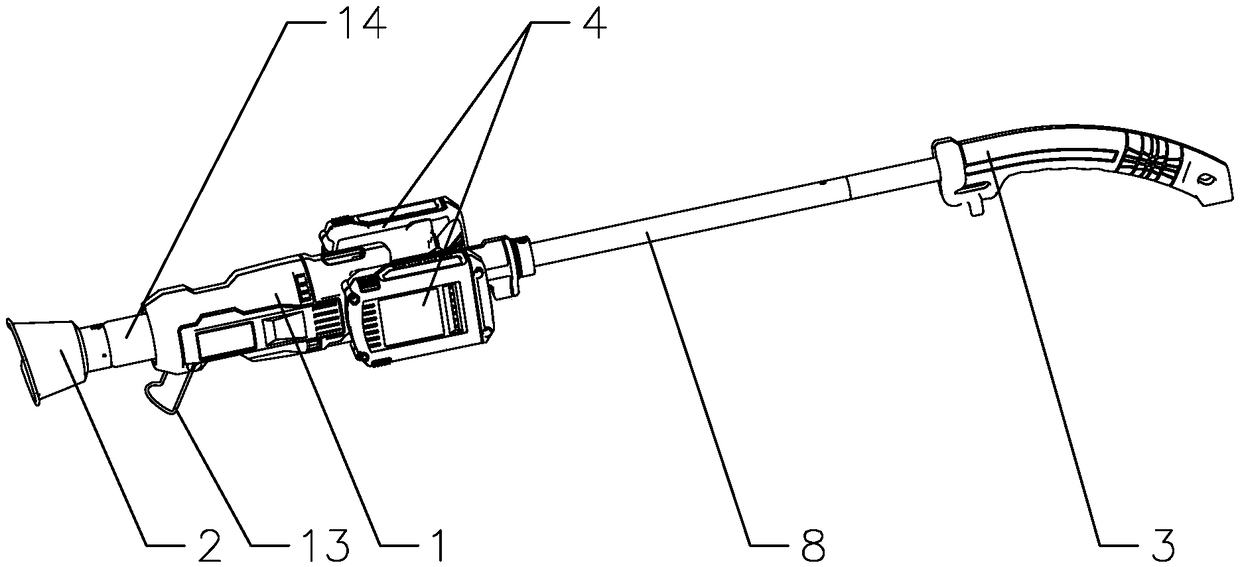

Hand-held high-temperature weeding machine convenient to operate

InactiveCN108925542AImprove operational convenienceIncrease flexibilityWeed killersElectricityWorking environment

The invention provides a hand-held high-temperature weeding machine convenient to operate. The weeding machine comprises a machine head, a weeding attachment and a handle; a high-temperature generating device is arranged in the machine head, and the weeding attachment communicates with the high-temperature generating device; and the weeding machine further comprises a battery pack, and the batterypack is electrically connected with the high-temperature generating device and supplies power to the high-temperature generating device to make the high-temperature generating device operate. According to the weeding machine provided by the invention, the power is supplied to the high-temperature generating device through the battery pack, so that the weeding machine works; and compared with a current power supply mode through a power line, the power supply mode disclosed by the invention makes the weeding machine more convenient to operate, the weeding machine is not pulled by the power linewhen working, the weeding machine can be operated in any directions, the weeding machine is not affected by a length of the power line to affect operation distance, and the weeding machine can be conveniently held to each working environment; and the problem that operation cannot be performed because a socket cannot be found when working is performed outdoors is well avoided, the weeding machinecan be very suitable for outdoor work, an application range of the weeding machine is improved, and operational convenience of the weeding machine is improved.

Owner:ZHEJIANG PRULDE ELECTRIC APPLIANCE CO LTD

Remote control ball delivery device

PendingCN110857618ASolve crossingImprove securityFluid removalWell/borehole valve arrangementsRemote controlControl engineering

The invention discloses a remote control ball delivery device. The remote control ball delivery device comprises a ball containing mechanism, a ball storing mechanism, and a hydraulic system. The upper end of the ball containing mechanism communicates with the ball storing mechanism, the lower end of the ball containing mechanism communicates with the hydraulic system, and the device further comprises a remote control mechanism for storing fracturing balls on the ball storing mechanism. According to the remote control ball delivery device, the problem existing in passing through a high-voltagearea by a constructor can be effectively solved, constructor safety coefficient is improved, work continuity is improved, construction cost is reduced, use of fracturing liquid is reduced, the construction success rate is improved, the construction over displacement is solved, independent choice is achieved, work is intelligent, an operator can be thoroughly away from the high-voltage work area,and the high-voltage thorn leakage danger possibly bringing by the high-voltage area is avoided.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

Viscous material extruder and application thereof

The invention discloses a viscous sugar material extruder and application thereof, and solves the problem that the structure of an existing extruder is relatively complex, the structure comprises a rack and a stock bin, the upper end and the lower end of the stock bin are provided with a feeding port and a discharging port respectively, and a channel for materials to advance is formed between the feeding port and the discharging port in the stock bin. An extrusion roller connected with a power mechanism is arranged in the stock bin, a plurality of protruding pushing edges are arranged on the peripheral face of the extrusion roller, the pushing edges are evenly distributed in the circumferential direction of the extrusion roller, and the pushing edges on the extrusion roller extend into the channel. A containing cavity is formed between every two adjacent pushing edges on the extrusion roller, a scraping plate is arranged on the outer side of the extrusion roller and is close to the position of the discharging port, the outer end of the scraping plate is used for movably stretching into the containing cavity, and the scraping plate shovels and scrapes materials in the containing cavity into the channel before the pushing edges leave the channel. And an avoiding mechanism acting on the scraping plate enables the scraping plate to move, and enables the scraping plate to adapt to the rotation of the extrusion roller so as to sequentially avoid the pushing edges extending into the channel.

Owner:DONGYING ZHIDA FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com