Hand-held high-temperature weeding machine convenient to operate

A hand-held, weeding machine technology, used in weed eradication equipment, applications, animal husbandry, etc., can solve problems such as inability to construct, slow chemical degradation, and no complete weed roots, and achieve simple and convenient operation. , Improve the convenience of operation, the effect of convenient charging and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

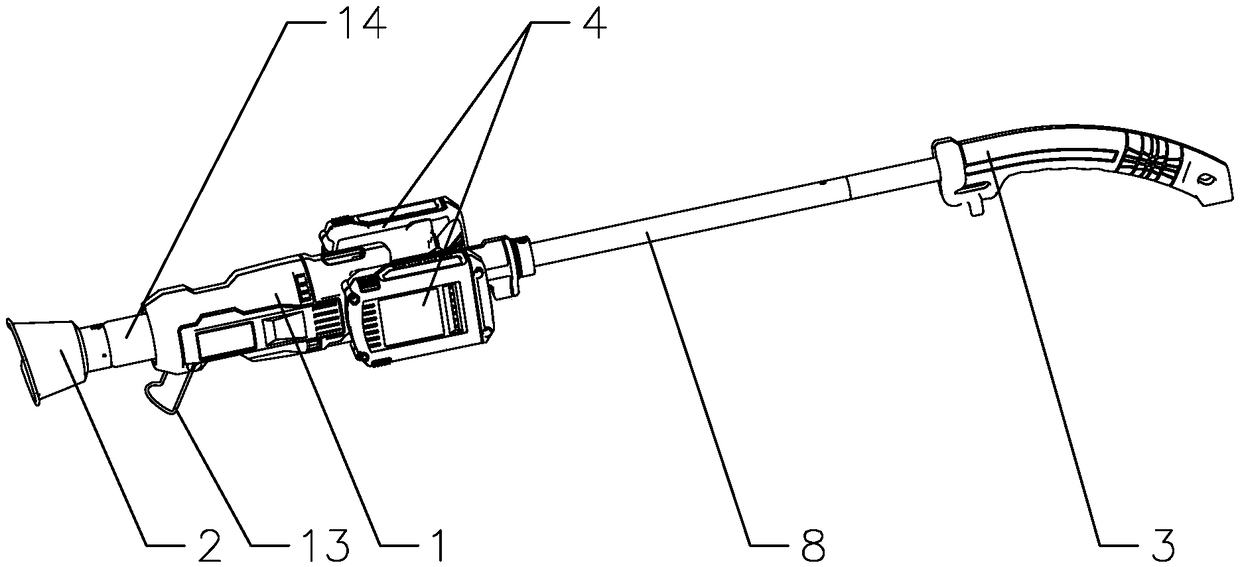

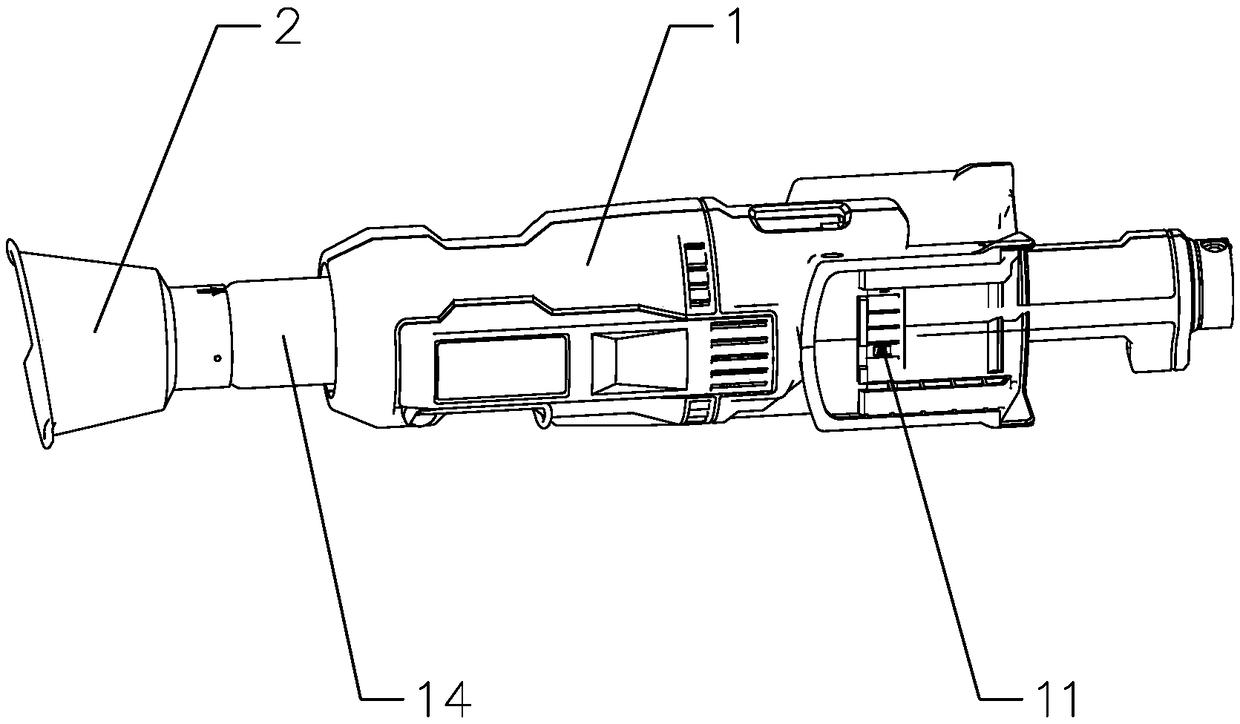

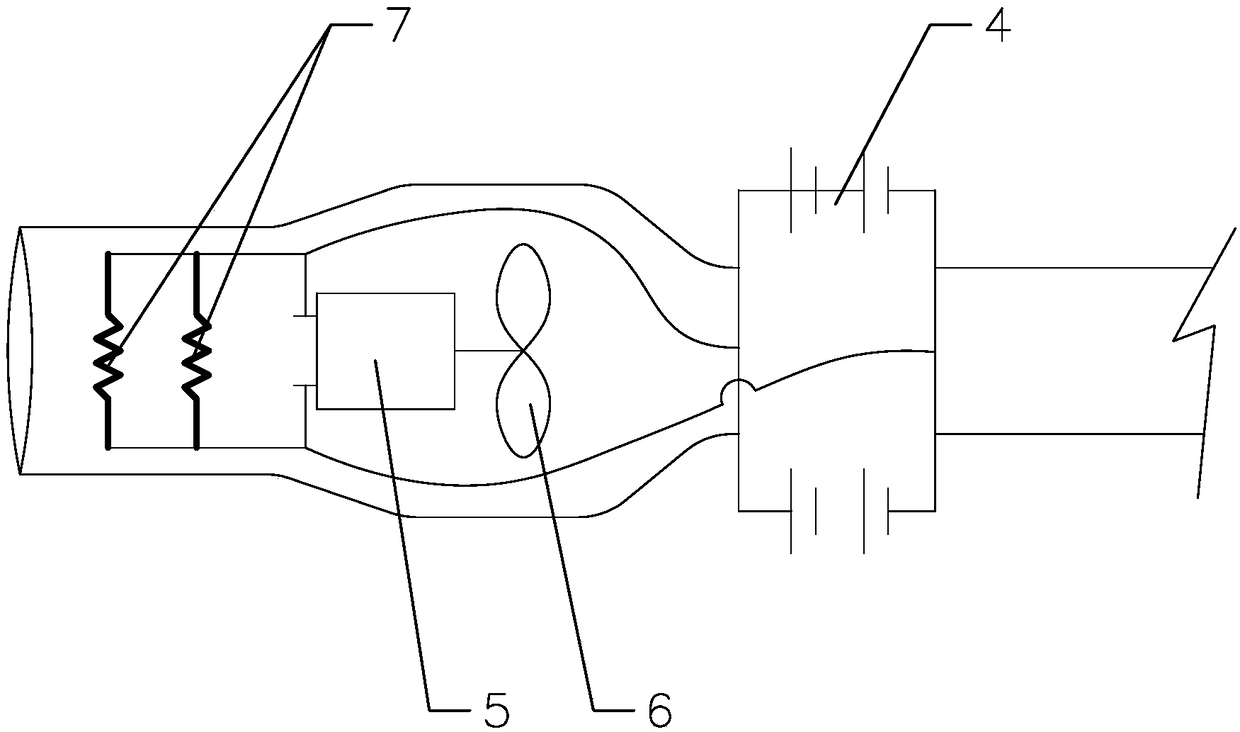

[0045] Such as Figures 1 to 8 As shown, the present invention provides a hand-held high-temperature weeding machine that is easy to operate, including a head 1, a weeding attachment 2 and a handle 3, a high-temperature generating device is arranged in the head 1, and a weeding attachment 2 is connected to the high-temperature generating device. Attachment 2 is an air outlet cover, specifically a trumpet-shaped air outlet cover. The handle 3 is arranged at the rear end of the machine head 1, which is convenient for the user to operate the weeding machine and improves the user experience; at the same time, the handle 3 is set to be plastic, It not only reduces the processing cost of the weeder, but also plays the role of anti-slip and heat insulation, which greatly improves the user experience.

[0046] In this embodiment, the weeder also includes a battery pack 4, the battery pack 4 is electrically connected to the high temperature generating device and supplies power to the h...

Embodiment 2

[0080] The difference between this embodiment and the first embodiment lies in that the structure of the mounting bracket is different.

[0081] In this example, if Figure 9 As shown, the longitudinal section of the mounting bracket 71 is Y-shaped. Correspondingly, there are three closely wound sections 721 and are distributed at the three inner corners of the mounting bracket 71. In this way, the closely wound sections can also be separated, so that It does not affect the work between the closely wound sections, but also ensures that the heat between the closely wound sections is concentrated together and is not easy to disperse, so as to ensure that the temperature of the air outlet is sufficient to ensure the working effect of the weeder and Improve the working efficiency of the weeder.

[0082] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0084] The difference between this embodiment and the first embodiment lies in that the structure of the mounting bracket is different.

[0085] In this example, if Figure 10 As shown, the longitudinal section of the mounting bracket 71 is Correspondingly, there are six tightly wound sections 721 and they are distributed at the six inner corners of the mounting bracket 71. In this way, the closely wound sections can also be separated, so that it does not affect the connection between the closely wound sections. Working, it can also ensure that the heat between the closely wound sections is concentrated and not easy to disperse, so as to ensure that the temperature of the air outlet is sufficient to ensure the working effect of the weeding machine and improve the working efficiency of the weeding machine.

[0086] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com