Flexible kinetic energy carborundum and net composite huller

A kind of peeling machine, flexible technology, applied in grain husking, grain processing, application, etc., can solve the problems of weakening peeling ability, not very wide adaptability, affecting peeling quality, etc., to improve peeling efficiency and peeling quality, high promotion Good application value and work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

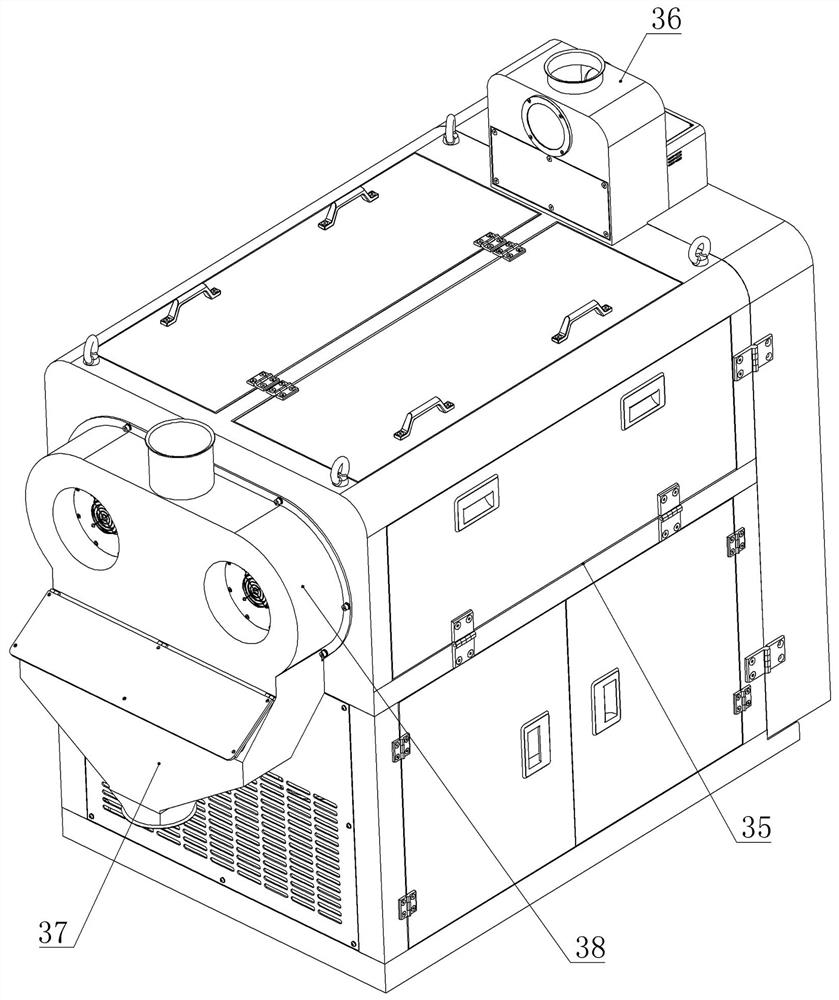

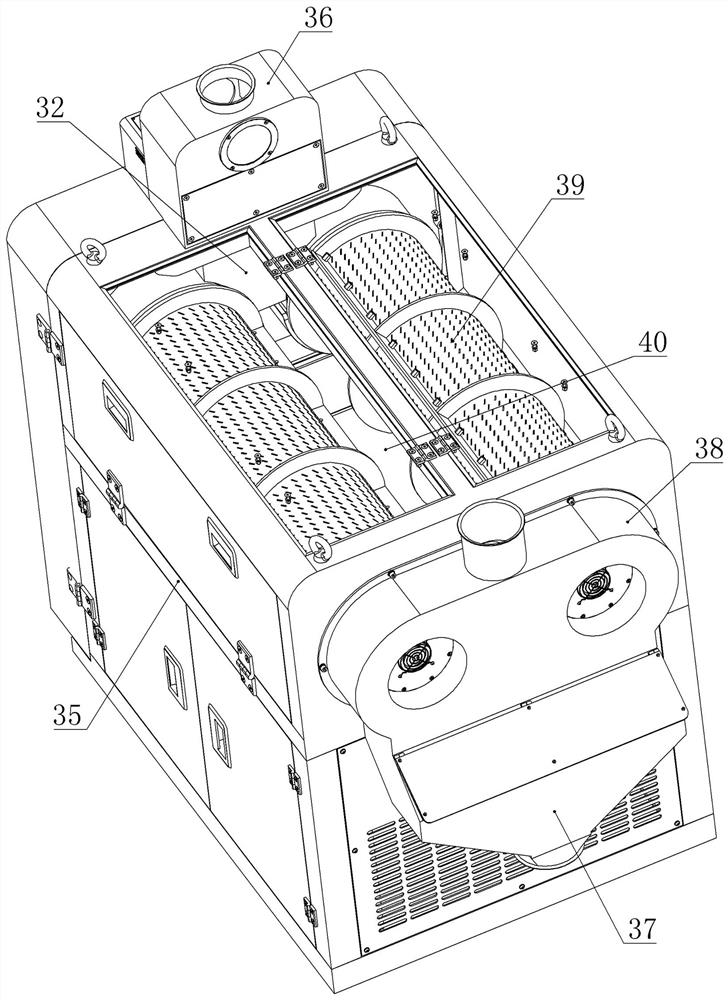

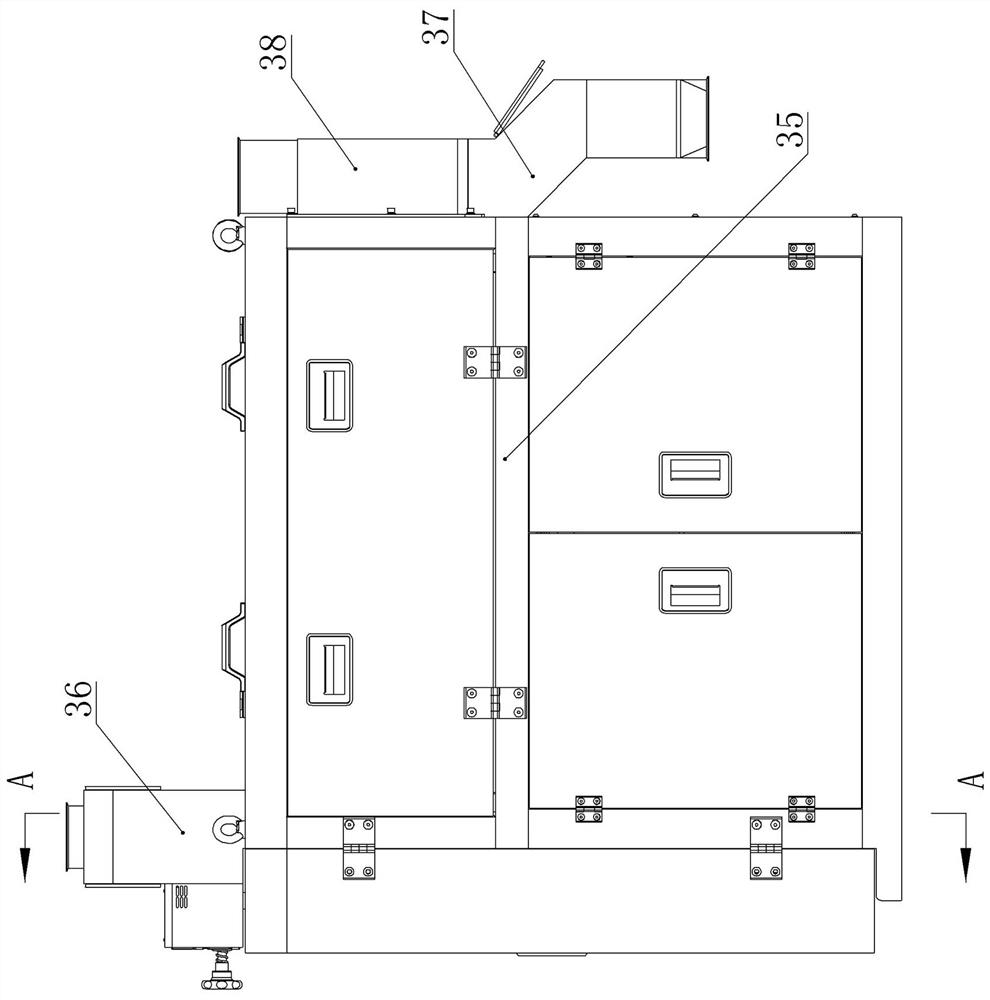

[0035] Embodiment one, see Figure 1-18 , a flexible kinetic energy sand mesh compound peeling machine, including a frame, a feeding chamber installed on the frame, a discharge chamber, two sets of flexible kinetic energy sand mesh peeling devices, and a bran collection bucket located at the lower part of the flexible kinetic energy sand mesh peeling device ;

[0036] Two sets of flexible kinetic energy sand net peeling devices are arranged in parallel. The device includes a cylindrical roller body, a cylindrical screen mesh set outside the roller body, and flexible rollers uniformly distributed along the circumferential direction are fixed on the peripheral surface of the roller body. The blade assembly and several deflectors arranged along the helical direction, the flexible blade assembly includes a blade made of elastic steel plate, the blade is comb-shaped and protrudes along the tangential direction of the outer peripheral surface of the roller body, at the working end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com