Snow removal and briquetting all-in-one machine

An all-in-one machine and snow block technology, applied in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of environmental pollution, high cost, limited use range, etc., and achieve good operation continuity, scientific and reasonable design, compact and reliable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

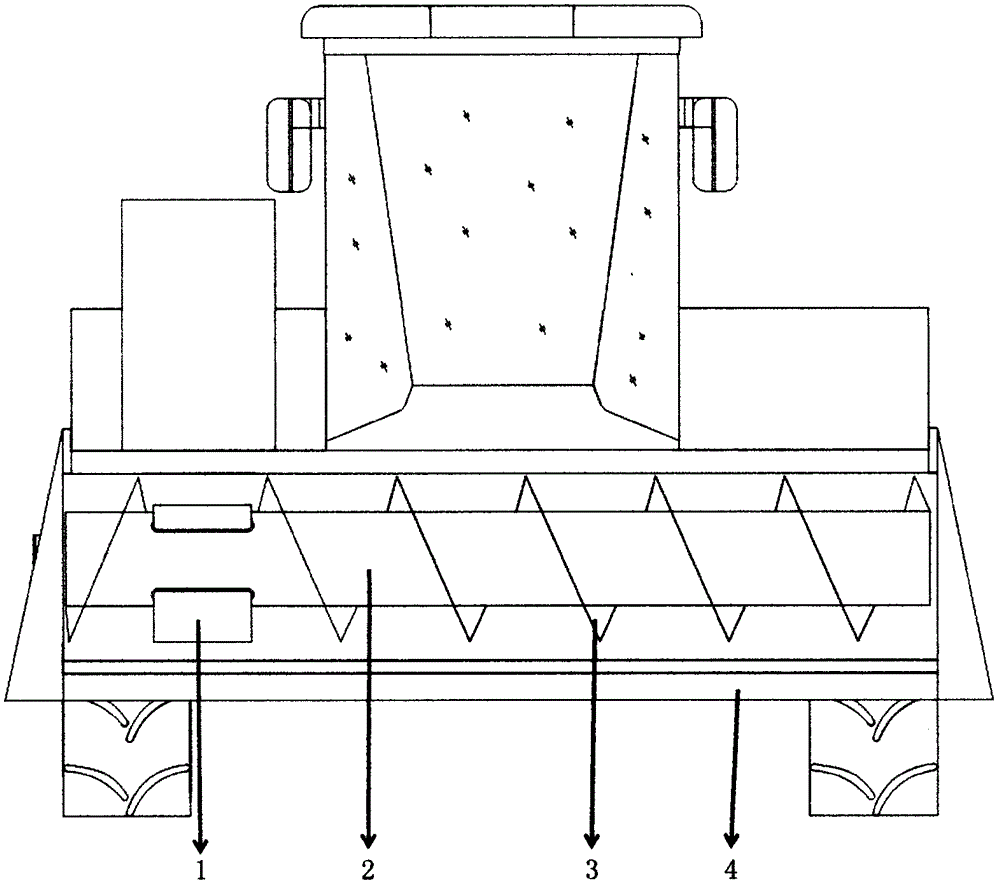

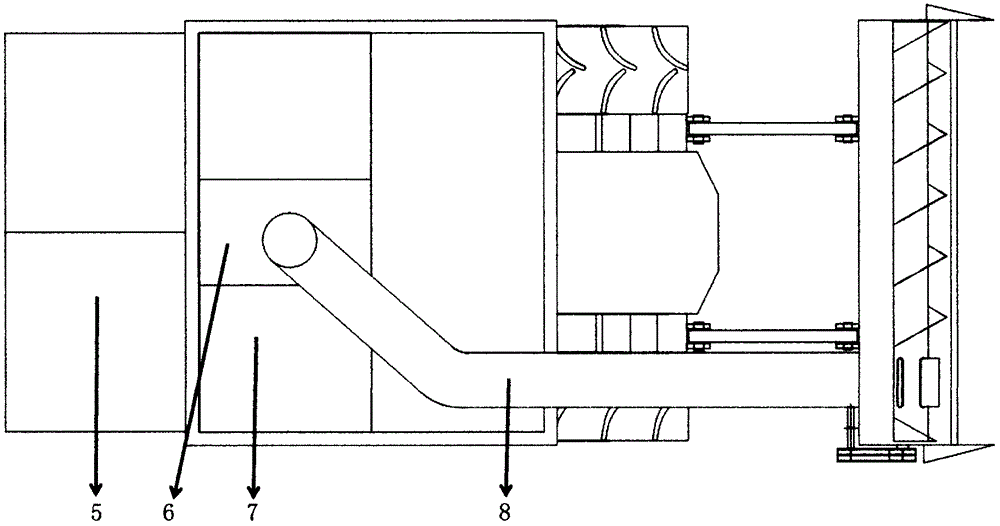

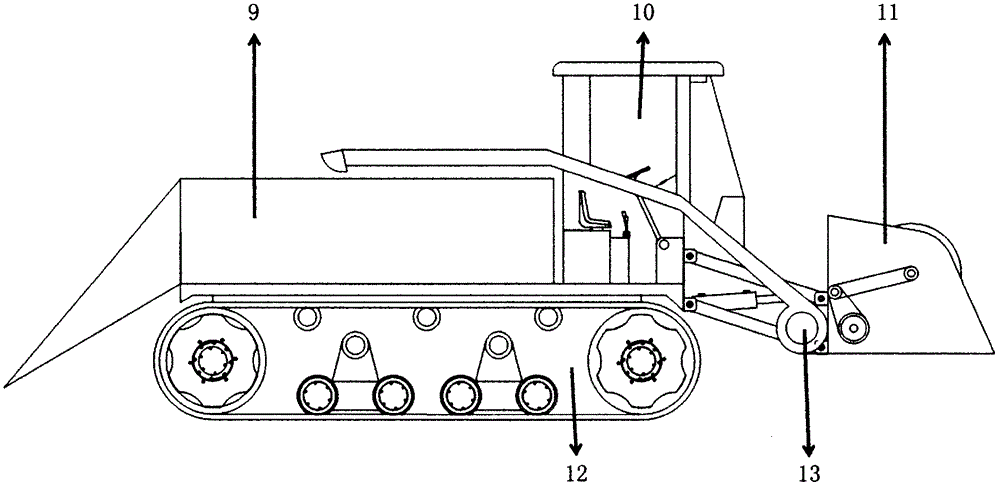

[0016] The preferred embodiment of the present invention is described in detail below in conjunction with accompanying drawing, the all-in-one machine for clearing snow and briquetting is made of: briquetting machine 9, driver's cab 10, clearing snow and rolling machine 11, walking chassis 12, snow blower 13.

[0017] It is characterized in that: in the walking system, the engine cooperates with the main clutch, the main clutch cooperates with the gearbox, the gearbox cooperates with the main drive, the main drive cooperates with the end drive, the end drive cooperates with the steering clutch, the steering clutch cooperates with the brake, and the brake Cooperate with the driving wheel, the driving wheel cooperates with the track, the supporting wheel and the tensioning device, the power is transmitted from the engine to the main clutch, the main clutch is transmitted to the gearbox, the gearbox is transmitted to the main drive, and the main drive is transmitted to the final dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com