Patents

Literature

107results about How to "Improve anchoring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

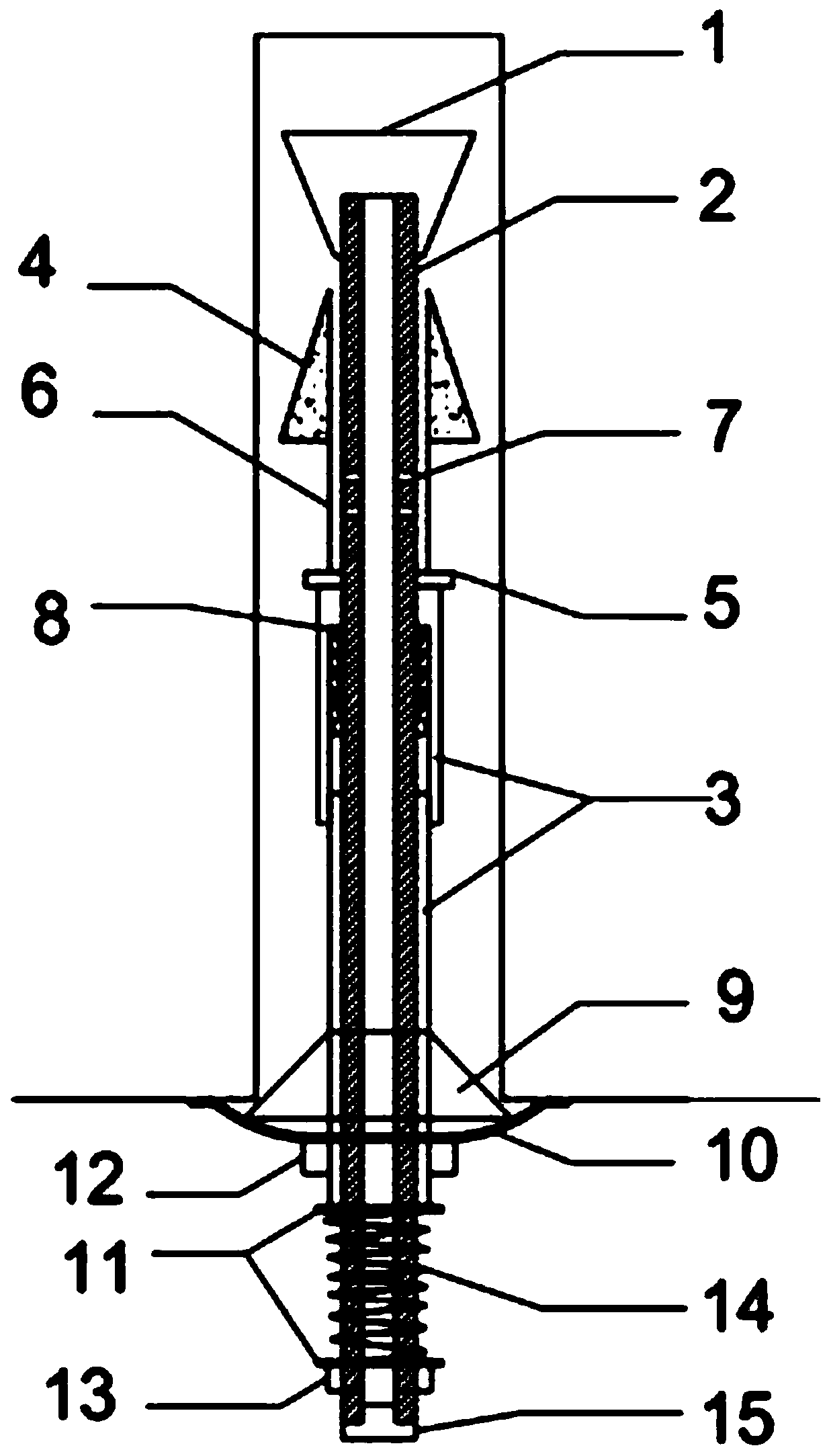

Carbon fiber cable strand inner sleeve conical bonded anchorage device

InactiveCN102002911AImprove adhesionAct as a stiff skeletonBridge structural detailsBuilding reinforcementsFiberCarbon fibers

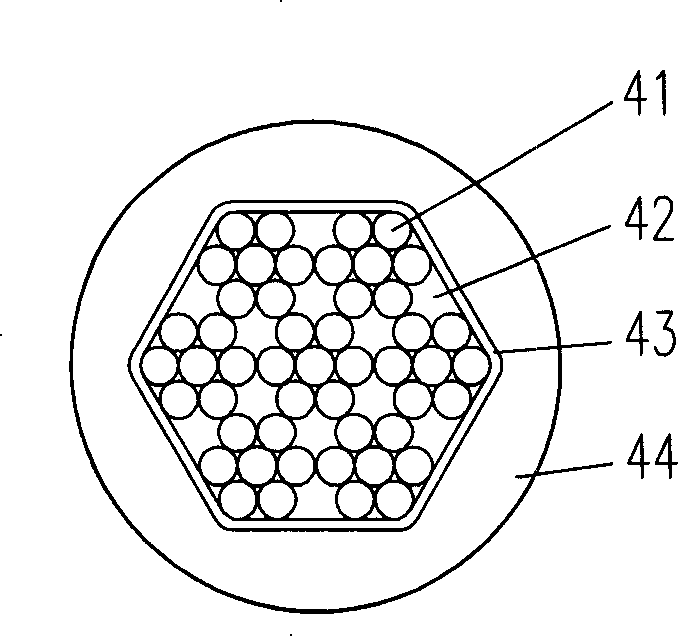

The invention discloses a carbon fiber cable strand inner sleeve conical bonded anchorage device. In the carbon fiber cable strand inner sleeve conical bonded anchorage device, a reinforced thread reinforcing steel bar is arranged on the outer side of a sleeve; an axial wedge-shaped hollow groove is formed in the sleeve; and a wedge tip of the hollow groove faces the small hole end of an anchor ring conical hole. By the anchorage device of the invention, the condition of non-uniform transverse and longitudinal stress of carbon fiber reinforced plastic (CFRP) cable strands can be improved; the anchorage device can be prestressed; all the CFRP wires can exert limit bearing capacity at the same time; the anchoring efficiency is improved; the anchoring efficiency coefficient can reach 100 percent; and the anchorage device has excellent static performance and dynamic performance and low manufacturing cost, is simple and convenient in assembly and is easy in construction.

Owner:CCCC HIGHWAY CONSULTANTS +1

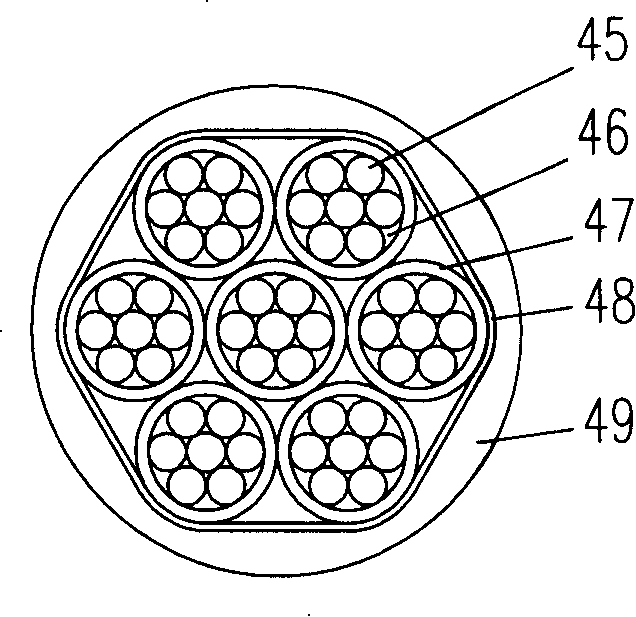

Steel strand integral bundle extrusion anchor cable guy cable

ActiveCN101210447AImprove reliabilityIncreased durabilityBuilding roofsBridge structural detailsScrew threadHigh frequency vibration

The invention relates to a draw-rope used in major construction projects, in particular to an anchor draw-rope formed by compressing a whole bundle of stranded steel ropes and composed of a finished stranded steel rope body and anchor fasteners on the two ends. The anchor fastener is divided into an anchor fastening unit and a sealing unit. The anchor fastening unit comprises a compressing anchorage sleeve, a screw nut and an end cover. Mounting holes for embedding the stranded steel rope in equal number with the compressed stranded steel ropes are drilled inside the compressing anchorage sleeve; the stranded steel ropes are disposed in the mounting holes and compressed with the anchorage sleeve into a whole; main components of the sealing unit includes a sealing cylinder, a sealing ring and antiseptic materials. The end of the compressing anchorage sleeve is provided with external screw thread; one end of the sealing cylinder is sleeved on the end of the compressing anchorage sleeve through the screw thread; the sealing ring and a restraining ring sleeved on the rope body are arranged in sequence inside the other end of the sealing cylinder; a gland bush is screwed on the sealing cylinder through the inner screw thread of the sealing cylinder which is filled with antiseptic materials; a through-slit is opened between the mounting holes for embedding the stranded steel ropes inside the compressing anchorage sleeve. The stranded steel rope in the anchor rope is able to perform firm anchoring, not easy to slip off under high-frequency vibration, small in anchor head volume and low in manufacture cost.

Owner:LIUZHOU OVM MASCH CO LTD

Secondary tensile prestressed anchorage

The invention relates to a twice spreading prestressing force anchor tool that can make the middle or short prestressing force tendon take twice spreading. The invention is made up of sole plate, bearing nut, anchor circle and clamping piece. That can anchor fix 1-20 prestressing steel strand and high intension steel bundle. It can be widely used for anchor fixing the prestressing force tendon of road and bridge, railway girder, and so on.

Owner:万国强 +1

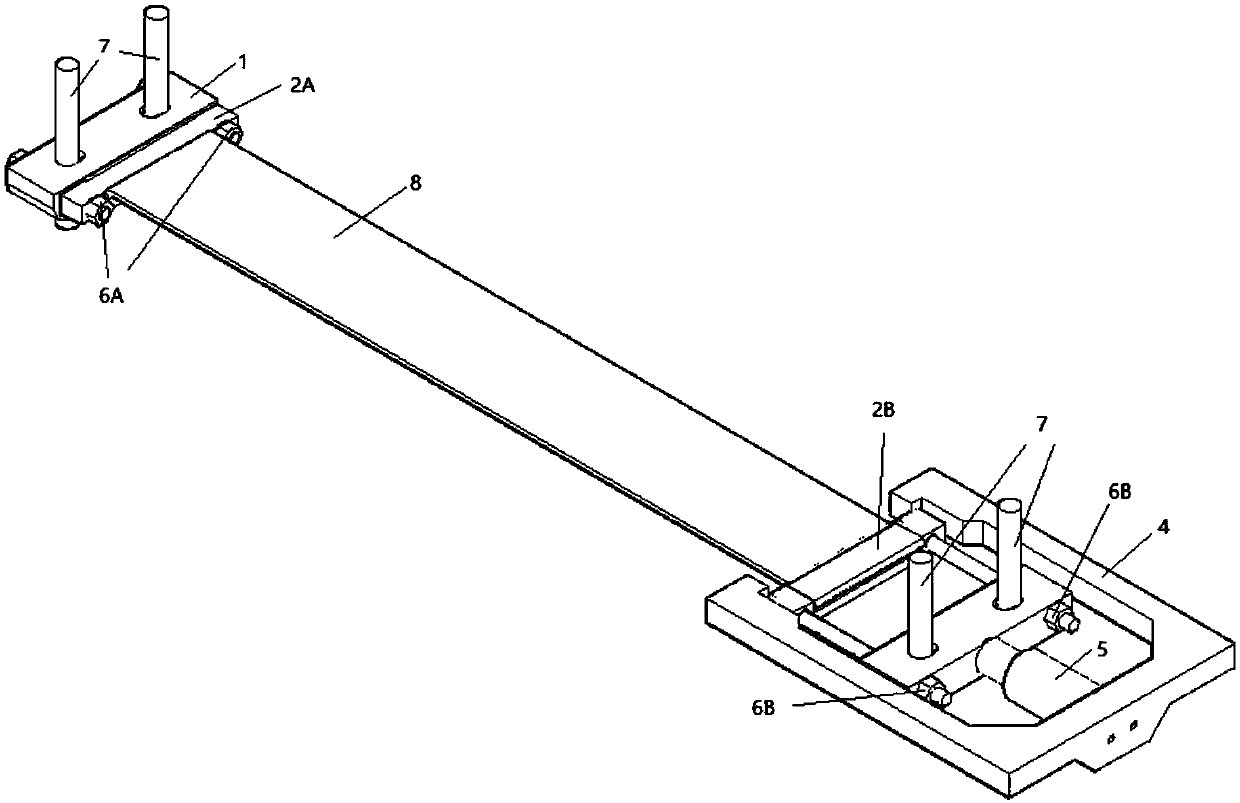

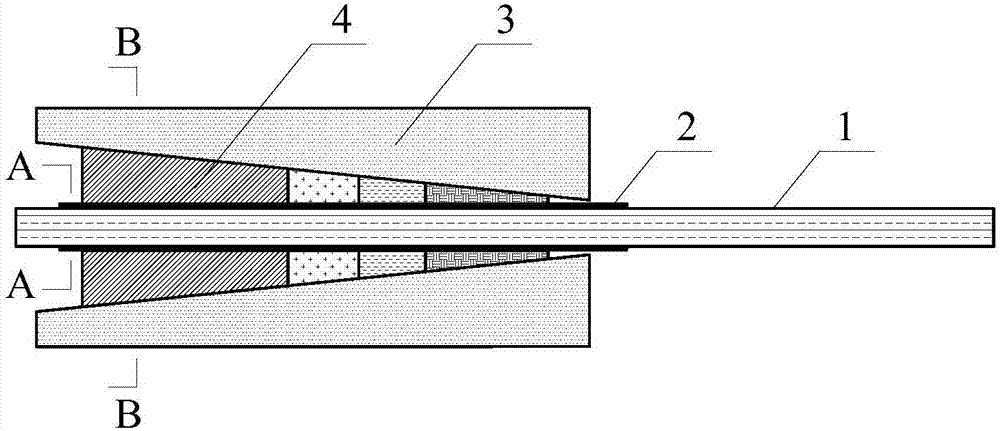

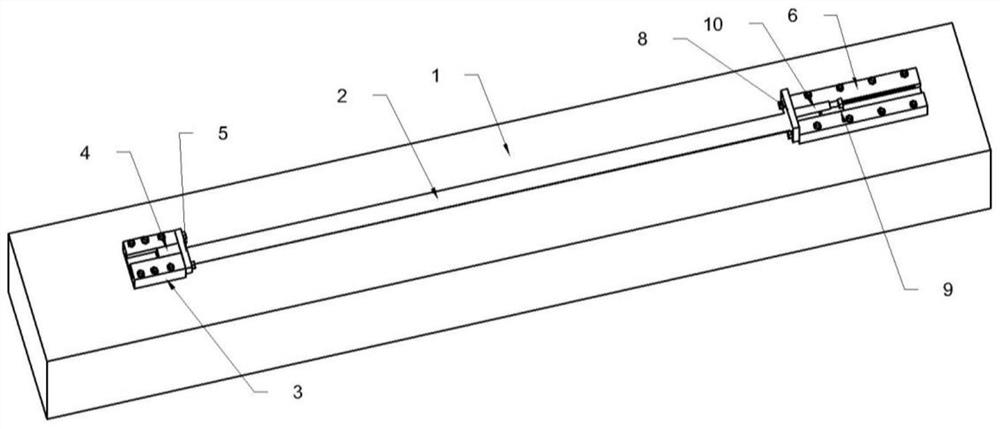

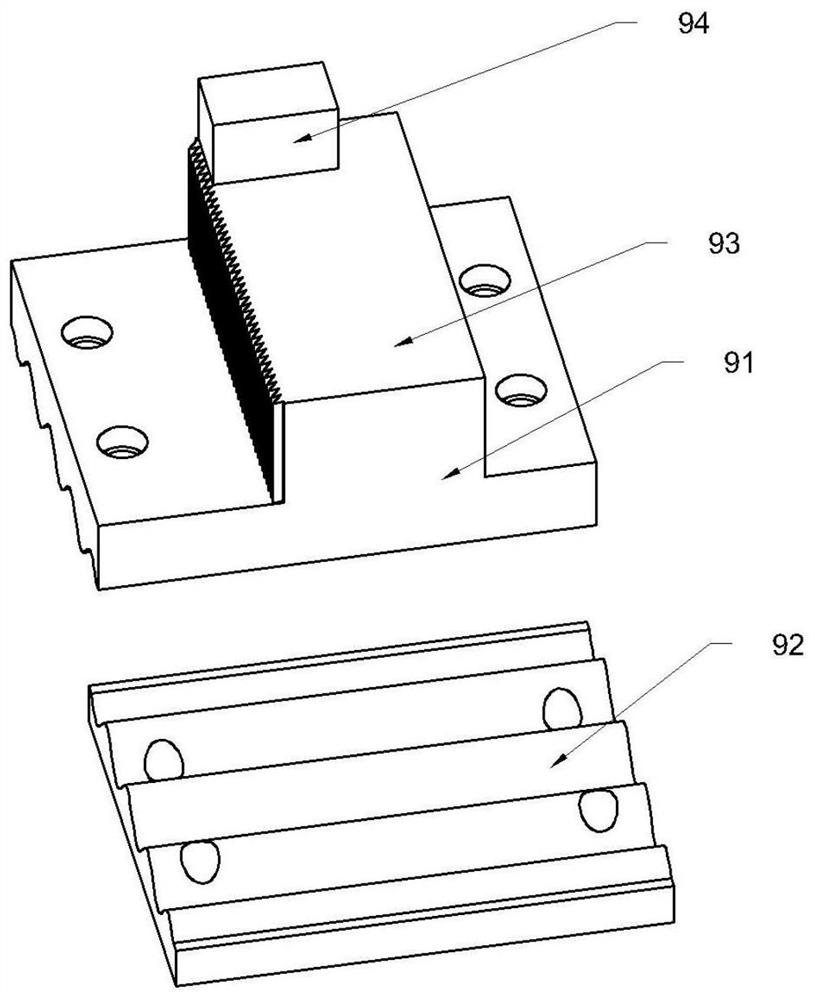

Tensioning and anchoring device for prestressed fiber cloth reinforced beams and construction method of device

ActiveCN108843037APrevent slippageImprove anchoring efficiencyBuilding repairsBuilding material handlingFiberPre stress

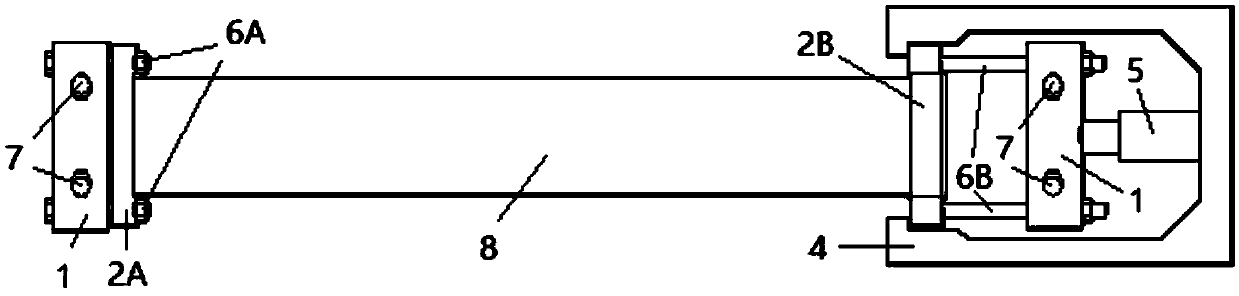

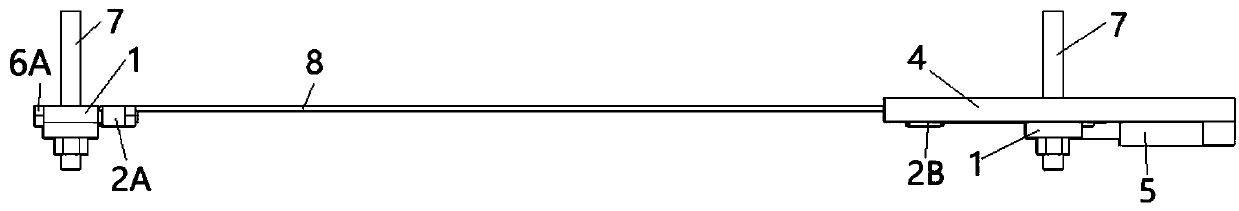

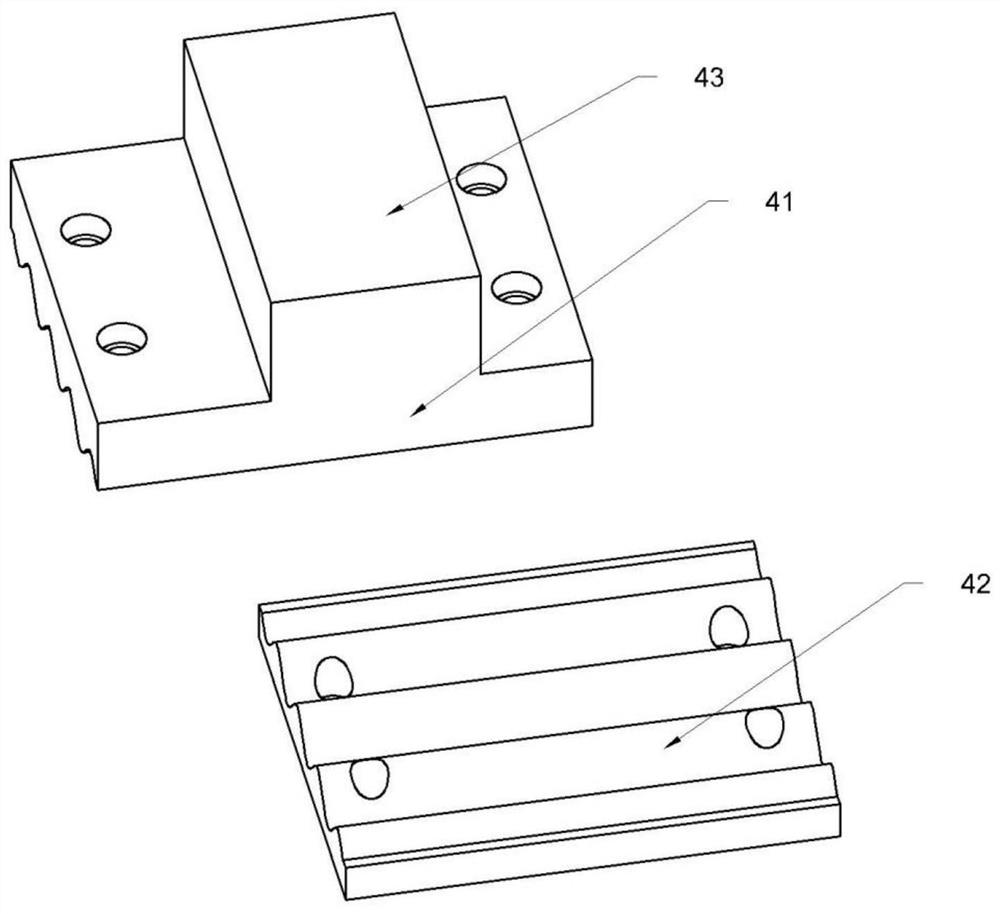

The invention discloses a tensioning and anchoring device for prestressed fiber cloth reinforced beams and a construction method of the device. The device comprises fixed supports, a fixed end anchorage device, a tensioning end anchorage device, clamping pieces, short anchoring screws, long anchoring screws, chemical bolts, fiber cloth, a prestress application frame and a jack, wherein the fixed supports, the fixed end anchorage device and the tensioning end anchorage device are cuboid; the fixed supports are fixed with a to-be-reinforced beam through the chemical bolts; the fixed end anchorage device and the tensioning end anchorage device are connected with the fixed supports through the short anchoring screws and the long anchoring screws respectively; a rectangular through seam allowing the fiber cloth to pass is formed in the fixed end anchorage device; wedge-shaped holes allowing insertion of the clamping pieces are formed in the tensioning end anchorage device, and the clampingpieces are wedged into the wedge-shaped holes, so that clamping of the fiber cloth is realized. The construction method comprises steps as follows: firstly, the anchorage devices are mounted, then thefixed supports are assembled and the anchorage devices are fixed, finally, the prestress application frame and the jack are mounted, and tensioning and anchoring are implemented. The device is reasonable and simple in structure and convenient to operate and can be reused, and the applied prestress is large.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

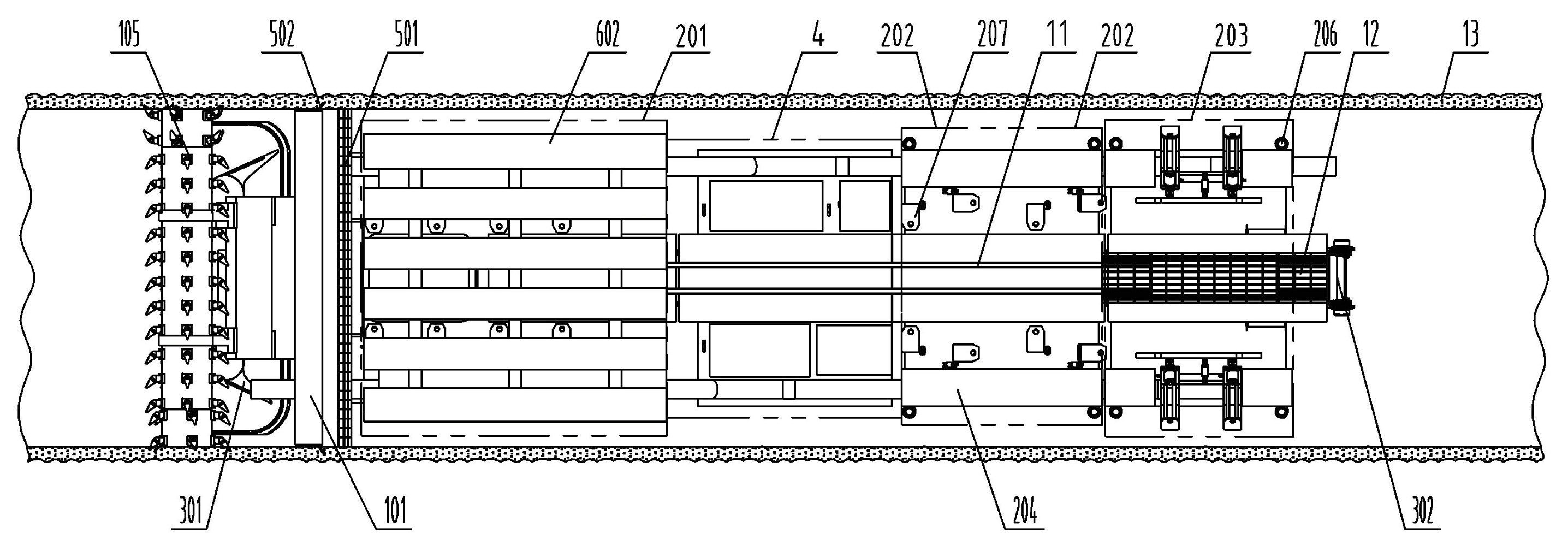

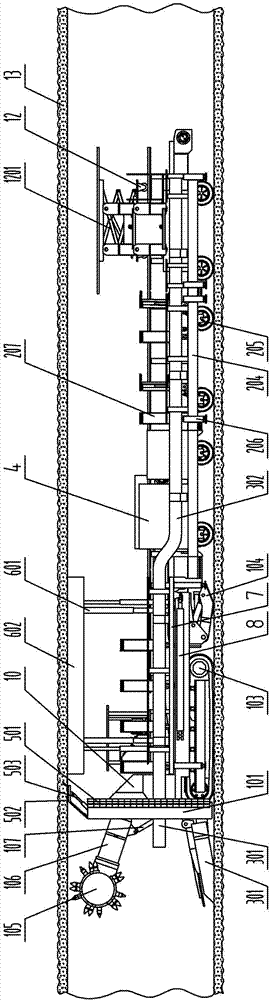

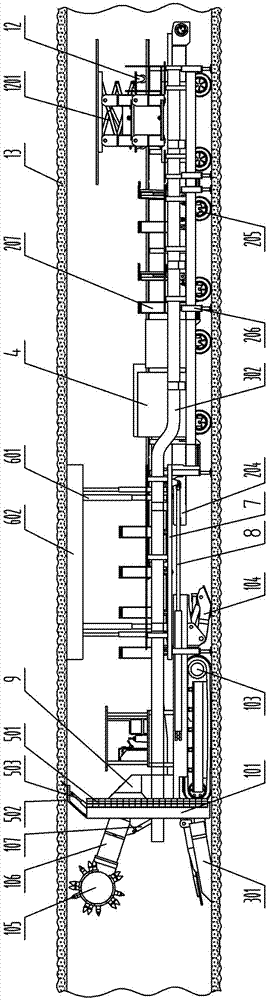

Fully sealed coal roadway tunneling and anchoring synchronous machine

ActiveCN102606153AImprove tunneling efficiencyImprove safety factorSlitting machinesAnchoring boltsVehicle frameMining engineering

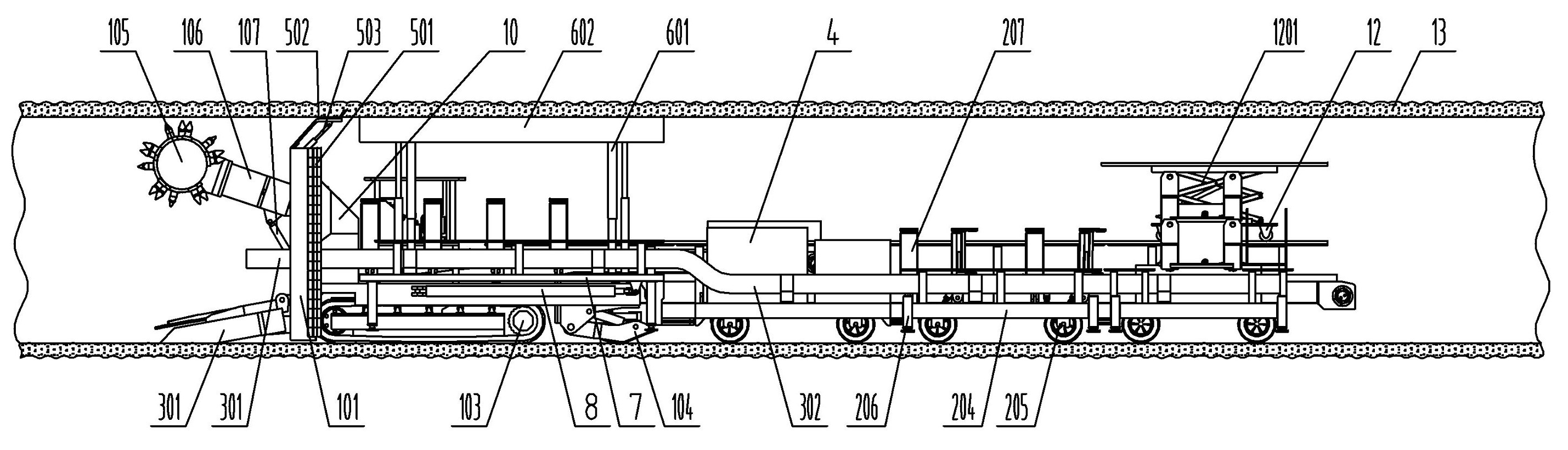

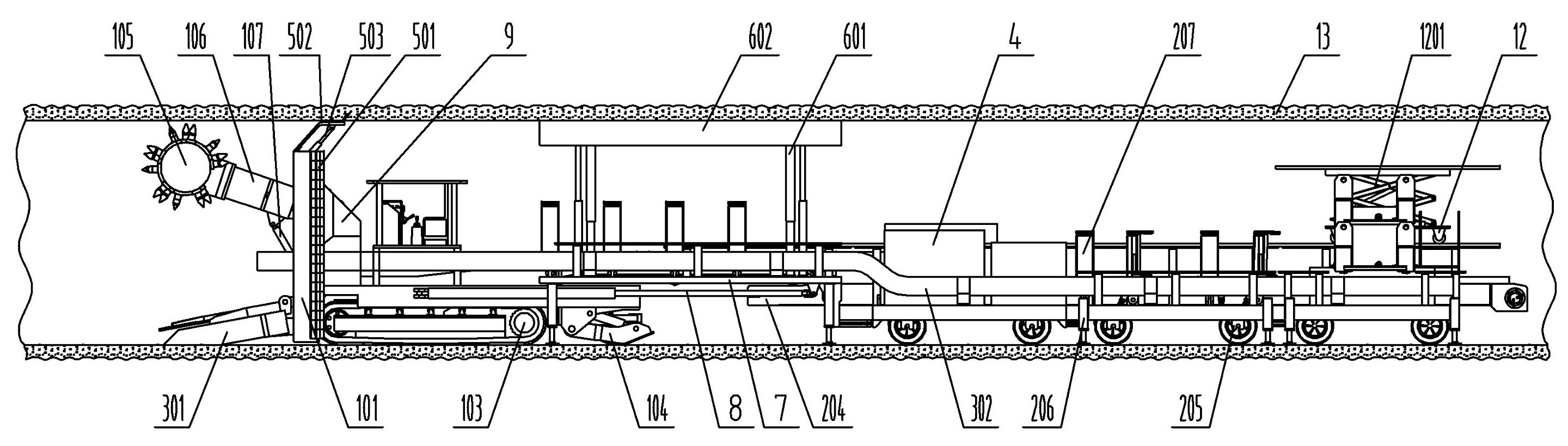

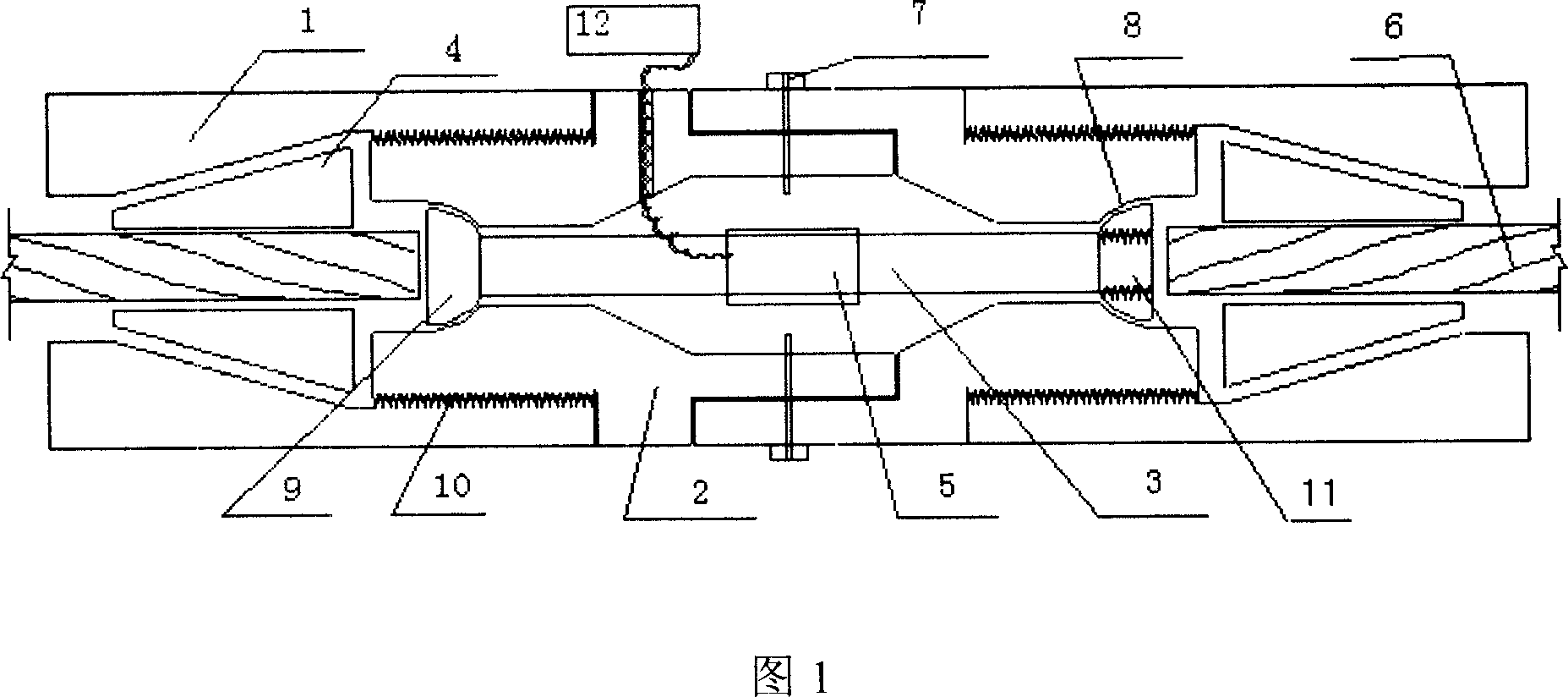

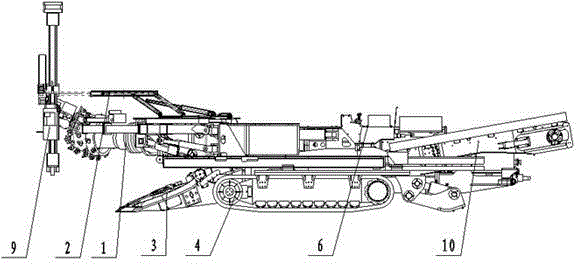

The invention relates to coal mine roadway tunneling machinery, in particular to a fully sealed coal roadway tunneling and anchoring synchronous machine, comprising a tunneling device, a sealing and dust removing device, an anchoring device, a coal loading and conveying device, a power system and a hydraulic system, wherein the tunneling device comprises a body part, a telescopic cutting part arranged at the front end of the body part, a walking part arranged at the lower part of the body part and a rear support part arranged at the rear end of the body part; the anchoring device comprises at least one first anchor rod drill carriage; the first anchor rod drill carriage is arranged between the cutting part of the tunneling device and the power system; other anchor rod drill carriages are arranged behind the power system sequentially; each anchor rod drill carriage comprises a frame, an anchor rod drilling machine group fixedly arranged on the frame, wheels arranged at the four corners of the lower part of the frame and a hydraulic oil cylinder; the body part of the tunneling device is in overlap joint with the two sides of the frame of the first anchor rod drill carriage through a sliding rail and is fixedly connected with a dragging oil cylinder; and the anchor rod drill carriages are hinged with one another. The fully sealed coal roadway tunneling and anchoring synchronous machine is unique in design, reasonable in structure, high in the degree of automation, efficient and safe and is very suitable for extended application.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Fiber reinforced composite rib/ cable anchorage

InactiveCN102747812AAvoid surface stress concentrationAvoid premature entry into the broken state phenomenonBridge structural detailsBuilding reinforcementsComing outPeak value

The invention discloses a fiber reinforced composite rib / cable anchorage which comprises an anchor shell used for anchoring an FRP(Fiber Reinforced Plastic) rib / cable; a conical through hole is coaxially arranged inside the anchor shell; the fiber reinforced composite rib / cable anchorage is characterized in that a sleeve assembly which matches with the conical through hole and is equipped with the FRP rib / cable is embedded in the conical through hole; a seal cap is fixedly arranged at the end part of the anchor shell; and the diameter of the conical through hole increases from the free end to the load-bearing end of the anchor shell. The fiber reinforced composite rib / cable anchorage has the advantages that the stress of the anchoring area is fundamentally changed and tends to be more reasonable; the size of the anchorage is greatly reduced; the stress on the surface of the FRP rib / cable at the anchoring area increases from the load-bearing end to the free end, so the damage caused by centralized stress at the surface of the FRP rib / cable at the load-bearing end can be avoided; the peak value of the binding powder between a binding medium in the anchoring area and the binding interface of the FRP rib / cable comes out at the free end, so the anchoring efficiency is greatly improved, with the anchoring efficiency coefficient reaching 100%; and the fiber reinforced composite rib / cable anchorage has good durability.

Owner:NINGBO UNIV

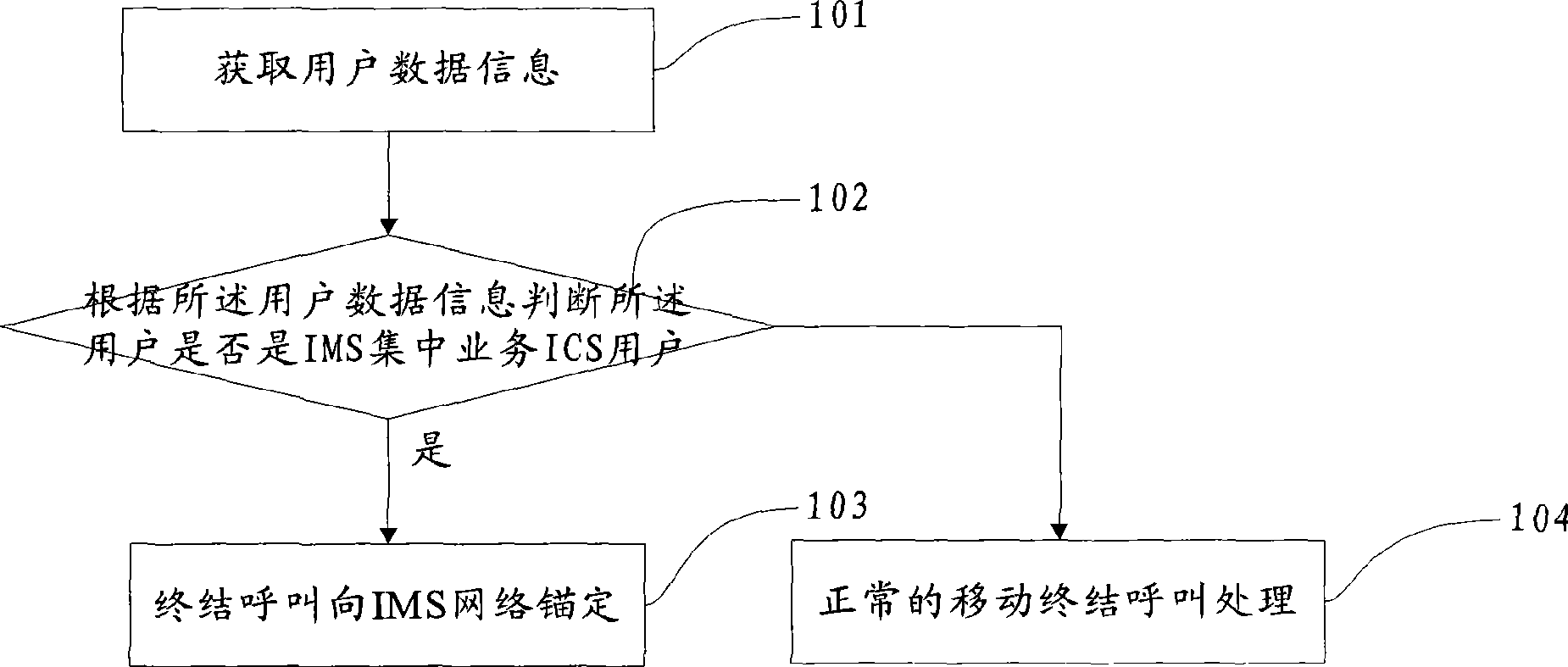

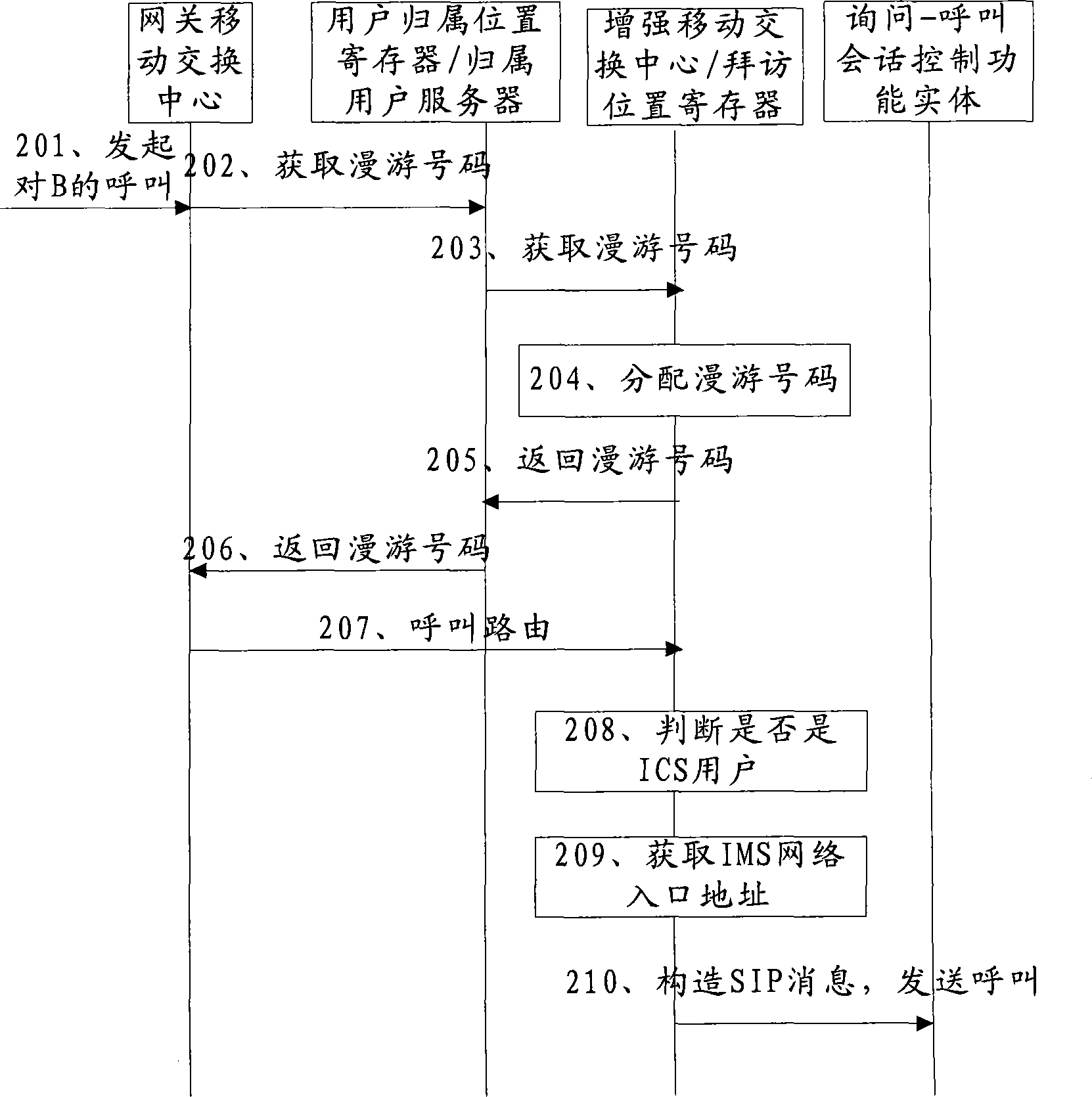

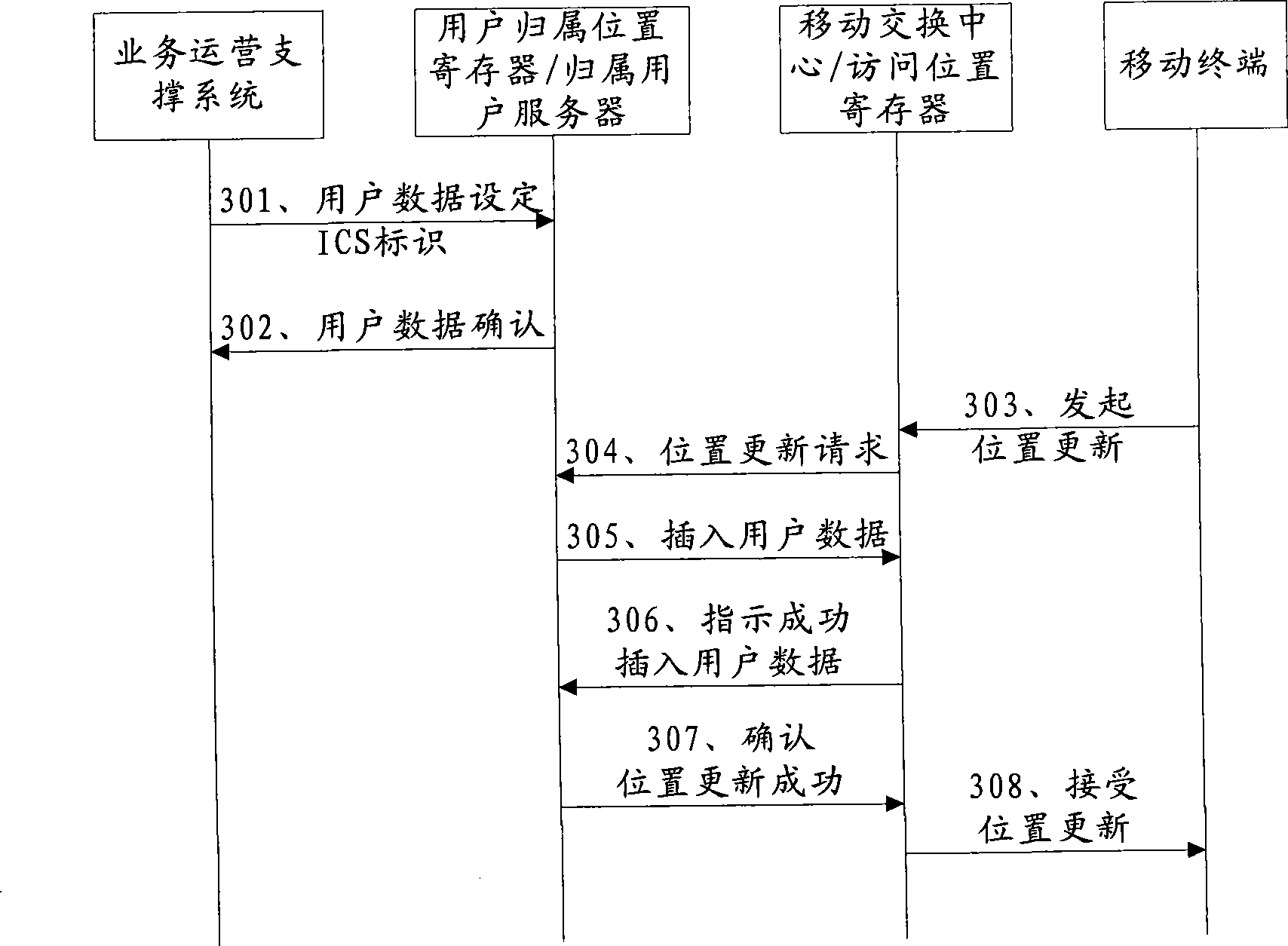

Communication network anchorage method and device

ActiveCN101505344AImprove anchoring efficiencyInterconnection arrangementsSpecial service for subscribersIntegrated services

Owner:HUAWEI TECH CO LTD

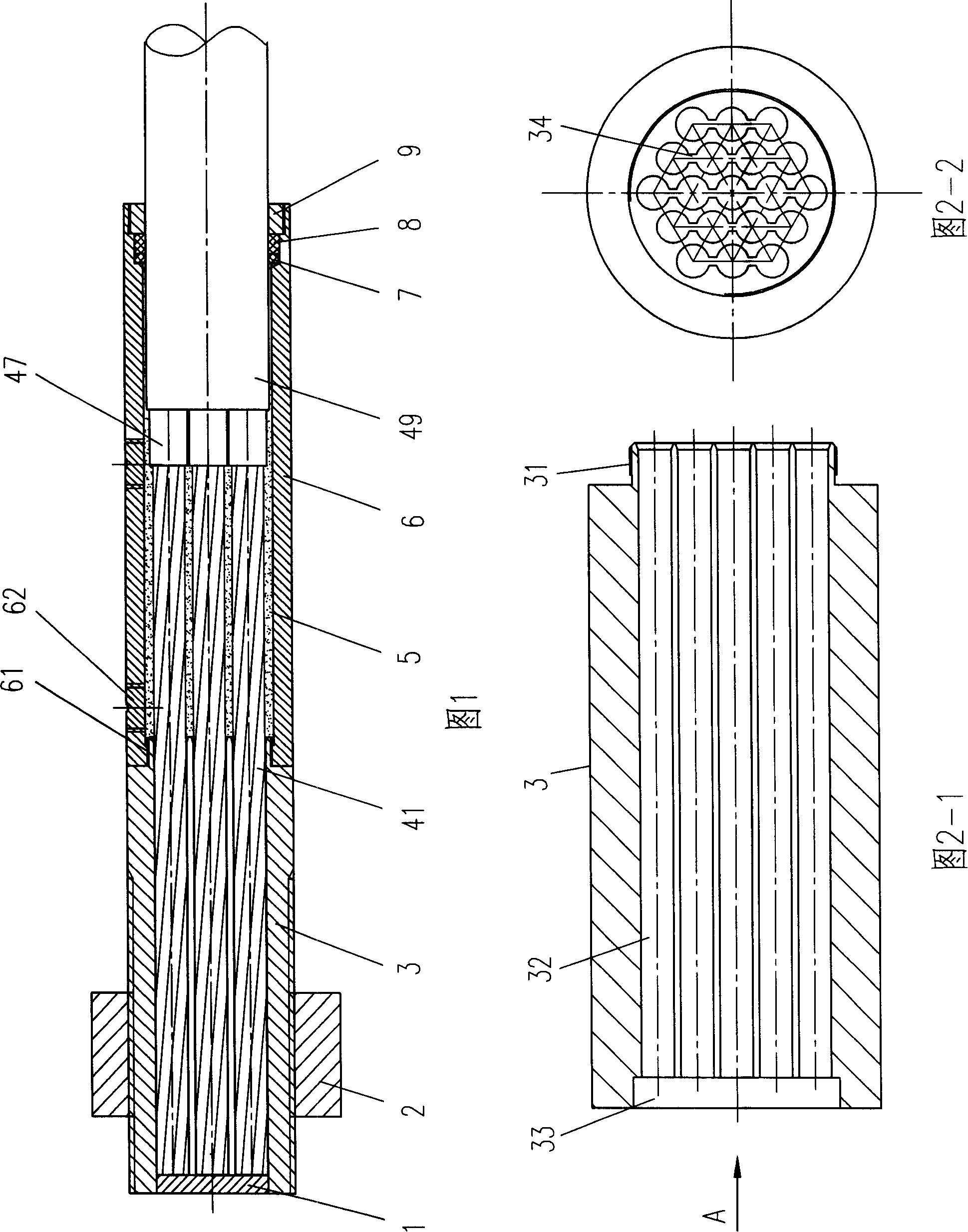

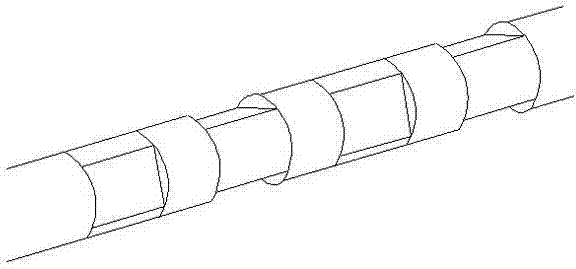

Large-tonnage FRP stay cable anchoring method

ActiveCN108004926AImprove anchoring efficiencyRelieve lateral stress concentrationBridge structural detailsBridge erection/assemblyYarnTransmission medium

The invention discloses a large-tonnage FRP stay cable anchoring method. The method comprises steps: forming a taper variable stiffness load transmission medium on a FRP stay cable anchoring region, wherein the variable stiffness load transmission medium being formed by fiber yarns which are winded along a length direction of the FRP stay cable anchoring region in a segmented manner through mouldpressing, heating, and solidifying, using fiber yarns in different kinds in different segments, to form variable stiffness load, the fiber yarns being soaked by resin before being winded; along an axial direction of the variable stiffness load transmission medium, cutting a plurality of kerfs; using a taper anchorage device matched with the taper variable stiffness load transmission medium to anchor. The anchoring method is advantaged by simple manufacturing, easy control, good coordination force property, high anchoring efficiency, continuous variation of load transmission medium stiffness, and more uniform load transmission medium stiffness. Fiber content and transverse stiffness of the variable stiffness load transmission medium gradually increase from a loading end to a free end, to relieve or eliminate notch effect of the loading end of the FRP stay cable, and prevent lateral shearing damages from preceding tensile damages of the large-tonnage FRP stay cable caused by stress concentration.

Owner:SOUTHEAST UNIV +1

Tensioning and anchoring device of prestressed CFRP plate reinforced beam and use method thereof

ActiveCN111749492ALimited retractionGive full play to high-strength performanceBuilding repairsMaterial strength using tensile/compressive forcesStructural engineering

The invention discloses a tensioning and anchoring device of a prestressed CFRP plate reinforced beam and a use method thereof. The device comprise a CFRP plate, an anchoring assembly and a tensioningassembly; the tensioning assembly comprises tensioning sliding chambers, a second clamp, a fixed plate and a tensioning mechanism; and the contact surfaces of a telescopic plate and the second clampare provided with sawteeth facing oppositely. According to the device and the method, two groups of clamps fixedly clamped at two ends of the CFRP plate are installed in two groups of sliding chambersto apply the prestress, so that the eccentric tension can be prevented, the self-locking of the CFRP plate after the prestress is applied is realized through the mutual matching of the sawteeth between the telescopic plate and the second clamp, and the retraction of the CFRP plate is limited. The CFRP plate is mechanically clamped through the clamps, the anchoring efficiency is high, the qualityperformance is stable, and the high-strength performance of the CFRP plate can be fully exerted. After the prestress is applied, a jack can be dismantled, the design is integrated, the operation process is simple and convenient, and the working efficiency is improved.

Owner:BEIBU GULF UNIV

Steel twisted-line tension-force measuring device

InactiveCN1979108AImprove anchoring efficiencyAccurate tensionTension measurementStrain gaugeEngineering

Owner:SOUTH CHINA UNIV OF TECH

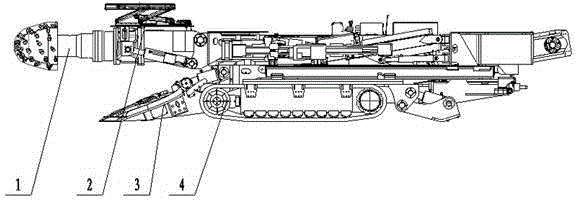

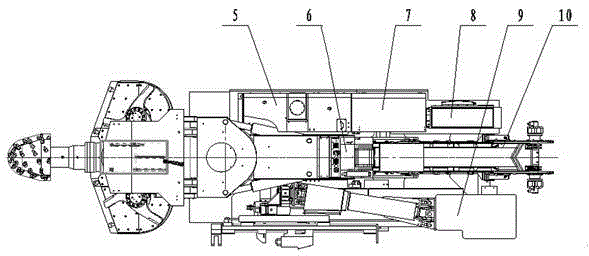

Digging, anchoring and drilling integrated hard rock tunneling machine

InactiveCN104564096ADoes not affect heightSave spaceTunnelsAnchoring boltsEngineeringElectric control

The invention belongs to the technical field of a tunneling machine, and particularly relates to a digging, anchoring and drilling integrated hard rock tunneling machine, which solves the problems of the existing digging and anchoring integrated machine. The digging anchoring and drilling integrated hard rock tunneling machine comprises a clipping part, a loading part, a drilling machine system, an operating platform, a caterpillar track, a pump station oil tank, a hydraulic control box, an electric control box, an operating platform and a transport machine, wherein a drilling machine supporting frame is arranged above the caterpillar track on the left side of the entire machine, a slide guide rail which can move back and forth relative to the drilling machine supporting frame is arranged on the drilling machine supporting frame, and the slide guide rail is provided with the drilling machine system which can move back and forth relative to the slide guide rail; the integrated pump station oil tank is arranged in front the right side of the entire machine, the hydraulic control box is arranged on the right middle part of the entire machine, and the electric control box is arranged on the right rear part of the entire machine; the operating platform is arranged in the middle part of the entire machine and on the front part of the transport machine between the hydraulic control box and the drilling machine system. By adopting the digging, anchoring and drilling integrated hard rock tunneling machine, the drilling machine is finally and actually integrated into the entire machine, the height of the machine body is consistent with that of the original machine body, the influence of the drilling machine for the height of the entire machine is minimized, and the overall height of the entire machine is not affected.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

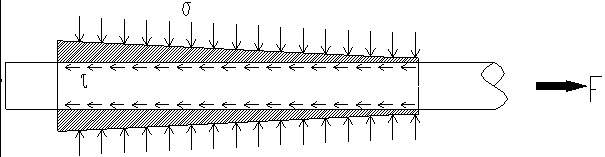

Anchoring method of flat cross section of carbon fiber composite reinforcement material

The invention relates to an anchoring method of a flat cross section of a carbon fiber composite reinforcement material. The anchoring method is characterized in that the carbon fiber composite reinforcement material is locally heated and softened at a part close to the tail of an anchorage device, when the temperature of the carbon fiber composite reinforcement material is close to the solidifying temperature of the reinforcement material, the heated part is rolled to be flat by a tool, the reinforcement material is subjected to four-times rolling, the rolling is respectively carried out two times in the orthogonal direction and the vertical direction of the reinforcement material, and after cooling, the rolled part is solidified again; after the reinforcement material passes through location holes of an end plug and a sealing cover, the anchorage device is vertically placed, the end plug is moved away, and an epoxy resin mortar anchoring filler is poured into the anchorage device from the small end of the anchorage device, after the anchorage device is filled with the filler, the end plug is put at an original location, and after the anchorage device is vertically placed for one day and the epoxy resin mortar anchoring filler is solidified, the glue pouring and solidifying of the other end are carried out. The anchoring method has the advantages that the local surface of the carbon fiber composite reinforcement material can be rapidly and conveniently flattened, the contact area between the reinforcement material and the epoxy resin mortar anchoring filler is enlarged, the mechanical bite force is generated, the anchorage bonding length is reduced, and meanwhile, the reinforcement material is prevented from slipping off from the anchoring filler.

Owner:FASTEN HONGSHENG GRP CO LTD

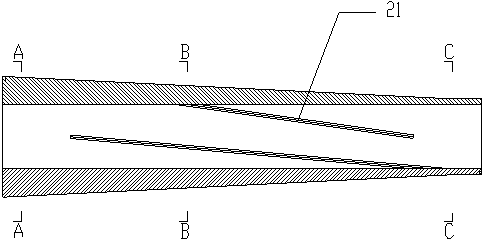

Large-tonnage carbon fiber superimposed plate bundle anchorage

InactiveCN105839856AImprove anchoring efficiencyAvoid destructionBridge structural detailsBuilding reinforcementsFiberCarbon fibers

The invention discloses a large-tonnage carbon fiber superimposed plate bundle anchorage including an anchorage tube and a carbon fiber fixing plate bundle; the anchorage tube is provided with a filling through hole; the tail end of the filling through hole is provided with a sealing cover plate, and the front end of the filling through hole is provided with an end sealing piece; the carbon fiber fixing plate bundle passes through the end sealing piece and then enters the filling through hole. The anchorage is characterized in that the sealing cover plate is provided with a wedge block; the wedge block extends inward into the filling through hole; the carbon fiber fixing plate bundle is divided into a first plate bundle and a second plate bundle which are symmetrical; two sides of the wedge block is symmetrically provided with two wedge block slopes which gradually approach to each other when the two wedge block slopes extend inward from the tail end of the filling through hole; the first plate bundle and the second plate bundle are arranged on the wedge block slopes at two sides of the wedge block in a reclining manner; the tail end of the first plate bundle and the tail end of the second plate bundle are respectively fixedly connected with the sealing cover plate; and a gap in the filling through hole is filled with an epoxy resin mixed medium. The anchorage has the advantages that the anchorage can effectively anchor the carbon fiber fixed plate bundle having large bearing capacity.

Owner:NINGBO UNIV

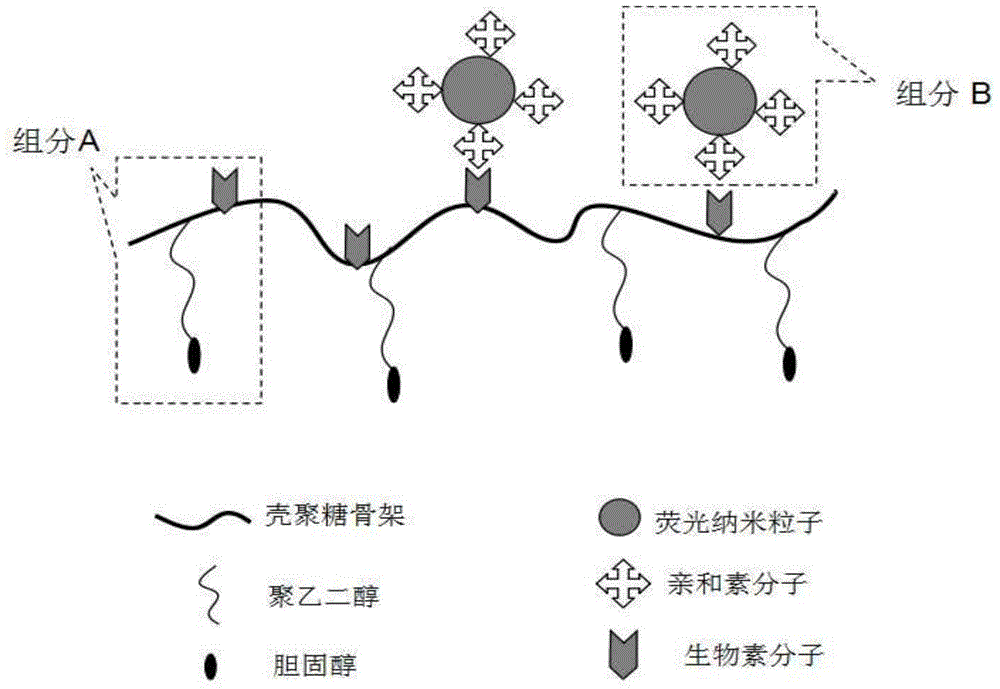

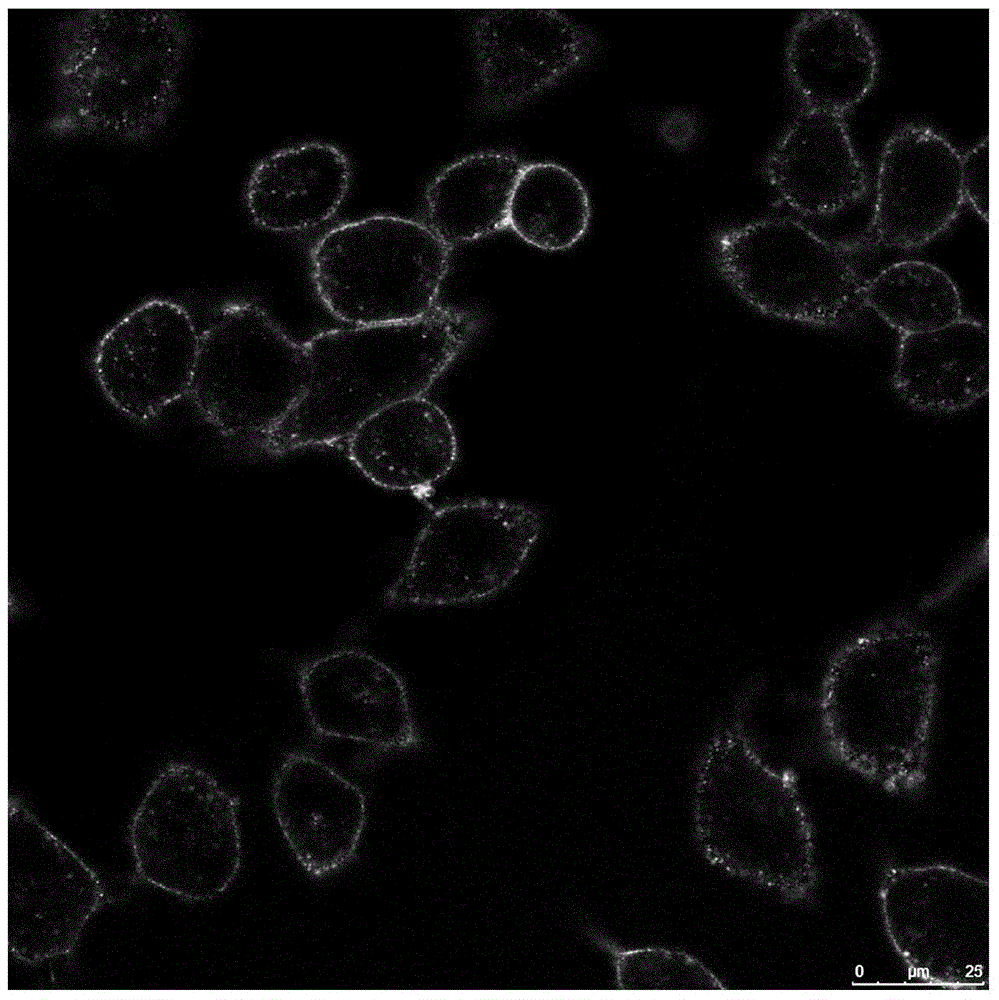

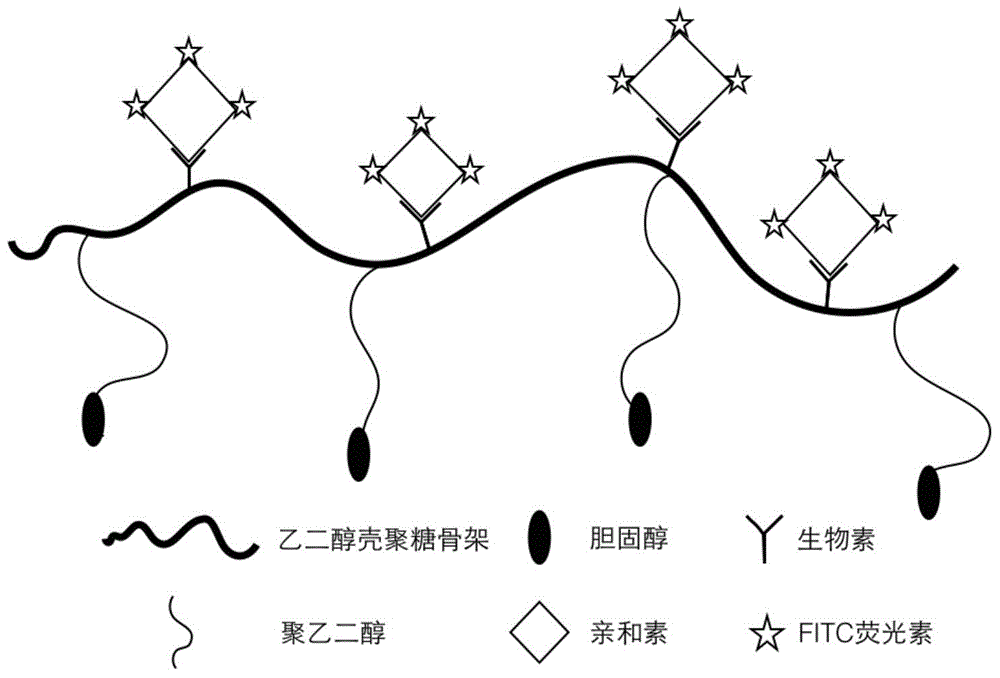

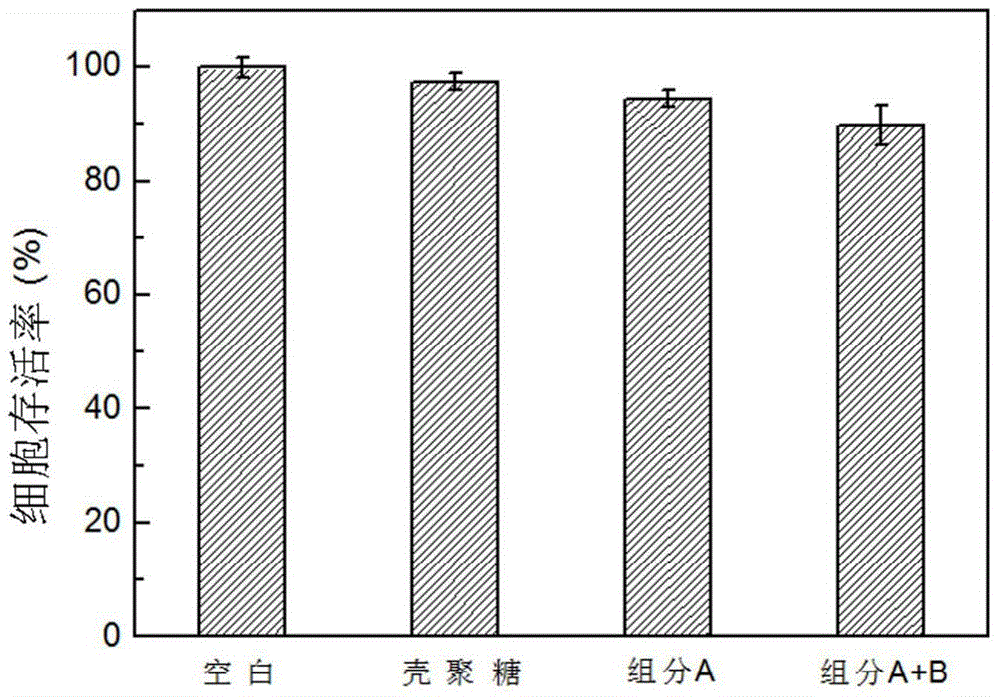

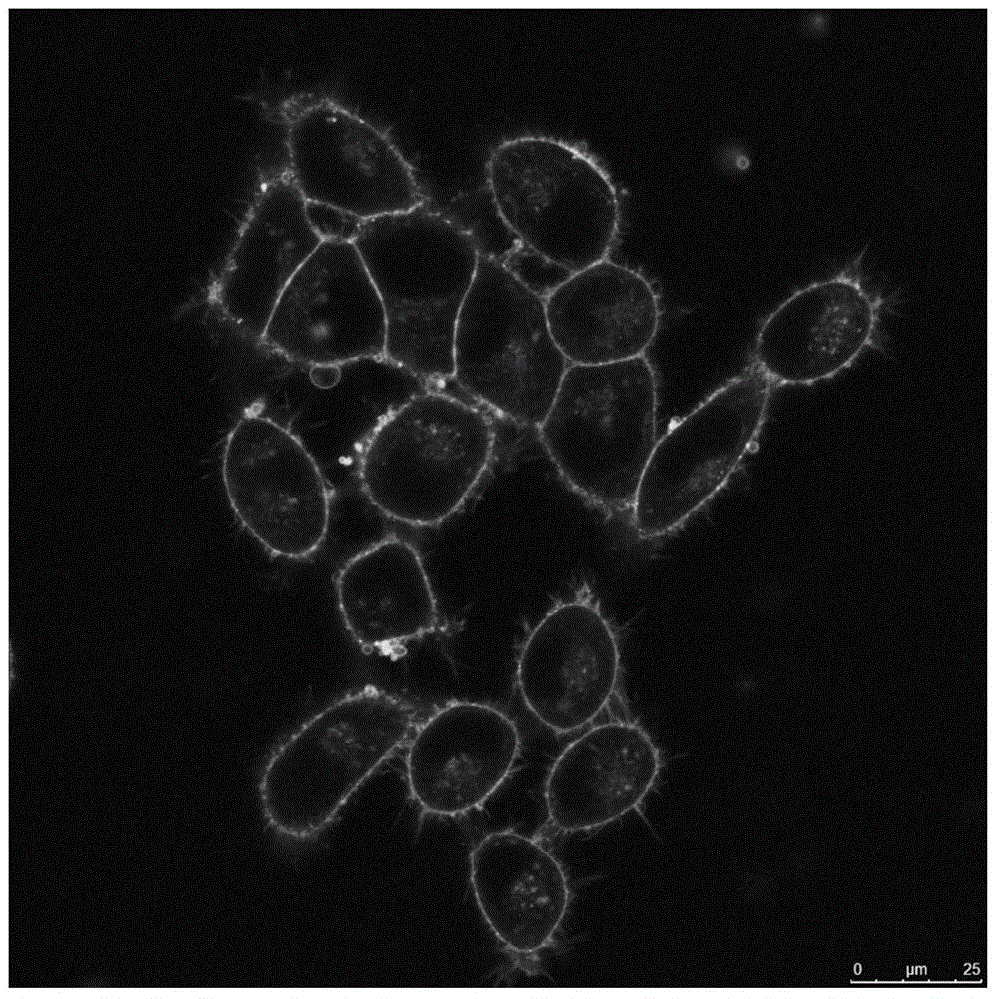

Fluorescent nano-particle based cell membrane imaging reagent and preparation method thereof

ActiveCN104458685AGuaranteed Imaging SpecificityKeep for a long timeFluorescence/phosphorescenceMulti siteSide chain

The invention discloses a fluorescent nano-particle based cell membrane imaging reagent which comprises a component A and a component B, wherein the component A adopts an amino-contained polymer whose side chain contains a biotin molecule unit and a hydrophobic anchoring unit; and the component B adopts avidin module grafted fluorescent nano-particles. The reagent is based on fluorescent nano-particles and a multi-site anchoring technology and has good biocompatibility and good imaging effect, and the fluorescent particles are on a cell membrane, are not endocytosed, are not prone to quenching after long-time laser radiation and can be used for long-time tracing labeling of the cell membrane.

Owner:SOUTHEAST UNIV

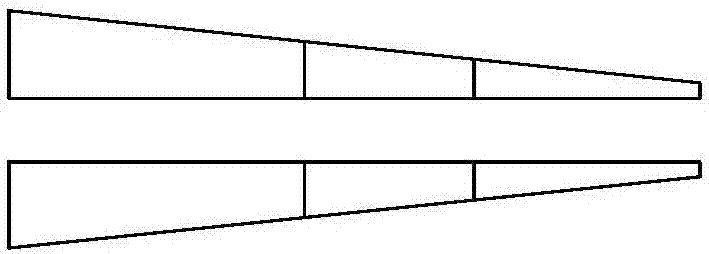

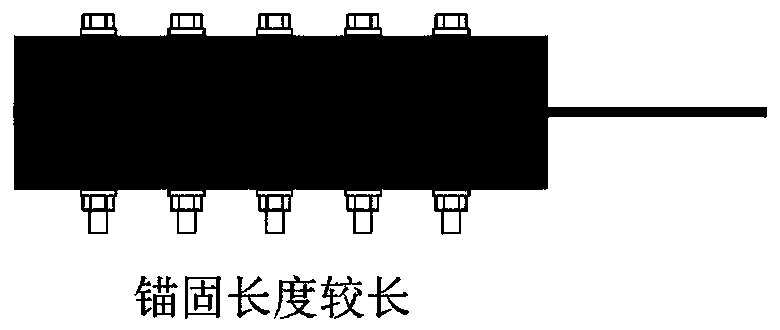

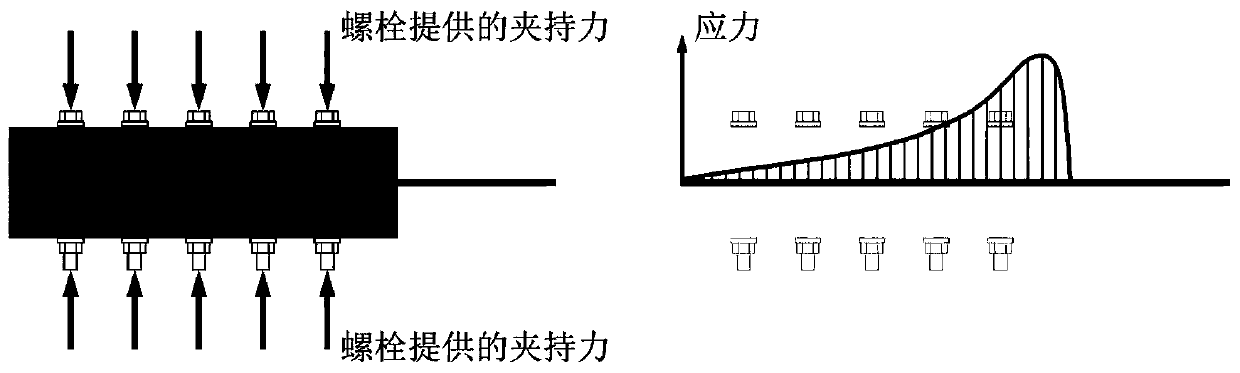

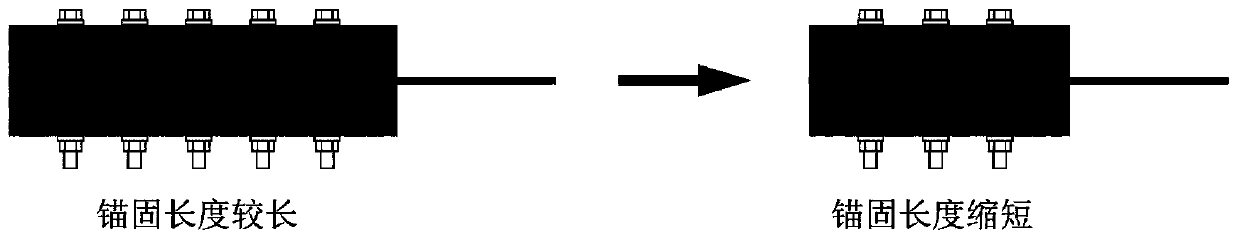

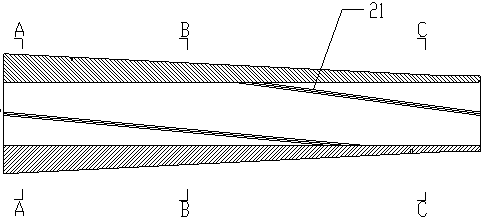

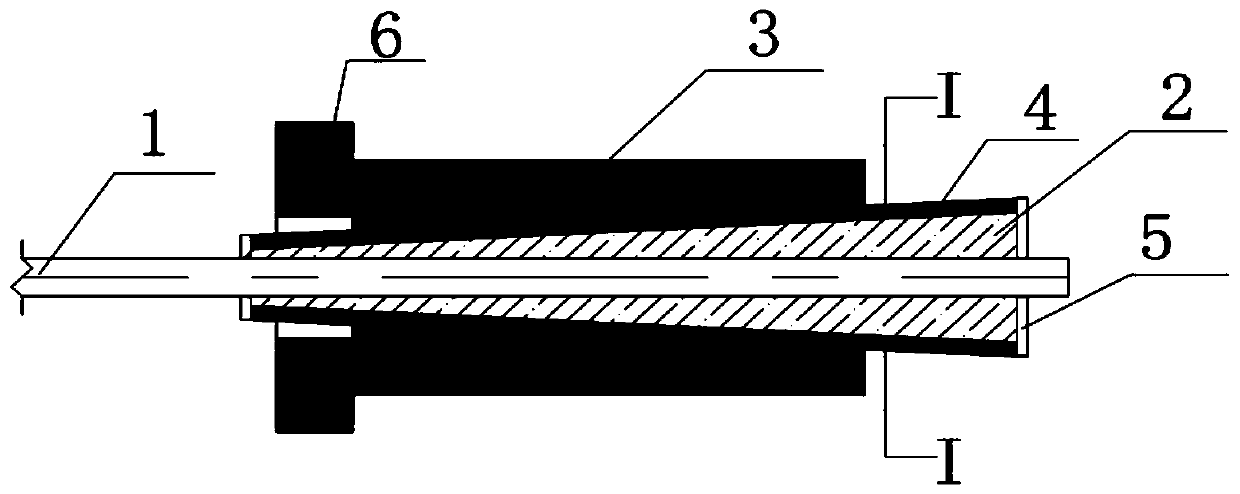

Variable-clamping-force corrugated clamping plate anchor for FRP sheet

ActiveCN109881842AReduce anchor lengthSave materialBridge structural detailsBuilding reinforcementsEngineering structuresAnchor bolt

The invention discloses a variable-clamping-force corrugated clamping plate anchor for an FRP sheet, and relates to an anchor for an engineering structure in the field of high-strength composite materials. The variable-clamping-force corrugated clamping plate anchor for the FRP sheet includes an upper corrugated clamping plate, a lower corrugated clamping plate, bolts, nuts, washers and the FRP sheet. The FRP sheet passes through the upper corrugated clamping and the lower corrugated clamping plate, the upper corrugated clamping plate and the lower corrugated clamping plate clamp the FRP sheettightly, the washers are arranged at bolt holes of the upper corrugated clamping plate and the lower corrugated clamping plate, the nuts penetrate through the upper corrugated clamping plate and thelower corrugated clamping plate, and the FRP sheet is anchored by tightening the nuts. The anchor adopts the corrugated clamping plates to replace flat clamping plates to clamp the FRP sheet, and theanchoring bolt radius gradually increases from an outlet to the end part of the anchor, the clamping force provided by the anchoring bolts further gradually increases from the outlet to the end part of the anchor, the stress peak at the outlet of the anchor can be effectively reduced, the anchoring efficiency is improved, the anchoring length is shortened, materials are saved, and economy is improved.

Owner:重庆卓越强森新材料科技有限公司

Tension self-locking device for grouting anchor cable

The invention discloses a tension self-locking device for a grouting anchor cable. The device comprises a locking jaw seat fixedly connected to the front end of a cable body. A central grouting pipe penetrates through the cable body, and is extended into the locking jaw seat. The front end of the locking jaw seat is sharpened. A ring groove is reserved on the sidewall of the locking jaw seat. 4 to 16 annularly distributed single-piece locking jaws are hinged in the ring groove. The bottom ends of the single-piece locking jaws are outwards tilted. Locking teeth are arranged at the bottom ends of the single-piece locking jaws, and can be embedded into the inner wall of pore passages. Spring rings are sleeved at the front ends of the annularly distributed single-piece locking jaws. A central grouting pore passage is reserved in the locking jaw seat, and is communicated with the front end of the central grouting pipe. A communicated radial grouting pore passage is reserved outside the central grouting pore passage. The single-piece locking jaws and pore walls keep a good contact state, and the locking teeth are arranged at the bottom ends of the single-piece locking jaws, and can be embedded into the inner walls of the pore passages, so that the single-piece locking jaws can be flexibly embedded into the inner walls of the pore passages when the whole anchor cable is tensioned, and can be reversely stressed and self-locked, and smooth grouting is ensured.

Owner:ANHUI JINXING PRESTRESSING ENG TECHCO

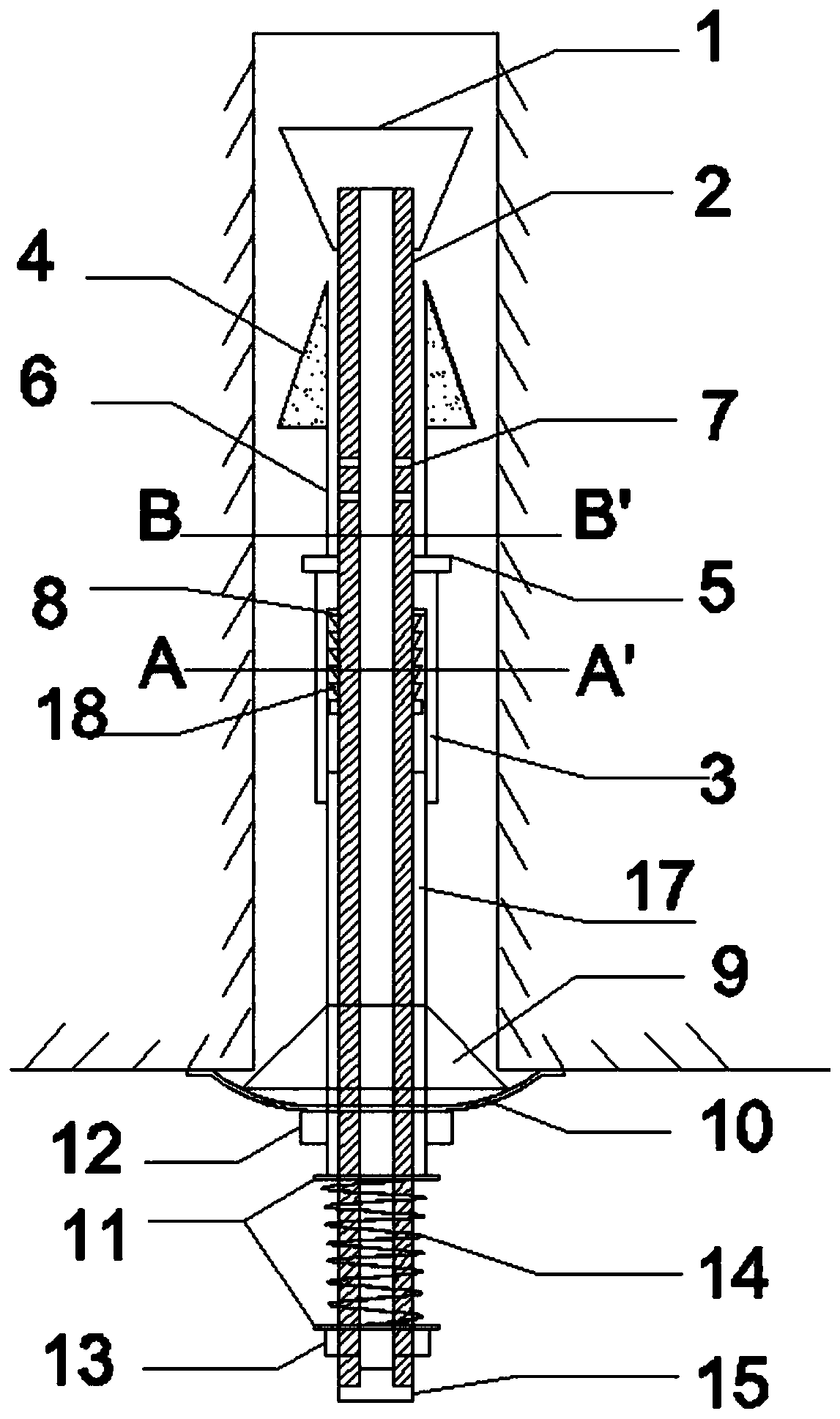

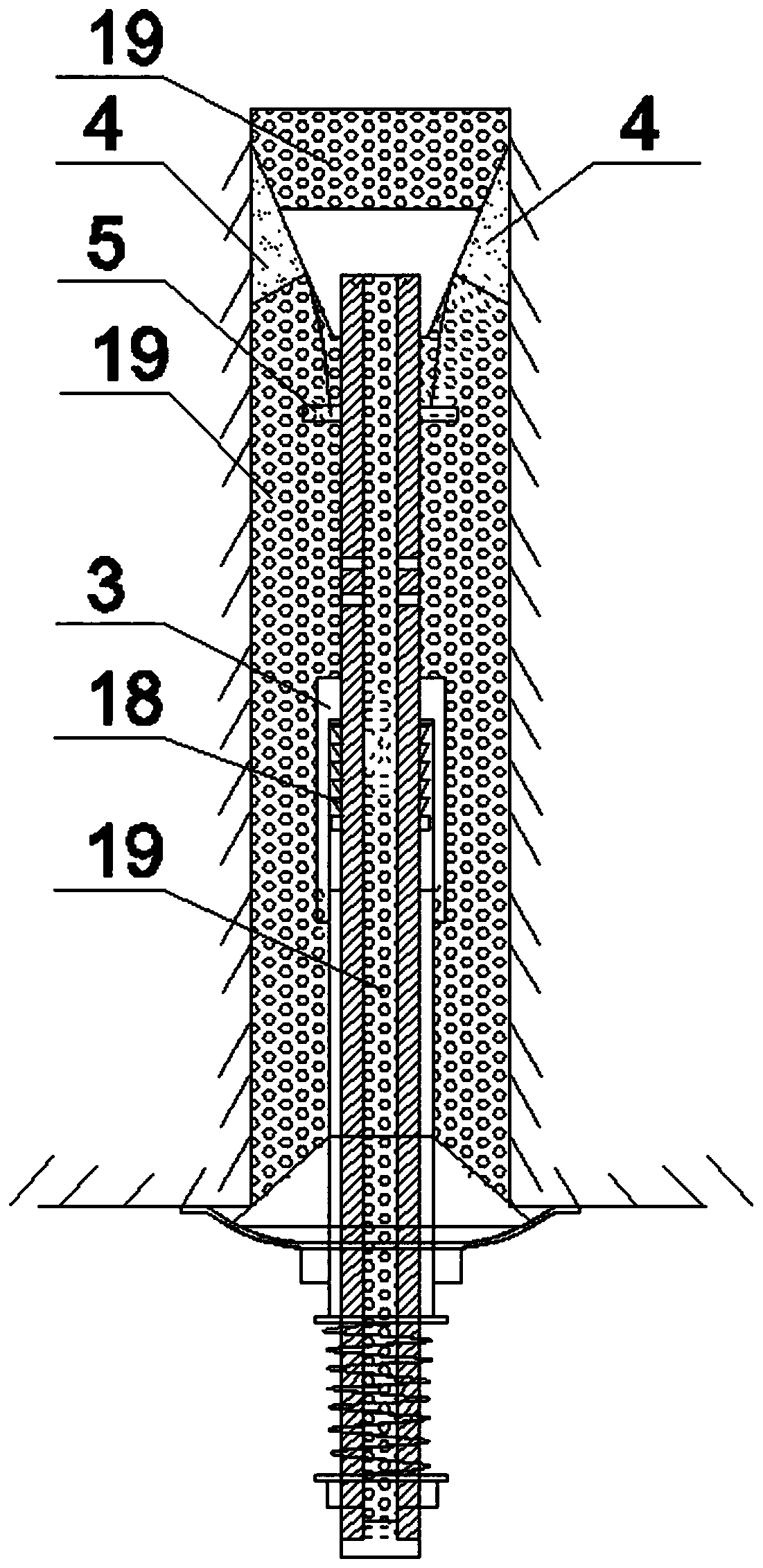

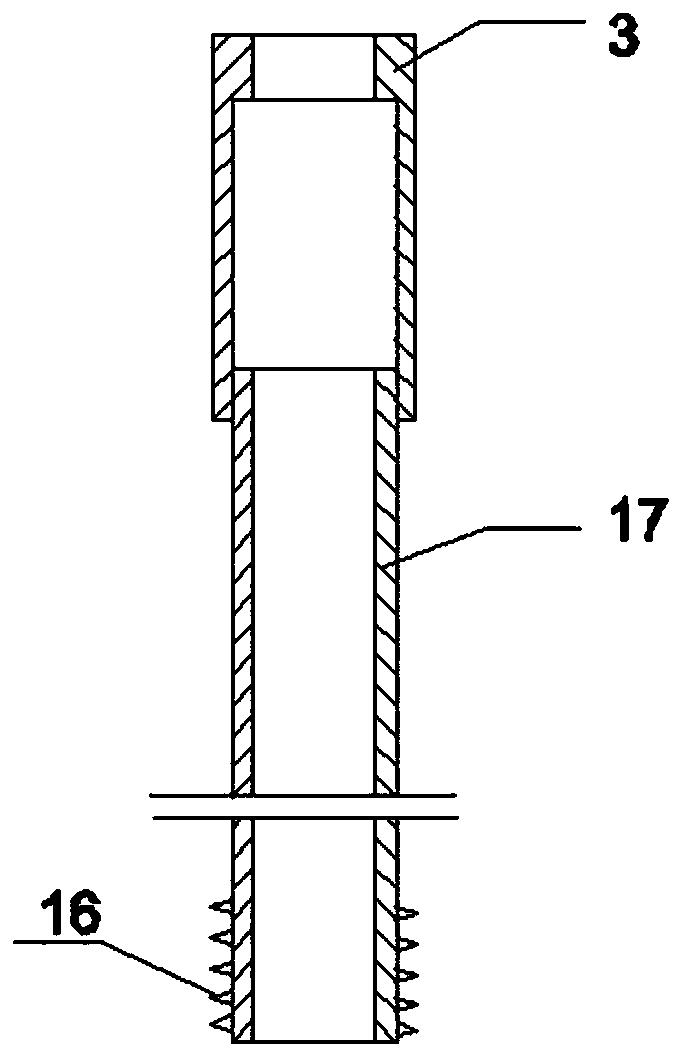

Self-adaption decompression type grouting anchor rod

InactiveCN110331998AImprove the anchoring effectAchieve a fastening effectAnchoring boltsRubber ringEngineering

The invention discloses a self-adaption decompression type grouting anchor rod and solves the problem in the prior art that the reinforcing capacity of the anchor rod remains to be improved. The self-adaption decompression type grouting anchor rod comprises an anchor rod body, a self-adaption locking device, a grouting hole, a pulp stopping plug, a pulp stopping plug base plate, a fastening nut and a pulp blocking plug, wherein the anchor rod body is of a hollow pipe and is connected in the self-adaption locking device in a sleeving manner; the grouting hole is formed in the side wall, connected in rock in a sleeving manner, of the anchor rod body; one side, stretching out of the rock, of the anchor rod body penetrates through the pulp stopping plug and the middle of the pulp stopping plugbase plate, is connected with the self-adaption locking device in a sleeving manner, and is fixedly connected through the fastening nut; the pulp stopping plug is arranged at the end part of the anchor rod body; and the self-adaption locking device comprises a locking wedge mechanism, an upper sleeve, an isolating rubber ring, a positioning lower sleeve, a pulp stopping plug nut, a screw mat anda spring. According to the self-adaption decompression type grouting anchor rod, the upper sleeve decompress the anchor rod body through cutting a bulge, and the anchor rod body unloads the bulge beforehand, so that large deformation of surrounding rock is effectively controlled, the anchoring efficiency is improved, and the requirement of the anchor rod supporting technology in deep geotechnicalengineering is met.

Owner:魏志范

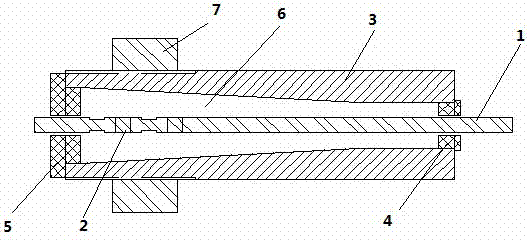

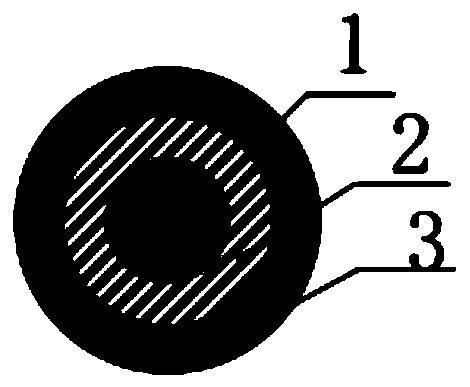

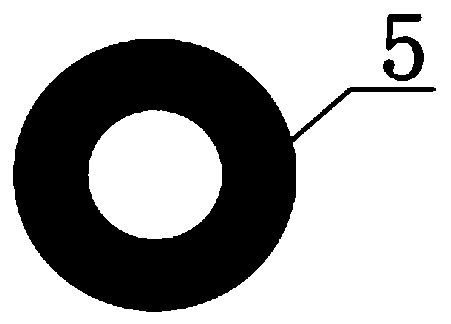

Novel FRP rib adhesive type anchorage device with screw plug and mounting method of anchorage device

ActiveCN104234325AEnhanced interactionEnhanced vertical slipBuilding reinforcementsBuilding material handlingFiberMechanical engineering

The invention discloses a novel FRP (Fiber Reinforced Polymer) rib adhesive type anchorage device with a screw plug and a mounting method of the anchorage device. The anchorage device comprises an anchor drum and annular gaskets, wherein the annular gaskets are respectively adhered to the two ends of the anchor drum; the anchorage device further comprises the screw plug; the screw plug is in threaded connection with the pulled end of the anchor drum; a central through hole for mounting an FRP rib is formed in the center of each of the annular gaskets; the centers of the annular gaskets are positioned on a center line of the anchor drum. The FRP rib adhesive type anchorage device with the screw plug, disclosed by the invention, adopts the screw plug design at the end part to improve interaction between the anchor drum and the adhesive agent, enhance longitudinal sliding restraining of the adhesive agent, effectively prevent the adhesive agent from sliding out, and reduce the length of the anchorage device; compared with the conventional adhesion method on the anchorage device, the anchor drum with the same length can improve the bearing load; furthermore, the anchorage device is not required to be specially processed, low in material requirements, simple in structure, reasonable in design, convenient to use, simple in mounting technology, low in cost, and capable of increasing the anchorage efficiency as the screw plug is in threaded connection with the anchor drum.

Owner:ZHENGZHOU UNIV

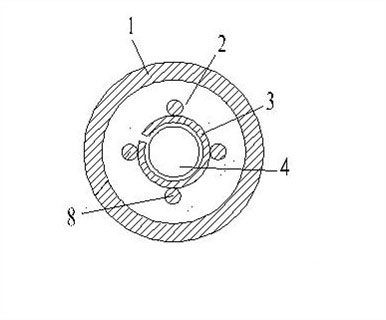

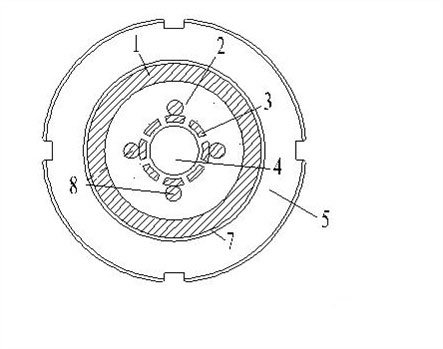

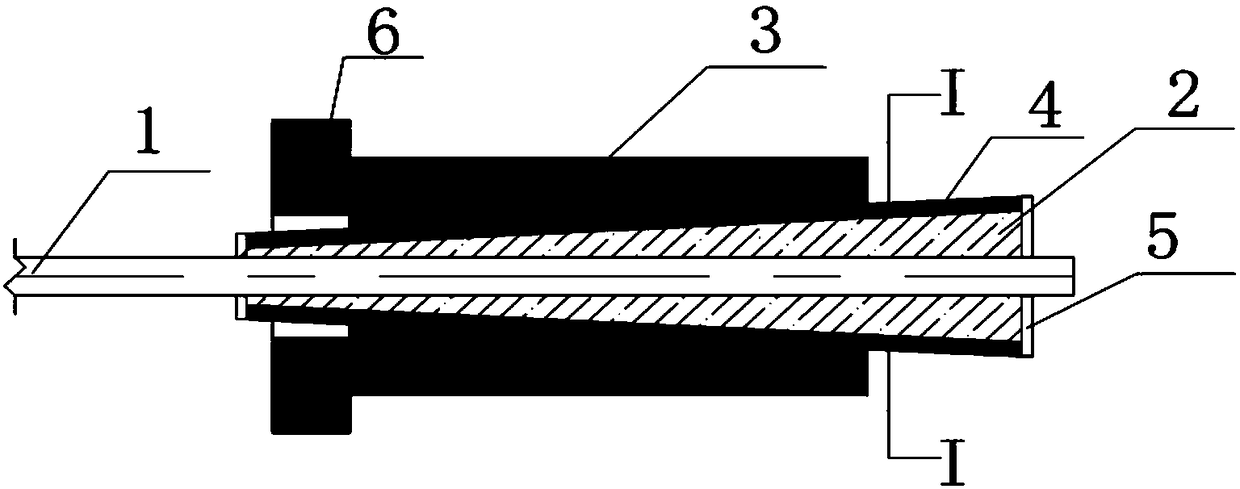

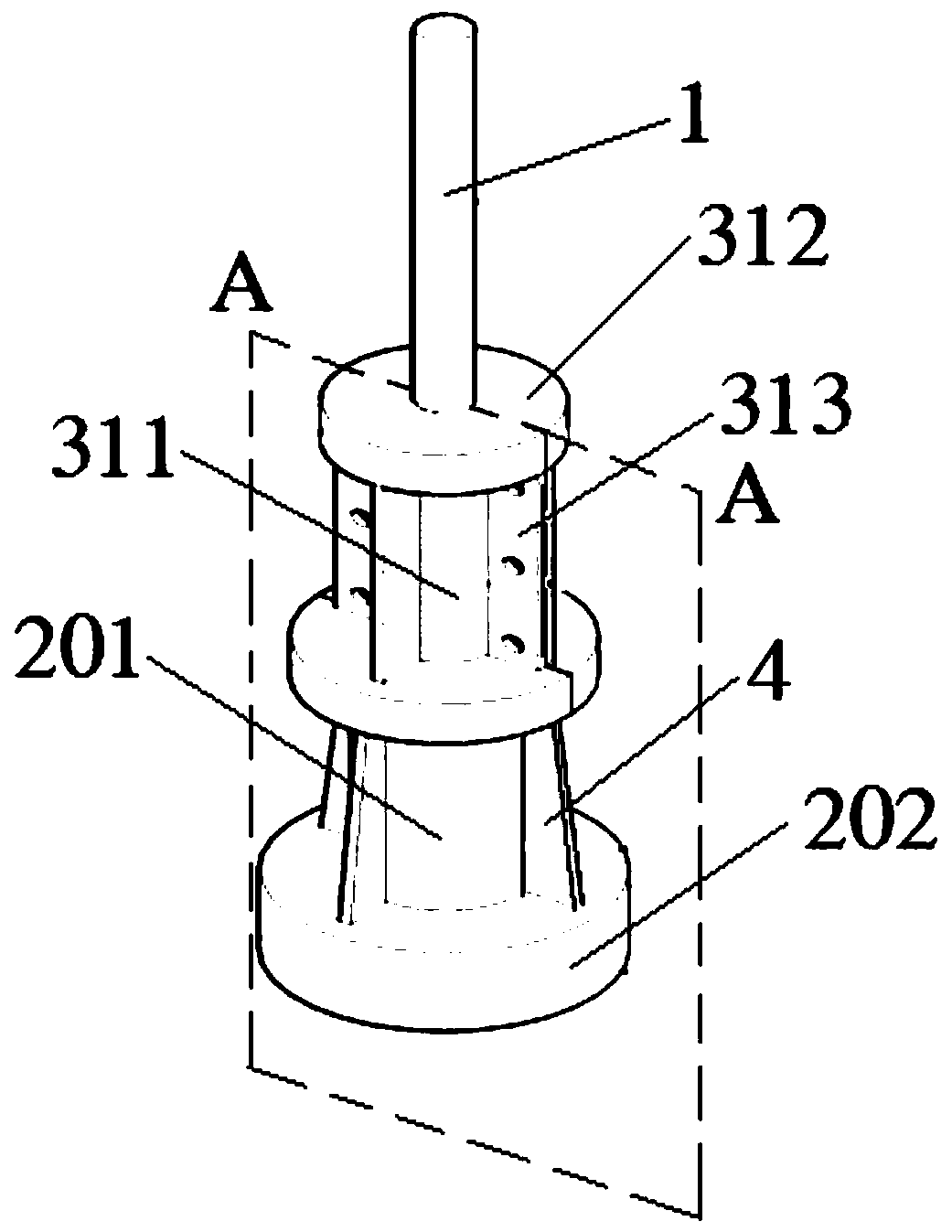

Composite anchor for FRP ribs

ActiveCN108221666ALow number of componentsEasy to assembleBridge structural detailsBridge materialsAdhesiveEngineering

The invention discloses a composite anchor for FRP ribs, and relates to the field of anchorage. The anchor comprises an anchor ring, a metal barrel and an end plug; a conical through hole is formed inthe center of the anchor ring; the metal barrel is mounted in the conical through hole of the anchor ring, and two ends of the metal barrel are protruded out of the anchor ring; the metal barrel is aconical empty barrel; and a CFRP rib is arranged in the center of the metal barrel, the CFRP rib penetrates through the metal barrel, and the metal barrel is filled with an adhesive and is positionedand plugged by the end plug to form an FRP rib combination. After maintaining is finished, the anchor ring is assembled on the combination, and the anchor can be stretched after pretightening force is applied. The anchor is simple to manufacture and operate, high in anchorage efficiency and short in anchorage length, and can be applied to reinforcing engineering.

Owner:JIANGSU UNIV

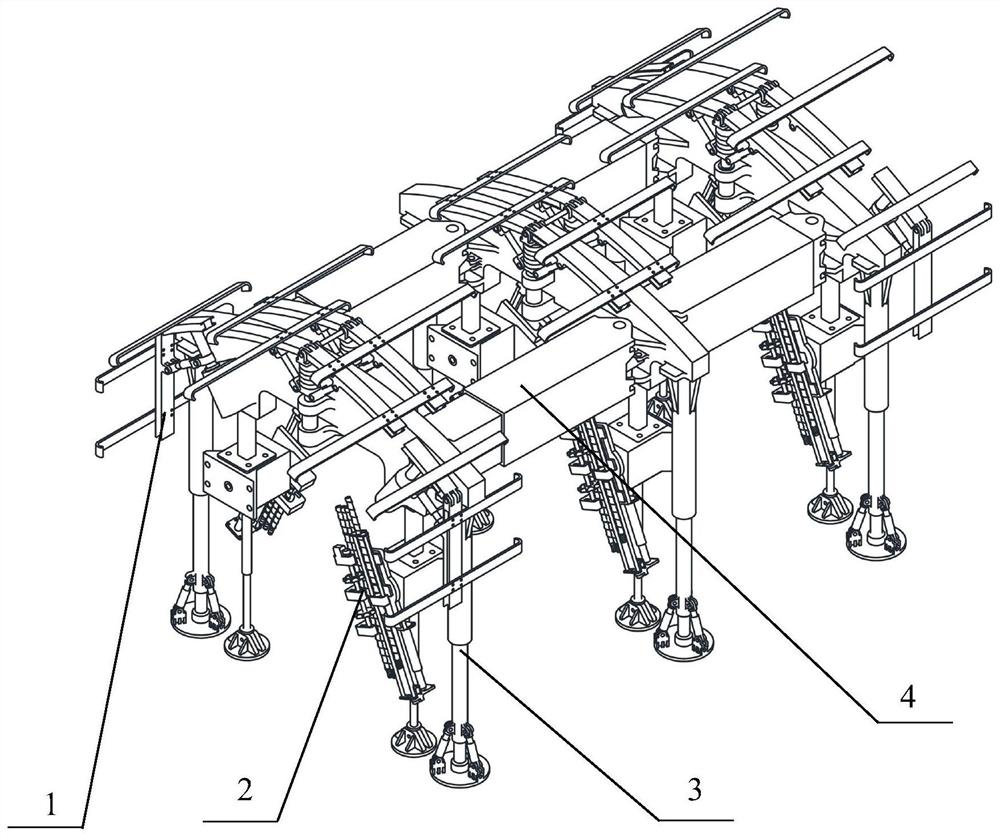

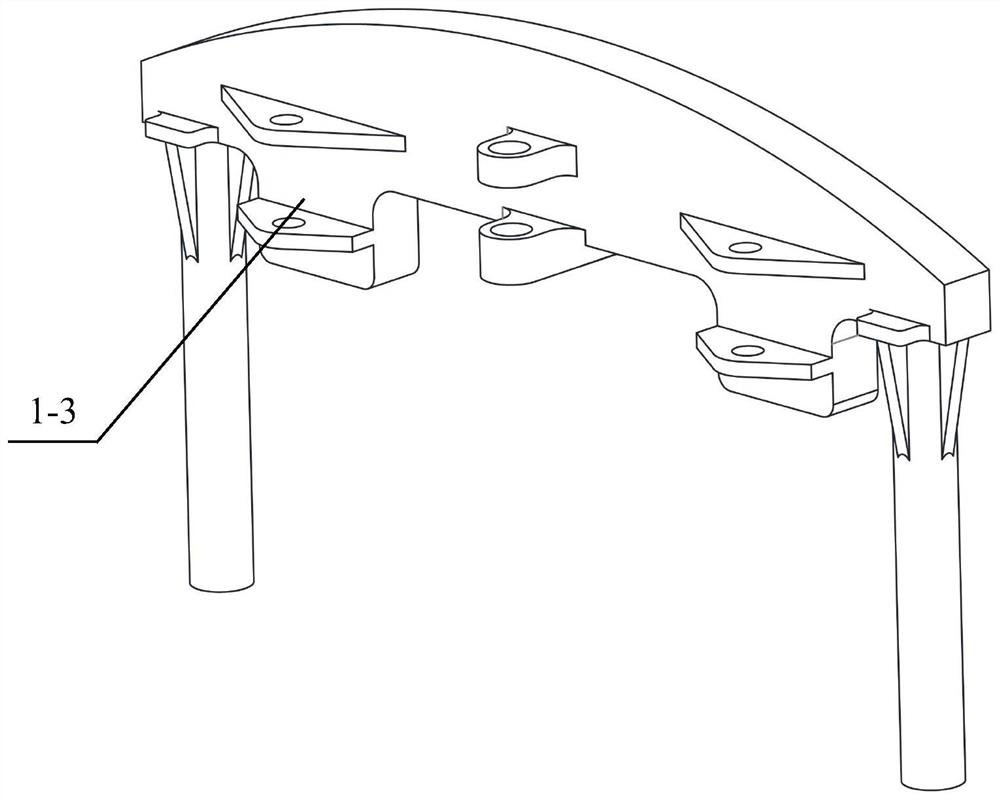

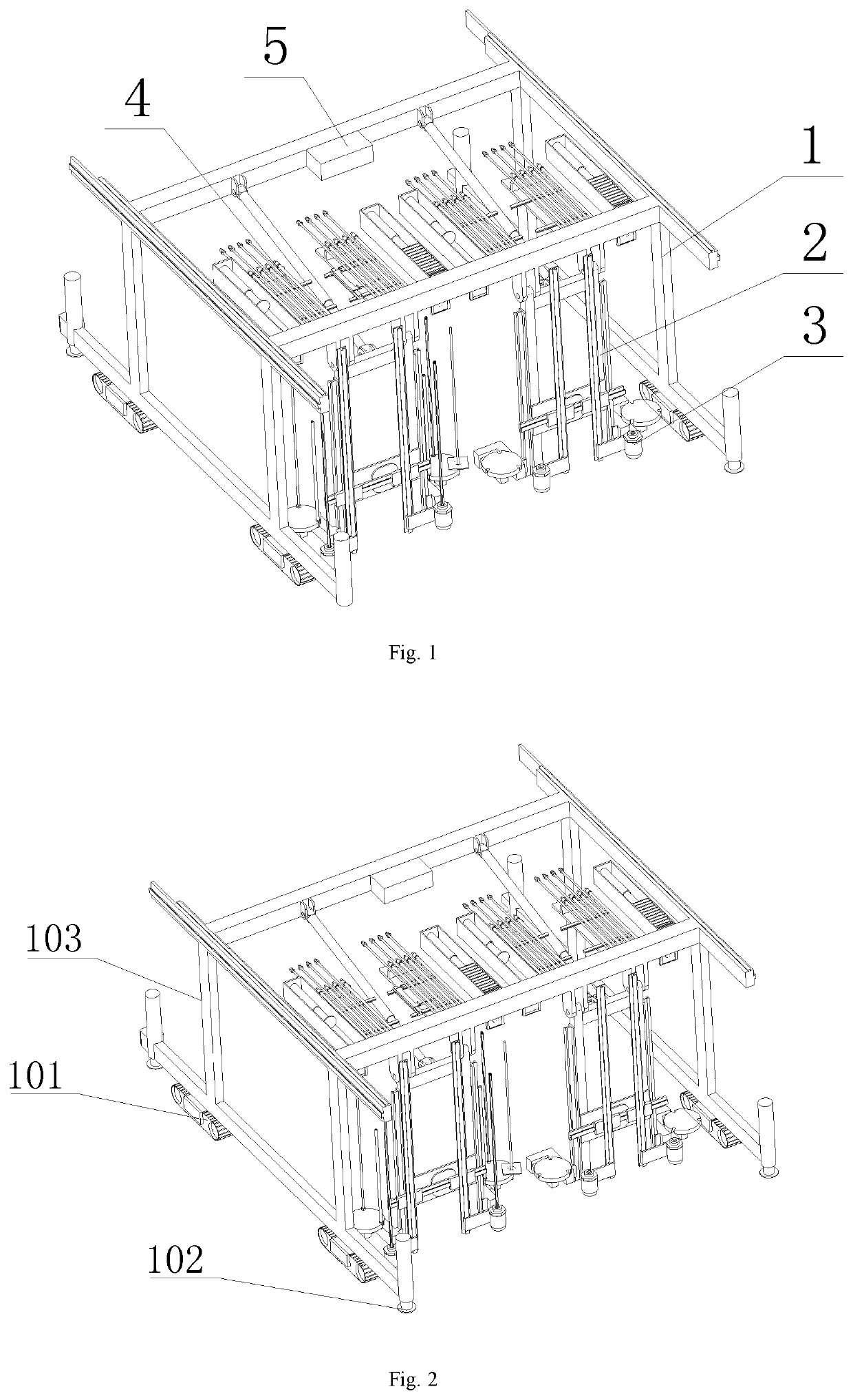

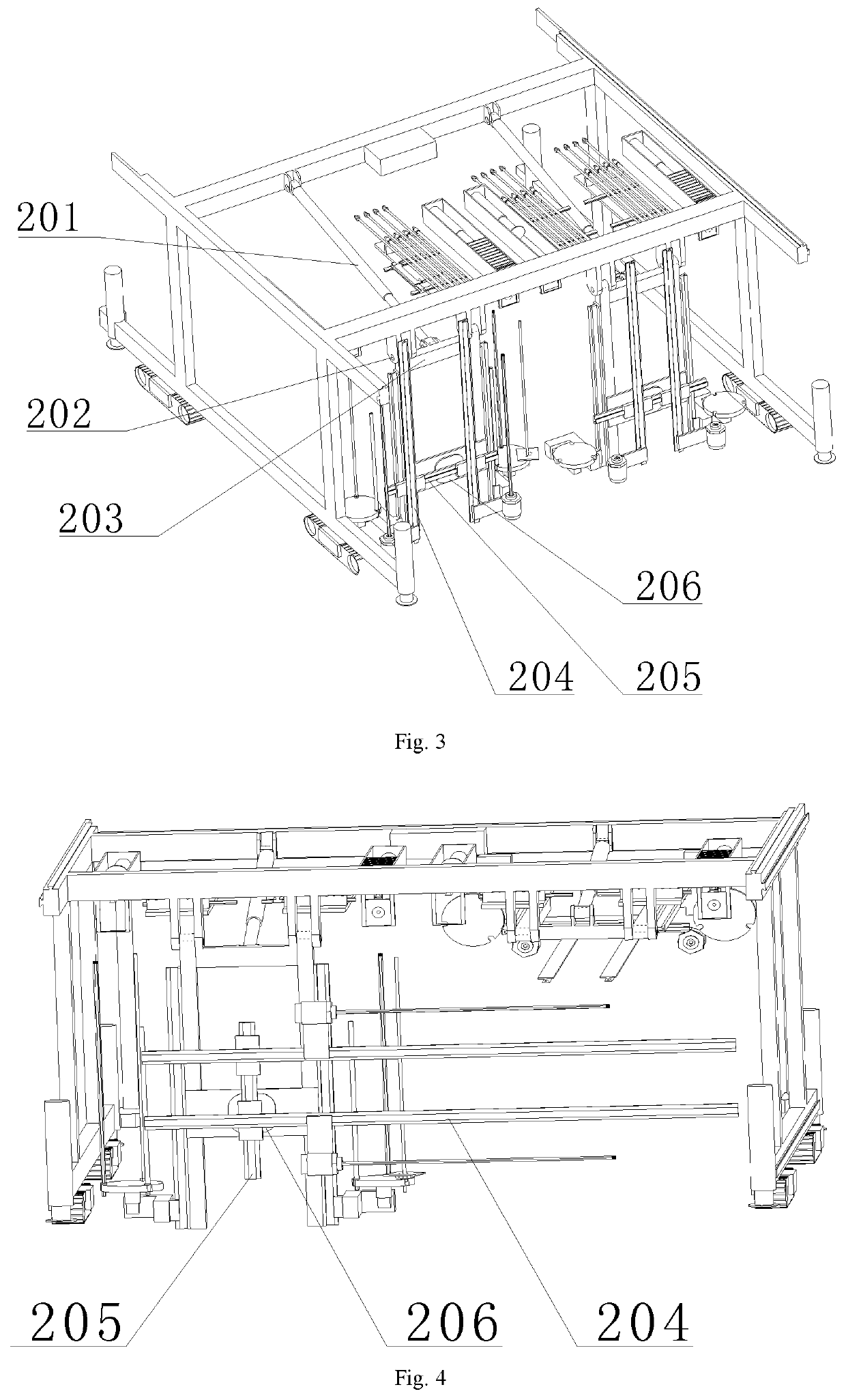

Step-type anchoring robot of fully mechanized excavation face

PendingCN111608705ASimple structureSmooth goingDrilling rodsUnderground chambersSupporting systemControl engineering

The invention discloses an anchoring intelligent device, belongs to the field of fully mechanized excavation face mechanical and electrical equipment and comprises four parts including a net struttingsystem, an anchoring system, a ground supporting system and a power and turning system, wherein the net strutting system is installed above the ground supporting system; the anchoring system is installed by screws under a main beam and a middle main bear inside the net strutting system; the ground supporting system is installed under the middle beam and the middle main beam inside the net strutting system and provides support for the whole device; and through pin connection, two ends of the power and turning system are connected to the main beam and the middle main beam inside the net strutting system respectively. Further, the robot disclosed by the invention is small in size and compact in structure, has functions of realizing multi-anchor-rod coordinated operations and auxiliary pavement of an anchor net and has high anchoring efficiency; and the device adopts a step-type advancing mode, so that running is steady, turning is flexible and maneuvering performance is good.

Owner:ANHUI UNIV OF SCI & TECH

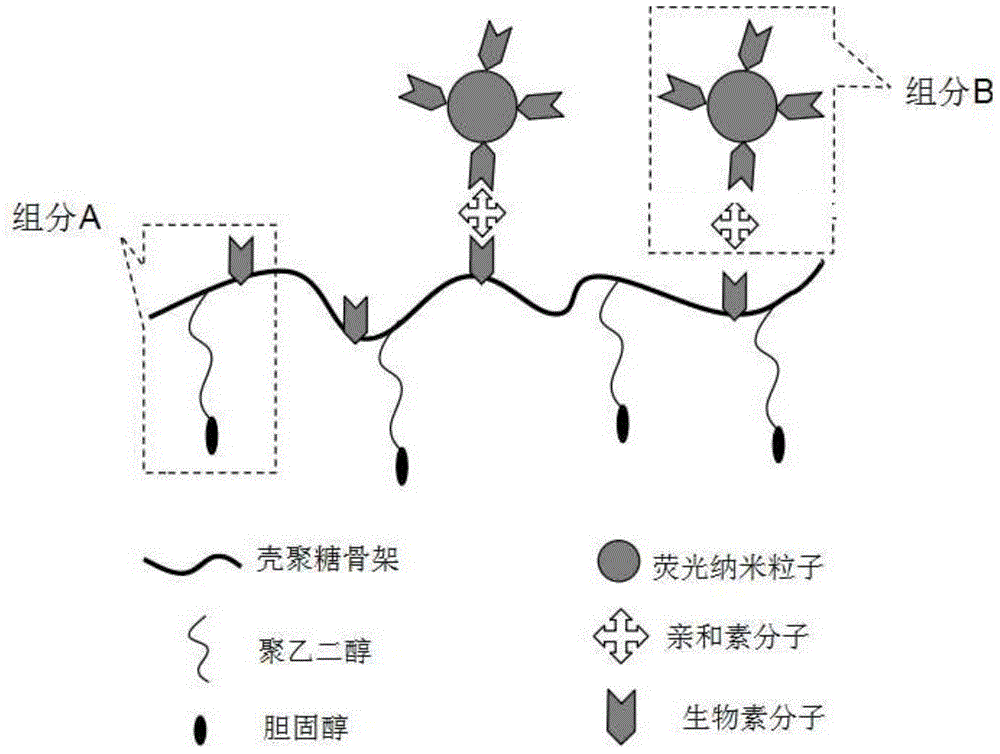

Long-time cell membrane imaging agent and preparation method thereof

ActiveCN104316500AGood biocompatibilityImprove imaging effectFluorescence/phosphorescenceLuminescent compositionsSide chainImaging agent

The invention discloses a long-time cell membrane imaging agent, which is characterized by comprising a component A and a component B. The component A is a glycol chitosan polymer with the side chain containing biotin and a hydrophobic unit; and the component B is an avidin molecule grafted with fluorescein isothiocyanate FITC. The cell membrane imaging reagent provided by the invention has good biological compatibility and good imaging effect, and can stay on the cell membrane for a long time without being swallowed, and can be used as a novel cell membrane imaging agent.

Owner:SOUTHEAST UNIV

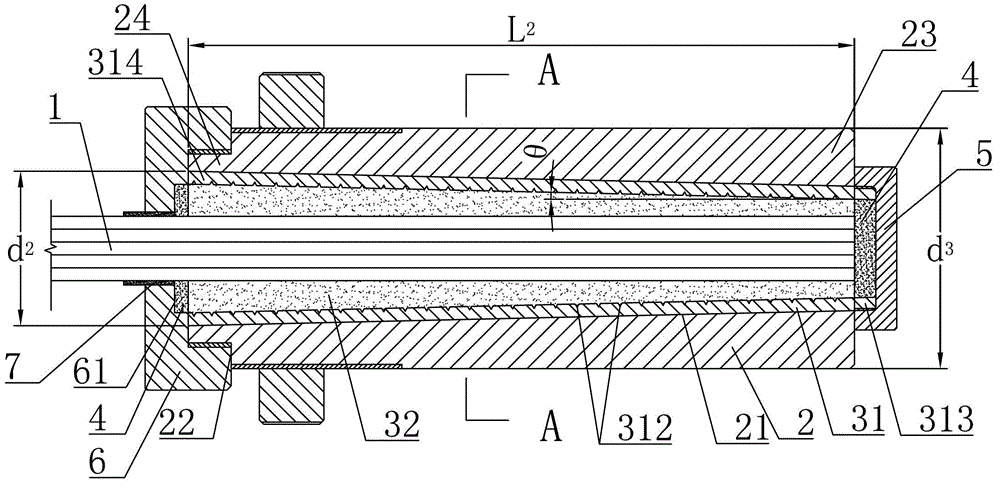

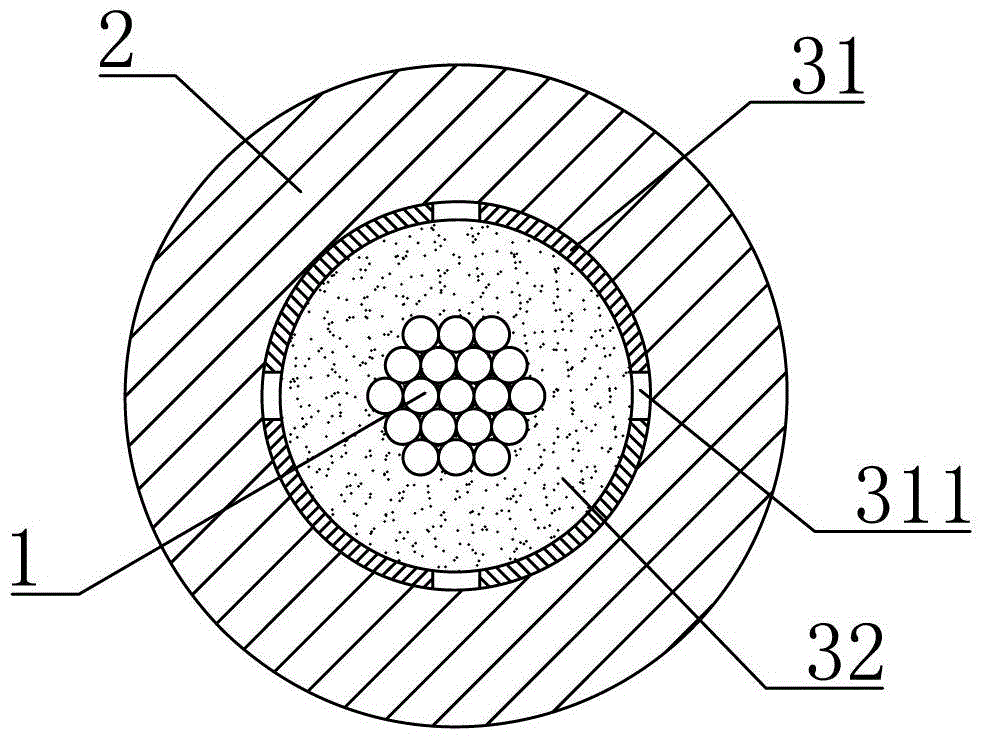

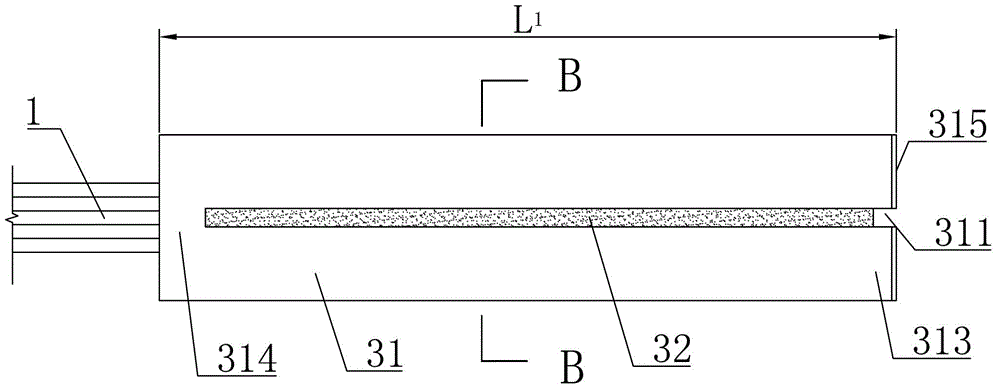

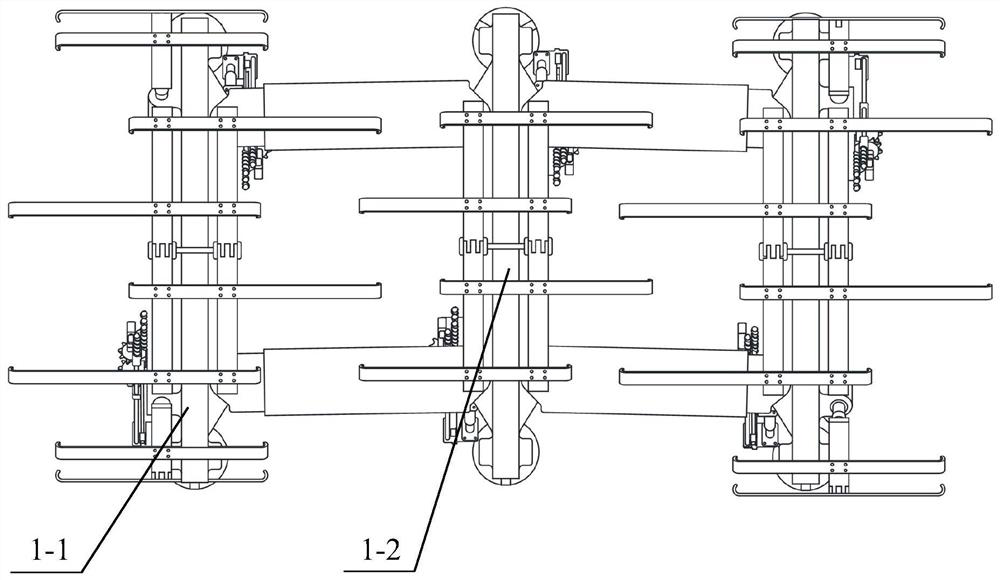

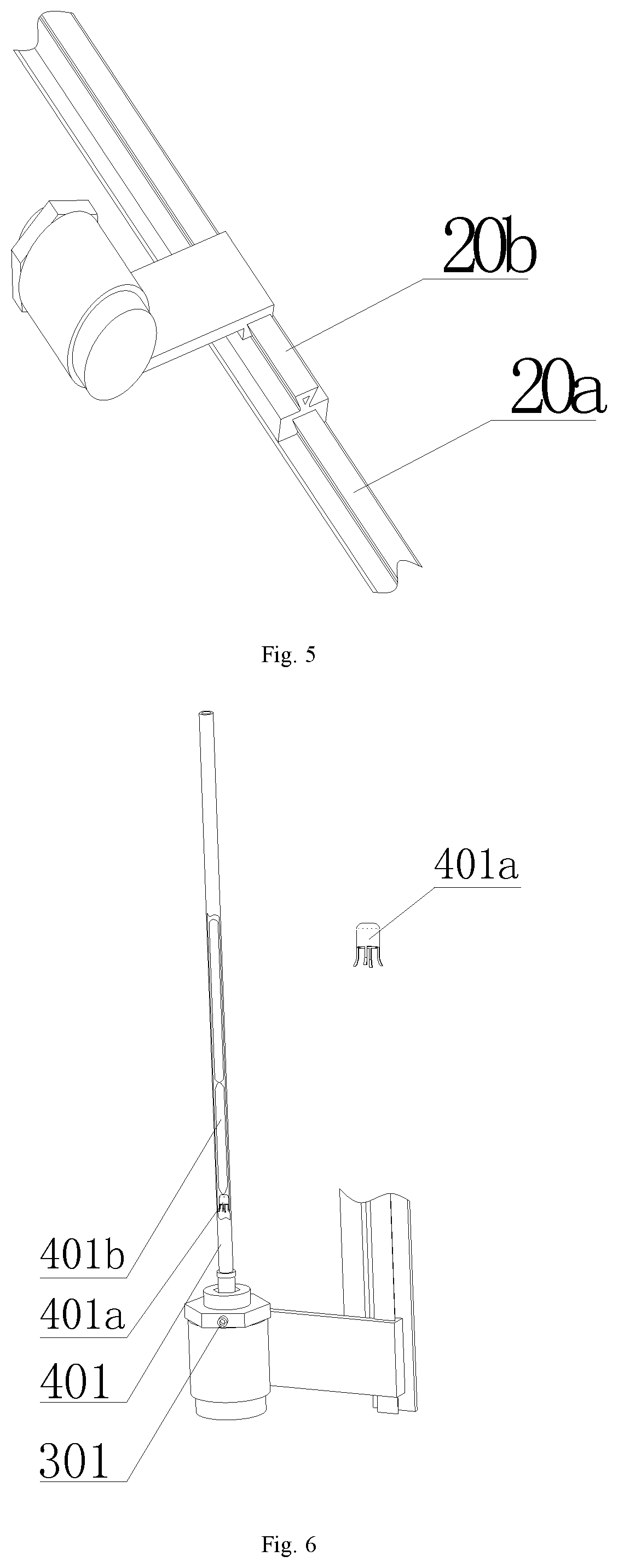

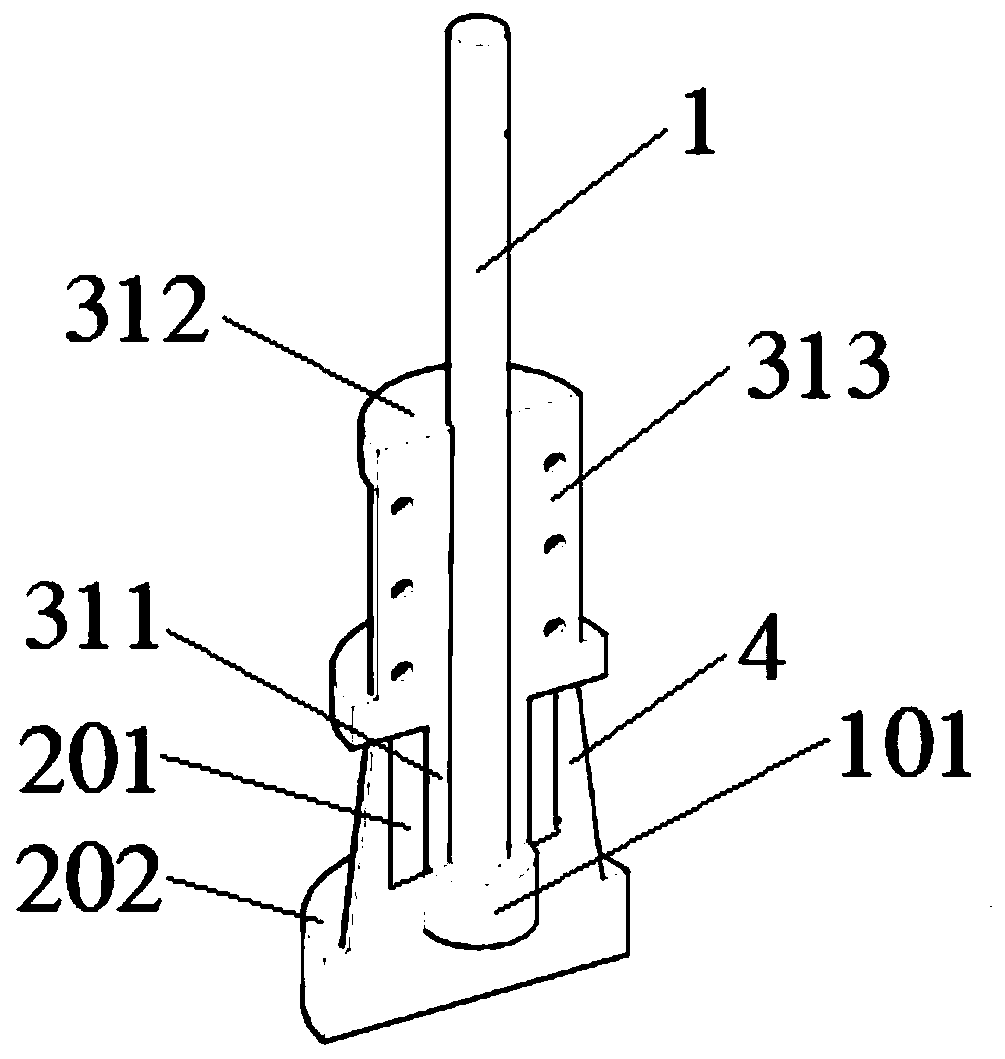

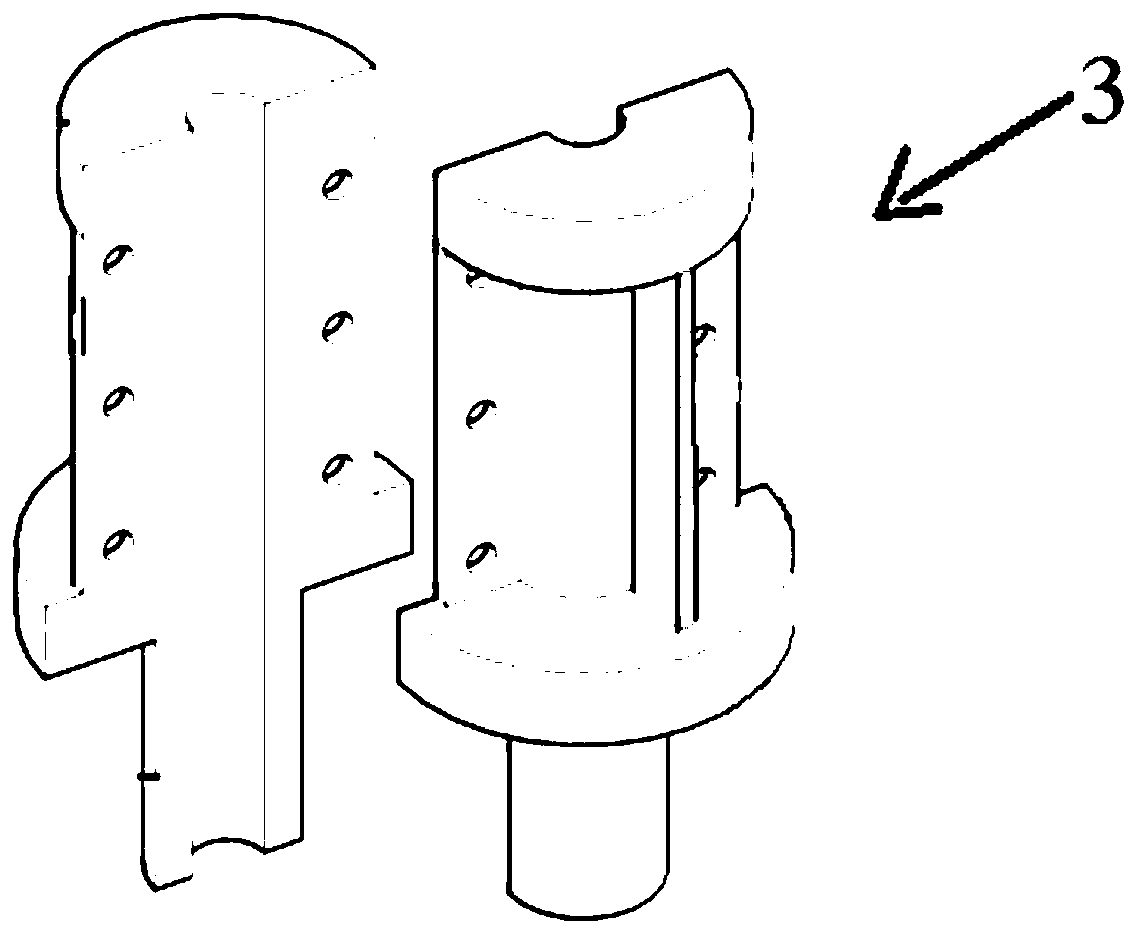

Anchoring apparatus and operation method thereof

ActiveUS20210062654A1Reduce labor intensityImprove anchoring efficiencyUnderground chambersTunnel liningPower control systemControl system

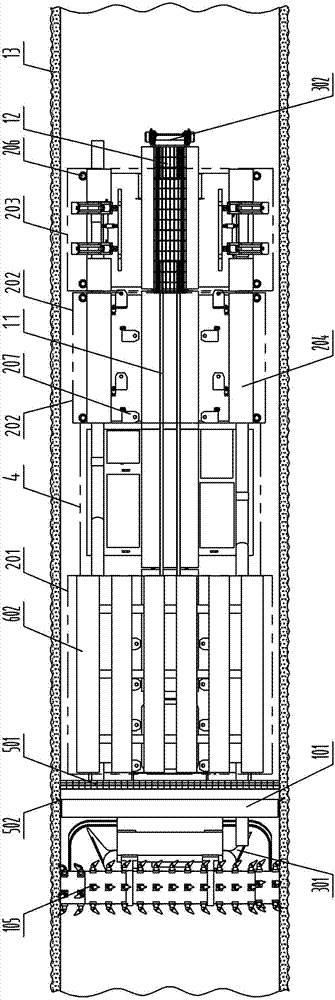

The present invention discloses an anchoring apparatus and an operation method thereof. The anchoring apparatus includes: a movable framework (1); a folding-type working platform (2) that includes a working platform frame (203), a longitudinal guide (204), a transverse guide (205) and a central turntable (206), the longitudinal guide (204) being movable along the transverse guide (205), and the central turntable (206) driving the longitudinal guide (204) and the transverse guide (205) to rotate relative to the working platform frame (203); a drilling machine (3); a workpiece supply system (4); and a power control system (5) that drives the movable framework (1) to move. With the anchoring apparatus, the mechanical and automatic anchoring with anchor bolts and anchor cables can be implemented in anchoring, the labor intensity in anchoring can be greatly reduced, the efficiency of anchoring can be improved, and the safety in the entire process can be enhanced.

Owner:HENAN POLYTECHNIC UNIV

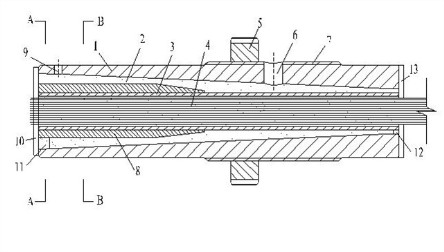

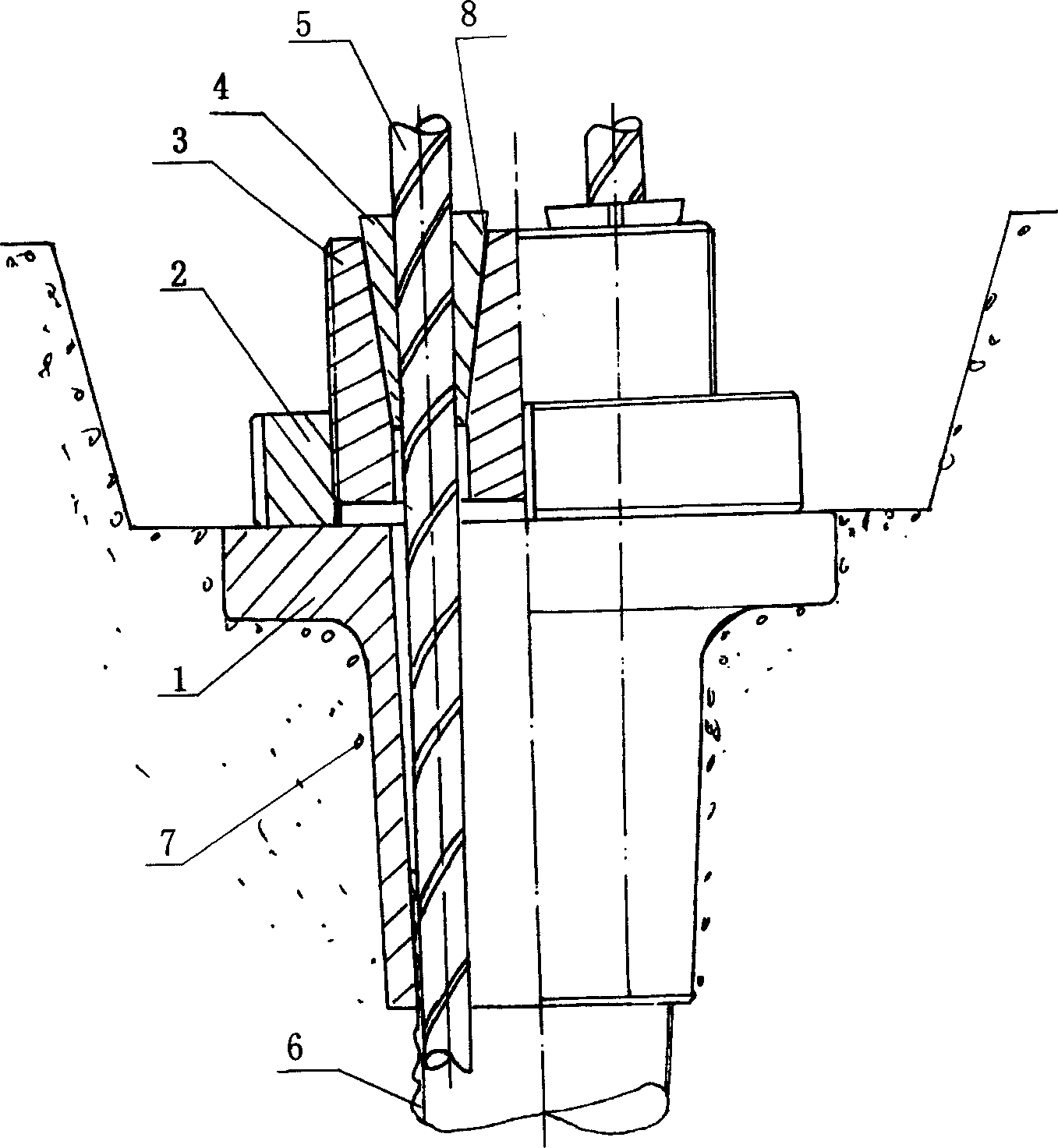

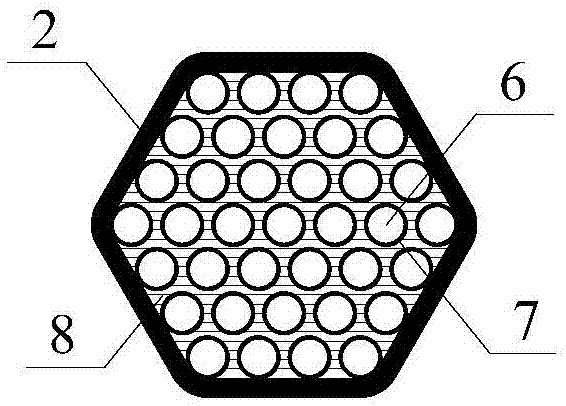

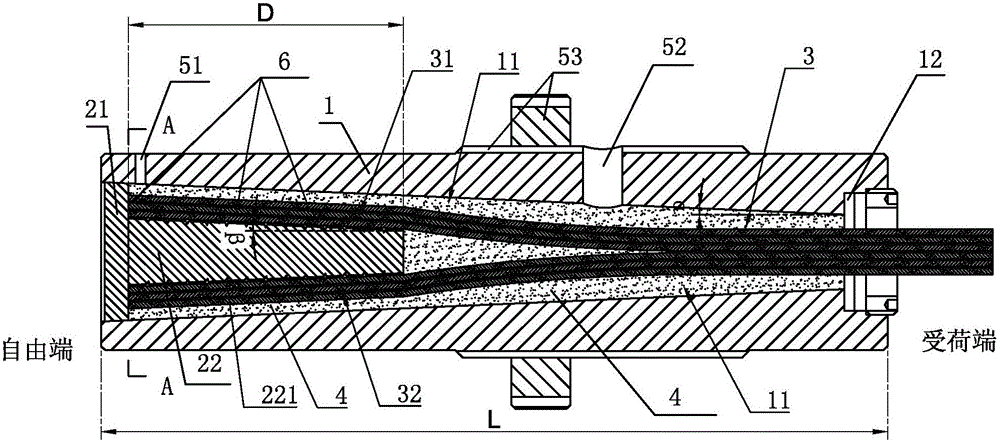

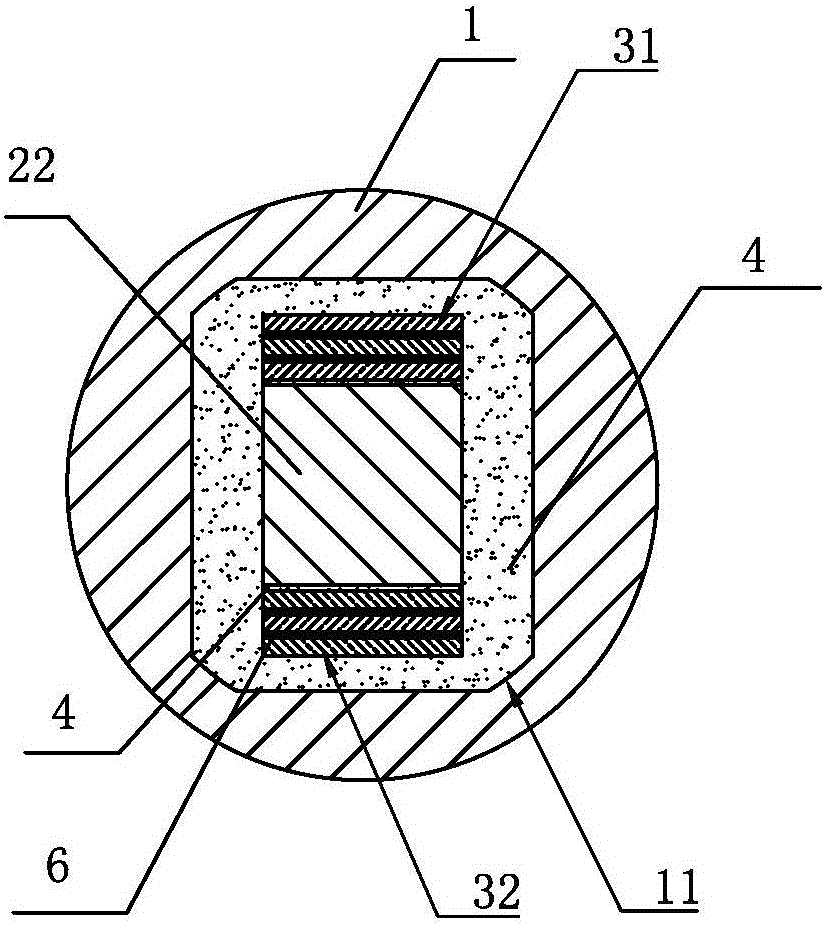

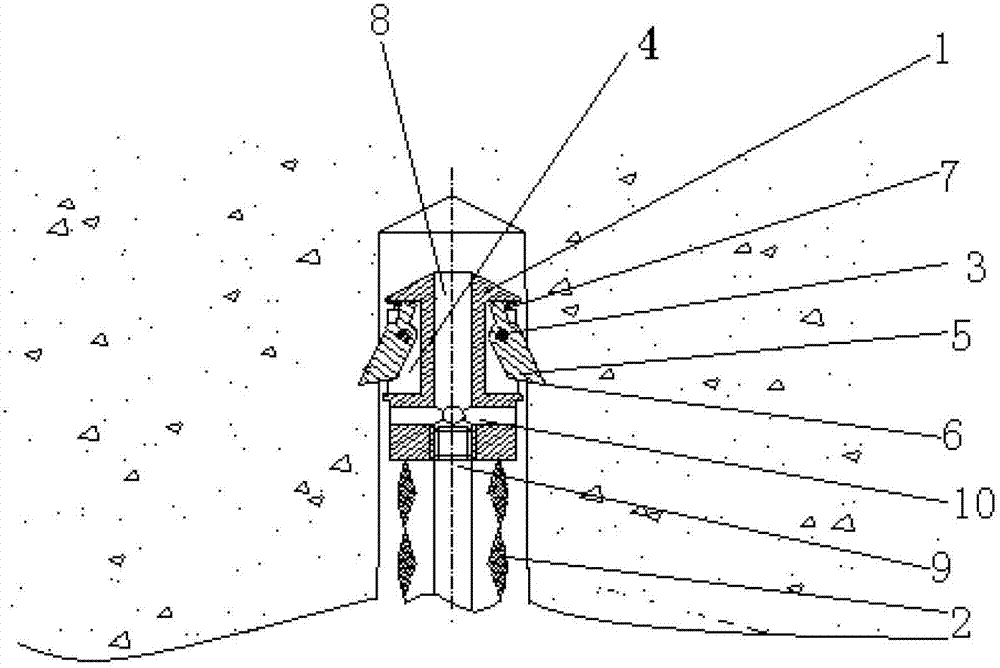

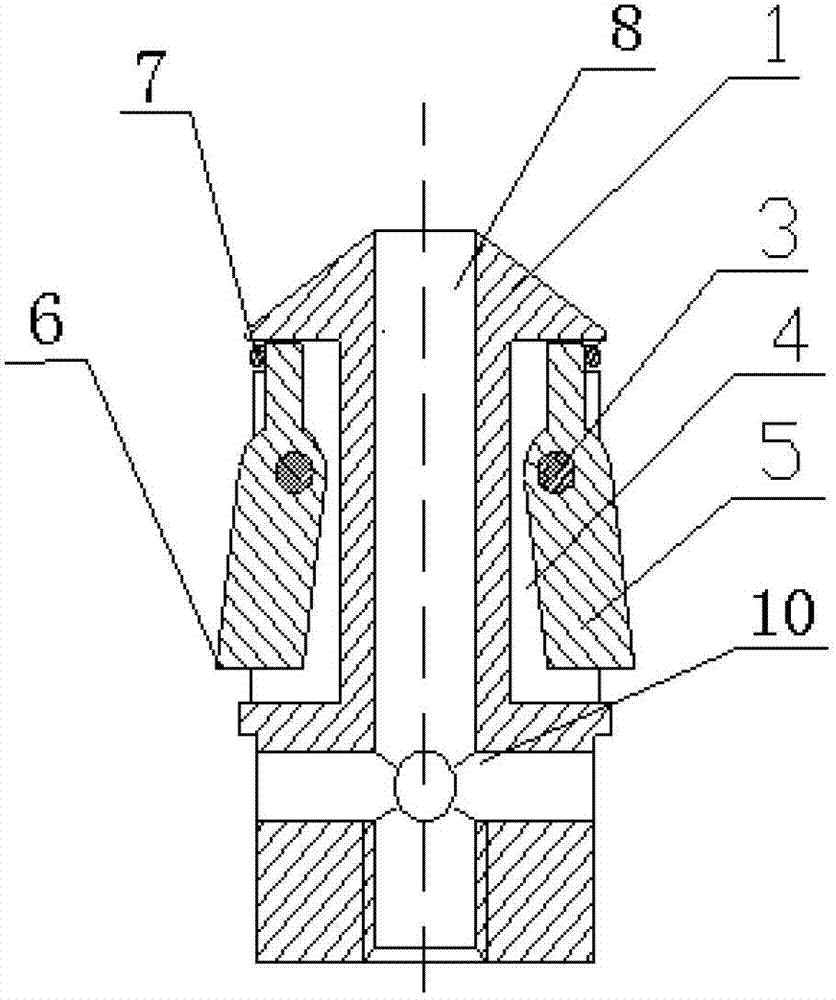

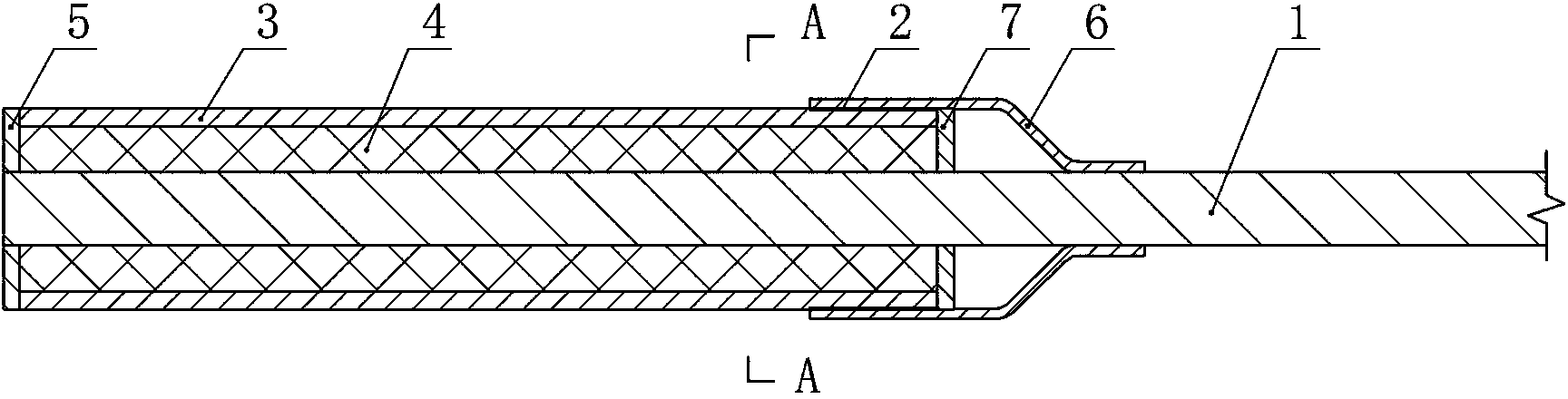

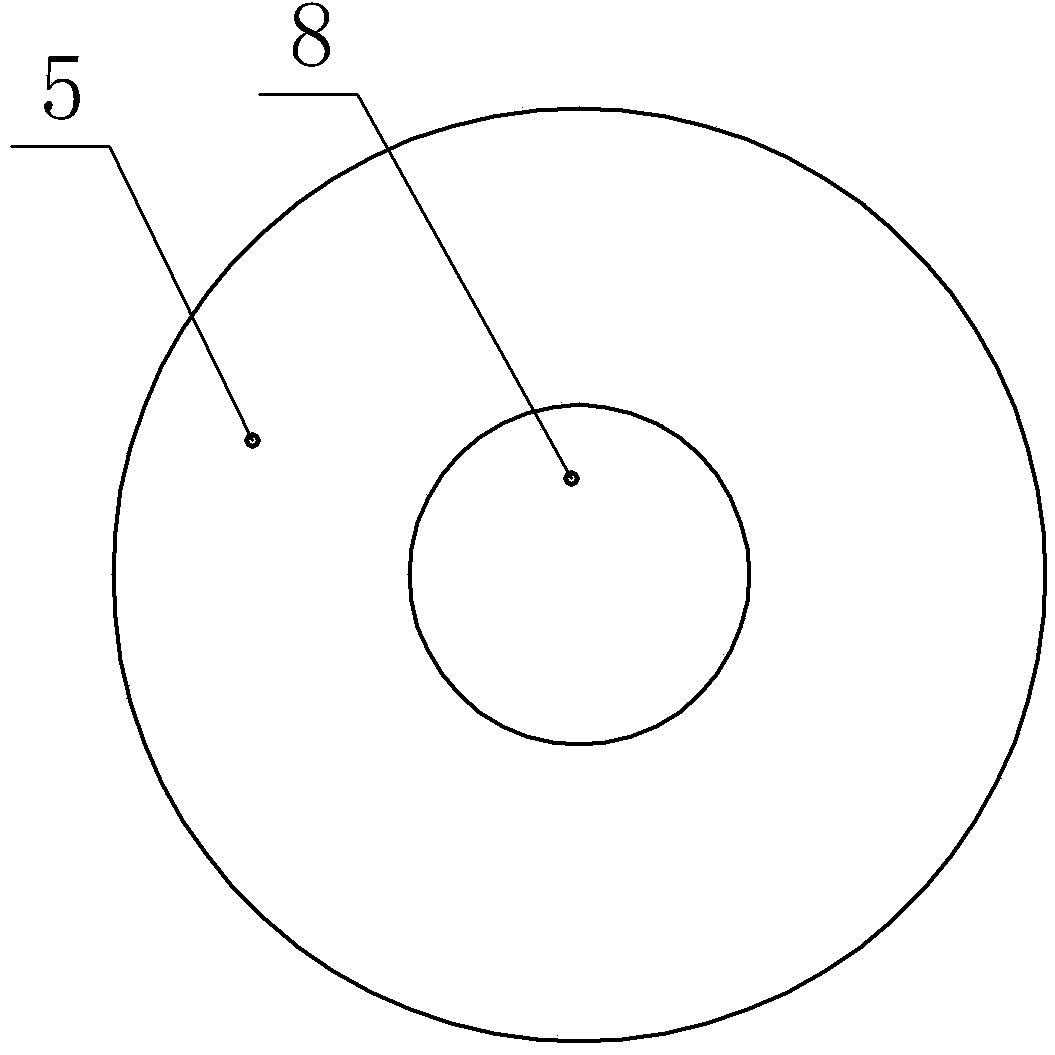

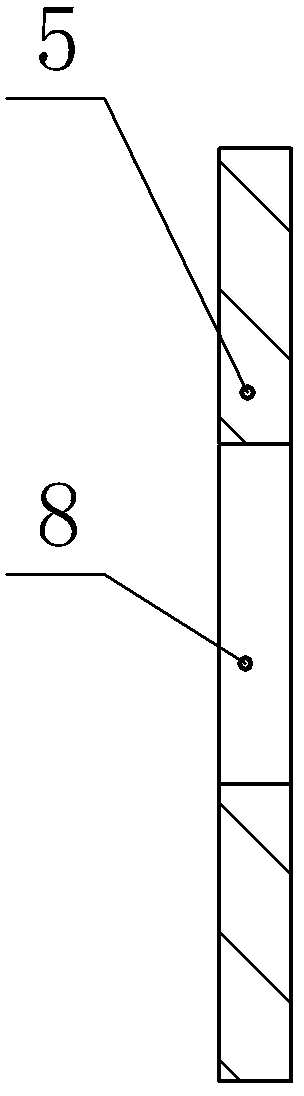

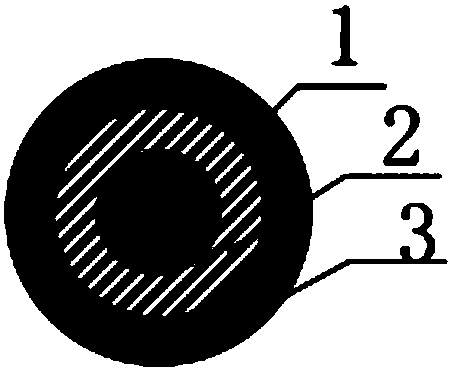

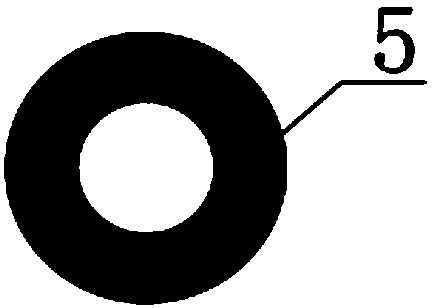

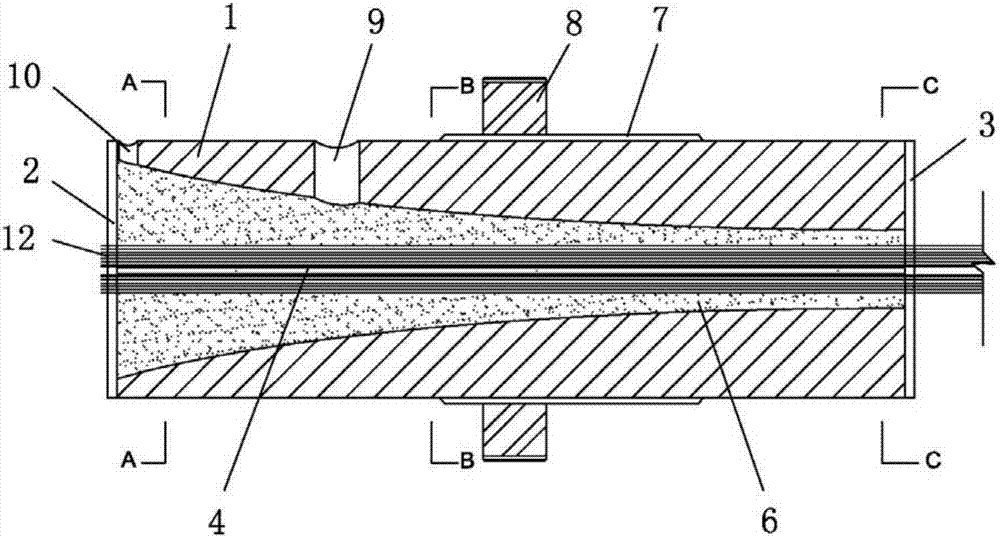

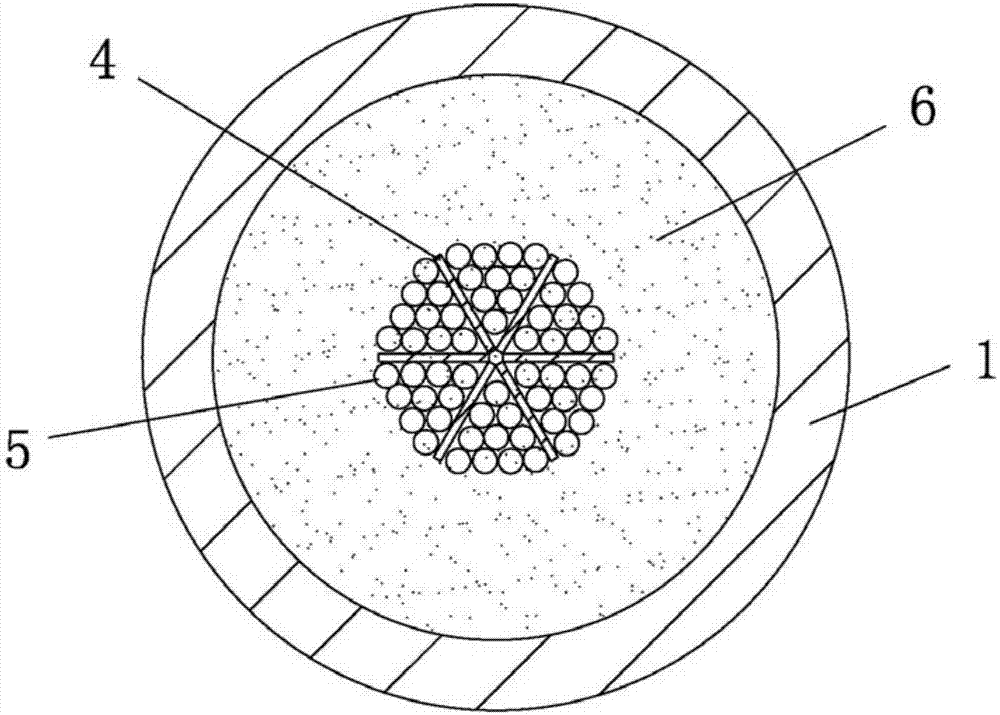

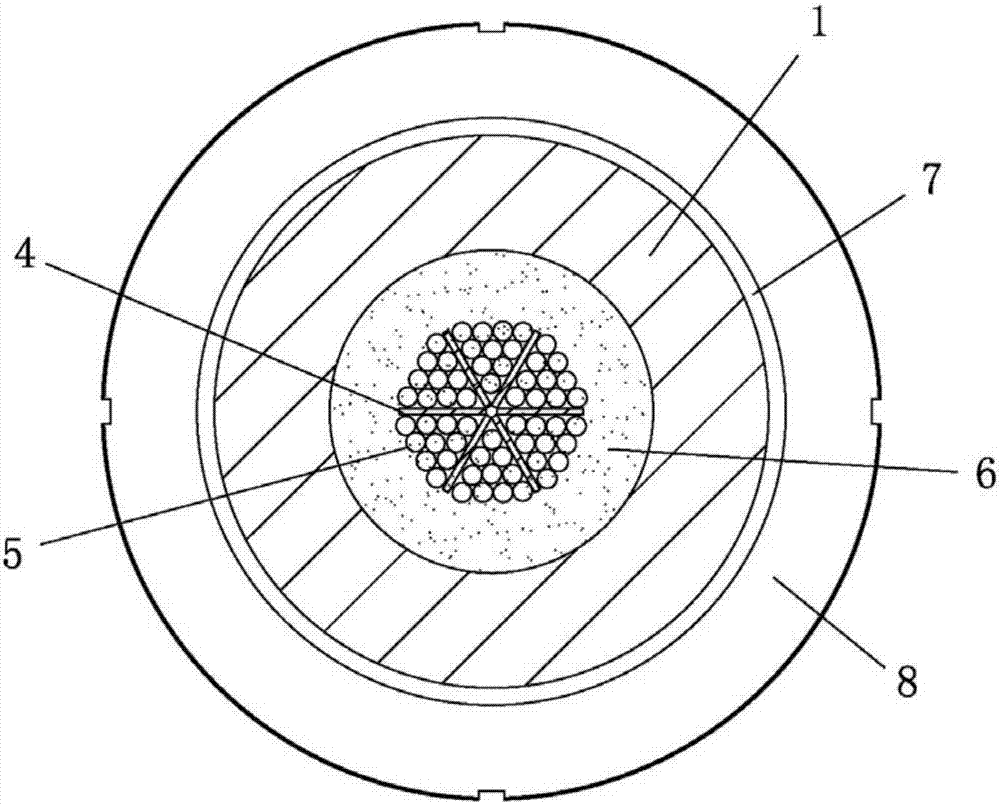

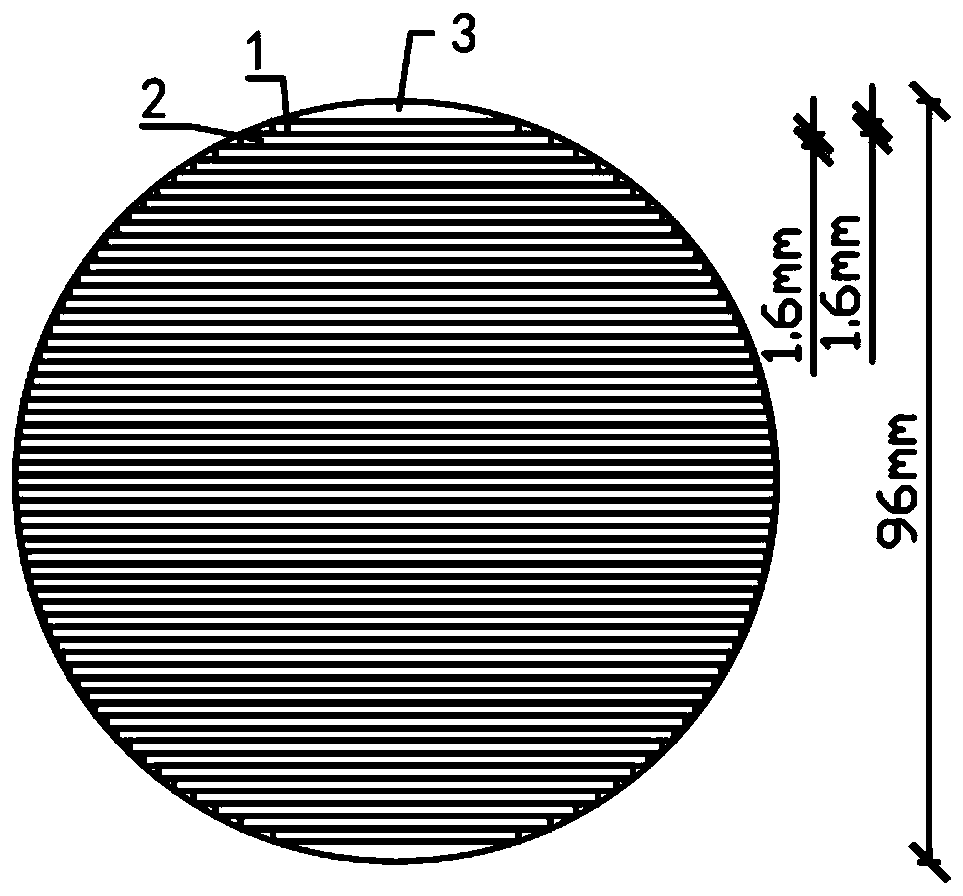

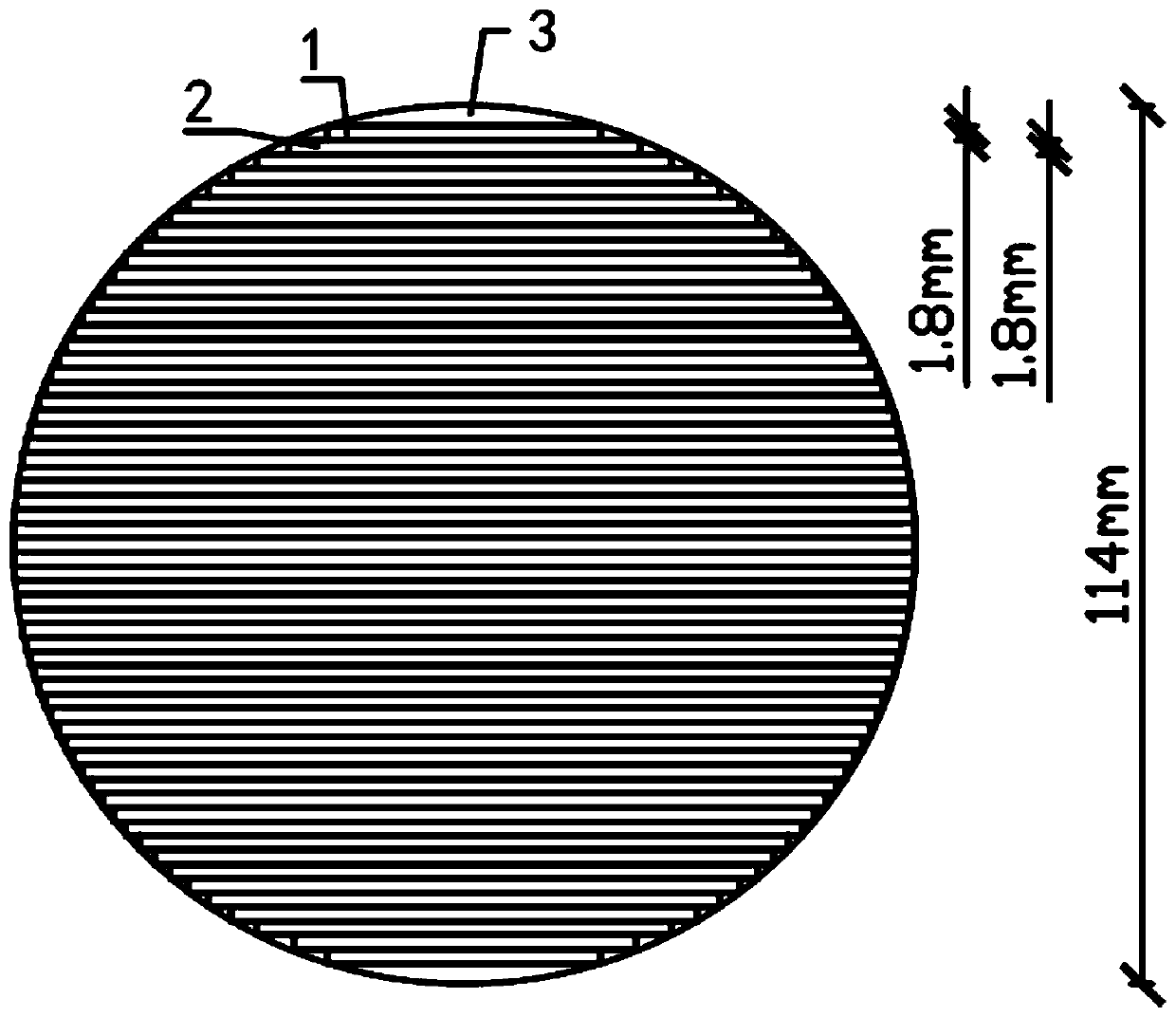

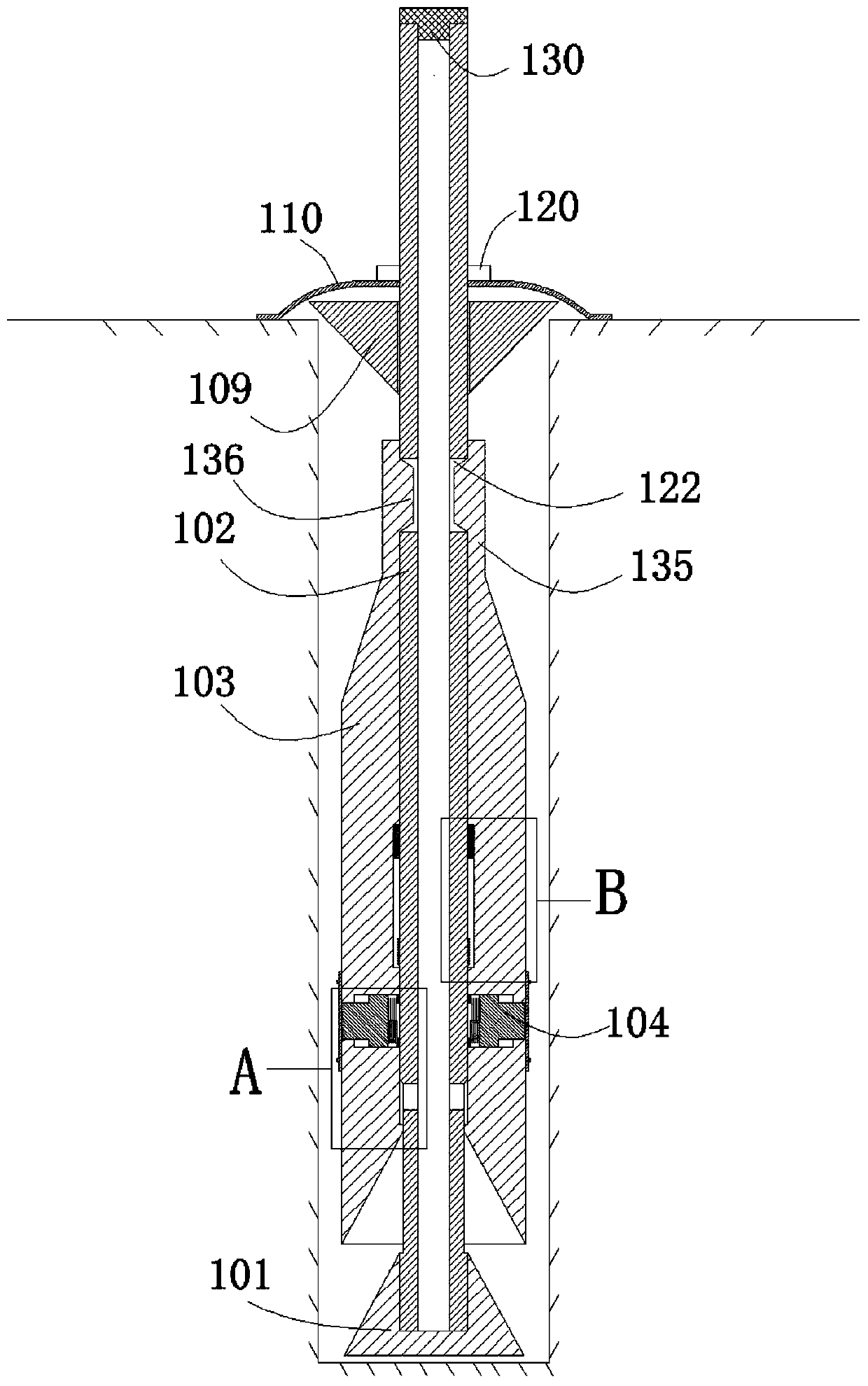

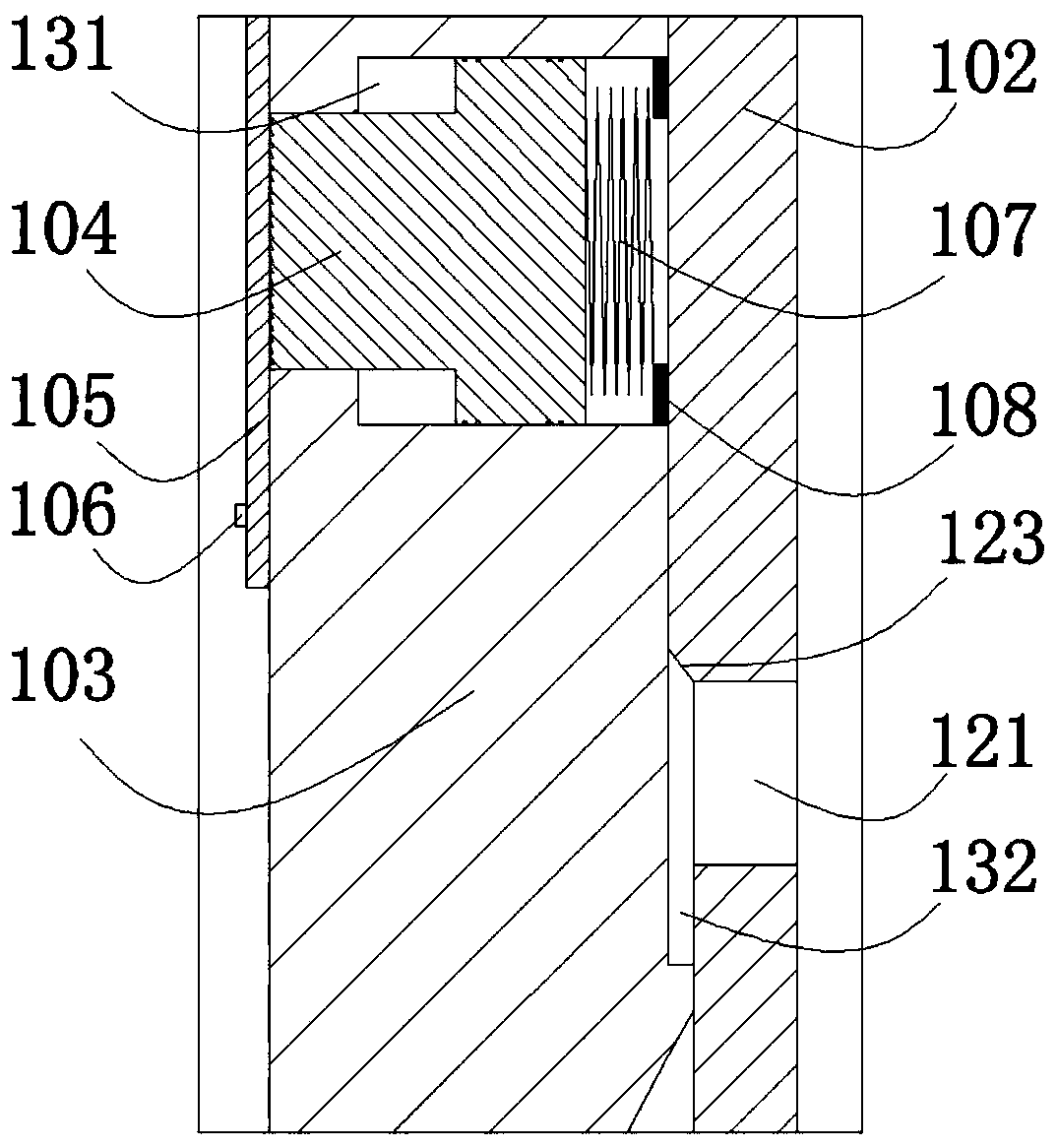

Internal-curved-surface-partitioned bond-type anchorage device for carbon fiber reinforced plastics (CFRP) cable strands

ActiveCN107143091AAvoid cutsReduce unevennessBridge structural detailsBuilding reinforcementsFiberEpoxy

The invention relates to an internal-curved-surface-partitioned bond-type anchorage device for carbon fiber reinforced plastics (CFRP) cable strands. The anchorage device comprises an anchor ring, a large hole end plug and a small hole end plug, wherein the interior of the anchor ring is of a horn-shaped curved surface shape; partition grooves are arranged inside the anchor ring, each partition of the partition grooves is filled with CFRP cable strands; a cavity between the horn-shaped curved surface inside the anchor ring and the CFRP cable strands is filled with epoxy resin adhesives; the longitudinal axial section line of the curved surface inside the anchor ring is a curved section, the curved section is close to a straight line at the small hole end of the anchor ring, and the curvature of the curved section gradually increases from the small hole end to a large hole end to allow the interior of the anchor to be of the horn-shaped curved surface shape. The anchorage device has the advantages that the horn-shaped curved surface inside the anchor ring can allow the radial extrusion force borne by the cable strands to be in an optimal distribution state in the longitudinal direction; the cable strands are arranged in a partitioned manner, the uneven transverse stress of large-diameter cable strands can be improved, a size effect can be lowered, the anchorage efficiency coefficient can reach 100% when the CFRP cable strands are large in diameter, and the device is excellent in static and dynamic performance.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

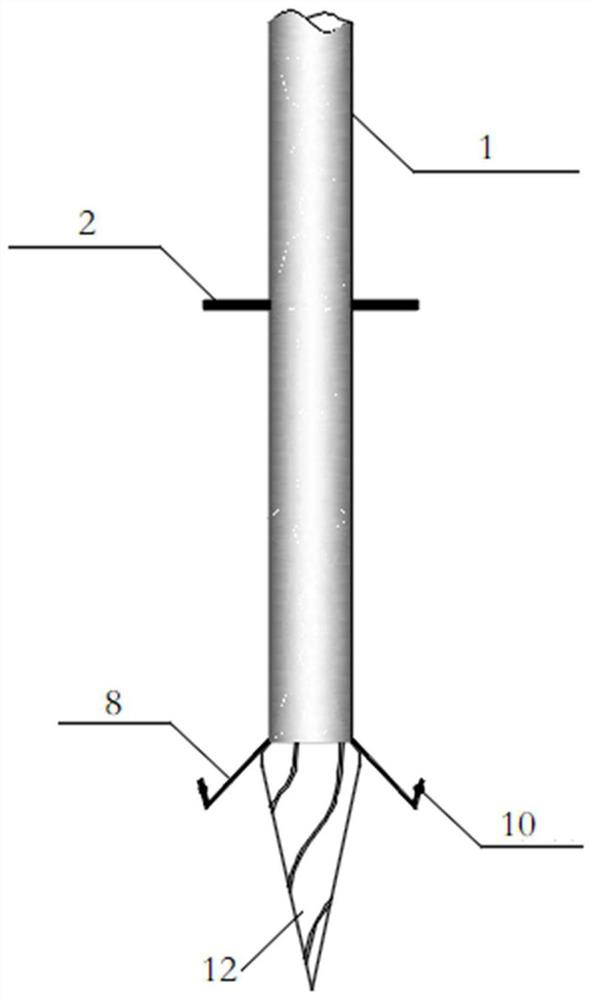

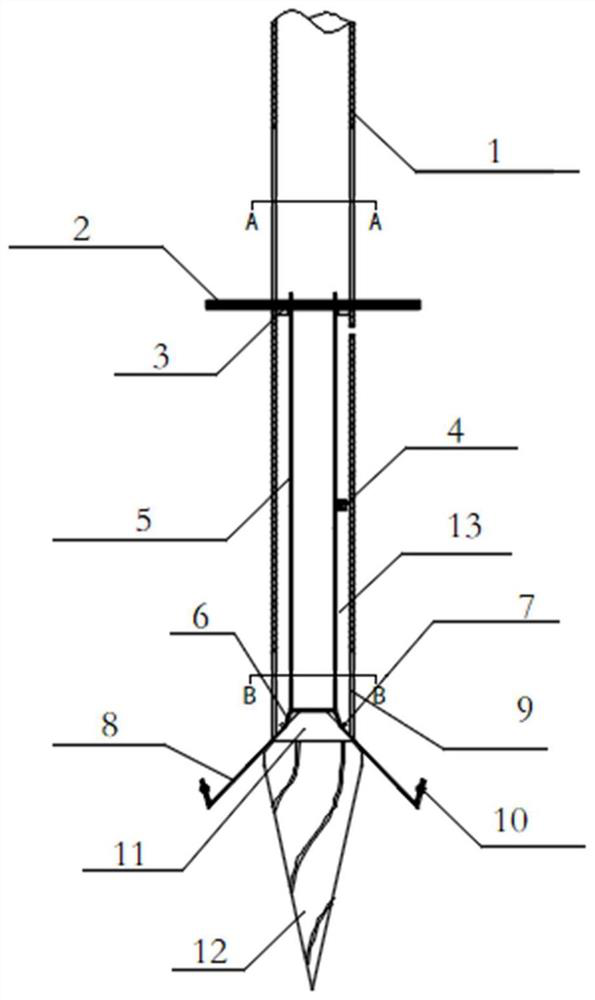

Recyclable sleeve type fixing anchor and using method thereof

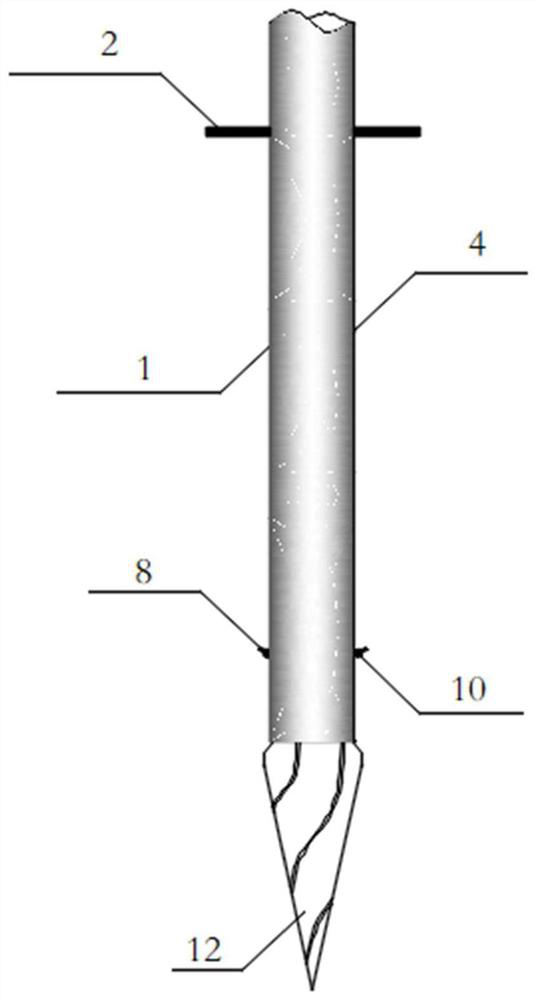

PendingCN113818438AThe extraction process is smoothImprove stabilityBulkheads/pilesStructural engineeringMechanical engineering

The invention discloses a recyclable sleeve type fixing anchor and a using method thereof. The recyclable sleeve type fixing anchor comprises a sleeve type rod body and a conical head connected with the bottom of the sleeve type rod body; an inner anchoring rod body used for conducting anchoring and recycling operation is arranged in the sleeve type rod body; the top of the inner anchoring rod body is connected with an anchoring operation rod transversely penetrating through the section of the inner anchoring rod body and the section of the sleeve type rod body; the bottom of the inner anchoring rod body is connected with at least three anchoring hooks arranged in the circumferential direction of the inner anchoring rod body; an opening allowing the anchoring operation rod to move up and down is formed in the upper portion of the side wall of the sleeve type rod body; and notches allowing the anchoring hooks to move are formed in the lower portion of the side wall of the sleeve type rod body, wherein the number of the notches corresponds to the number of the positions of the anchoring hooks. The recyclable sleeve type fixing anchor can be rapidly mounted and dismounted in use, is convenient to store and transport, can be repeatedly used and is economical and efficient; and after the recyclable sleeve type fixing anchor is mounted, when advancing of an engineering working face is affected, changing and moving are quite convenient, the changing and moving cost is low, and construction is safe.

Owner:CHINA FIRST METALLURGICAL GROUP

Anchoring device adopting spiral slotting clamping piece for prestressed FRP (Fiber Reinforced Polymer) cables

InactiveCN103352540ADisposableClamping does not affectBuilding reinforcementsFiberMechanical engineering

The invention discloses an anchoring device adopting spiral slotting clamping pieces for prestressed FRP (Fiber Reinforced Polymer) cables. The anchor device comprises an anchor block, polymer cable anchor clamping pieces arranged inside openings of the anchor block and polymer cables arranged inside the polymer cable anchor clamping pieces, wherein each polymer cable anchor clamping piece adopts an integral structure and is provided with two ends extending out of each opening of the anchor block; n spiral grooves are formed in the main body of the polymer cable anchor clamping piece in the vertical direction. According to the invention, the anchoring device is applied to the anchoring of the FRP cables, the clamping pieces are adopted to clamp while linear grooves in the traditional anchor clamping pieces are designed and changed into curve grooves, and each elastic groove turns for an angle of 90 degrees on the projection of the cross section of each clamping piece from the top of each clamping piece to the bottom of each clamping piece, so that the anchor device has the advantages of the capability of reuse, high anchoring efficiency and the like.

Owner:SOUTHEAST UNIV

Circular section muti-layer sheet type CFRP inhaul cable system

ActiveCN111021631AIncrease self-dampingHigh resistance to wind-induced vibrationBuilding reinforcementsClassical mechanicsEngineering

The invention discloses a circular section muti-layer sheet type CFRP inhaul cable system and relates to the technical field of civil engineering and composites. The circular section muti-layer sheettype CFRP inhaul cable system comprises CFRP sheets, sheet type foam, circular-arc type foam, a polyethylene protection sleeve, an upper corrugated clamping plate, a lower corrugated clamping plate, corrugated clamping sheets, bolts, nuts and gaskets. The CFRP sheets different in width are stacked in the rule that the width dimensions of the CFRP sheets are gradually reduced from the middle to theupper and lower layers, the sheet type foam different in width is used for spacing the CFRP sheets at a free section of an inhaul cable, top points of the outer edges of all the CFRP sheets and the sheet type foam are internally connected with one circle together to form a virtual circular section, and the outer portions of the CFRP sheets and the sheet type foam are wrapped with the polyethyleneprotection sleeve. The CFRP sheets are spaced through the corrugated clamping sheets in an anchoring section and are clamped and anchored through the corrugated clamping plates. The circular sectionmuti-layer sheet type CFRP inhaul cable system overcomes the defect that a circular section stick type CFRP inhaul cable is difficult to anchor, solves the problem that a rectangular section sheet type CFRP inhaul cable is poor in wind-induced vibration resistance and can be applied to cable-stayed bridges, suspension bridges and space cable structures.

Owner:重庆卓越强森新材料科技有限公司

High-strength steel bar anchoring device and implementation method thereof

The invention discloses a high-strength steel bar anchoring device and an implementation method thereof. The anchoring device comprises a first anchoring part, a second anchoring part and a high-strength steel bar which are sequentially arranged from outside to inside. The tip of an anchoring end of the high-strength steel bar is upset to form a pier head, the pier head end of the high-strength steel bar is sleeved by the first anchoring part, and the upper end of the first anchoring part is higher than the upper surface of the pier head; the high-strength steel bar located on the upper side of the pier head is sleeved by the second anchoring part, and the lower end of the second anchoring part is tightly attached to the upper surface of the pier head; and the upper end of the first anchoring part is detachably and fixedly connected with the lower end of the second anchoring part. Steel sleeves with different diameters are matched with anchoring plates with different diameters, so thatmulti-point matching anchoring of the high-strength steel bar in the longitudinal direction and the transverse direction is achieved, weak anchoring areas are avoided, and stable anchoring is achieved; and through the anchoring mode that the steel sleeve is combined with the pier head, the pier head is manufactured in advance, and the low anchoring efficiency caused by manufacturing the pier headon site is avoided.

Owner:CHANGAN UNIV +1

Fully sealed coal roadway tunneling and anchoring synchronous machine

ActiveCN102606153BImprove tunneling efficiencyImprove safety factorSlitting machinesAnchoring boltsVehicle frameMining engineering

The invention relates to coal mine roadway tunneling machinery, in particular to a fully sealed coal roadway tunneling and anchoring synchronous machine, comprising a tunneling device, a sealing and dust removing device, an anchoring device, a coal loading and conveying device, a power system and a hydraulic system, wherein the tunneling device comprises a body part, a telescopic cutting part arranged at the front end of the body part, a walking part arranged at the lower part of the body part and a rear support part arranged at the rear end of the body part; the anchoring device comprises at least one first anchor rod drill carriage; the first anchor rod drill carriage is arranged between the cutting part of the tunneling device and the power system; other anchor rod drill carriages are arranged behind the power system sequentially; each anchor rod drill carriage comprises a frame, an anchor rod drilling machine group fixedly arranged on the frame, wheels arranged at the four corners of the lower part of the frame and a hydraulic oil cylinder; the body part of the tunneling device is in overlap joint with the two sides of the frame of the first anchor rod drill carriage through a sliding rail and is fixedly connected with a dragging oil cylinder; and the anchor rod drill carriages are hinged with one another. The fully sealed coal roadway tunneling and anchoring synchronous machine is unique in design, reasonable in structure, high in the degree of automation, efficient and safe and is very suitable for extended application.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A composite anchor for frp tendons

ActiveCN108221666BLow number of componentsEasy to assembleBridge structural detailsBuilding reinforcementsStructural engineeringTendon

The invention discloses a composite anchor for FRP ribs, and relates to the field of anchorage. The anchor comprises an anchor ring, a metal barrel and an end plug; a conical through hole is formed inthe center of the anchor ring; the metal barrel is mounted in the conical through hole of the anchor ring, and two ends of the metal barrel are protruded out of the anchor ring; the metal barrel is aconical empty barrel; and a CFRP rib is arranged in the center of the metal barrel, the CFRP rib penetrates through the metal barrel, and the metal barrel is filled with an adhesive and is positionedand plugged by the end plug to form an FRP rib combination. After maintaining is finished, the anchor ring is assembled on the combination, and the anchor can be stretched after pretightening force is applied. The anchor is simple to manufacture and operate, high in anchorage efficiency and short in anchorage length, and can be applied to reinforcing engineering.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com