Digging, anchoring and drilling integrated hard rock tunneling machine

A hard rock roadheader, an integrated technology, applied in cutting machinery, earthwork drilling, installation of bolts, etc., to achieve the effect of reducing labor intensity, labor cost, and strong ability to adapt to roadways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

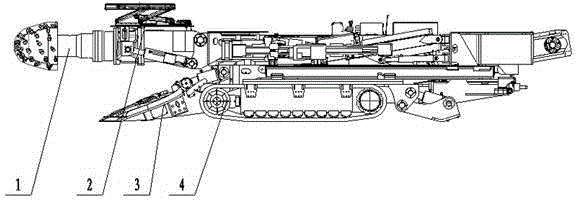

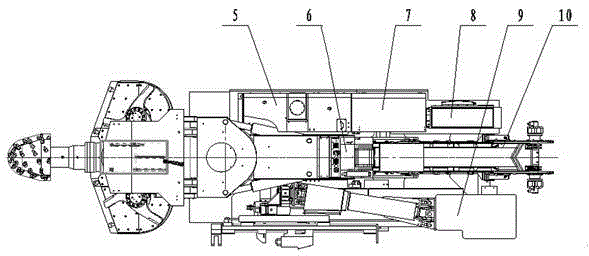

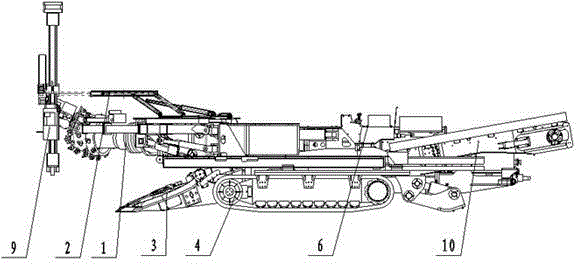

[0025] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0026] Bolt-digging and drilling integrated hard rock roadheader, including cutting part 1, loading part 3, drilling rig system 9, working platform 2, crawler belt 4, pumping station oil tank 5, hydraulic control box 7, electric control box 8, operation console 6 and A drilling rig support frame is provided above the crawler belt on the left side of the conveyor 10, a sliding guide rail 16 that can move back and forth relative to the drilling rig support frame is provided, and a drilling rig system 9 that can move back and forth relative to it is provided on the sliding guide rail 16;

[0027] An integrated pump station oil tank 5 is installed in front of the right side of the machine, a hydraulic control box 7 is installed in the middle right, and an electric control box 8 is installed in the right rear;

[0028] The console is arranged in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com