Patents

Literature

64results about How to "Improve job productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

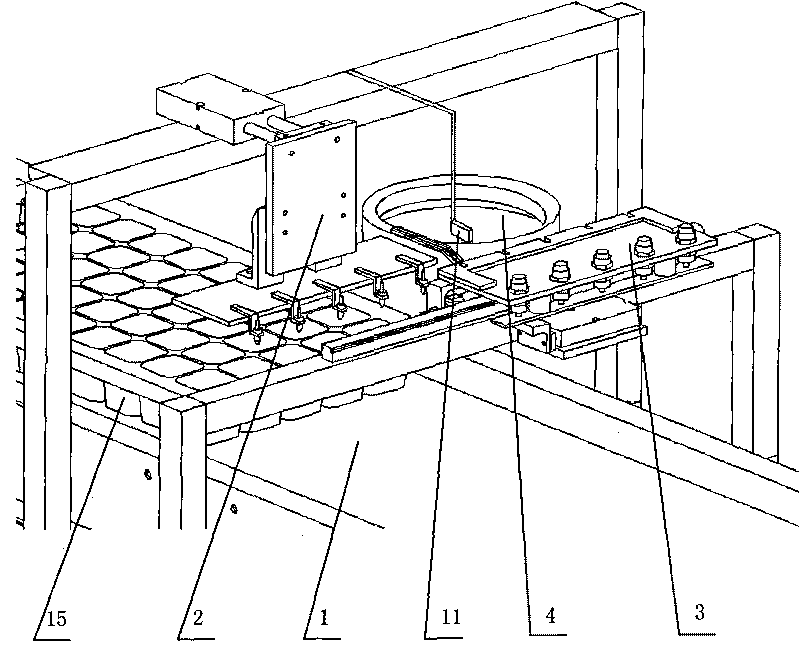

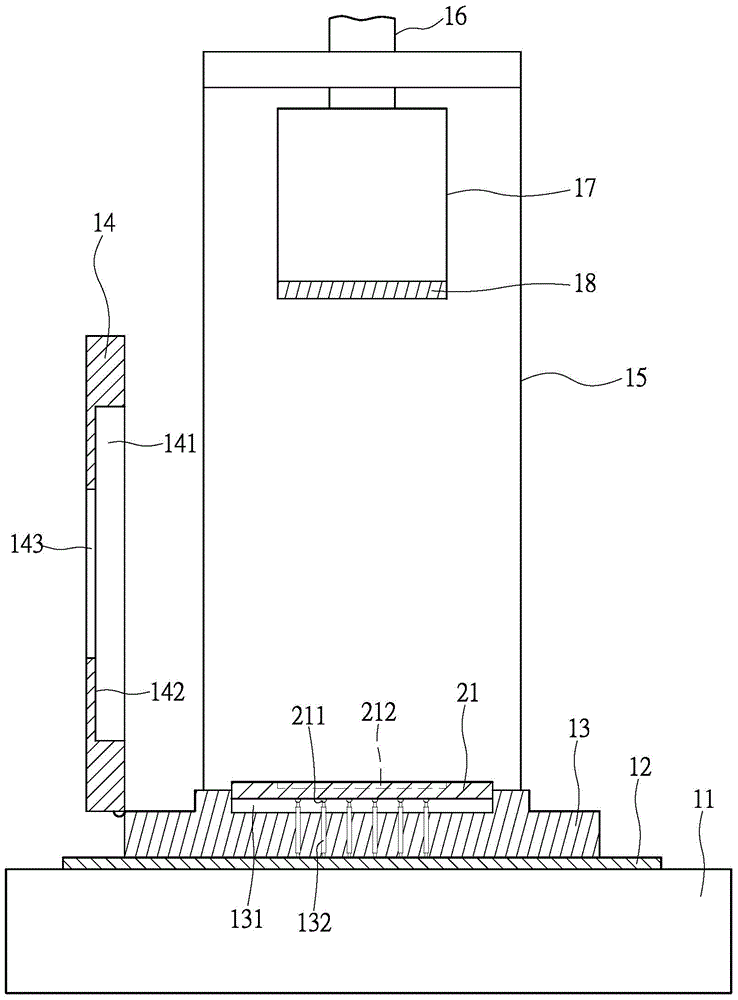

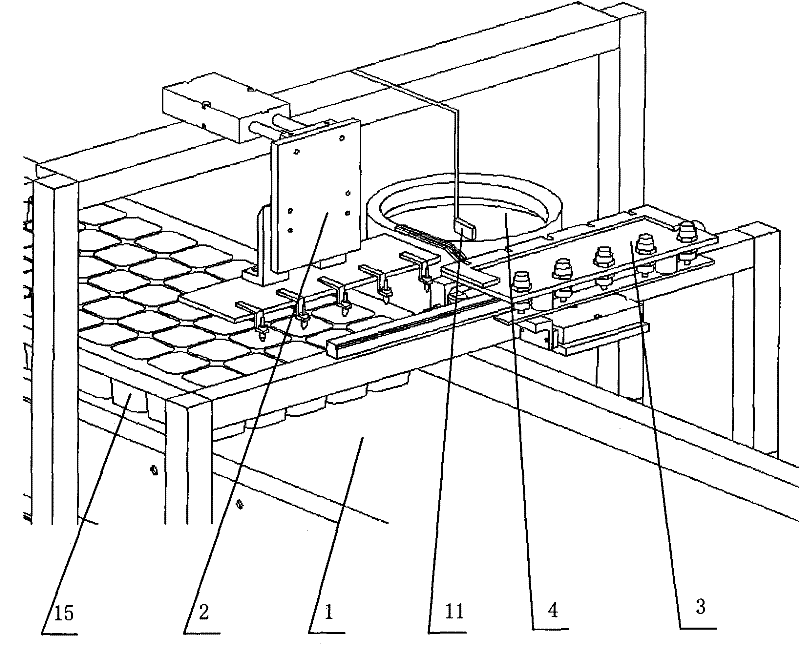

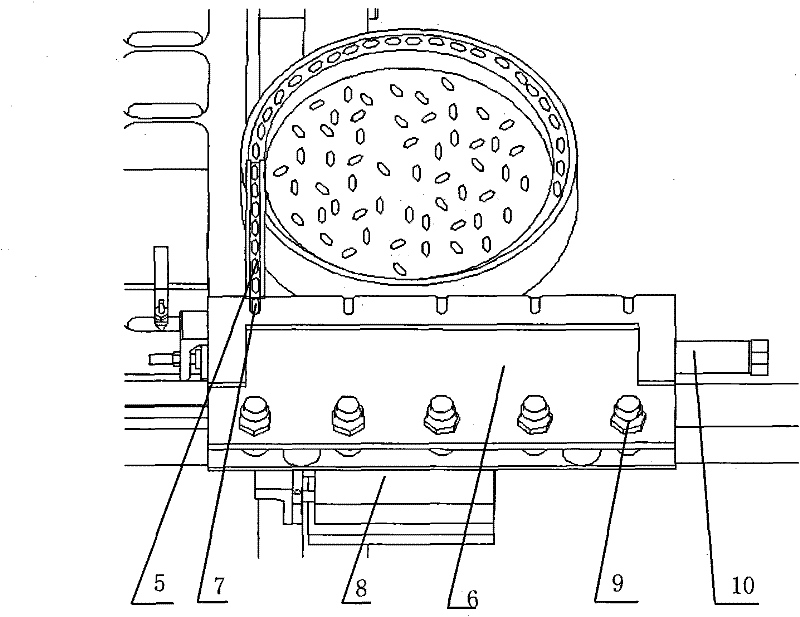

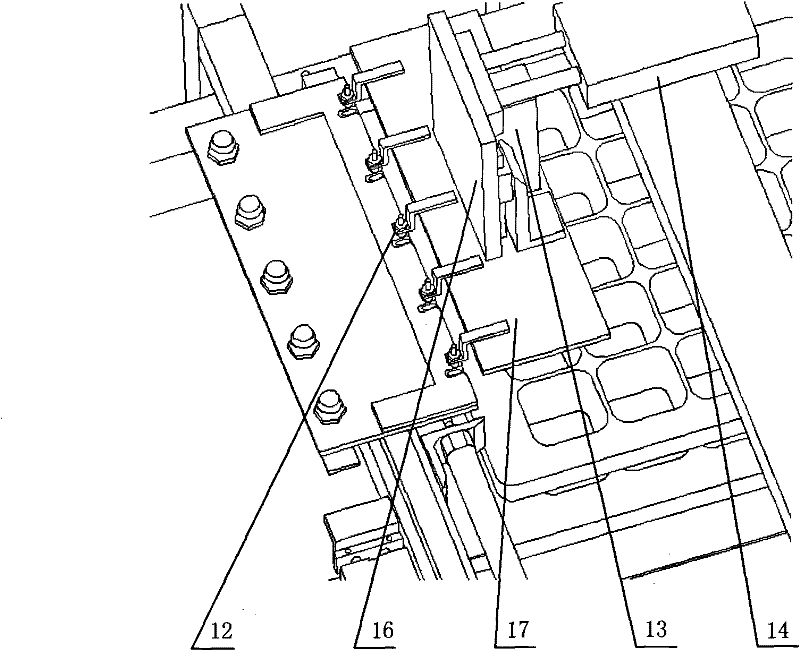

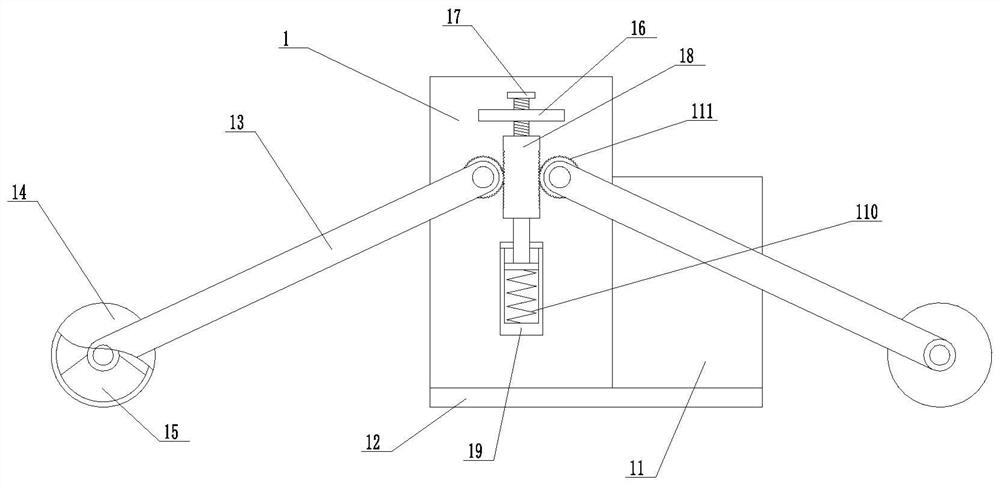

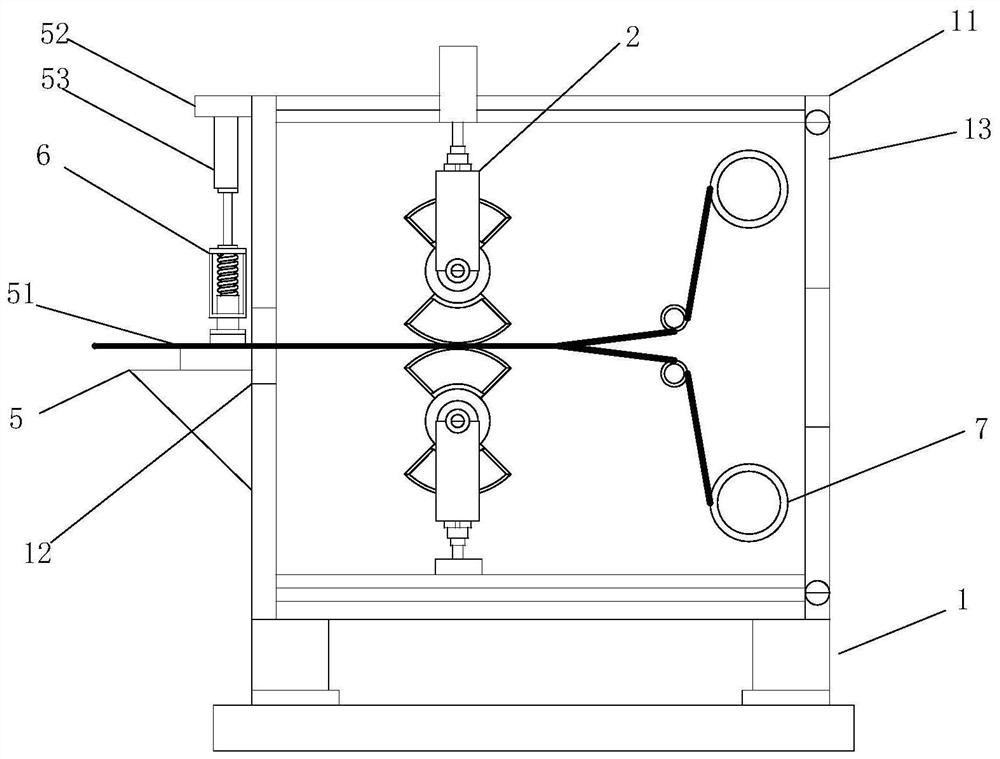

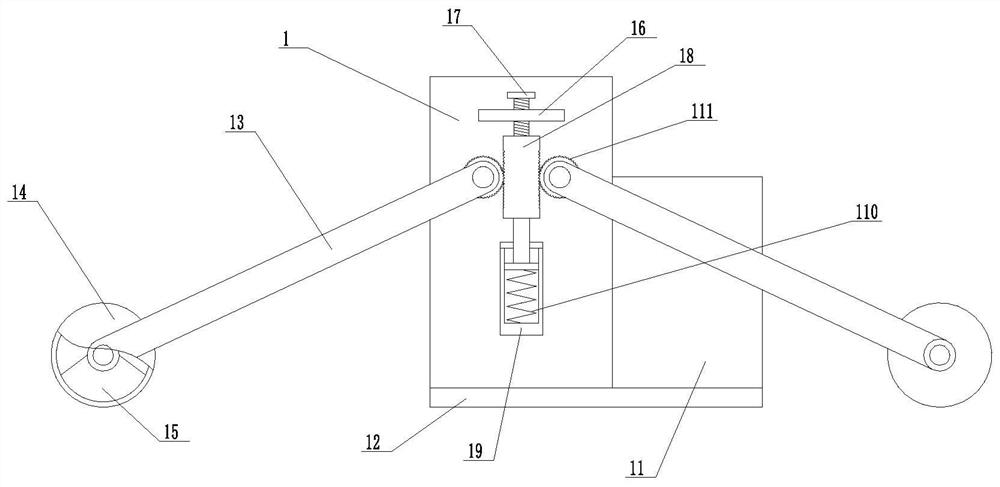

Long grained seed steering precision seeding device and seeding method thereof

InactiveCN101702969ATo achieve the purpose of batch directional seedling cultivationImprove job productivitySeed depositing seeder partsProduction rateEngineering

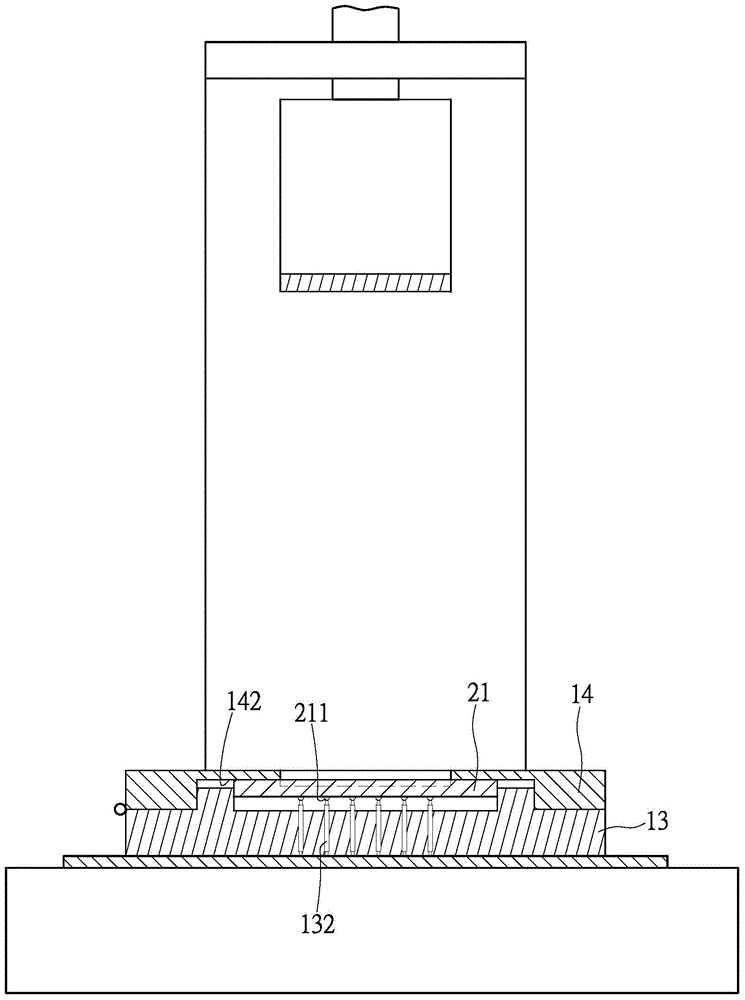

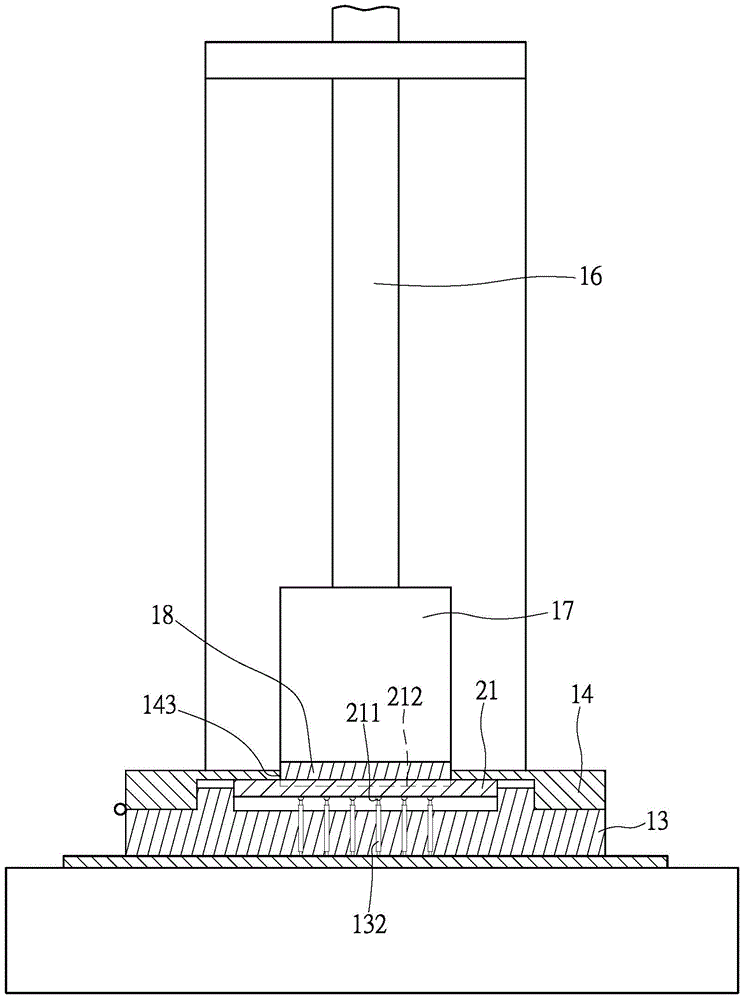

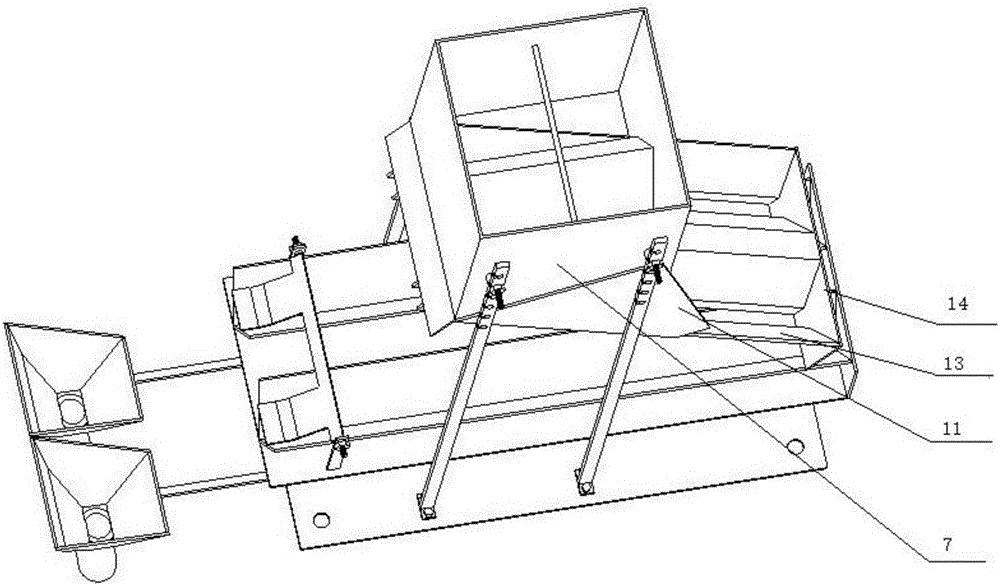

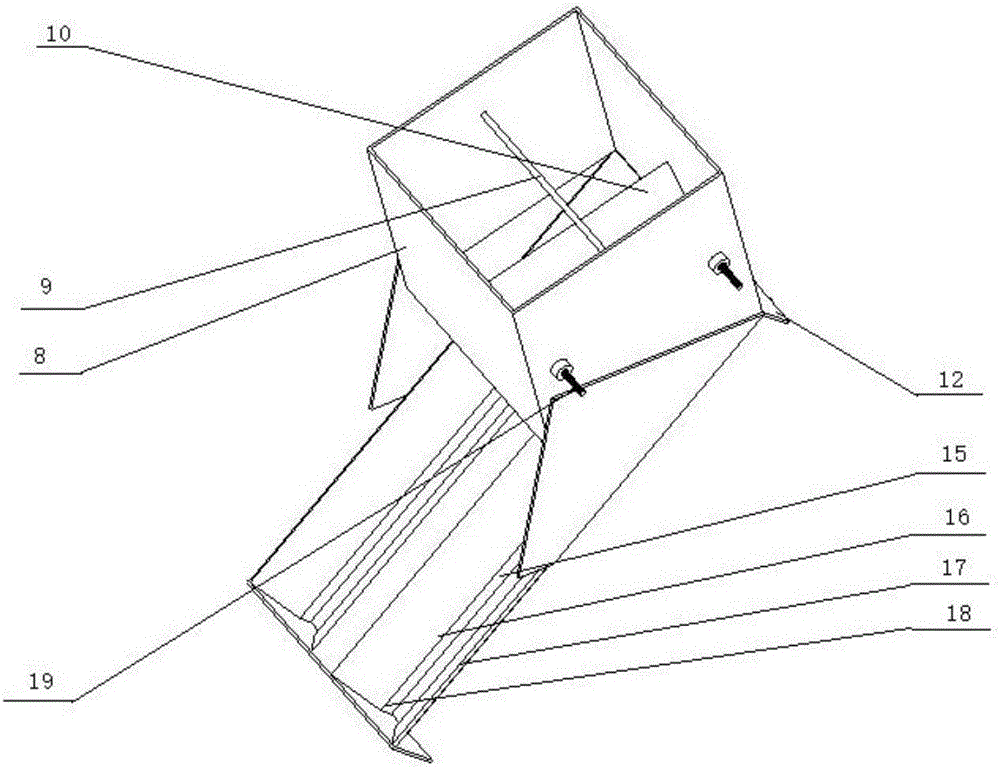

The invention provides a long grained seed steering precision seeding device comprising a plug conveyer belt, a directional seed delivering device, a directional seed dividing mechanism and an air-aspiration seeding mechanism, wherein the directional seed delivering device and the direction seed dividing mechanism are connected and are arranged at the same side of the plug conveyer belt; the air-aspiration seeding mechanism is arranged above the plug conveyer belt; a seed delivering slide way is arranged in the tangential direction of the edge of the directional seed delivering device; the seed delivering slide way and the directional seed dividing mechanism are connected; and the plug conveyer belt, the directional seed delivering device, the directional seed dividing mechanism and the air-aspiration seeding mechanism are fixed on a stand. The invention also provides a seeding method for realizing the seeding device; long grained seeds are delivered and absorbed into the hole of a plug respectively by the directional seed delivering device, the directional seed dividing mechanism and the air-aspiration seeding mechanism, thereby realizing precision seeding. The invention can provide seedlings with even germination and uniform cotyledon direction for melon crop full automatic engrafting devices and other equipment and has the advantages of high work productivity, stable work quality and the like.

Owner:SOUTH CHINA AGRI UNIV

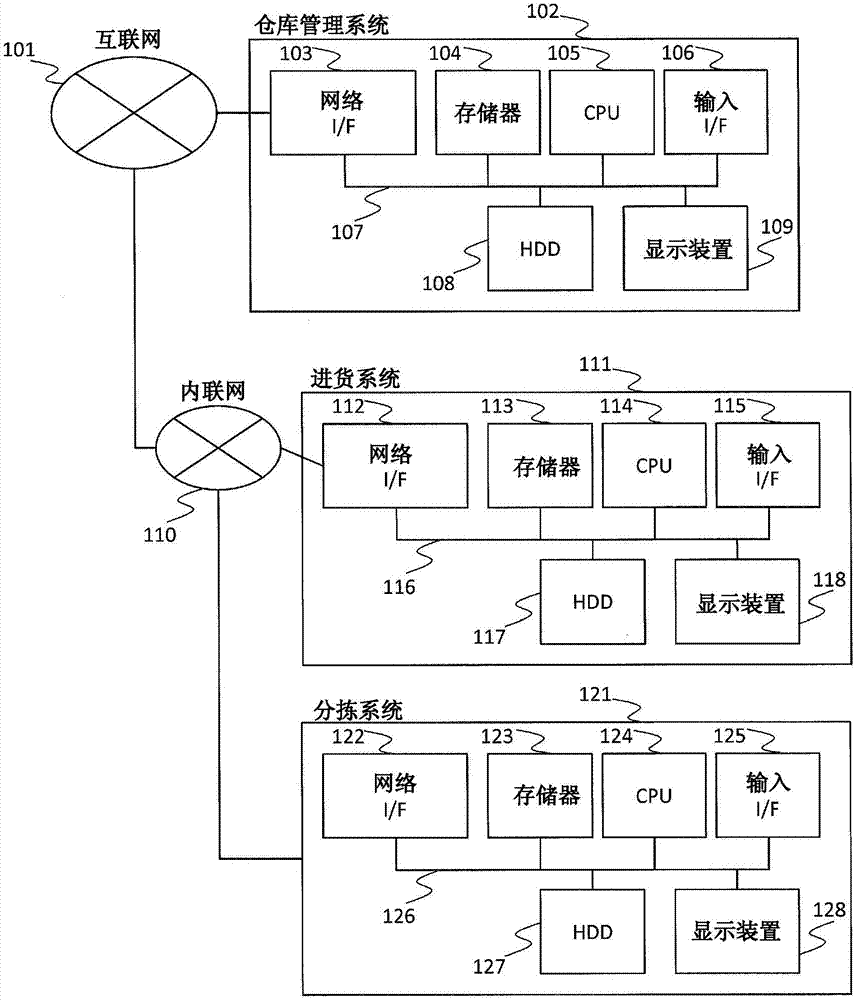

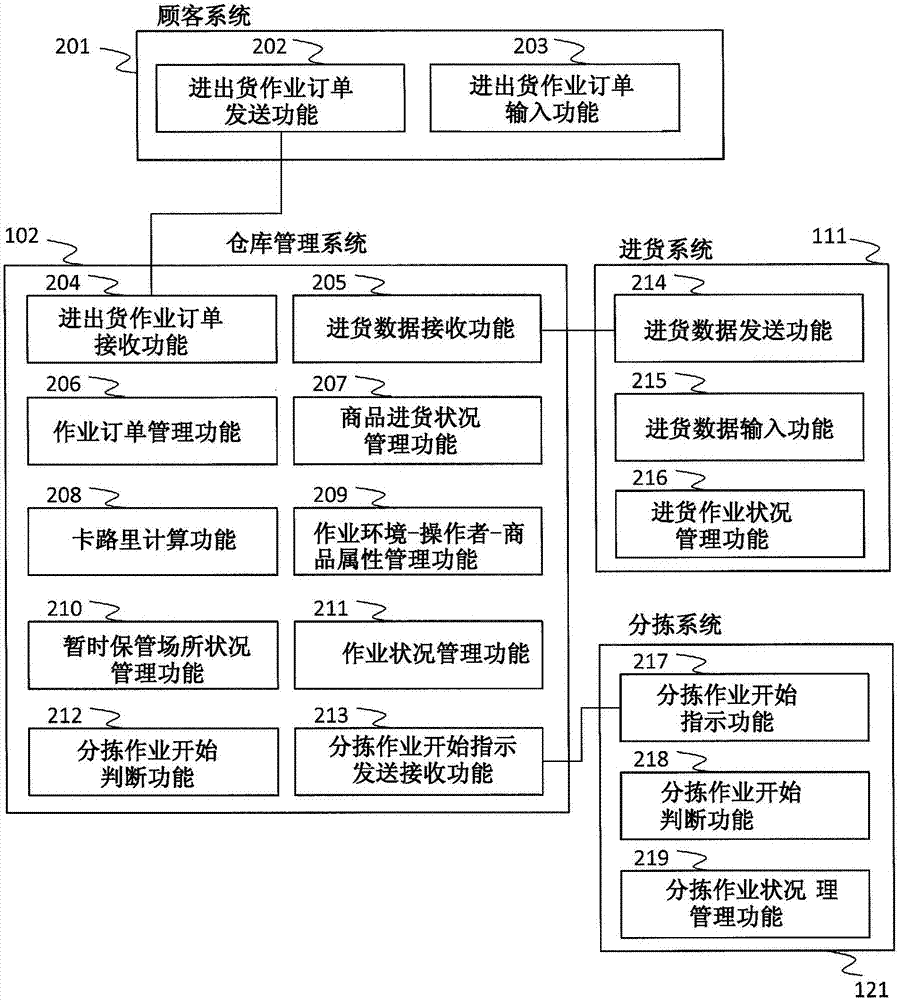

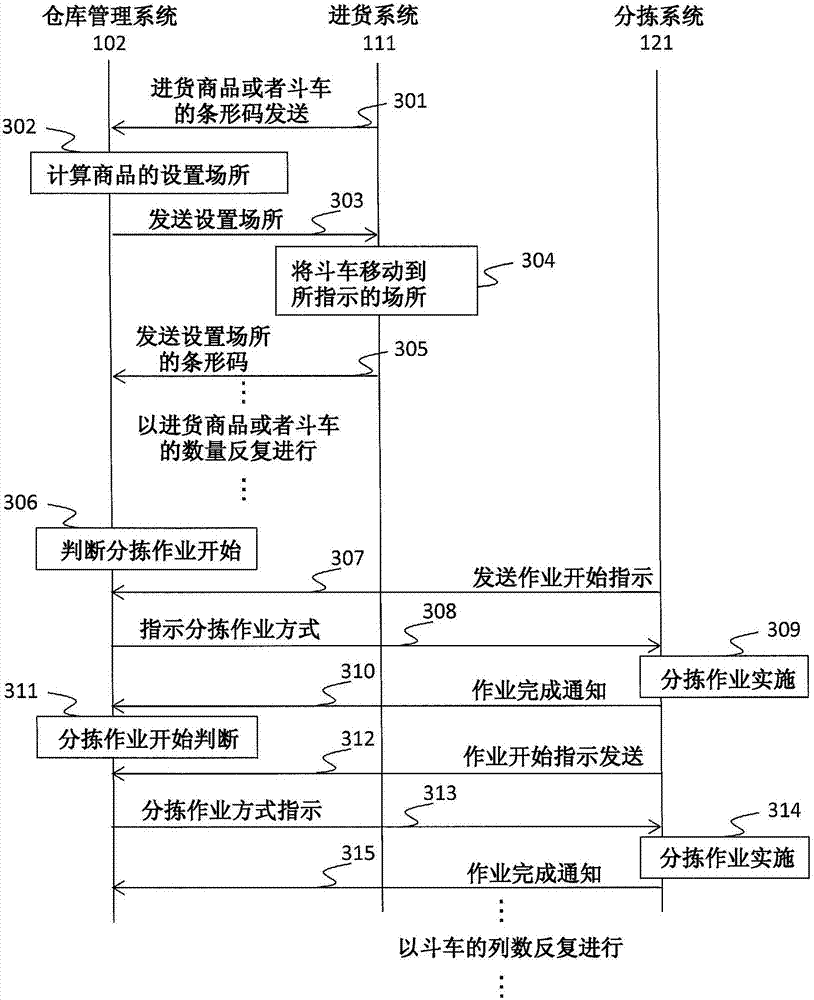

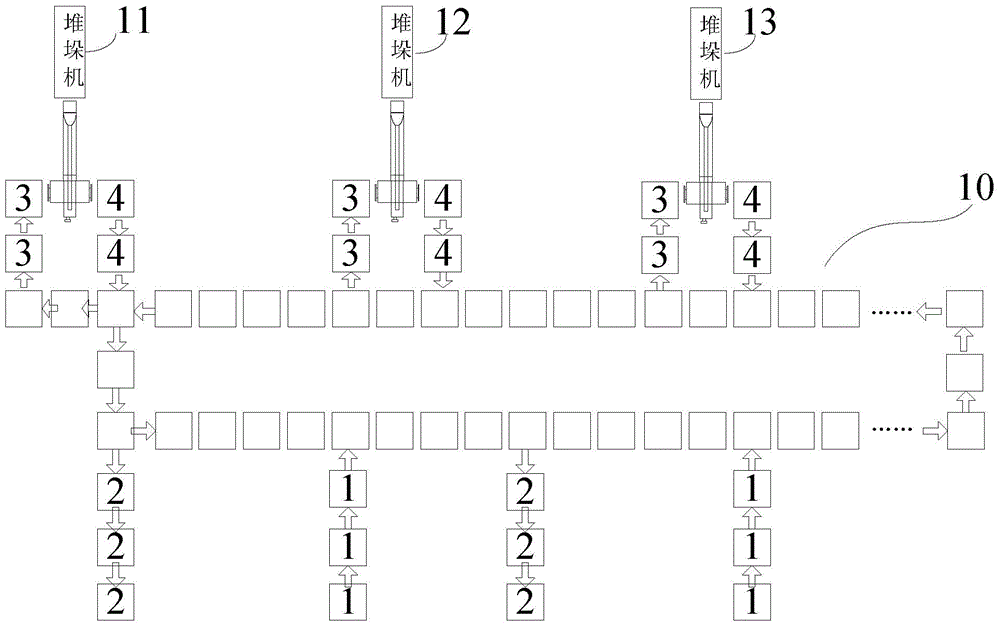

Warehouse management system, warehouse, and warehouse management method

ActiveCN107408285AImprove job productivityForecastingStorage devicesEnergy consumptionManagement system

Owner:罗集帝株式会社

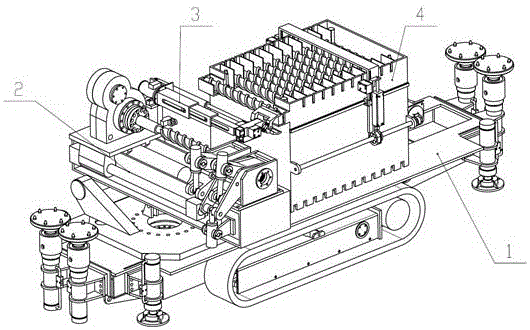

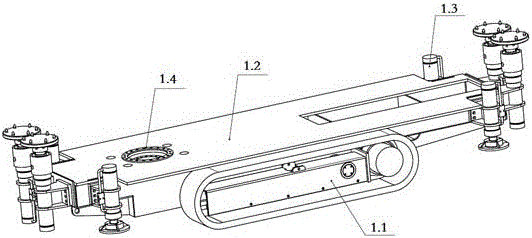

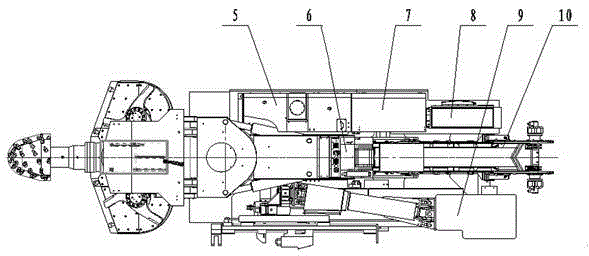

Automatic hydraulic drilling machine for coal mine

ActiveCN106677699AEasy to moveChange the disadvantage of not being able to moveDrilling rodsConstructionsControl systemHydraulic pump

An automatic hydraulic drilling machine for a coal mine comprises a drilling execution device, a manipulator, an automatic drill rod box and a caterpillar band travelling mechanism, wherein the caterpillar band travelling mechanism is used for supporting and moving the drilling execution device, the manipulator and the automatic drill rod box. The manipulating manipulator is controlled by a PLC programmable control system to extract drill rods from the automatic drill rod box and place the drill rods on the drilling execution device, and drilling operation is completed through the drilling execution device. According to the automatic hydraulic drilling machine for the coal mine, power is supplied to the drilling machine by a hydraulic pump and a motor; and through the PLC programmable control system, the automatic drill rod feeding and discharging function of the drill rod box of the drilling machine, the automatic drill rod disassembling function of the drilling execution device and the automatic drill rod grabbing function of the manipulator are achieved, so that labor intensity of workers is effectively lowered, operation and production efficiency is improved, and the personal safety coefficient of the workers is increased.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

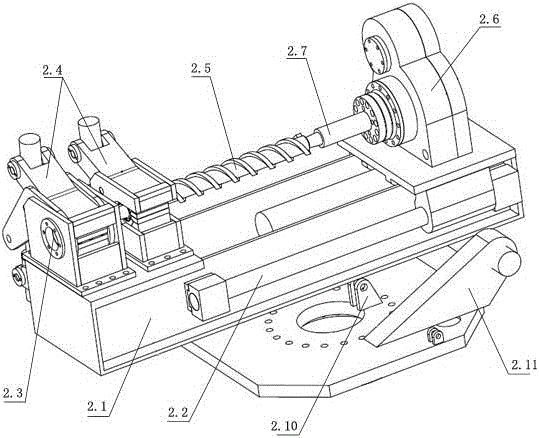

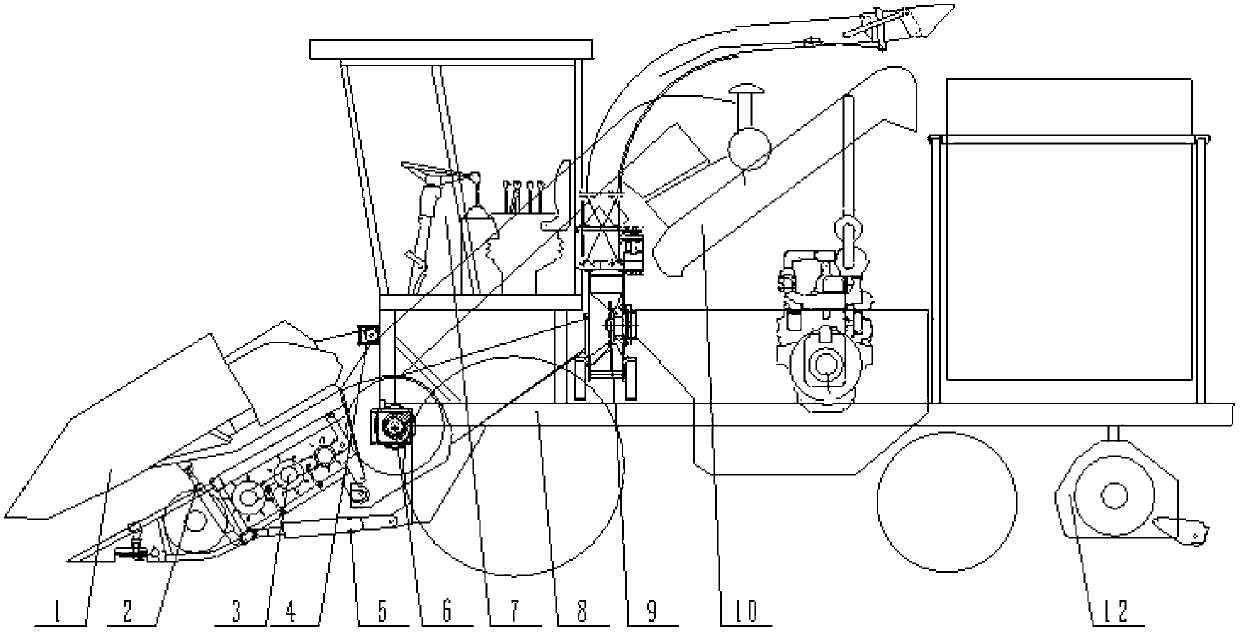

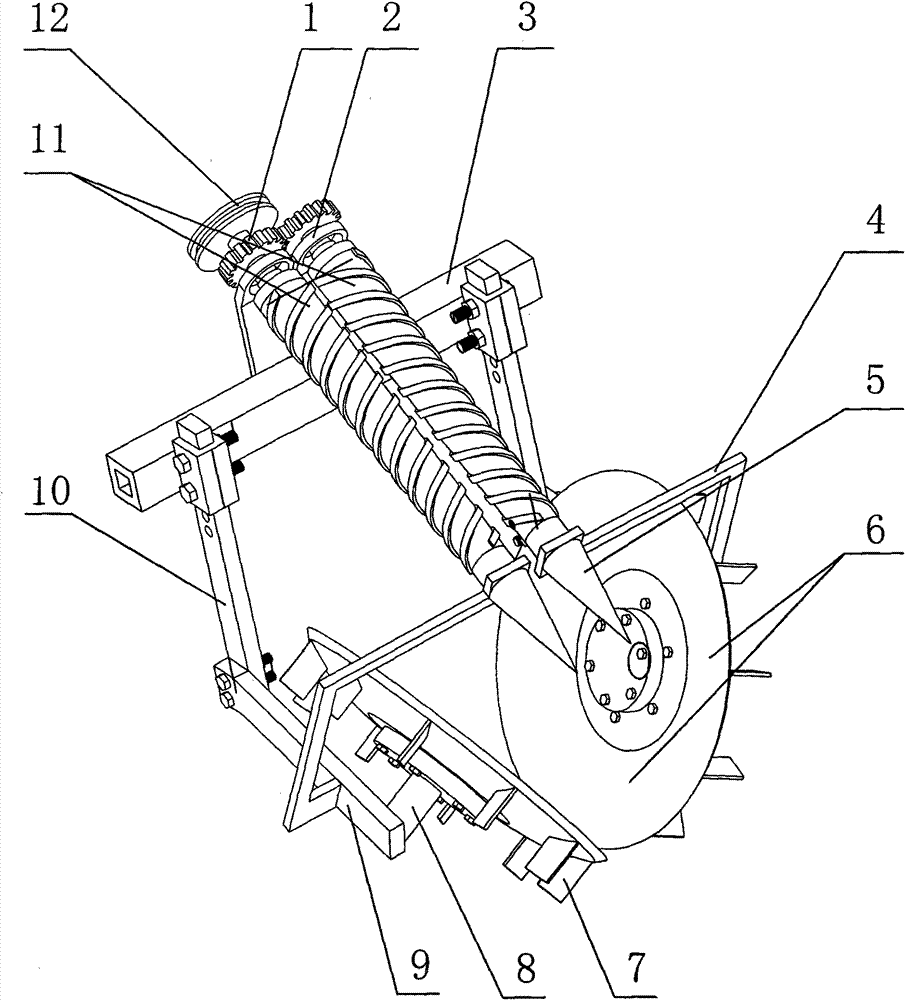

Small and medium size self-propelled corncob-stem both-gaining corn combine harvester

The invention discloses a small and medium size self-propelled corncob-stem both-gaining corn combine harvester which comprises a walking base disc. The walking base disc is provided with an upper layer header, a lower header, a drive cab, a fruit-corncob conveyer, an engine, a grass chamber, a crop chamber, an oil chamber, a dialing wheel assembly, a straw feeding device and a kicker. One end of the upper layer header is connected with an installing base of the upper layer header in a hanging mode. A lower end is connected with the lower layer header through an oil cylinder of the upper layer header. The lower layer header is located below the upper layer header. One end of the upper layer header is connected with an installing base of the lower layer header in a hanging mode. The lower end of the lower layer header is connected with the walking base disc through an oil cylinder of the upper layer header. The installing base of the lower layer header and the installing base of the upper layer header are respectively connected with the walking base disc. The dialing wheel assembly, the straw feeding device and the kicker are connected with the front portion of the walking base disc. The small and medium size self-propelled corncob-stem both-gaining corn combine harvester can be used for completing corn harvest in the field, corn straw cutting, chopping, collecting and stubble cleaning operations in one time. The small and medium size self-propelled corncob-stem both-gaining corn combine harvester can not only harvest corn corncobs and straws, but also avoid resource wasting and environment pollution brought from straw burning.

Owner:SHANDONG AGRI MACHINERY RES INST

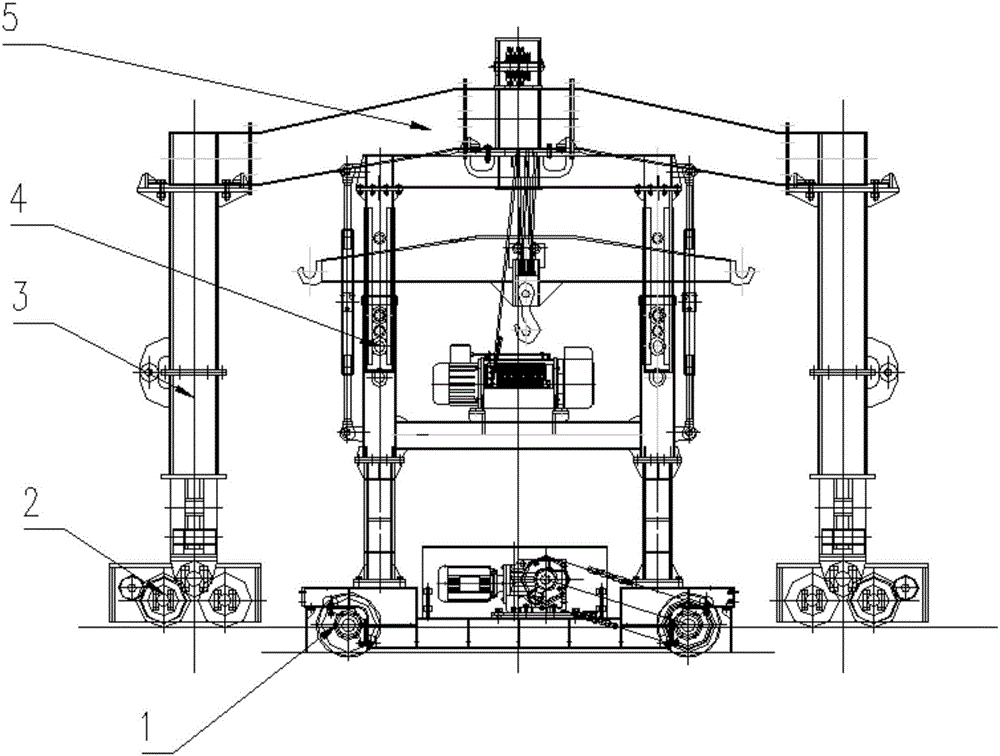

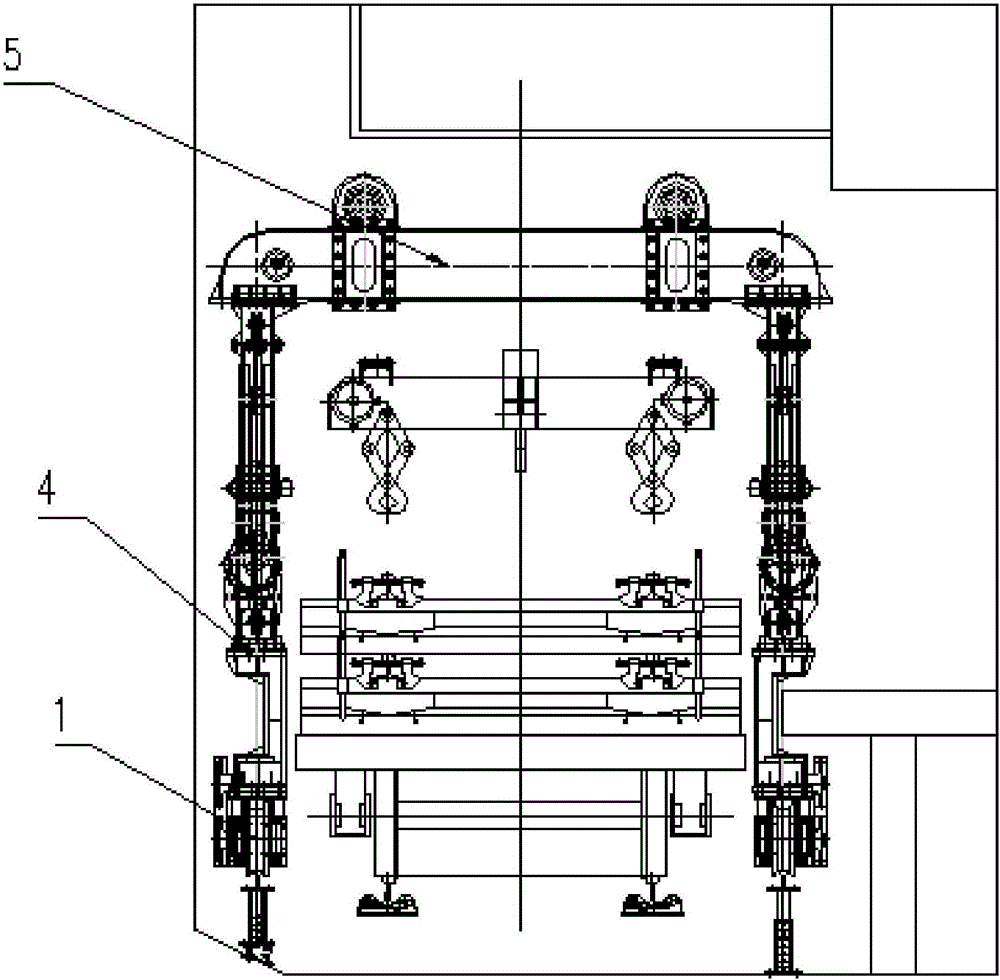

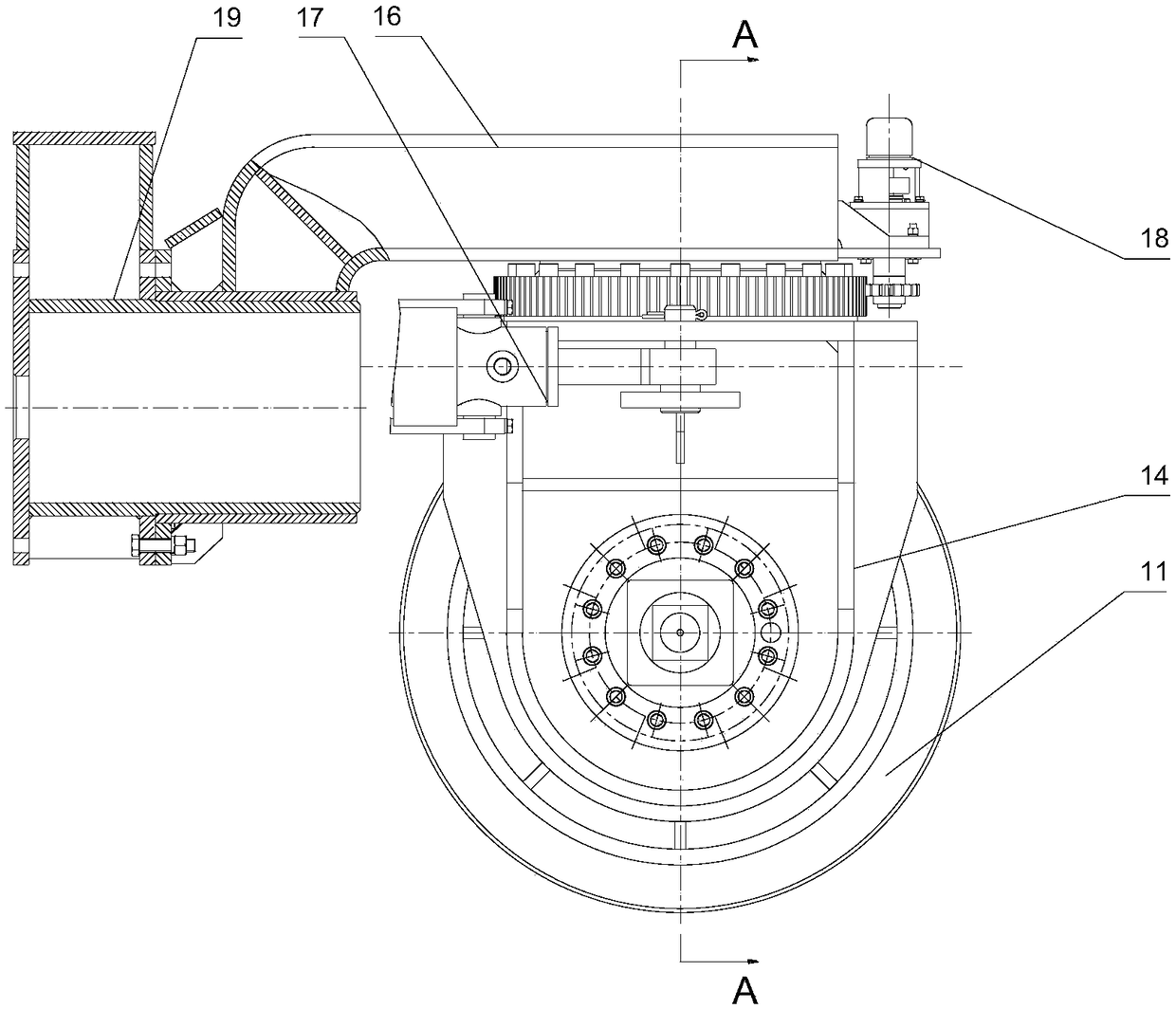

Rail-mounted and wheel-mounted combined type tunnel track-laying crane and construction method thereof

ActiveCN106044576ASolve the problem of not being able to use bothAvoid damageLoad-engaging girdersTrolley cranesDual purposeTunnel construction

The invention relates to a crane and a construction method, belongs to the field of engineering equipment, and especially relates to a rail-mounted and wheel-mounted combined type tunnel track-laying crane and a construction method thereof. The crane provided by the invention comprises a rail-mounted wheel set and a wheel-mounted wheel set, wherein the top of the rail-mounted wheel set is movably provided with a connecting beam; and both ends of the connecting beam are provided with support-angle-adjustable wheel-mounted wheel set. Therefore, the invention has the following advantages: the design structure is simple; by the double walking modes of rail walking and wheel walking, the problem that different cross-sections of tunnel construction cannot be dual-purpose can be solved; and different walking modes can be rapidly switched, thus improving production efficiency and reducing damage to duct pieces.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

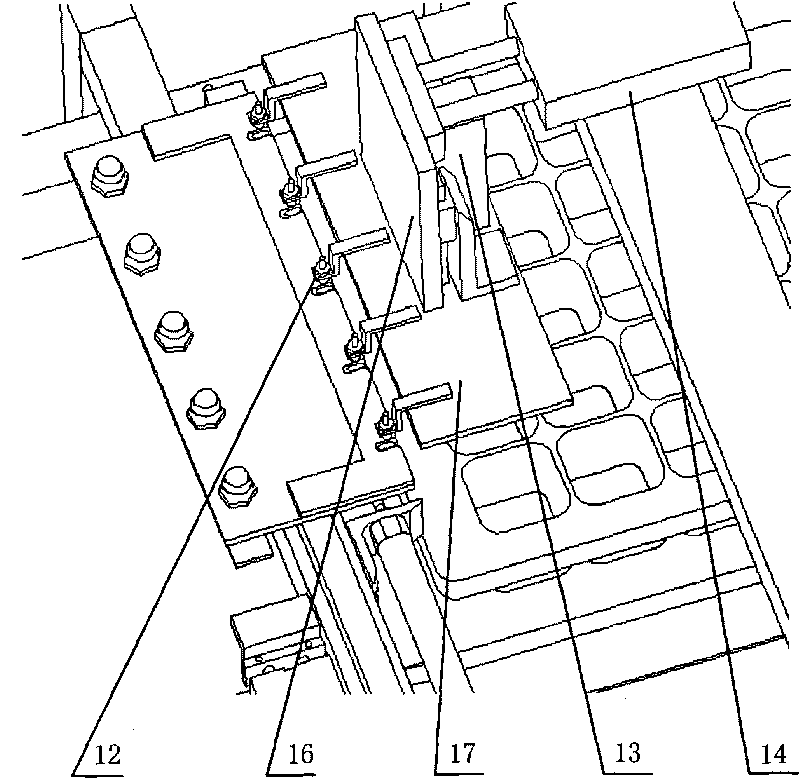

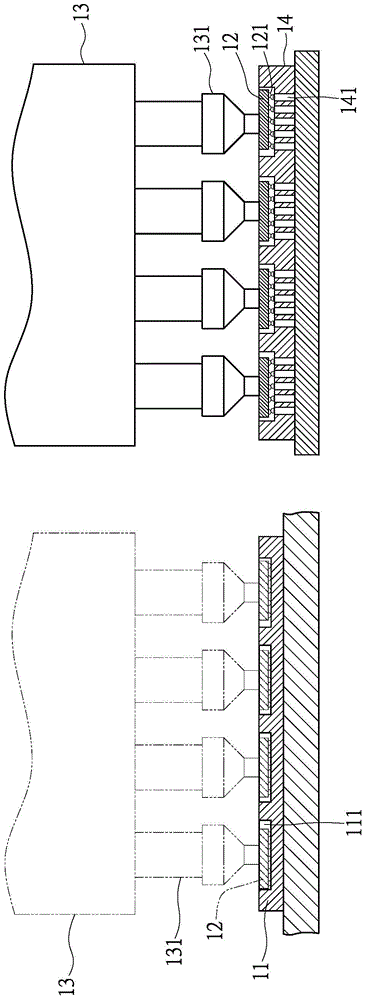

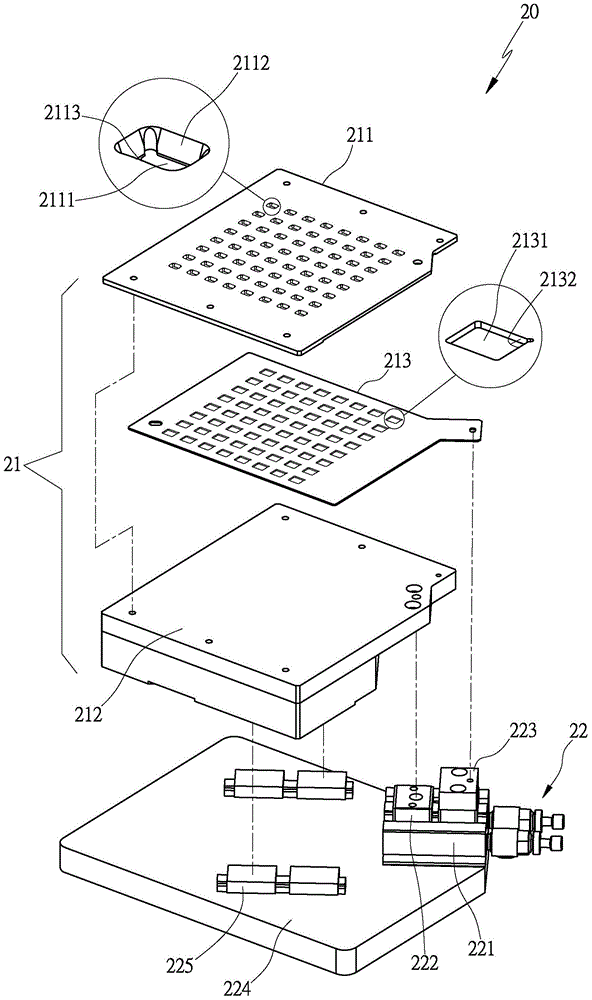

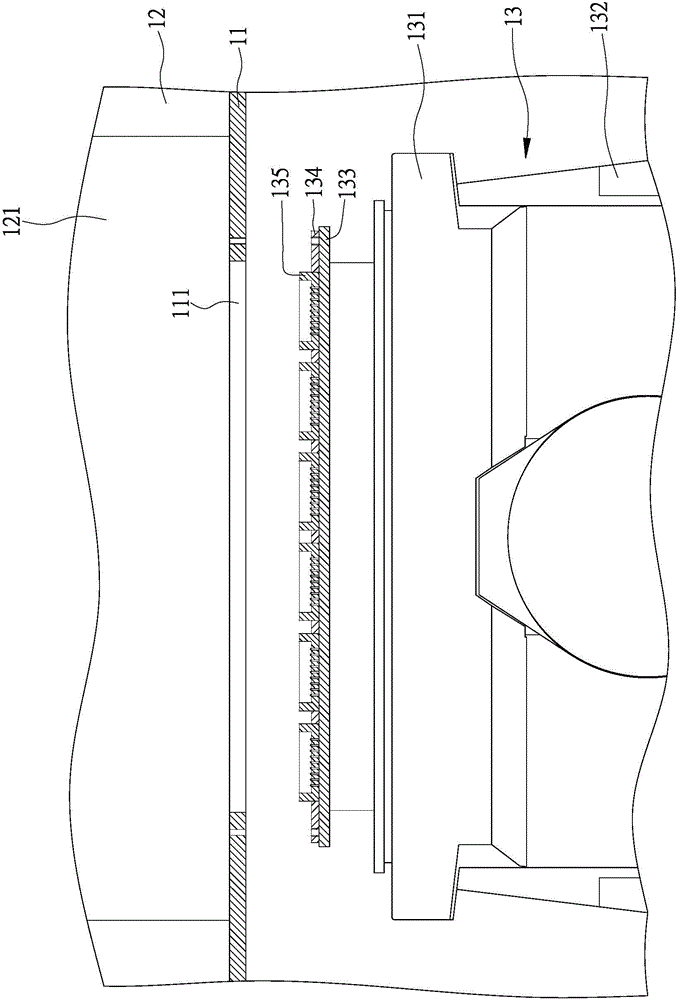

Fingerprint identification electronic element operation apparatus and test classification device utilizing same

ActiveCN106269581AShorten working timeIncrease production capacitySortingEngineeringElectronic component

The invention provides a fingerprint identification electronic element operation apparatus and a test classification device utilizing same. The fingerprint identification electronic element operation apparatus comprises a test mechanism and a multi-section press moving mechanism, wherein the test mechanism is provided with a test circuit board with at least one test seat, the test circuit board is used for testing a fingerprint identification electronic element with a sensing portion and an electric connector, the multi-section press moving mechanism is provided with a press fetcher moving in at least one direction, the press fetcher adsorbs a non-sensing portion of the fingerprint identification electronic element to be operated and moves the fingerprint identification electronic element to be operated into the test seat to perform the non-sensing fingerprint state test program, a press measuring part which can move is arranged inside the press fetcher, the press measuring part presses against the sensing portion of the fingerprint identification electronic element, so that the fingerprint identification electronic element simulates and executes a sensed fingerprint state test program; and after the test operation is completed, the press measuring part of the press moving mechanism is separated from the sensing portion of the fingerprint identification electronic element, and the operated fingerprint identification electronic element is moved out of the test seat by virtue of the press fetcher.

Owner:HON PRECISION INC

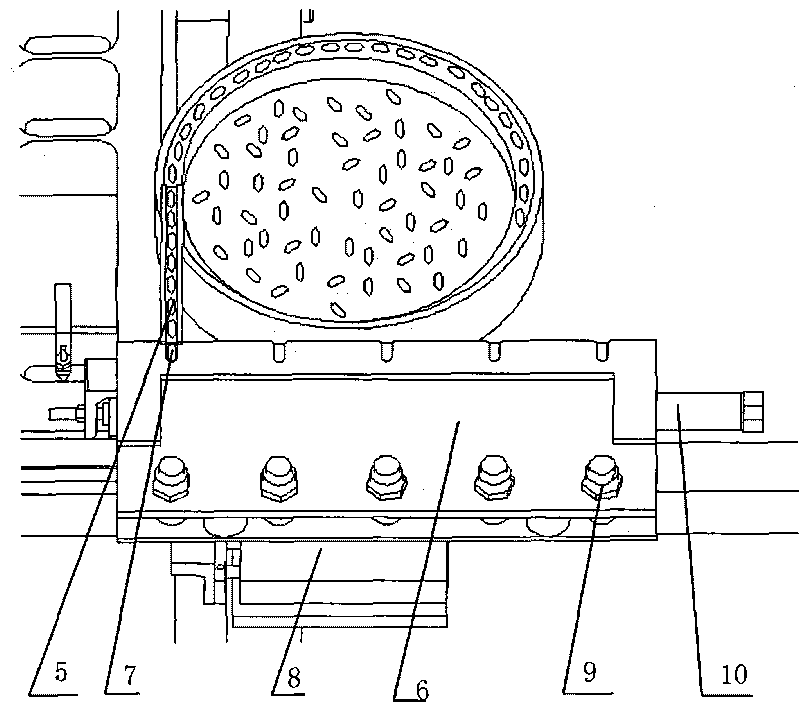

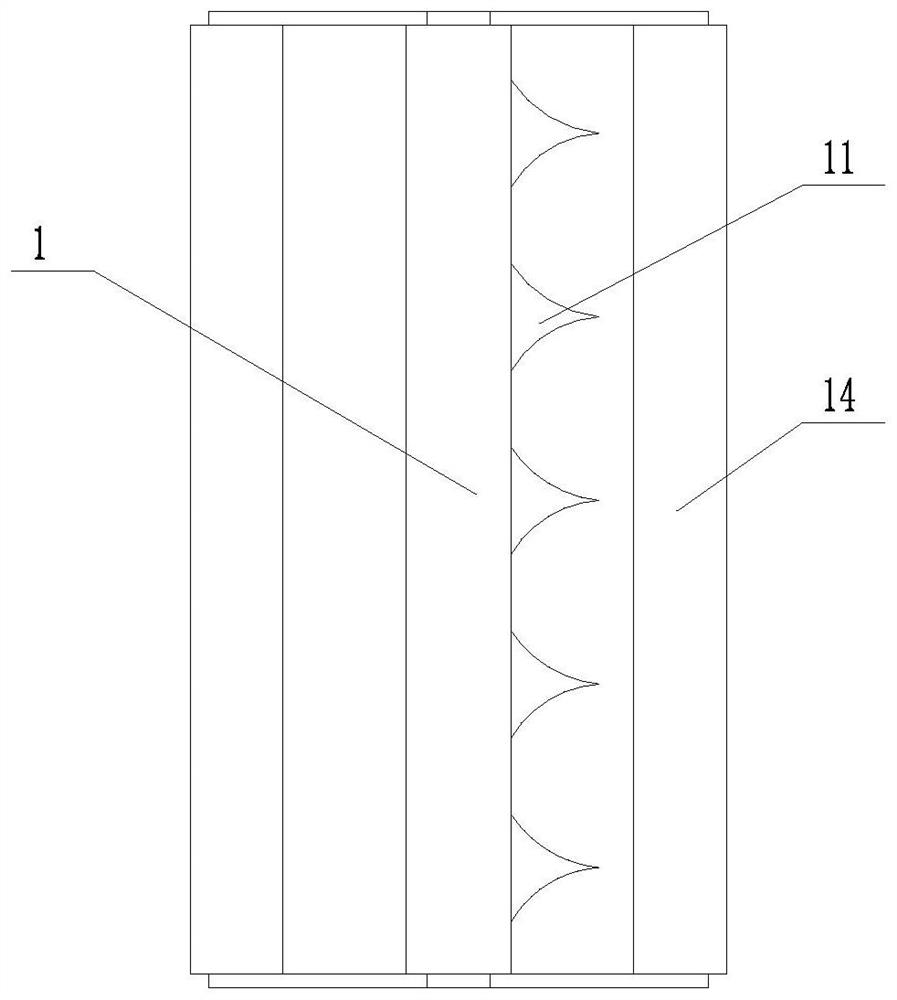

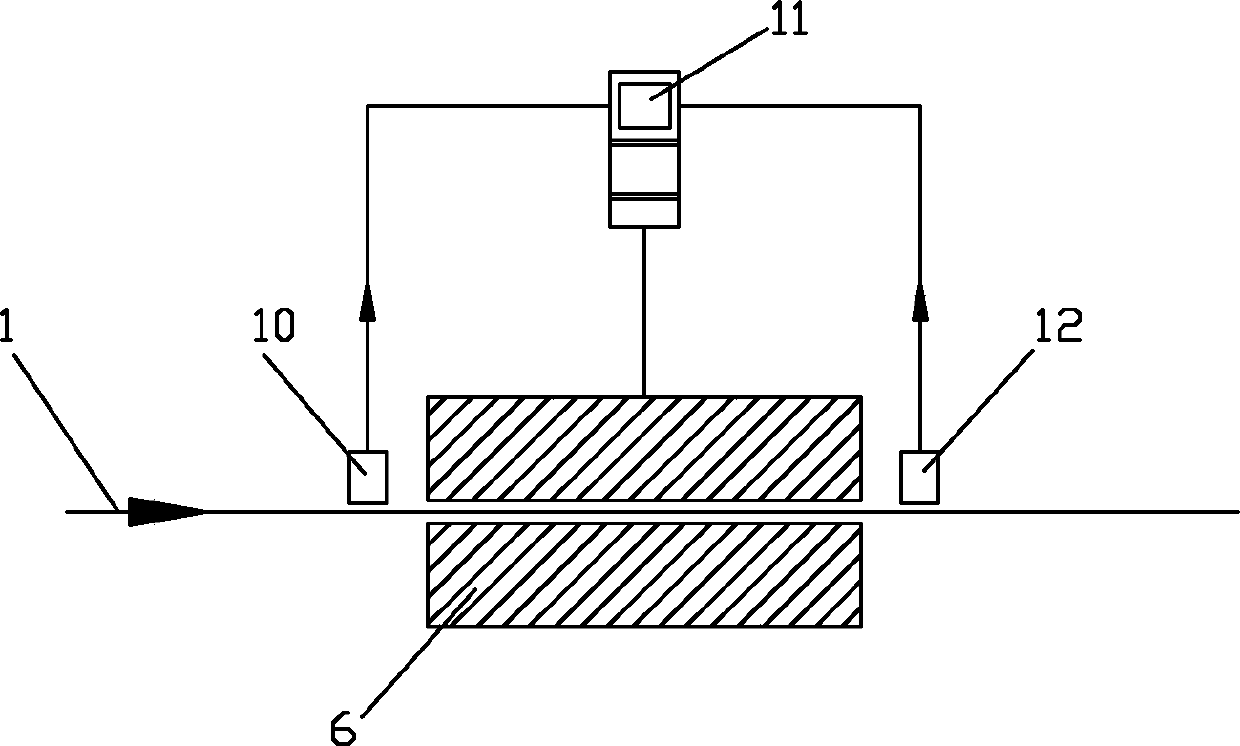

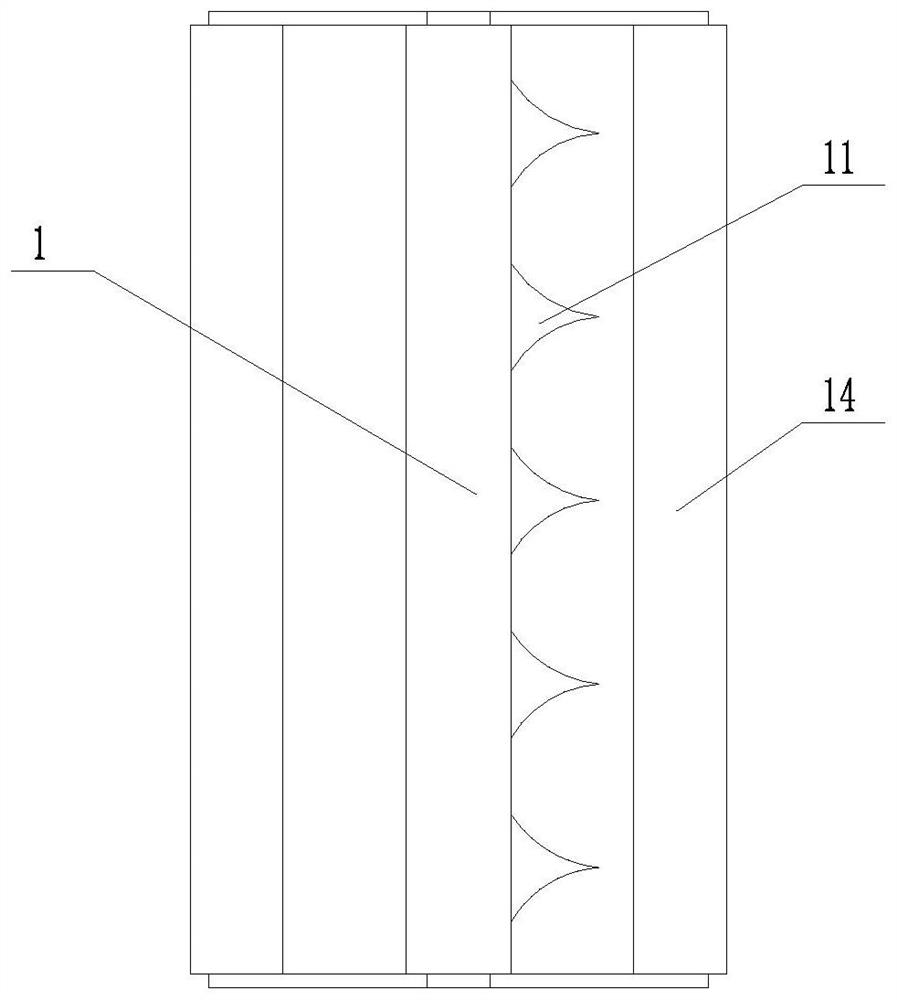

Batch type rice hole sowing seeding apparatus

InactiveCN100998280ARealize orderly and precise live broadcast operationQuality improvementSeed depositing seeder partsRegular seed deposition machinesDetentEngineering

An intermittent sower for the punch planting of paddy rice with precise row spacing and spacing in rows is composed of supporting frame, at least one seed hopper with discharging holes on its bottom, a rotary sowing disc under said bottom and with sowing holes arranged on a circumference, a ratchet wheel on the axle of sowing disc, a detent on a slide linking plate and matched with said ratchet wheel, a motor to drive said linking plate via linking axle and crank, etc.

Owner:ZHANGJIAGANG AGRI TECHN POPULARIZATION STATION

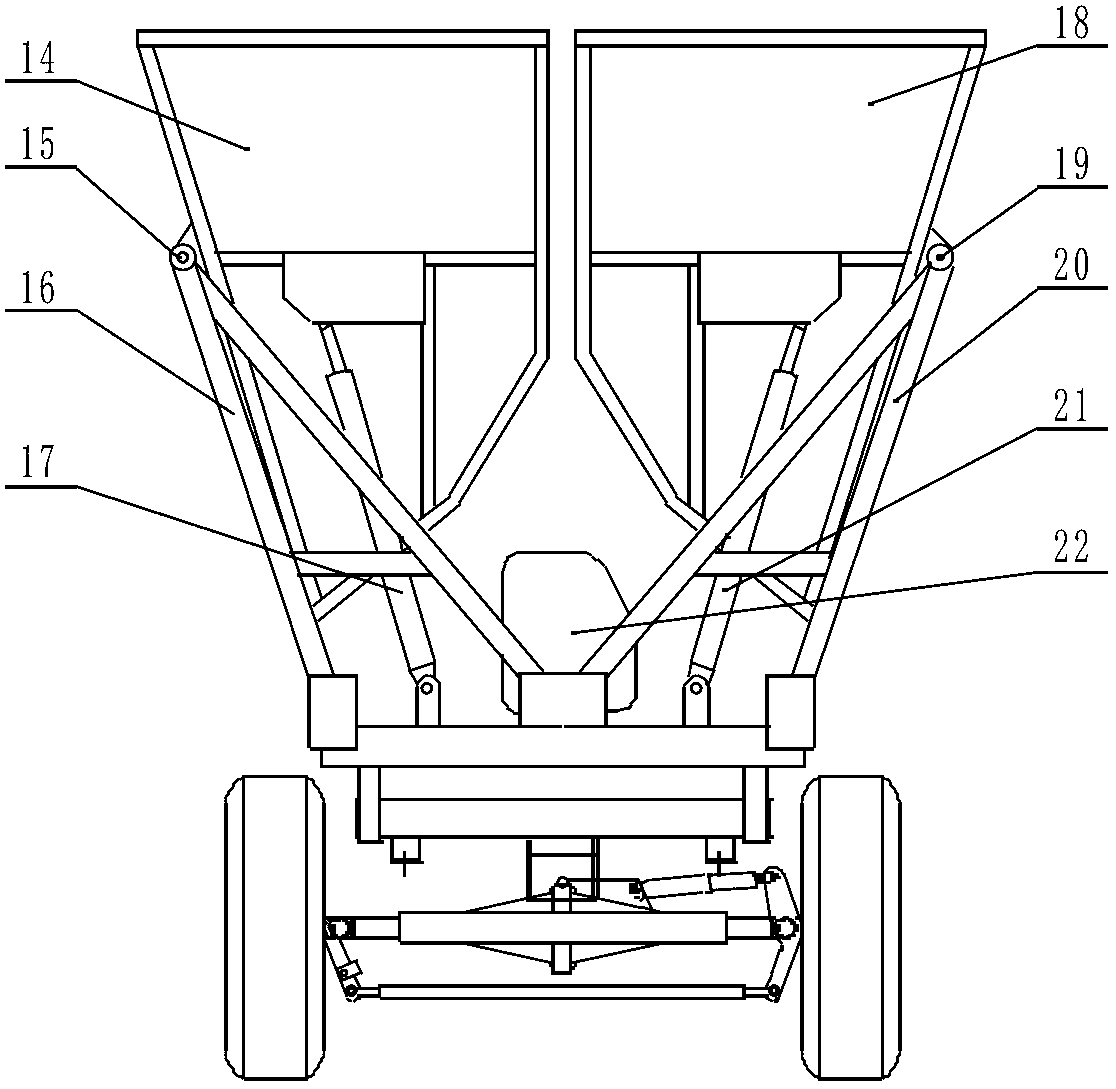

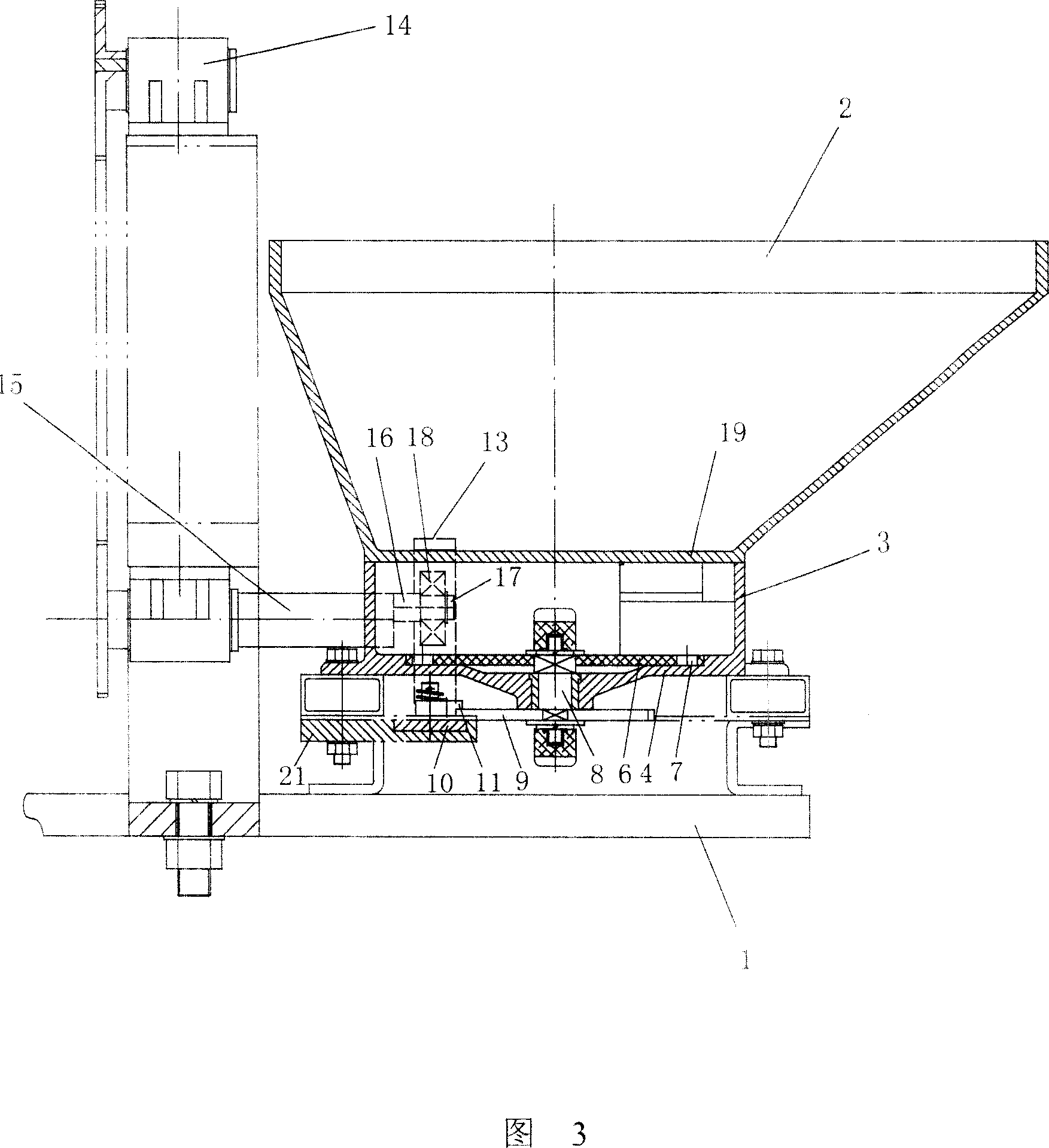

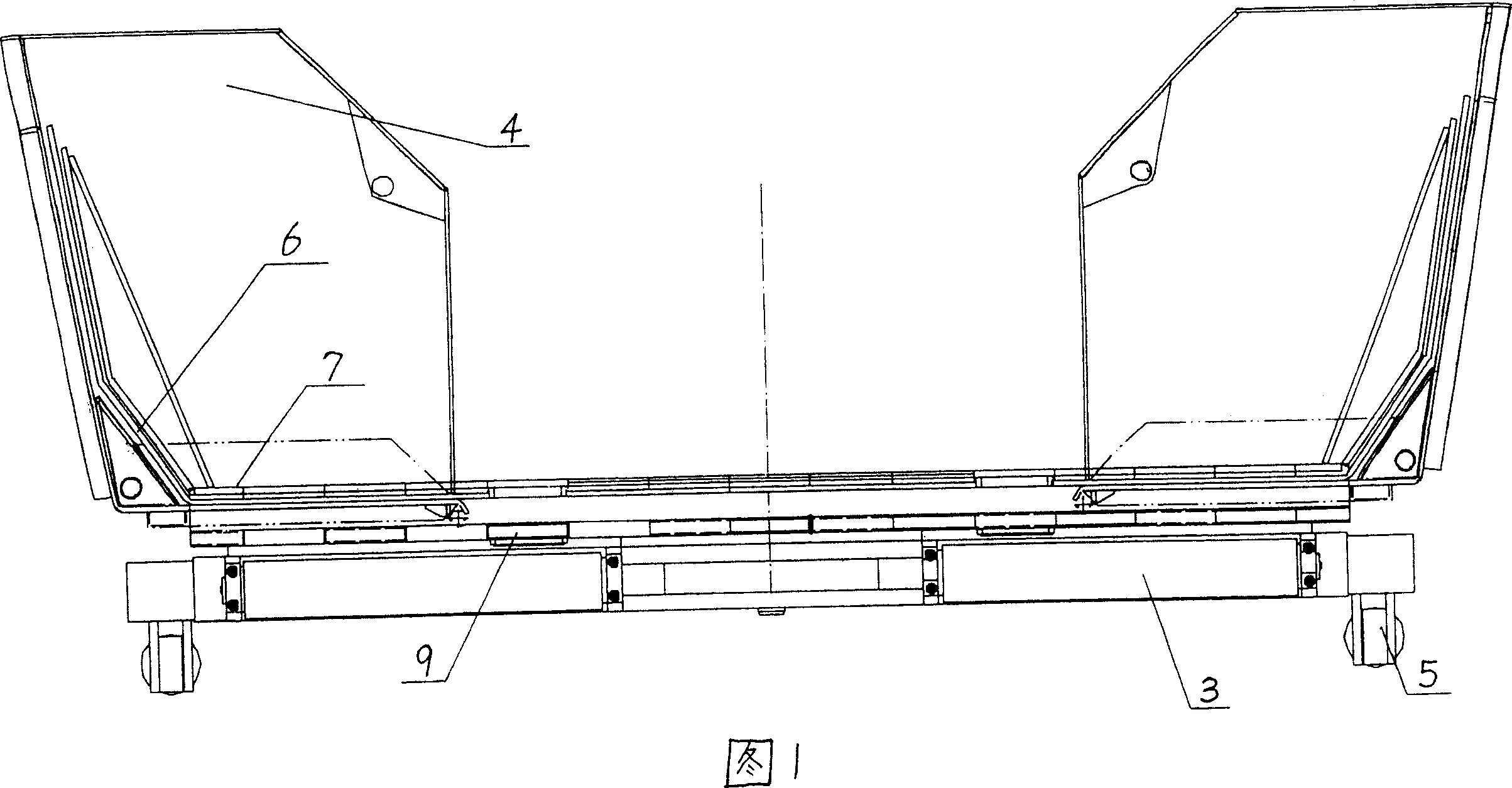

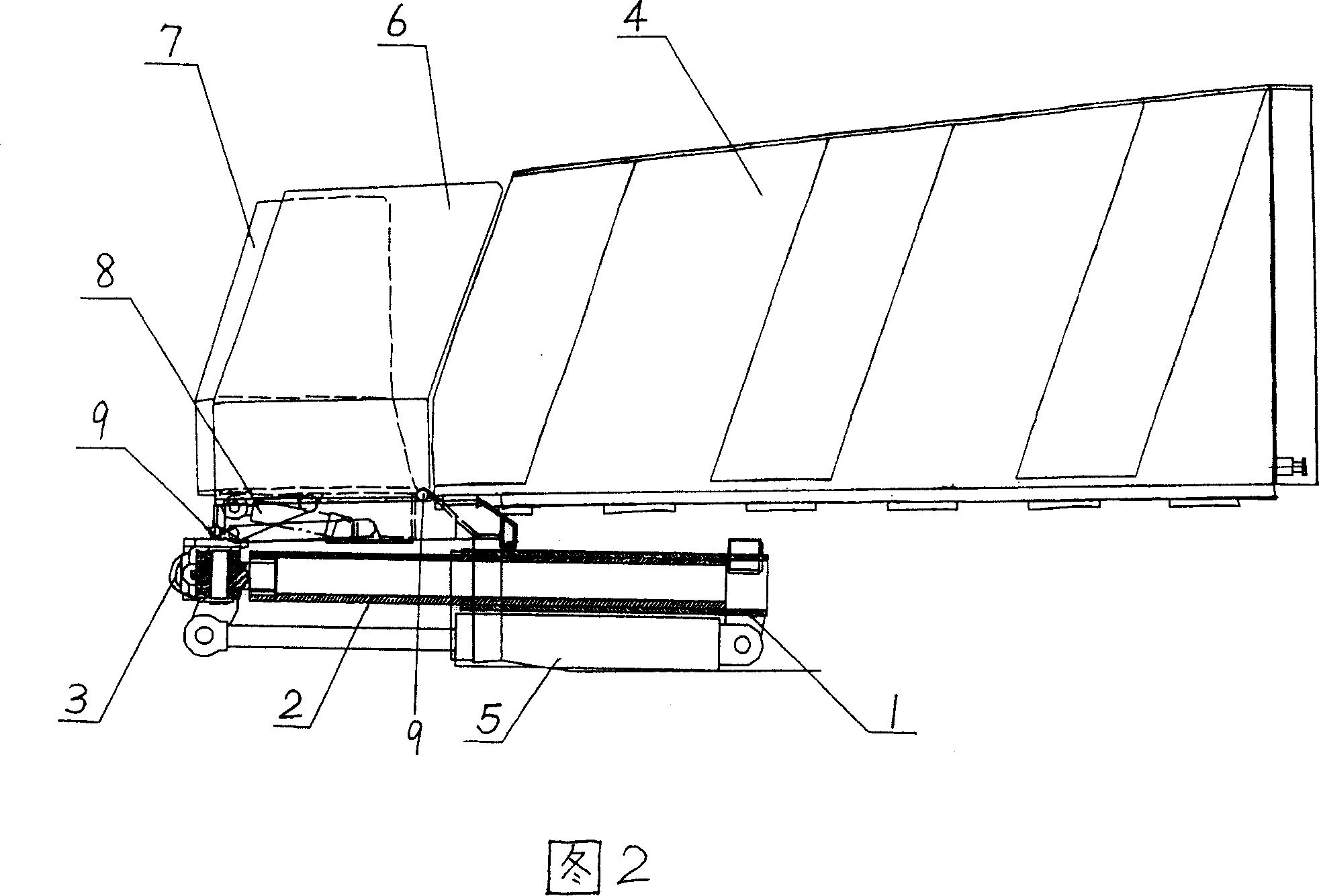

Flex overturning type auxiliary movable hopper for spreading machine

This invention discloses one spreader contract tilting assistant active bunker, which comprises guide channel set on both sides of spreader with one end of slide axis into guide channel and with other end connected to pull assemble fixed with fix bunker and tilt bunker, wherein, the contract cylinder one end is hinged on guide channel and other end hinged onto pull assembly; the active bunker contracts front and back under contract cylinder; the tilt cylinder one end is hinged onto fix bunker and other end connected with tilt with tilt cylinder fixed on middle or both sides of active bunker to realize tilt under tilt cylinder.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

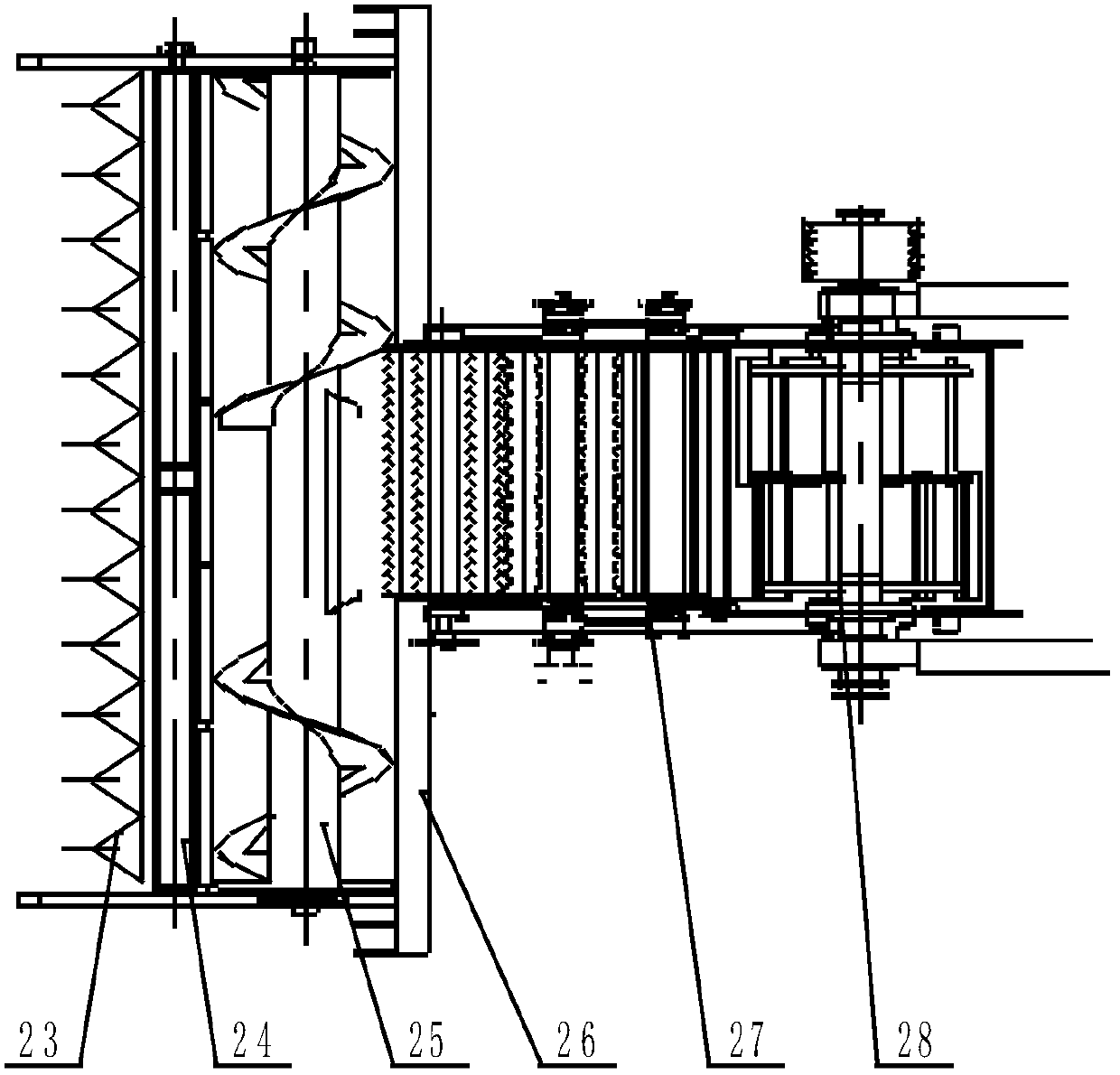

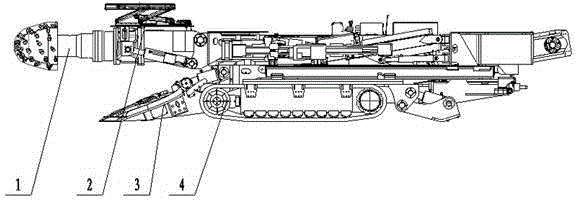

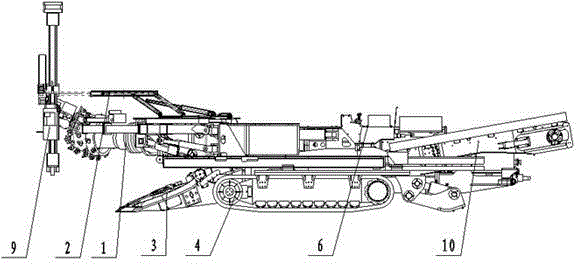

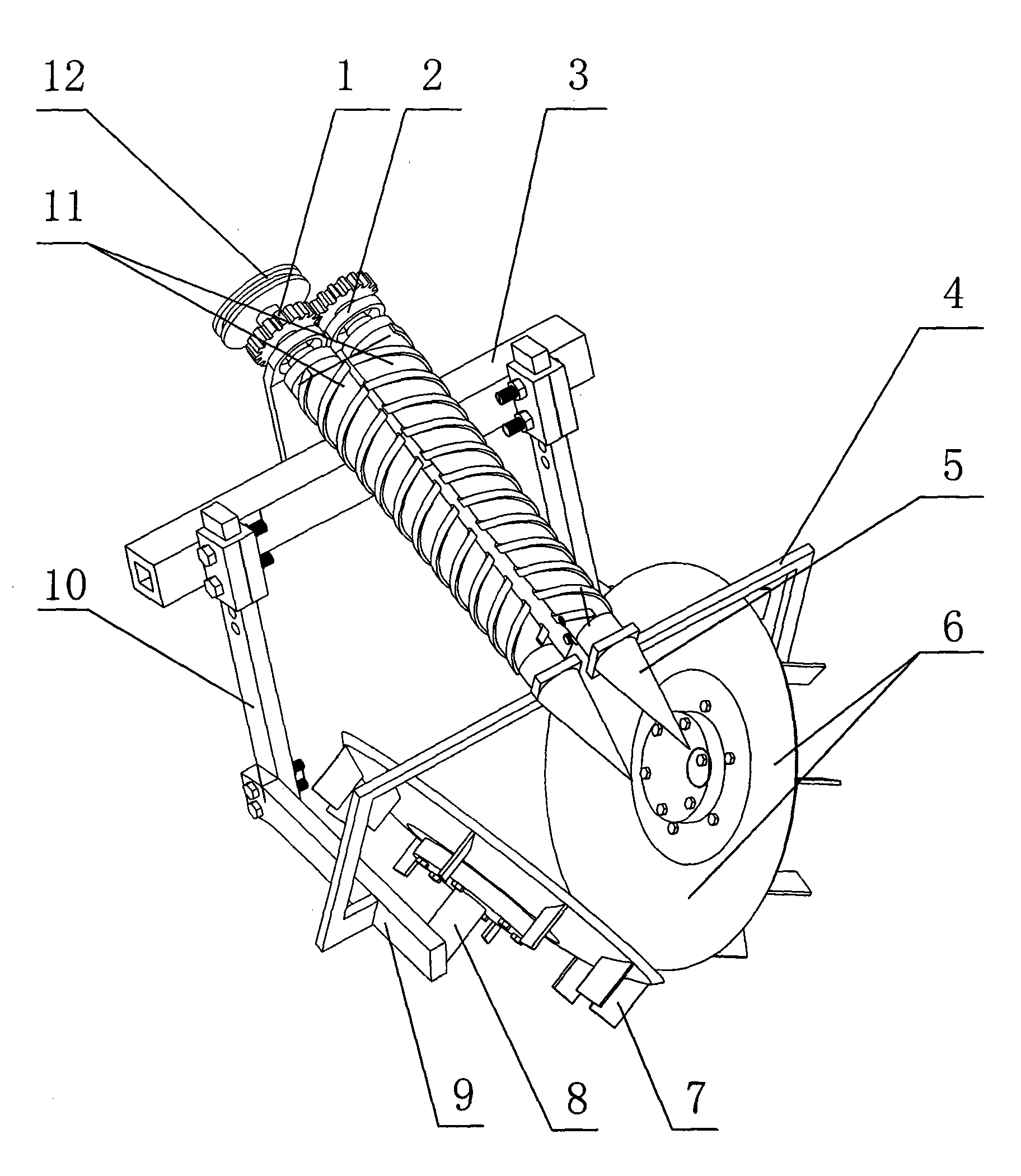

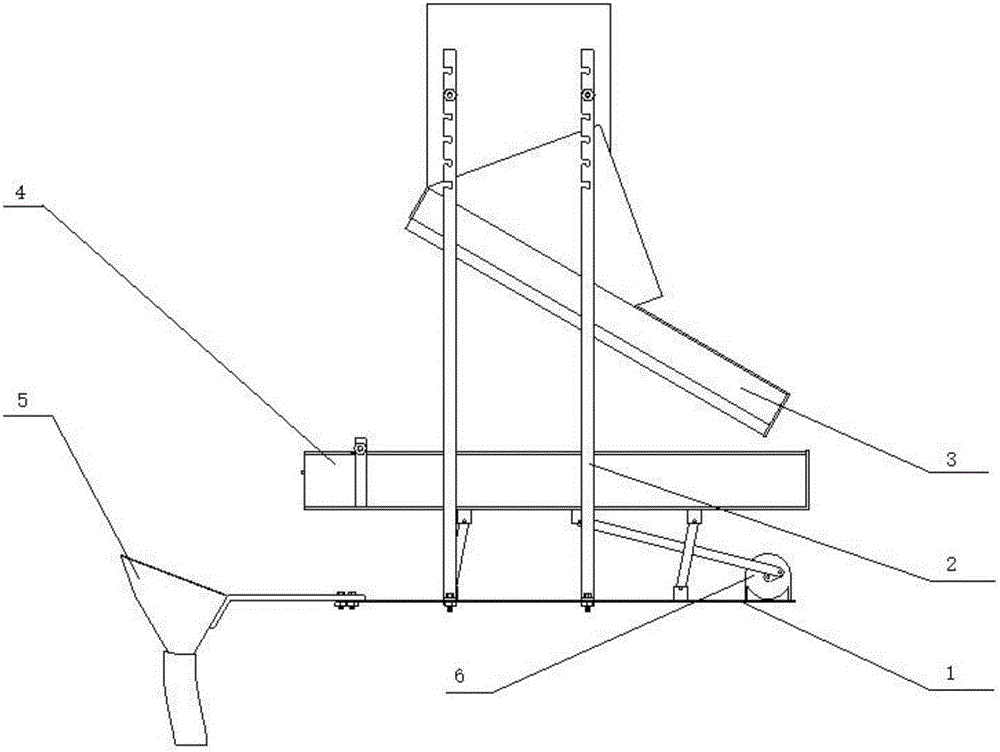

Digging, anchoring and drilling integrated hard rock tunneling machine

InactiveCN104564096ADoes not affect heightSave spaceTunnelsAnchoring boltsEngineeringElectric control

The invention belongs to the technical field of a tunneling machine, and particularly relates to a digging, anchoring and drilling integrated hard rock tunneling machine, which solves the problems of the existing digging and anchoring integrated machine. The digging anchoring and drilling integrated hard rock tunneling machine comprises a clipping part, a loading part, a drilling machine system, an operating platform, a caterpillar track, a pump station oil tank, a hydraulic control box, an electric control box, an operating platform and a transport machine, wherein a drilling machine supporting frame is arranged above the caterpillar track on the left side of the entire machine, a slide guide rail which can move back and forth relative to the drilling machine supporting frame is arranged on the drilling machine supporting frame, and the slide guide rail is provided with the drilling machine system which can move back and forth relative to the slide guide rail; the integrated pump station oil tank is arranged in front the right side of the entire machine, the hydraulic control box is arranged on the right middle part of the entire machine, and the electric control box is arranged on the right rear part of the entire machine; the operating platform is arranged in the middle part of the entire machine and on the front part of the transport machine between the hydraulic control box and the drilling machine system. By adopting the digging, anchoring and drilling integrated hard rock tunneling machine, the drilling machine is finally and actually integrated into the entire machine, the height of the machine body is consistent with that of the original machine body, the influence of the drilling machine for the height of the entire machine is minimized, and the overall height of the entire machine is not affected.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

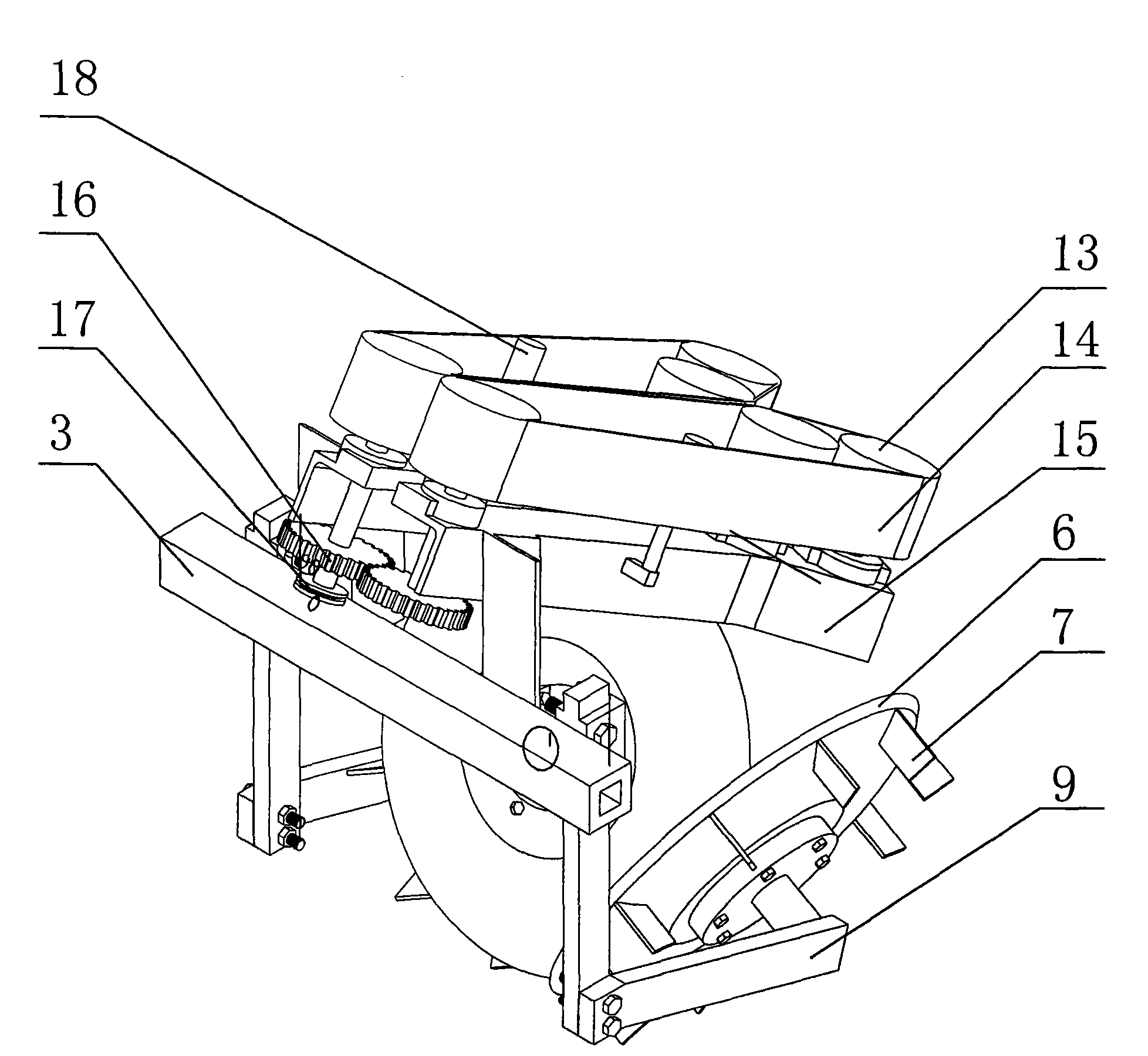

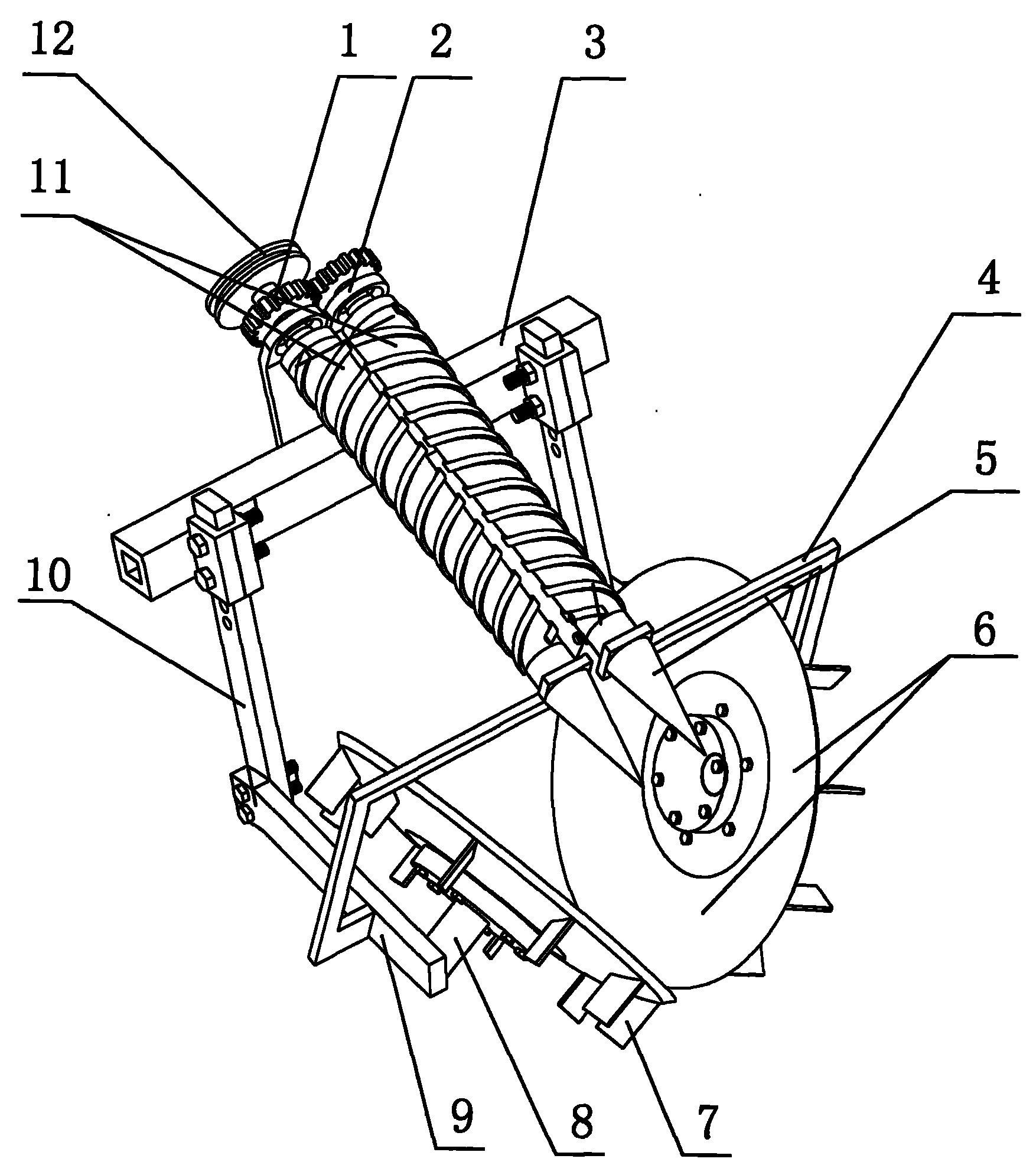

Round disc type plant straw uprooting device

InactiveCN102027838AReduce disturbanceReduce power consumptionHarvestersGatherer machinesProduction rateAgricultural engineering

Owner:HENAN AGRICULTURAL UNIVERSITY

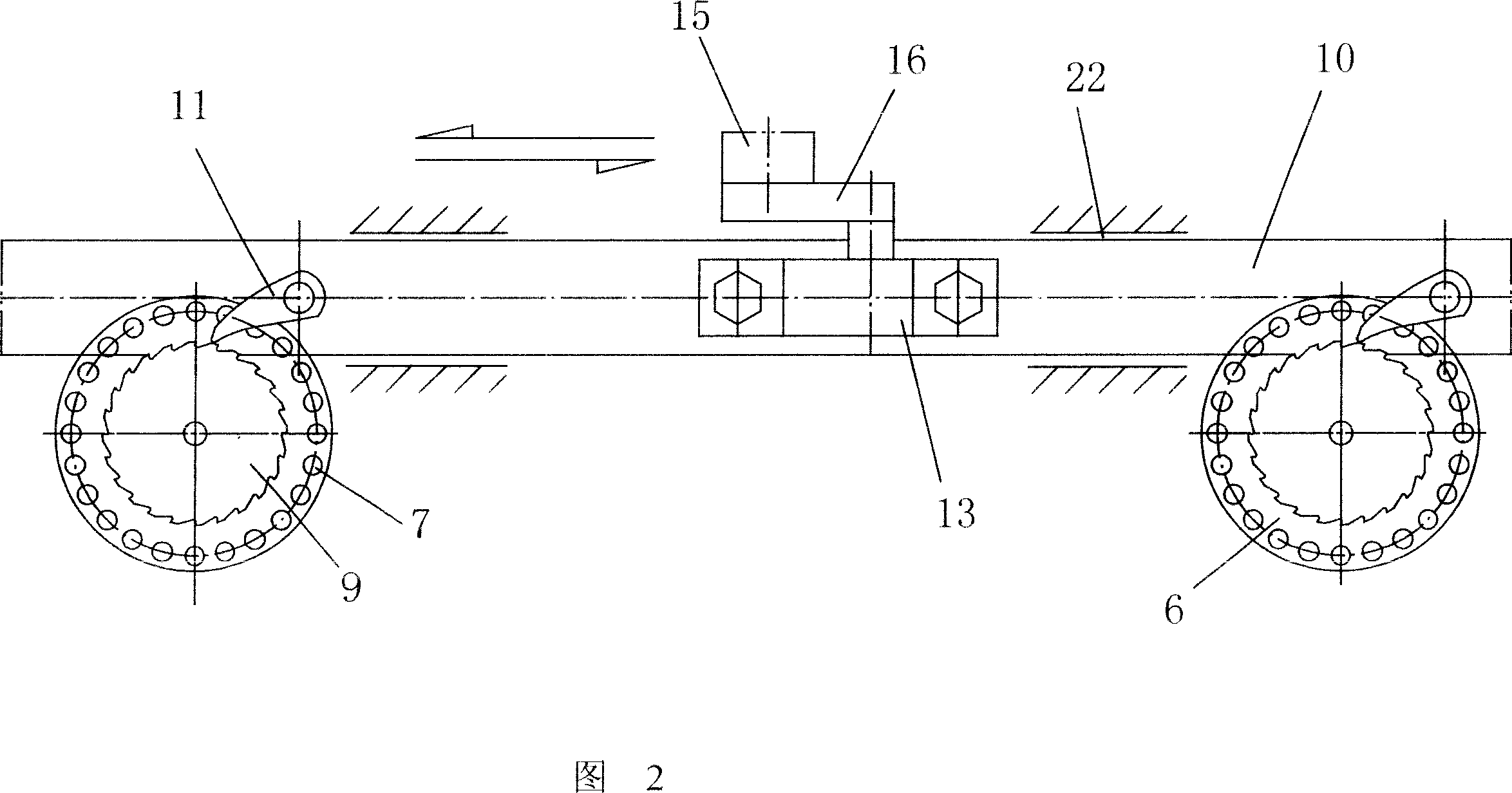

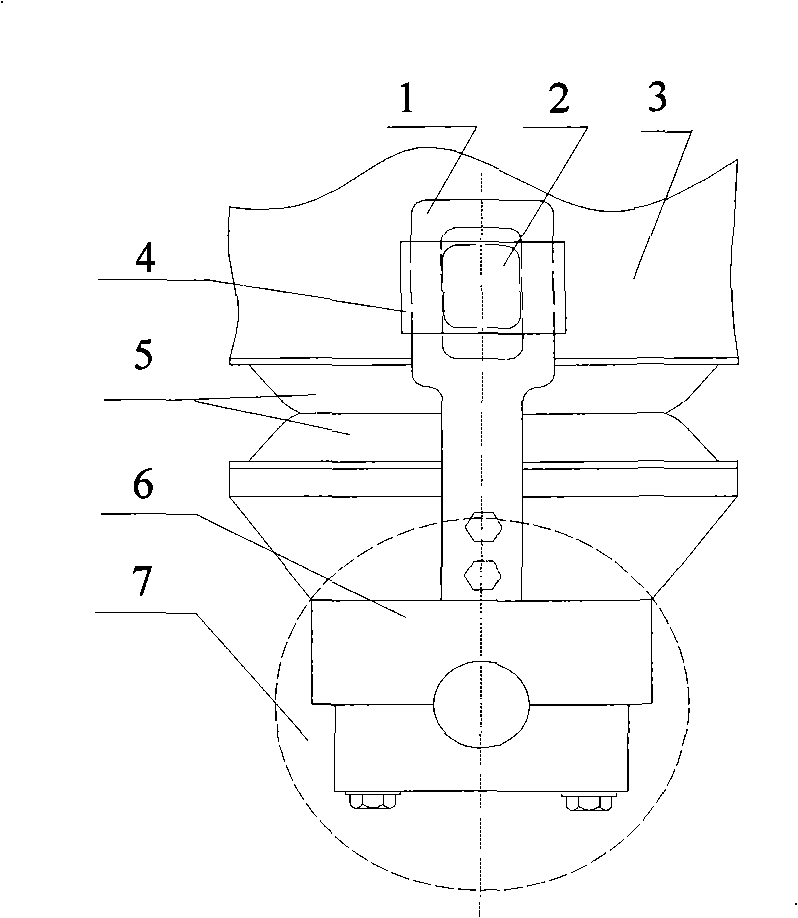

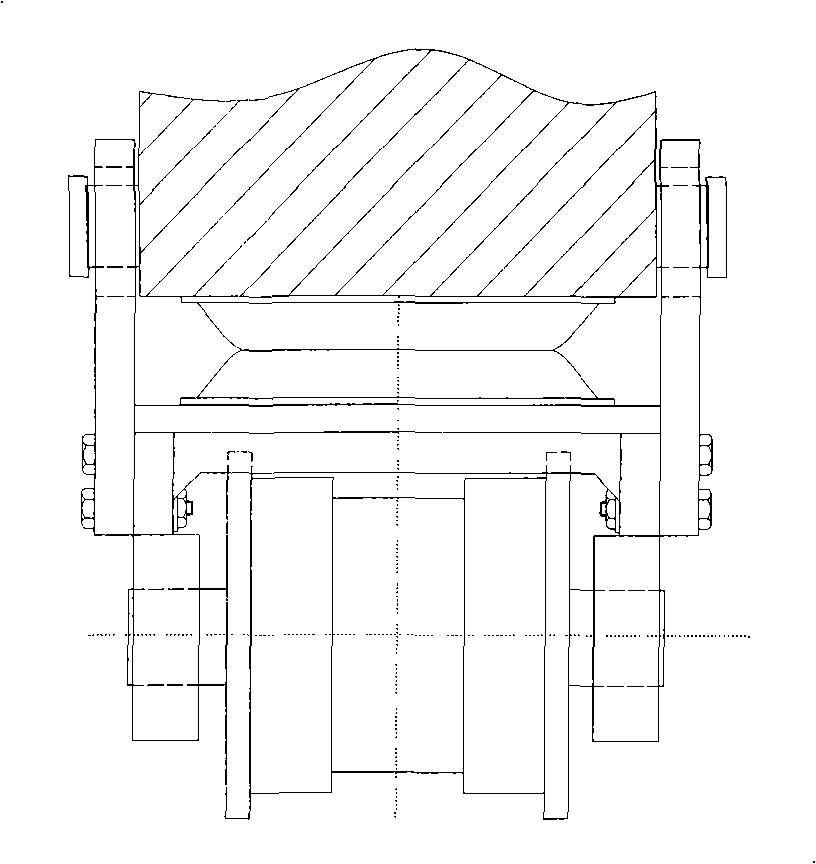

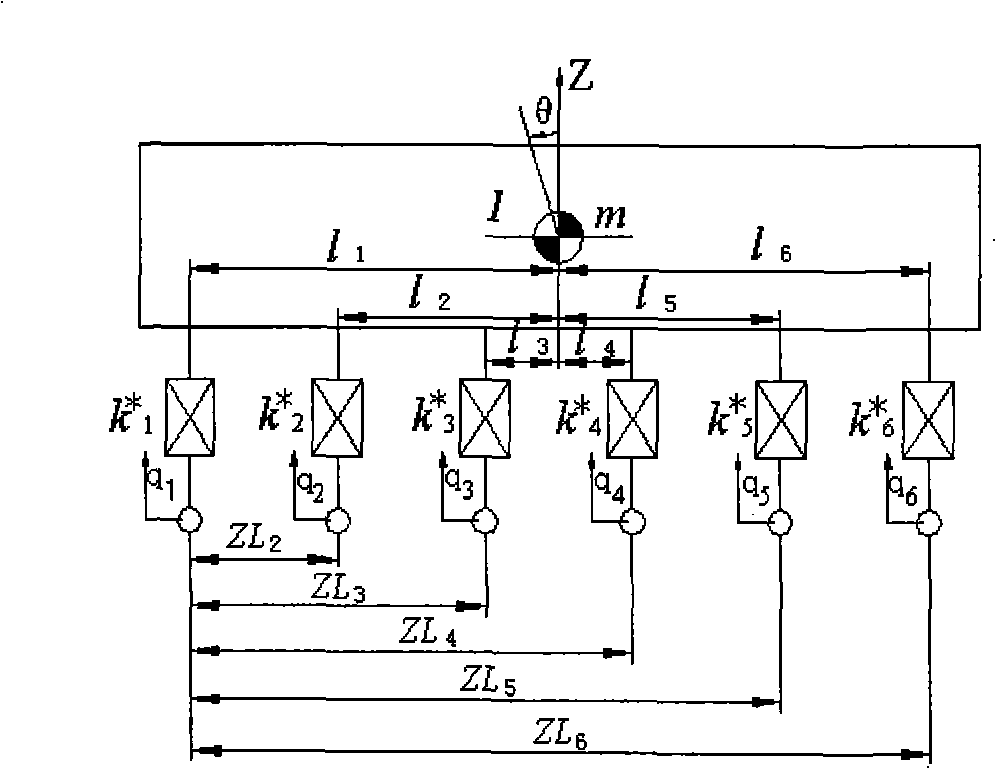

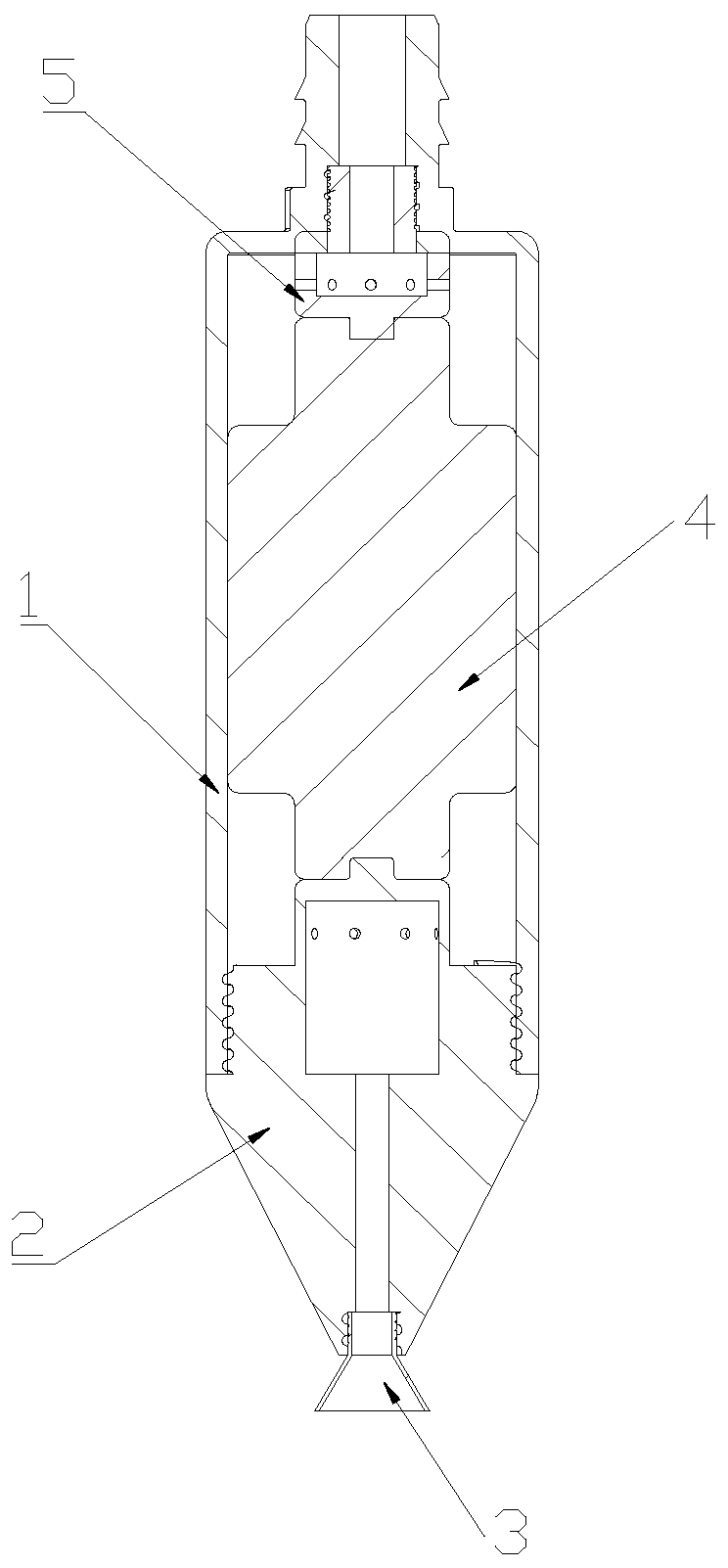

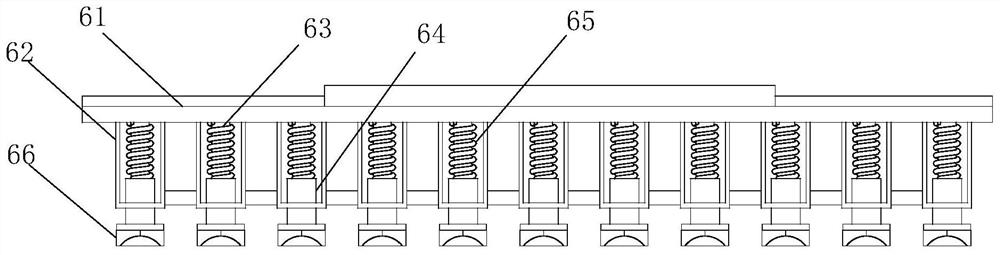

Sliding type damping buffering thrust wheel device

InactiveCN101525009AReduce vibration and shockIncreased component durabilityEndless track vehiclesProduction rateAutomotive engineering

The invention belongs to a crawler type engineering vehicle thrust wheel device, in particular to a sliding type damping buffering thrust wheel device which solves the problem that the prior crawler type engineering vehicle thrust wheel device uses rigid connections, so a traveling mechanism produces dramatic vibration and impact easily, thereby influencing the service life of vehicle components and the comfort of driving and also being likely to cause the hazard of the digression of the crawler . The sliding type damping buffering thrust wheel device comprises a thrust wheel, a support frame and a suspension mechanism. A viscoelastic vibration damper is installed between the support frame and a trolley frame. The suspension mechanism is a slide rod guideway type structure. The sliding type damping buffering thrust wheel device has the beneficial effects as follows: 1. the sliding type damping buffering thrust wheel device ensures that contact area of the crawler when traveling and reduces the vibration and the impact, the service life can be 8,000 to 10,000 hours, and the vehicle can obtain large traction and avoids the hazard of the digression of the crawler; 2. the sliding type damping buffering thrust wheel device improves the comfort for driving the vehicle, and the vibration measured at the position of a driving seat is reduced by 7 percent; and 3. the vehicle operation productivity is increased by 10 percent.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

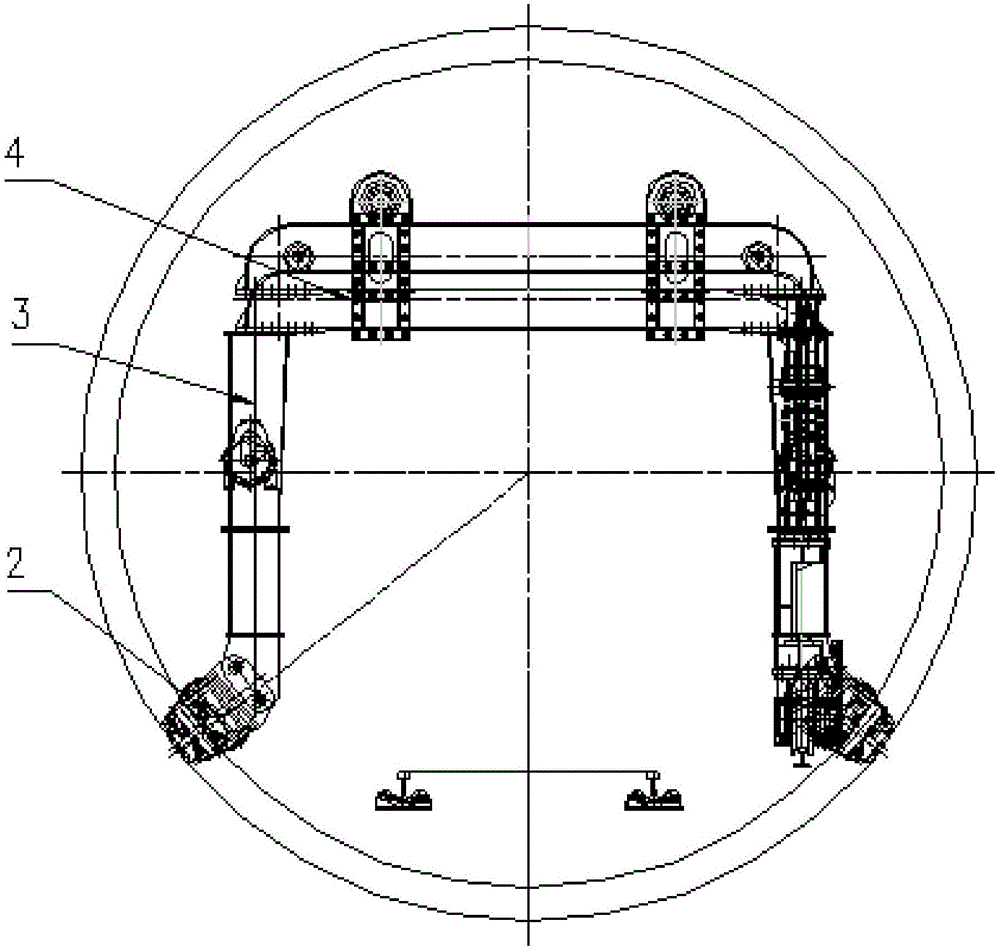

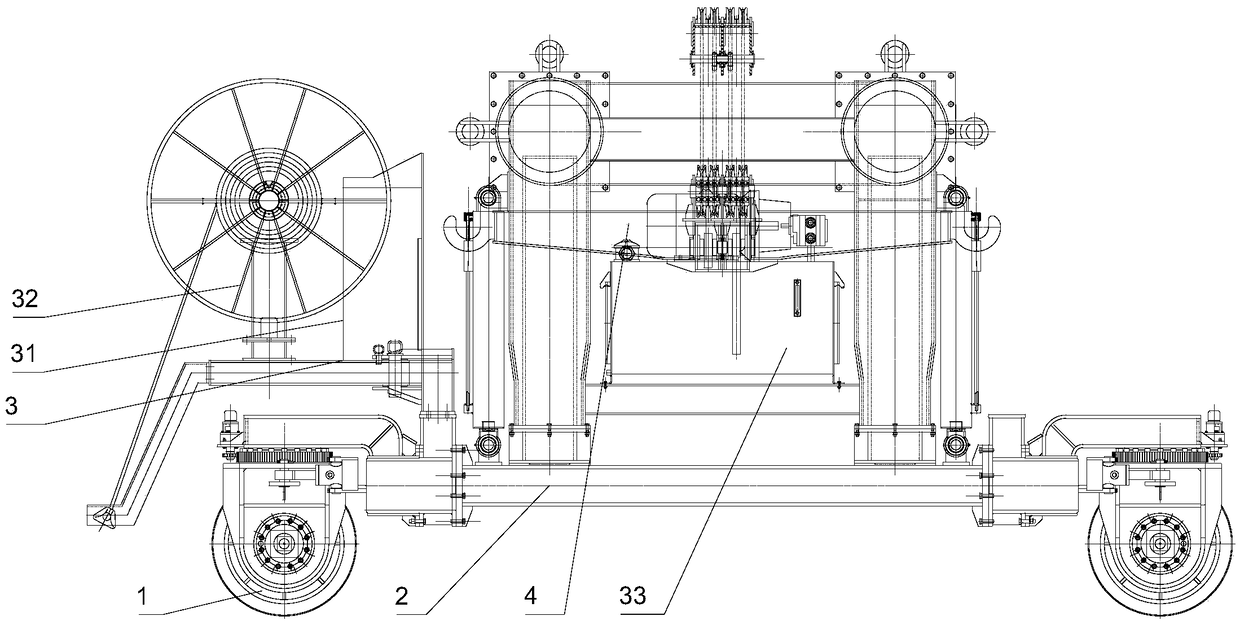

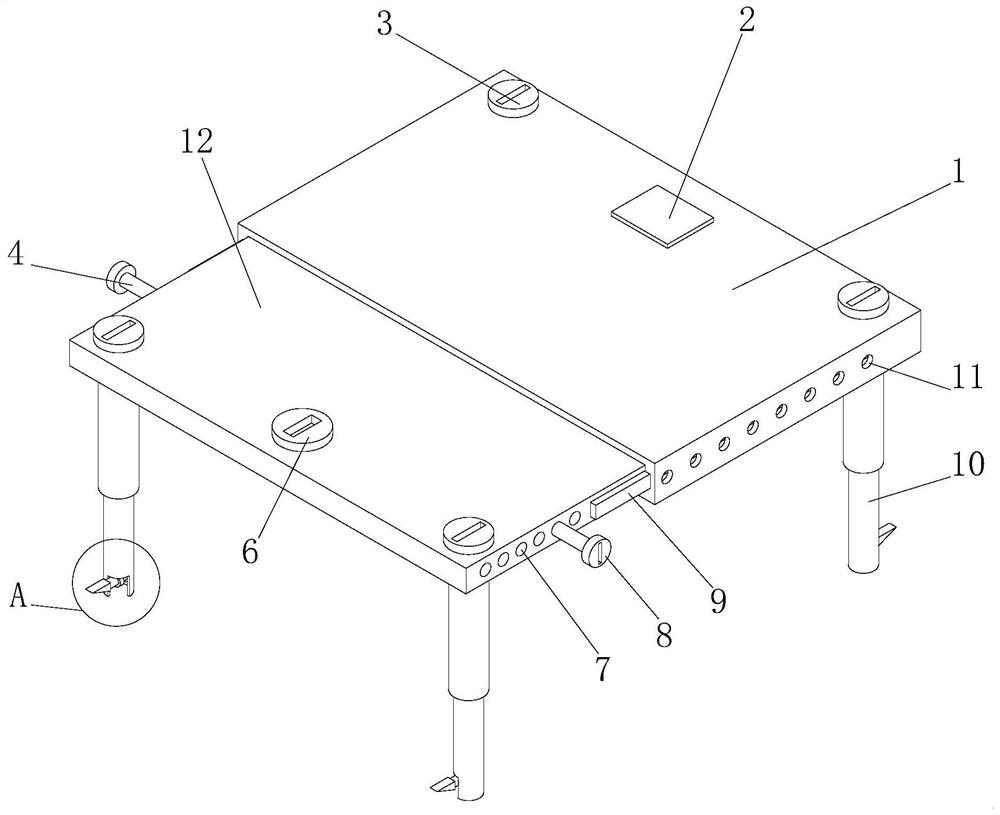

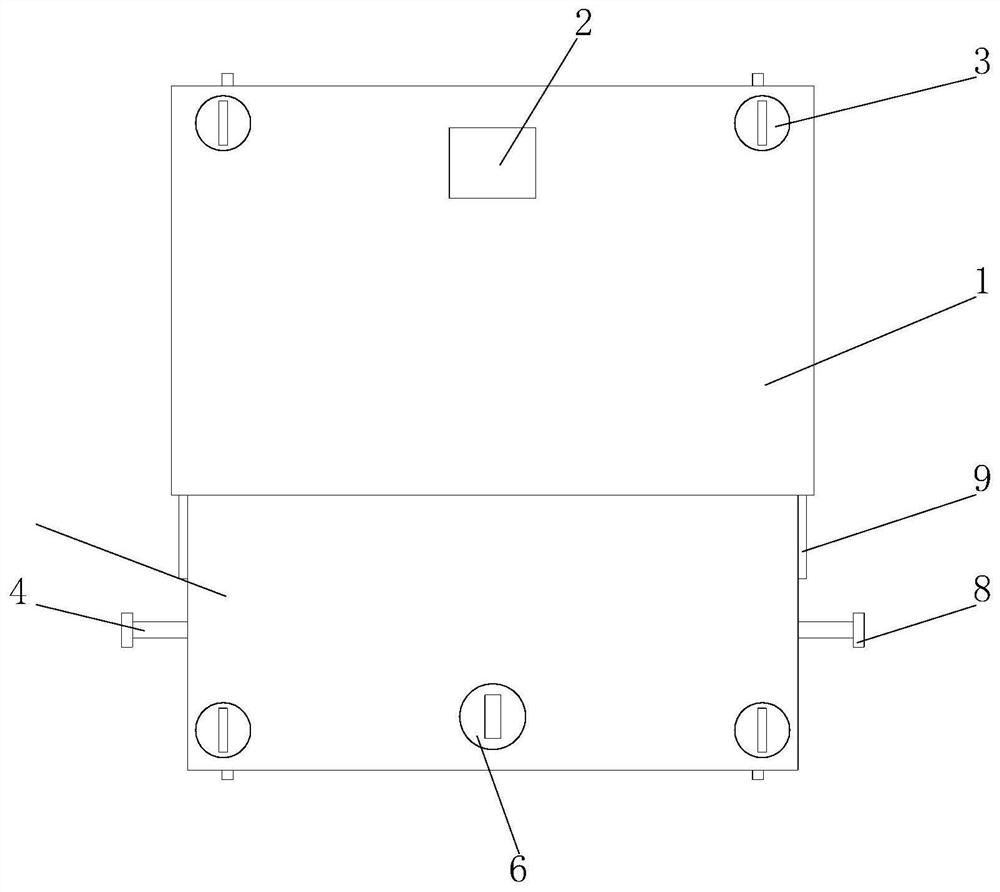

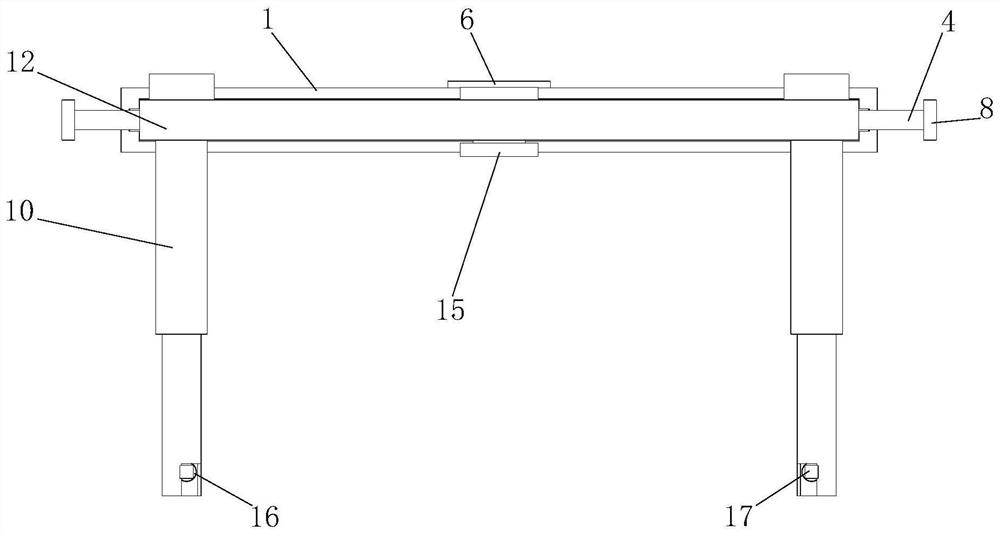

Tire type tunnel track laying crane and construction method

PendingCN109132875AAvoid harmReduce workloadLoad-engaging girdersBase supporting structuresEngineeringWinch

The invention discloses a tire type tunnel track laying crane and a construction method. The crane comprises wheel groups, a gantry, a working platform and a lifting device, wherein the wheel groups are arranged around the bottom of the gantry respectively; the working platform comprises a console, a power supply device and a hydraulic device; the console and the power supply device are respectively mounted on one wheel group; the hydraulic device is fixedly mounted on the gantry; the lifting device comprises a lifting appliance and a winch; the winch is fastened on the gantry and is linked with the lifting appliance through a steel wire rope. The construction method comprises the following steps: carrying out preparation before construction, constructing a shield tunnel, and carrying outtransferring operation. By adopting the tire type tunnel track laying crane, the technical problems that the prior art is only applicable to a single cross section size, tube pieces are greatly damaged if a track is temporarily laid in a tunnel, and the construction efficiency is low, can be solved, a whole-process tire type walking mode is achieved, construction of different cross sections such as tunnels, platforms and defense doors in tunnels can be achieved, construction steps can be simplified, the working and production efficiency can be improved, and damage of temporary tracks to tube sheets can be also reduced.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

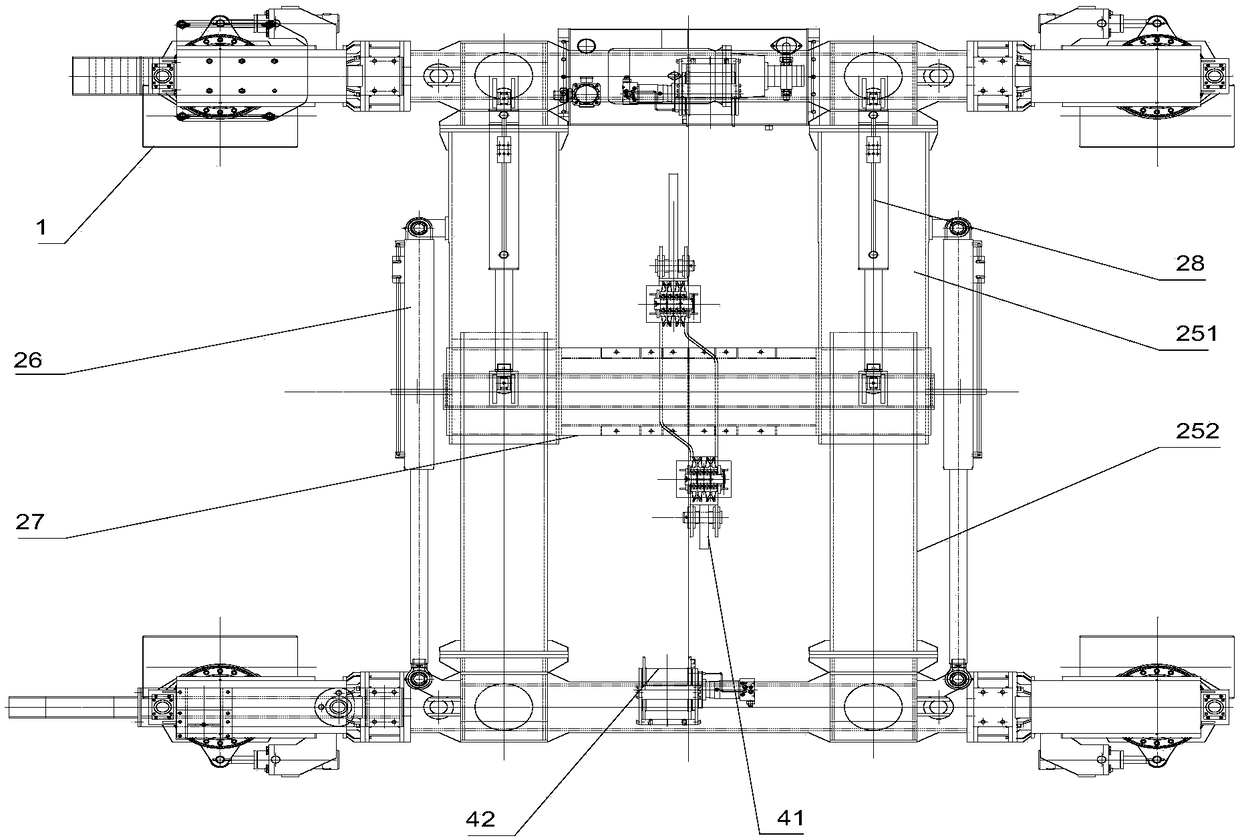

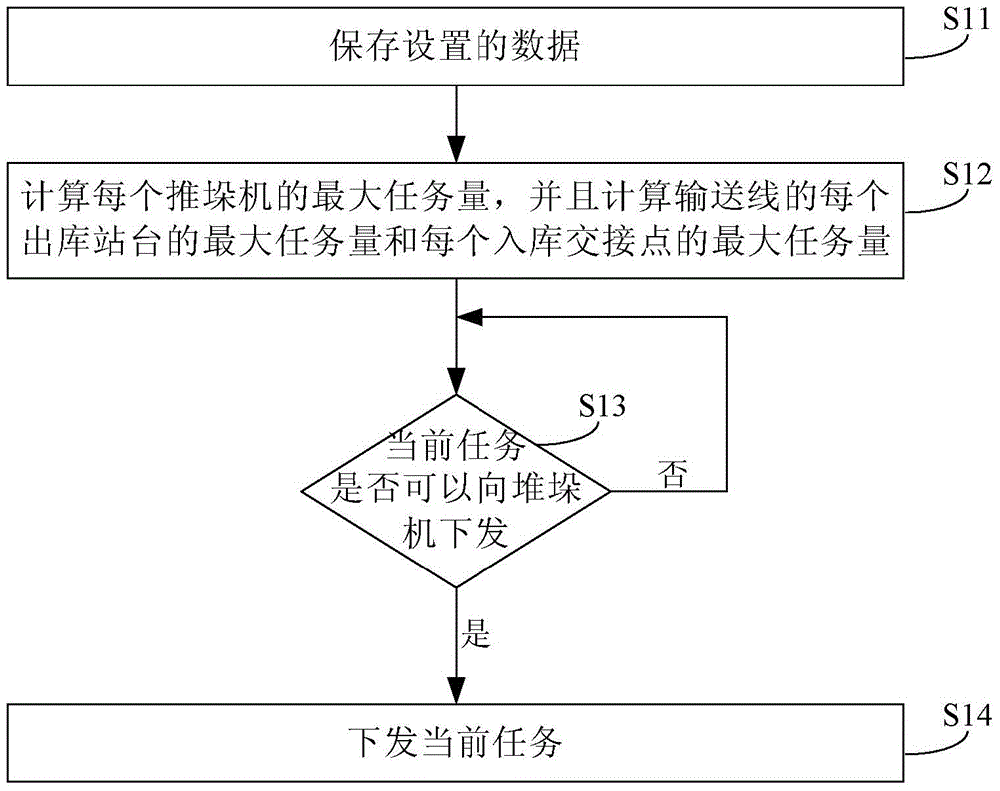

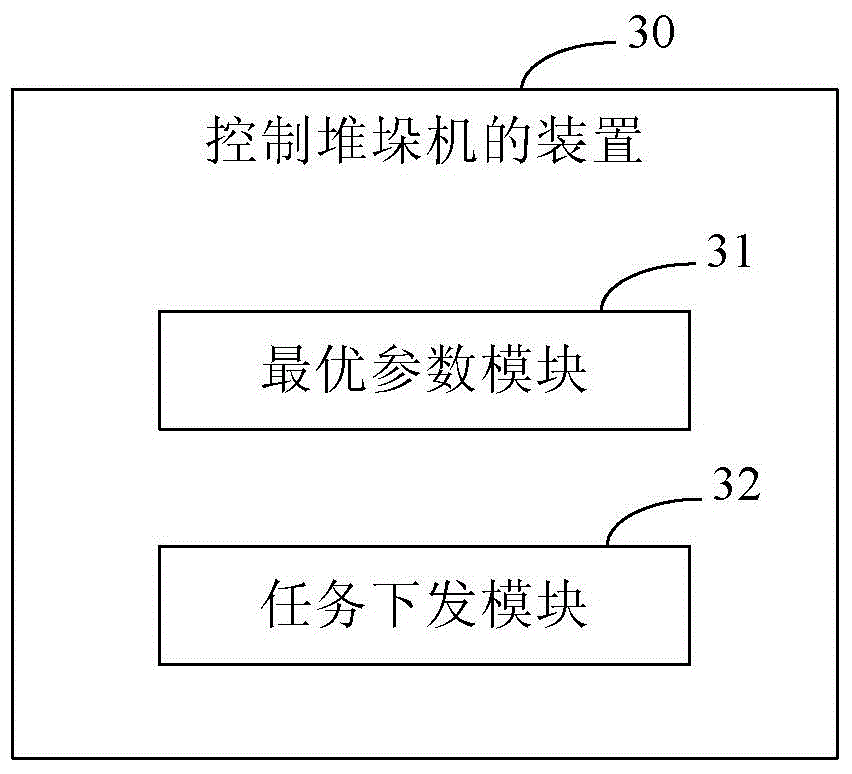

Method and device for controlling stacking machine and stacking machine control system

ActiveCN104444017AImprove job productivityReduced risk of blockageStorage devicesMachine controlStack machine

The invention provides a method and device for controlling a stacking machine and a stacking machine control system. The risk that a stacking machine conveying line is blocked can be reduced, and the operation and production efficiency of the stacking machine can be improved. The method for controlling the stacking machine comprises the steps that the maximum task quantity of the stacking machine is determined, and the maximum task quantity of an ex-warehouse platform of the conveying line and the maximum task quantity of a storage take-over point are determined; before a current task is issued to the stacking machine, judgment is carried out according to the current task quantity of the stacking machine and the current task quantity of the target position of the task, if the current task quantity of the stacking machine does not exceed the maximum task quantity of the stacking machine and the current task quantity of the target position does not exceed the maximum task quantity of the target position after the current task is issued, the current task is issued, and otherwise the task is delayed, and the judgment continues to be carried out until the two conditions are met at the same time; the target position is the ex-warehouse platform or the storage take-over point of the current task.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

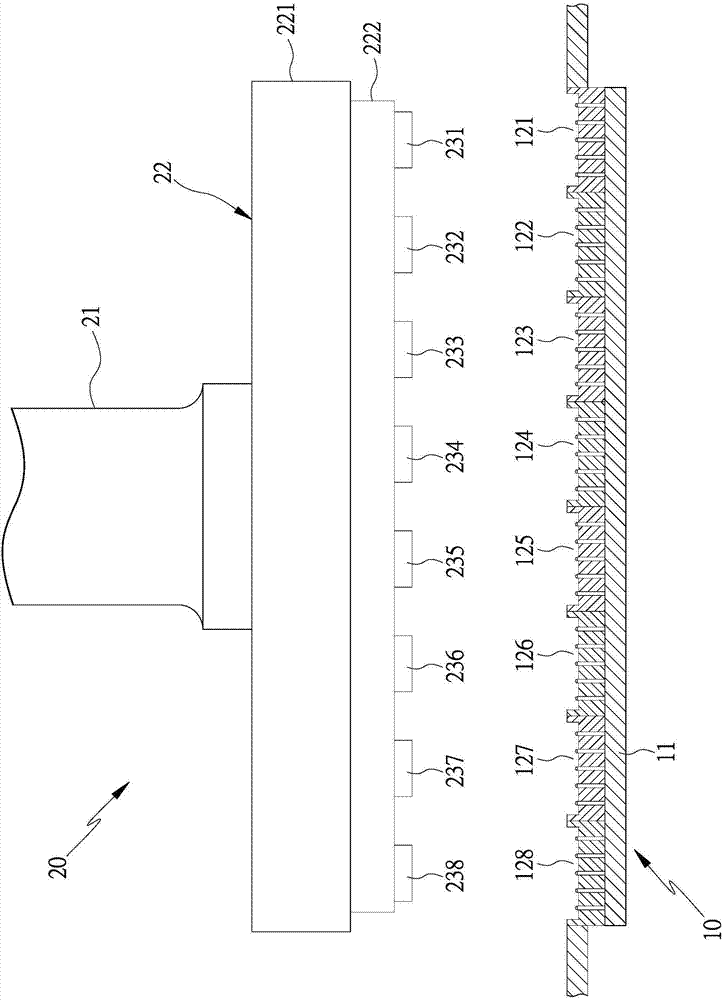

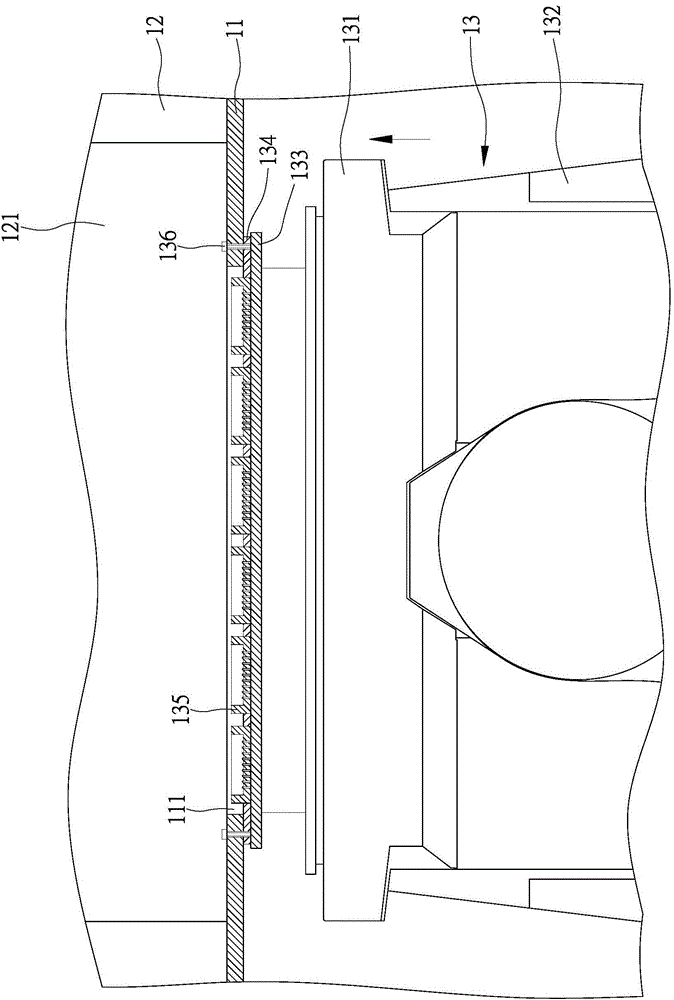

Positioning device capable of positioning multiple electronic components at same time and operation equipment adopting same positioning device

InactiveCN106290990AAccurate transfer and placementPrevent arbitrary driftElectrical testingMeasurement instrument housingEngineeringElectronic component

The invention provides a positioning device capable of positioning multiple electronic components at the same time. The positioning device comprises a positioning mechanism and a driving mechanism. The positioning mechanism is provided with a plurality of clamping devices, and each clamping device is provided with a plurality of abut-against parts for abutting against multiple electronic components. The driving mechanism is provided with at least one driving source and is used for driving the plurality of clamping devices of the positioning mechanism to generate relatively-oblique displacement, and thus the plurality of abut-against parts of each clamping device push the multiple electronic components at the same time and abut against angle parts of the multiple electronic components, and the plurality of clamping devices can clamp and position the multiple electronic components, and prevent the multiple electronic components from being drifted at will. The positioning device can be used for positioning the multiple electronic components at the same time at a time, reference parts of the electronic components are enabled to be fixed at preset reference positions, and relative positions of centers of the electronic components are fixed when a pick-and-place device of a transfer device carries out picking and placing, and thus the electronic components can be accurately transferred and placed in an accommodation tank of a bearing container, and the positioning efficiency and the practical benefits of operation quality are improved.

Owner:HON PRECISION INC

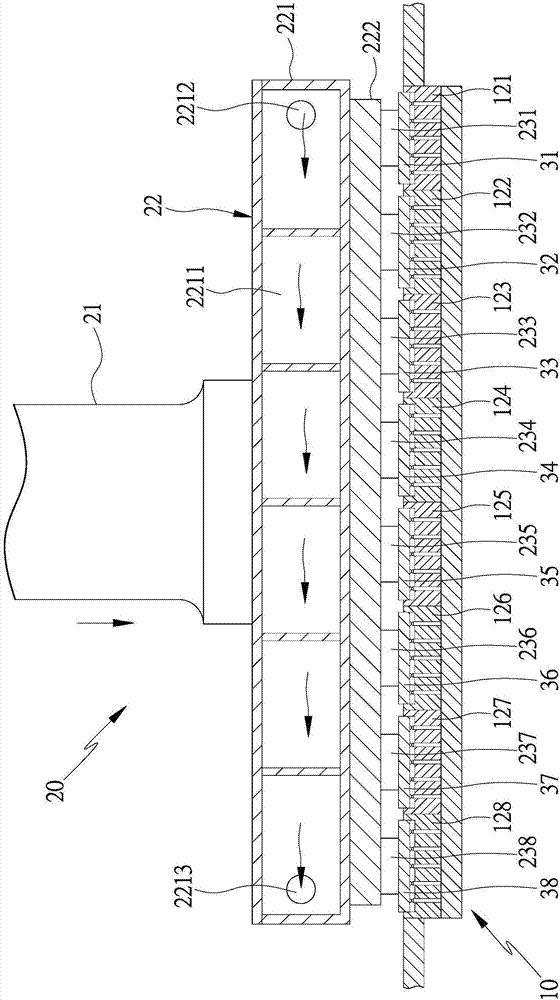

Temperature control mechanism for electronic component bonding device, method and test equipment provided with same

ActiveCN106896842AImprove test qualityImprove test throughputAuxillary controllers with auxillary heating devicesEnvironmental/reliability testsTemperature controlTest quality

The invention discloses a temperature control mechanism for an electronic element bonding device and a temperature control method. The temperature control mechanism for the electronic component bonding device is provided with a temperature control mechanism to drive by the mobile arm moving in at least one direction, a cooling module is provided with a temperature control mechanism of the cold source, and beneath the cooling module assembly of a plurality of heating the module with a heat source, a plurality of heating module assembly has a plurality of adapter, and the adapter contacted by contact with electronic components, a plurality of heating module equipped with a temperature sensing module, a temperature sensing module temperature data to the controller, controller of multiple temperature data to judge, to determine how a heating module meets the preset test temperature range, output power and real-time control compensation multiple heating module, multiple heating module temperature to meet the preset temperature range, and the plurality of adapter to test the preset temperature contact electronic components and test to improve the test quality and production efficiency.

Owner:HON PRECISION INC

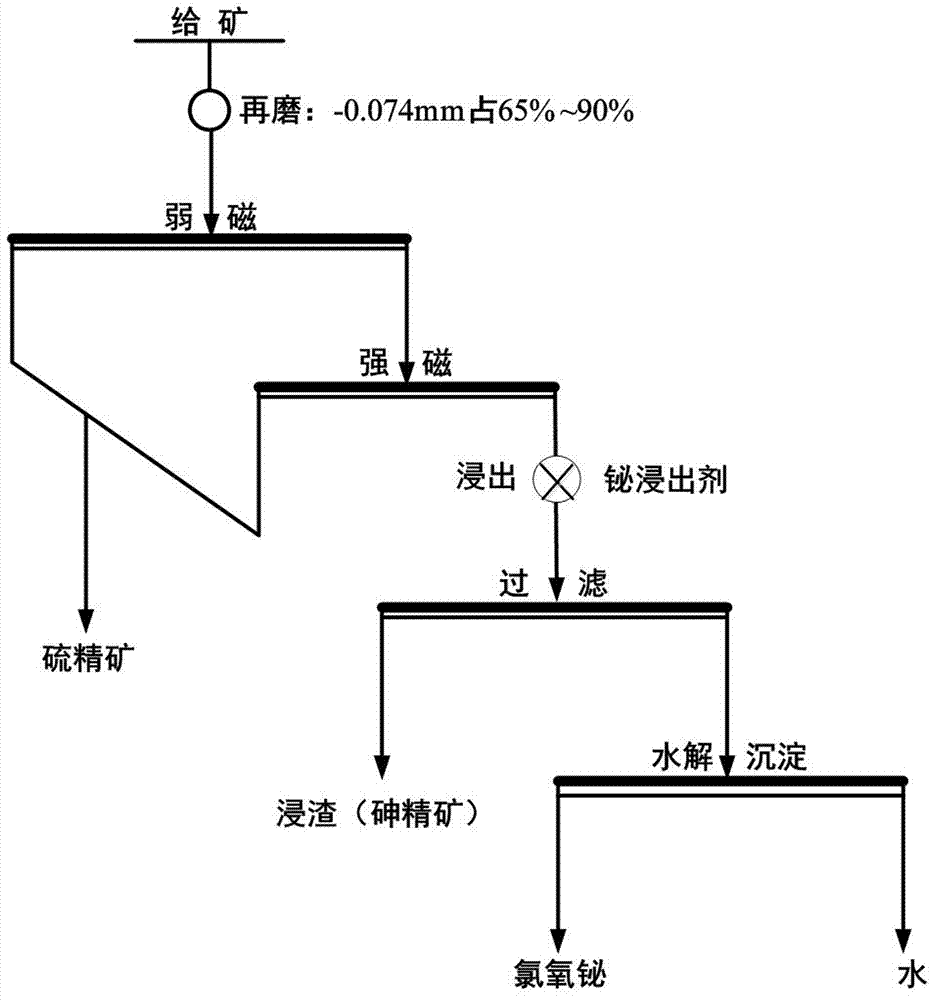

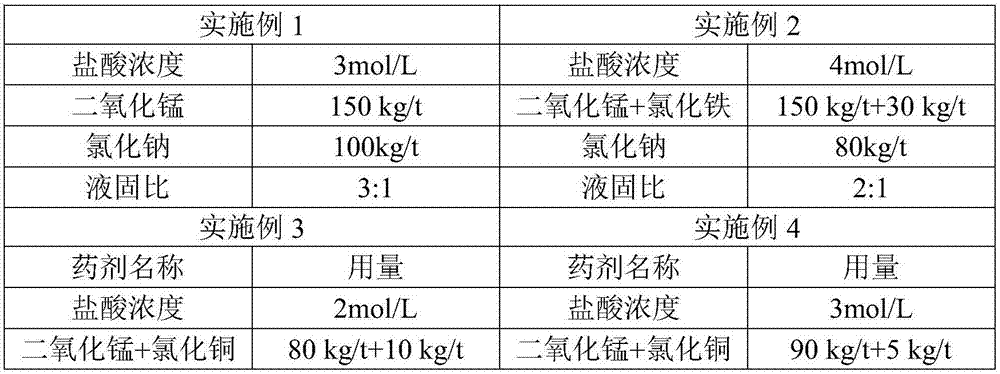

Method for separating bismuth from arsenic in high-bismuth and arsenic sulfur concentrate

The invention discloses a method for separating bismuth from arsenic in high-bismuth and arsenic sulfur concentrate. According to the method, firstly, pyrrhotite with relatively high magnetism is sorted out through low intensity magnetic separation in advance; and then, pyrrhotite with relatively low magnetism is sorted out through strong magnetic separation, the pyrrhotite with relatively high magnetism and the pyrrhotite with relatively low magnetism are combined to form the sulfur concentrate mainly with the pyrrhotite, effective removing of the pyrrhotite is achieved through the action ofthe magnetic separation, preconcentration of bismuth is achieved through the scientific control of a magnetic separation condition, the handling capacity of following bismuth leaching is effectively reduced, the leaching rate of the bismuth is increased, the in-leaching grade of the bismuth is remarkably improved, a bismuth leaching agent is reasonably added in magnetic separation of tailings so that normal temperature and normal pressure leaching of the bismuth can be carried out, the chemical stability of arsenopyrite is utilized by creating conditions, the thorough separation of the bismuthfrom the aesenic is achieved, the bismuth leachate is obtained, the leachate is further hydrolyzed, a chlorine, oxygen and bismuth product is obtained, and leaching residue is arsenic concentrate.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

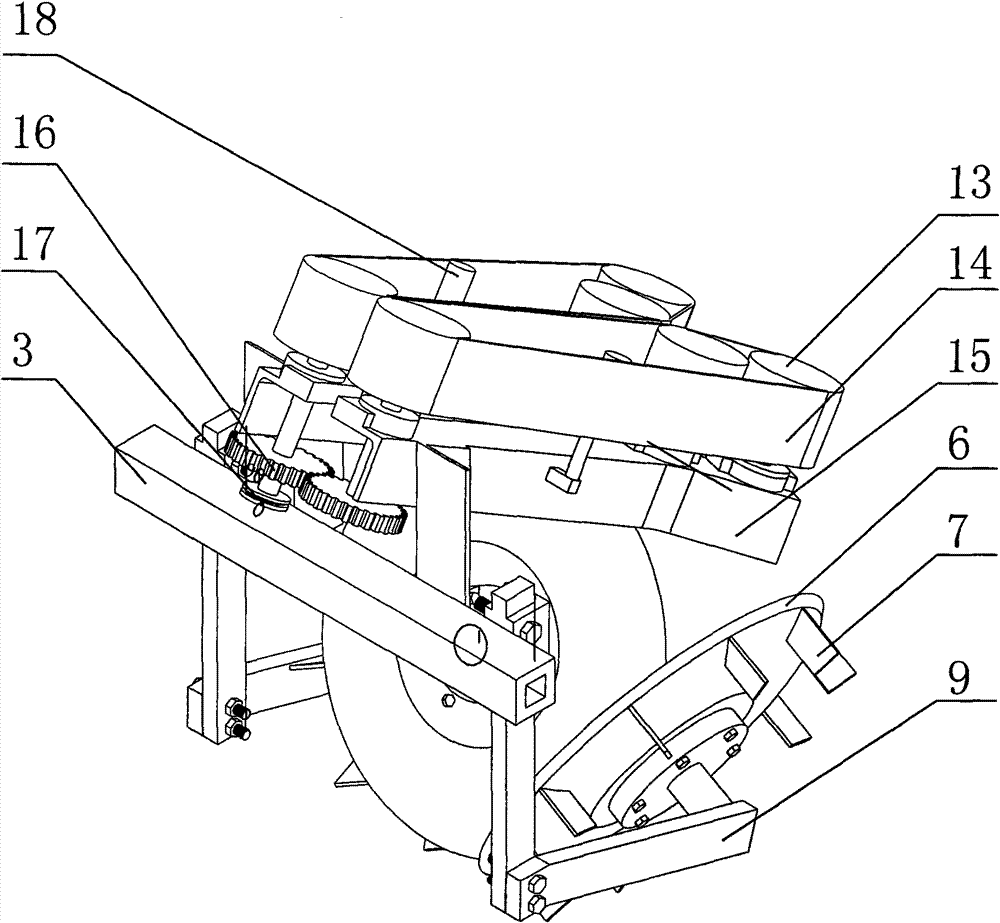

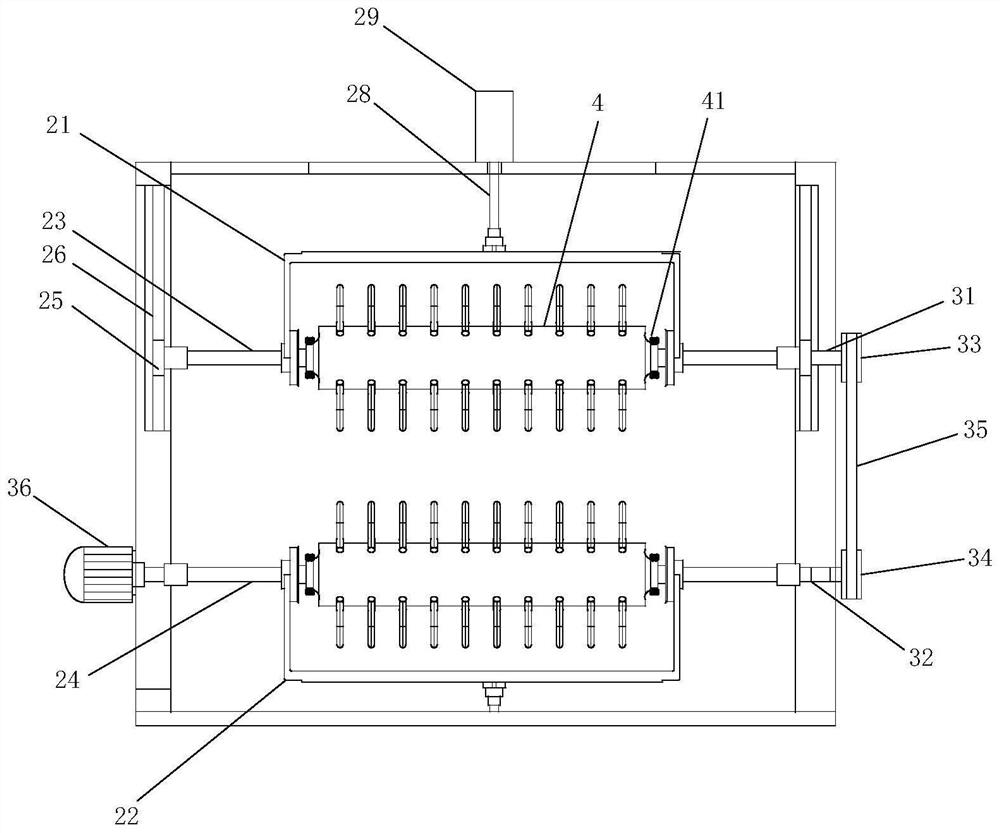

Vibrating sugarcane sowing device

ActiveCN106717358AGuaranteed decentralizationSort evenlySeed depositing seeder partsProduction rateDispersity

The invention discloses a vibrating sugarcane sowing device, which comprises a substrate, a support frame, an automatic dispersing and sorting device, a vibrating sowing device, a receiving funnel and a DC motor, wherein the automatic dispersing and sorting device is arranged on the support frame; the vibrating sowing device is located at the lower part of the automatic dispersing and sorting device and is connected with the base through a four-bar mechanism and a crank-link mechanism; and the receiving funnel is arranged in front of the base. By adopting the vibrating sugarcane sowing device, the dispersity of sugarcanes before sowing can be ensured; the replanting rate is reduced; the sugarcanes are sorted and branched, so that sowing is more uniform, the injury rate is low and the sowing speed is high. The vibrating sugarcane sowing device is conveniently carried on a sugarcane planter carrier, the labor intensity can be reduced and the operation productivity is improved.

Owner:GUANGXI UNIV

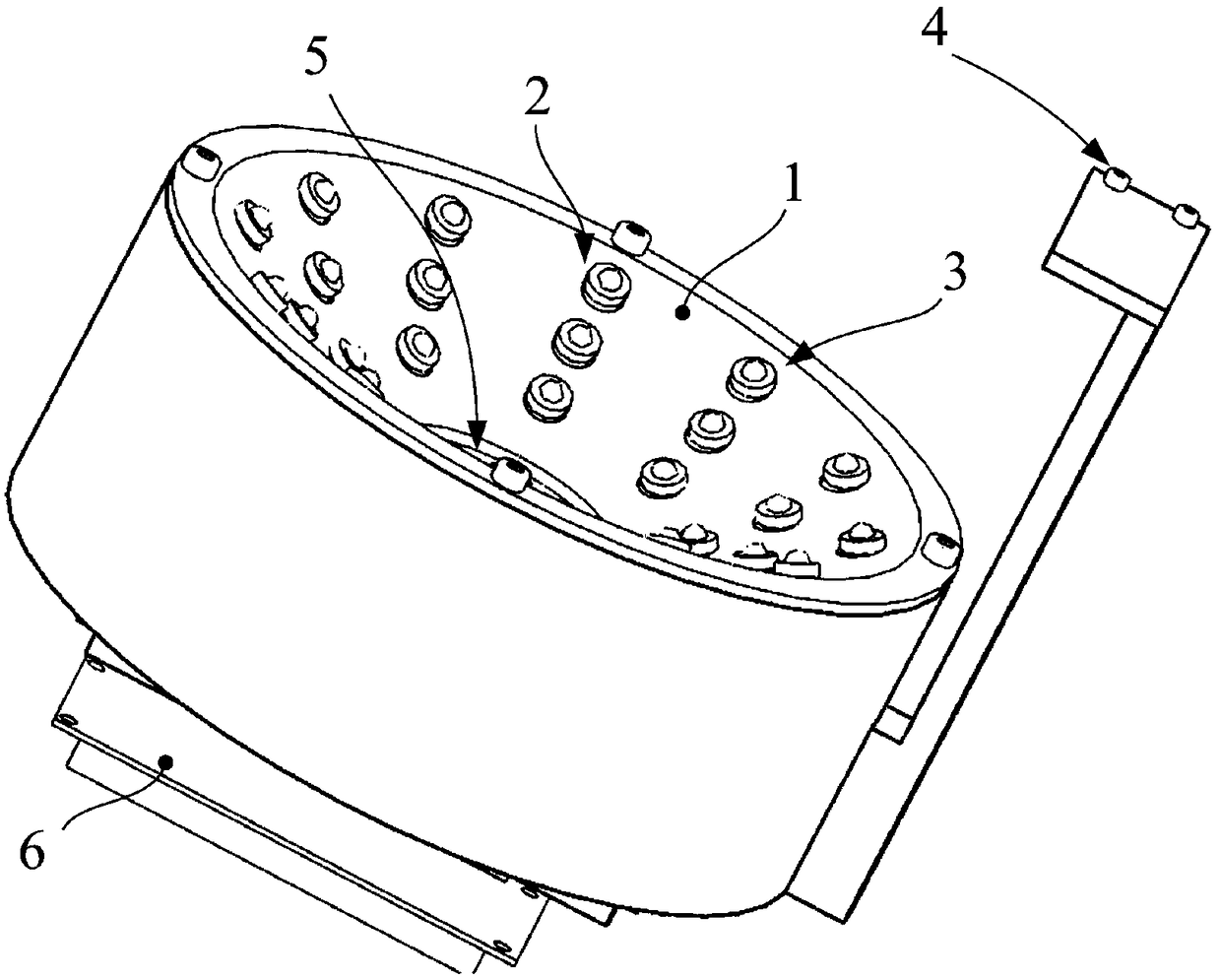

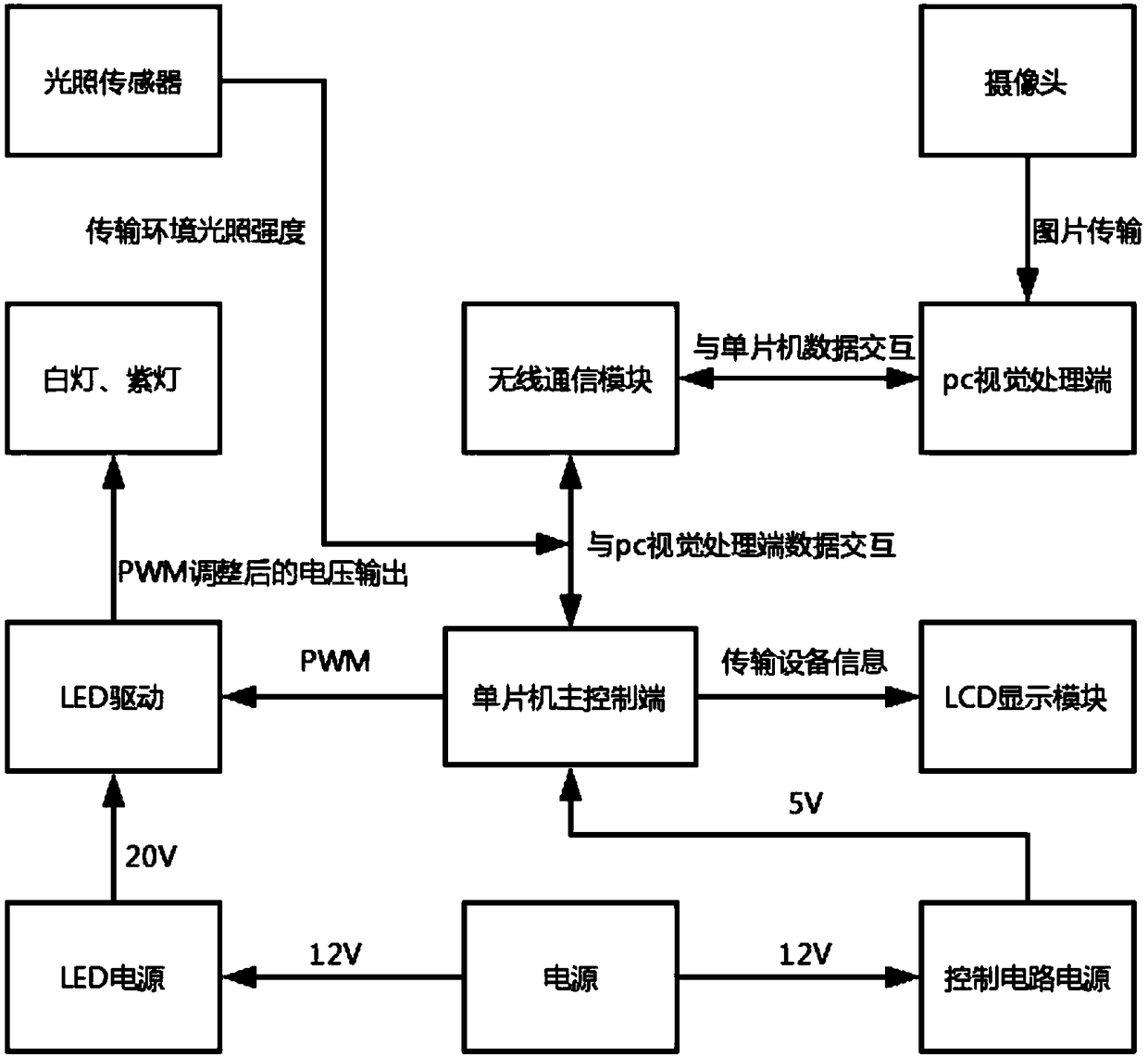

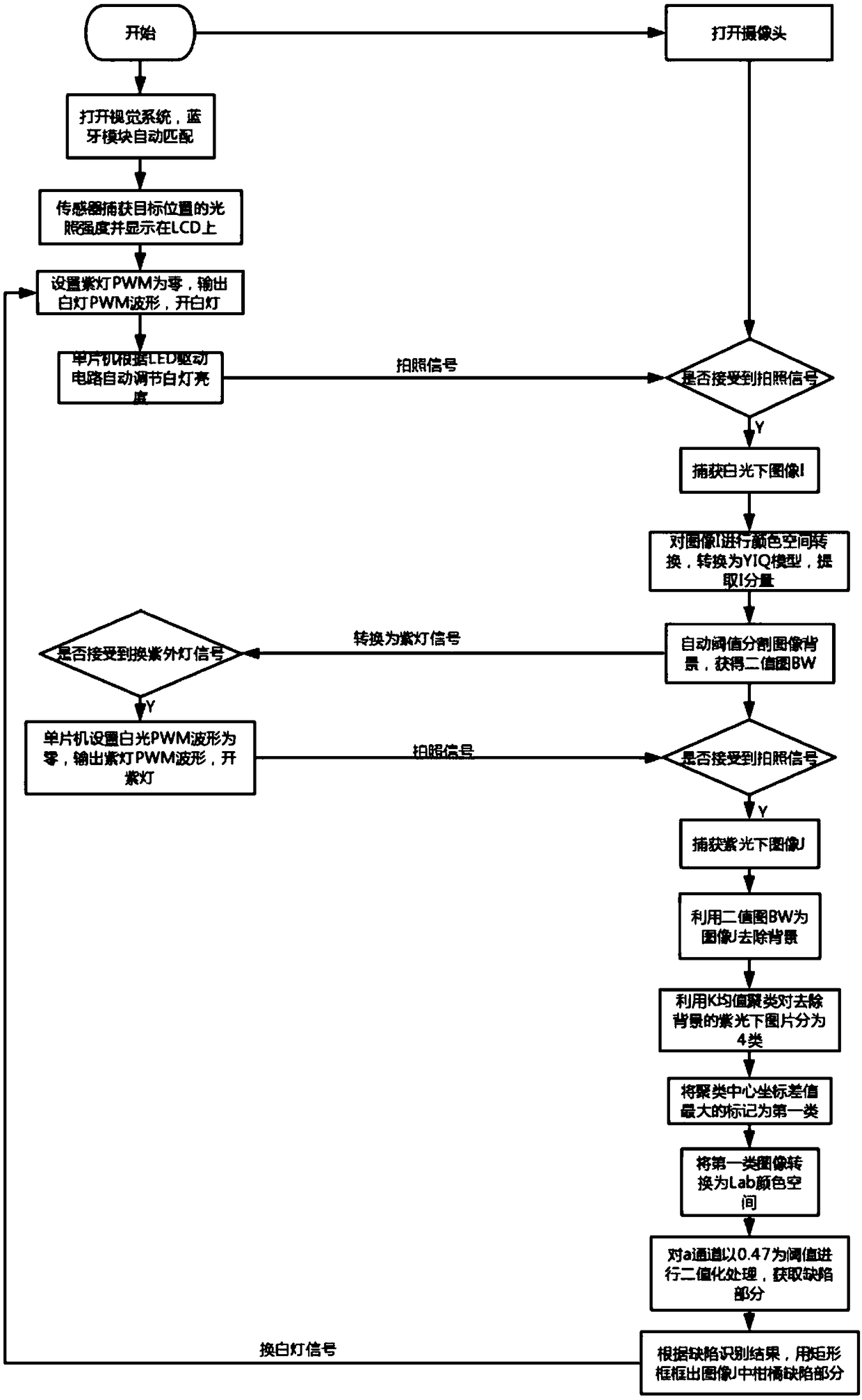

Fruit defect detection method based on image recognition and detection system

ActiveCN109001206AEfficient sortingQuality improvementOptically investigating flaws/contaminationMicrocontrollerUltraviolet lights

The invention discloses a fruit defect detection method based on image recognition and a detection system. The system realizes fruit surface defect detection through ultraviolet fluorescence phenomenon excitation, excites ketone substances of defect on the surface of a fruit through ultraviolet light to produce the fluorescence phenomenon, and detects defects which cannot be seen with naked eyes,thereby effectively sorting out high-quality fruits, and meanwhile, the system is provided with a light source, and can perform operation at night, thereby effectively utilizing night time to improvethe operation production efficiency. Image data requiring high operational capability are processed by a PC visual processing terminal through cooperative control of the PC visual processing terminaland a single chip microcomputer control terminal, an underlay with high timeliness requirement is processed by the single chip microcomputer control terminal, and the two terminals realize accuraterecognition and positioning picking on fruits through a wireless communication module, a lamp light structure is simple and convenient to control, and the system has high robustness, accuracy and timeliness, and is simple and practical, and suitable for industrialization promotion.

Owner:SOUTH CHINA AGRI UNIV

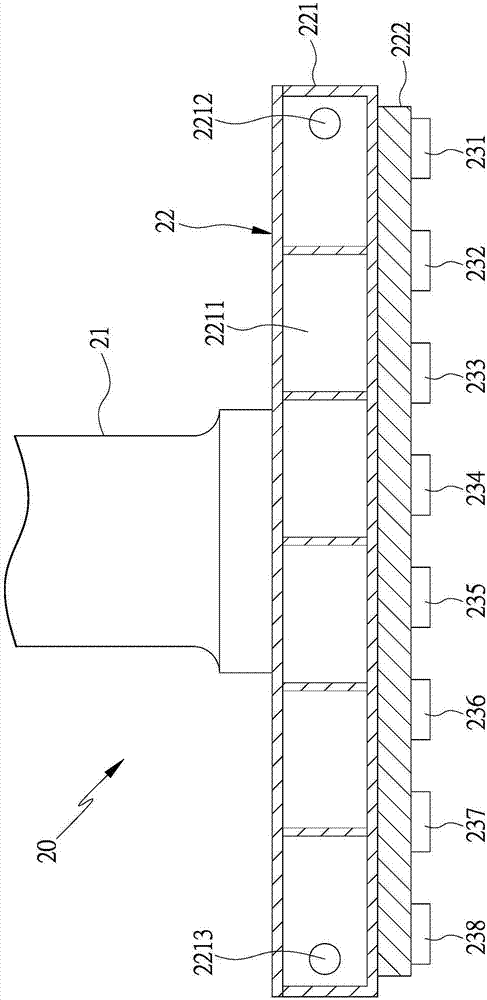

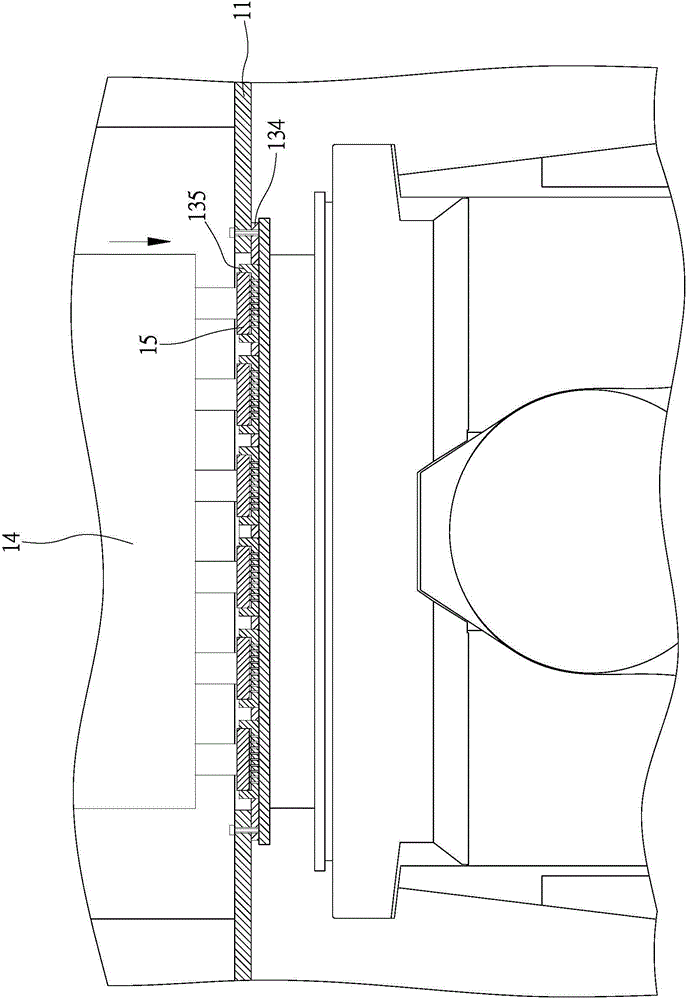

Test unit positioning mechanism of test equipment and test equipment provided with test unit positioning mechanism

ActiveCN106290993AReduce replacement work timeImprove ease of useMeasurement instrument housingEngineeringTest fixture

The present invention provides a test unit positioning mechanism of test equipment and test equipment provided with the test unit positioning mechanism. The bottom surface of the machine table of the test equipment is provided with a positioning mechanism. The positioning mechanism comprises a fixing plate provided with an accommodating space. At least one power source is arranged on the fixing plate. The power source drives at least one abutting member to move in at least one direction. A test unit comprises a carrier provided with a test bench. The test mechanism of the test unit drives the carrier to move into the accommodating space of the fixing plate. The positioning mechanism is driven by the power source to drive the abutting member to move, so that the carrier is pushed to attach to the machine table. In this way, the test unit provided with the test bench is positioned. During the replacement of the test bench, the positioning mechanism is driven by the power source to drive the abutting member to be separated from the carrier, so that the test unit with the test bench can be removed. The test mechanism drives the test unit to get away from the machine table. Therefore, the test unit provided with the test bench is automatically positioned or removed by the positioning mechanism, so that the replacement operation time is saved. As a result, the usage convenience and the production efficiency are improved.

Owner:HON PRECISION INC

Corrugated edge and copper scale preventing method suitable for divided cutting of flexible printed circuit board

The invention relates to a corrugated edge and copper scale preventing method suitable for divided cutting of a flexible printed circuit board. The method comprises the steps that before divided cutting is performed on the flexible printed circuit board, a copper layer, arranged at the position of a lower knife edge of a cutting knife in the divided cutting process, on the flexible printed circuit board is removed, and a cutting area only with a circuit board base material is formed; when divided cutting is performed on the flexible printed circuit board, a lower knife in the cutting area cuts the flexible printed circuit board. Before divided cutting is performed on the flexible printed circuit board, the copper layer at the position of a divided cutting knife edge is removed, so that when divided cutting is performed on the flexible printed circuit board, the cutting knife can not cut the copper layer, and therefore the corrugated edge phenomenon can be avoided in the copper layer at the position of the knife edge or the copper scale is prevented from being cut down. Meanwhile, the service life of the cutting knife can be prolonged, the work production efficiency is improved, the cutting edge after cutting cannot cut work staff, and the work safety is improved.

Owner:CHUNHUA TECHNOLOGICAL KUSN

Long grained seed steering precision seeding device and seeding method thereof

InactiveCN101702969BTo achieve the purpose of batch directional seedling cultivationImprove job productivitySeed depositing seeder partsProduction rateEngineering

Owner:SOUTH CHINA AGRI UNIV

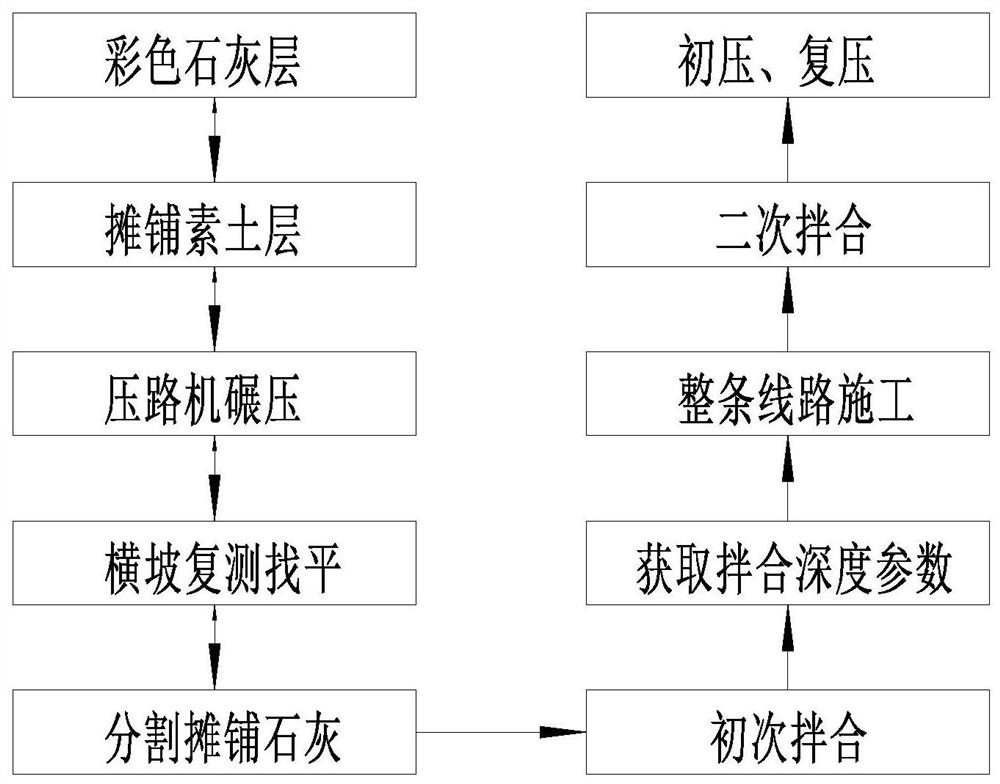

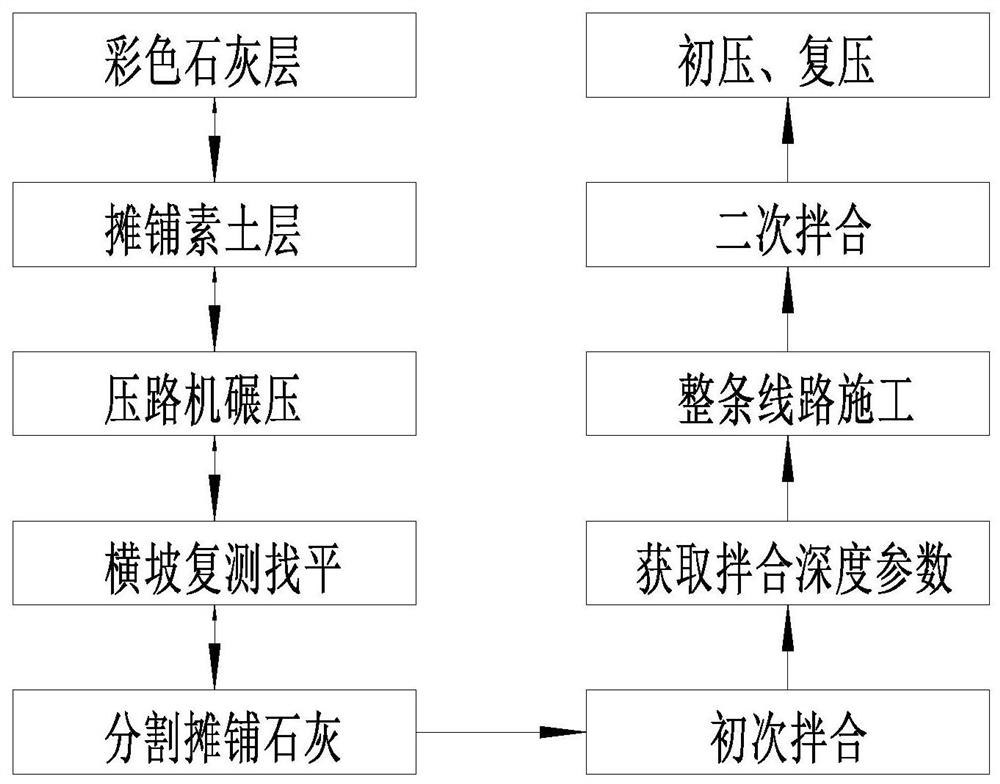

Lime soil filling construction method

ActiveCN111794029AConstruction Depth GuaranteeAvoid long-term fatigue workRoadwaysWater contentAgricultural engineering

The invention discloses a lime soil filling construction method, and belongs to the field of filling construction. According to the invention, secondary mixing is adopted, and lime is spread in grids,so that the on-site lime soil construction depth is effectively guaranteed and the existence of a plain soil interlayer is avoided; meanwhile, a specially-assigned person does not need to follow themachine to carry out digging depth inspection, long-term fatigue operation of the personnel is avoided; besides, by adopting the method, depth errors caused by adopting an expensive road mixer with the automatic depth adjusting function are avoided, and the problem that the mixing operation efficiency cannot be guaranteed due to the fact that the size and the water content of concrete materials cannot be guaranteed by both the person and the machine is solved. Lime is paved by adopting the grid scraping plate, so that the lime is paved more smoothly, two hands of an operator are liberated, andthe operation production efficiency is improved.

Owner:CHINA MCC17 GRP

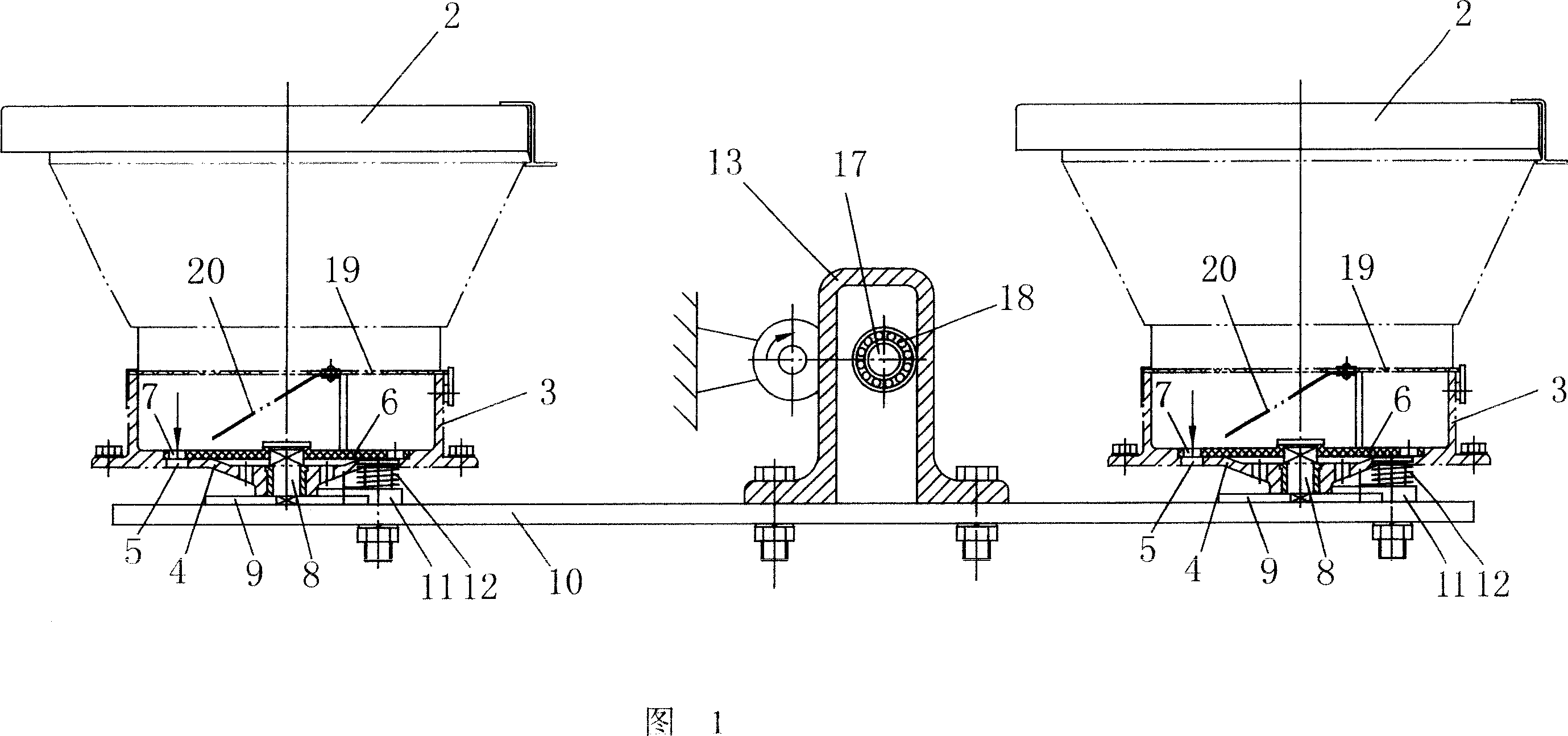

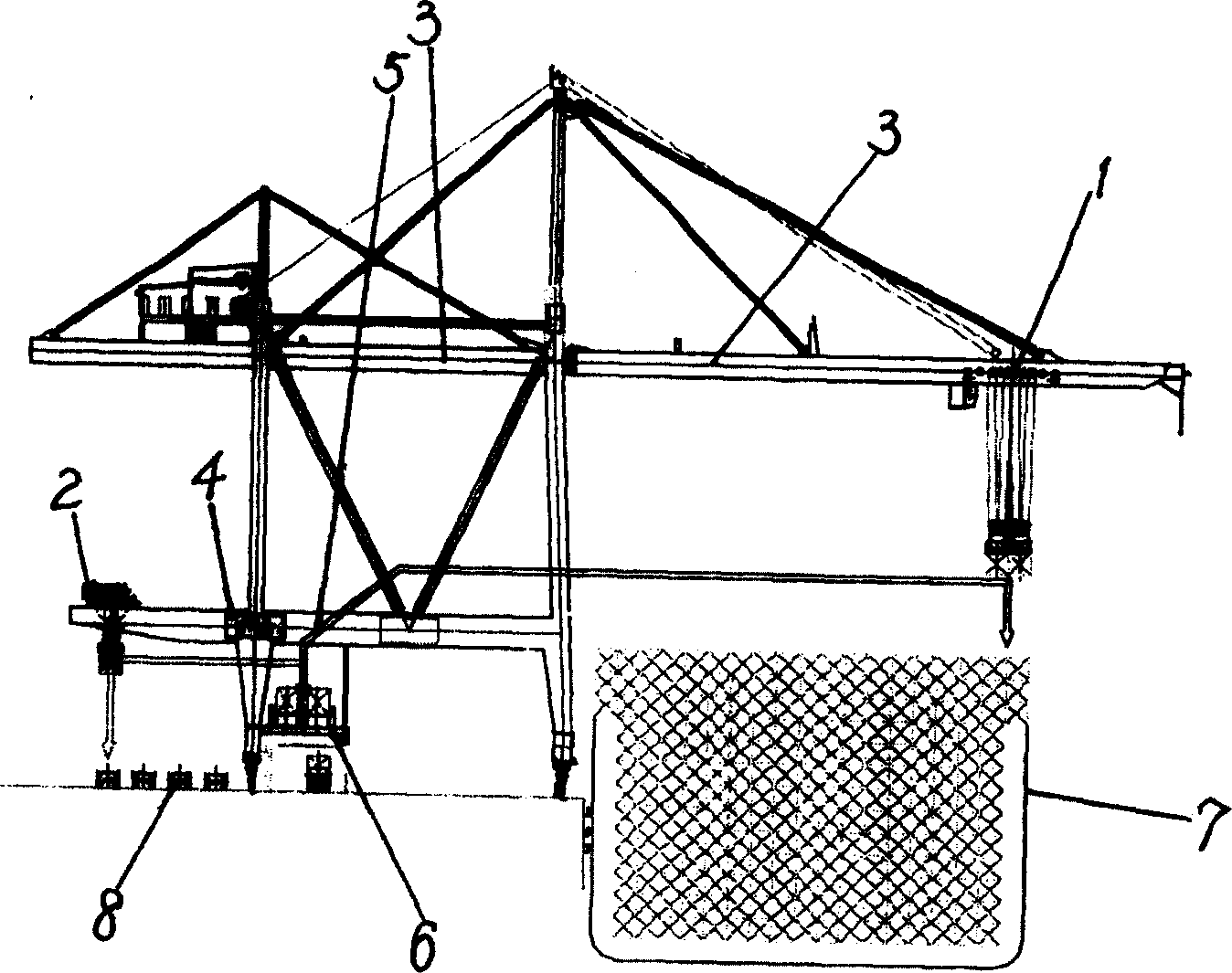

Dual-dan container crane capable of hoisting dual 40-foot box

InactiveCN100341771CEasy loading and unloadingSolve the problem of anti-shake in loading and unloading positioningTrolley cranesContainer craneEngineering

The present invention relates to a double-trolley container crane capable of lifting two 40-foot contaniers. Said container is equiped with two trolleys, on the upper track of crane girder the front trolley is mounted and can be run on said track, under the cross beam of gate frame a transfer platform for container position of container is set, the front troley can utilize the operation track to lift two 40-foot containers on the transfer platform, then the rear trolley can be used for utilizing operation track to one-by-one lift containers on the transfer platform onto the ground transportation truck. Said invention can greatly raise leading-unloading speed and loading-unloading efficiency.

Owner:SHANGHAI ZHENHUA HEAVY IND

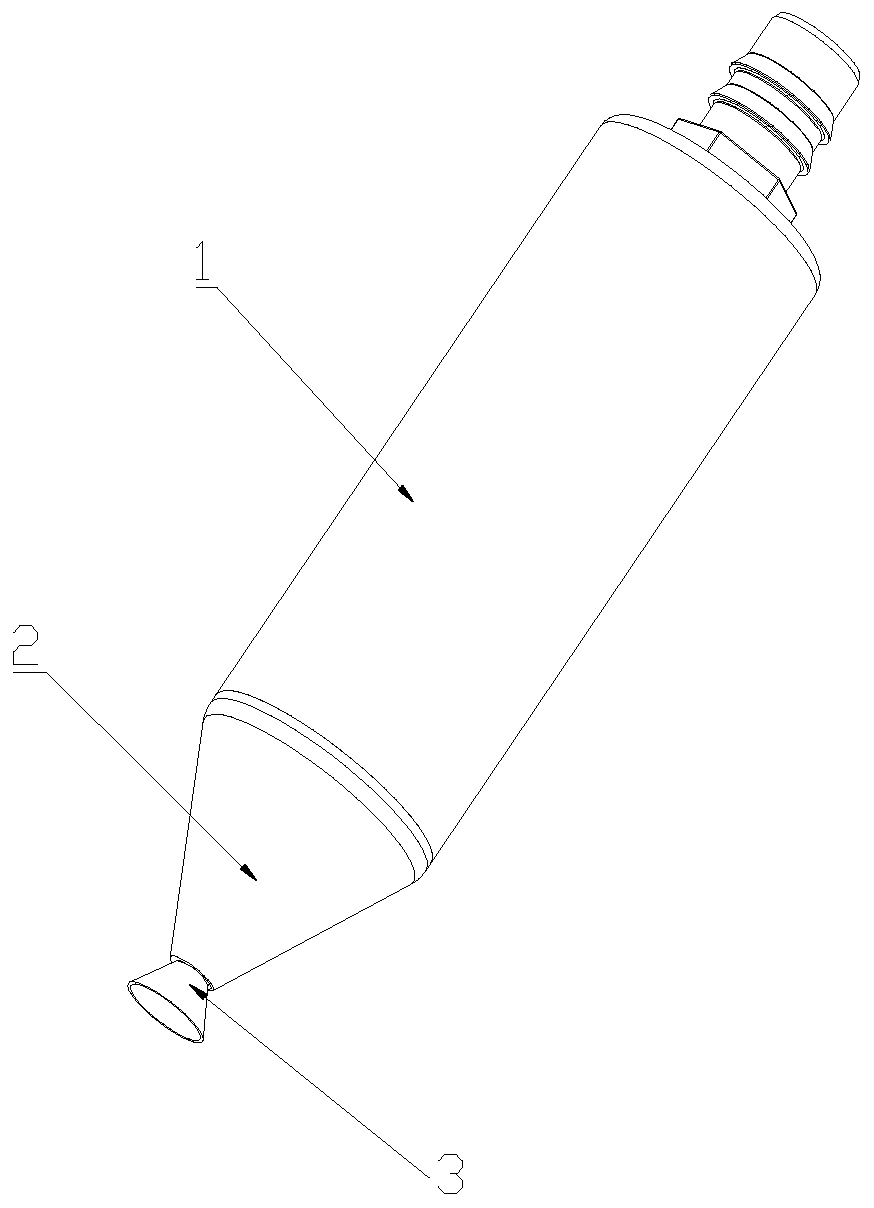

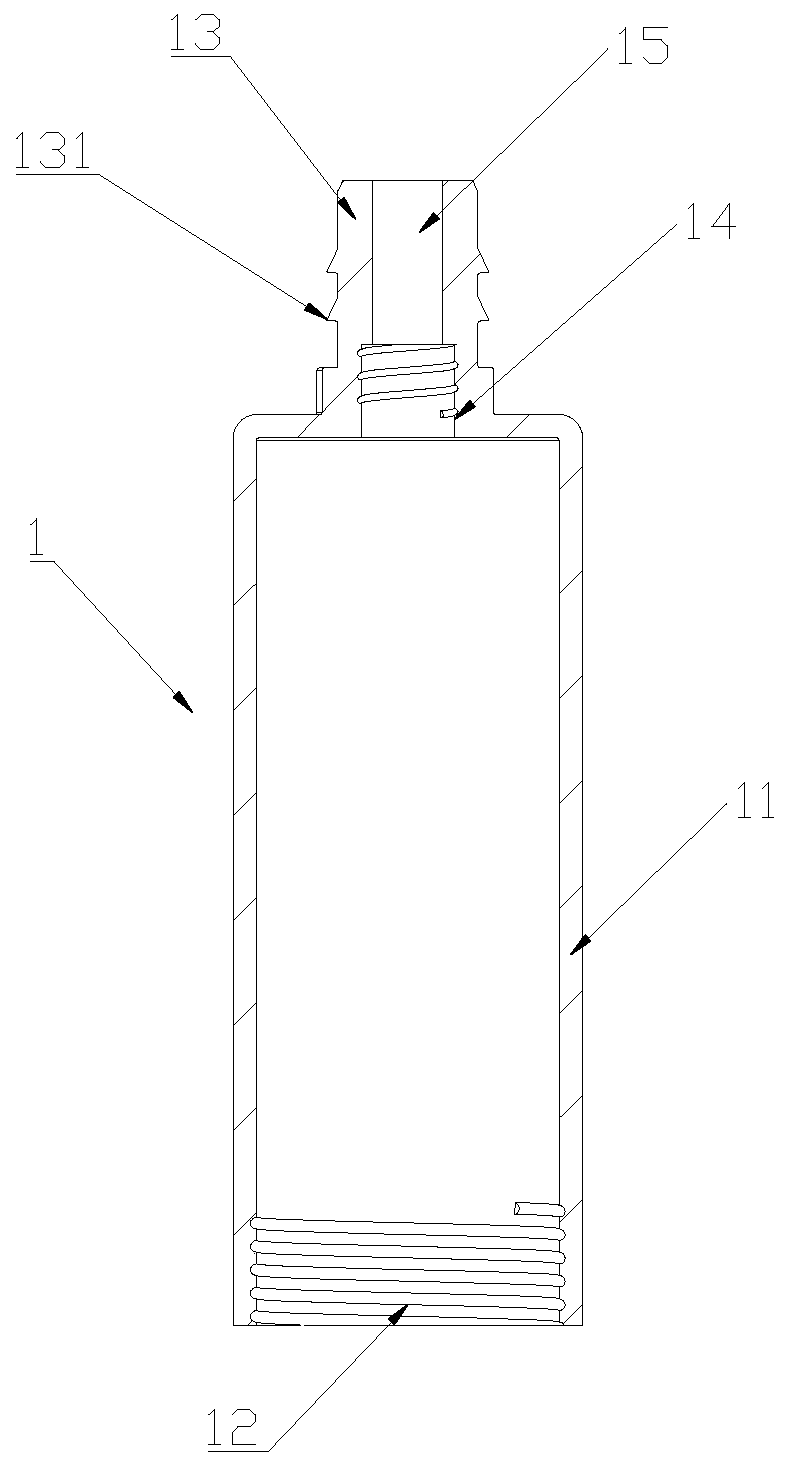

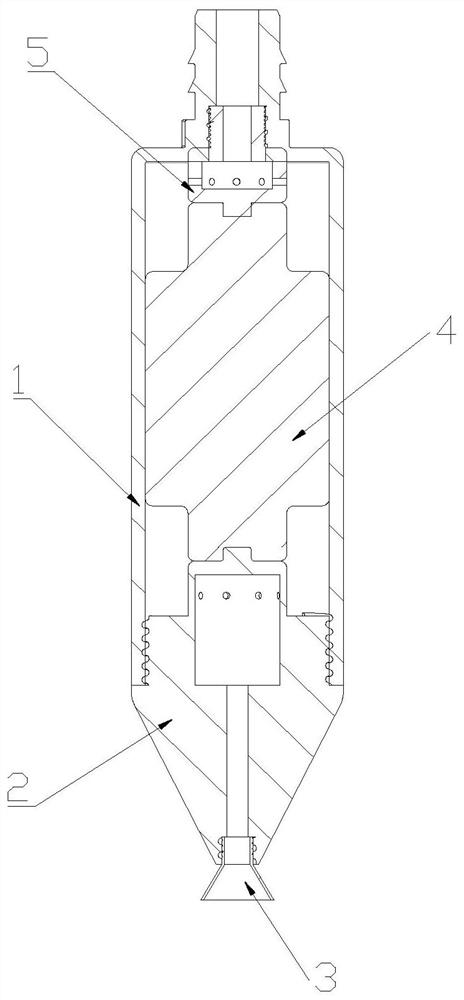

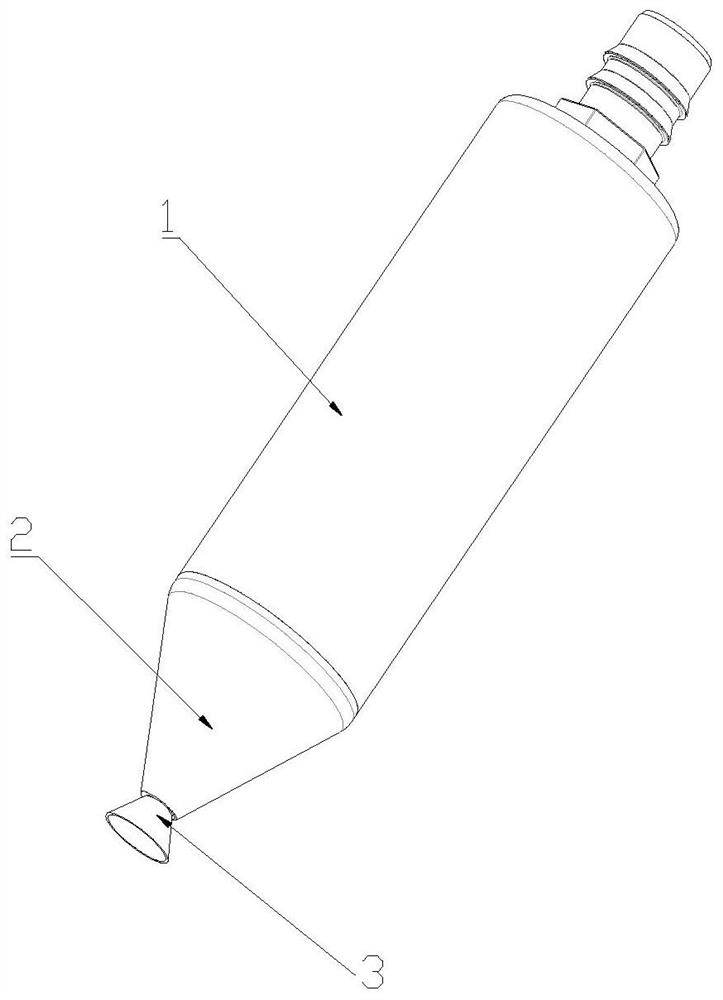

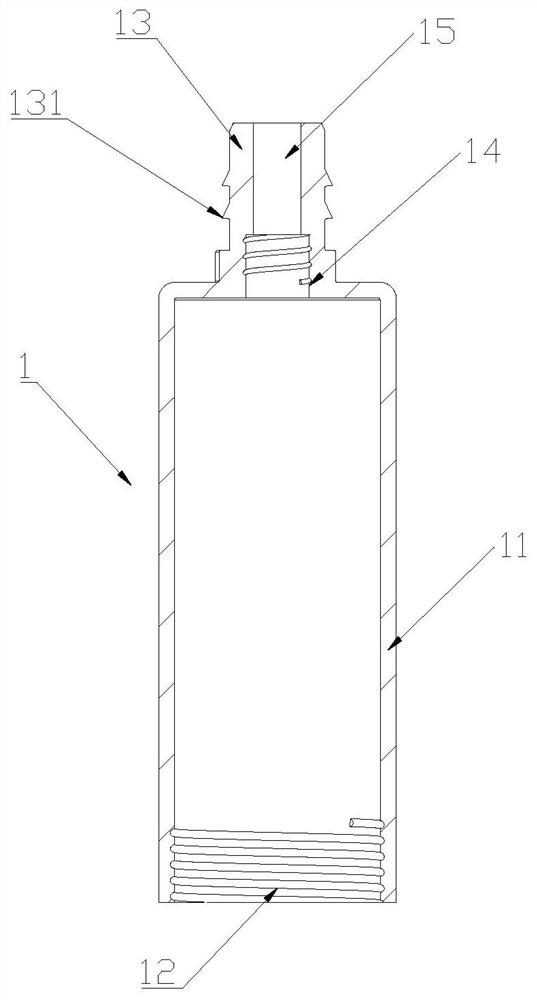

Foreign object dust collection pen applied to backlight module

ActiveCN109954725AAvoid wrinkles and other defectsImprove job productivityCleaning using gasesProduction lineForeign matter

The invention discloses a foreign object dust collection pen applied to a backlight module. The dust collection pen comprises a pen holder. A pen point is arranged at one end of the pen holder, one end of the pen point is in fastening connection with the pen holder through a thread structure, and the other end of the pen point is in fastening connection with a dust collection hood through a threadstructure. A support member is arranged in the pen holder, and an air filter element is arranged between the support member and the pen point in the pen holder. The dust collection pen adsorbs foreign objects on a diaphragm through vacuum negative pressure, the foreign objects are adsorbed on the air filter element, the dust collection pen is not in contact the diaphragm in the whole dust collection process, harmful problems that the diaphragm is contained and wrinkles occur to the diaphragm and the like are solved, the operation production efficiency of the backlight module in the electronics industry is improved, and the production yield of the backlight module in the electronics industry is improved; the air filter element can be disassembled to facilitate the timely cleaning of the adsorbed foreign objects and replacement of the air filter element; and a traditional method of using sticky sticks to improve the production line diaphragm foreign object situation is replaced, the generation of defective products is reduced, and production efficiency is improved.

Owner:博讯光电科技(合肥)有限公司

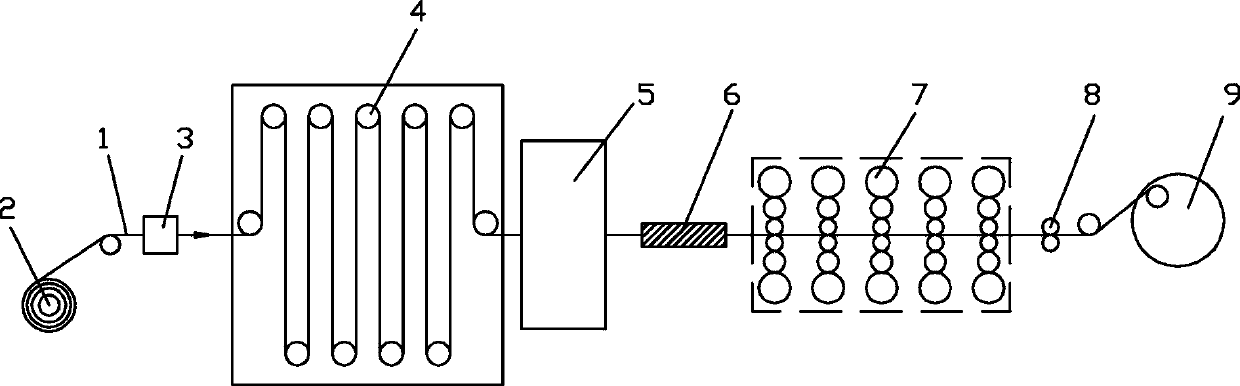

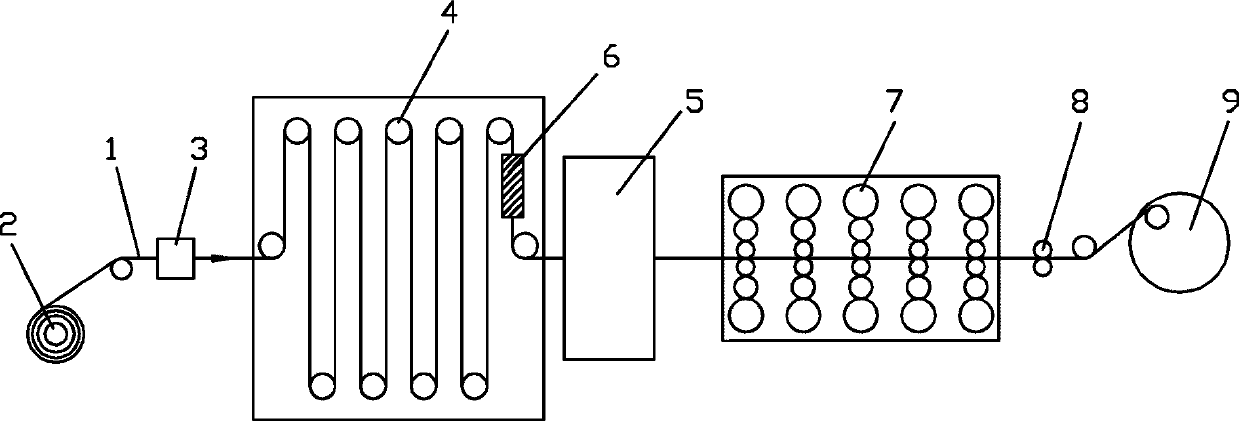

Cold rolled strip steel production technology

ActiveCN103962398AReduce vibrationImprove productivityWork treatment devicesMetal rolling arrangementsStrip steelContinuous rolling

The invention discloses a cold rolled strip steel production technology. The cold rolled strip steel production technology comprises the following steps: uncoiling the strip steel by an uncoiler, allowing the uncoiled strip steel to pass through a welder, feeding to an entry looper of a rolling mill, entering a entry tension unit of the rolling mill, entering a cold continuous rolling unit, conveying the cold rolled strip steel to a flying shear unit, and then using a recoiling machine to recoil the strip steel. The cold rolled strip steel production technology is characterized in that before entering the cold continuous rolling unit, the strip steel is firstly heated by a strip steel heating device, wherein strip steel temperature detectors are arranged at the inlet and the outlet of the strip steel heating device, and used to detect the strip steel temperature at the inlet and the outlet of the strip steel heating device, in order to control heating of the strip steel, enable the strip steel temperature at the outlet of the strip steel heating device to be close to or up to the strip steel targeted temperature before the strip steel enters the rolling mill, so as to meet the required strip steel temperature at the rolling mill inlet. The cold rolled strip steel production technology disclosed by the invention can reduce influence degree of the strip steel temperature to internal friction state of cleaning between the rolls, and improves the lubricating performance in the rolling process, so as to reduce strip steel surface tear defect and rolling mill vibration due to poor lubricating performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Round disc type plant straw uprooting device

InactiveCN102027838BReduce disturbanceReduce power consumptionHarvestersGatherer machinesProduction rateCircular disc

The invention discloses a round disc type plant straw uprooting device, which comprises a machine frame, and left and right push rods which are symmetrically arranged on the left and right sides of the machine frame, wherein a straw holding device is arranged on the upper part of the machine frame; a round disc uprooter is arranged at the lower front of the bracket and consists of left and right round disc slices which are at an angle to each other; blades are arranged on the outer edges of the round disc slices; shafts are arranged at the front ends of the push rods; and the left and right round disc slices are assembled on the left and right shafts through bearings. When the round disc type plant straw uprooting device is used, soil disturbance is small, power consumption is low and operation productivity is high; and the device has a simple structure and is convenient to use and maintain.

Owner:HENAN AGRICULTURAL UNIVERSITY

A fully automatic wire stripping machine wire feeding and pressing mechanism and operation method

ActiveCN111081432BGuaranteed lamination effectGuaranteed cutting effectBasic electric elementsElectronic waste recyclingMachineSingle station

Owner:FEILKE NANJING IND EQUIP

A construction method of lime-soil filling

ActiveCN111794029BConstruction Depth GuaranteeAvoid long-term fatigue workRoadwaysEnvironmental resource managementMechanical engineering

The invention discloses a lime soil filling construction method, which belongs to the field of filling construction. The present invention adopts secondary mixing and paving lime in grids, so that the construction depth of lime soil on site is effectively guaranteed, and the existence of plain soil interlayer is avoided. This method also avoids the depth error caused by the expensive road mixer with automatic depth adjustment, and solves the difficulty that the mixing efficiency cannot be guaranteed due to the size and water content of the concrete material that cannot be guaranteed by humans or machinery. . The use of grid scrapers to pave lime also makes lime paving smoother, liberates the hands of operators, and improves the production efficiency of operations.

Owner:CHINA MCC17 GRP

Novel air switch signboard

The invention discloses a novel air switch signboard. The air switch signboard comprises a signboard sleeve body and a movable plate, wherein a magnet block is fixedly installed at the top of the signboard sleeve body, a limiting plate is fixedly installed at the top of an inner cavity of the signboard sleeve body, and an extension spring is fixedly installed on the side, away from the signboard sleeve body, of the limiting plate; sliding grooves are formed in the two sides of an inner cavity of the sign sleeve body, and sliding blocks are movably installed in the sliding grooves. By arrangingthe movable plates and the iron sheets, different character and color identifiers are printed on the movable plates, then the different movable plates are attracted to the outer sides of the magnet blocks through the iron sheets, then the movable plates are clamped to the outer side of the signboard sleeve body, and different signboard prompts can be replaced according to use conditions; according to the signboard with the safety warning function, the safety warning function and the work prompt function are provided for needed work, the problem that in the using process of the signboard, multiple problems are produced for different signboards is solved, operation is easy, and the work efficiency is improved so as to cope with different work conditions.

Owner:JIANGSU ELECTRIC POWER CO

A kind of foreign matter vacuum cleaner used in backlight module

ActiveCN109954725BAvoid wrinkles and other defectsImprove job productivityCleaning using gasesForeign matterAdsorptive membrane

The invention discloses a dust-absorbing pen for foreign objects in a backlight module. The dust-absorbing pen includes a penholder, one end of the penholder is provided with a pen tip, one end of the pen tip is fastened to the penholder through a thread structure, and the other end is fastened through a thread structure. A dust suction cover is connected, a support is arranged in the pen holder, and an air filter is arranged in the pen holder, between the support and the pen tip. The dust suction pen of the present invention absorbs foreign matter on the diaphragm through vacuum negative pressure, and absorbs the foreign matter on the air filter element, and the dust suction pen does not contact the diaphragm during the entire adsorption process, avoiding diaphragm pollution, diaphragm folds and other defects. Improve the production efficiency of the backlight module operation in the electronics industry and improve the production yield of the backlight module in the electronics industry; the air filter element is detachable, which facilitates timely cleaning and replacement of the adsorbed foreign matter; replaces the traditional use of sticky dust sticks to improve the production line diaphragm Foreign matter situation reduces the occurrence of defective products and improves production efficiency.

Owner:博讯光电科技(合肥)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com