Temperature control mechanism for electronic component bonding device, method and test equipment provided with same

A technology of electronic components and temperature control mechanism, which is applied to auxiliary controllers with auxiliary heating devices, temperature control and measuring devices using electric methods, and can solve the problems of inability to provide, increase test time, and inability to use different batches of electronic components Test and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order for the examiner to have a further understanding of the present invention, a preferred embodiment is hereby given together with the drawings, and the details are as follows:

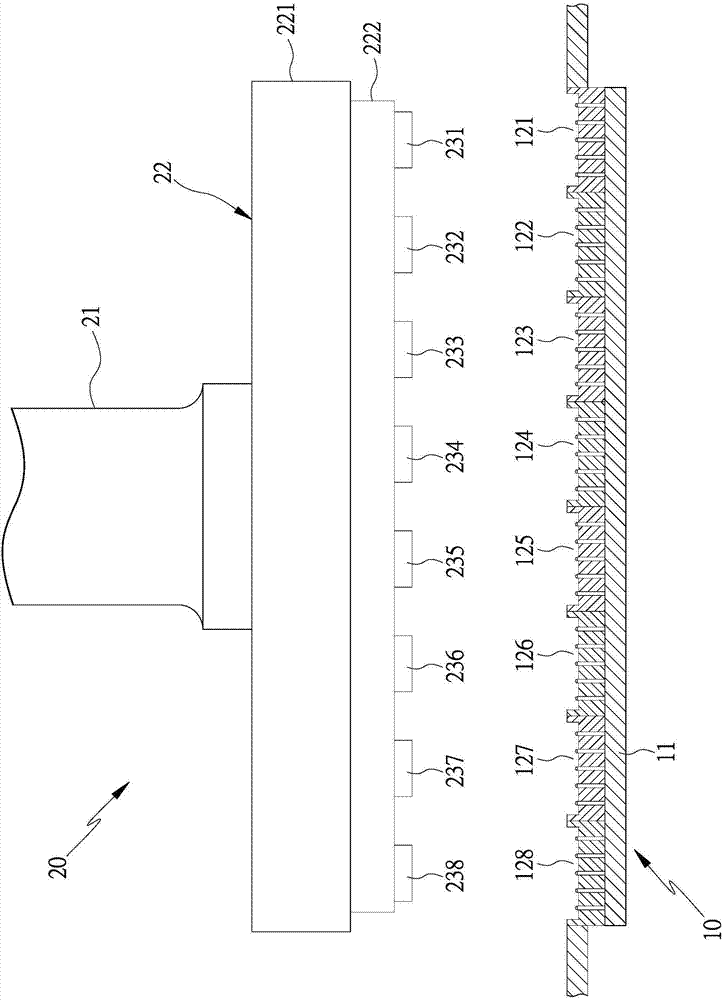

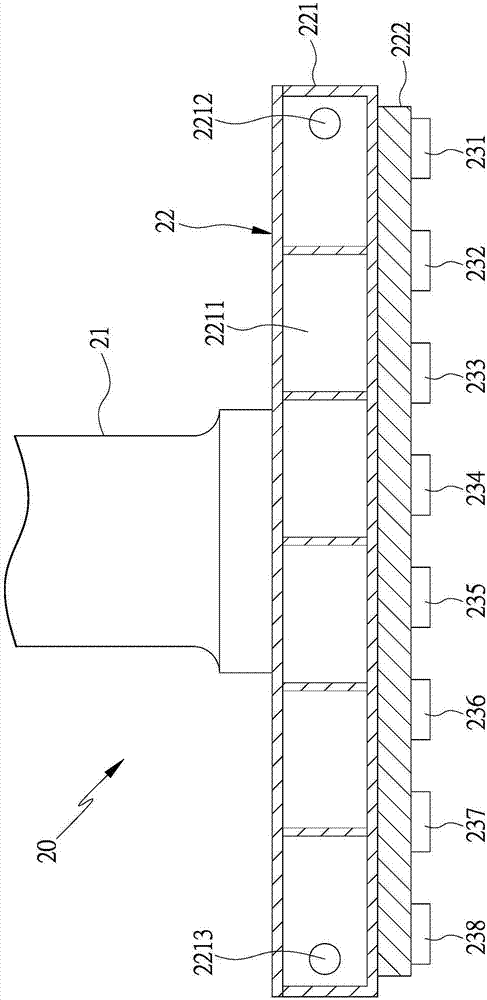

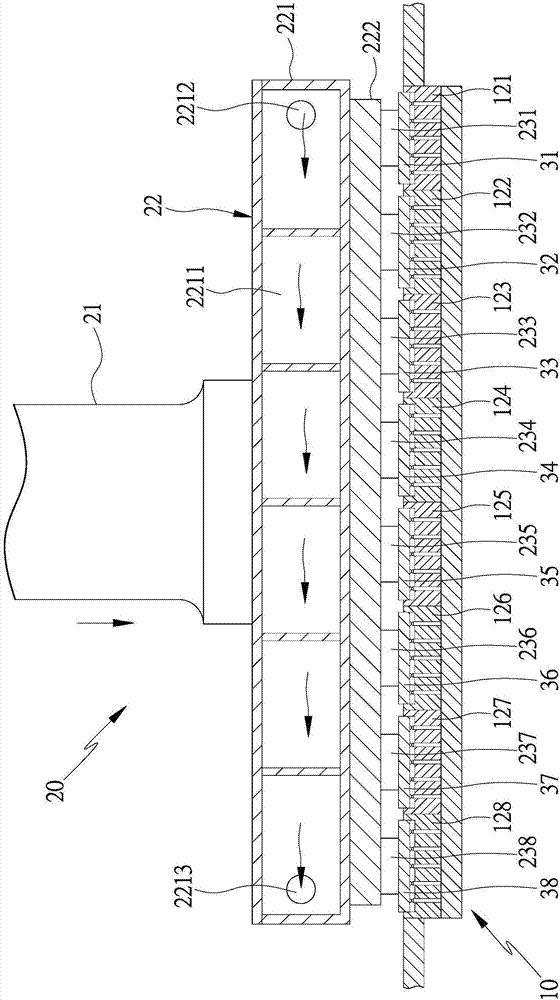

[0043] like Figure 4 , Figure 5 As shown, the joint device 40 in the present invention is provided with a moving arm 41 that moves in at least one direction. In this embodiment, the moving arm 41 is driven by a driving source (not shown) to move in the Z direction, and the joint The device 40 is equipped with a temperature control mechanism 42 below the moving arm 41. The temperature control mechanism 42 is provided with a cooling module 421 with a cold source. The cold source can be a cryogenic fluid (such as a refrigerant) or a cooling chip. In this embodiment Among them, the cooling module 421 is installed under the moving arm 41, and an S-shaped flow channel 4211 is provided inside. One end of the flow channel 4211 is connected to a fluid input pipe 4212 that can input low-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com