Patents

Literature

51results about How to "Achieve spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

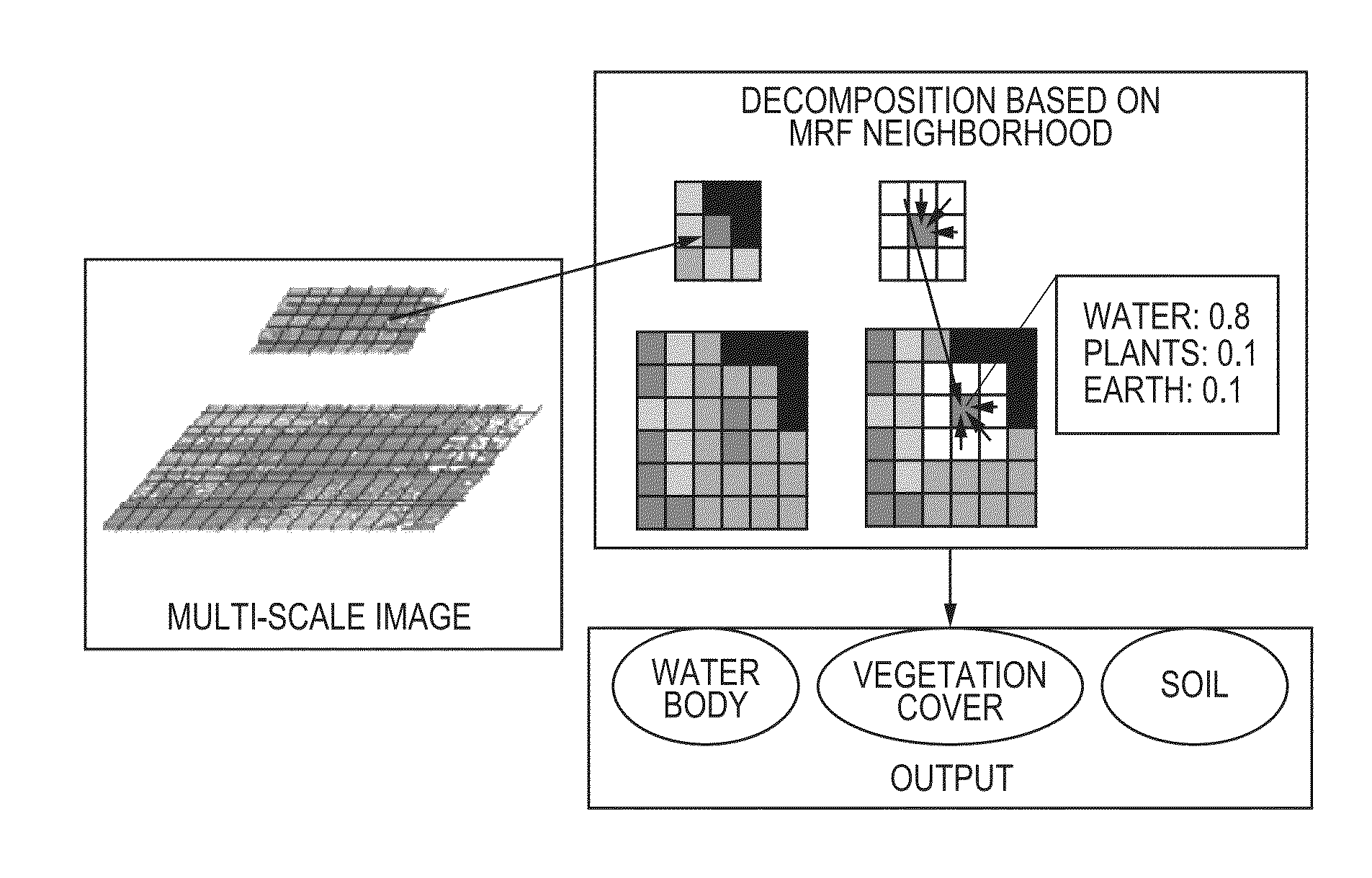

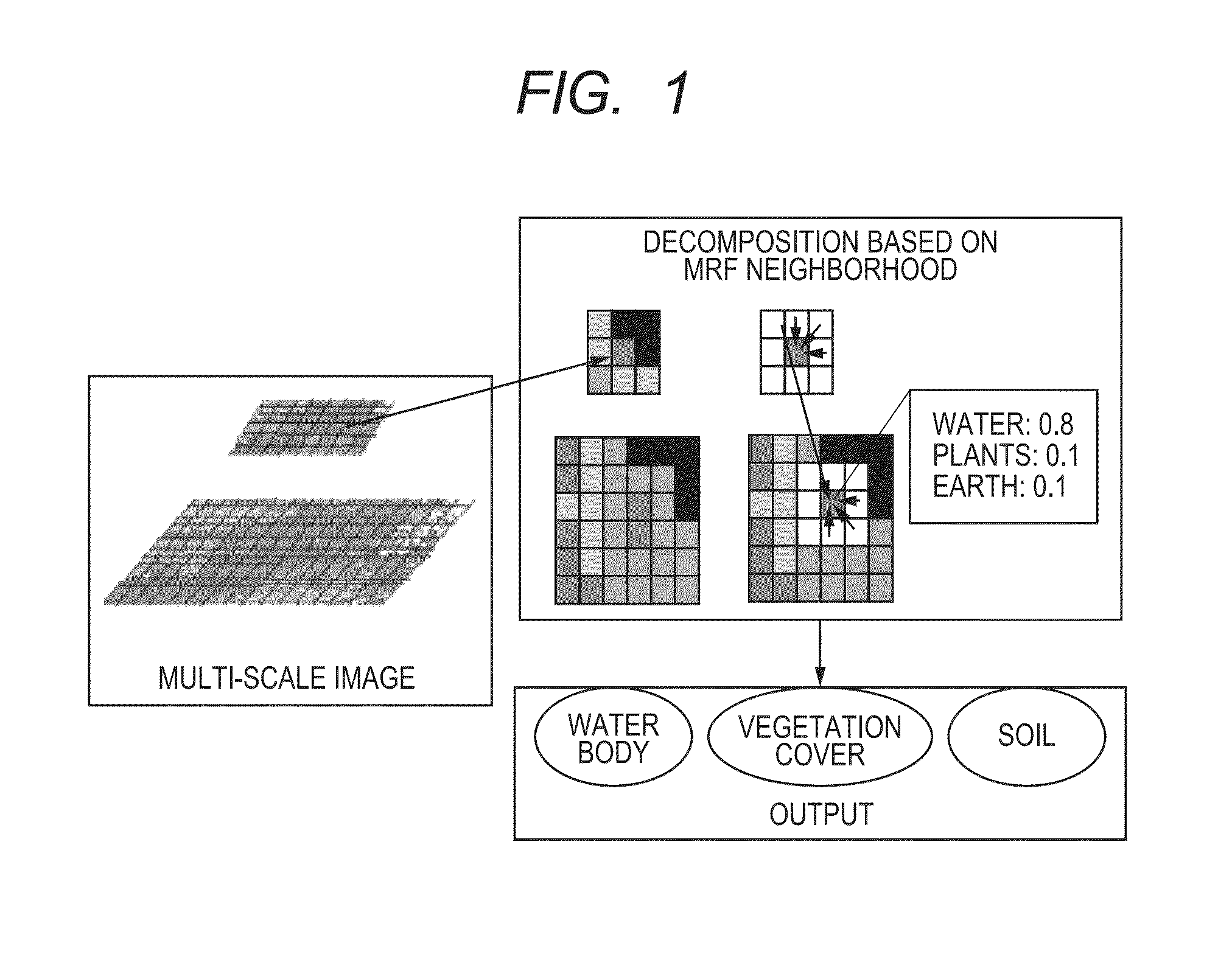

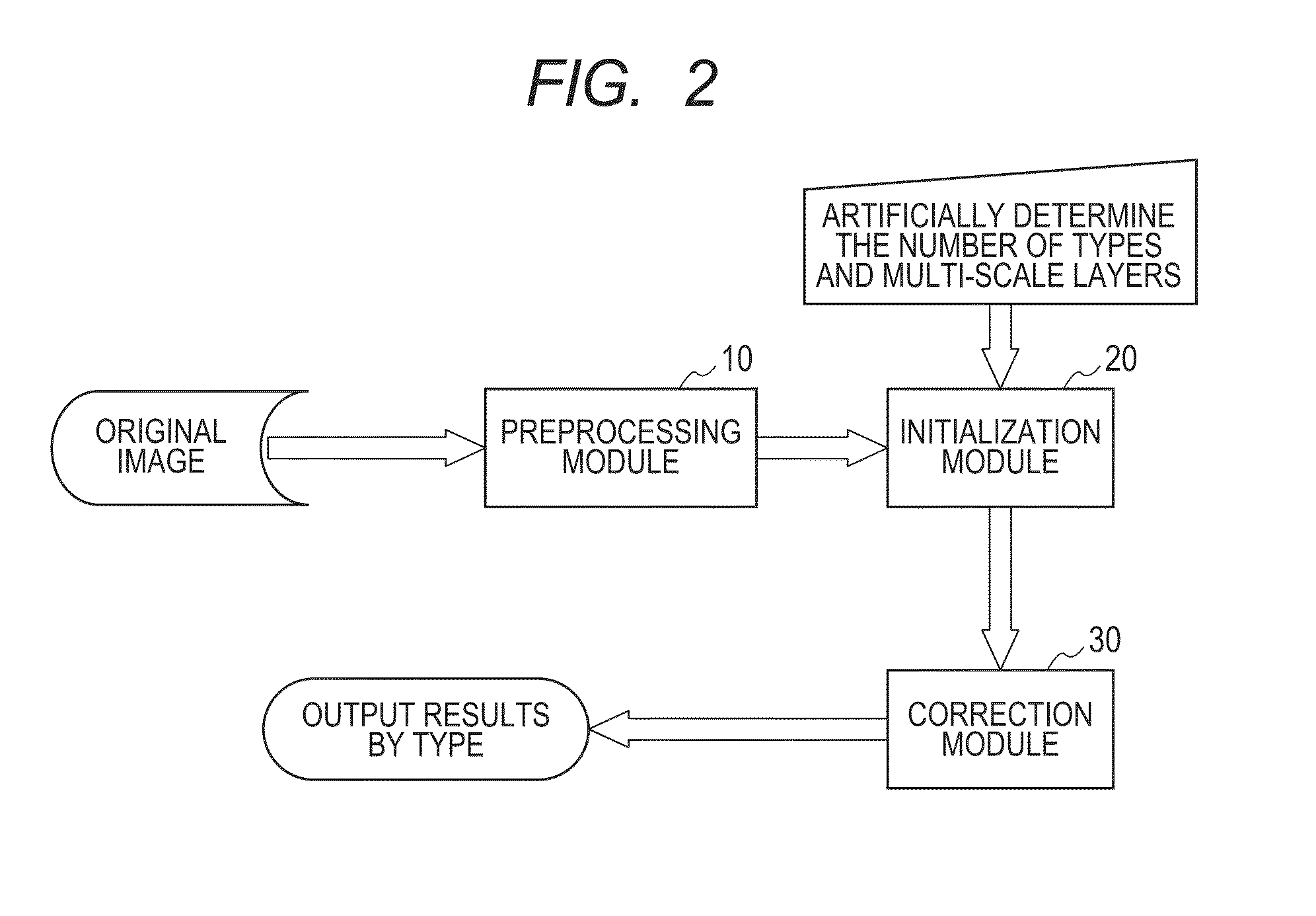

Decomposition apparatus and method for refining composition of mixed pixels in remote sensing images

ActiveUS20130336540A1Accurate land cover informationImprove accuracyImage enhancementImage analysisLand coverDecomposition

To achieve space correlation of pixel decomposition results and reduce noise problem caused by isolation, there is provided a decomposition apparatus and method for refining composition of mixed pixels in remote sensing images, including: a preprocessing step for temporarily determining the provability value of the composition ratio of the different land cover types of each pixel in the image, based on a received remote sensing image and spectral information, to obtain first material composition information; and a neighborhood correlation calculation step for analyzing the correlation between a main pixel and the neighboring areas by using the first material composition information of each of the pixels present in the neighboring areas within a predetermined range in which the pixels are adjacent to each other, and optimizing the first material composition information of the main pixel by the result of the correlation analysis, to obtain second material composition information.

Owner:HITACHI LTD

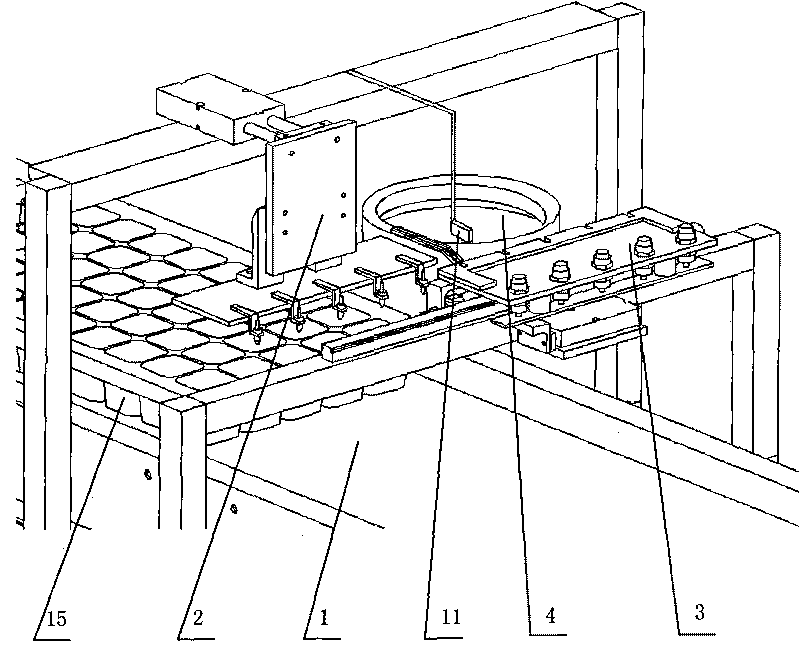

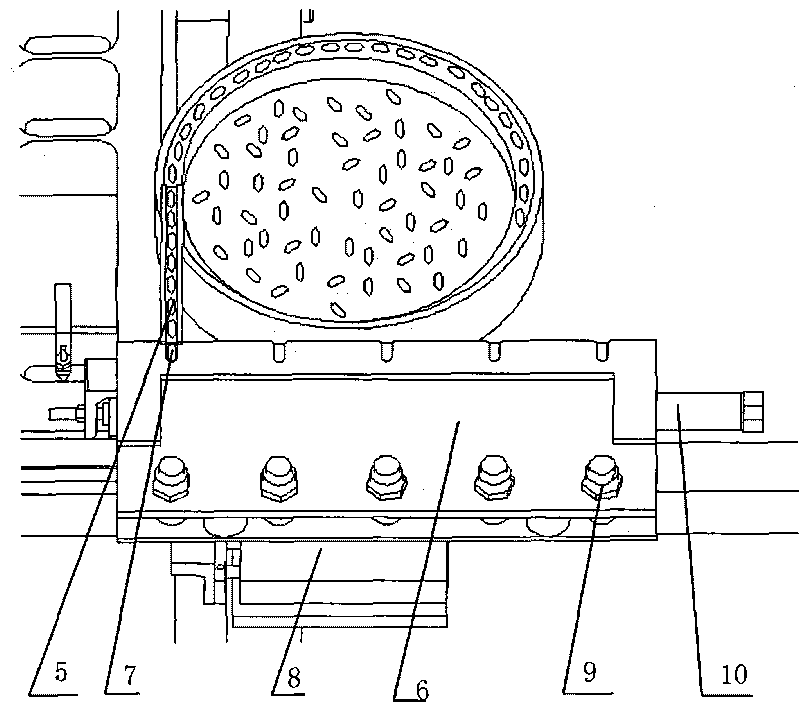

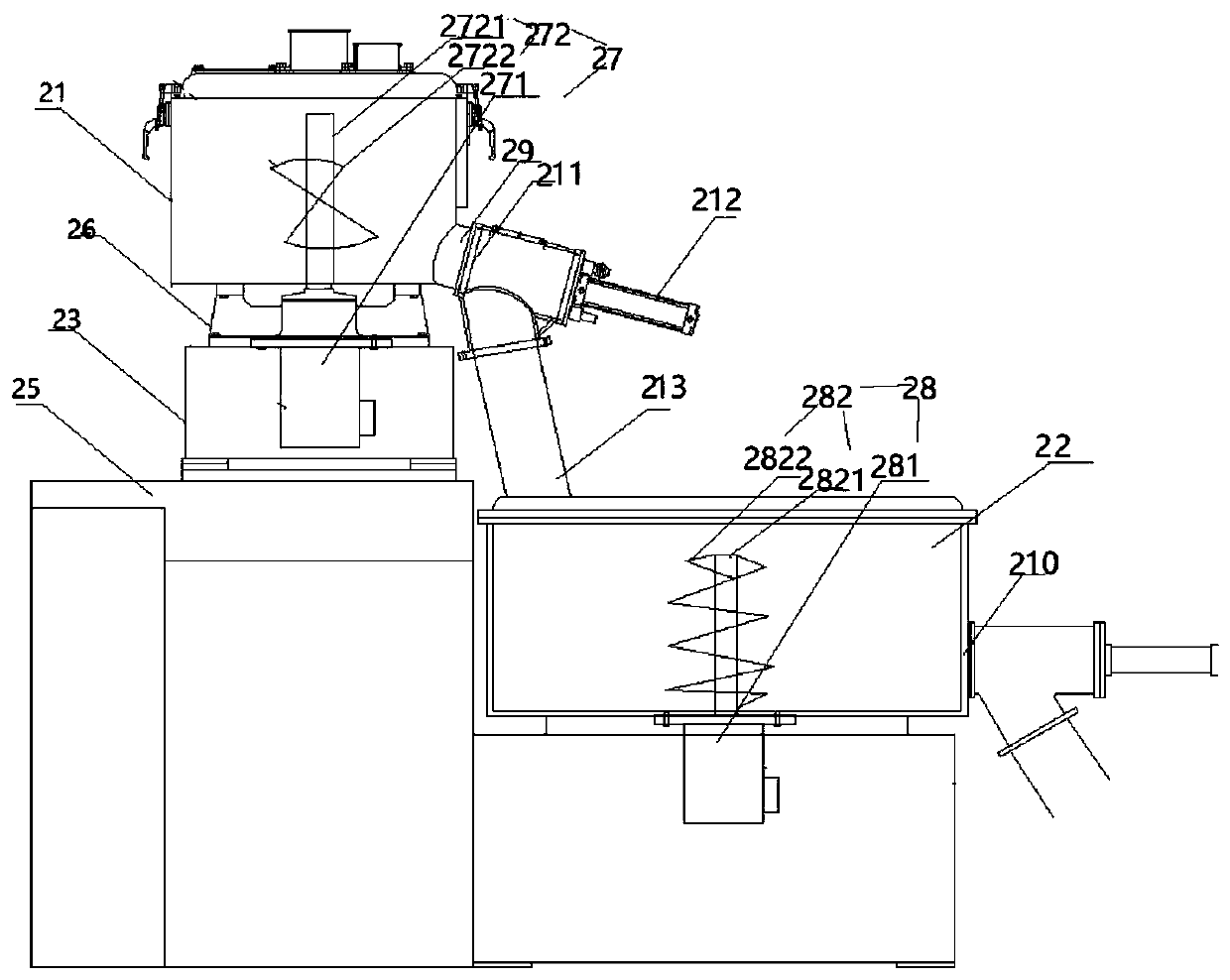

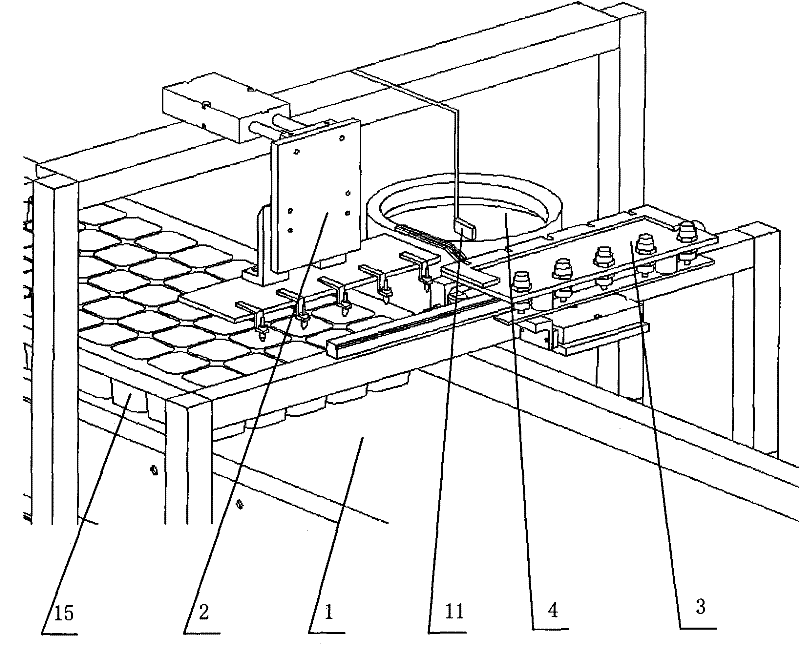

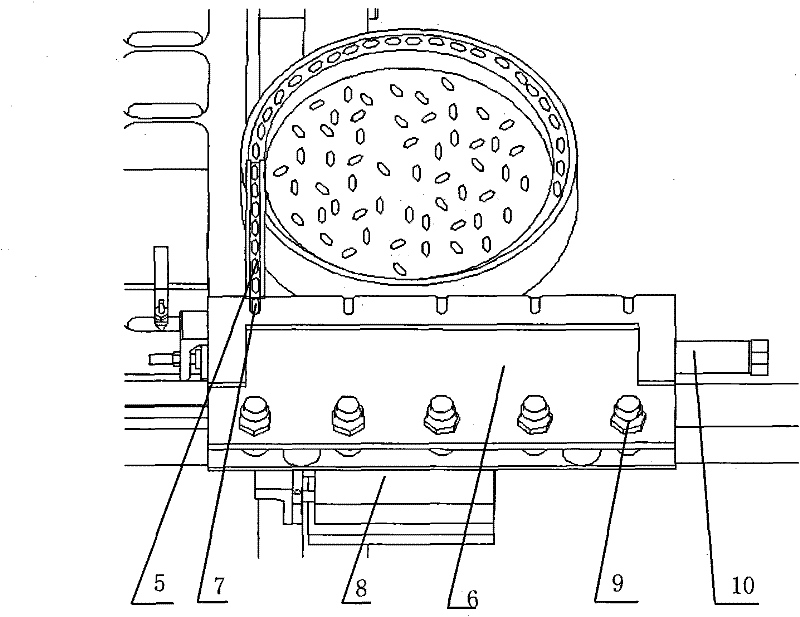

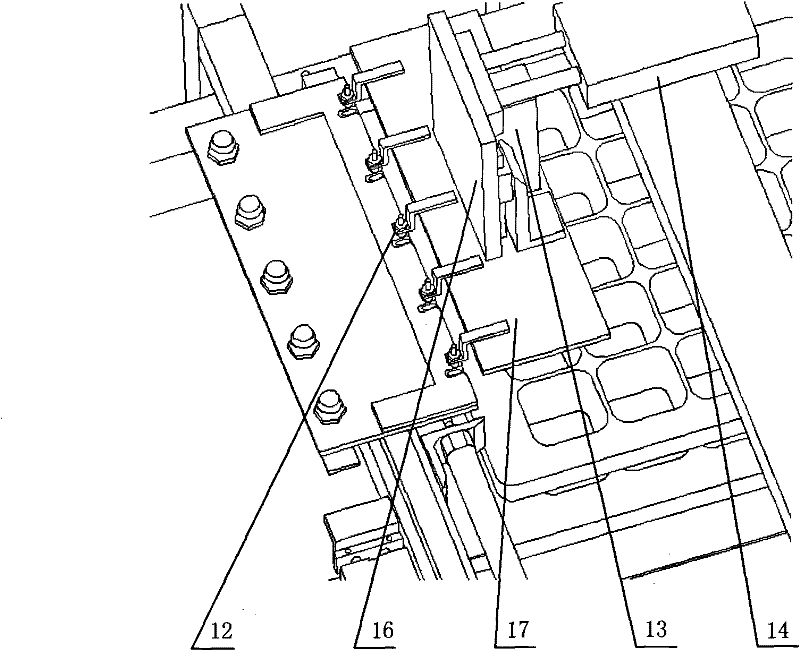

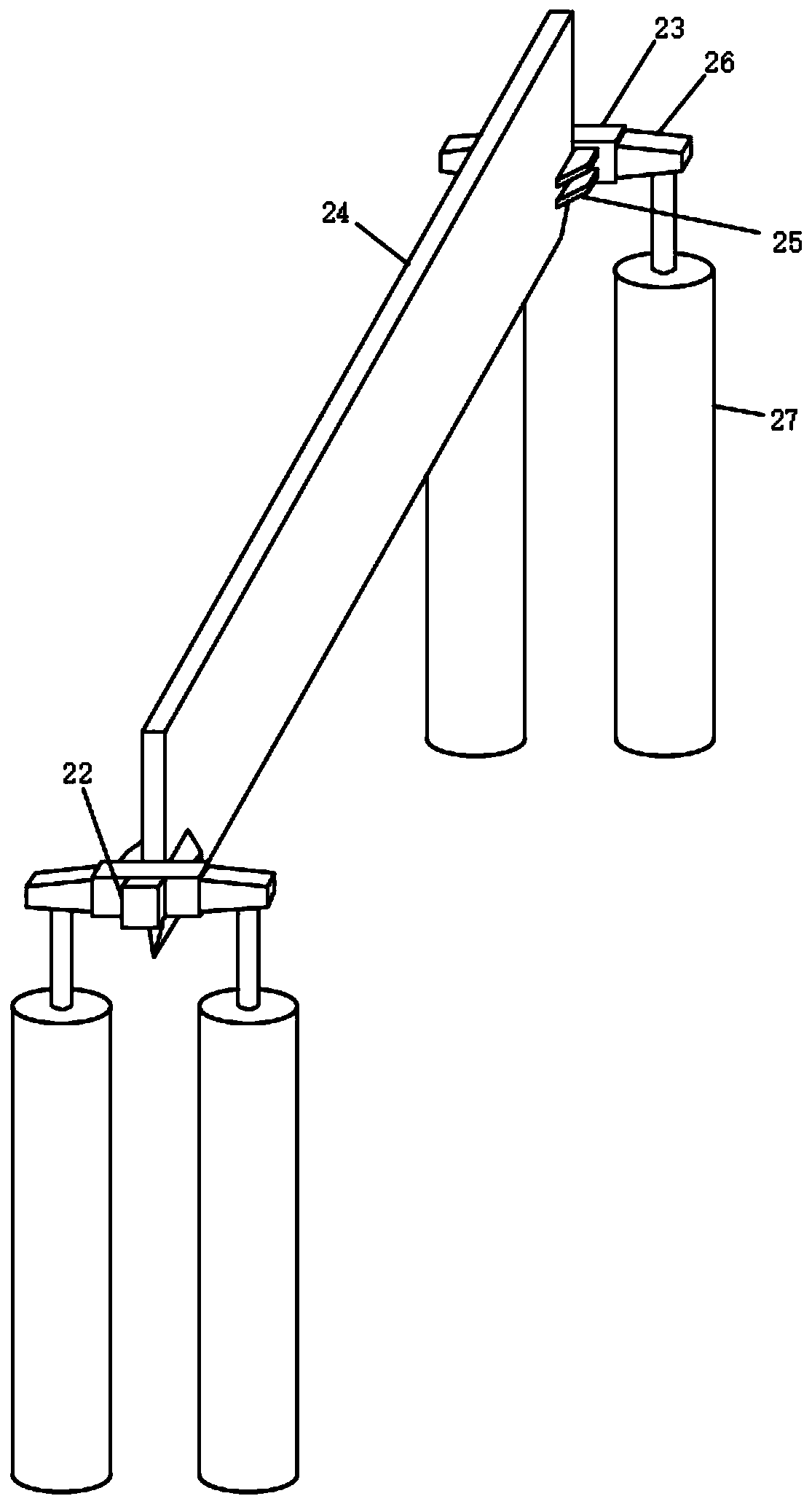

Long grained seed steering precision seeding device and seeding method thereof

InactiveCN101702969ATo achieve the purpose of batch directional seedling cultivationImprove job productivitySeed depositing seeder partsProduction rateEngineering

The invention provides a long grained seed steering precision seeding device comprising a plug conveyer belt, a directional seed delivering device, a directional seed dividing mechanism and an air-aspiration seeding mechanism, wherein the directional seed delivering device and the direction seed dividing mechanism are connected and are arranged at the same side of the plug conveyer belt; the air-aspiration seeding mechanism is arranged above the plug conveyer belt; a seed delivering slide way is arranged in the tangential direction of the edge of the directional seed delivering device; the seed delivering slide way and the directional seed dividing mechanism are connected; and the plug conveyer belt, the directional seed delivering device, the directional seed dividing mechanism and the air-aspiration seeding mechanism are fixed on a stand. The invention also provides a seeding method for realizing the seeding device; long grained seeds are delivered and absorbed into the hole of a plug respectively by the directional seed delivering device, the directional seed dividing mechanism and the air-aspiration seeding mechanism, thereby realizing precision seeding. The invention can provide seedlings with even germination and uniform cotyledon direction for melon crop full automatic engrafting devices and other equipment and has the advantages of high work productivity, stable work quality and the like.

Owner:SOUTH CHINA AGRI UNIV

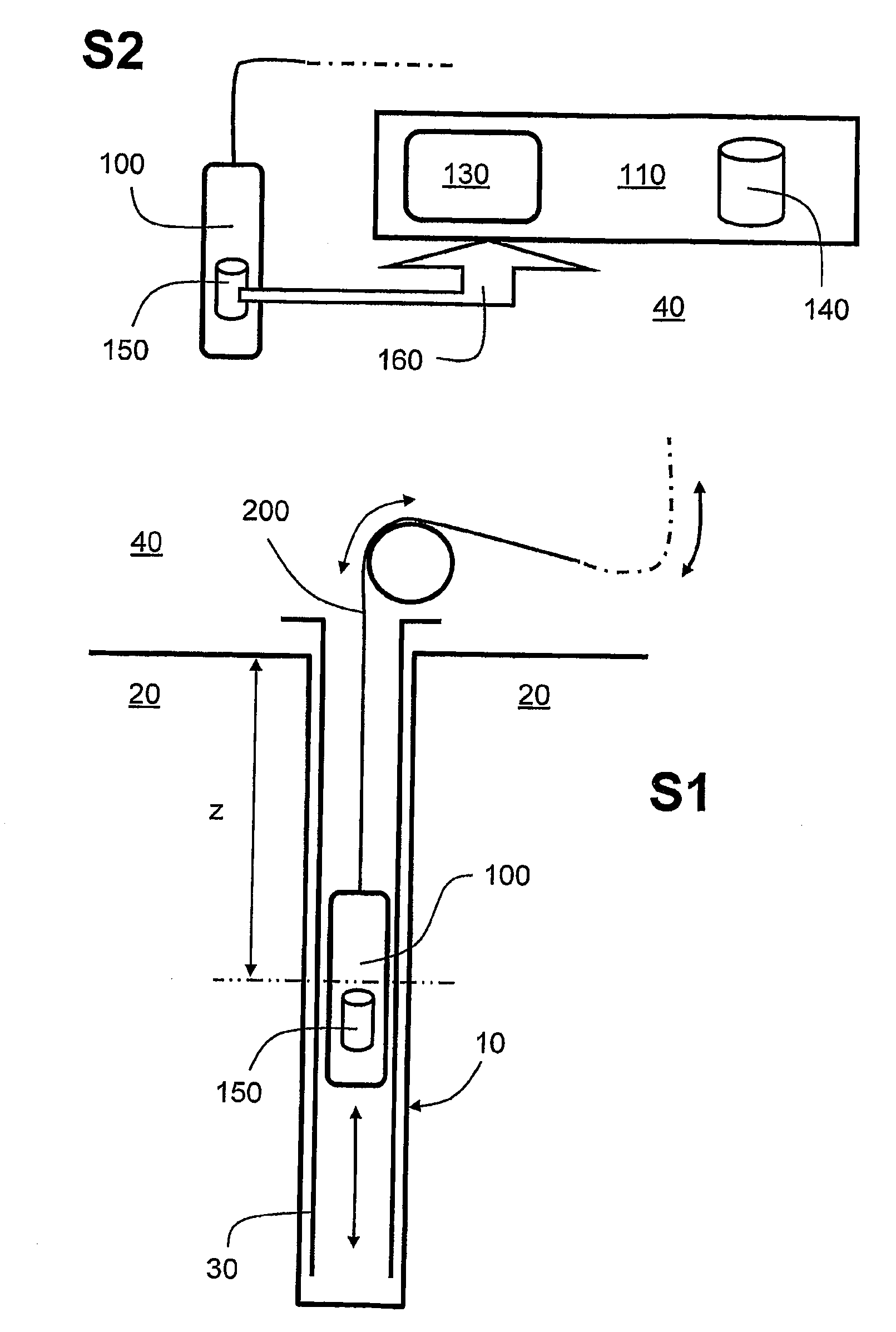

Monitoring system

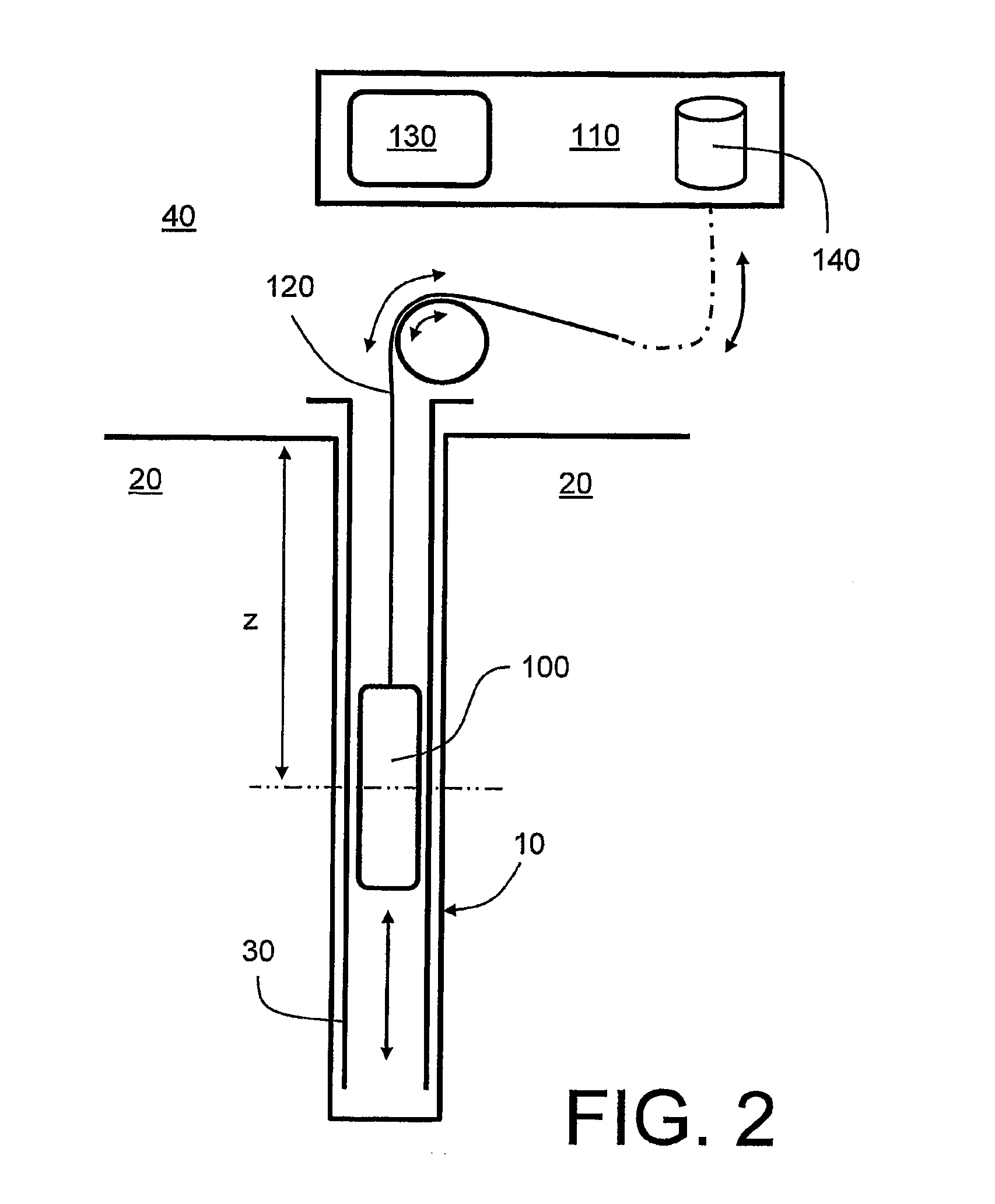

InactiveUS20110087434A1Real time monitoringAchieve spacingElectric/magnetic detection for well-loggingSurveyDigital signal processingMonitoring system

There is provided a monitoring system (300) for monitoring within a borehole (10). The system (300) comprises a probe assembly (100) operable to be moved within the borehole (10) for sensing one or more physical parameters therein, a data processing arrangement (110) located outside the borehole (10), and a data communication link (120) operable to convey sensor data indicative of the one or more physical parameters from the probe assembly (100) to the data processing arrangement (110) for subsequent processing and display and / or recording in data memory (140). The probe assembly (100) includes one or more sensors (320) for spatially monitoring within the borehole (10) and generating corresponding sensor signals (360). Moreover, the probe assembly (100) includes a digital signal processor (310) for executing preliminary processing of the sensor signals (360) to generate corresponding intermediately processed signals (370) for communication via the data communication link (120) to the data processing arrangement (110). Furthermore, the data processing arrangement (110) is operable to receive the intermediately processed signals (370) and to perform further processing on the intermediately processed signals (370) to generate output data for presentation (130) and / or for recording in a data memory arrangement (140). The system (300) is of benefit in that it enables real-time spatial monitoring of the borehole (10) to be achieved.

Owner:BERGEN TECH CENT

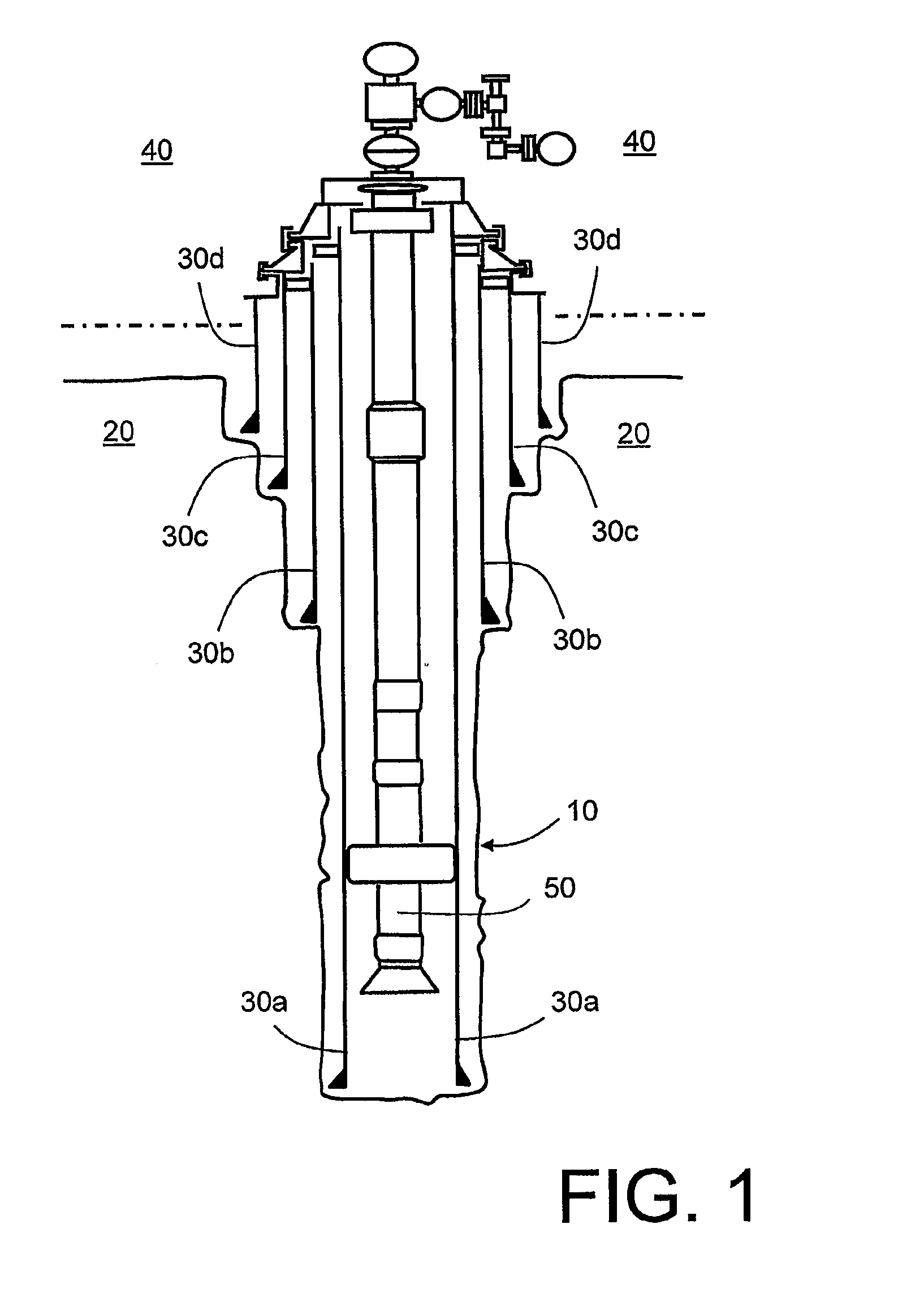

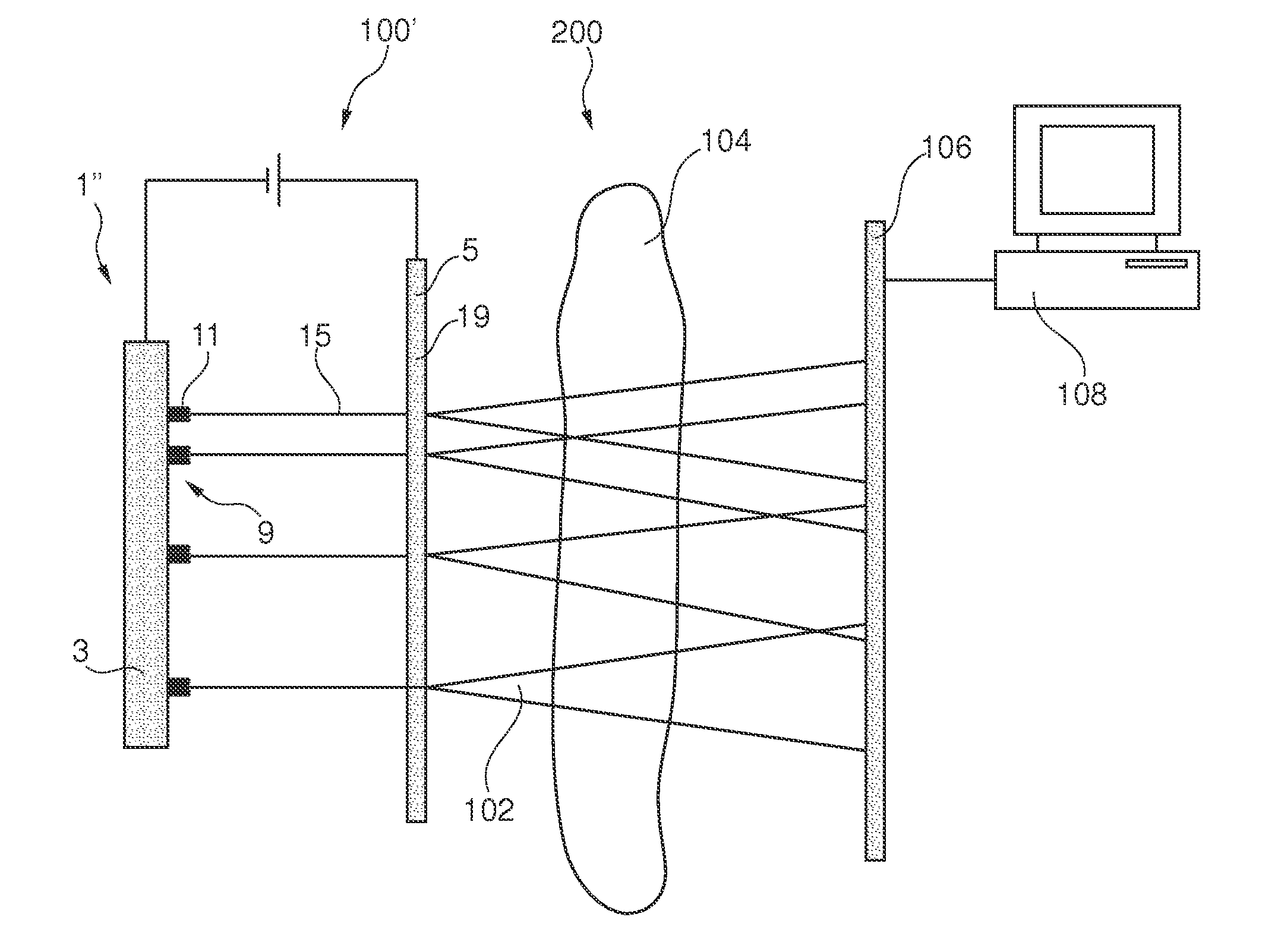

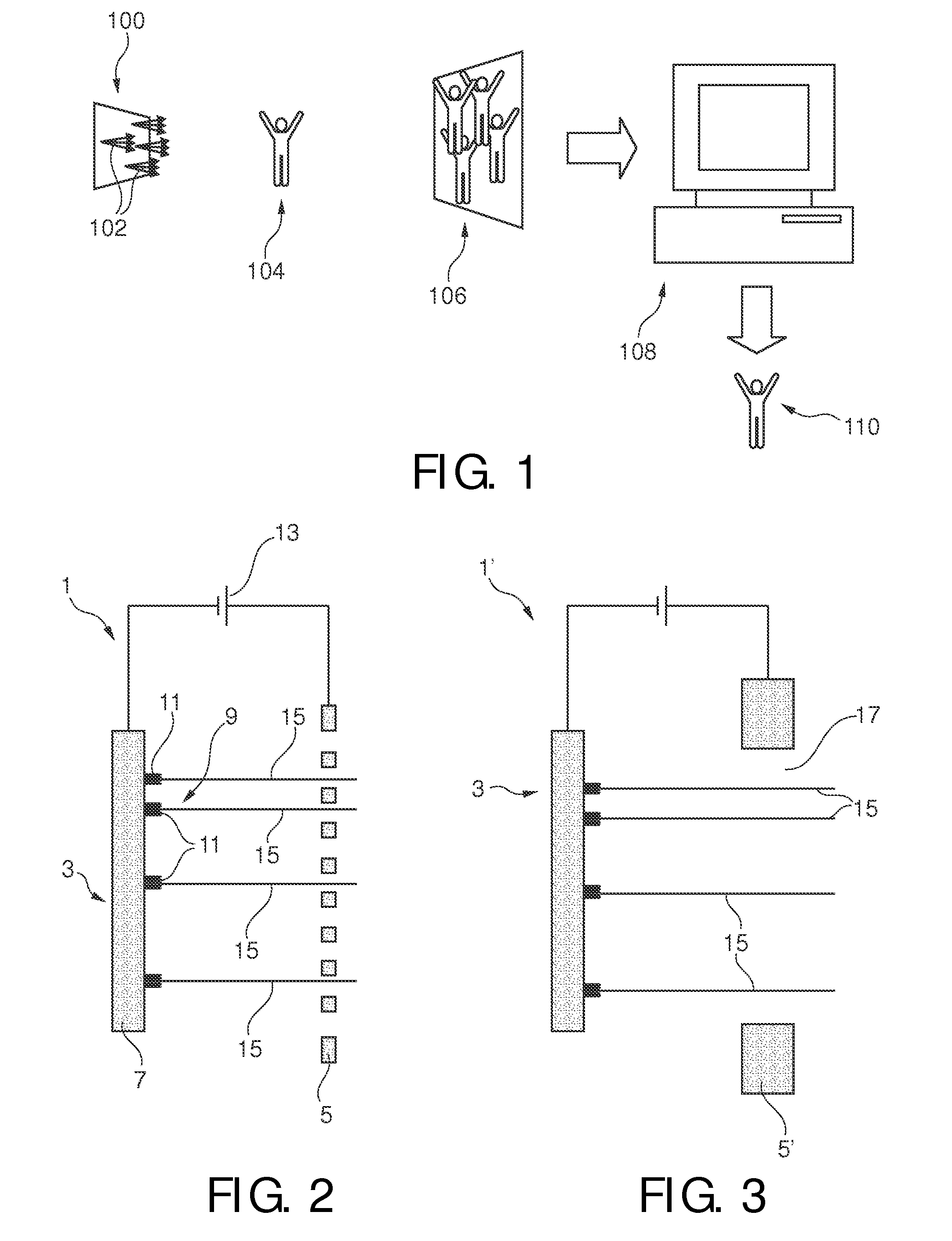

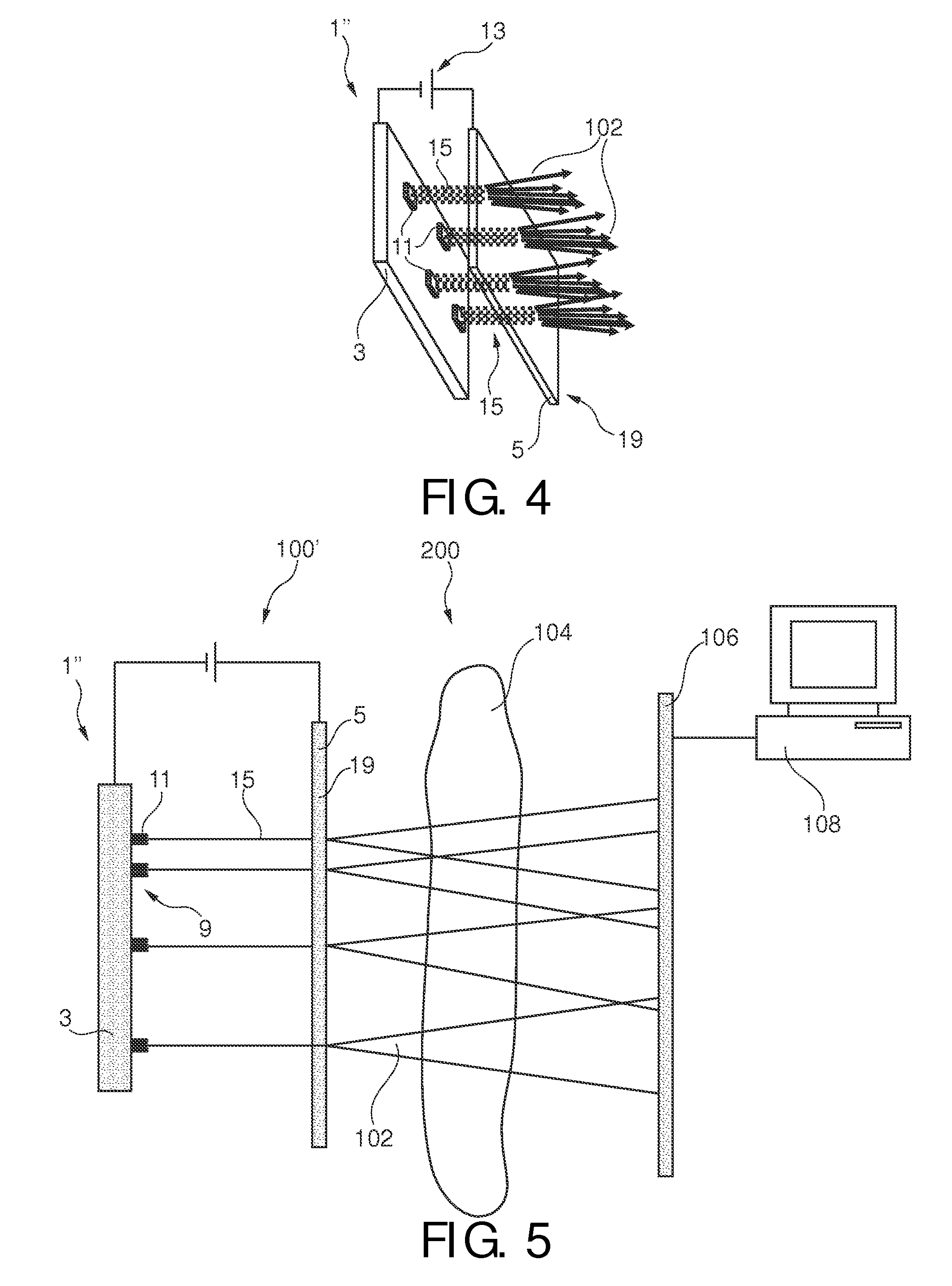

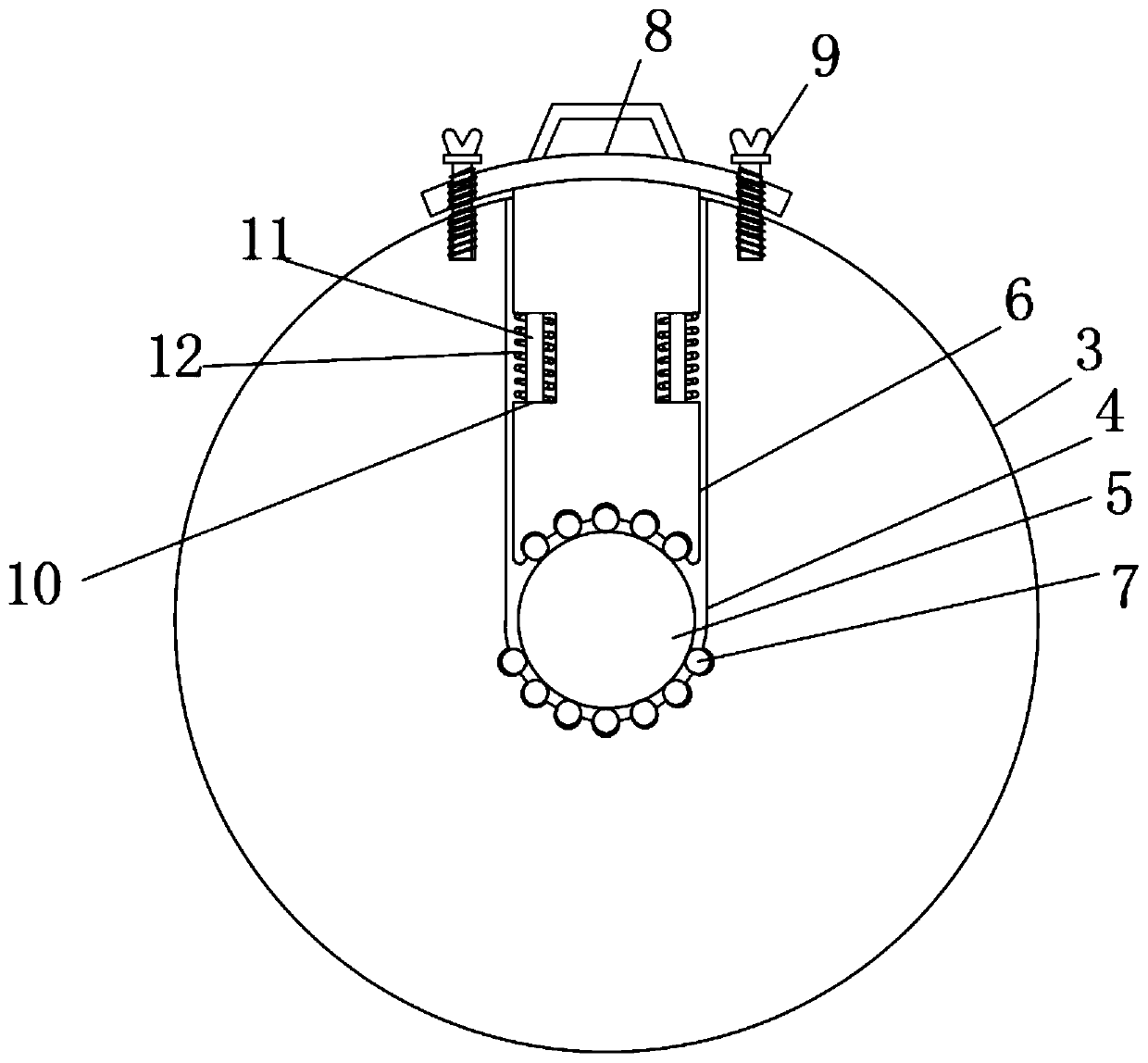

Structured electron emitter for coded source imaging with an x-ray tube

InactiveUS20120027173A1High mechanical strengthGood effectX-ray tube electrodesNanoopticsImage resolutionX-ray

An electron emitter (1) and an X-ray tube (100) comprising such electron emitter (1) are presented. The electron emitter (1) comprises a cathode (3) and an anode (5) wherein the cathode (3) comprises an electron emission pattern (9) of a plurality of local areas (11) spaced apart from each other, each area being adapted for locally emitting electrons via field emission upon application of an electrical field between the cathode (3) and the anode (5). Electron beams (15) emitted from the local areas (11) may generate several X-ray source intensity maxima in a specific geometric pattern. An apparent loss in spatial resolution due to overlapping images on a detector can be corrected by using specific intensity patterns for the X-ray source (100) and by applying dedicated decoding algorithms on the acquired image such as coded source imaging (CSI).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

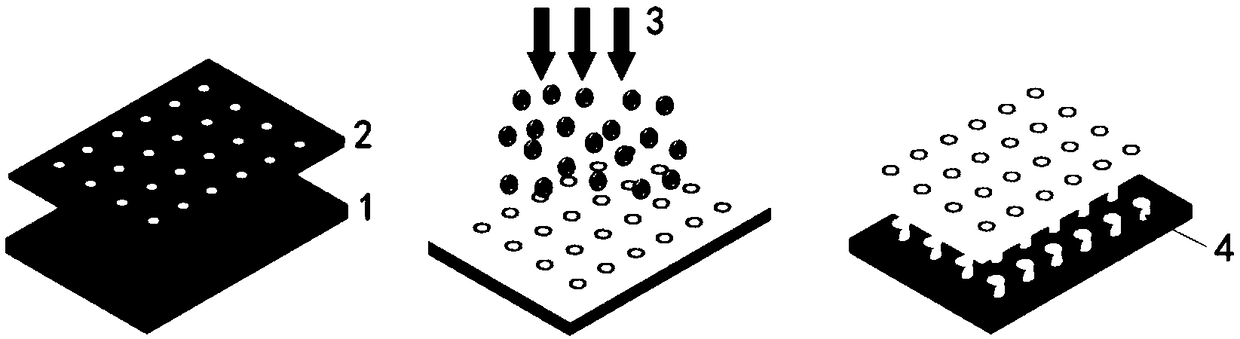

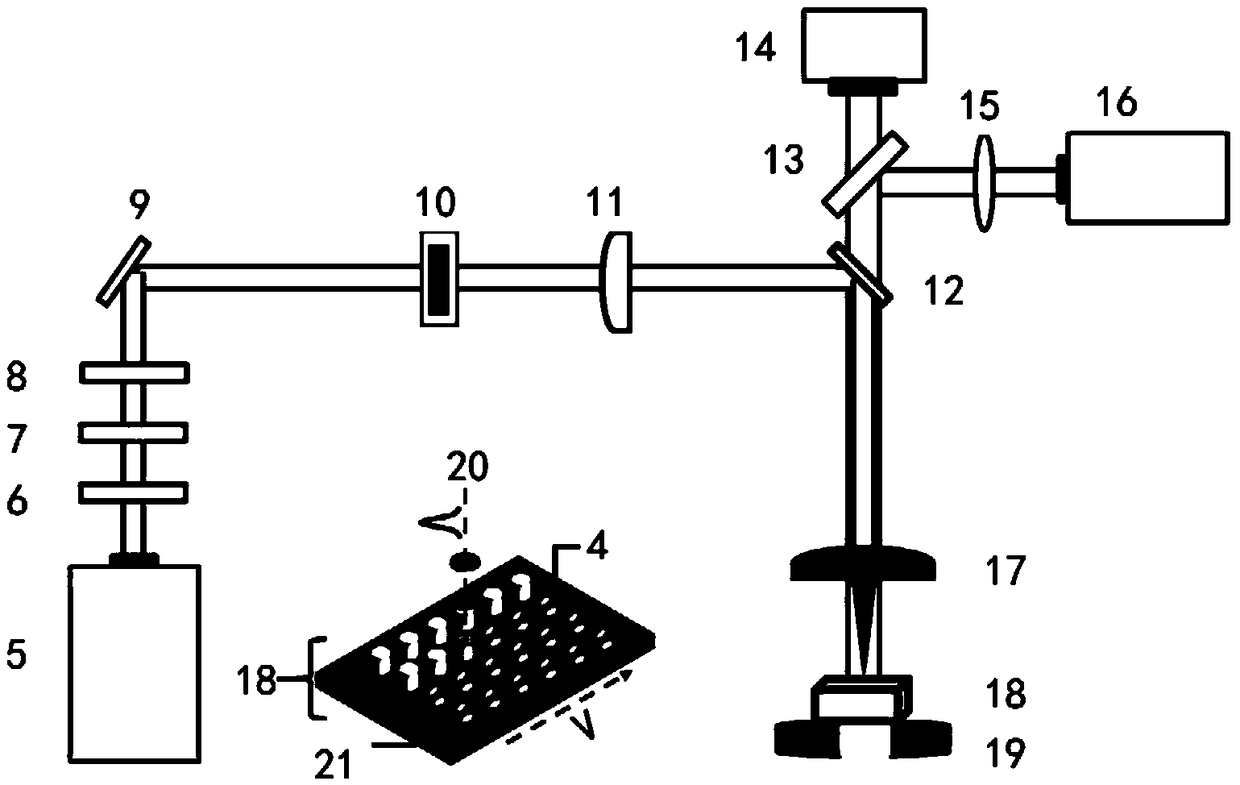

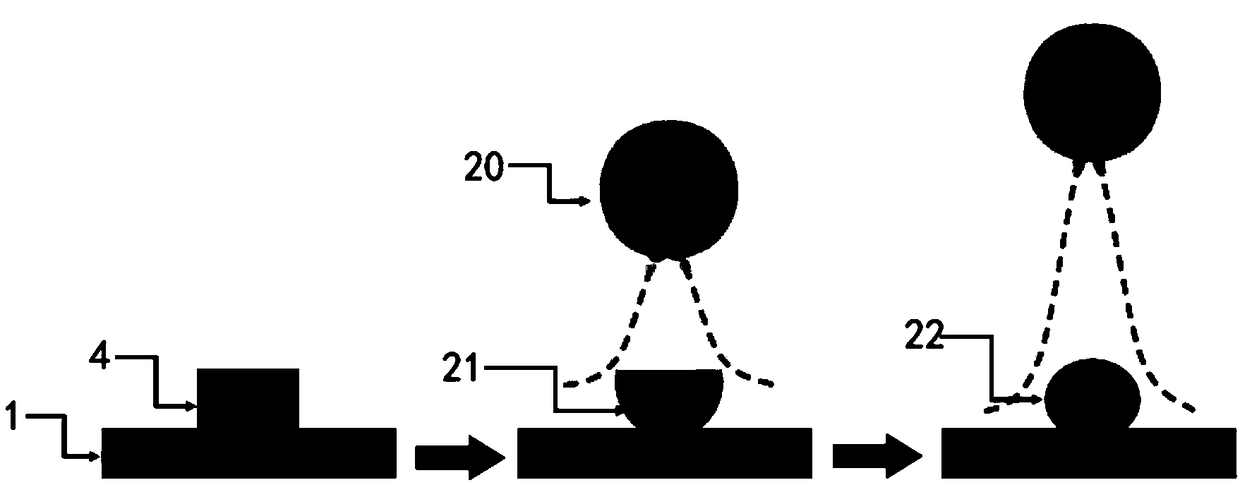

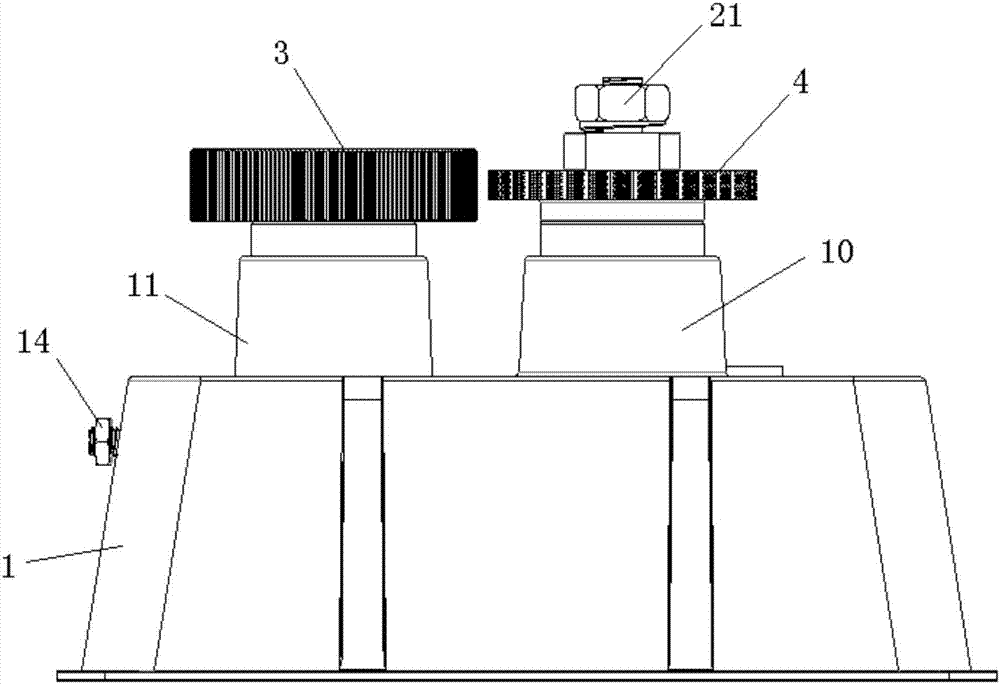

Femtosecond laser manufacturing method for tunable phase change nanostructure super surfaces

ActiveCN109434289ASimple and preciseAchieve spacingVacuum evaporation coatingSputtering coatingHolographic imagingPhase state

The invention relates to a femtosecond laser manufacturing method for tunable phase change nanostructure super surfaces, and belongs to the technical field of femtosecond laser application. The femtosecond laser manufacturing method aims to solve the problem that in the current super-surface nanostructure processing process, the technology is complicated, and the shortcomings of accurate, efficient, orderly and large-area processing of nano structure units exist are solved. According to a femtosecond laser manufacturing method, the expected morphology of the nano structure is prepared in accurate, efficient, orderly and large-scope manner with the relatively-simple technology, instantaneous electronic excitation dynamics during action of femtosecond laser and phase-change material surfacesare regulated, modulation of the distance, the morphology, the phase state and the arranging manner of the nano structure units of the phase-change material super surfaces and large-format manufacturing and modification are achieved. Critical application values are achieved in the aspects of gradient super-surfaces, information storage, holographic imaging, electromagnetic wave manipulation, switchable or reconfigurable components and the like.

Owner:BEIJING UNIV OF TECH

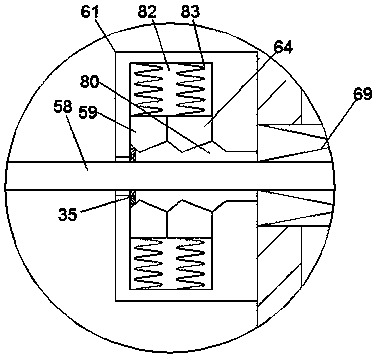

Resistance-type moisture meter with grinding mechanism

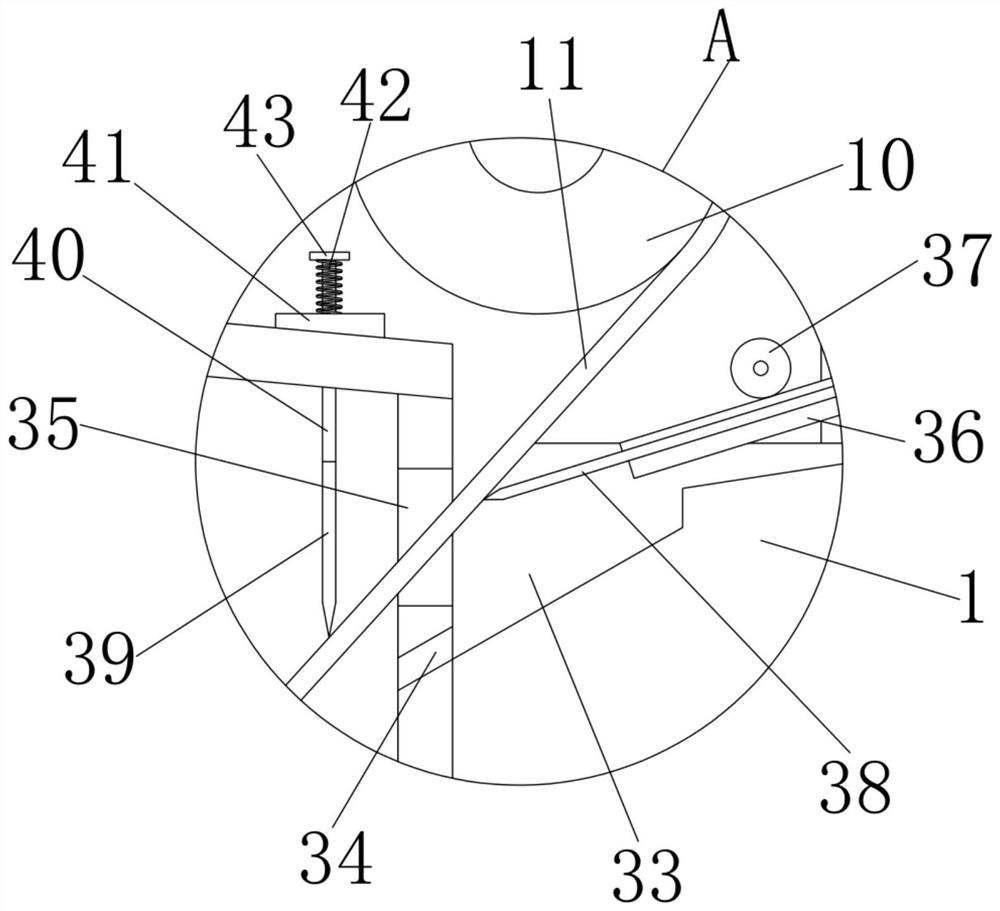

InactiveCN107238633AAchieve spacingReduce use costPreparing sample for investigationMaterial resistanceDrive shaftEngineering

The invention discloses a resistance-type moisture meter with a grinding mechanism. The resistance-type moisture meter comprises a shell, wherein a grinding module is arranged in the shell through a driving shaft; the grinding module comprises a wide grinding wheel and a narrow grinding wheel; a bearing base of the wide grinding wheel is fixedly arranged on a slide block; a pushing plate is fixed at the bottom of the slide block; the pushing plate is fixedly provided with an adjusting screw rod which is horizontally arranged on a side wall of the shell; a threaded hole for thread connection with the adjusting screw rod is formed in the side wall of the shell; one end of the adjusting screw rod is fixedly provided with the pushing plate; the other end of the adjusting screw rod penetrates through the threaded hole and extends to the exterior of the shell; a sliding slot for mounting the pushing plate is formed in the shell; the length of the sliding slot is more than the length of the pushing plate; the width of the sliding slot is matched with the pushing plate; the sliding direction of the slide block is parallel to a connecting line of the circle center of the wide grinding wheel and the circle center of the narrow grinding wheel. The resistance-type moisture meter can adjust the distance between the wide grinding wheel and the narrow grinding wheel at any time, so that the use scope of the grinding device is widened and the cost is saved.

Owner:HEFEI AIRUIDE ELECTRICAL

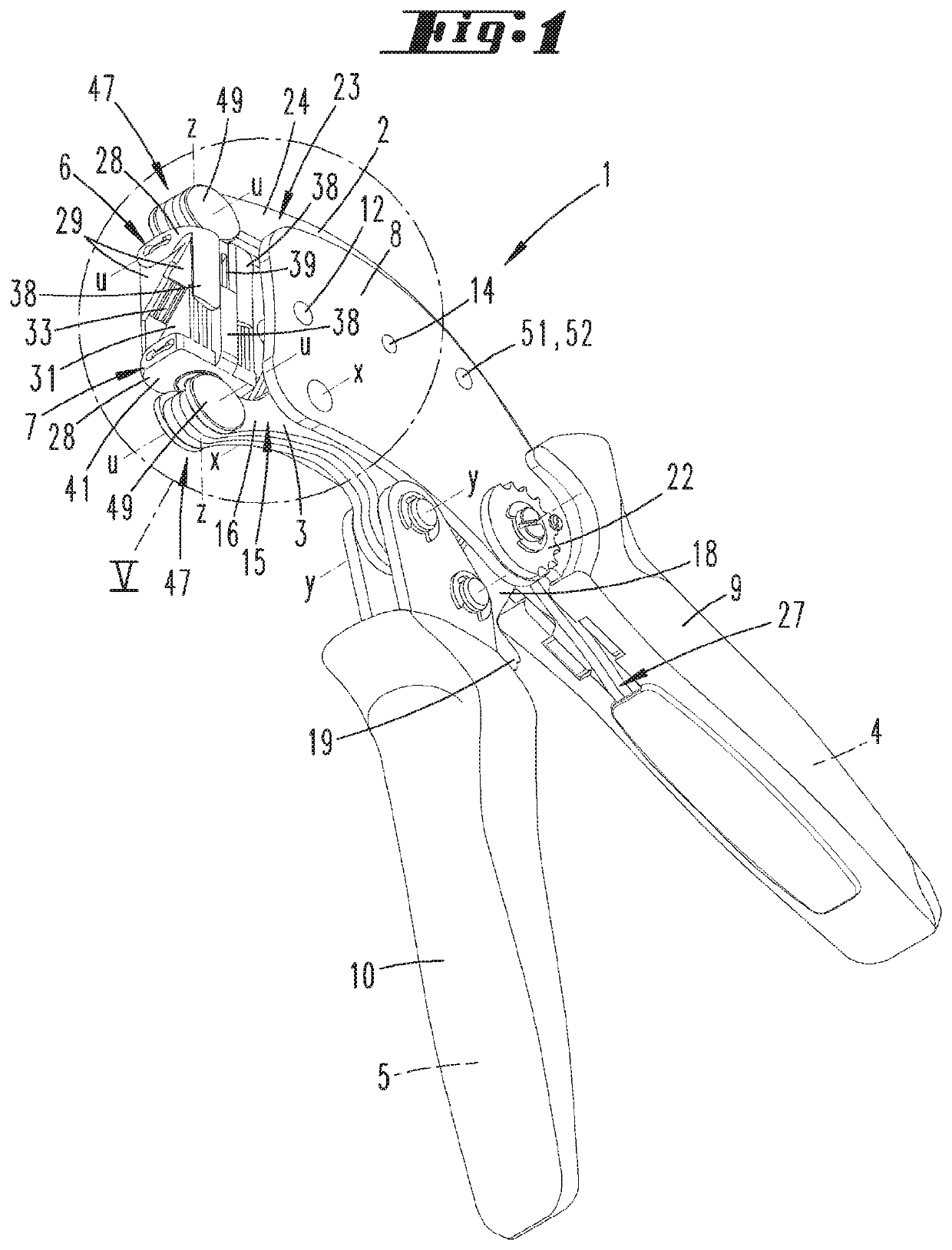

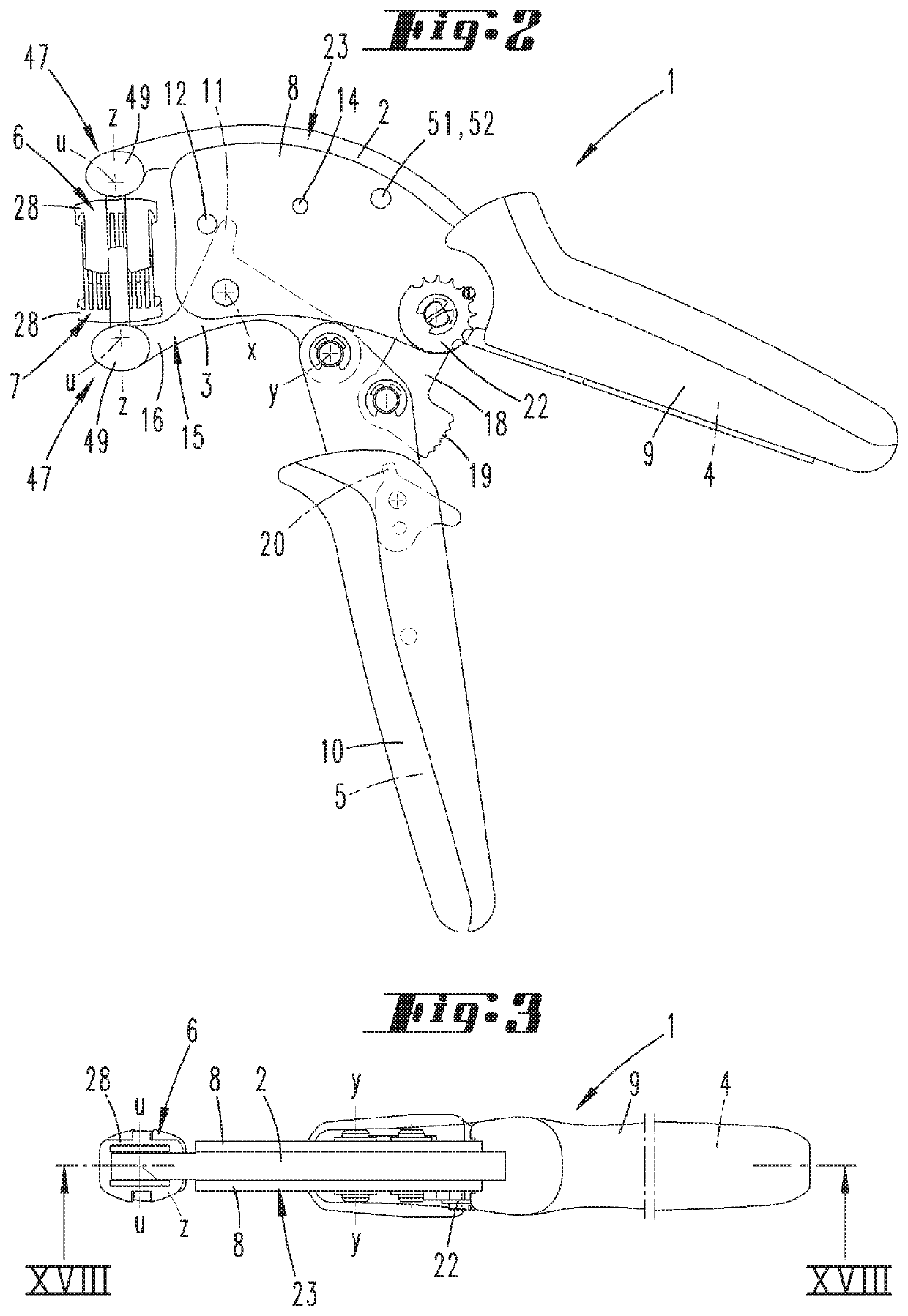

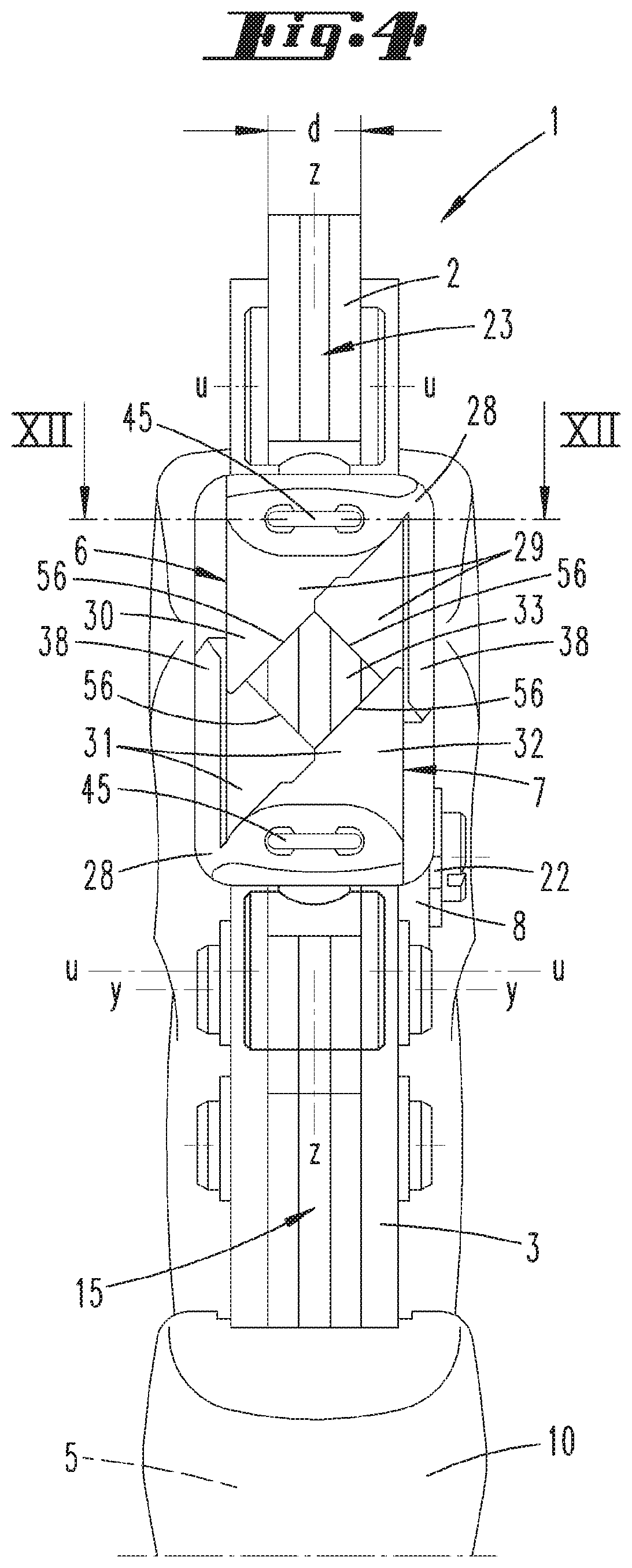

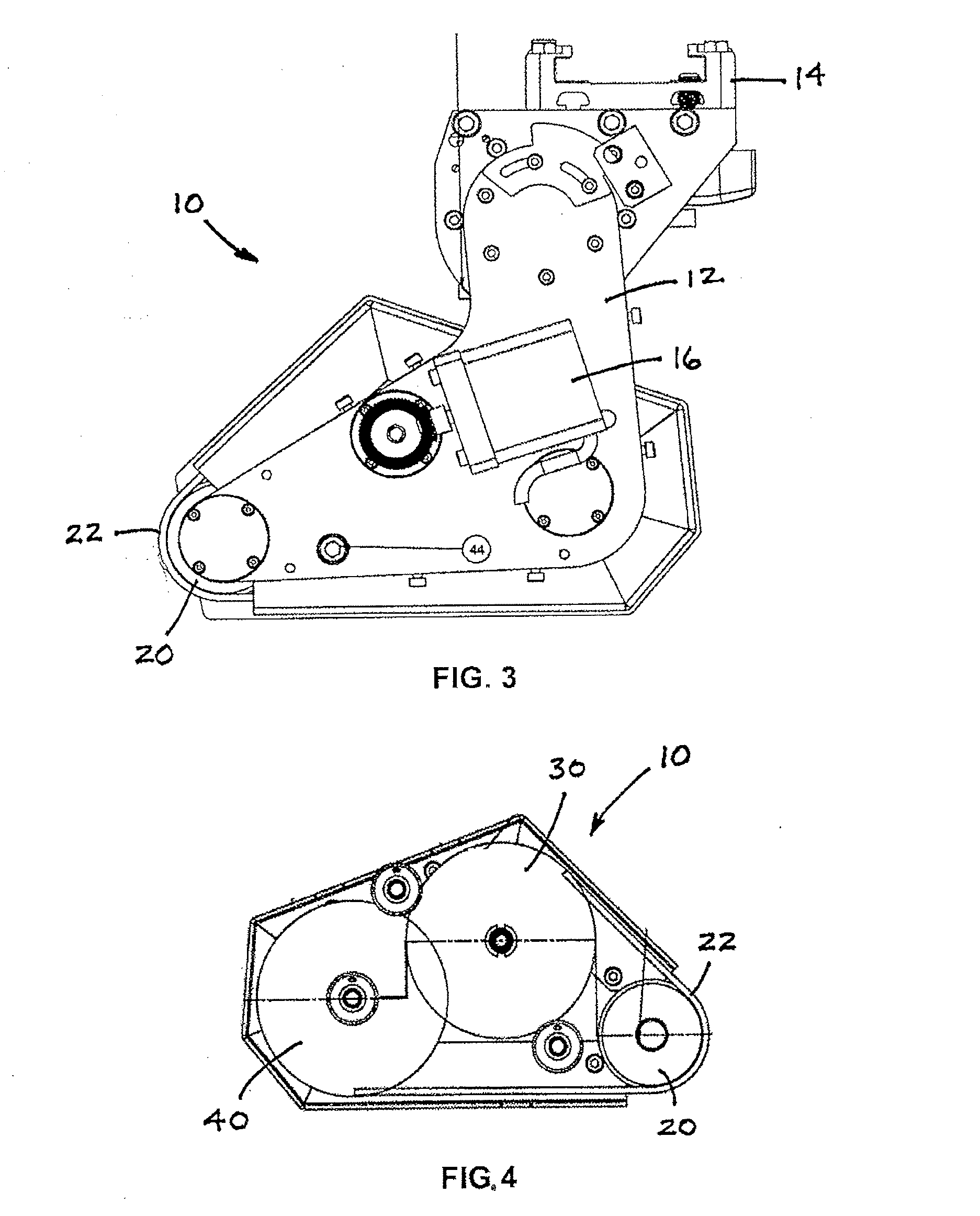

Pressing jaws, and crimping pliers having two plier jaws

PendingUS20210194198A1Large deformationConvenient guidanceLine/current collector detailsPliersMouth openingStructural engineering

Pressing jaws for opposite arrangement in crimping pliers, the pressing jaws having ribs, which extend in a rib longitudinal direction and move into each other during pressing. A guide surface extending transversely to the rib longitudinal direction outside of a working region of the ribs is formed, which guide surface interacts with a guide protrusion extending from the opposite pressing jaw. In another version, the pressing jaws have ribs, which are designed to mesh with each other and which have a rib longitudinal direction. Crimping pliers comprise two plier jaws, which are provided with oppositely arranged pressing jaws having ribs, which extend in a rib longitudinal direction and which, during pressing, move into each other and delimit a pressing jaw opening.

Owner:RENNSTEIG WERKZEUGE

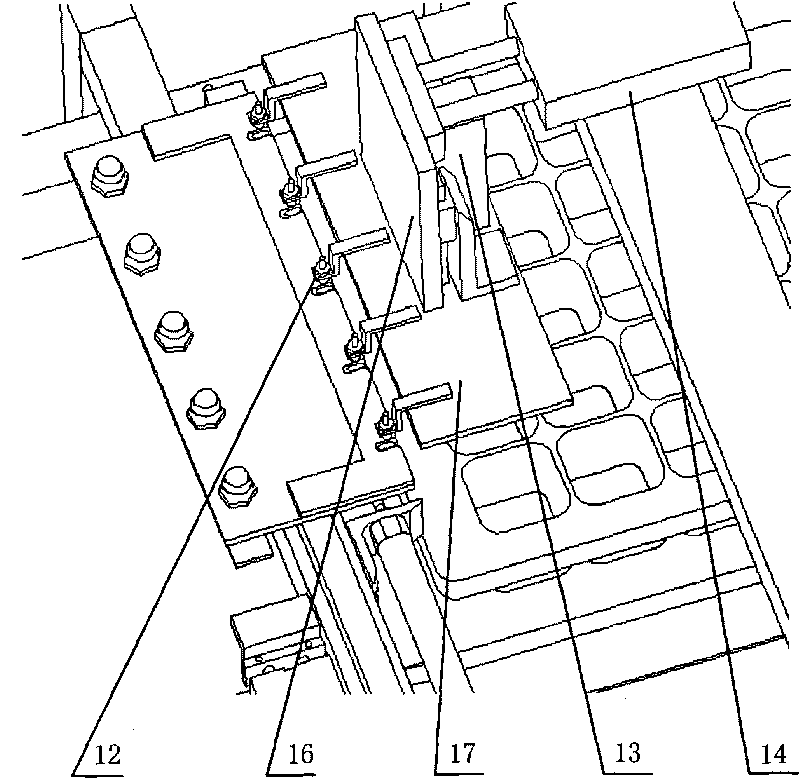

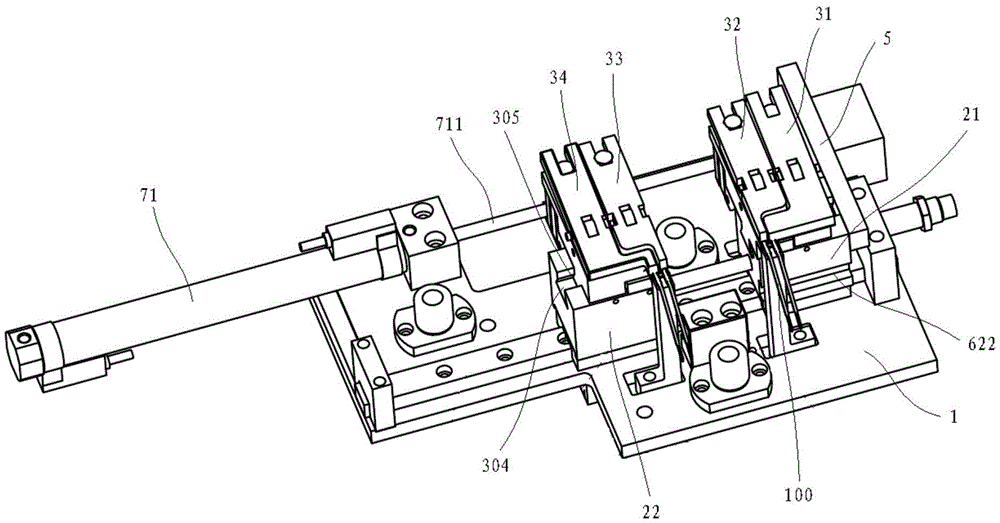

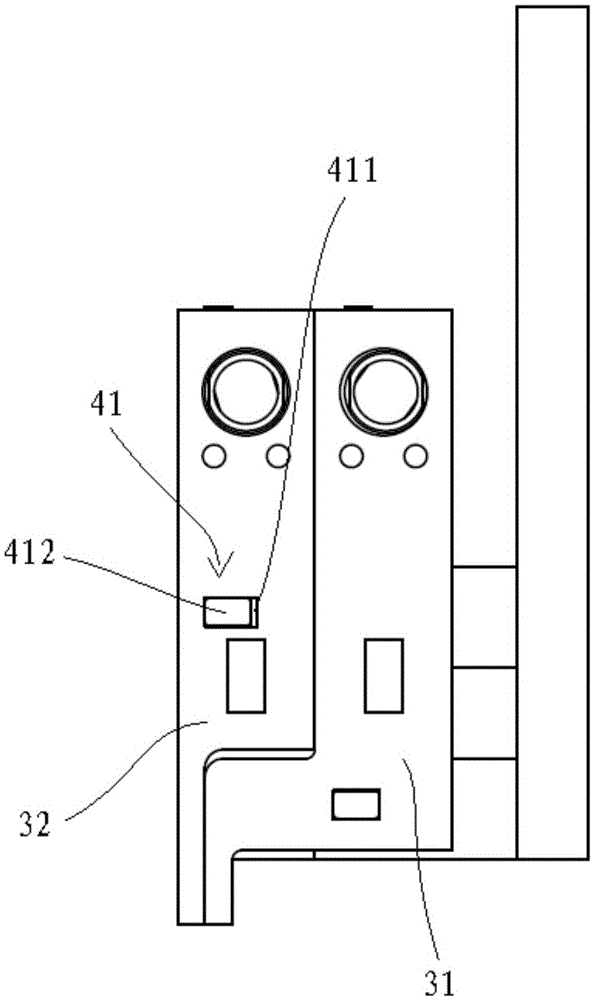

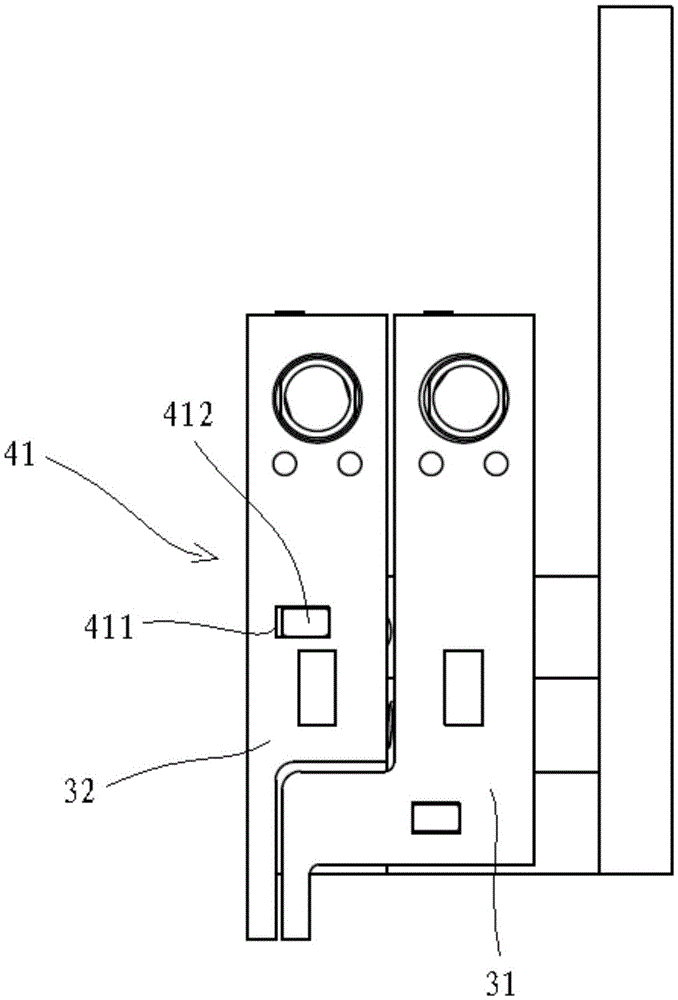

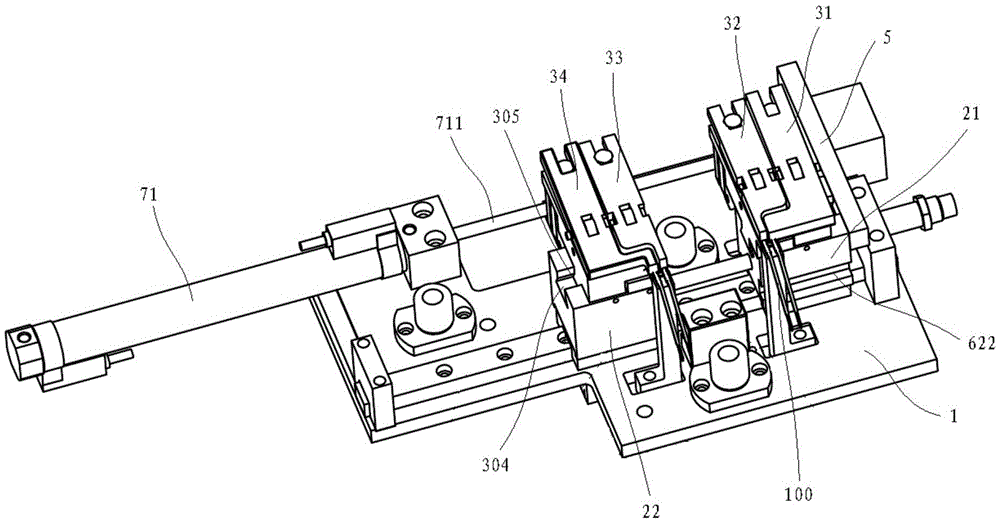

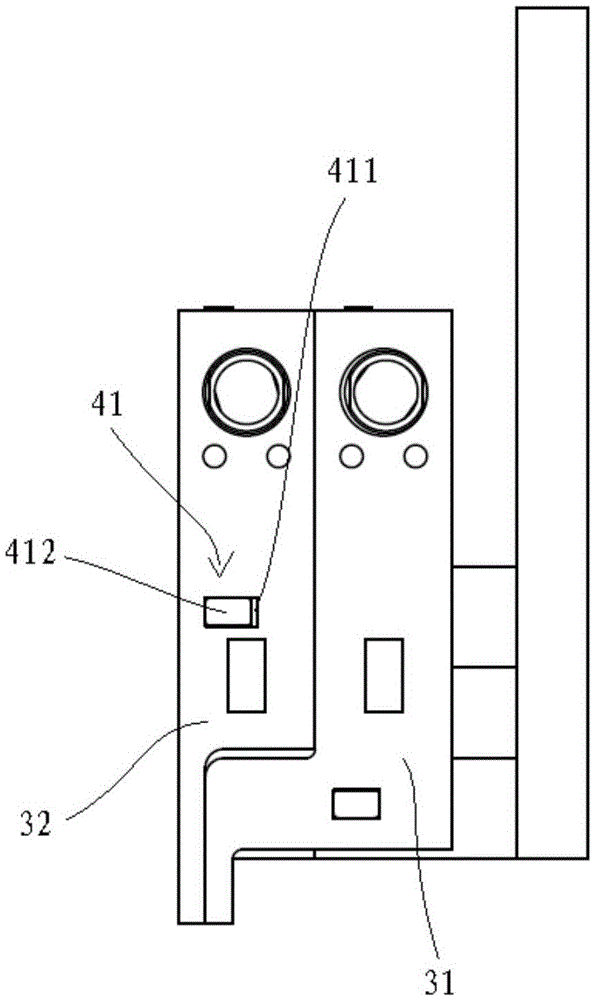

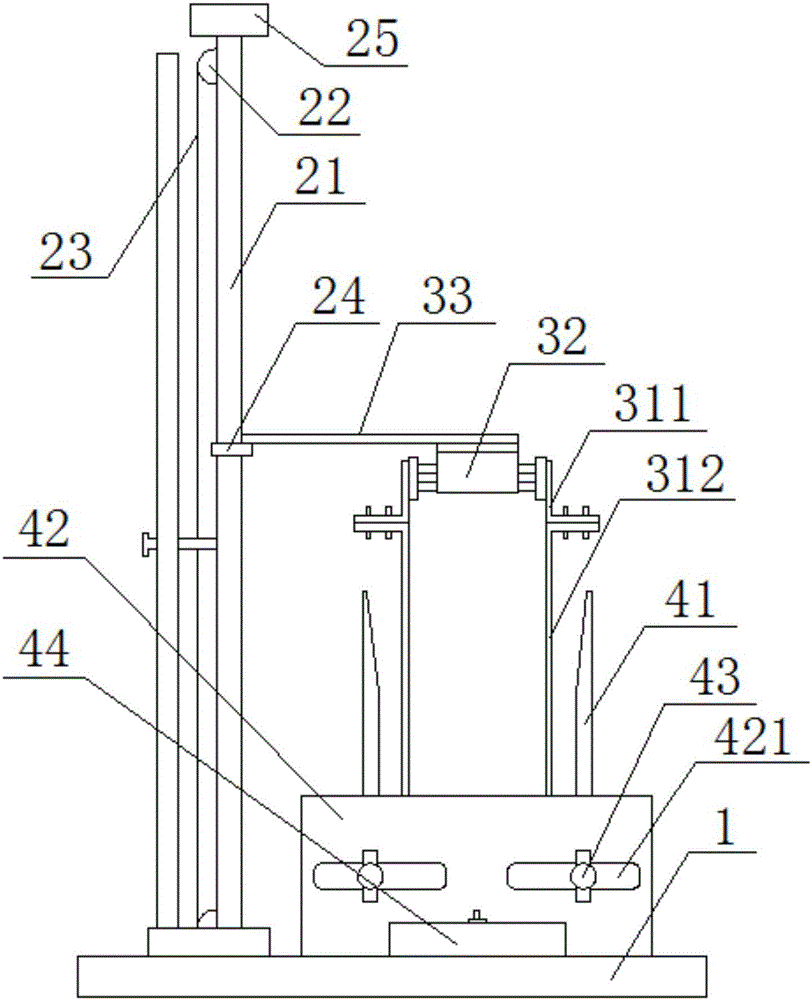

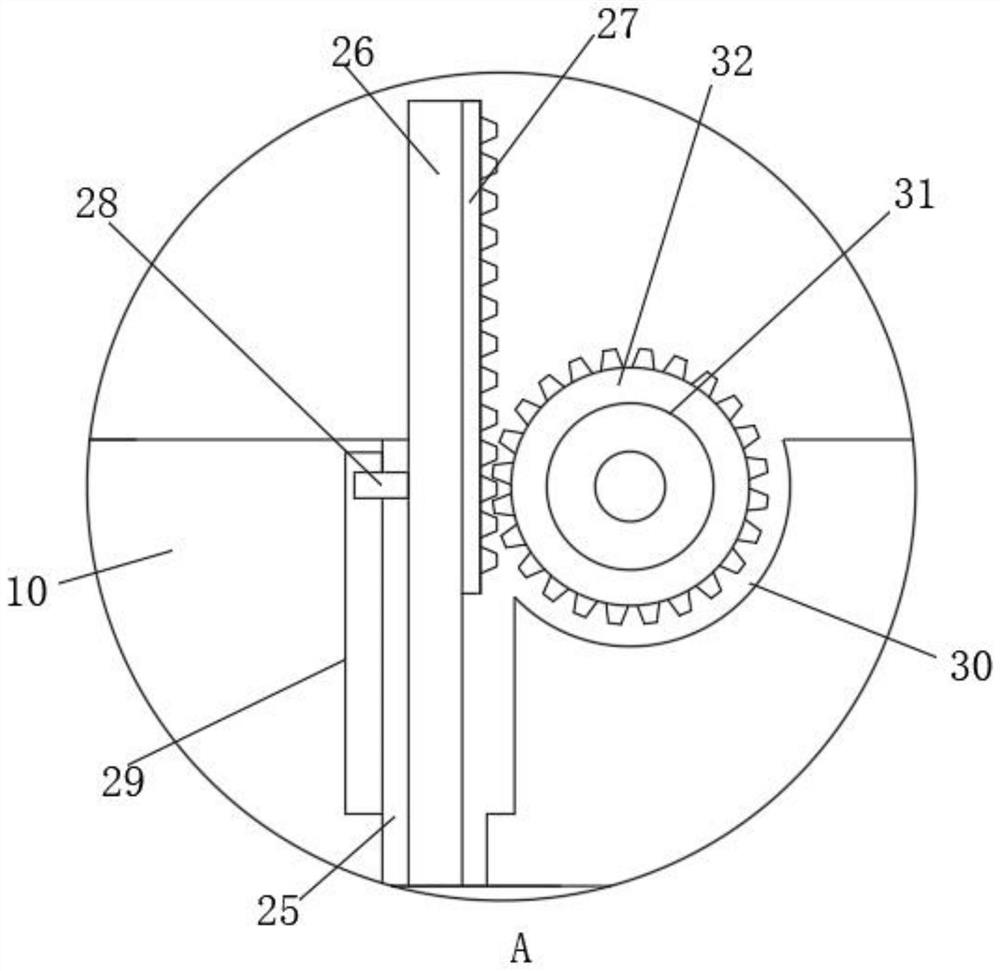

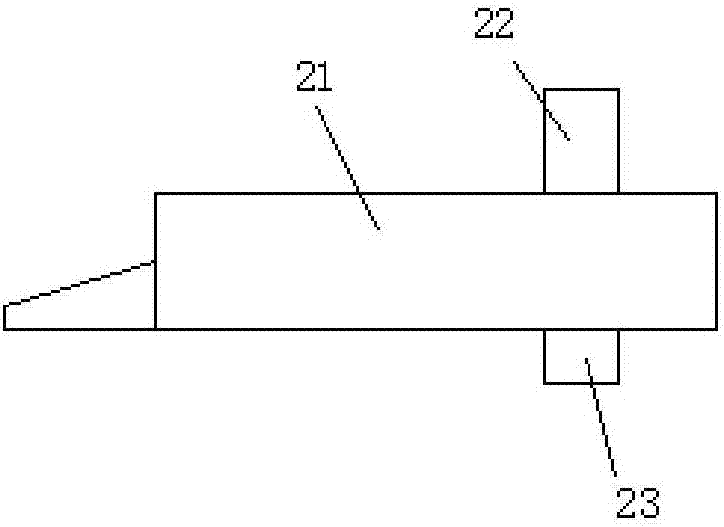

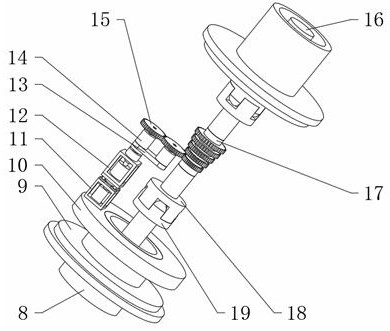

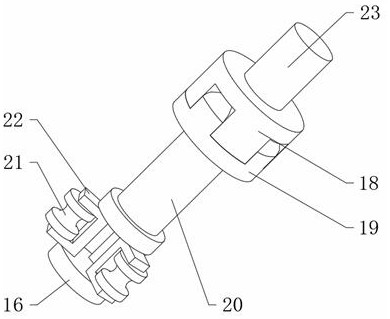

PIN separating mechanism

ActiveCN105633767AConstant spacingGuaranteed PIN effectContact member assembly/disassemblyEngineeringMechanical engineering

The invention discloses a PIN separating mechanism. The PIN separating mechanism comprises a base, a power plant, a moving mechanism, a clamp structure, an elastic element and a limiting structure, wherein the moving mechanism comprises a first sliding block and a second sliding block; the clamp structure comprises multiple clamps capable of clamping PINs arranged side by side, including a first clamp, a second clamp, a third clamp and a fourth clamp in sequence; the elastic element comprises a first elastic element and a second elastic element for enabling the adjacent two clamps on the first sliding block and the second sliding block to generate relative distances respectively; the limiting structure comprises a first limiting structure and a second limiting structure for limiting predetermined displacements between the adjacent two clamps on the first sliding block and the second sliding block respectively; a first connecting part drives the first sliding block to slide close to or far from the second sliding block under the drive of the power plant; when the first sliding block is tightly adhered to the second sliding blocks, the clamps are gathered together; and when the first sliding block performs the predetermined displacement in a direction far from the second sliding block, the clamps are separated. The PIN separating mechanism is high in efficiency, low in error, and capable of realizing automatic preparation process for electronic parts and components.

Owner:CWB AUTOMOTIVE ELECTRONICS

Resistance-type moisture meter with adjustable relative positions of wide and narrow grinding wheels

InactiveCN107238631AAchieve spacingAvoid damage to rollersPreparing sample for investigationMaterial resistanceEngineeringGrinding wheel

The invention discloses a resistance-type moisture meter with adjustable relative positions of wide and narrow grinding wheels. The resistance-type moisture meter comprises a grinding module, wherein the grinding module comprises a wide grinding wheel and a narrow grinding wheel; a bearing base of the wide grinding wheel is fixedly arranged on a slide block; a pushing plate is fixed at the bottom of the slide block; the pushing plate is fixed to an adjusting screw rod which is horizontally arranged on a side wall of a shell; a threaded hole for threaded connection with the adjusting screw rod is formed on the side wall of the shell; one end of the adjusting screw rod is fixed to the pushing plate; the other end of the adjusting screw rod is penetrated through the threaded hole and extends to the exterior of the shell; a sliding slot for mounting the pushing plate is formed in the shell; the length of the sliding slot is more than the length of the pushing plate; the width of the sliding slot is matched with the pushing plate; the sliding direction of the slide block is parallel to a connecting line of the circle center of the wide grinding wheel and the circle center of the narrow grinding wheel. According to the resistance-type moisture meter provided by the invention, the distance between the wide grinding wheel and the narrow grinding wheel can be adjusted at any time, so that the use scope of the grinding device is widened and the cost is saved.

Owner:HEFEI AIRUIDE ELECTRICAL

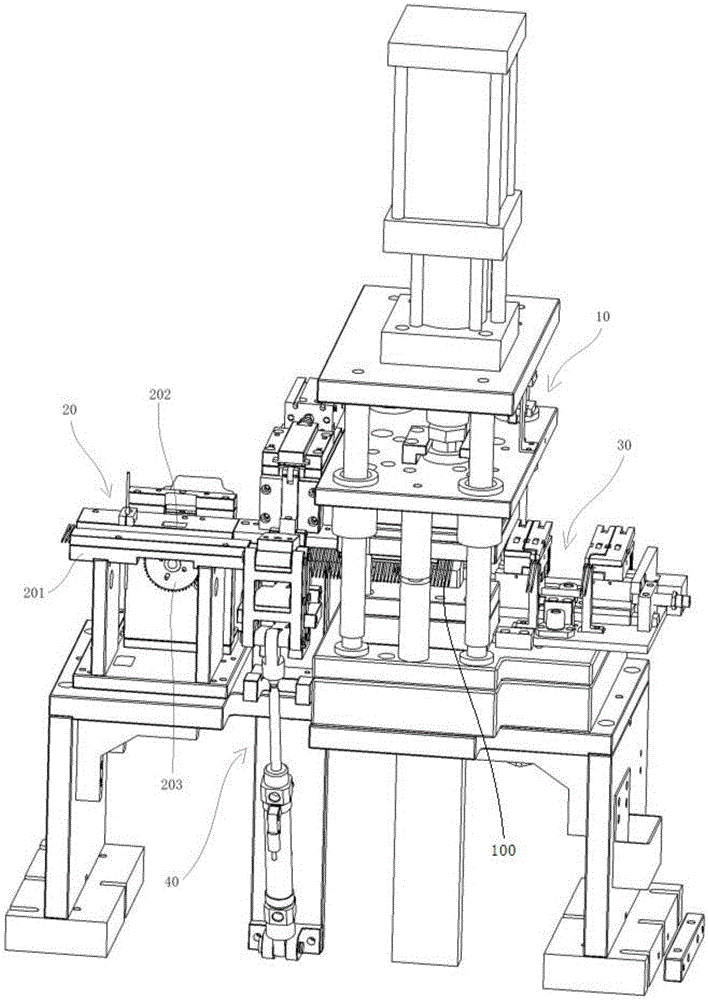

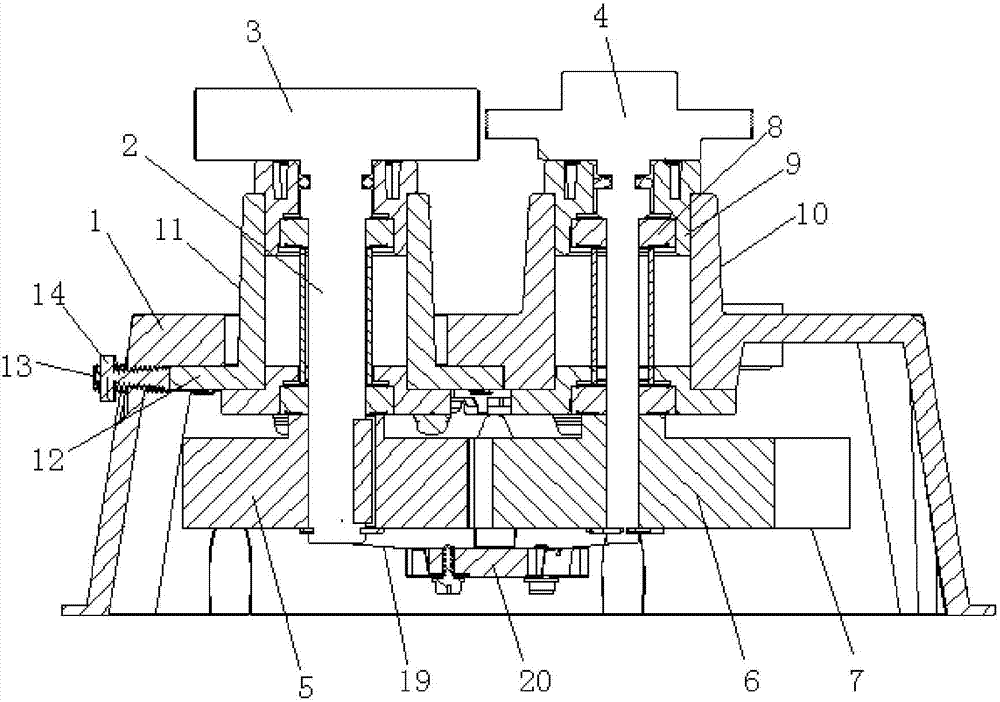

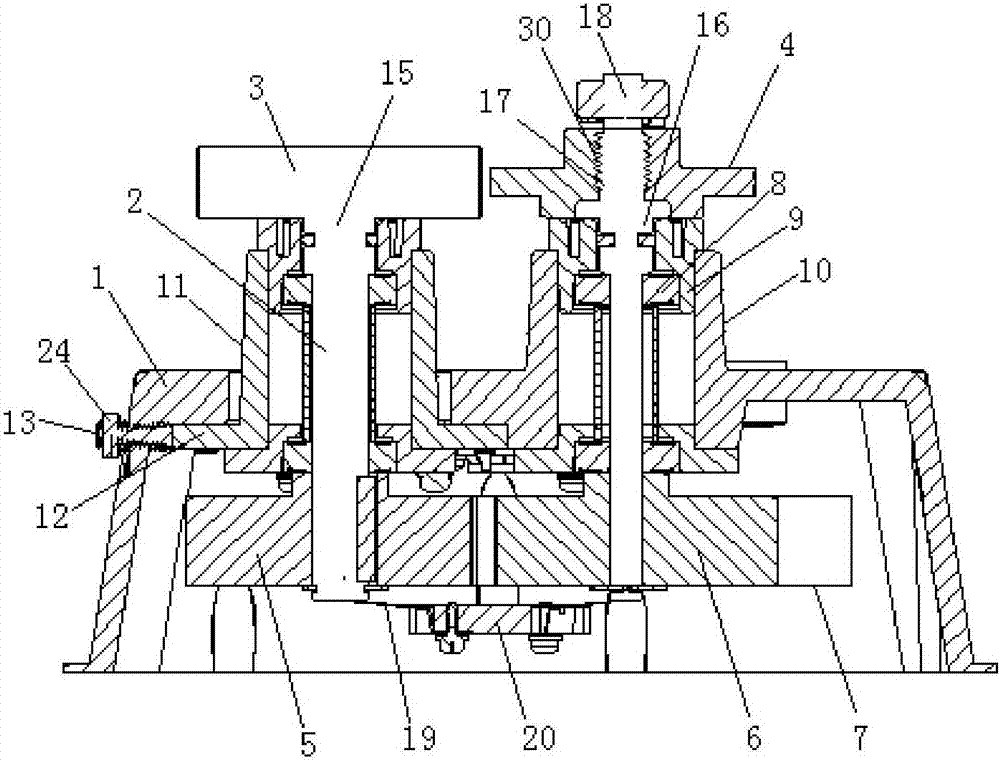

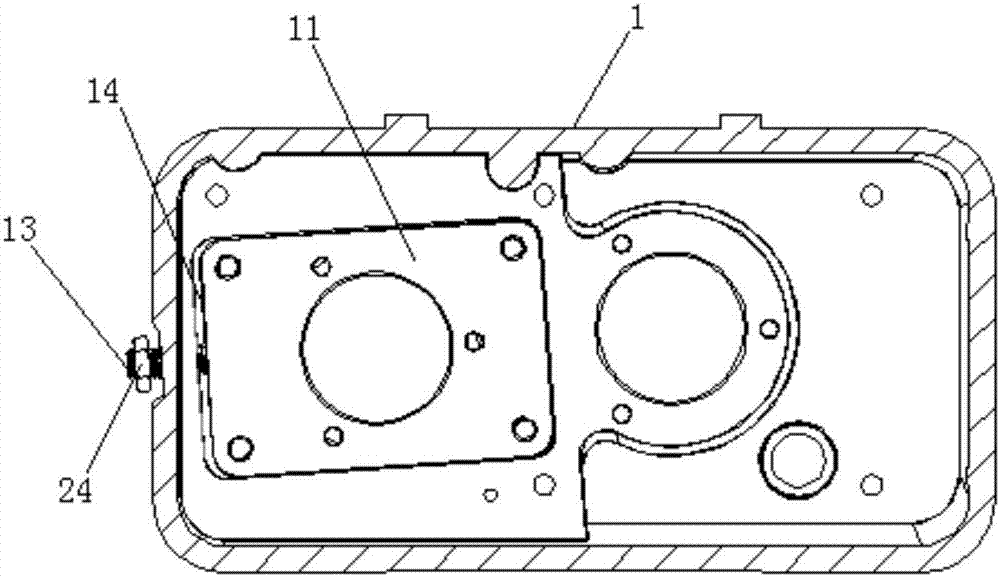

Cropping working station for PIN material strap

ActiveCN105598524AFully automatedIncrease productivityShearing machinesShearing machine accessoriesEngineeringAutomation

The invention provides a cropping working station for a PIN material strap. The cropping working station comprises a cropping mechanism cropping the PIN material strap into separated PINs, a feeding mechanism feeding the PIN material strap to the cropping mechanism, and a PIN distributing mechanism. The PIN distributing mechanism is used for clamping a set number of PINs from the cropping mechanism and distributing the clamped PINs so as to enable the PINs to be distributed according to preset intervals. According to the cropping working station for the PIN material strap, the PIN material strap can be cropped into the separated PINs, the set number of PINs can be distributed so that the PINs can be distributed according to the preset intervals, full automation of the PIN cropping and distributing technology can be achieved, production efficiency is high, the interval accuracy of the PINs is high, and manpower cost is reduced.

Owner:CWB AUTOMOTIVE ELECTRONICS

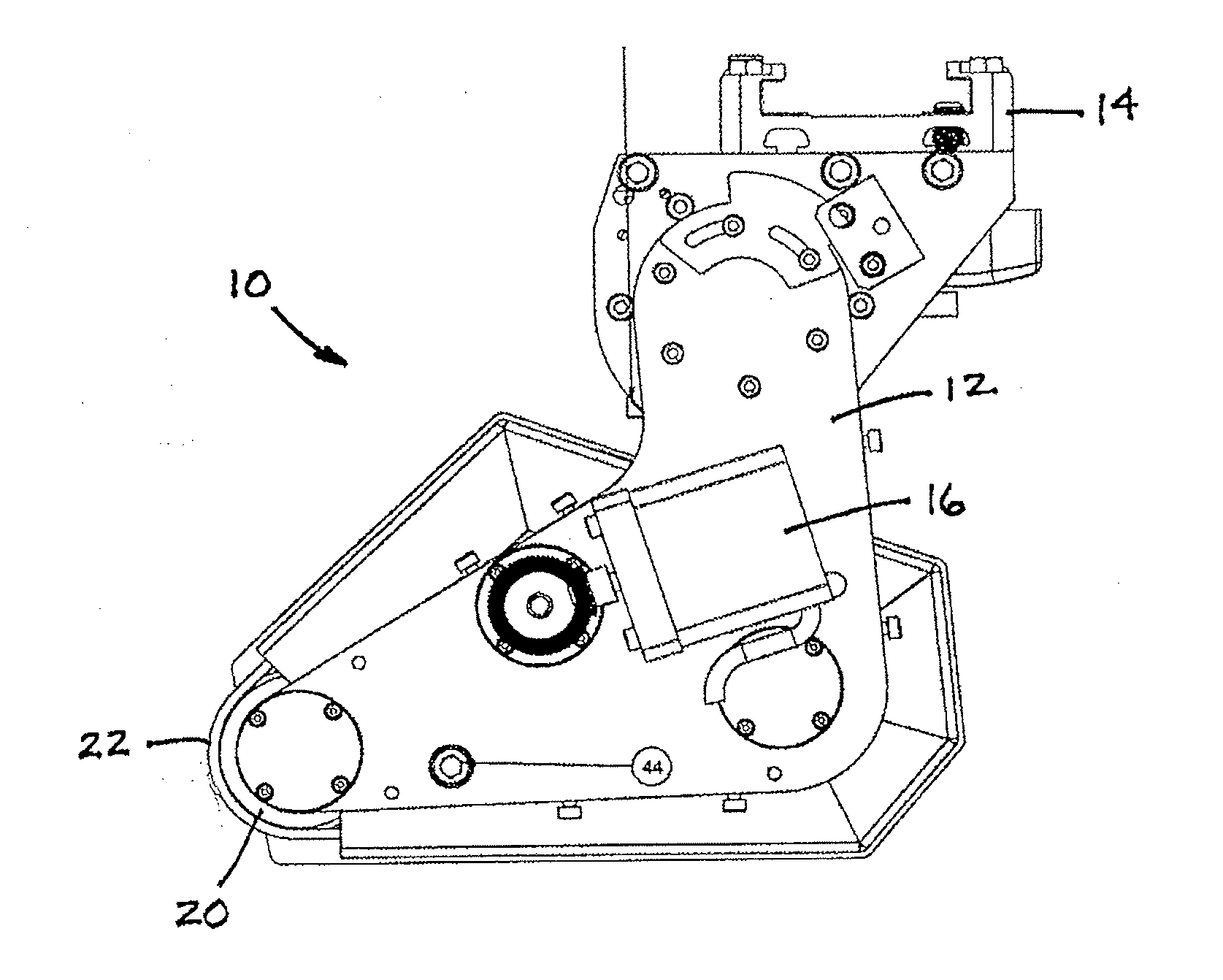

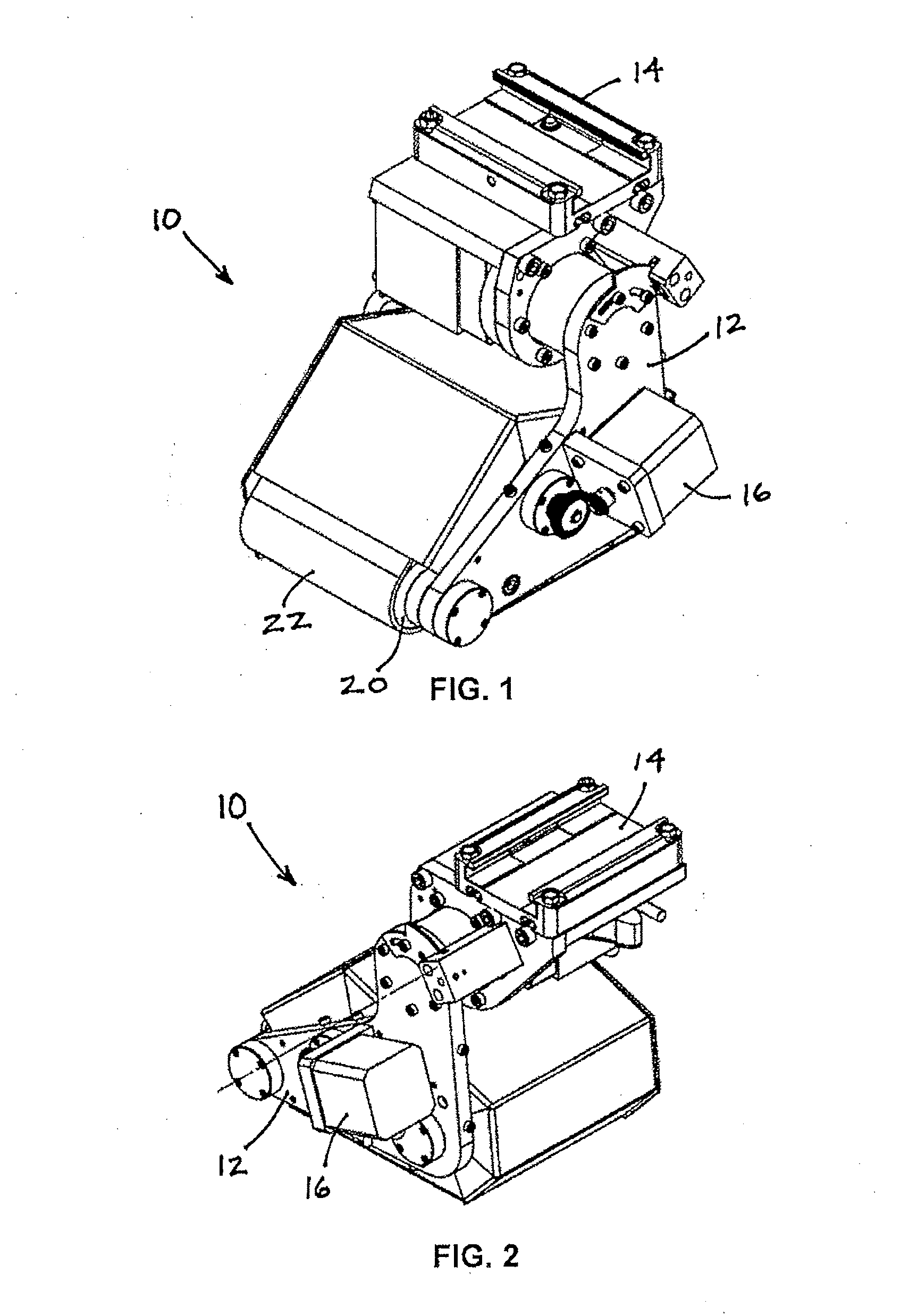

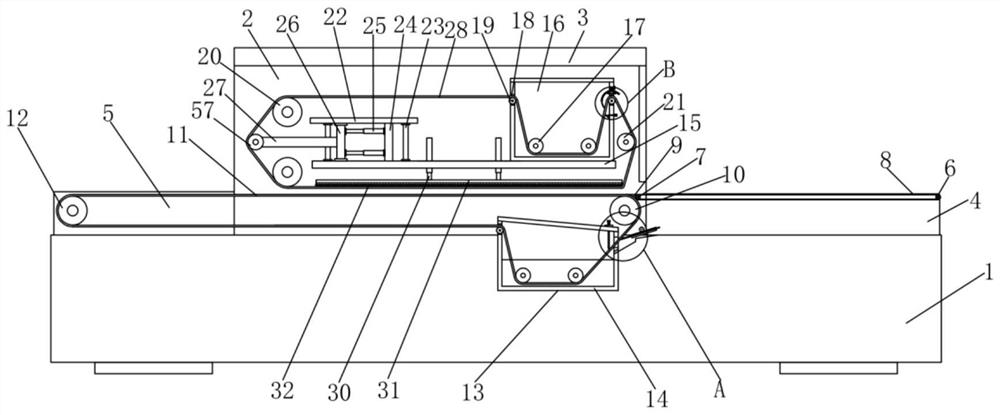

Apparatus, assembly and method for dry cleaning a flexographic printing plate carried on a plate cylinder that includes optimized cleaning functionalities

ActiveUS20150090142A1Avoids press downtimeMaintain production speedOffice printingPrinting press partsEngineeringPrinting press

A dry cleaning apparatus, assembly and method provides for a dry flexographic plate cleaner apparatus that is configured as a unitary subassembly to be used within a printing press assembly. The cleaner apparatus and subassembly comprise a plurality of motorized drives such that, among other things, a cleaning roller can be moved towards and away from the rotating printing plate so as to achieve optimum spacing. This also allows the press operator to make adjustments to the cleaner apparatus and subassembly without having to stop the printing press assembly. The apparatus and subassembly is further removable from the printing press assembly as may be desired or required for service. Additionally, the apparatus, assembly and method of the present invention also provides for use of at least one controller for electronically controlling the apparatus in accordance with the method and implementing optimized cleaning capabilities and functionalities.

Owner:THE DIAGNOSTIC GRP

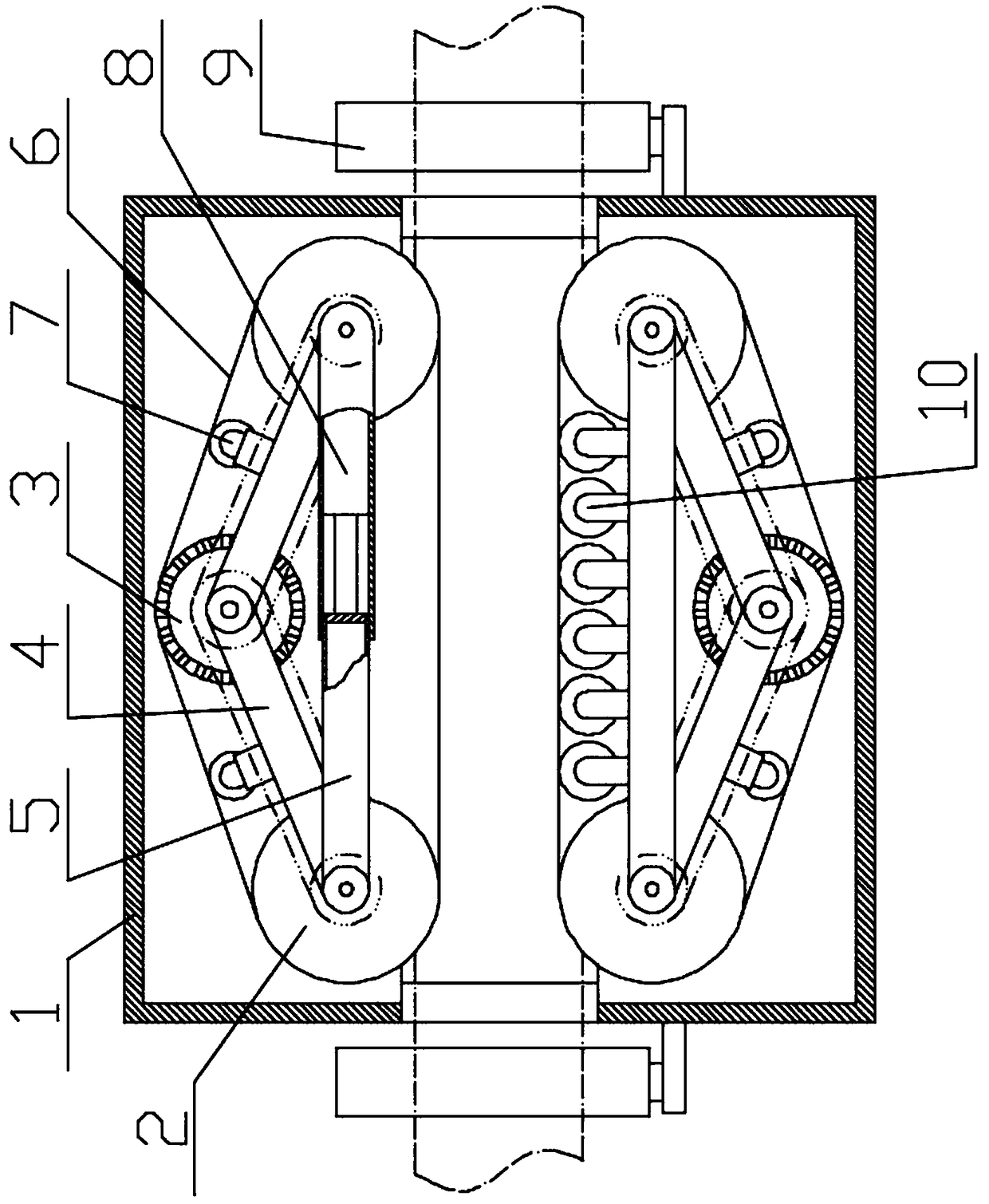

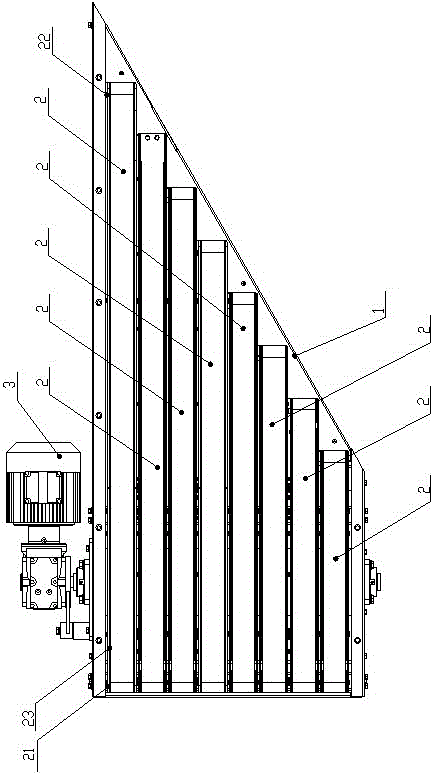

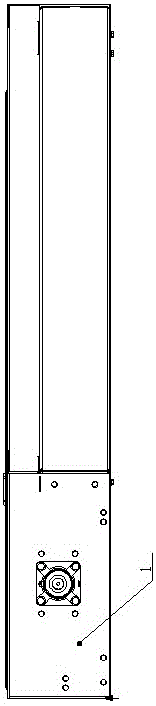

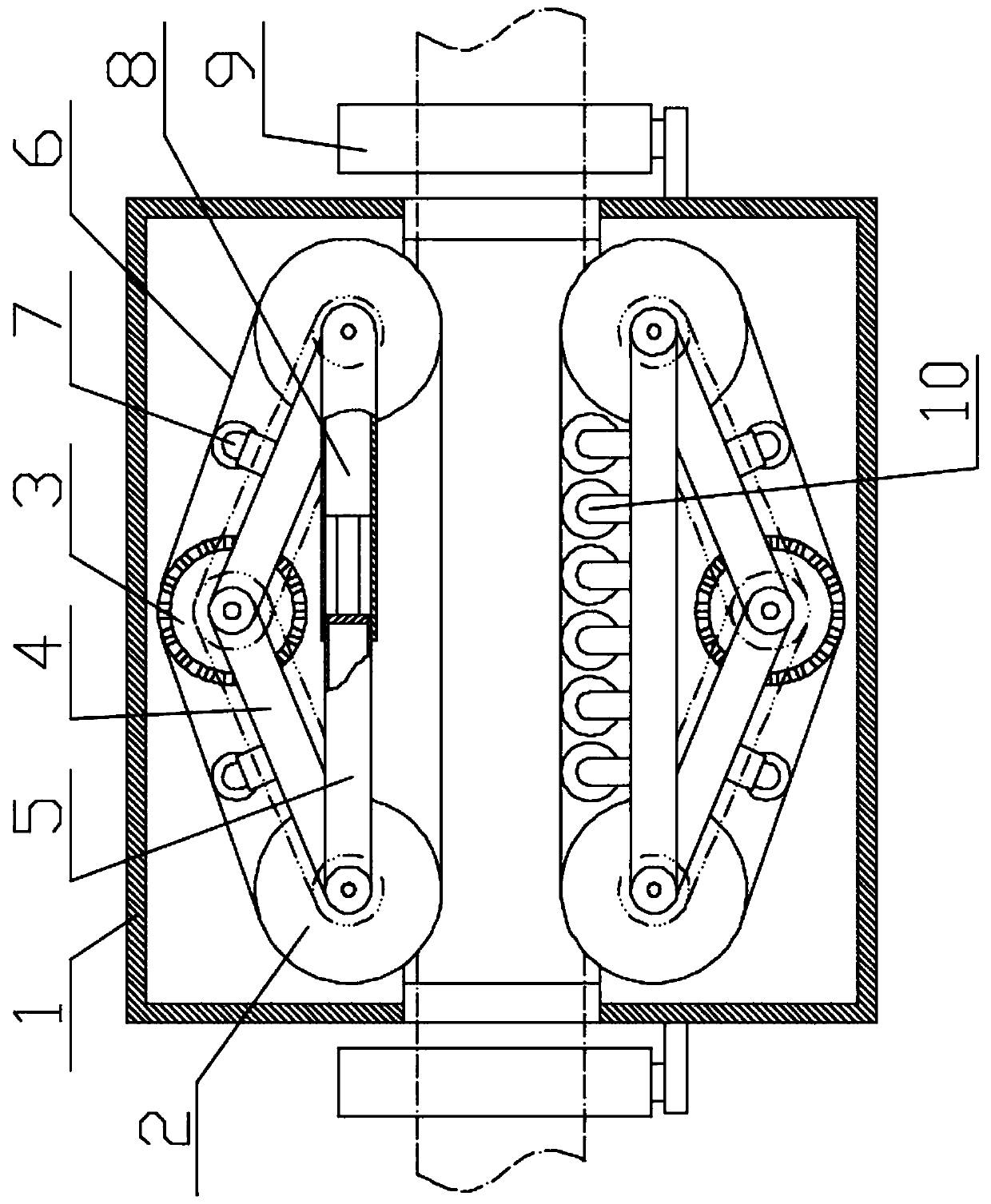

Cable conveyor with adjustable spacing

The invention discloses a cable conveyor with adjustable spacing. An opposite crawler clamping device comprises oppositely disposed crawler clamping mechanisms and a roller drive, each crawler clamping mechanism comprises two bottom rollers and a top roller in isosceles triangle structures,the top roller is fixedly erected and mounted on a frame, the bottom edges of the isosceles triangle structures are oppositely arranged, the bottom rollers and the top roller are connected by a side connecting rod, the two bottom rollers are connected through a bottom connecting rod, and the bottom rollers and the top roller adopt chain drive connection;a clamping crawler is of an annular structure surrounding the bottom rollers and the top roller, and a crawler tensioning member is further disposed on the side connecting rod;the bottom connecting rod of at least one crawler clamping mechanism of the oppositely disposed crawler clamping mechanism is of a telescopic tube structure, and the telescopictube structure is provided with a telescopic adjustment member. The cable conveyor is easy to operate and convenient to use, and can achieve the adjustment of the spacing between opposite crawler structures without the need to move the crawler structures as a whole.

Owner:STATE GRID CORP OF CHINA +1

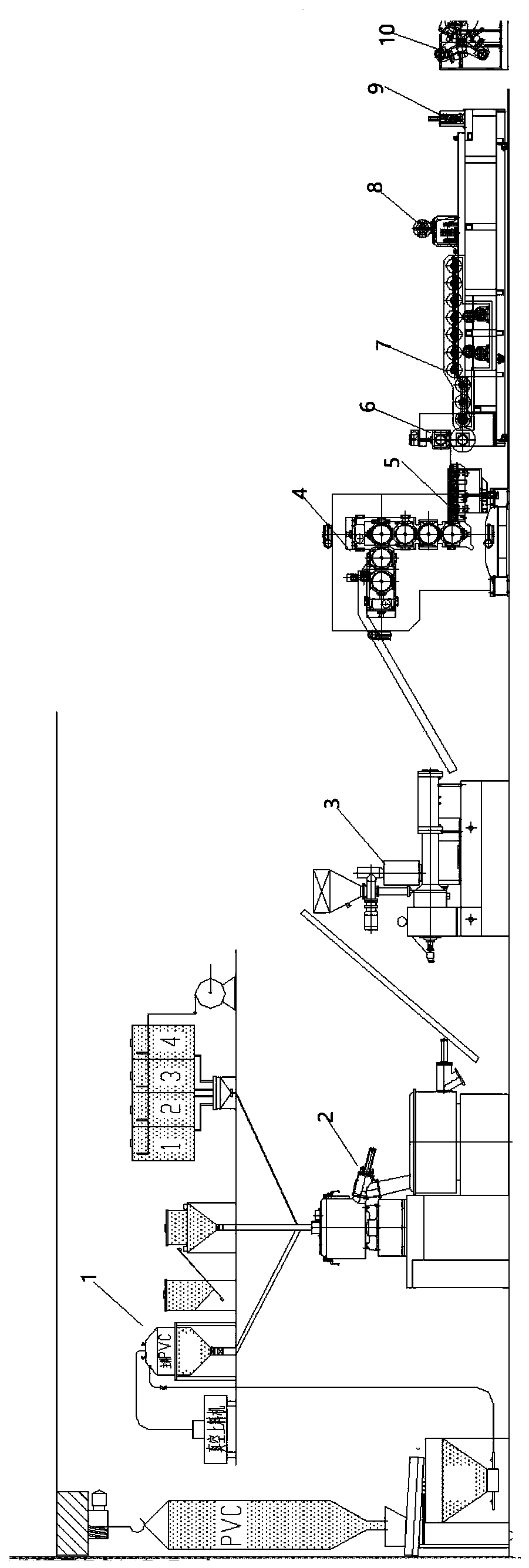

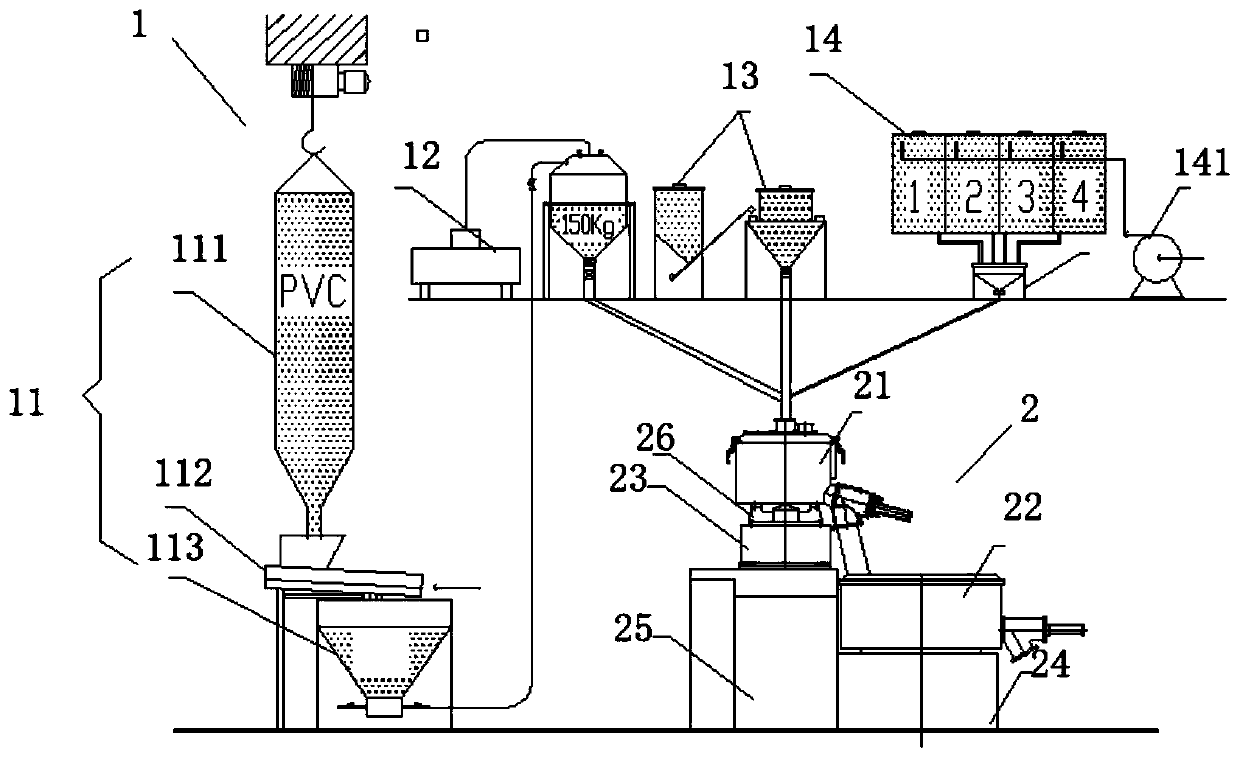

Efficient automatic production line for PVC processing and working method of efficient automatic production line

PendingCN111098467ASimple structureReasonable designFlat articlesProduct processingProcess engineering

The invention discloses an efficient automatic production line for PVC processing. The efficient automatic production line comprises an automatic feeding mechanism, a mixing mechanism, a planetary extruder, a six-roll calendaring primary and auxiliary machine, a roll stripping mechanism, a calender roll, a roll cooling mechanism, an offcut removing mechanism, a traction roll and a sheet coiler, araw material storage device, a vacuum feeding machine and a group of auxiliary material storage devices and a group of processing auxiliary tanks are arranged in the automatic feeding mechanism, a discharging opening of the mixing mechanism is connected with a feeding opening of the planetary extruder through a feeding pipe, a discharging opening of the planetary extruder is connected with the six-roll calendaring primary and auxiliary machine through a transmission belt, and the roll stripping mechanism, the calender roll, the roll cooling mechanism, the offcut removing mechanism, the traction roll and the sheet coiler are sequentially arranged on the rear portion of the six-roll calendaring primary and auxiliary machine. The efficient automatic production line is simple in structure, reliable in design and easy to operate, the automation from raw material processing to finished product coiling is achieved thoroughly, the product processing quality is improved, and the PVC film production efficiency is also improved.

Owner:苏州锐驰朗新材料有限公司

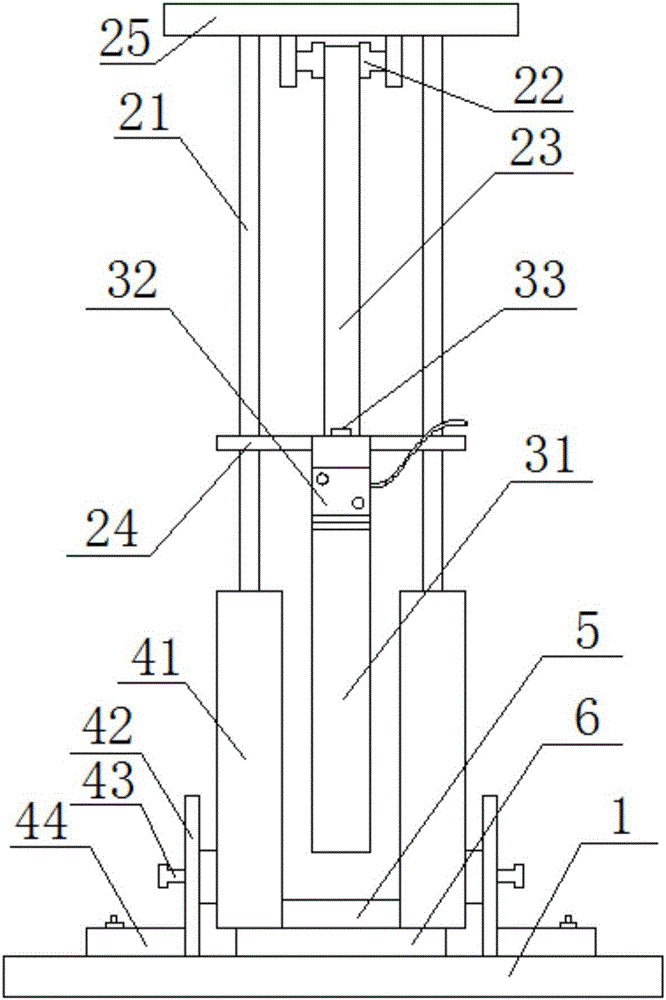

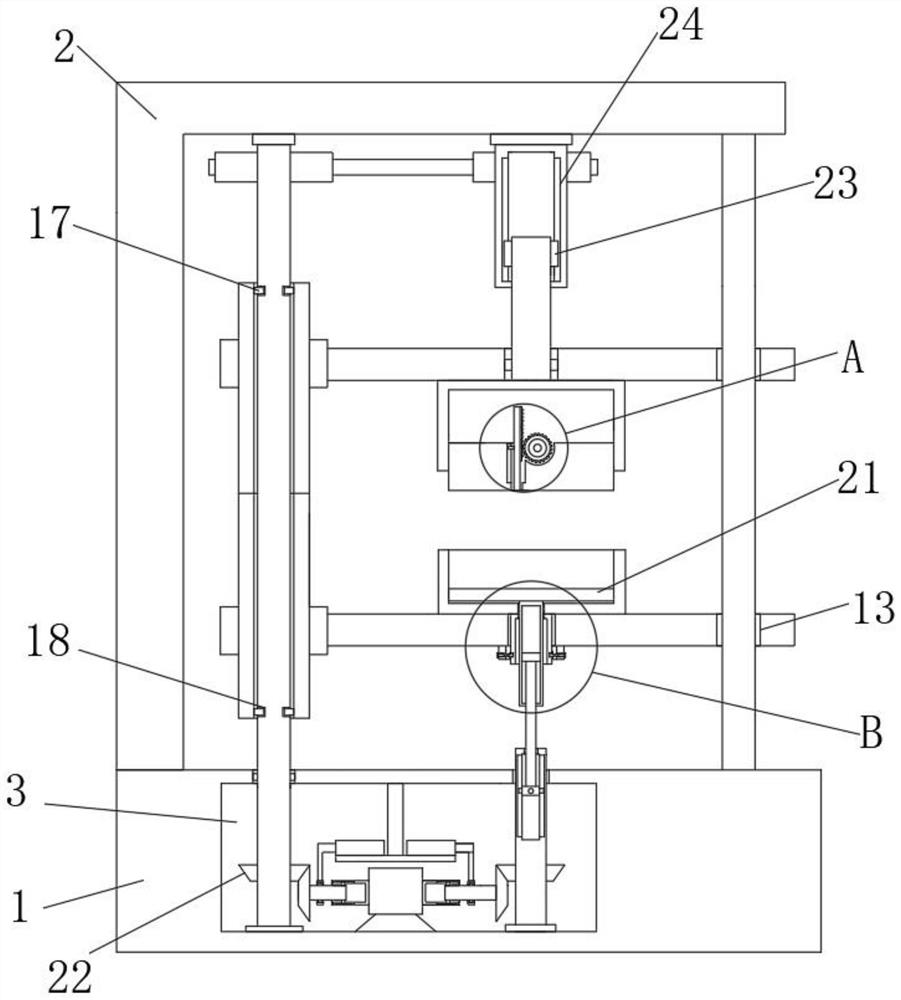

Mobile phone repeated drop test device

The present invention belongs to the drop test device technology field, and especially relates to a mobile phone repeated drop test device. The device comprises a workbench and a clamping mechanism. The workbench is provided with a spacing mechanism for restricting running of a mobile phone and is provided with a lifting mechanism, the clamping mechanism is installed on the lifting mechanism, the clamping mechanism clamps the mobile phone, and the lifting mechanism drives the lifting of the clamping mechanism. The clamping mechanism comprises a clamping plate, a driving head and a connection plate, the clamping plate is installed on the driving head which drives the closing and the opening of the clamping plate, and the driving head is connected with the lifting mechanism through the connection plate. The spacing mechanism comprises two side plates which are oppositely arranged with each other, and the front and back ends of the side plates are respectively provided with spacing plates. The mobile phone repeated drop test device is simple in structure and convenient to operate, employs the spacing mechanism to allow the mobile phone to be restricted to drop down at the assigned position, employs the lifting mechanism to regulate the drop height, employs the clamping mechanism to rapidly and conveniently clamp, is coherent in the clamping lifting dropping motion and improves the test efficiency.

Owner:重庆哈迪斯科技有限公司

Polishing device by utilizing impulsator to measure speed

InactiveCN108857609AAchieve grindingAvoid damageGrinding feed controlOther manufacturing equipments/toolsGear wheelEngineering

The invention discloses a polishing device by utilizing an impulsator to measure speed. The polishing device comprises a working box and a cooling water tank arranged in the work box, a transmission cavity is formed in the working box, and a belt wheel cavity located on the lower side of the transmission cavity is formed in the work box; a polishing cavity located on the right side of the transmission cavity is formed in the work box, a first rotary shaft with the lower end extending into the belt wheel cavity is rotatably connected to the bottom wall of the belt wheel cavity and rotatably arranged on the bottom wall of the transmission cavity, and a first bevel gear fixedly connected to the upper end of the first rotary shaft is arranged in the transmission cavity; a second rotary shaft rotatably connected to the left and right walls of the transmission cavity is arranged in the transmission cavity, a second bevel gear meshed with the first bevel gear is fixedly arranged on the secondrotary shaft, and a first gear located on the right side of the second bevel gear is fixedly arranged on the second rotary shaft.

Owner:朱宽

Moisture detector allowing test distance to be adjusted

InactiveCN107064231AAvoid damage to rollersAchieve spacingMaterial resistanceEngineeringGrinding wheel

The invention discloses a moisture detector allowing the test distance to be adjusted. The moisture detector comprises a grinding module, wherein the grinding module comprises a broad grinding wheel and a narrow grinding wheel, wherein a bearing block of the broad grinding wheel is fixedly mounted on a slider; a push plate is fixed at the bottom of the slider and fixed with an adjusting screw horizontally arranged on the side surface of a casing; a thread hole in threaded connection with the adjusting screw is formed in the side surface of the casing, one end of the adjusting screw is fixed with the push plate, and the other end of the adjusting screw penetrates through the thread hole and extends out of the casing; a sliding chute used for mounting of the push plate is arranged in the casing and has the length larger than that of the push plate and the width according with that of the push plate, and the sliding direction of the slider is parallel to the connecting line of a circle center of the broad grinding wheel and a circle center of the narrow grinding wheel. According to the moisture detector allowing the test distance to be adjusted, the moisture value obtained by a moisture sensor is processed by a switch module and an operational amplifier module, noise signals in the sampling process can be reduced, and the moisture detection result accuracy is further improved.

Owner:HEFEI AIRUIDE ELECTRICAL

Resistance-type grain moisture detector

InactiveCN107179335AAchieve spacingFirmly connectedMaterial resistancePulp and paper industryGrain moisture

The invention discloses a resistance-type grain moisture detector, which comprises a grinding module; the grinding module comprises a wide grinding wheel and a narrow grinding wheel; a bearing base of the wide grinding wheel is fixedly installed on a slide block. The bottom part of the slide block is fixed with a push plate, and the push plate is fixed with an adjusting screw crossly arranged at the side face of the shell body; the side face of the shell body is provided with a thread hole used for performing the threaded connection with the adjusting screw; one end of the adjusting screw is fixed with a push plate, and the other end crosses through the thread hole and extends to the outer part of the shell body. A chute for mounting the push plate is arranged in the shell body, the length of the chute is more than that of the push plate, and the wide of the chute is matched with that of the push plate. The resistance-type grain moisture detector has advantages of adjusting distance between the wide grinding wheel and the low grinding wheel at any time, accurately adjusting a gap between the grinding wheels after replacing the grinding wheel, and improving the detecting precision.

Owner:HEFEI AIRUIDE ELECTRICAL

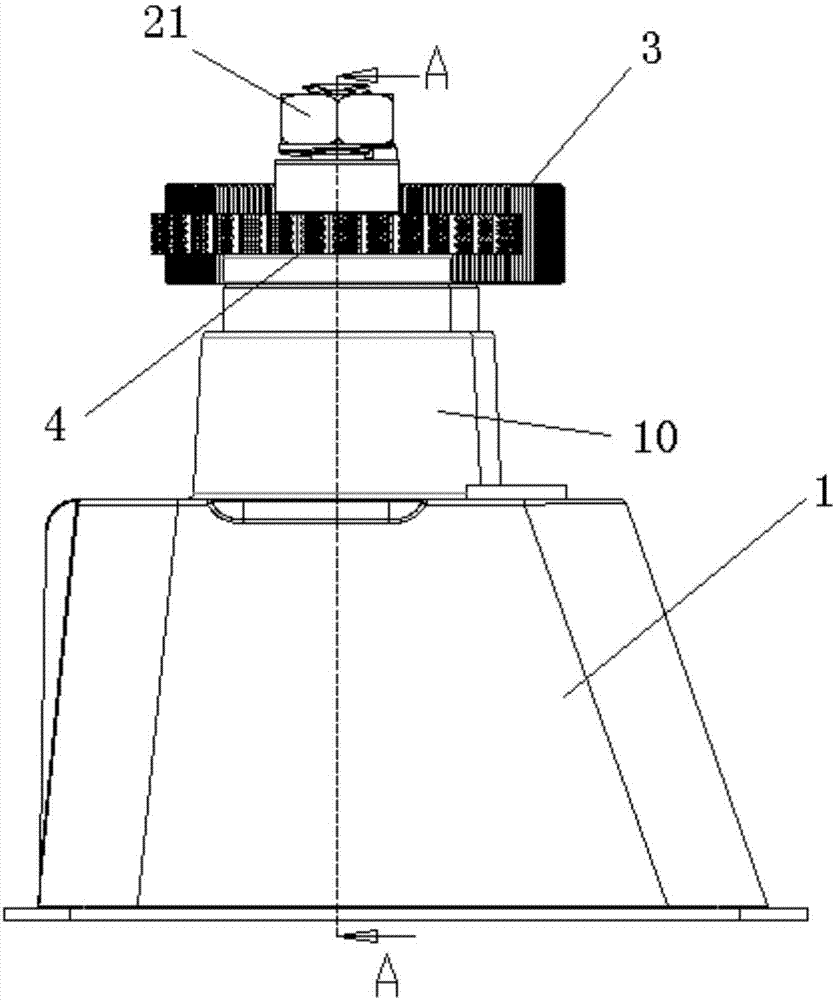

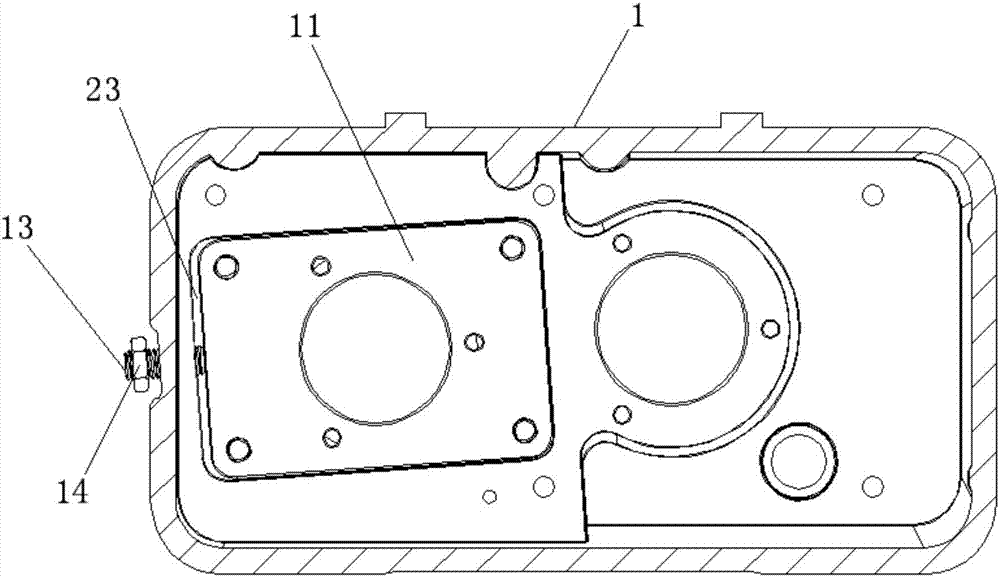

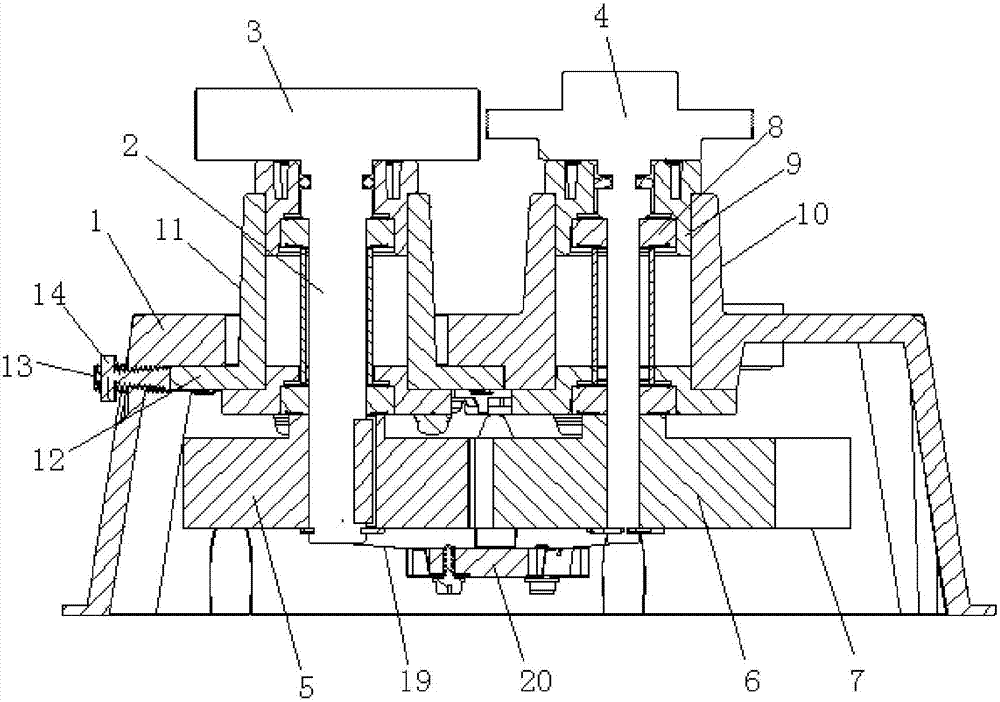

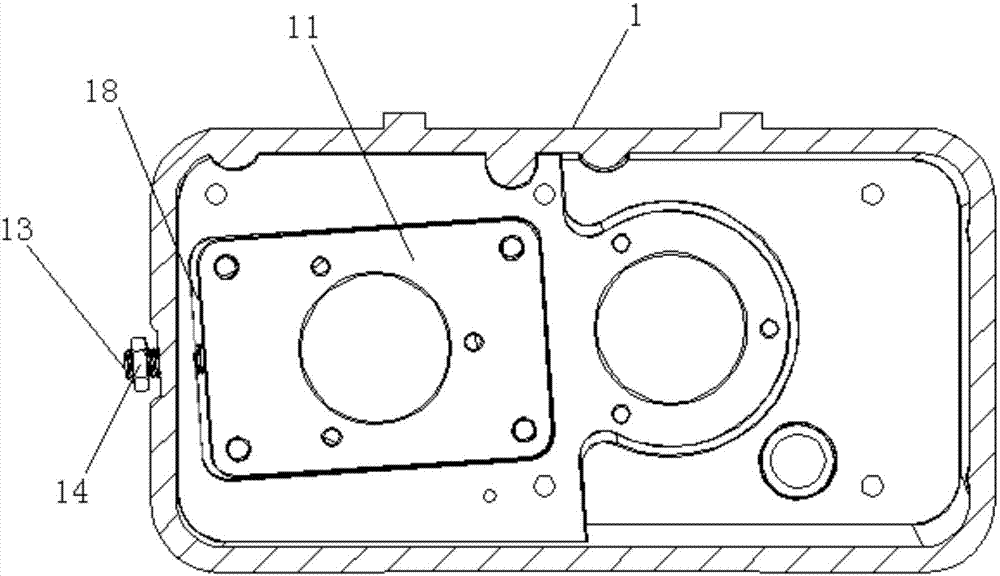

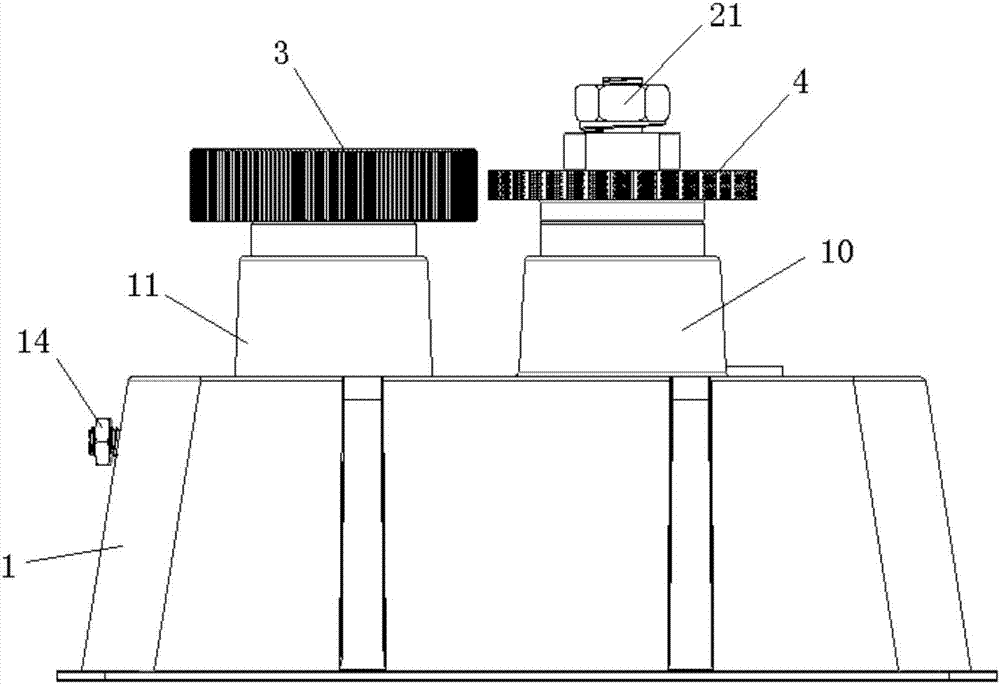

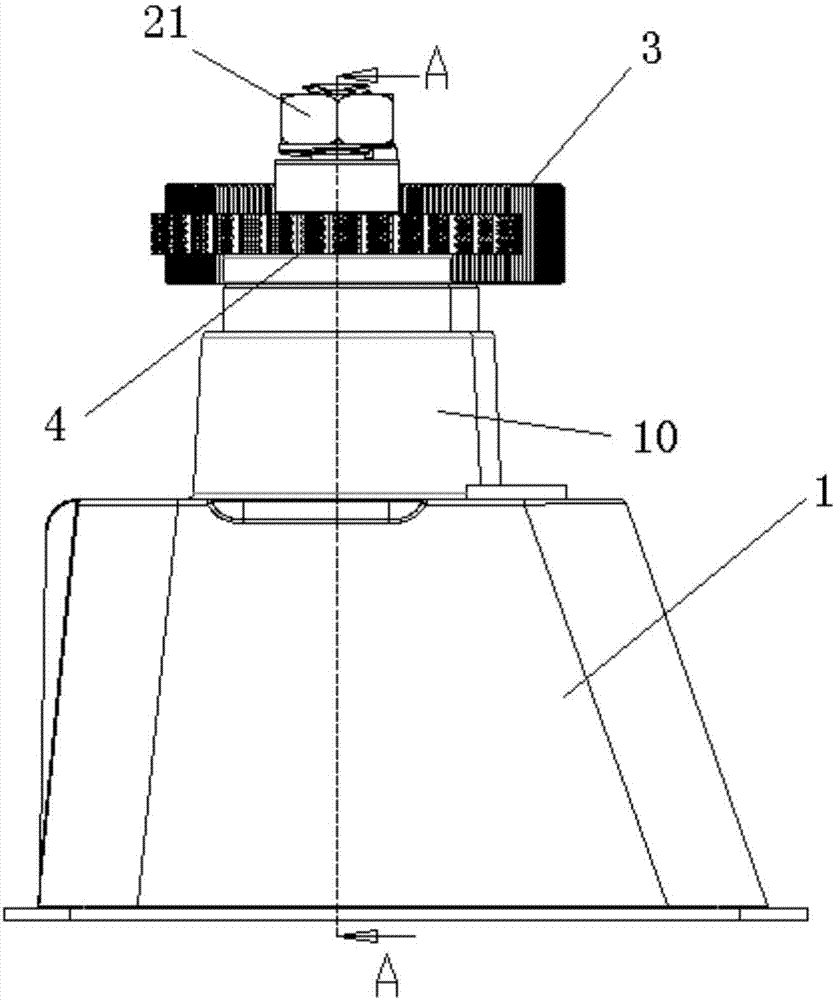

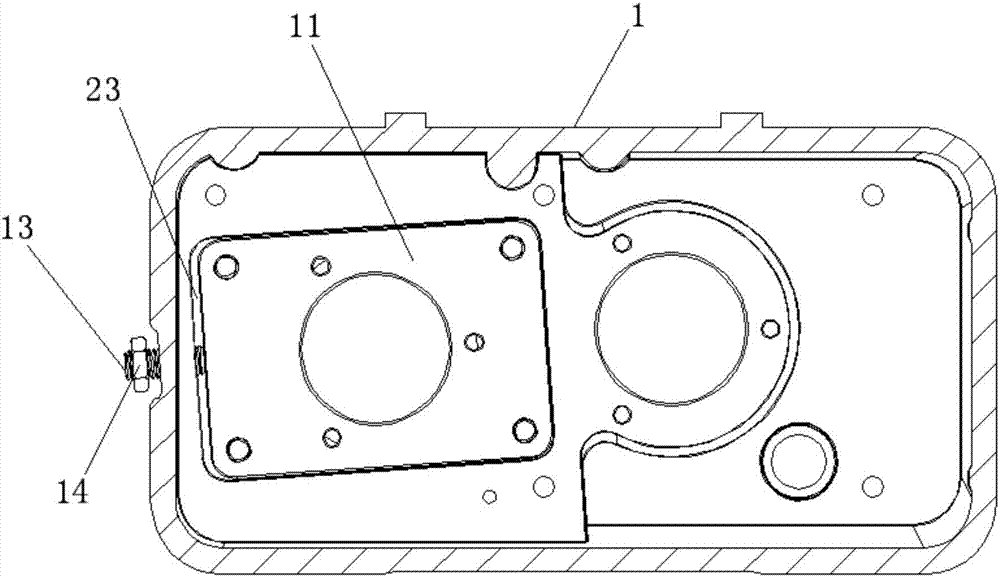

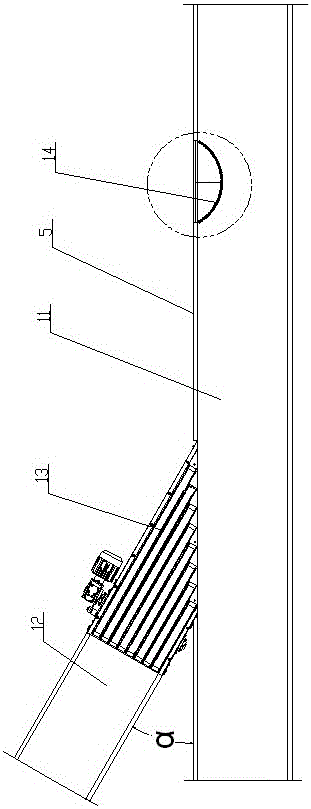

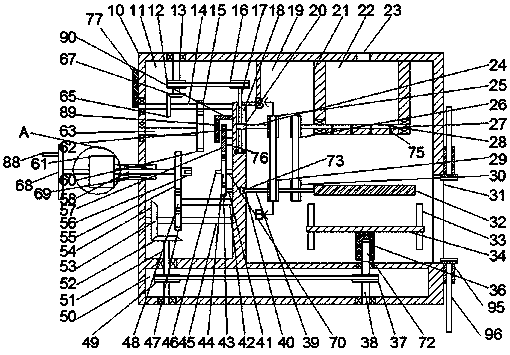

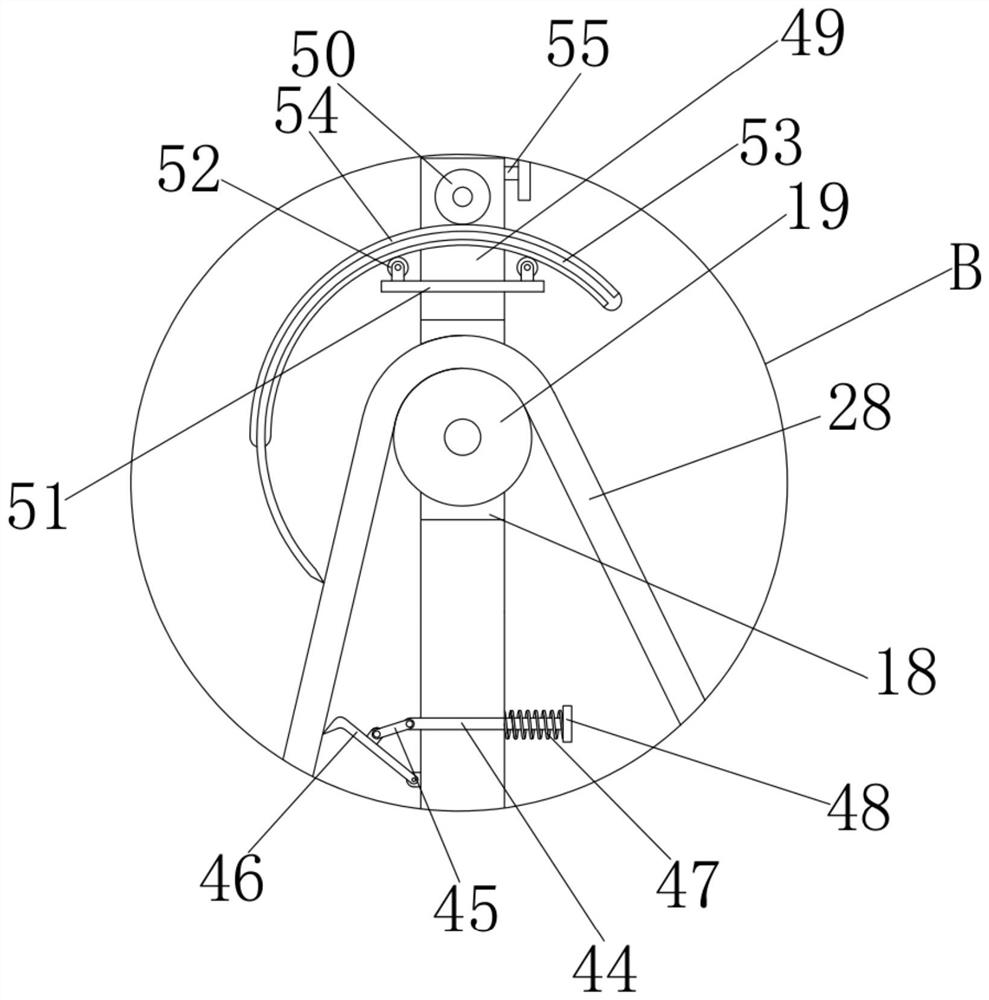

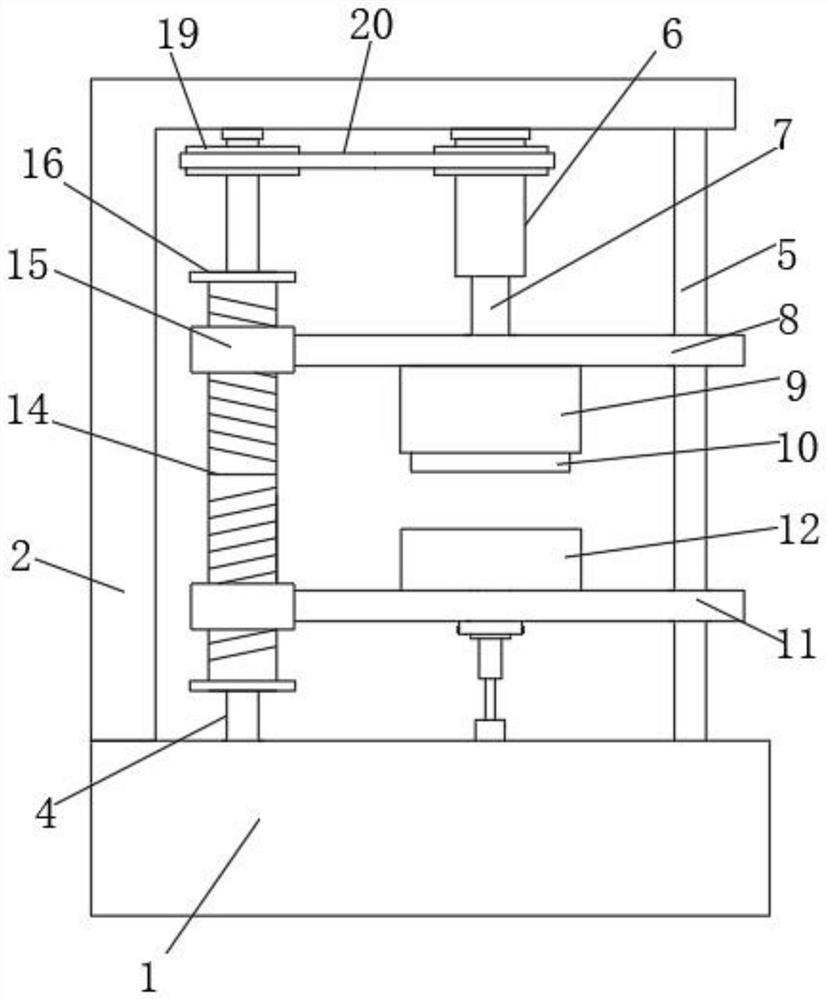

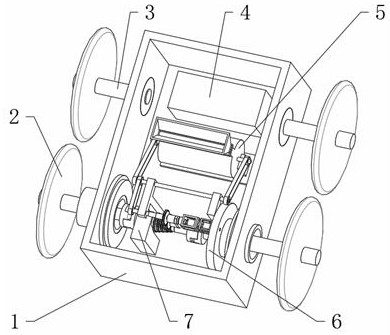

Multi-dimension cereal moisture detector

InactiveCN107219259ALow costImprove accuracyMaterial analysis by electric/magnetic meansMotor driveDrive shaft

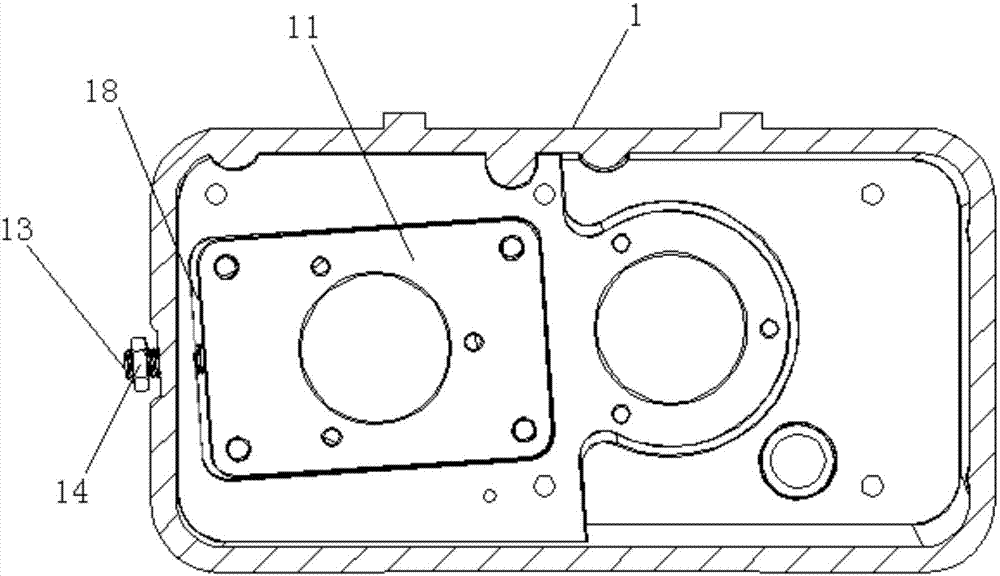

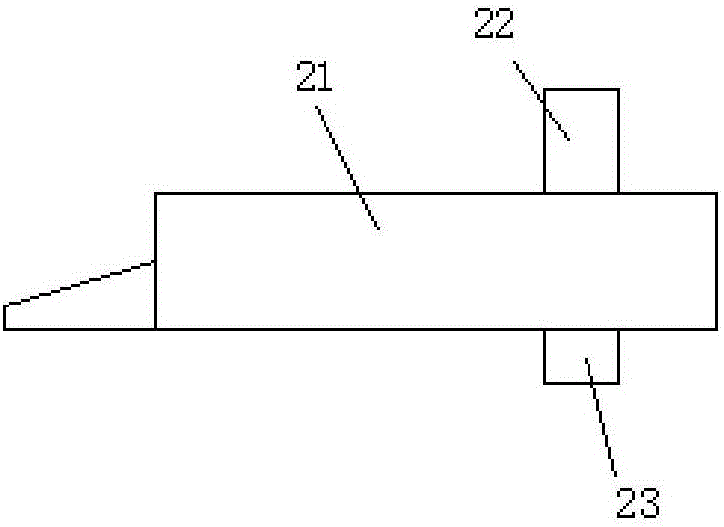

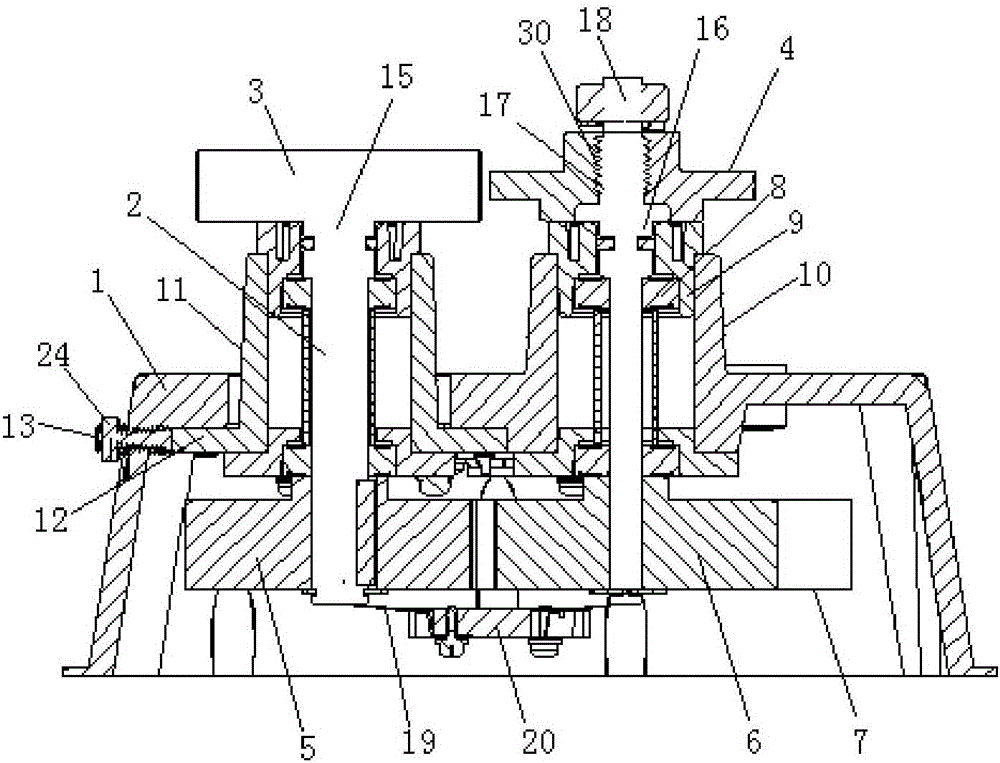

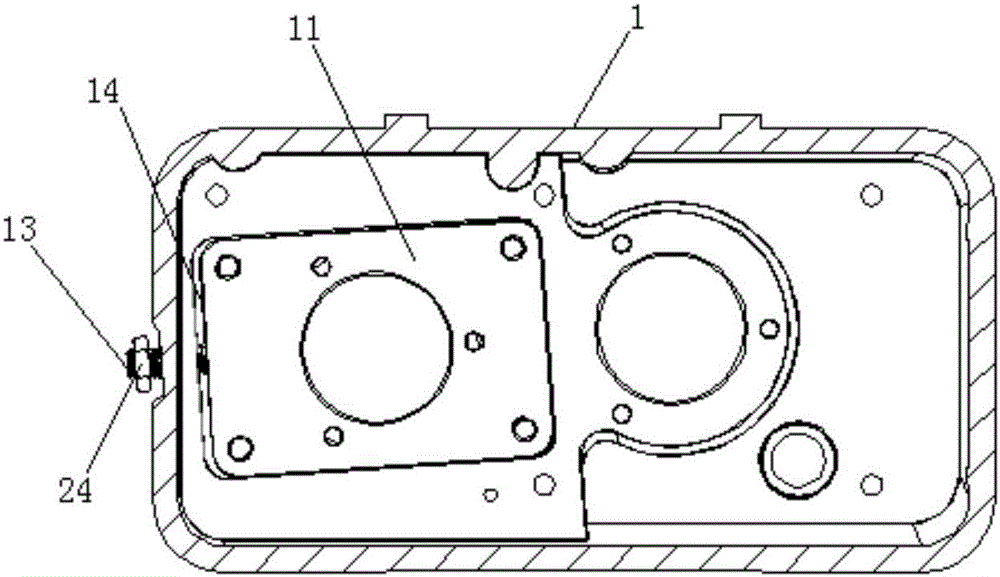

The invention discloses a multi-dimension cereal moisture detector. Grinding wheels are mounted in a shell (1) in through transmission shafts (2) and include a wide grinding wheel and a narrow grinding wheel; the wide grinding wheel and the narrow grinding wheel are rotatably mounted the shell respectively through one transmission shaft, a gear I is mounted at the bottom of the transmission shaft connected with the wide grinding wheel, a gear II is mounted at the bottom of the transmission shaft connected with the narrow grinding wheel and is meshed with the gear I, and one side, far from the gear I, of the gear II is meshed with a gear III; the gear III is driven through an integrated control circuit located below the shell, the integrated control circuit comprises a moisture collection module, a master control module, an indication lamp module, a motor driving module, a communication module and a power supply module, and the power supply module is used for supplying power to all the modules. According to the multi-dimension cereal moisture detector, the distance from the wide grinding wheel to the narrow grinding wheel can be adjusted at any time, so that the use range of a grinding device is expanded, and the cost is saved.

Owner:HEFEI AIRUIDE ELECTRICAL

Accelerated converging device for cigarette box conveying

InactiveCN106429361AReduce waiting timeImprove work efficiencyConveyorsConveyor partsDrive motorEngineering

The invention discloses an accelerated converging device for cigarette box conveying. The accelerated converging device comprises a main conveying track and a branch conveying track. An accelerated converging structure is arranged between the outlet of the branch conveying track and the main conveying track. The accelerated conveying structure comprises a driving support, driving units and a driving motor. Each driving unit is composed of a driving wheel, a tail wheel and a driving belt which is arranged on the driving wheel and the tail wheel in a sleeving mode. The multiple driving units are arranged in the width direction of the branch conveying track. A posture adjusting structure is arranged at the position, in front of the accelerated converging structure, of the main conveying track and arranged on the side, close to the branch conveying track, of the main conveying track. The posture adjusting structure comprises an adjusting wheel set formed by arranging multiple adjusting wheels in an arc shape. The arc top of the arc where the adjusting wheel set is located is protruded into the conveying face of the main conveying track from outside to inside from the position above the main conveying track. The accelerated converging device is wide in using range, simple in structure, high in reliability, multifunctional and high in working efficiency, and waiting time of the main conveying track is shortened.

Owner:CHINA TOBACCO HENAN IND

Pulse generator

InactiveCN108907910AAchieve grindingAvoid damageGrinding drivesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a pulse generator. The pulse generator comprises a work box and a cooling water tank arranged in the work box. A transmission cavity is formed in the work box, a belt wheel cavity located on the lower side of the transmission cavity is arranged in the work box, a polishing cavity located in the right side of the transmission cavity is formed in the work box, a first rotaryshaft, the lower end of which stretches into the belt wheel cavity, rotatably connected to the bottom wall of the belt wheel cavity is rotatably arranged on the bottom wall of the transmission cavity,a first bevel gear fixedly connected to the upper end of the first rotary shaft is arranged in the transmission cavity, a second rotary shaft rotatably connected to the left and right walls of the transmission cavity is arranged in the transmission cavity, a second bevel gear engaged to a first bevel gear is fixedly arranged on the second rotary shaft, and a first gear located on the right side of the second bevel gear is fixedly arranged on the second rotary shaft.

Owner:朱宽

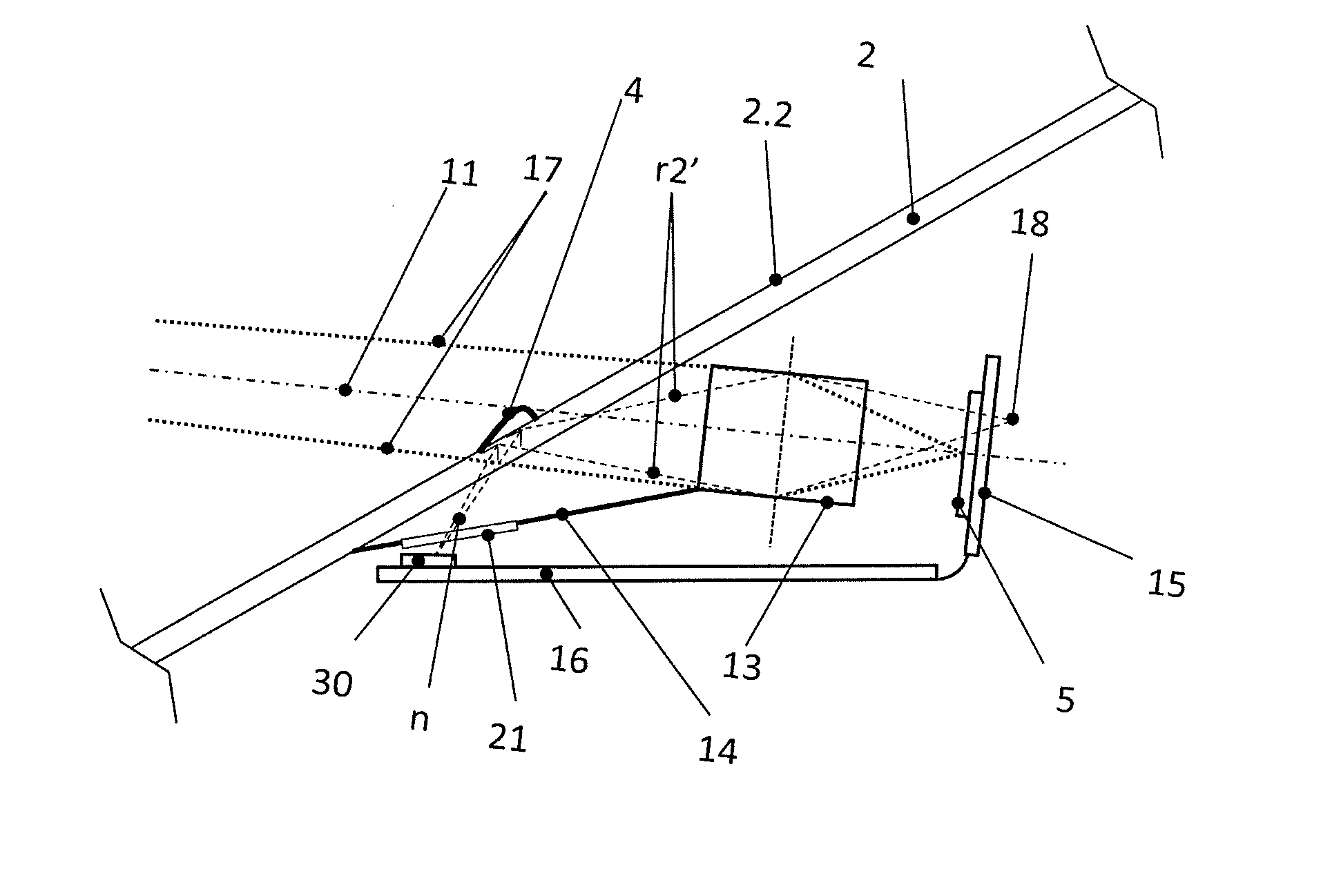

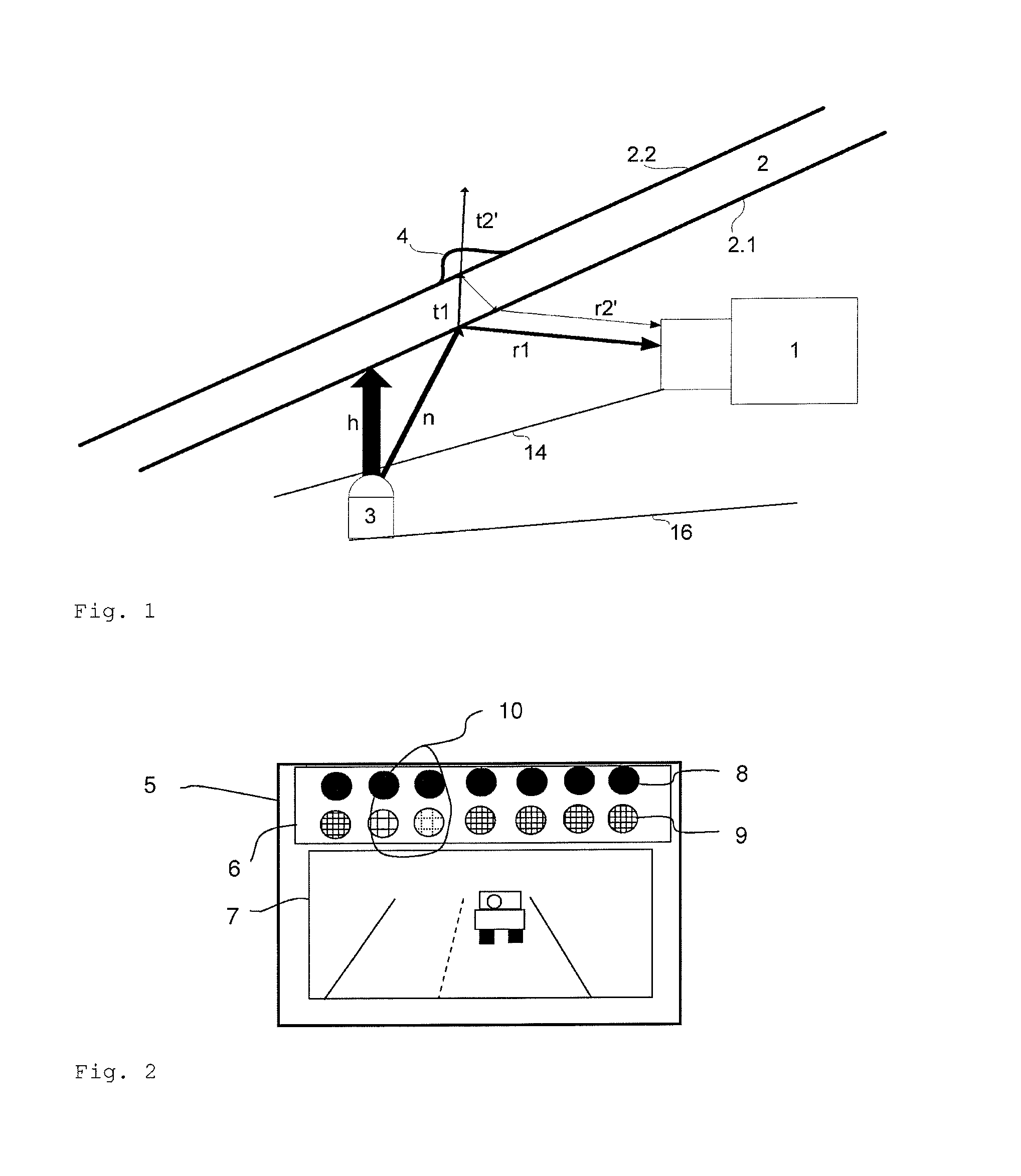

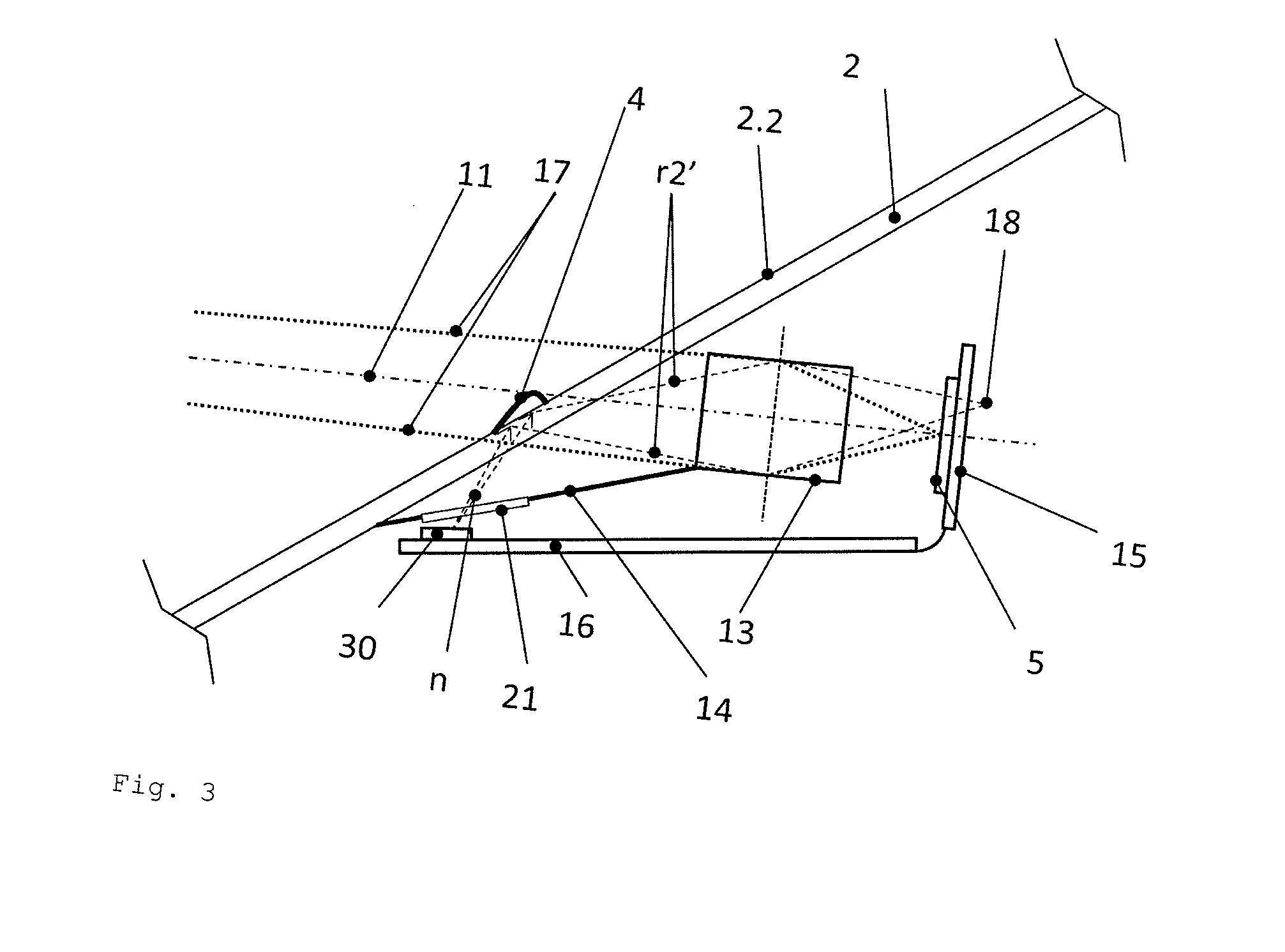

Illumination for the detection of raindrops on a window by means of a camera

ActiveUS20150276982A1Propagation of light is reducedAchieve spacingRainfall/precipitation gaugesPhase-affecting property measurementsVisible spectrum

A device for detecting rain includes a camera and a lighting source for emitting visible light onto a window. The camera and the lighting source are configured and arranged in such a way that the camera can detect a signal of the visible light which the lighting source emits onto the window. The signal which is detected by the camera correlates with visible light of the lighting source, which visible light is reflected or scattered at the inner face of the window or outer face of the window and / or at the raindrop. The visible light passes through a shutter device which causes the light to be blocked or highly attenuated in a predefined direction perpendicular to the illumination direction of structures of the shutter device. In contrast, the light in the direction perpendicular to the predefined direction and to the illumination direction can propagate virtually unimpeded through the shutter device.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

Long grained seed steering precision seeding device and seeding method thereof

InactiveCN101702969BTo achieve the purpose of batch directional seedling cultivationImprove job productivitySeed depositing seeder partsProduction rateEngineering

Owner:SOUTH CHINA AGRI UNIV

Leather clamping device on leather double-sided roller coater

InactiveCN113046497AAchieve simultaneous dyeingAvoid the problem of poor roller coating effectLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingElectric machineryEngineering

The invention relates to the technical field of roller coater, in particular to a leather clamping device on a leather double-sided roller coater. The leather clamping device comprises a base, wherein side plates are fixedly mounted on the upper side wall of the base respectively, top plates are fixedly mounted at the ends, away from the base, of the two sets of side plates, first conveying plates are fixedly mounted on the right side walls of the two sets of side plates, a first conveying roller driven by a motor is rotationally installed on the right sides of the two sets of first conveying plates, a second conveying roller is rotationally installed on the left sides of the two sets of first conveying plates, and a conveying belt is installed between the first conveying roller and the first conveying plates in a transmission mode. Compared with the prior art, the leather double-sided roller coater of the invention can conduct roller coating on the two faces of leather at the same time, and avoids the problem that due to the fact that most leather is in an irregular shape, leather wrinkles are prone to occurring when a leather clamping device on a traditional leather double-sided roller coater conducts clamping and roller coating on the leather, and the roller coating effect is poor is solved.

Owner:沈波

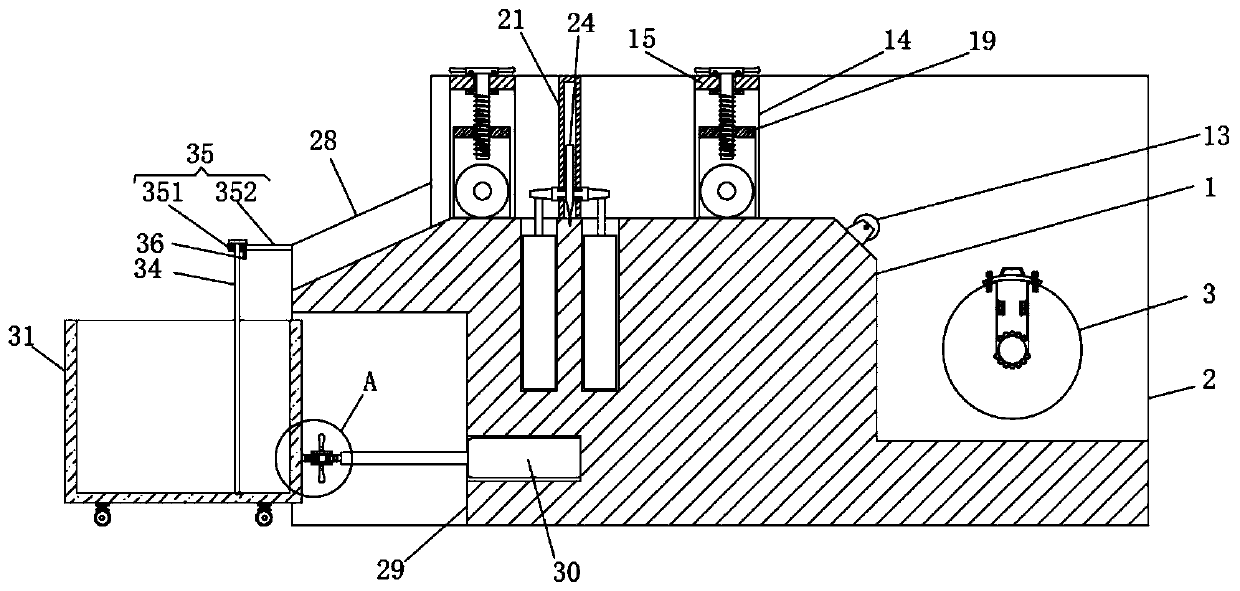

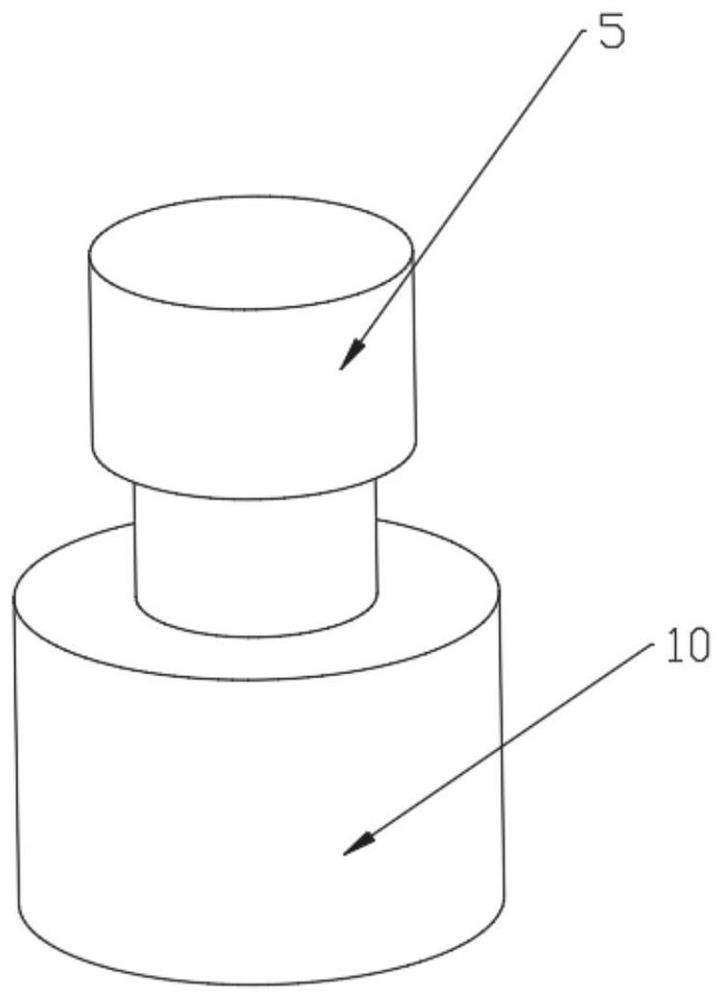

Method and equipment for making lightly pressed Fuzhuan tea

PendingCN114403249AEasy to drillImprove press molding efficiencyPre-extraction tea treatmentProcess engineeringFermentation

The invention relates to the technical field of Fuzhuan tea processing, discloses a making method and equipment of lightly pressed Fuzhuan tea, and solves the problems that during making of the Fuzhuan tea, the Fuzhuan tea needs to be manually taken for discharging, so that discharging is inconvenient, and the making speed of the Fuzhuan tea is slow. S2, the tender shoots in the step S1 are subjected to impurity removal and screening, the screened tender shoots are washed and cut up, the cut tender shoots are placed in a worm wheel fermentation machine to be steamed for 30 minutes, the tea leaves are softened for standby application, water is added into the tea leaves in the step S4, and the tea leaves are steamed again through the worm wheel fermentation machine for 1 minute; and through the design of the pushing mechanism and the pushing plate, the pushing plate can conveniently push the pressed and formed tea leaves to be discharged, manual discharging is effectively avoided, the discharging efficiency of the tea leaves is further improved, and the production efficiency of the tea leaves is further improved.

Owner:益阳冠隆誉黑茶发展有限公司

Cereal moisture detector

The invention discloses a cereal moisture detector which comprises a rolling module. The rolling module comprises a wide rolling wheel and a narrow rolling wheel, wherein a bearing seat of the wide rolling wheel is fixedly installed on one sliding block, a push plate is fixed to the bottom of the sliding block and is fixed to an adjusting screw transversely arranged on the side face of a housing, the side face of the housing is provided with a threaded hole for threaded connection with the adjusting screw, one end of the adjusting screw is fixed to the push plate, and the other end of the adjusting screw penetrates through the threaded hole and extends to the outside of the housing. A sliding groove for installing the push plate is formed in the housing, is greater than the push plate in length and is matched with the push plate in width. The distance between the wide rolling wheel and the narrow rolling wheel can be adjusted at any time, the gap between the rolling wheels can be accurately adjusted after rolling wheel replacement, and the detection precision is improved.

Owner:HEFEI AIRUIDE ELECTRICAL

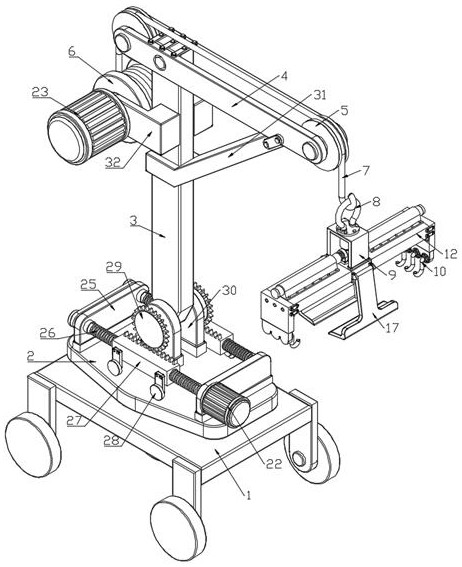

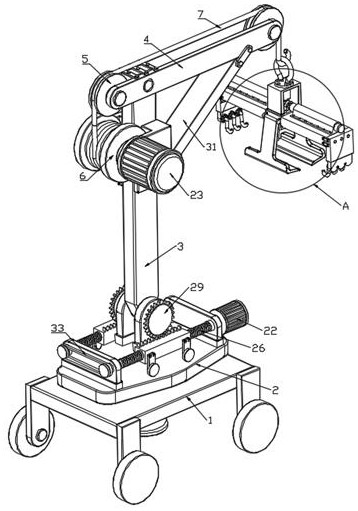

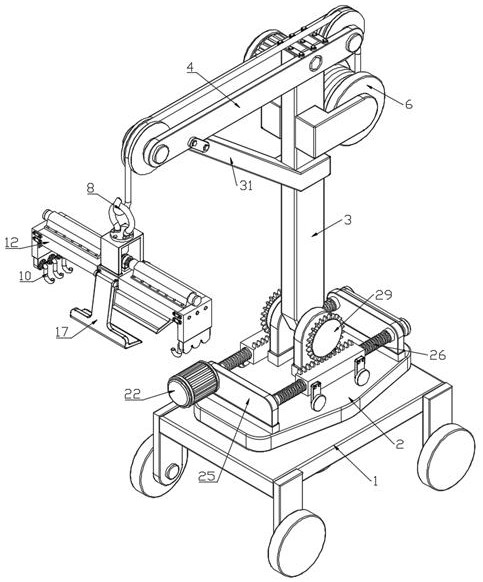

Template large-span hoisting device for building construction

InactiveCN114455487AGuaranteed stabilityEasy to fixLoad-engaging elementsCranesArchitectural engineeringElectric machinery

The invention relates to a large-span template hoisting device for building construction, which comprises a base, a steering plate rotationally mounted on the base and a vertical plate rotationally mounted on the steering plate, and a first driving motor for driving the steering plate to deflect is mounted on the base; the output end of the first driving motor is connected with a rotating shaft of the steering plate, two sets of thread driving mechanisms used for driving the vertical plate to deflect are installed on the steering plate, a winding mechanism is installed on the vertical plate, the end, away from the vertical plate, of the winding mechanism is connected with a mounting frame, the mounting frame is arranged in a U shape, and the rotating shaft of the mounting frame is connected with the rotating shaft of the steering plate. The winding mechanism is installed on the vertical plate and connected with the installation frame, a long plate is fixedly installed on the installation frame, and a plurality of hooks are movably arranged at the two ends of the long plate through thread adjusting mechanisms. And the working intensity of constructors is reduced.

Owner:湖南工商大学

Automatic tape cutting machine capable of automatically collecting finished products

ActiveCN111167971AReasonable structureFunctionalMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of automatic tape cutting machines, in particular to an automatic tape cutting machine capable of automatically collecting finished products. The automatictape cutting machine comprises a cutting machine body, wherein two rack surrounding plates are arranged on the surface of the cutting machine body, a wound material placing assembly is arranged between the two rack surrounding plates, and lifting grooves are formed in the surfaces of the rack surrounding plates; and a guide roller is arranged on the surface of the cutting machine body, two downward-pressing type material conveying assemblies are arranged inside the lifting grooves, and a guide rail is arranged between the two downward-pressing type material conveying assemblies. The automatictape cutting machine capable of automatically collecting the finished products has the beneficial effects that according to the automatic tape cutting machine capable of automatically collecting thefinished products, butt joint grooves are formed in two limiting plates for allowing winding columns to be placed, then the winding columns are clamped and fixed through splicing sealing plates, and balls are additionally arranged on the surfaces of the splicing sealing plates and the butt joint grooves to improve the rotating smoothness of the winding columns, so that the winding columns are easyand convenient to assemble and disassemble, and friction generated when the winding columns rotate is reduced.

Owner:绍兴鸿晨化纤有限公司

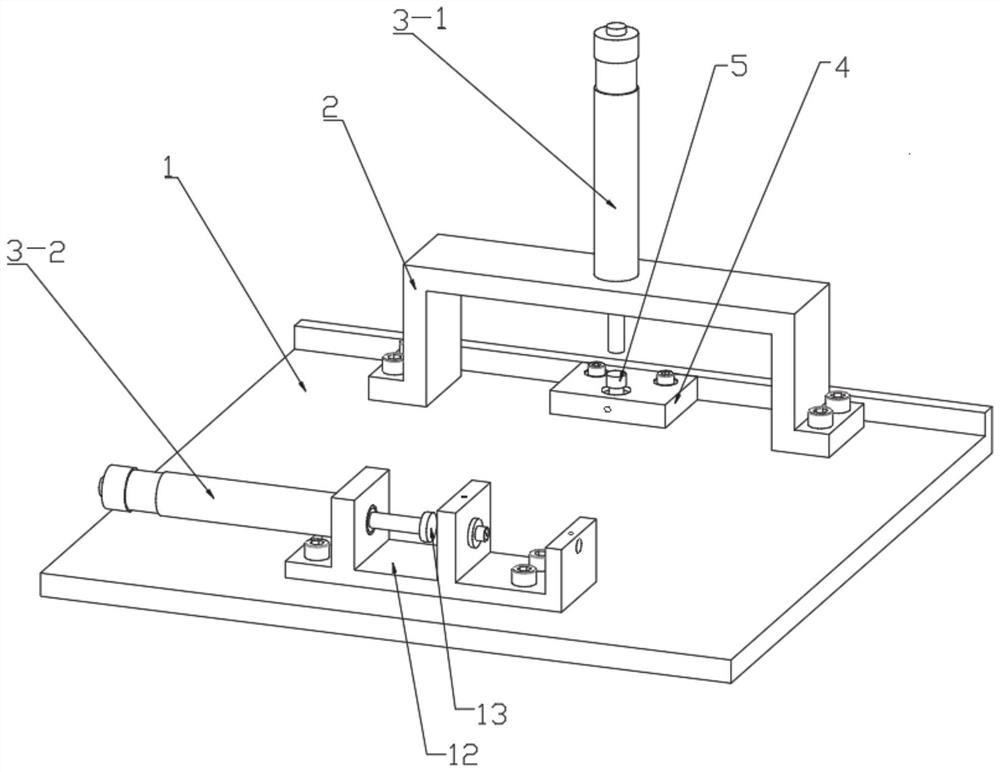

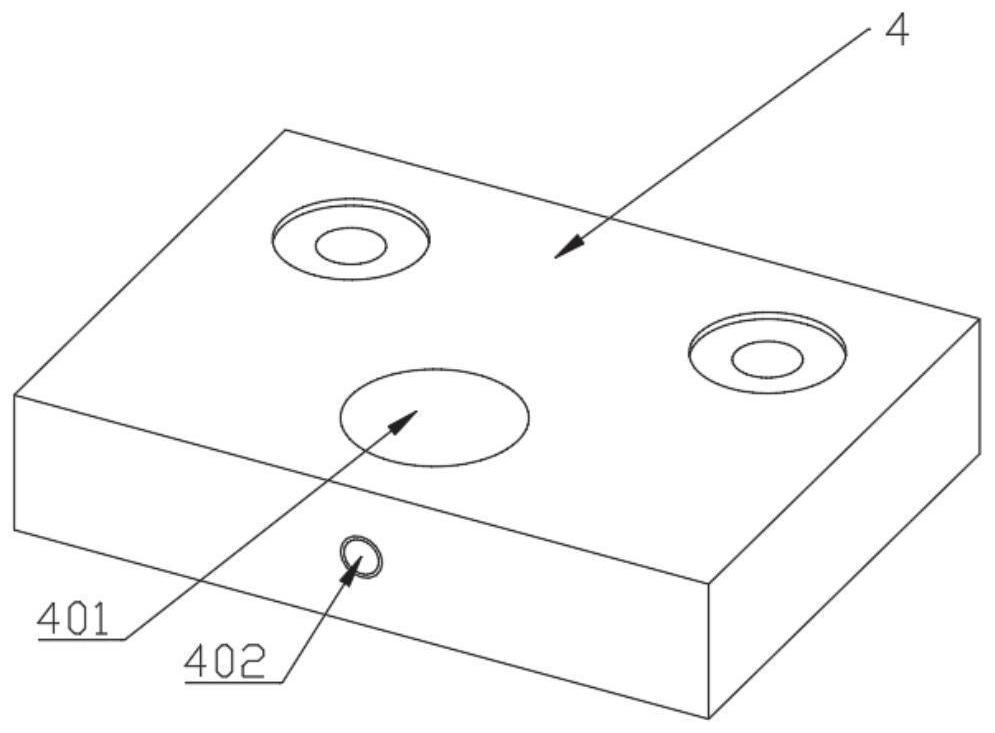

Assembly device of single-pole-plate capacitance sensor and assembly method

ActiveCN112959050AAchieve insulationRealize the shielding effectMaterial gluingMetal working apparatusMechanical engineeringCapacitance transducer

The invention belongs to the field of capacitance sensor assembly, and provides an assembly device of a single-pole plate capacitance sensor and an assembly method. The assembly device comprises a base plate, a sensor fixing table, a portal frame, a first micrometer head, a correction block, a flexible ring and a flexible disc. The sensor fixing table and the portal frame are both mounted on the base plate. The sensor fixing table is arranged below the portal frame. The correction block is arranged on a sensor to be assembled, and the first micrometer head is arranged on the portal frame and is opposite to the correction block. The two sides of the flexible disc are connected with the correction block and a measuring electrode of the sensor separately, so that longitudinal flexible assembly of the measuring electrode is achieved. The two sides of the flexible ring are connected with the correction block and an equipotential ring of the sensor separately, so that longitudinal flexible assembly of the equipotential ring is achieved. The first micrometer head is used for applying pressure to the correction block through longitudinal flexible pre-tightening, so that the measuring electrode of the sensor, the equipotential ring and a shielding ring are transversely limited and coaxially assembled, the bottom surfaces of the three are on the same horizontal plane, so that the flatness of the surface of the sensor is ensured.

Owner:SHANDONG UNIV

An adjustable distance cable conveyor

ActiveCN108975050BAchieve spacingReduce power consumptionFilament handlingStructural engineeringControl theory

Owner:STATE GRID CORP OF CHINA +1

Multifunctional rice seeder with adjustable spacing

InactiveCN112514612AAdjust seeding spacingAvoid twisting and bendingSeed depositing seeder partsBroadcast seedersSeederGear wheel

The invention discloses a multifunctional rice seeder with adjustable spacing, relates to the field of rice seeding, and aims to solve the problem that an existing device cannot conduct seeding in themoving process. The multifunctional rice seeder specifically comprises a shell, adjusting assemblies are fixedly connected to the inner walls of the two sides of the shell, and a material distributing assembly is fixedly connected to the inner wall of the bottom of the shell; and each of the adjusting assemblies comprises two clamping plates and two sleeves. By arranging the adjusting assemblies,a power box is started to drive a jacking column to rotate, when the jacking column rotates, an air cylinder on the inner wall of a first frame is started to drive a second frame to move, and an adjusting motor on the inner wall of the second frame is started, so that one connecting gear is engaged with a gear sleeve all the time, and stepless speed change can be achieved; and meanwhile, the other connecting gear obtains various rotating speed adjustments, different speeds can be output, the material distributing assembly can be controlled through speed adjustment, and then the sowing spacingcan be adjusted in the moving process of the device.

Owner:六安市叶集区辉耀农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com