Efficient automatic production line for PVC processing and working method of efficient automatic production line

An automated production line and high-efficiency technology, applied in applications, home appliances, other home appliances, etc., can solve problems such as the inability to meet the requirements of enterprise production, the impact of equipment production, and the impact on the quality of edge removal, so as to improve product processing quality and ensure quality. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

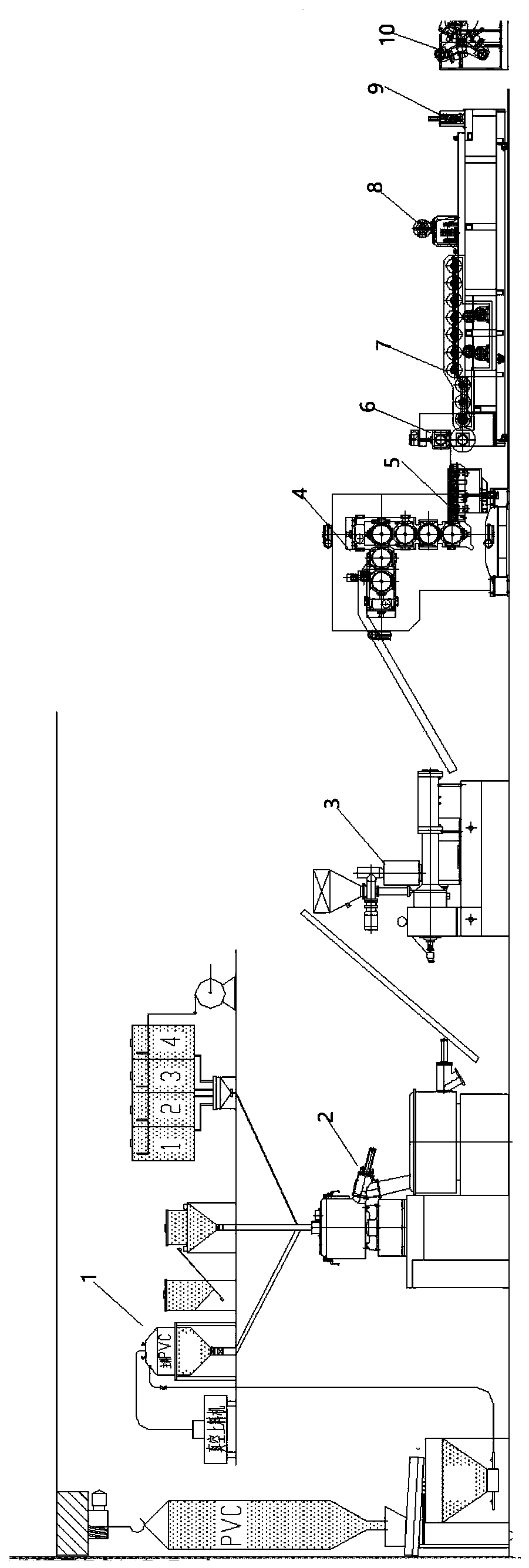

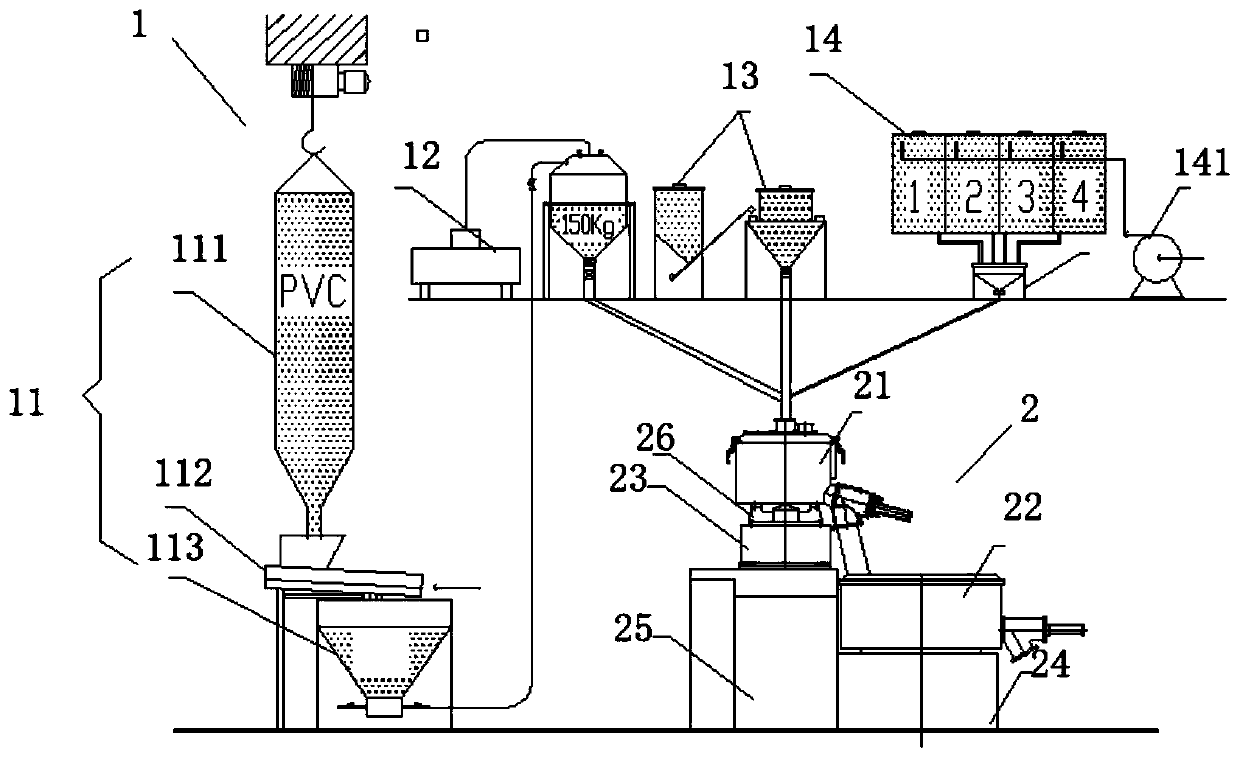

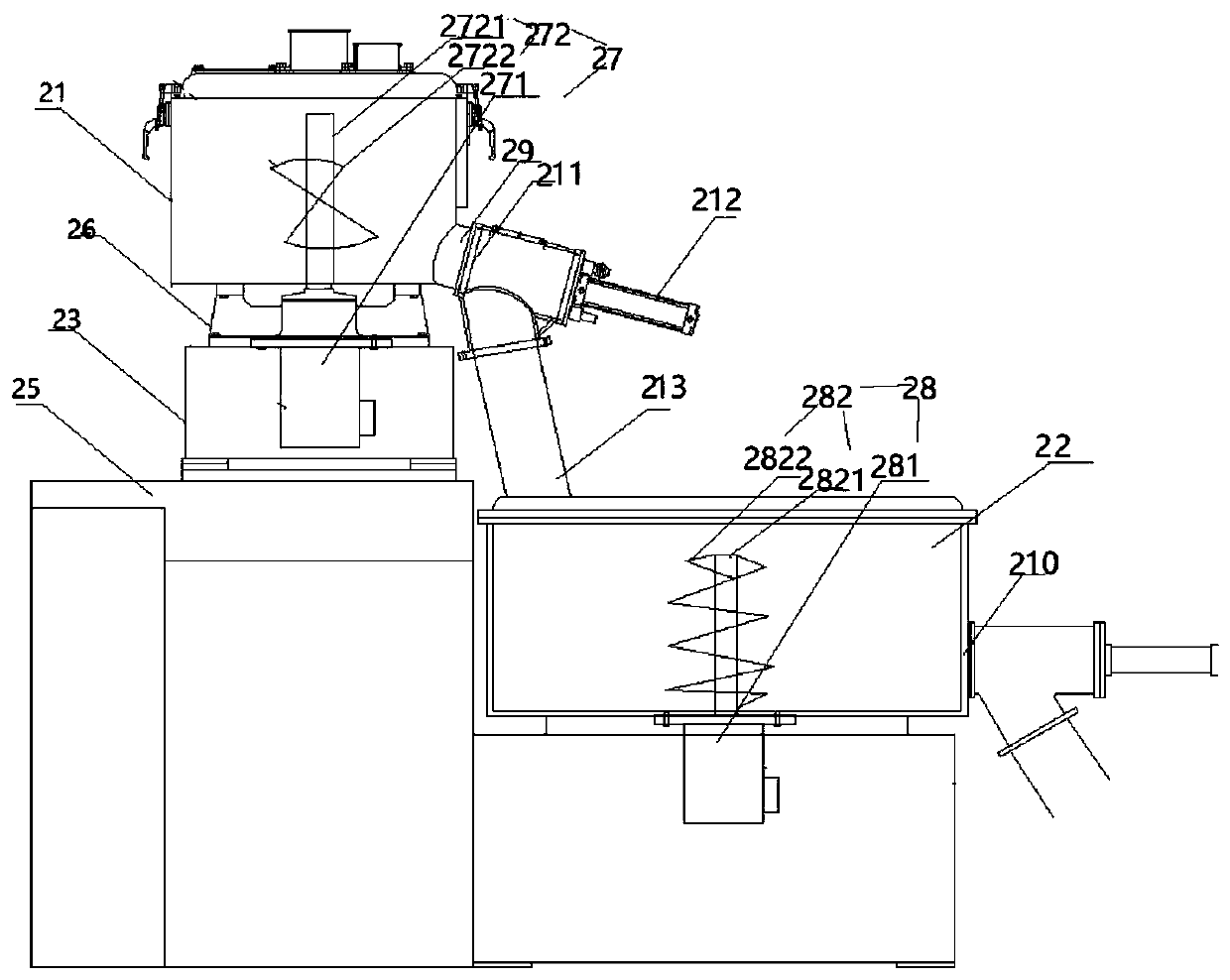

[0049] As shown in the figure, a high-efficiency automatic production line for PVC processing includes: automatic feeding mechanism 1, mixing mechanism 2, planetary extruder 3, six-roll calendering main and auxiliary machine 4, roll peeling mechanism 5, calendering Roller 6, roller cooling mechanism 7, trimming mechanism 8, traction roller 9 and sheet material coiler 10, wherein said automatic feeding mechanism 1 is provided with raw material storage device 11, vacuum feeding machine 12, a group of auxiliary materials Storage device 13 and a group of processing aid tanks 14, the output end of the raw material storage device 11 is connected with the material box in the vacuum feeder 12, the processing aid tank 14 is connected with the gear oil pump, the vacuum feeding The output ends of the material storage box in the machine 12, the auxiliary material storage device 13 and the processing aid tank 14 are respectively connected to the feed port of the mixing mechanism 2 through t...

Embodiment 2

[0062] As shown in the figure, a high-efficiency automatic production line for PVC processing includes: automatic feeding mechanism 1, mixing mechanism 2, planetary extruder 3, six-roll calendering main and auxiliary machine 4, roll peeling mechanism 5, calendering Roller 6, roller cooling mechanism 7, trimming mechanism 8, traction roller 9 and sheet material coiler 10, wherein said automatic feeding mechanism 1 is provided with raw material storage device 11, vacuum feeding machine 12, a group of auxiliary materials Storage device 13 and a group of processing aid tanks 14, the output end of the raw material storage device 11 is connected with the material box in the vacuum feeder 12, the processing aid tank 14 is connected with the gear oil pump, the vacuum feeding The output ends of the material storage box in the machine 12, the auxiliary material storage device 13 and the processing aid tank 14 are respectively connected to the feed port of the mixing mechanism 2 through t...

Embodiment 3

[0084] As shown in the figure, a high-efficiency automatic production line for PVC processing includes: automatic feeding mechanism 1, mixing mechanism 2, planetary extruder 3, six-roll calendering main and auxiliary machine 4, roll peeling mechanism 5, calendering Roller 6, roller cooling mechanism 7, trimming mechanism 8, traction roller 9 and sheet material coiler 10, wherein said automatic feeding mechanism 1 is provided with raw material storage device 11, vacuum feeding machine 12, a group of auxiliary materials Storage device 13 and a group of processing aid tanks 14, the output end of the raw material storage device 11 is connected with the material box in the vacuum feeder 12, the processing aid tank 14 is connected with the gear oil pump, the vacuum feeding The output ends of the material storage box in the machine 12, the auxiliary material storage device 13 and the processing aid tank 14 are respectively connected to the feed port of the mixing mechanism 2 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com