Method and equipment for making lightly pressed Fuzhuan tea

A production method and technology for Fu tea, which are applied in the field of Fu tea processing, can solve the problems of slow production speed and inconvenient discharging of Fu tea, and achieve the effects of improving pressing and forming efficiency, improving discharging efficiency and avoiding manual discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

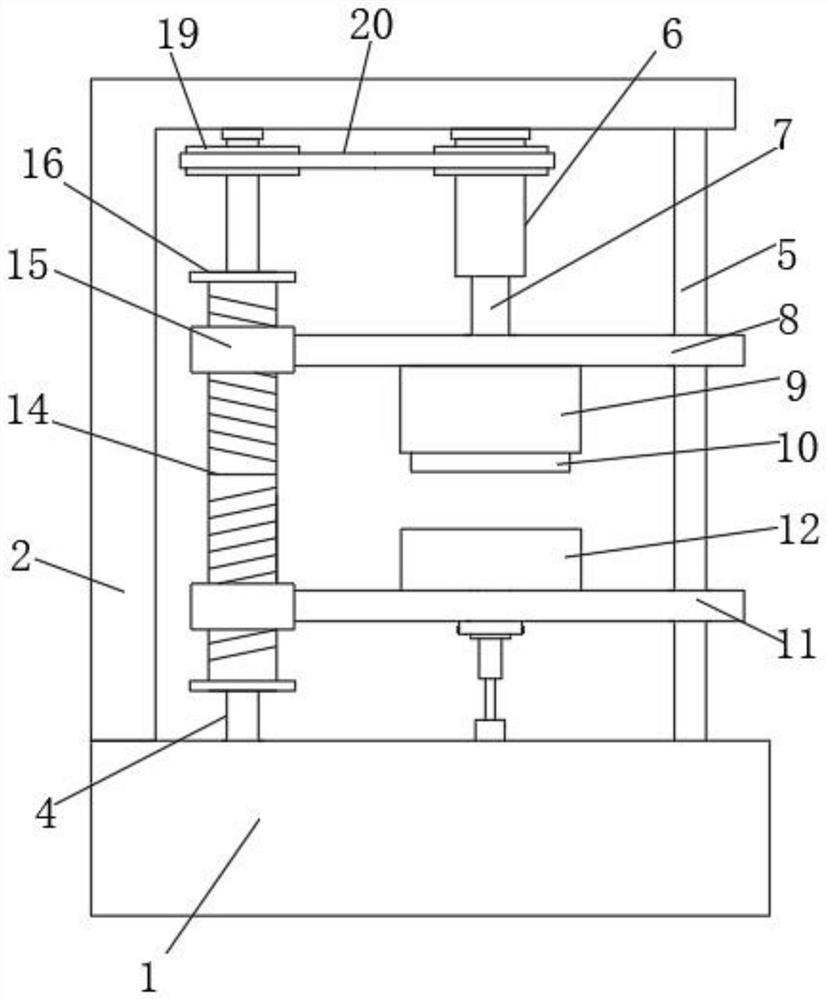

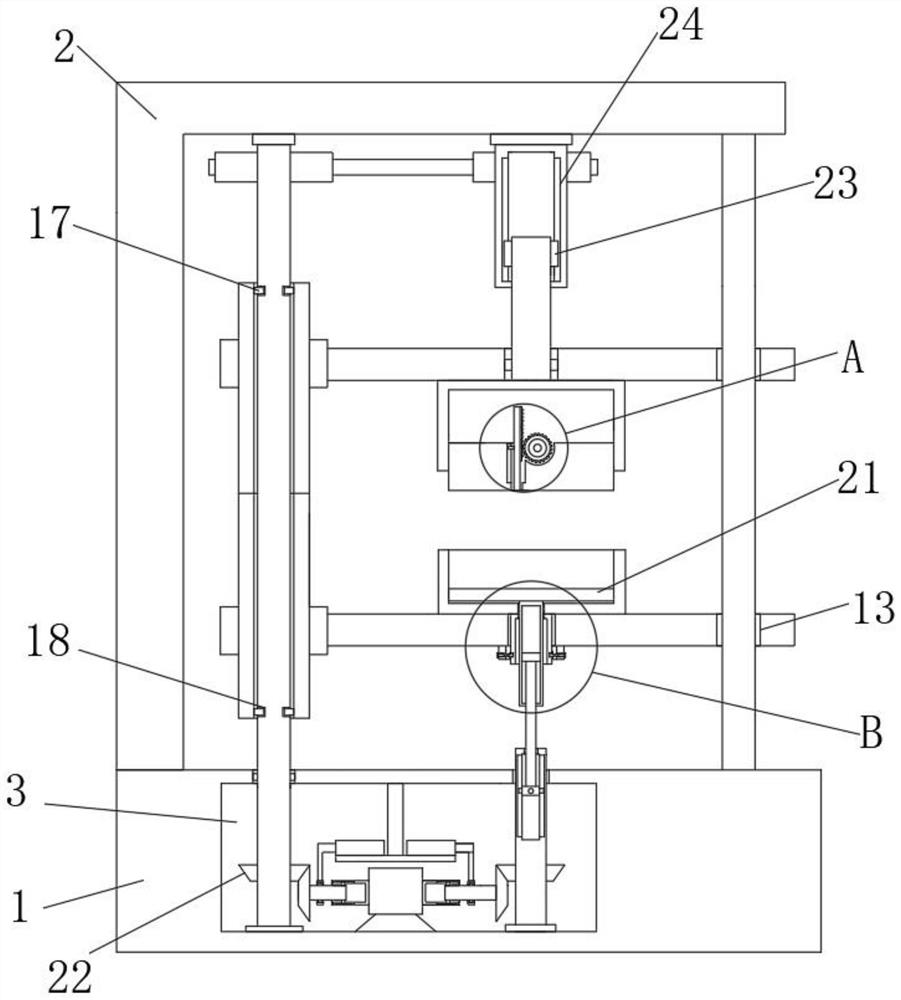

[0057] Embodiment two, on the basis of embodiment one, by figure 1 and figure 2 Given, the rotating group includes a pulley 19, an engaging belt 20, a slider 23 and a chute 24, and the outer wall of the transmission shaft 4 and the rotating cylinder 6 is provided with a pulley 19, and the two pulleys 19 are connected by an engaging belt 20 to rotate The top of the shaft 7 is symmetrically provided with a slider 23, and the inner wall of the rotating cylinder 6 is provided with a chute 24 slidingly connected with the slider 23;

[0058] When the transmission shaft 4 rotates, one of the pulleys 19 will be driven to rotate, and the connection between the connecting belt 20 will cause the other pulley 19 to rotate, and then the pulley 19 will drive the rotating cylinder 6 to rotate. Through the sliding connection between the slider 23 and the chute 24, The rotating cylinder 6 will drive the rotating shaft 7 to rotate, and then the rotating shaft 7 will drive the mounting seat 9 ...

Embodiment 3

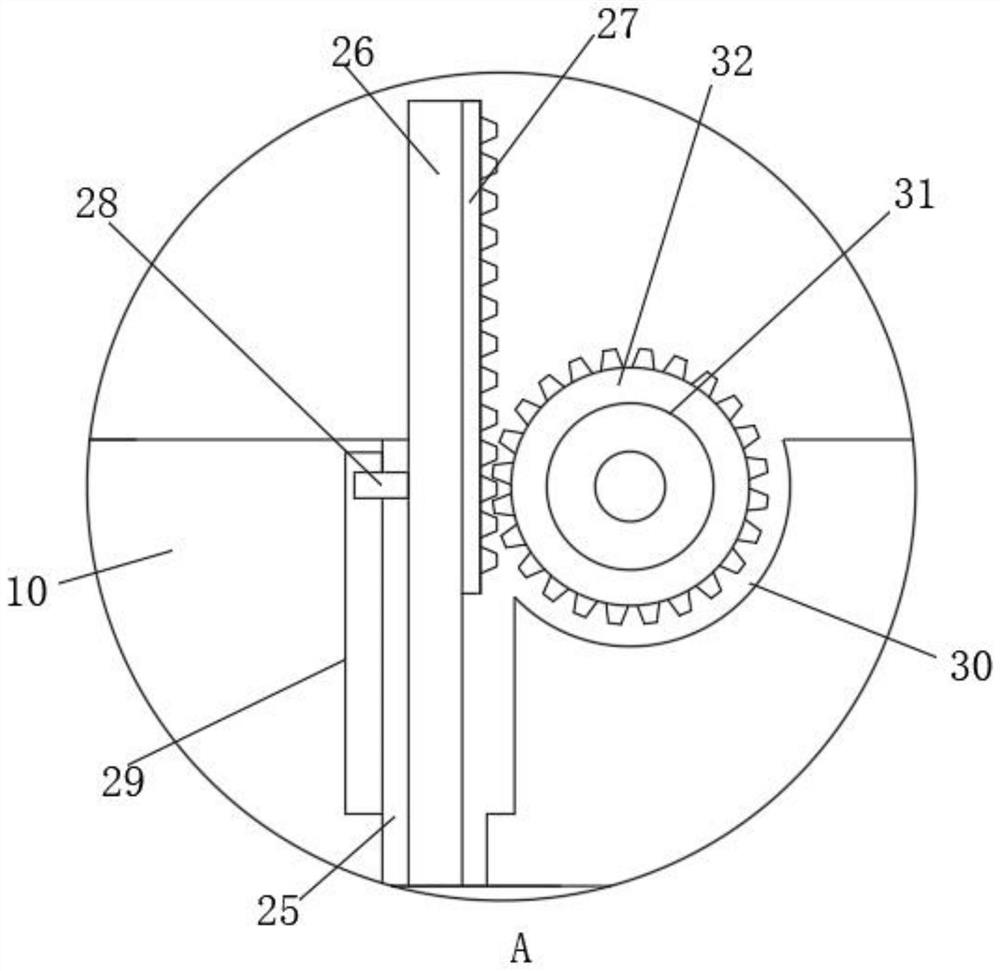

[0059] Embodiment three, on the basis of embodiment one, by figure 2 , Figure 4 and Figure 5 Given, the driver is composed of a pusher and a driver, the driver includes a biaxial motor 33, a rotating cylinder 34, a rotating shaft 36, a bevel gear 2 37 and a bevel gear 3 38, and the middle position of the inner bottom end of the accommodation groove 3 is set Biaxial motor 33 is arranged, and the output shaft of biaxial motor 33 is connected with rotating cylinder 34, and the inside of rotating cylinder 34 is all rotated and interspersed with rotating shaft 36, and one end of one of rotating shaft 36 is provided with bevel gear-22 meshing connection Bevel gear two 37, wherein one end of the other rotating shaft 36 is provided with bevel gear three 38, connected by a pusher between the two rotating shafts 36, the pusher includes a mounting rod 41, an electric push rod 42, a pull rod 43 and The connecting sleeve 44, the inner top end of the receiving groove 3 is provided with...

Embodiment 4

[0062] Embodiment four, on the basis of embodiment one, by figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7 Given, the pusher mechanism includes a mounting cylinder 46, an internally threaded cylinder 47, an externally threaded block 48, a connecting rod 49, a mounting shaft 50, a bevel gear four 51, a moving block 52, a threaded hole one 53, a clamping block 54, a clamping Connecting groove 55, threaded hole 2 56 and screw rod 57, height adjustment plate 2 11 runs through mounting cylinder 46, the top of mounting cylinder 46 contacts with the bottom end of mold base 12, and the inside of mounting cylinder 46 is interspersed with pushing plate 21 The internally threaded cylinder 47 connected to the bottom, the internal thread of the internally threaded cylinder 47 is connected with an externally threaded block 48, the bottom of the externally threaded block 48 is provided with a connecting rod 49, the inside of the receiving groove 3 is equipped with an installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com