Karst cave treatment method applied to karst area cast-in-situ bored pile construction

A technology of bored cast-in-place piles and a treatment method, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of different types of karst caves with different treatment effects, large concrete overfilling, and high engineering costs. The effect of reducing the amount of dumping and filling, simple construction materials and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

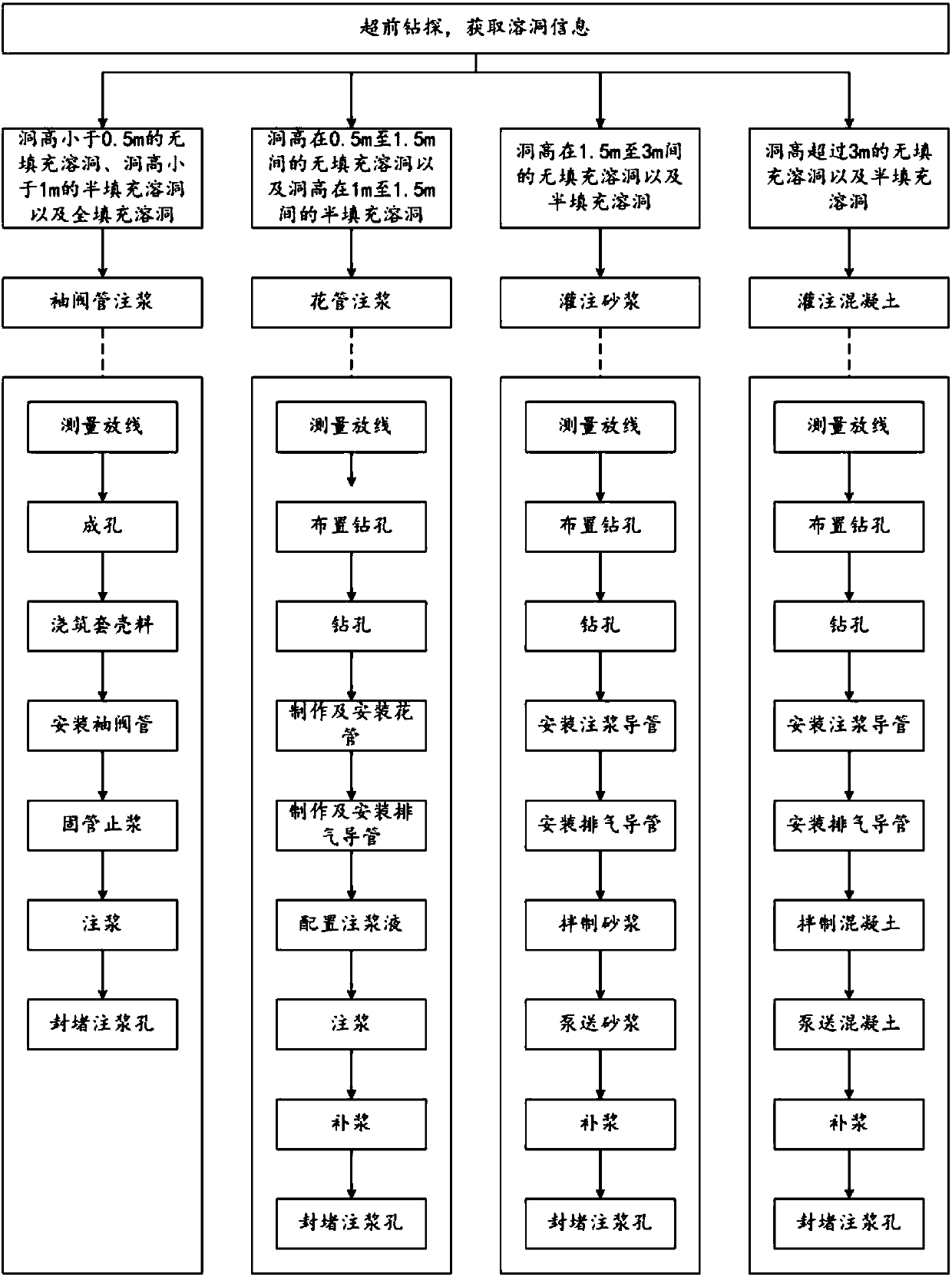

[0066] combine figure 1 As shown, this embodiment provides a method for treating karst caves applied in the construction of bored piles in karst areas, which includes the following steps:

[0067] Obtain the distribution of karst caves at the pile location, use advanced drilling technology to obtain the depth and height of karst caves at the pile location, and select the processing method according to the obtained karst cave height value according to the following methods:

[0068] (1) For unfilled karst caves and semi-filled karst caves with a cave height exceeding 3m, the method of pouring concrete shall be used for treatment;

[0069] (2) For unfilled caves and semi-filled caves with a cave height between 1.5m and 3m, the method of pouring mortar is used for treatment;

[0070] (3) For unfilled karst caves with a cave height between 0.5m and 1.5m and semi-filled karst caves with a cave height between 1m and 1.5m, adopt the method of floral tube grouting;

[0071] (4) For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com