Femtosecond laser manufacturing method for tunable phase change nanostructure super surfaces

A femtosecond laser and nanostructure technology, applied in the field of femtosecond laser applications, can solve problems such as complex processes and achieve simple and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

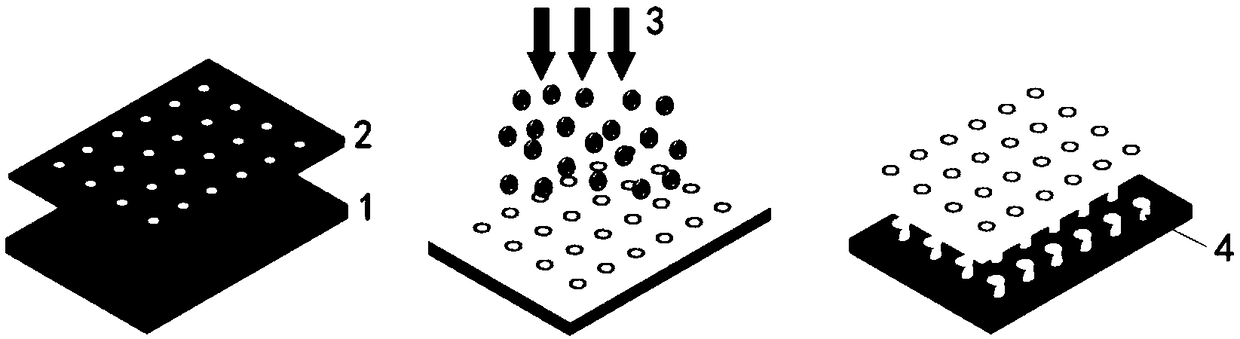

[0032] For amorphous columnar Ge 2 Sb 2 Te 5 Taking nanostructures for femtosecond laser morphology control as an example, the specific processing steps are as follows:

[0033] (1) Sample preparation: In this example, 40nm thick Ge was plated on a 10mm×10mm×1mm silicon dioxide substrate by magnetron sputtering. 2 Sb 2 Te 5 film, and then remove the AAO template to obtain columnar nanostructures;

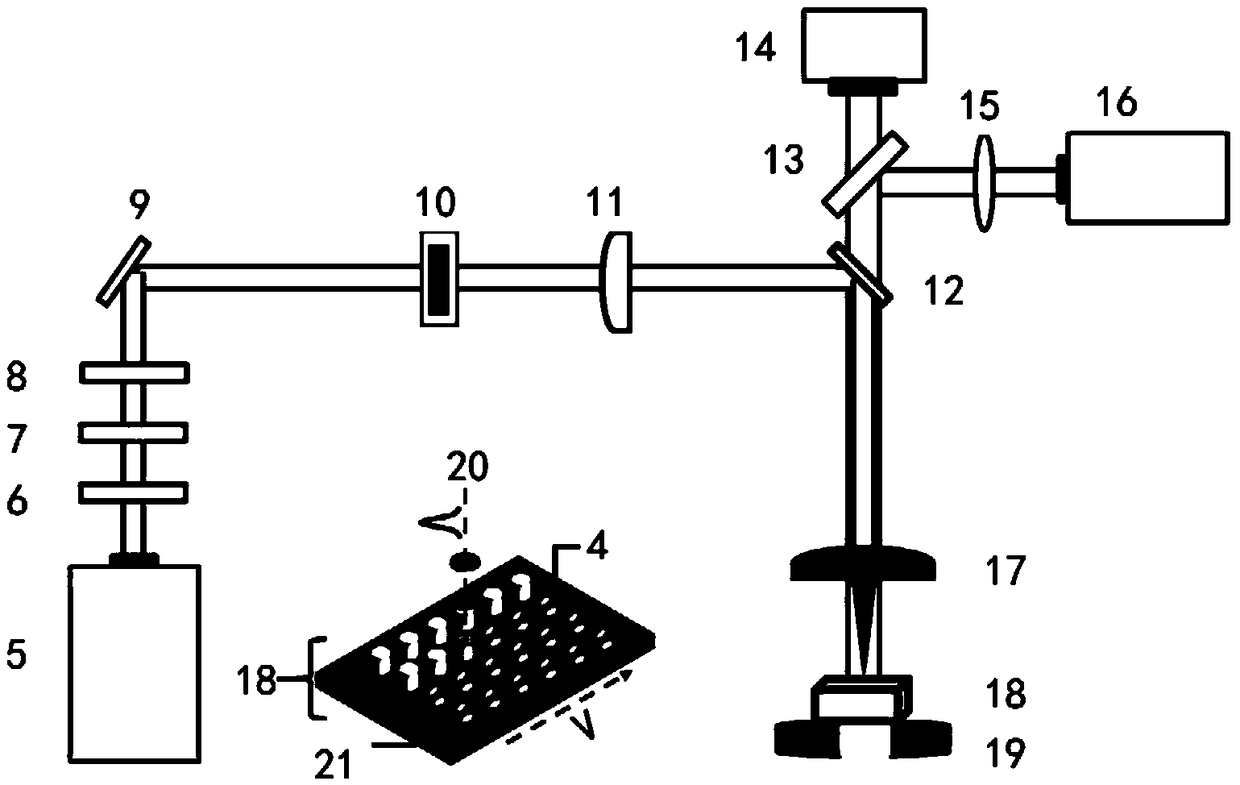

[0034] (2) The processed sample 18 is fixed on the six-dimensional mobile platform 19, and the femtosecond laser pulse is focused by a double-glued achromatic plano-convex lens 17 with a focal length of 100 mm, so that the circular Gaussian beam can act on the surface of the processed sample 18 , through the observation of the imaging CCD16, adjust the optical path so that the incident laser light is perpendicular to the surface of the sample 18;

[0035] (3) Utilize the combination of the half-wave plate 6 and the polarizer 7 and the continuous attenuation plate 8 to adjust t...

specific Embodiment 2

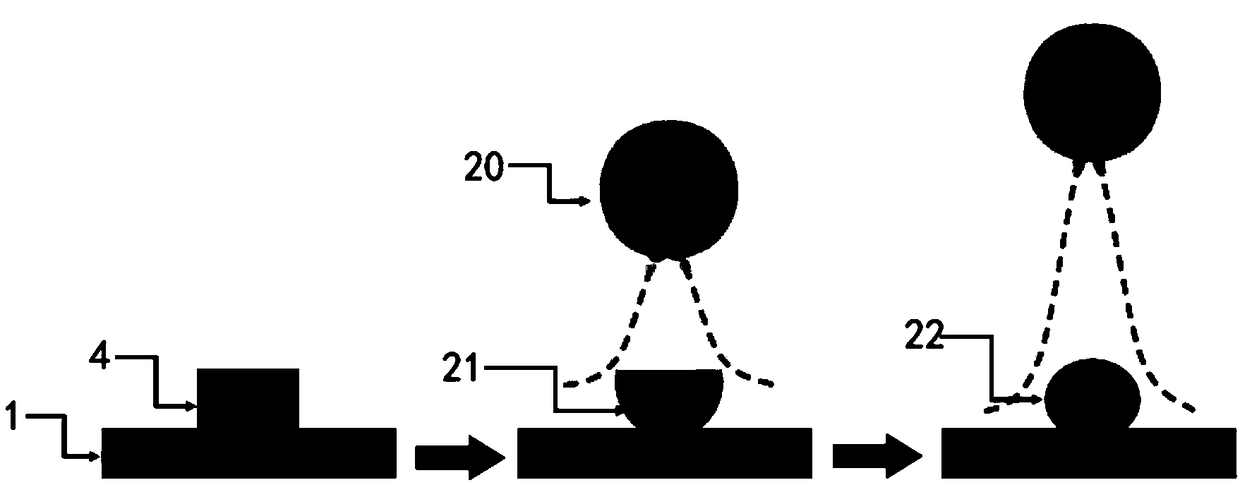

[0039] With the spherical Ge of the crystalline state that utilizes example one to make 2 Sb 2 Te 5 The nanostructure is used as a sample, and the control of femtosecond induced phase transition is taken as an example. The specific processing steps are as follows:

[0040] (1) Adjust the optical path: add a plano-convex cylindrical mirror 11 between the dichroic mirror 12 and the mechanical switch 10, use beam shaping to focus the beam line, and rotate the cylindrical mirror to make the long axis direction of the spot coincide with the translation stage Y Axis parallel;

[0041] (2) repeat the process (2) in the specific embodiment one;

[0042] (3) Utilize the combination of the half-wave plate 6 and the polarizer 7 and the continuous attenuation plate 8 to adjust the laser energy, so that the laser single pulse energy changes continuously from small to large between 0.5-1.1 times the ablation threshold;

[0043] (4) Using a single pulse to irradiate the surface of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com