Method and device for detecting the wear state of a component of a door drive system of a rail vehicle

A wear state and drive system technology, applied to vehicle components, registration/indication of vehicle operation, door/window accessories, etc., can solve problems such as inability to ensure rail vehicle operation, insufficient monitoring of wear state, and door system failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the subsequent description, identical or similar elements are assigned the same or similar reference symbols in different figures, wherein a repeated explanation of these reference symbols is avoided for reasons of clarity.

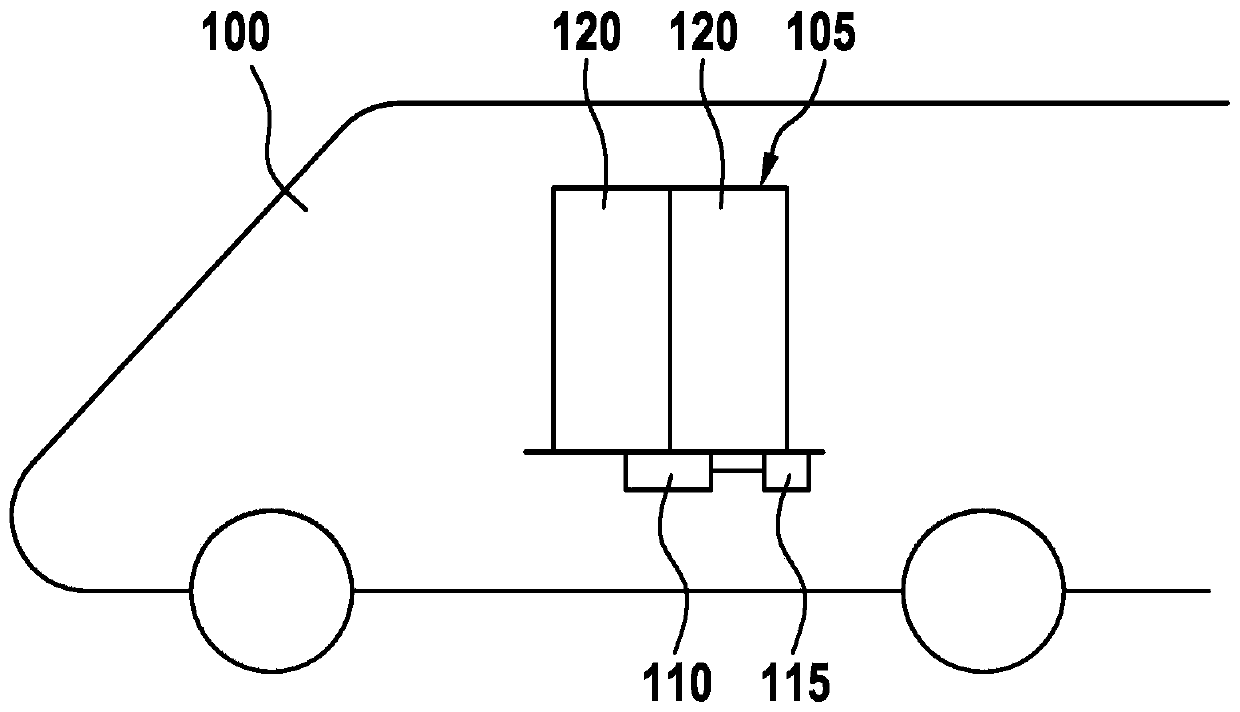

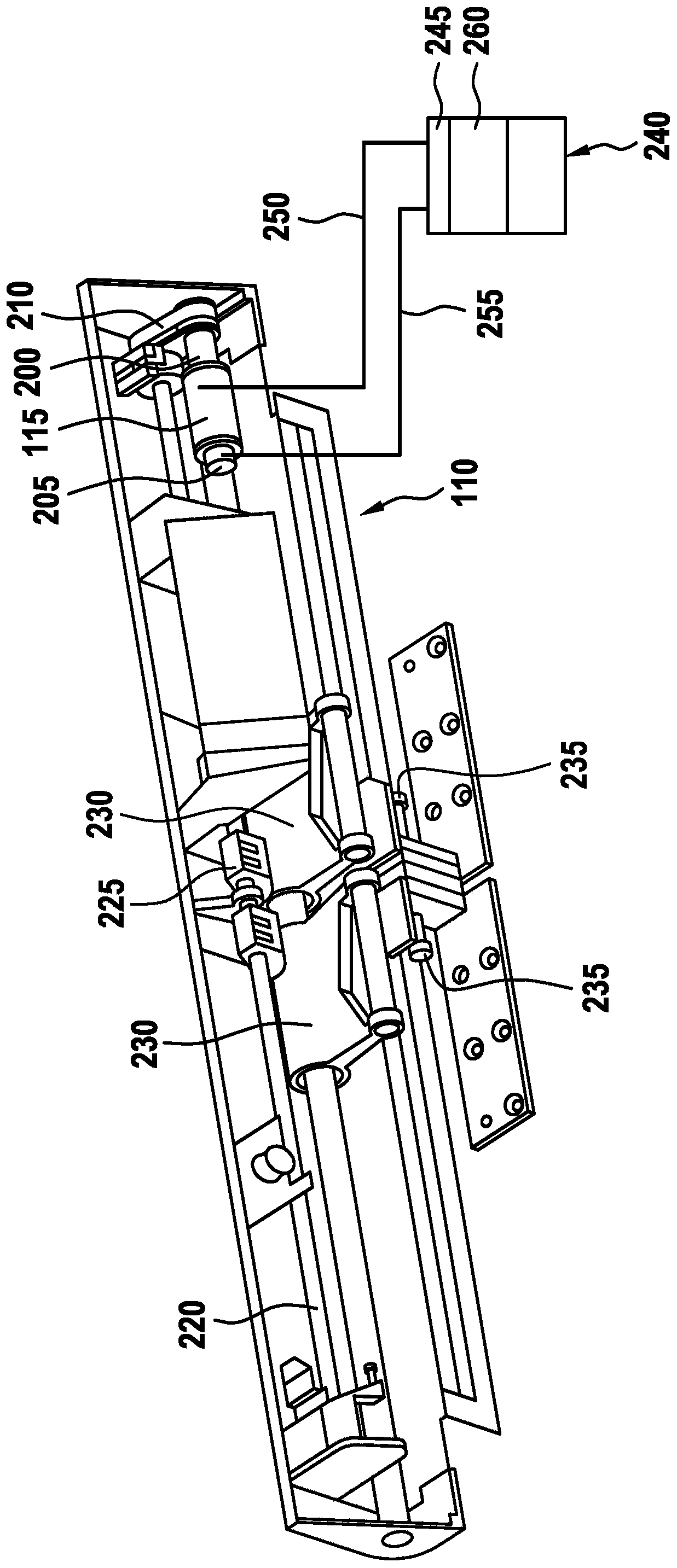

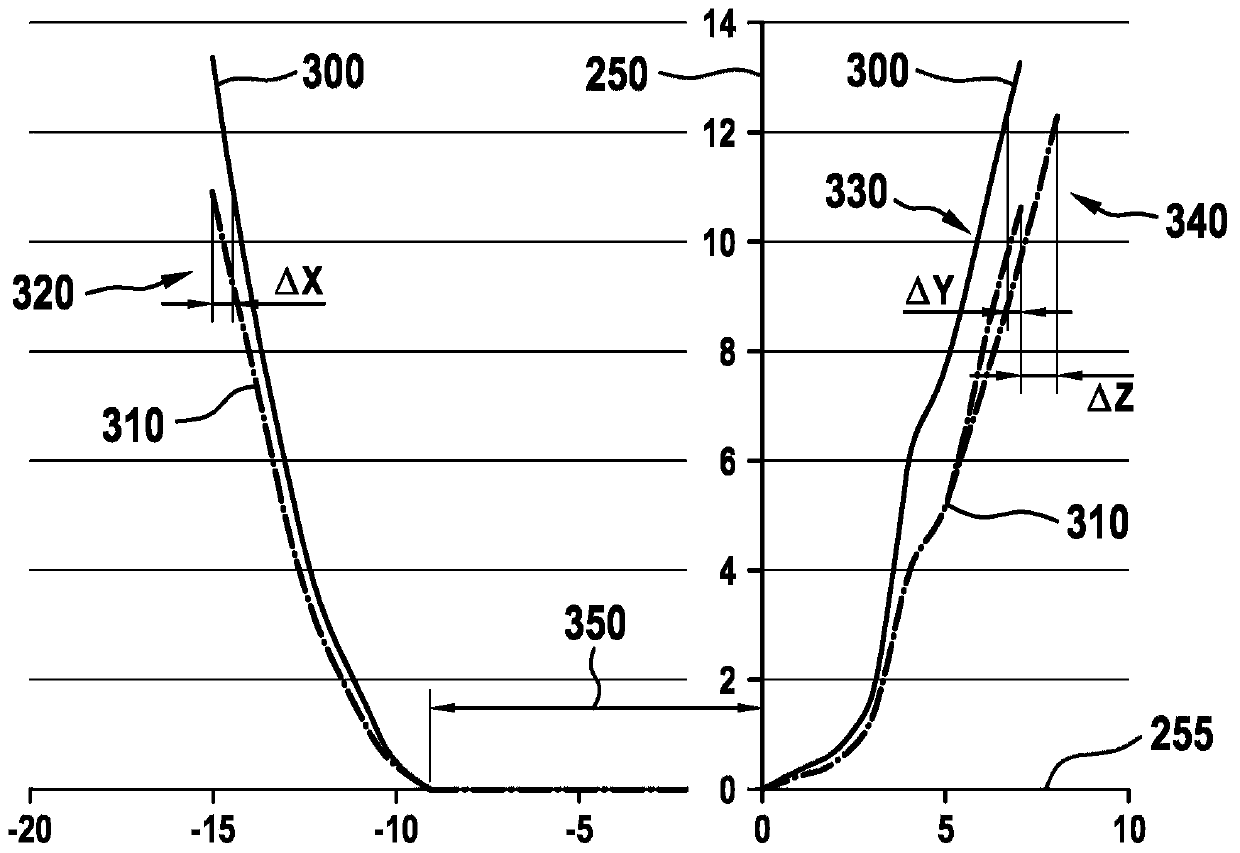

[0034] figure 1 A diagram of a rail vehicle 100 is shown, the doors 105 of which are driven by a door drive system 110 with an electric motor 115 to allow passengers to enter the interior of the rail vehicle 100 . The door drive system 110 can here be designed in such a way that the leaves 120 of the doors 105 are moved away from each other when the door 105 is opened or towards each other when the door 105 is closed. Because such a door drive system 110 is subjected to high and permanent loads during the operation of the rail vehicle 100, individual components of such a door drive system 110 (such as a power transmission belt for force transmission, for lightening the door leaf 120 during the movement stroke) The impact rubber buffer on the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com