Patents

Literature

62results about How to "Precision workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

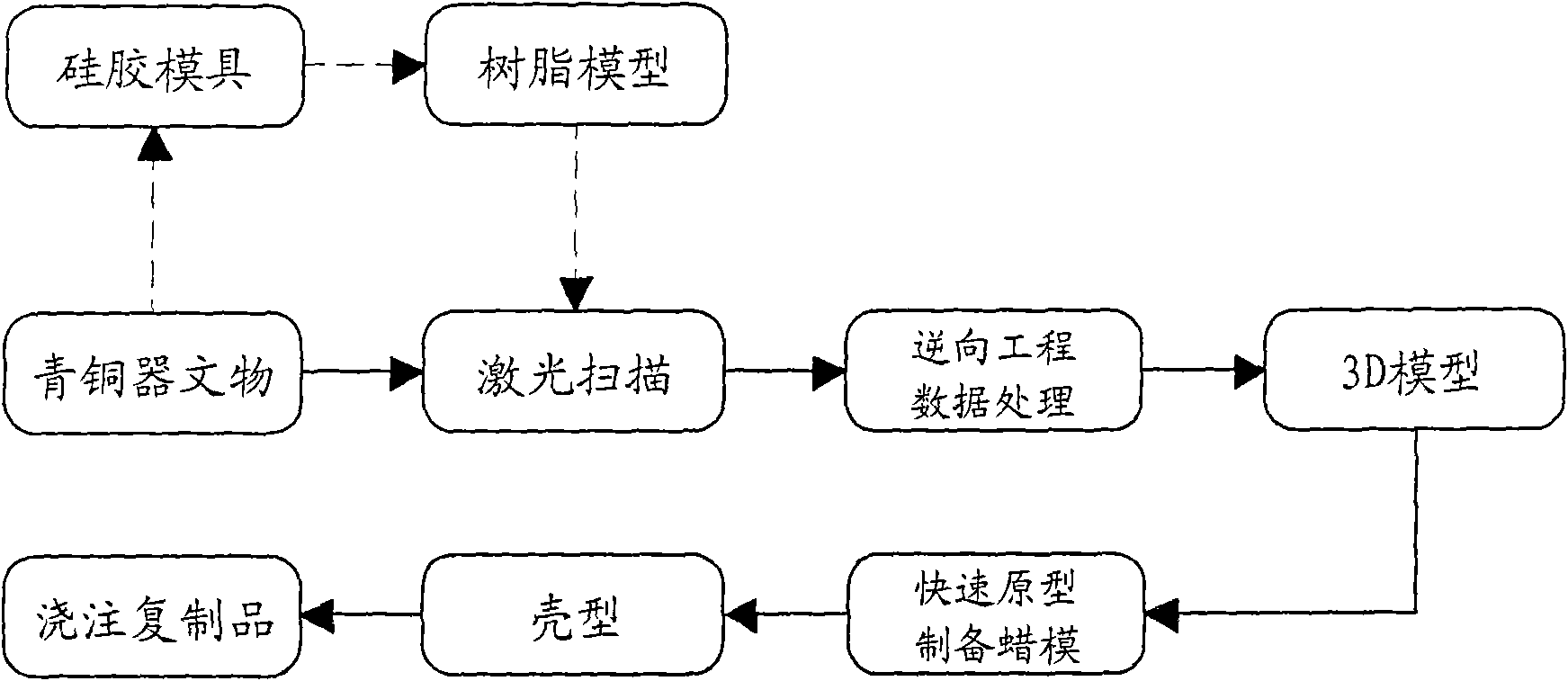

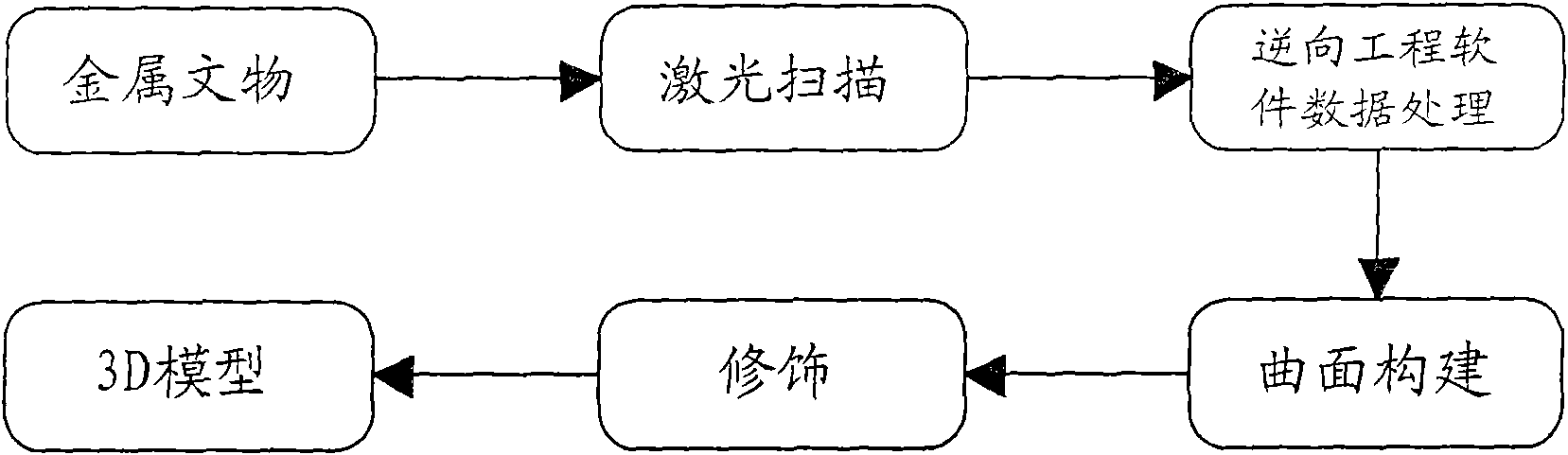

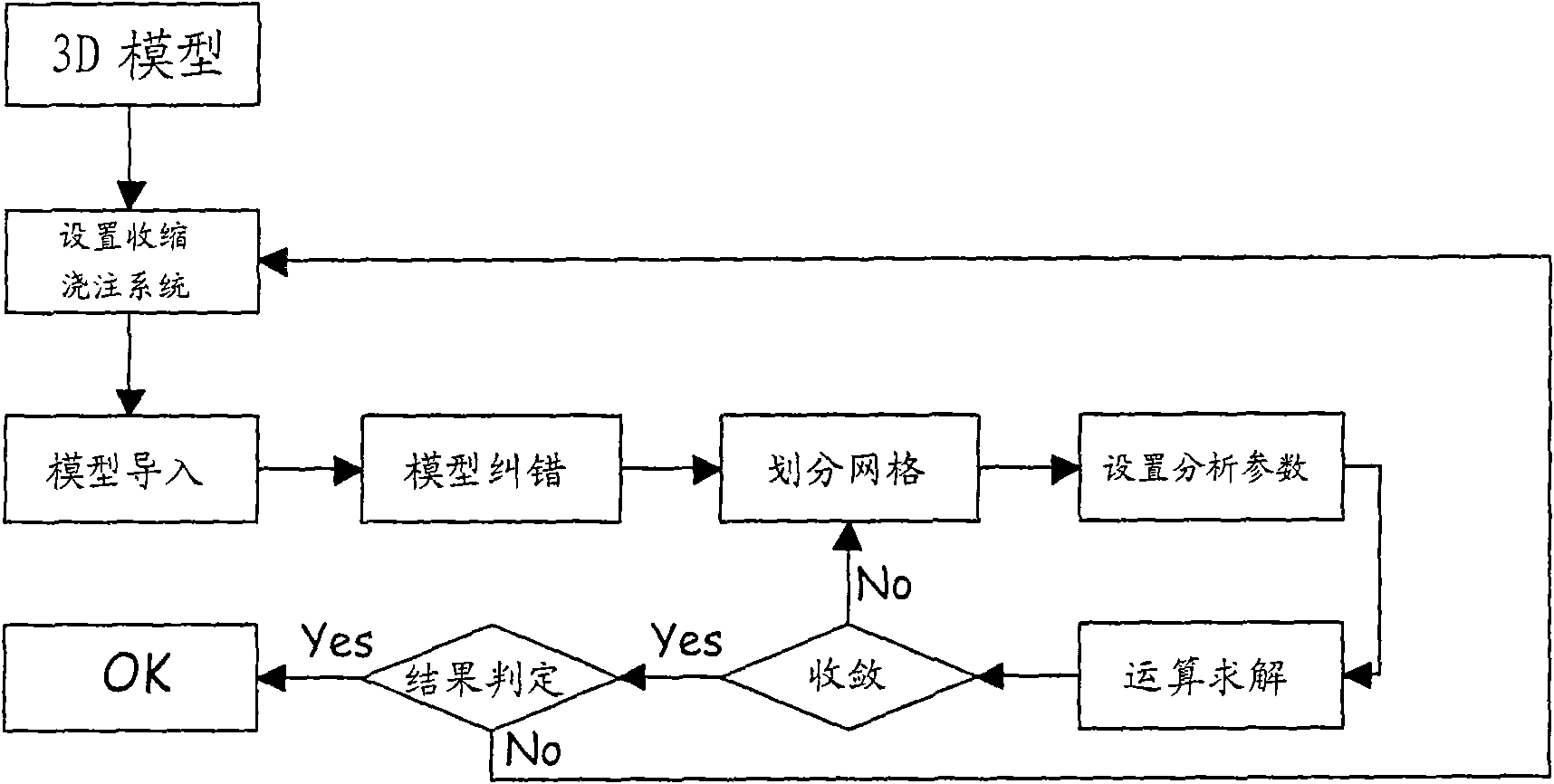

Method for replicating metal relic with high fidelity

InactiveCN101554647AAdvanced technologyPrecision workmanshipFoundry mouldsFoundry coresWaxLaser scanning

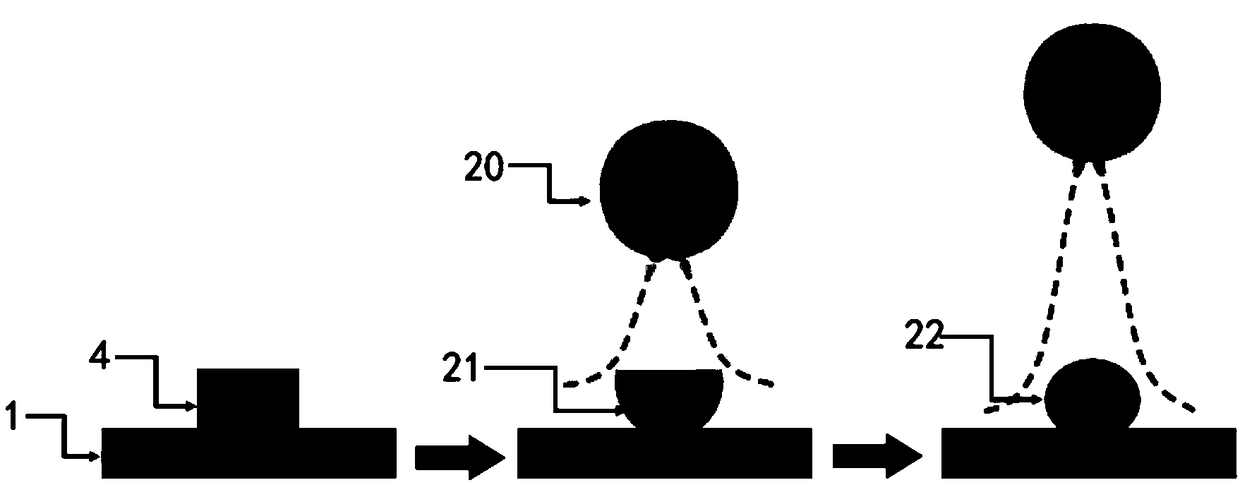

The invention discloses a method for replicating a metal relic with high fidelity, and the method comprises the following steps: (1) an original metal relic is scanned directly by utilizing a laser scanner and a three-dimensional (3D) model of the original metal relic is acquired by reverse engineering; (2) the real process of real investment shell casting is simulated by adopting a finite element method, and the 3D model is modified according to the simulation result (such as contraction); (3) according to the modified 3D model, an accurate wax model is produced by adopting a quick prototyping method; and (4) a shell is produced by utilizing the wax model and liquid metal is poured according to the best simulation technological parameters, thus obtaining the replication with high fidelity. In the method, the accurate wax model can be produced without touching the original relic, and therefore, the relic cannot be damaged; and the method also introduces reverse engineering, quick prototyping and casting process simulation technology into the replication of the metal relic, and compared with the traditional method, the produced metal relic replication has high fidelity and can achieve the effect of representing the relic verve.

Owner:XIAMEN UNIV OF TECH

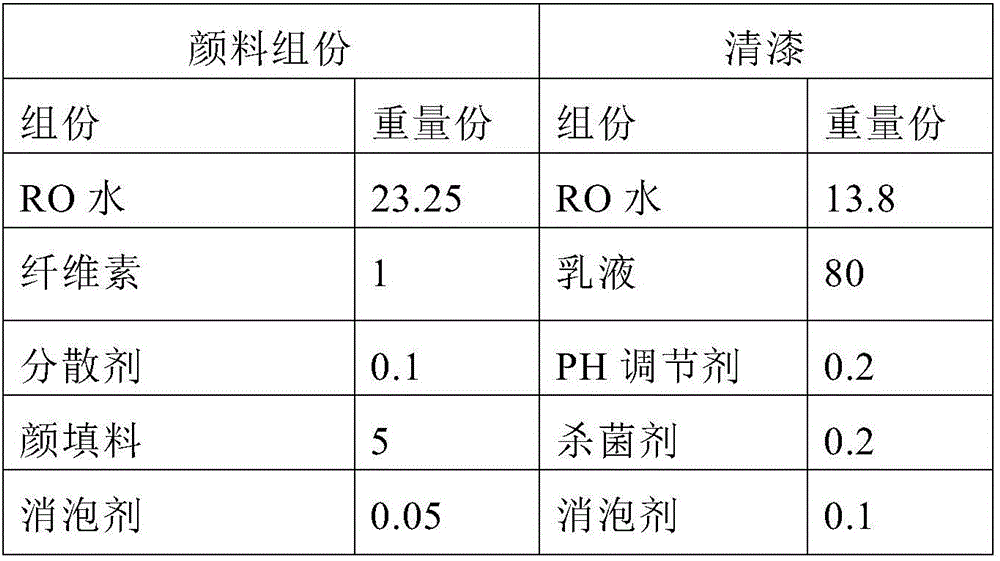

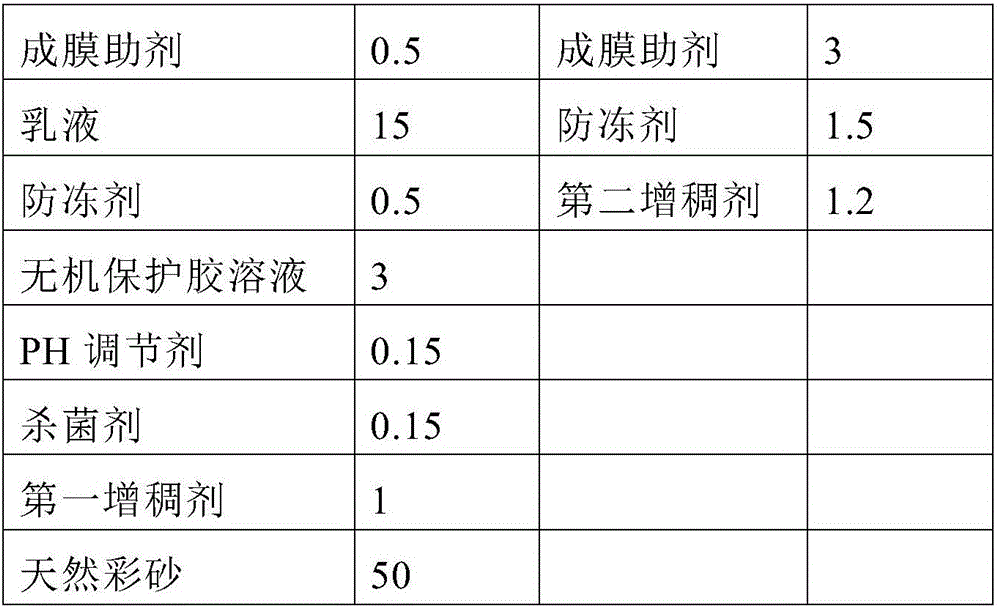

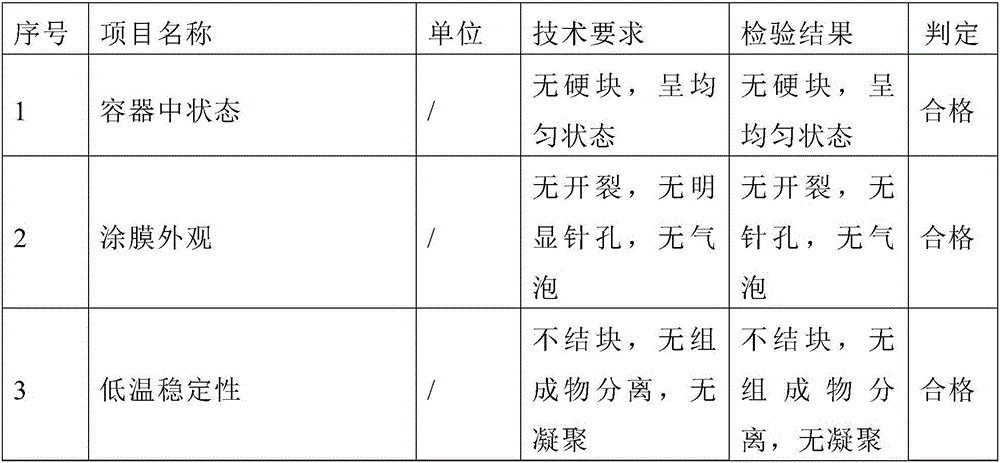

Sand-containing colorful environment-friendly coating and preparation method of same

ActiveCN106366814AGood storage stabilityGood construction stabilityMulticolor effect coatingsAdhesion forceClear Layer

The invention relates to a sand-containing colorful environment-friendly coating and a preparation method of the same. The coating is composed of a pigment component, a dispersion medium and varnish; the pigment component includes RO water, cellulose, a dispersant, pigments and fillers, a defoamer, a film forming additive, an emulsion, an anti-freeze agent, an inorganic protective glue solution, a pH regulator, a sterilizing agent, a first thickener, and natural colorful sands; the dispersion medium includes RO water, the film forming additive, a rheological agent, the emulsion, an organic protective glue solution, the defoamer and a coupling agent; and the varnish includes RO water, the emulsion, the pH regulator, the sterilizing agent, the defoamer, the film forming additive, the anti-freeze agent, and a second thickener. Compared with the prior art, the sand-containing colorful environment-friendly coating has good storage and construction stability, wherein a dried film of the coating is excellent in adhesion force and water resistant performance. The coating, when being used, has a good rough sense and has clear layer sense, thereby representing a texture effect of natural stone materials better.

Owner:上海磐彩环保科技股份有限公司

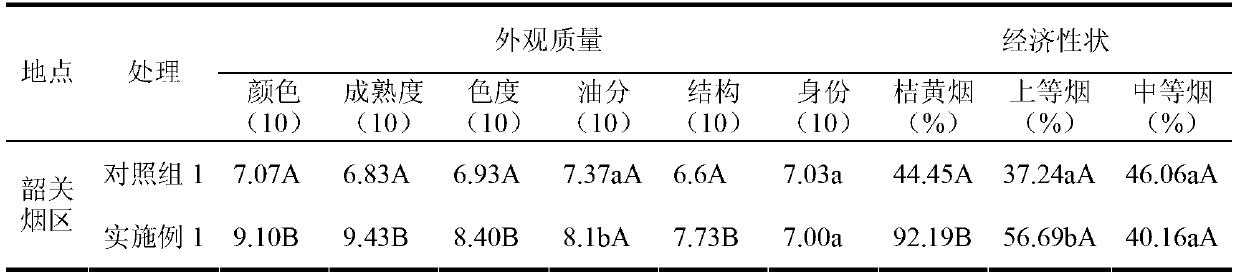

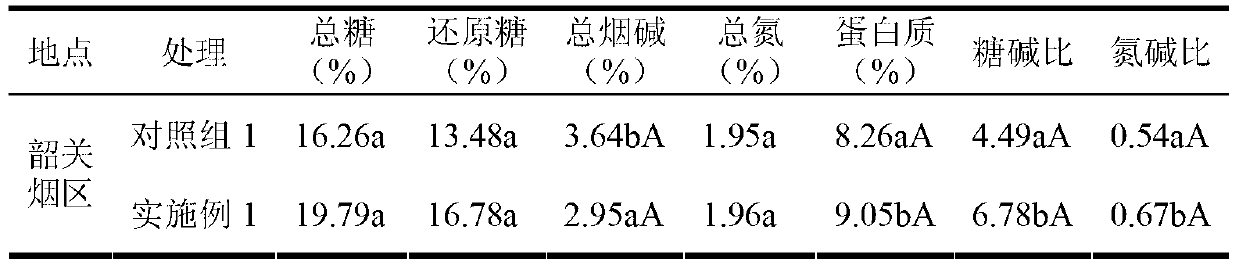

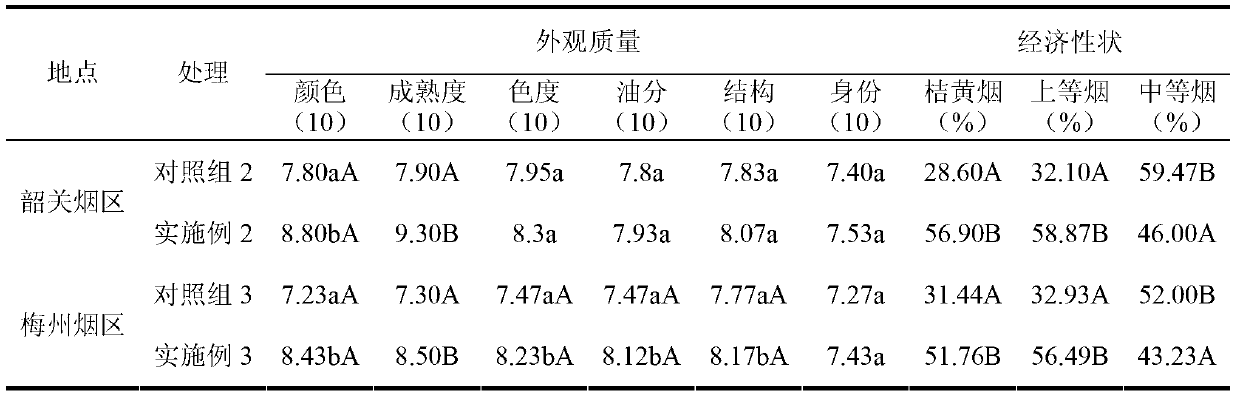

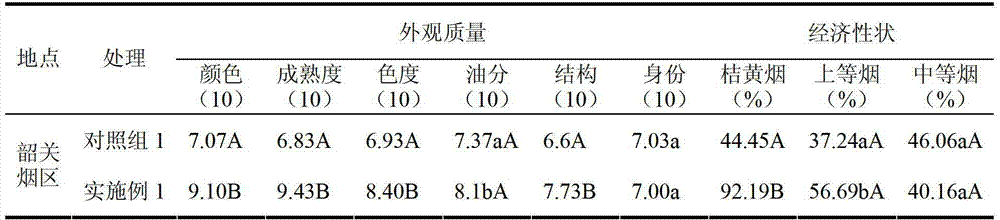

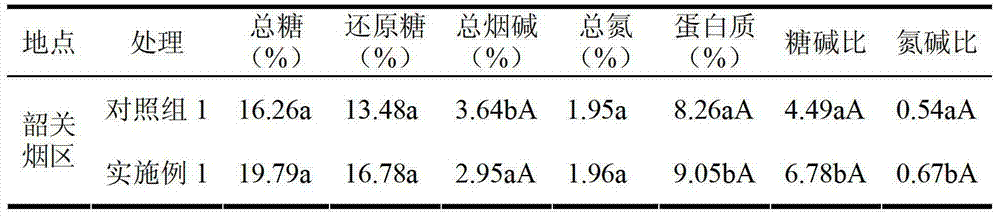

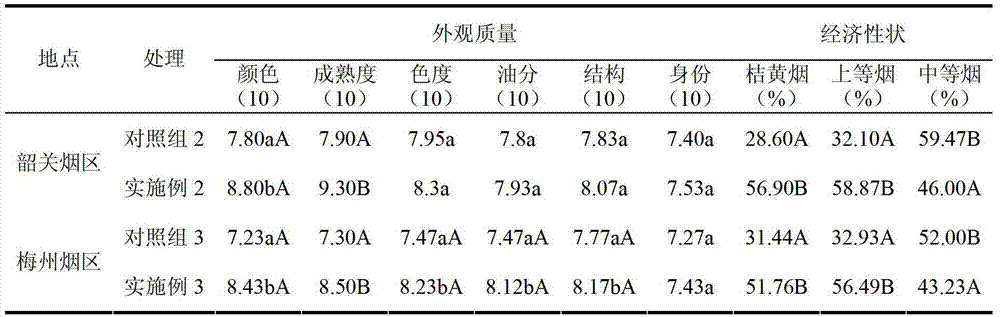

Flue-cured tobacco accurate intensive curing technology for tobacco high-temperature induced maturity

InactiveCN103271428AImprove qualityImprove appearance qualityTobacco preparationBiotechnologyChemistry

The invention discloses a flue-cured tobacco accurate intensive curing technology for tobacco high-temperature induced maturity. According to the flue-cured tobacco accurate intensive curing technology for tobacco high-temperature induced maturity, on the basis of an existing curing barn, the appearance quality of cured tobacco is obviously improved, greenish tobacco is greatly lowered, orange tobacco ratio and first-class tobacco ratio are improved by 25 percent points obviously (P>0.05), and tobacco chemical component coordination is obviously improved. Starch conversion is complete, sugar content is improved by 7 percent points obviously, sugar-alkali ratio is stably kept between 6 and 8, the requirements for strong-flavor style and characteristics are met, and accordingly the quality of tobacco of high-temperature induced maturity is obviously improved. Therefore, the flue-cured tobacco accurate intensive curing technology for tobacco high-temperature induced maturity is an accurate technology which integrates collecting, bonding / clamping, placing curing and curing design of the tobacco of high-temperature induced maturity, and the technology is specially for the tobacco of high-temperature induced maturity and has the advantages of being strong in pertinency, accurate in technology and convenient to produce and operate.

Owner:NANXIONG SCI RES INST OF GUANGDONG TOBACCO

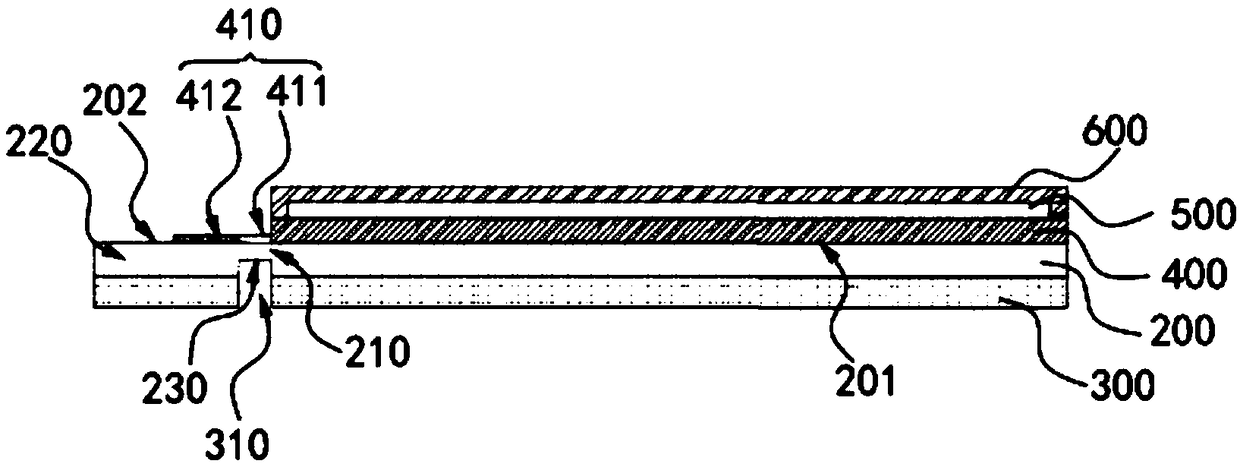

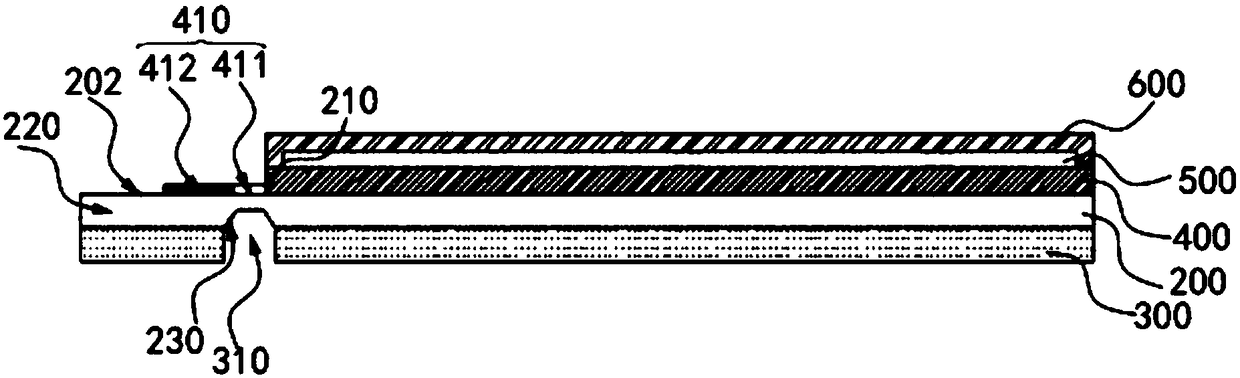

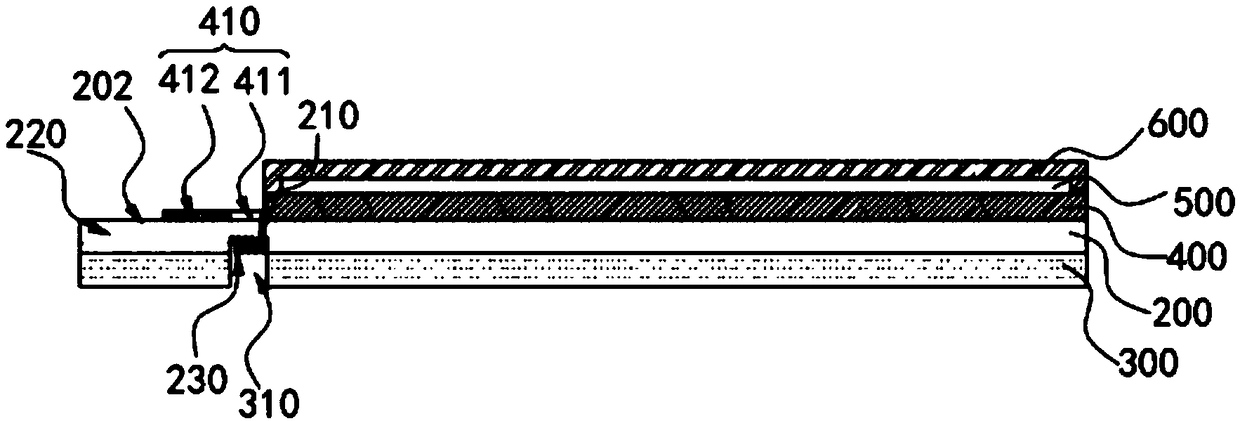

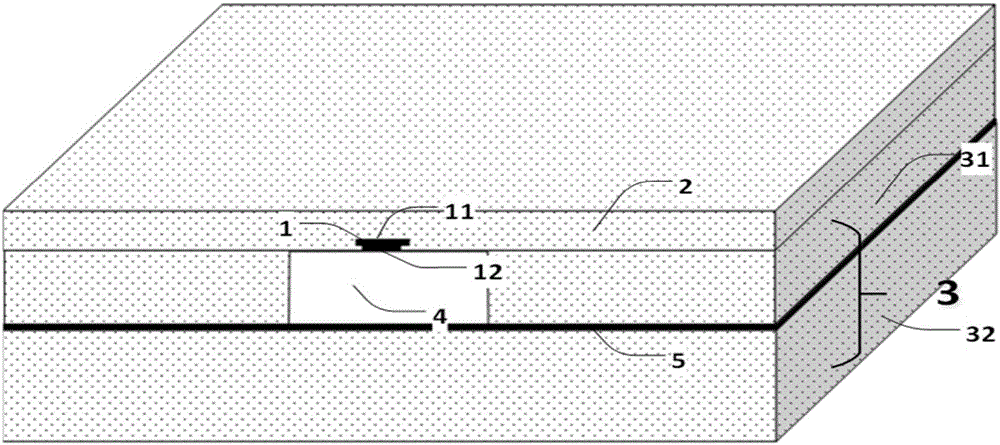

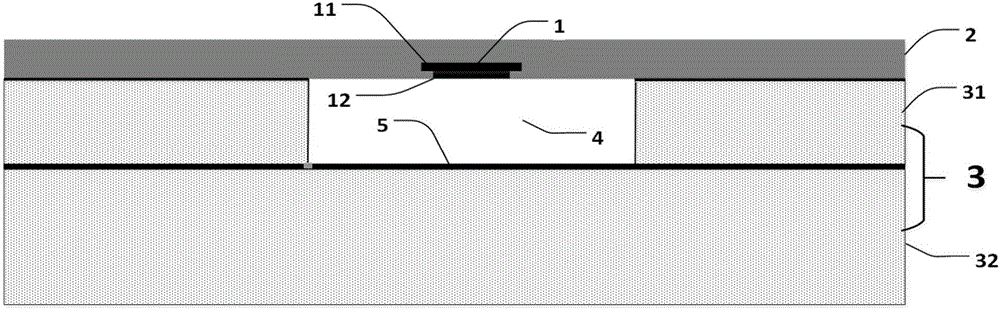

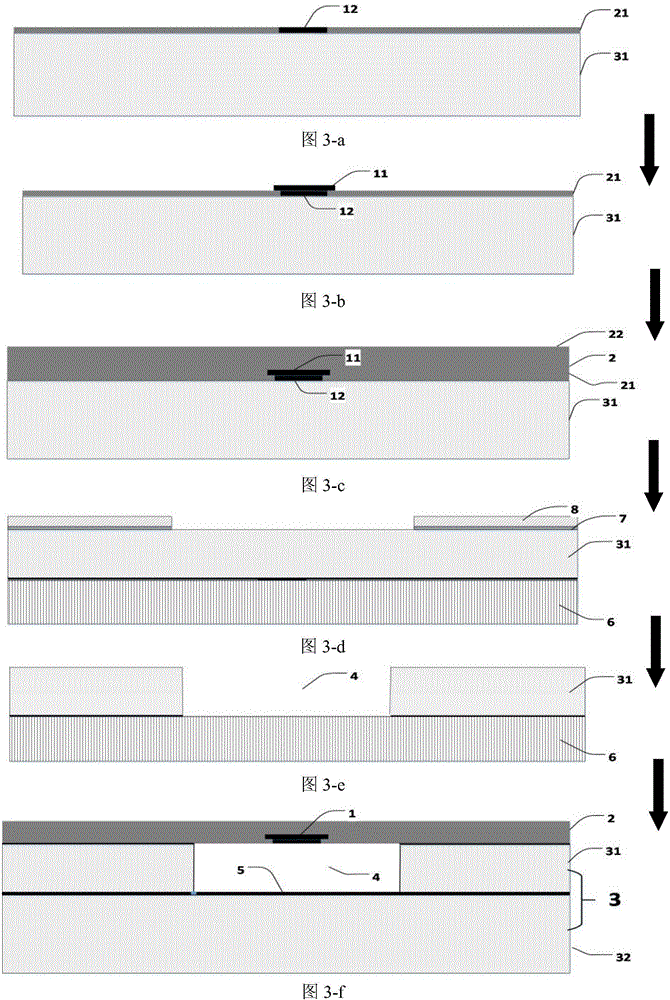

Display substrate, preparation method of display substrate, display device, preparation method of display device and display unit

InactiveCN109360845AReduce stressEasy bending processFinal product manufactureSolid-state devicesBackplaneDisplay device

The invention provides a display substrate, a preparation method of the display substrate, a display device, a preparation method of the display device and a display unit. The preparation method of the display substrate includes: providing a flexible substrate, wherein a display area and a circuit connection area are arranged on an upper surface of the flexible substrate, and a part, correspondingto the circuit connection area, of the flexible substrate is provided with a bending portion and a connecting portion; forming a groove in a lower surface of the flexible substrate, wherein an orthographic projection, of the groove, on an upper surface of the flexible substrate corresponds to the position of an orthographic projection, of the bending portion, on the upper surface of the flexiblesubstrate; arranging a backplate, an OLED (organic light emitting diode) luminescent device and a packaging structure successively in the display area on the upper surface of the flexible substrate, and arranging a circuit connection layer in the circuit connection area on the upper surface of the flexible substrate. By downwardly bending and extending the bending portion of the flexible substrate, the connecting portion is enabled to locate on the lower surface side of the flexible substrate.

Owner:BOE TECH GRP CO LTD

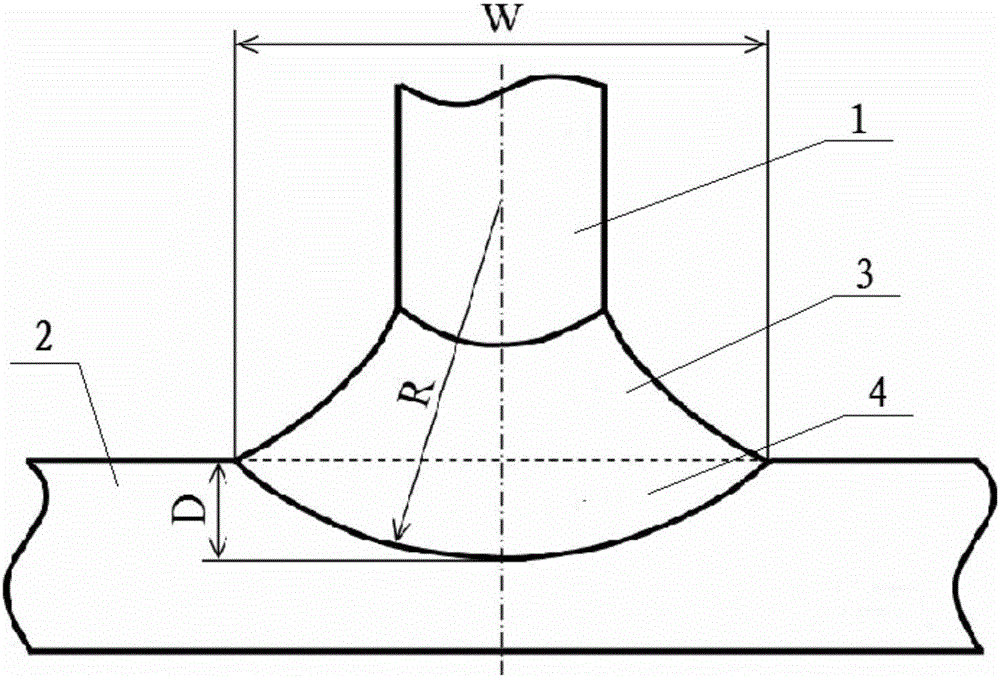

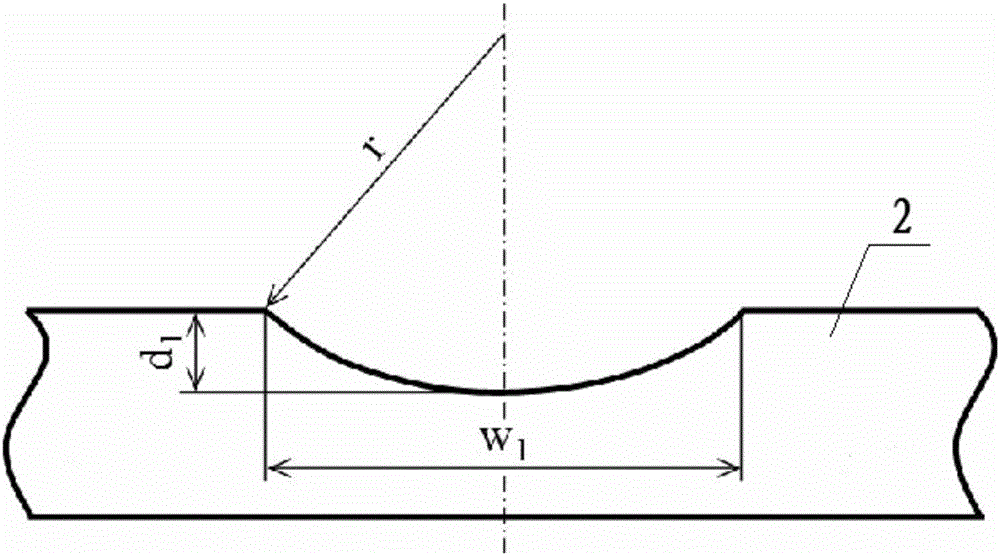

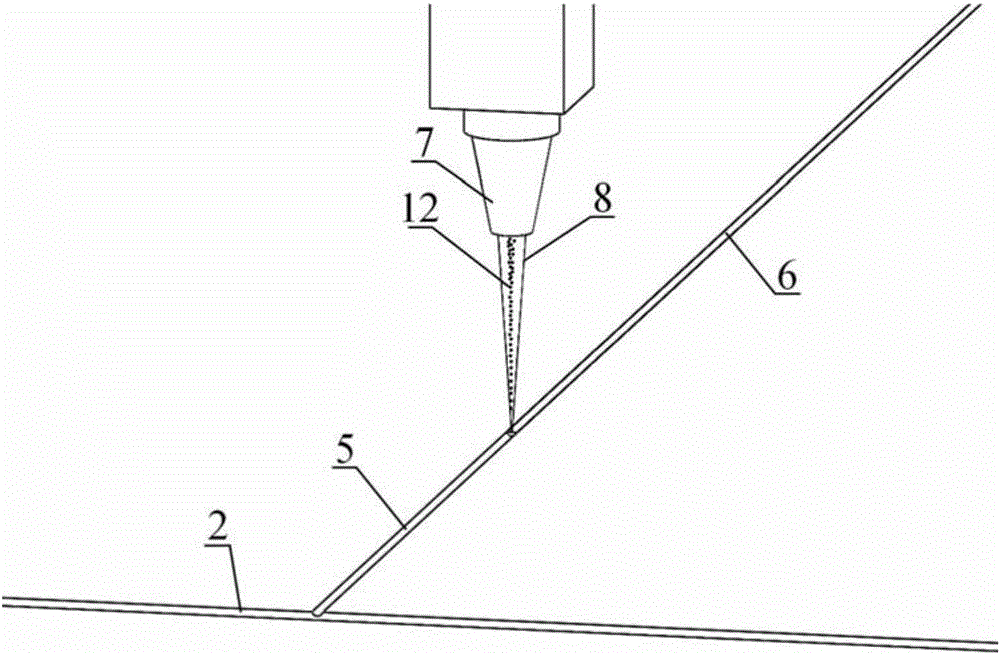

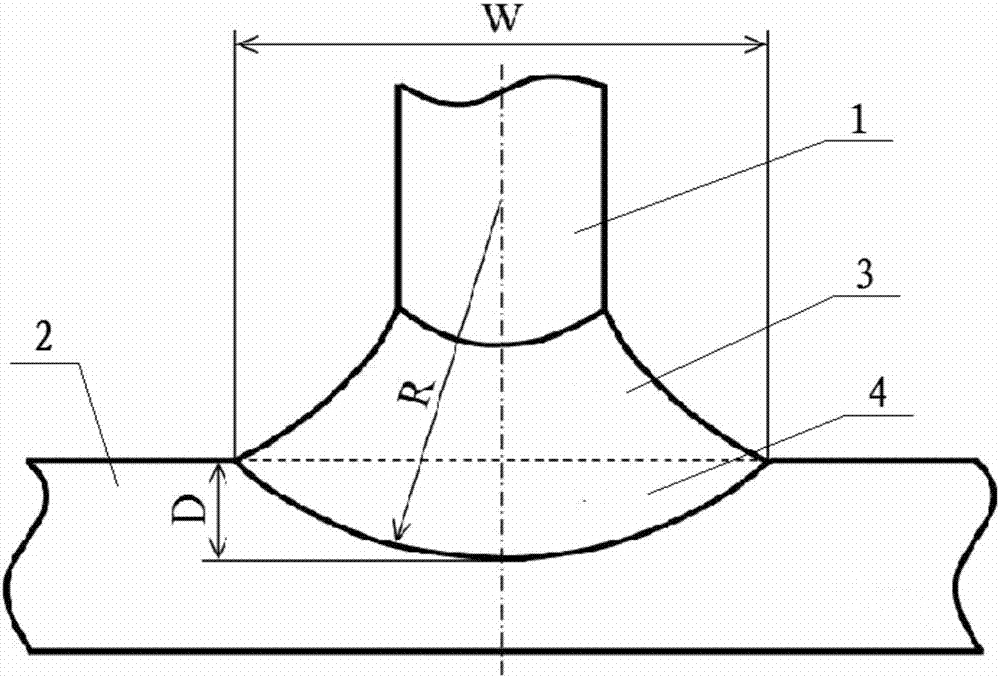

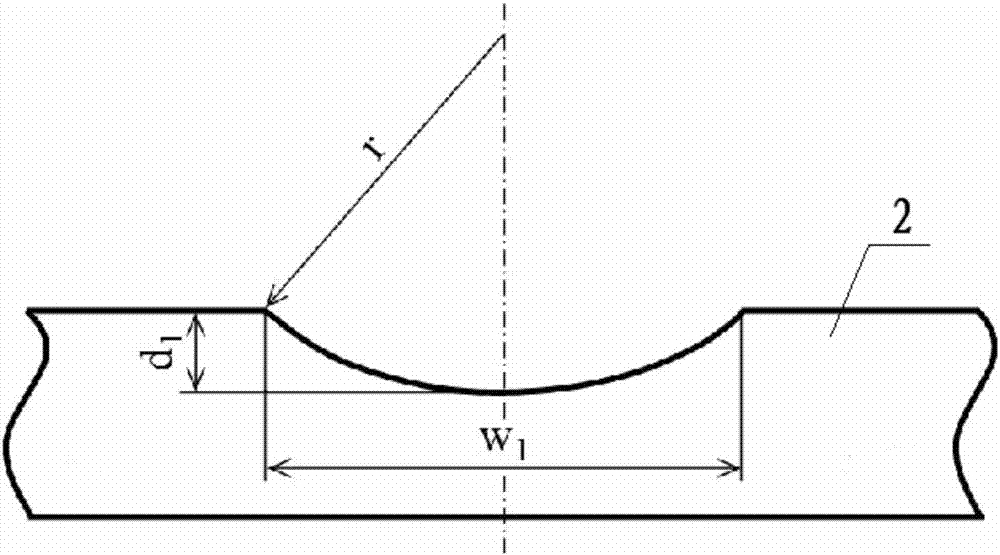

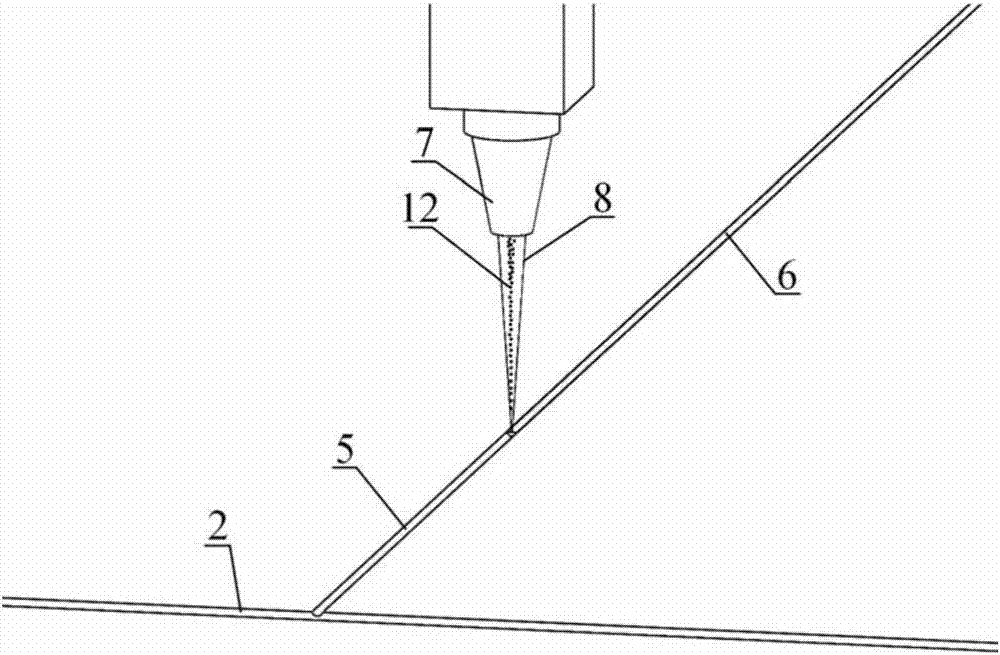

Double-side laser welding method for powder metallurgy control

ActiveCN105728944AImprove mechanical propertiesEvenly regulatedVehicle componentsMetal working apparatusAlloyLaser beams

The invention discloses a double-side laser welding method for powder metallurgy control, relates to a double-laser beam welding method, and solves the problem that welding wire elements cannot perform full alloy control for a welding line structure in the double-side laser welding process of a T-shaped structure. The method comprises the following steps: (1) a groove is mechanically milled in the center of a position to be welded on the upper surface of a cover in the welding direction; and the cover is chemically cleaned to remove an oxide film and machining stains; (2) alloy powder is prefilled in the groove to form a deposition layer; a laser cladding head is vertically placed rightly above the groove; the laser powder feeding material adding is performed on the surface of the groove to obtain the deposition layer by using a mode of coaxial feeding of laser beams and the alloy powder; and a deposition material higher than the surface of the cover is grinded off by using a grinding machine, so that a deposition surface is coplanar with the surface of the cover; and (3) the double-laser wire filling welding is performed for a long purlin and the cover to obtain symmetric welding lines on two sides. The method is used for double-laser beam welding of the T-shaped structure.

Owner:HARBIN INST OF TECH

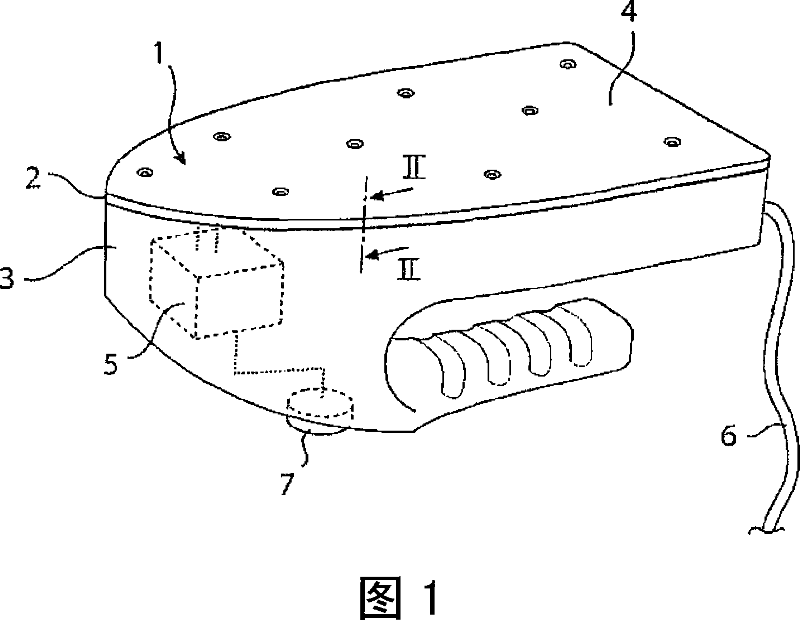

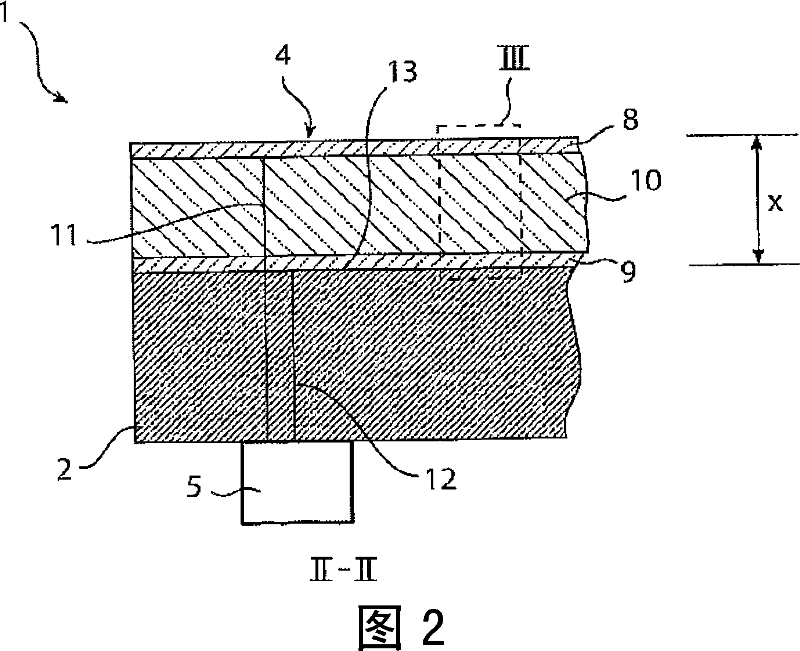

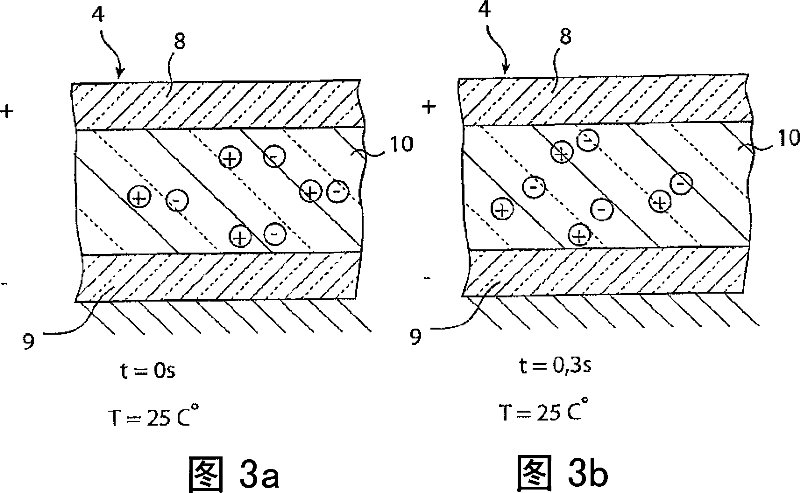

Temperature indicator

InactiveCN101040175AReduced risk of failure not indicating high temperatureReduce in quantityThermometers using physical/chemical changesElectrical polarityEngineering

A temperature indicator (1) for indicating a high temperature at a surface (13) comprises a light-emitting electrochemical cell (4) having a first electrode (8), a second electrode (9) and a light-emitting layer (10) being sandwiched between the two electrodes (8, 9). The light-emitting layer (10) comprises a matrix and ions being movable in the matrix, the mobility of said ions in said matrix being temperature dependent. A power source (5) is adapted for driving the light-emitting cell (4) with an AC voltage. The frequency of the AC voltage is tuned in such a way that, above a certain temperature level, the ions move fast enough in the matrix to provide a sufficient charge gradient in the light-emitting electrochemical cell (4) for the light-emitting electrochemical cell (4) to emit light before the AC power source (5) shifts the polarity of the voltage.

Owner:KONINK PHILIPS ELECTRONICS NV

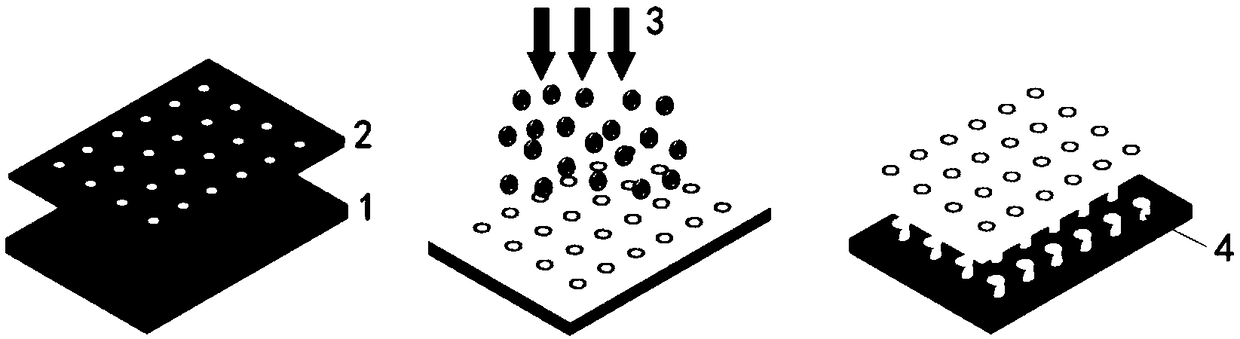

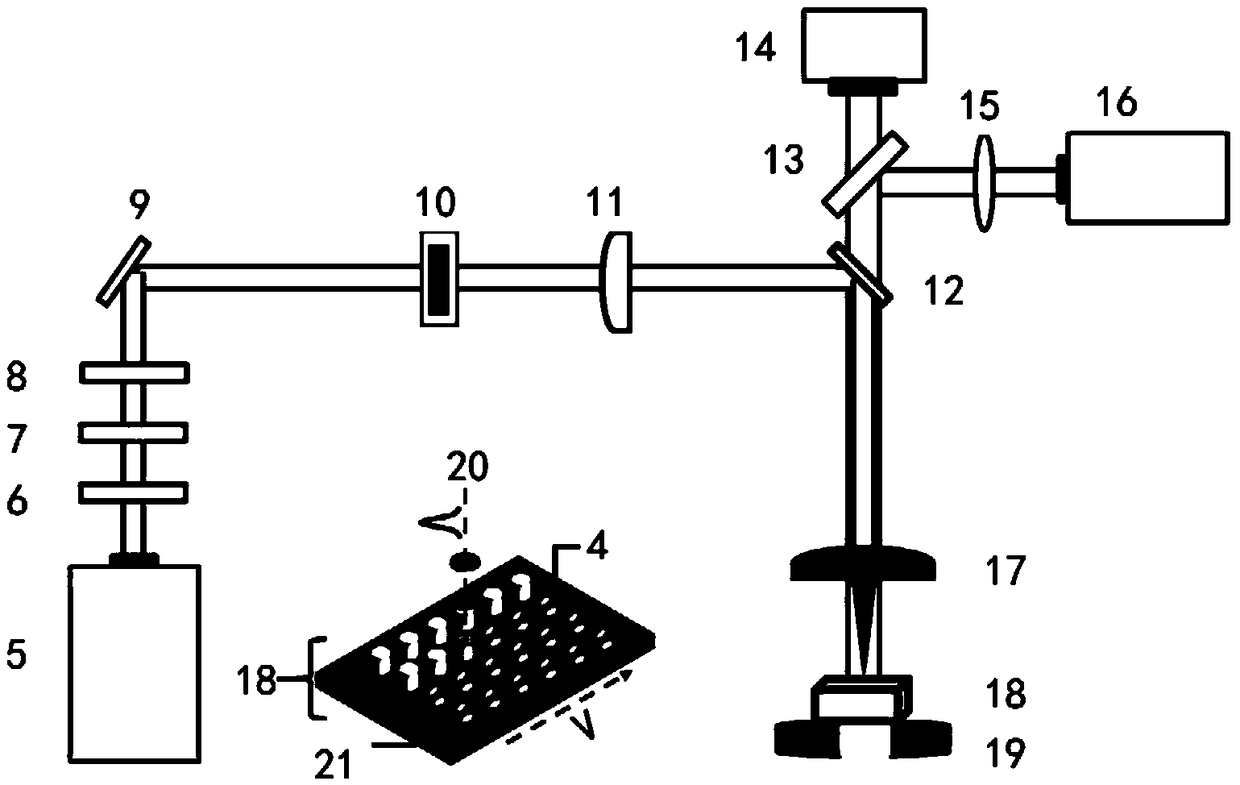

Femtosecond laser manufacturing method for tunable phase change nanostructure super surfaces

ActiveCN109434289ASimple and preciseAchieve spacingVacuum evaporation coatingSputtering coatingHolographic imagingPhase state

The invention relates to a femtosecond laser manufacturing method for tunable phase change nanostructure super surfaces, and belongs to the technical field of femtosecond laser application. The femtosecond laser manufacturing method aims to solve the problem that in the current super-surface nanostructure processing process, the technology is complicated, and the shortcomings of accurate, efficient, orderly and large-area processing of nano structure units exist are solved. According to a femtosecond laser manufacturing method, the expected morphology of the nano structure is prepared in accurate, efficient, orderly and large-scope manner with the relatively-simple technology, instantaneous electronic excitation dynamics during action of femtosecond laser and phase-change material surfacesare regulated, modulation of the distance, the morphology, the phase state and the arranging manner of the nano structure units of the phase-change material super surfaces and large-format manufacturing and modification are achieved. Critical application values are achieved in the aspects of gradient super-surfaces, information storage, holographic imaging, electromagnetic wave manipulation, switchable or reconfigurable components and the like.

Owner:BEIJING UNIV OF TECH

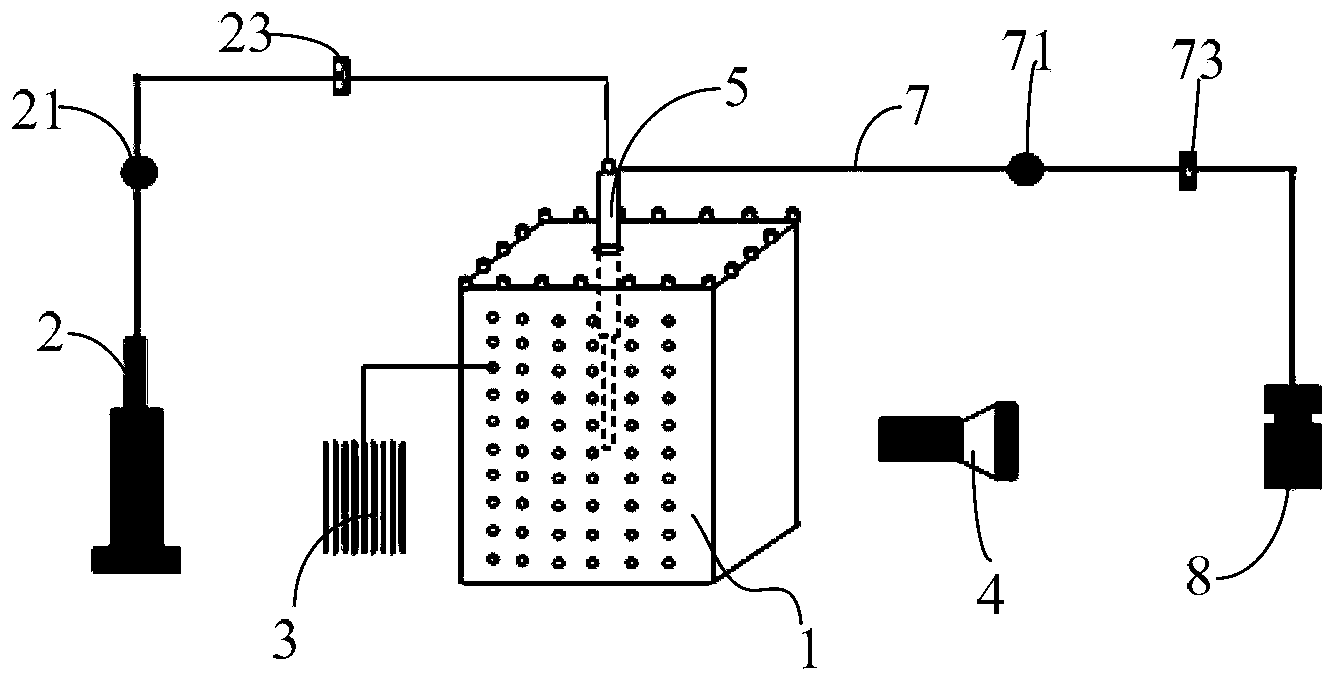

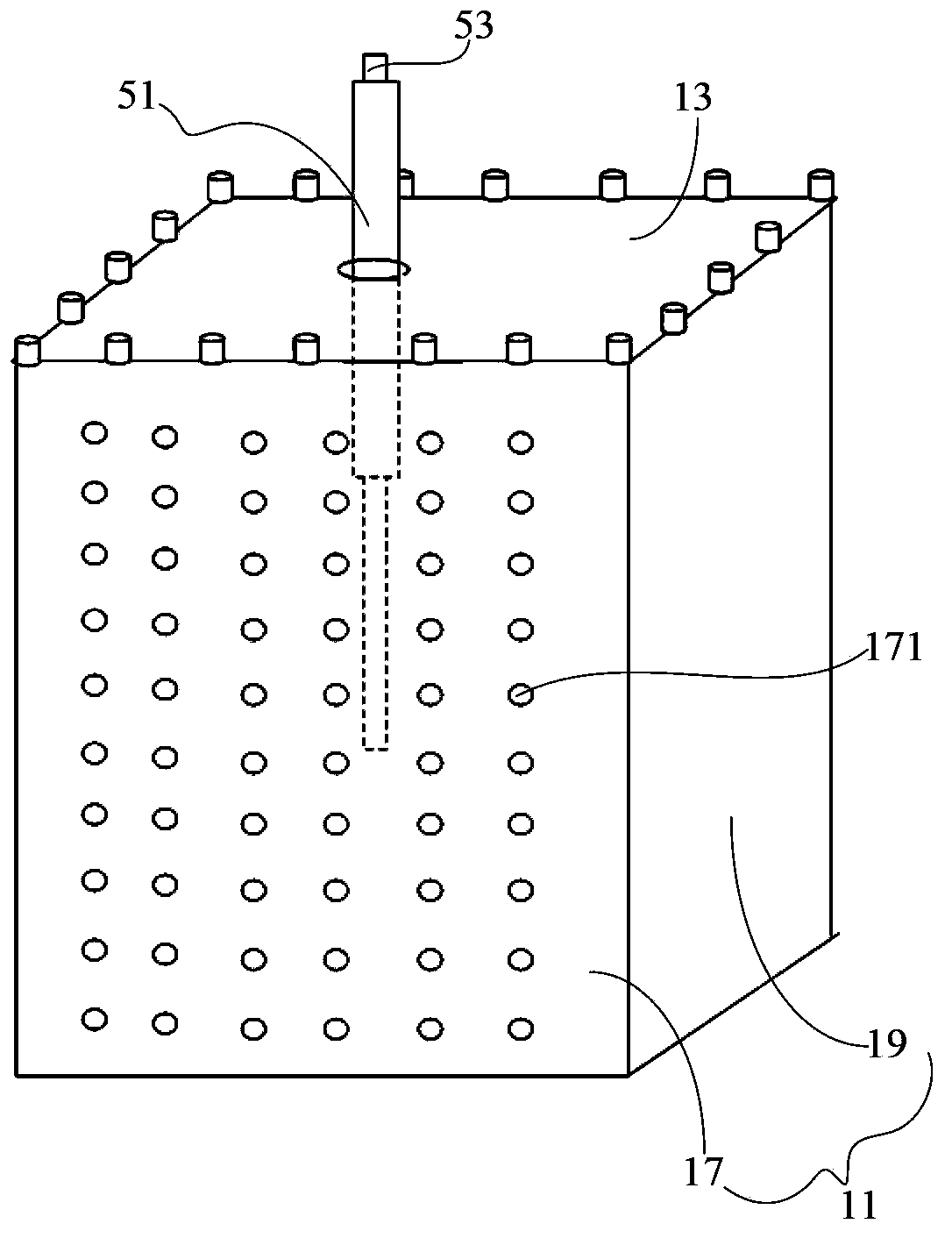

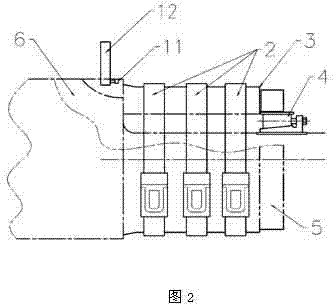

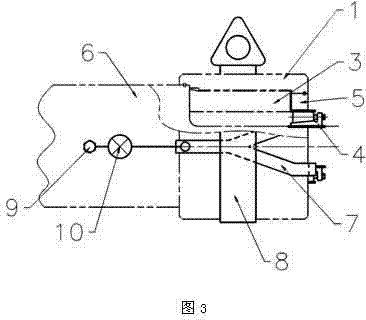

Physical simulation apparatus and method of convection and diffusion of salt-cavern gas storage cavity

The invention, which belongs to the technical field of establishment of an underground salt cavern gas storage, discloses a physical simulation apparatus and method of convection and diffusion of a salt-cavern gas storage cavity. The physical simulation apparatus comprises a simulation box, a displacement pump, a discharge pipe, a conductivity meter, a shooting device opposite to the simulation box, a cavity construction tubular column and a computer. The displacement pump and the discharge pipe are connected to the cavity construction tubular column; a first flowmeter is connected between the displacement pump and the simulation box; a second flowmeter is also arranged at the discharge pipe; and the shooting device, the first flowmeter, and the second flowmeter are connected to the computer by an operable way. According to the invention, simulation of various working conditions is carried out in the simulation box; fresh water is injected into the displacement pump and the discharge pipe discharges brine to make convection and diffusion phenomena, thereby reflecting the working condition and environment of the cavity construction process of the salt cavern gas storage actually. Therefore, the method and process parameters that are obtained based on the simulation apparatus and method and are used for accelerating a rock salt cavity construction speed become true and accurate, thereby improving the cavity construction speed and the cavity shape controlling beneficially.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

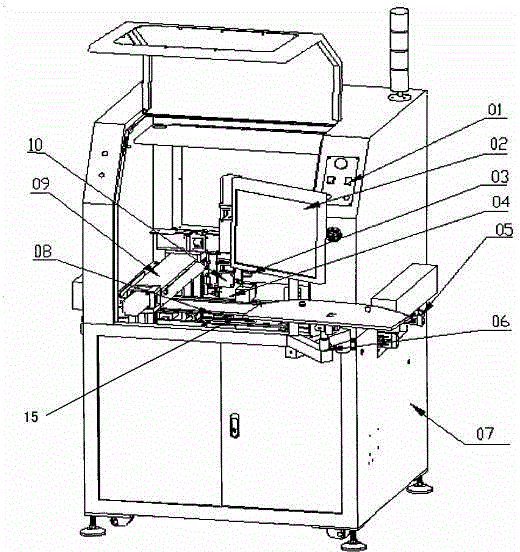

Intelligent high-speed contactless high-accuracy glue spraying method

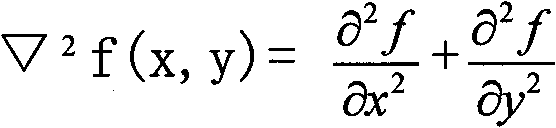

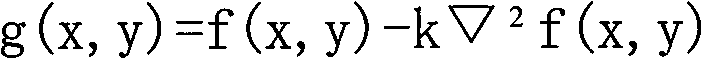

InactiveCN102847661APrecision workmanshipGuarantee product qualityLiquid surface applicatorsCoatingsMathematical modelVision algorithms

The invention relates to a glue spraying method, particularly to an intelligent high-speed contactless high-accuracy glue spraying method. The method includes establishing a corresponding mathematical model, and establishing a glue spraying vision algorithm and a machine vision system to provide a theoretical basis for the glue spraying method according to the forming principle of the glue spraying; collecting and processing images in motion to provide a dynamic positioning theoretical basis by using the geometric transformation technology; and measuring the glue spraying amount by using a precise weighing balance and a charge coupled device (CCD) visual positioning and measuring system to achieve closed-loop control for the glue spraying amount. According to the method, a CCD optical lens, a high-speed glue spraying valve, the precise weighing balance and a CCD measuring software are combined, a tri-axial motion platform is provided, the CCD optical lens is used for positioning components precisely, the high-speed high-accuracy glue spraying valve is matched, an on-line weighing or CCD measuring function is used for assistance, the glue amount is calibrated on line, the technical process of accurate glue spraying packaging can be achieved rapidly, quality of products is guaranteed, and the product percent of pass is improved.

Owner:XIAMEN TEYING AUTOMATION TECH CO LTD

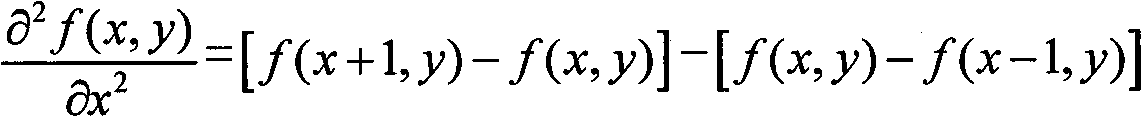

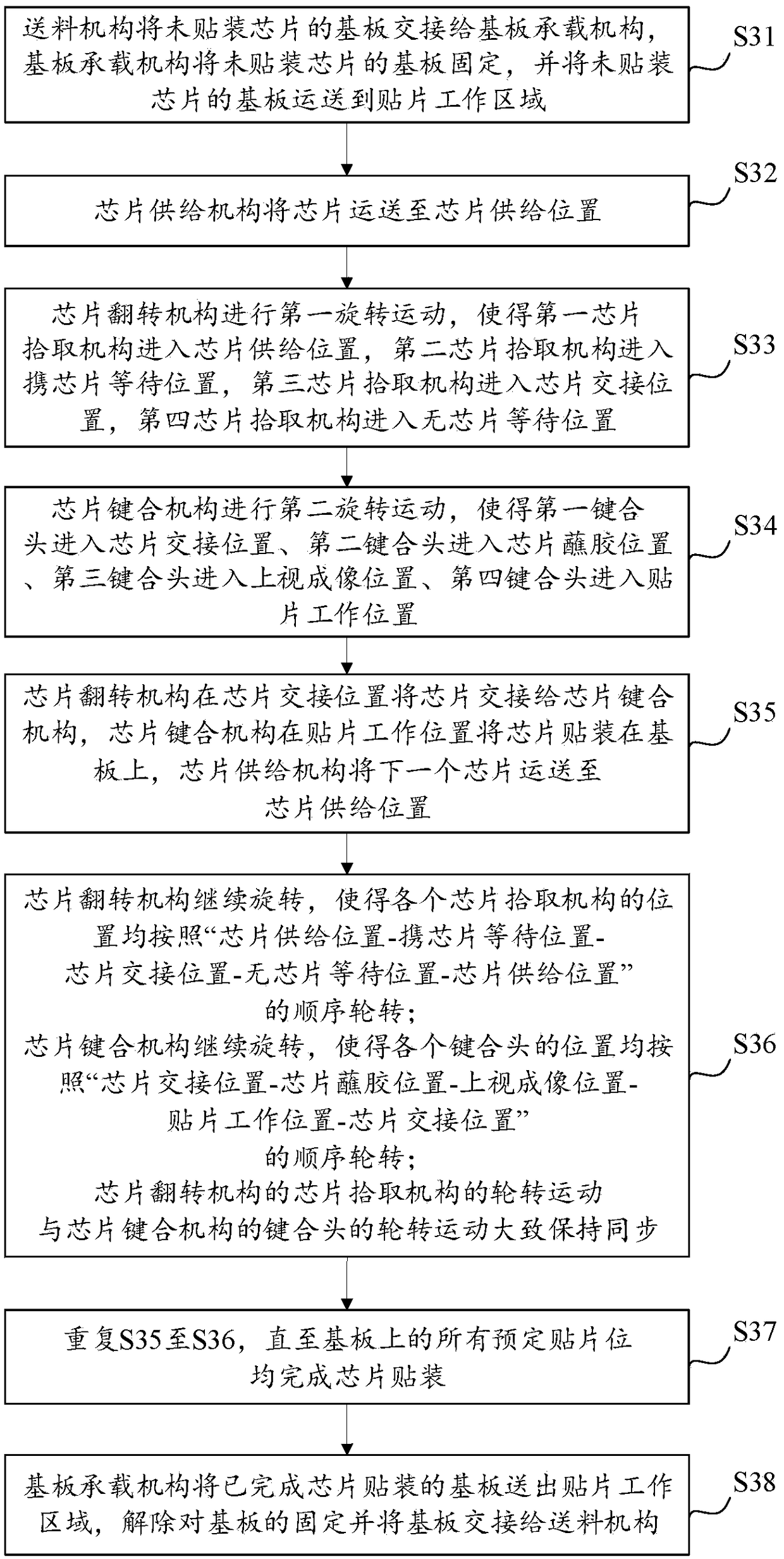

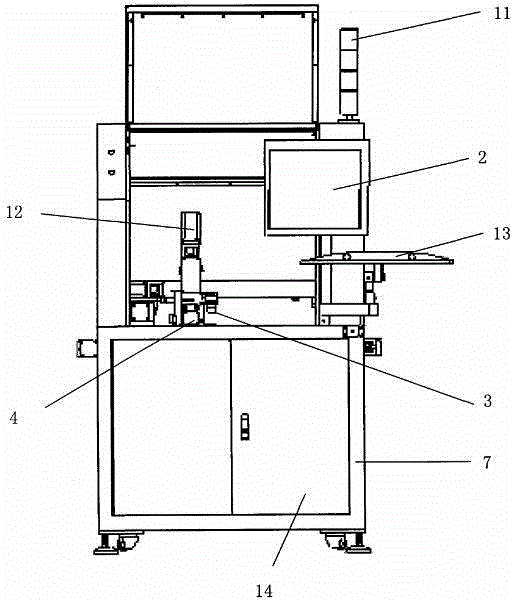

Chip alignment mounting device and method

ActiveCN108962791AQuick alignmentQuick craftSemiconductor/solid-state device manufacturingDie bondingHandover

The present invention provides a chip alignment mounting device. The chip alignment mounting device comprises a feed mechanism, a substrate carrying mechanism, a chip supply mechanism, a chip turnovermechanism and a chip bonding mechanism, the feed mechanism is configured to provide a substrate without mounting a chip and remove a substrate with a mounted chip; the substrate carrying mechanism isconfigured to load and fix the substrate and drive the substrate to move on a first plane; the chip supply mechanism is configured to provide the chip at the chip supply position on the chip supply mechanism; the chip supply mechanism can pick up the chip from the chip supply position, transmit the chip to a chip handover position through rotation motion and supply the chip to the chip bonding mechanism; the chip bonding mechanism is configured to pick up the chip from the chip handover position and mount the chip to a pre-determined mounting position through rotation motion; and the mountingoperation position, the chip supply position and the chip handover position are fixed positions. The present invention further provides a chip alignment mounting method. The chip mounting efficiencyand precision can be improved.

Owner:TANGREN MICROTELLIGENCE TECH CO LTD

Method for preventing avian influenza by nano photocatalyst

InactiveCN101036796ASolve the real problemPrecision workmanshipLavatory sanitoryDeodrantsWater basedLight energy

The invention relates to a method for control epidemic such as avian influenza. Using photocatalyst directly preparates, the air is treated by using medium on living or activity space of human and animal, and contiguous building, article and solid product. The textiles, clothes, air condition, filter screen of air clearing machine are prepared by photocatalyst coating. Photocatalytic nanostructured activated water is used to damp the air and spray the circumstance. Photocatalyst spraying power, photocatalyst water based paint, photocatalyst ultraviolet ray curing paint are fixed to the solid surface by mechanical disturbance type spraying, ultraviolet ray curing, high temperature curing and so on. In ultraviolet ray or sunlight, the nano photocatalyst generates photocatalysis activity to realize stereo sterilization, killing virus, preventing avian influenza. At the same time, SRS, hepatitis, phithistic, influenza and so on are also controlled and the indoor climate can also be purified. The invention has great photocatalysis activity and good effect. The textiles have abilities of anti-ultraviolet and anti-static electricity. The sun light energy can longacting sterilize. The cost is low. The invention is easy to spread and can increase the human quality of life.

Owner:张金龙

Shock-proof air column bag without opening points

PendingCN108820551APull quicklyPrecision workmanshipContainers to prevent mechanical damageEngineeringMechanical engineering

The invention relates to the field of airtight bag packaging and aims at providing a shock-proof air column bag without opening points. The shock-proof air column bag without the opening points is formed by connecting a plurality of air columns divided by vertical heat-sealing lines; a bag body of the shock-proof air column bag without the opening points comprises two outer films and two inner films, wherein the two inner films are arranged between the two outer films and form an air valve device in a mode of crossing the entire bag body; a heat-resisting ink strip is transversely arranged between the two inner films and along the upper ends of the inner films; the vertical heat-sealing lines cross through the heat-resisting ink strip in a left-right crossed mode and then converge into aninflatable expansion area; the two heat-sealing crossed sides of the inflatable expansion area form a bottleneck-shaped air inlet of neighboring air columns. The shock-proof air column bag without theopening points saves heat-resisting joints at intervals or heat-sealing opening points and changes heat-resisting ink strips originally arranged at intervals into one continuous linear one, thereby only requiring a direct linear operation at a fixed length instead of a benchmarking step during pressing. The shock-proof air column bag without the opening points is accurate and concise in process,table in product quality and high in production efficiency.

Owner:浙江迪弗莱包装科技股份有限公司

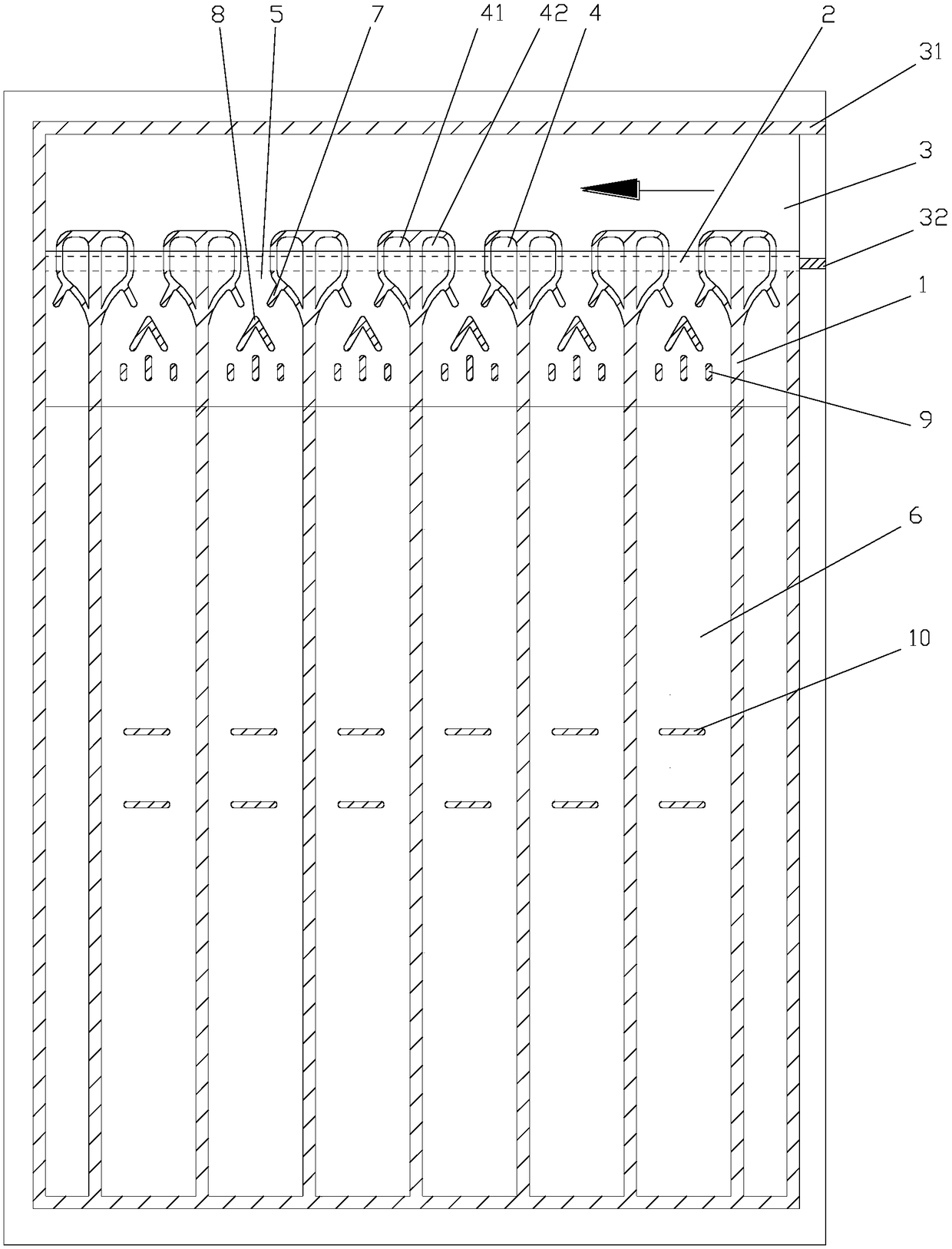

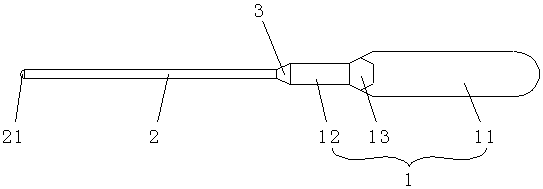

Capacitor guide pin and manufacturing method thereof

PendingCN108511194AReduce punctureEasy to controlCapacitor terminalsCapacitor manufactureFront end of lineEngineering

The invention discloses a capacitor guide pin and a manufacturing method thereof. The capacitor guide pin is composed of an aluminum wire and a tin-plated copper-clad steel wire. A part of the aluminum wire is punched to form a flat head, and another part of the aluminum wire is a cylinder located at the transverse center line of the flat head. A transitional portion is formed between the flat head and the cylinder and is in a square R shape. The flat head is an arc structure. The tin-plated copper-clad steel wire and the cylinder of the aluminum wire are soldered and have a solder joint therebetween in a truncated cone shape. The front end surface of the tin-plated copper-clad steel wire is a circular arc end face, and has a radius of a half of the diameter of the tin-plated copper-clad steel wire. The transitional portion is in a square R shape and has large bending strength so as to avoid damage and fracture during the assembly of a container. The flat head is an arc structure so asto reduce the probability of piercing the inner foil and improve product quality. The size and the appearance of the solder joint can be well controlled to avoid puncturing the rubber in the apertureor exposure after a rubber plug is inserted.

Owner:NANTONG NANMING ELECTRONICS

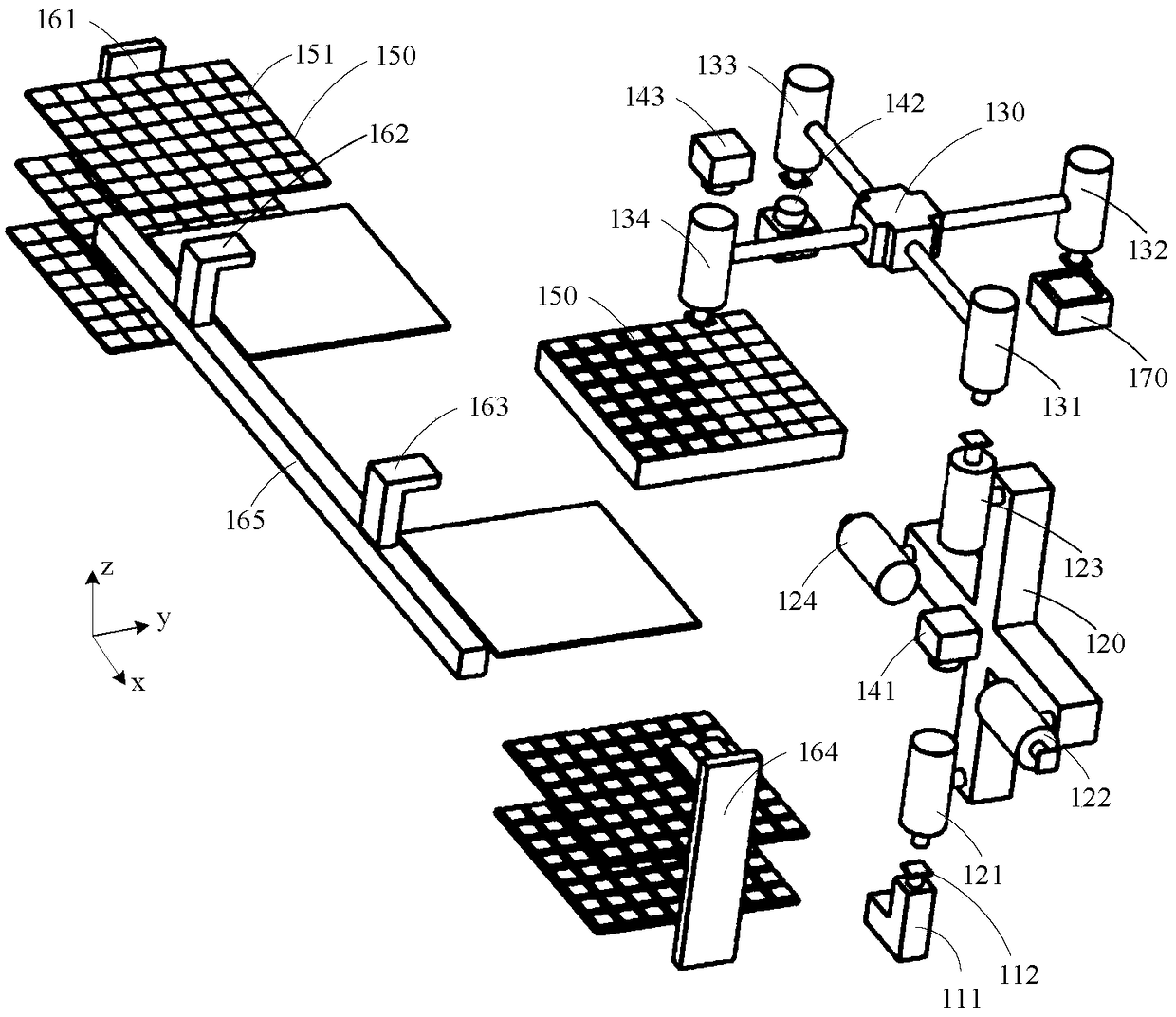

Ancient book reparation method based on flying spray robot

The invention discloses an ancient book reparation method based on a flying spray robot, and relates to an application of a technology combining a flying spray system, a CCD (charge coupled device) machine vision system, a laser measurement and calibration system, a digital automatic control system and a high-speed and high-precision robot in the field of ancient book reparation, so that digital high-precision positioning reparation can be performed on ancient books. The ancient book reparation method is characterized in that 1, a page of one ancient book is placed on a working table of the flying spray robot; 2, the CCD machine vision system performs target detection on the to-be-repaired ancient book; 3, mathematic positioning is performed; 4, a spray valve is adopted to perform high-precision, fixed-point and non-contact type glue spray on the periphery of the position requiring reparation, manipulator grabbing is performed, and laser detection is performed. The overall process replaces strenuous labor of a worker, a large quantity of manpower resources are saved, the precision of the ancient book reparation is greatly improved, the speed of the ancient book reparation is greatly increased, and the ancient book reparation enters the high-speed, high-precision and non-contact type automation field from the traditional manual industry.

Owner:周迪

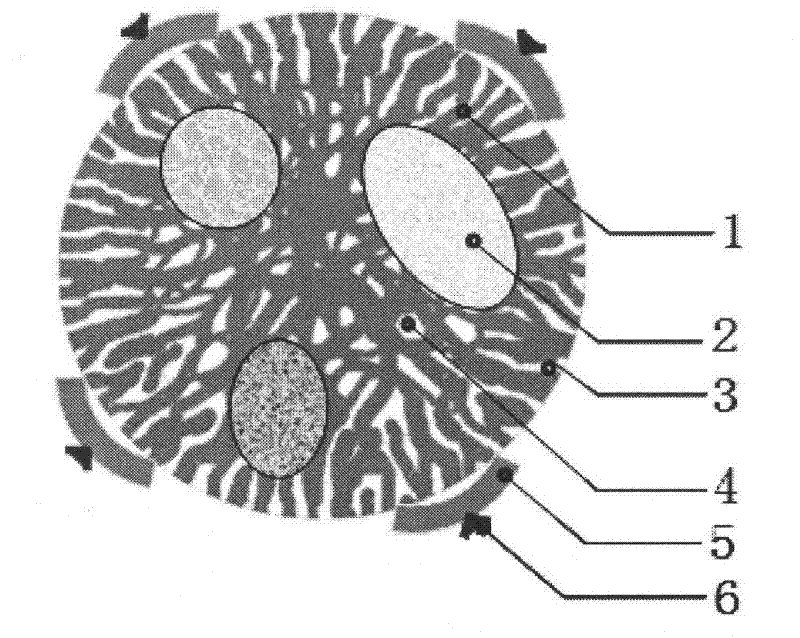

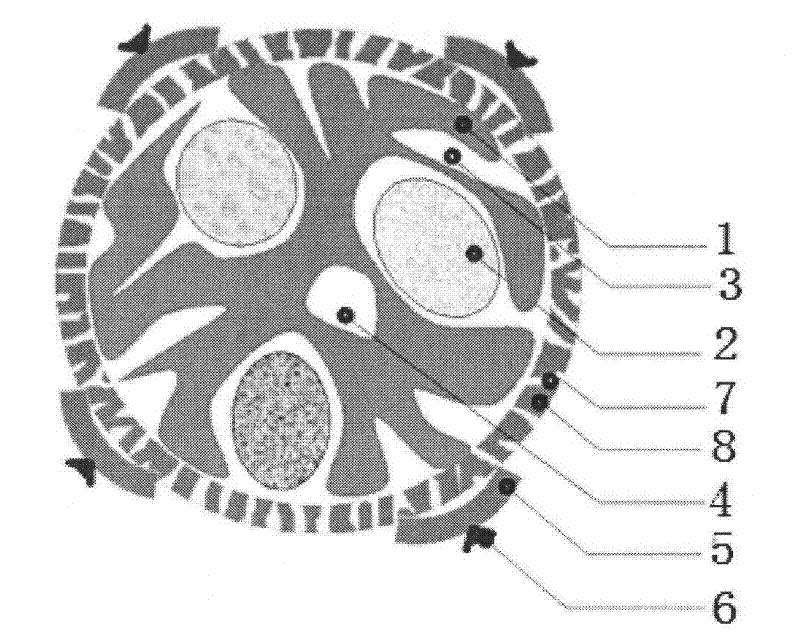

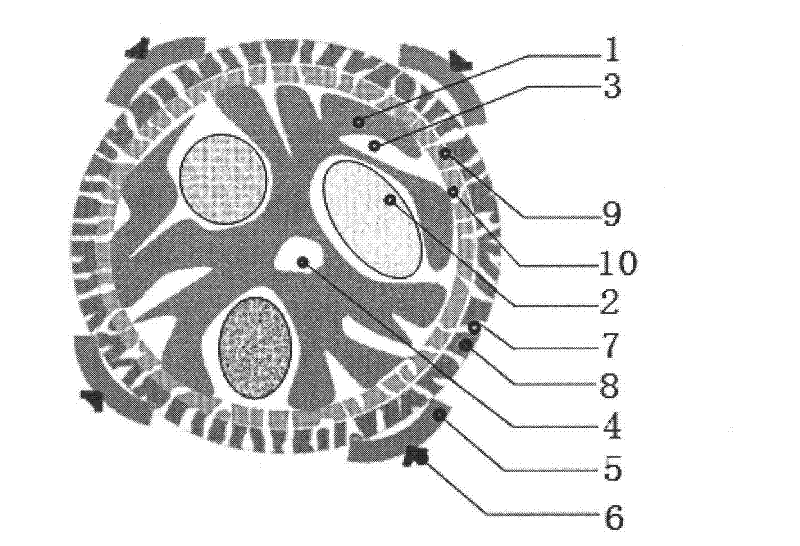

Plant cell microspheres and use thereof

ActiveCN102240531ARealized gainRealize intelligent requirementsMicroballoon preparationMicrocapsule preparationControlled releaseMicrosphere

The invention relates to plant cell microspheres and particularly discloses plant cell microspheres and use thereof. The plant cell microspheres are characterized by being processed and manufactured on the basis of plant protoplasts, plant cells and plant sporopollen or pollen, wherein the protoplast-derived plant cell microspheres contain matrix, matrix channels, middle cavities, internal spheres and external pendants; the cell-derived plant cell microspheres contain outer walls, matrix, matrix channels, middle cavities, internal spheres and external pendants; and the sporopollen-derived plant cell microspheres contain outer walls, inner walls, matrix, matrix channels, middle cavities, internal spheres and external pendants. The plant cell microspheres of the invention can conduct sustained-release, controlled-release and other physical and chemical functions, and can naturally degrade after being used.

Owner:济南菲特生态环保工程有限公司

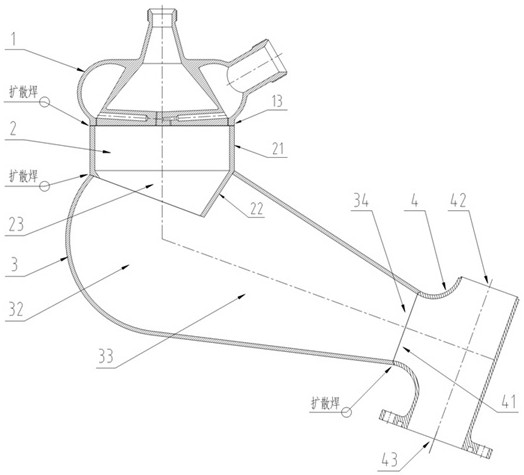

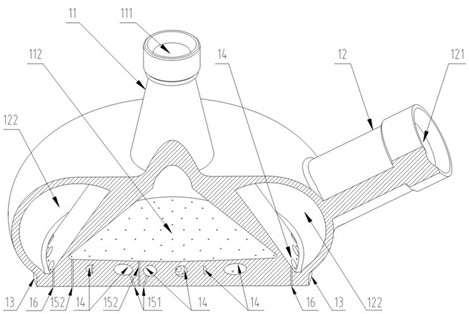

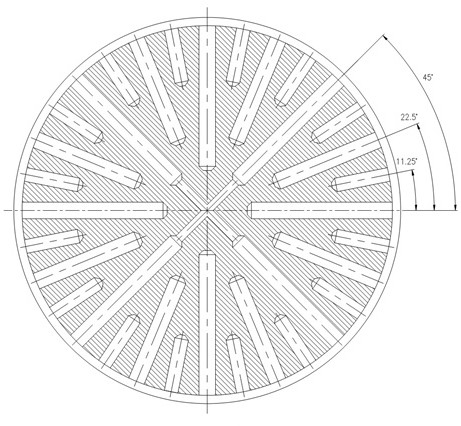

Fuel gas generator

The invention provides a fuel gas generator. The fuel gas generator is composed of an injector, an eccentric turbulent flow ring, a spherical-cone-shaped combustion chamber and a three-way bent pipe. The injector is in a round cake shape, the whole injector is printed through a 3D printer, the upper half part of the eccentric turbulent flow ring is a cylindrical ring, the top face of the cylindrical ring is fixedly welded with the edge of the bottom face of a lower boss of the injector, the bottom edge of the side face of the cylindrical ring is fixedly welded with the hole wall of a side hole of the spherical-cone-shaped combustion chamber, and the lower half part of the eccentric turbulent flow ring is a conical ring with an eccentric opening. The spherical-cone-shaped combustion chamber comprises a spherical cavity and a cone cavity, a side hole is formed in the side face of the spherical cavity, an outlet is formed in the top of the cone cavity and fixedly welded with a middle inlet of the three-way bent pipe, the three-way bent pipe is integrally in a side T shape, a left port is formed in the left side of the three-way bent pipe, a flange structure connection mode is adopted, a right port is formed in the right side of the three-way bent pipe, a middle inlet is formed in the middle part of the three-way bent pipe, and a boss positioning form is adopted. The structure of the fuel gas generator is optimized, propellants can be efficiently atomized, mixed and combusted, and the combustion efficiency is improved.

Owner:星河动力(北京)空间科技有限公司 +1

Silicon-based inverted microstrip line structure and manufacturing method therefor

ActiveCN106684515AEasy to prepareImprove machining accuracyTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringSubmillimeter wave

The invention discloses a silicon-based inverted microstrip line structure and a manufacturing method therefor, and mainly solves the problems of high loss and low processing precision in millimeter wave and submillimeter wave transmission by a standard microstrip line and a conventional inverted microstrip line. The silicon-based inverted microstrip line structure comprises a microstrip line, a suspension layer, a silicon substrate, a cavity and a metal grounding layer, wherein the silicon substrate comprises an upper silicon substrate and a lower silicon substrate; and inverted layer is positioned on the upper surface of the upper silicon substrate; the microstrip line comprises a lower metal layer and an upper metal layer; the upper metal layer is fixed in the inverted layer; the lower metal layer is prepared on the lower surface of the upper metal layer and exposed in the cavity; the cavity is formed in the upper silicon substrate in an etching manner, positioned below the microstrip line and suspends the microstrip line; and the metal grounding layer is positioned below the cavity and embedded between the upper silicon substrate and the lower silicon substrate. The manufacturing method is high in processing precision, and a low-loss and simple-manufacturing millimeter wave transmission line structure is realized.

Owner:XIDIAN UNIV

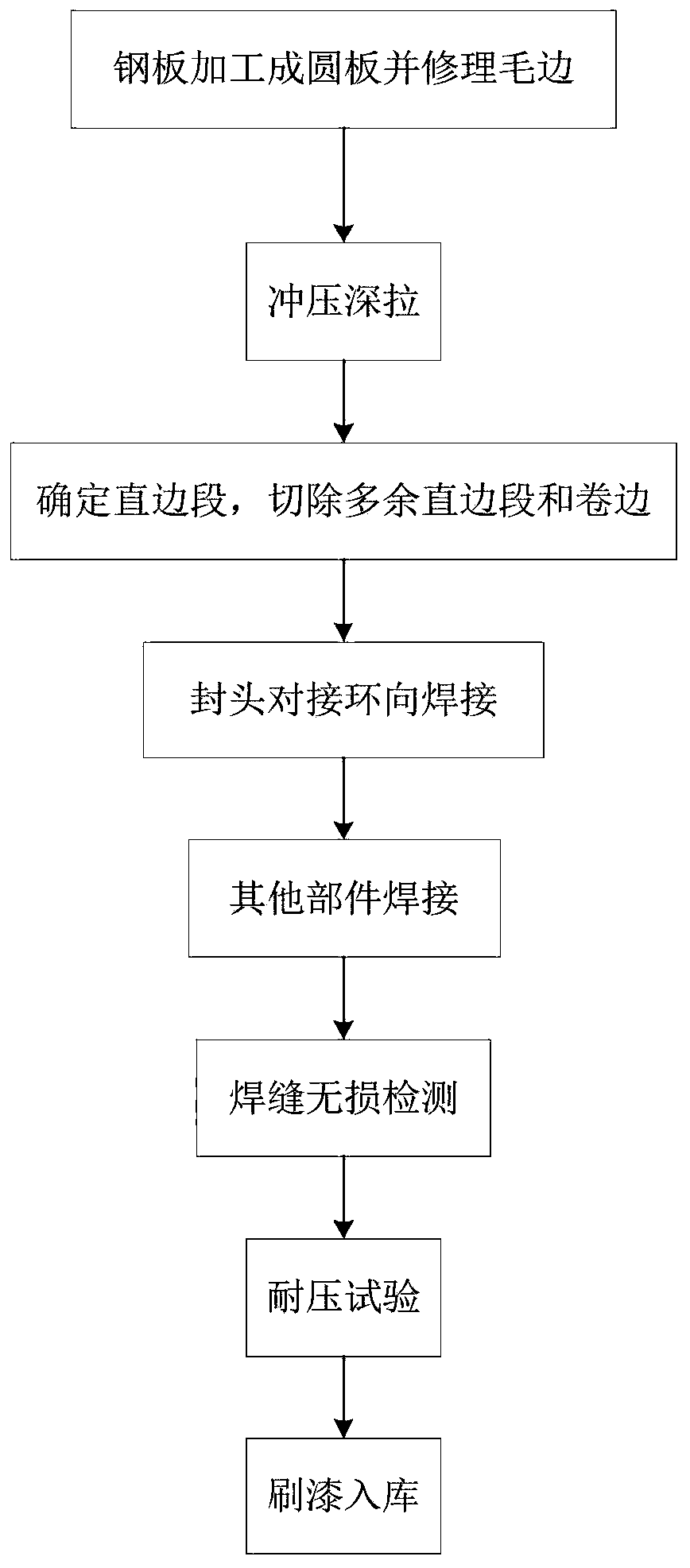

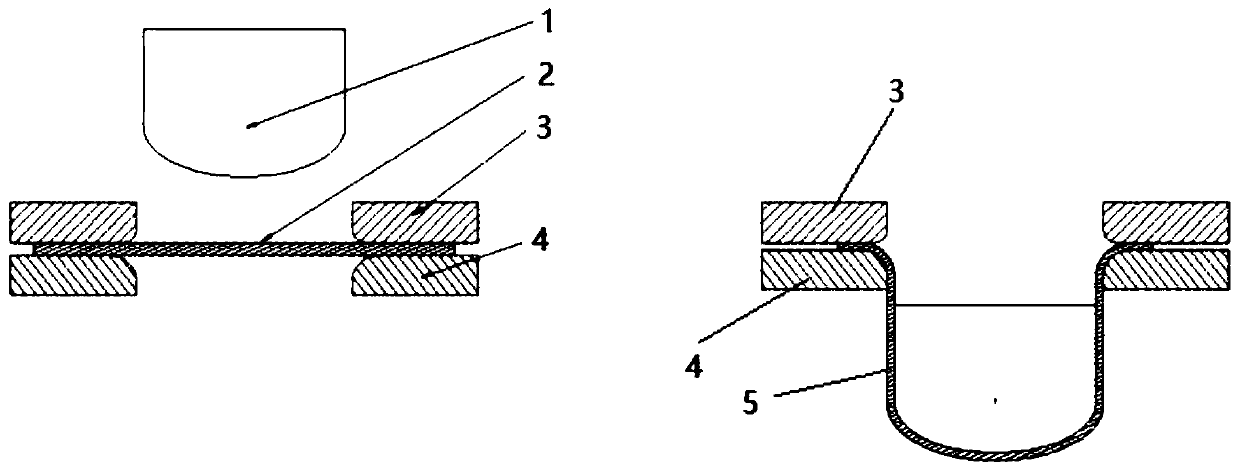

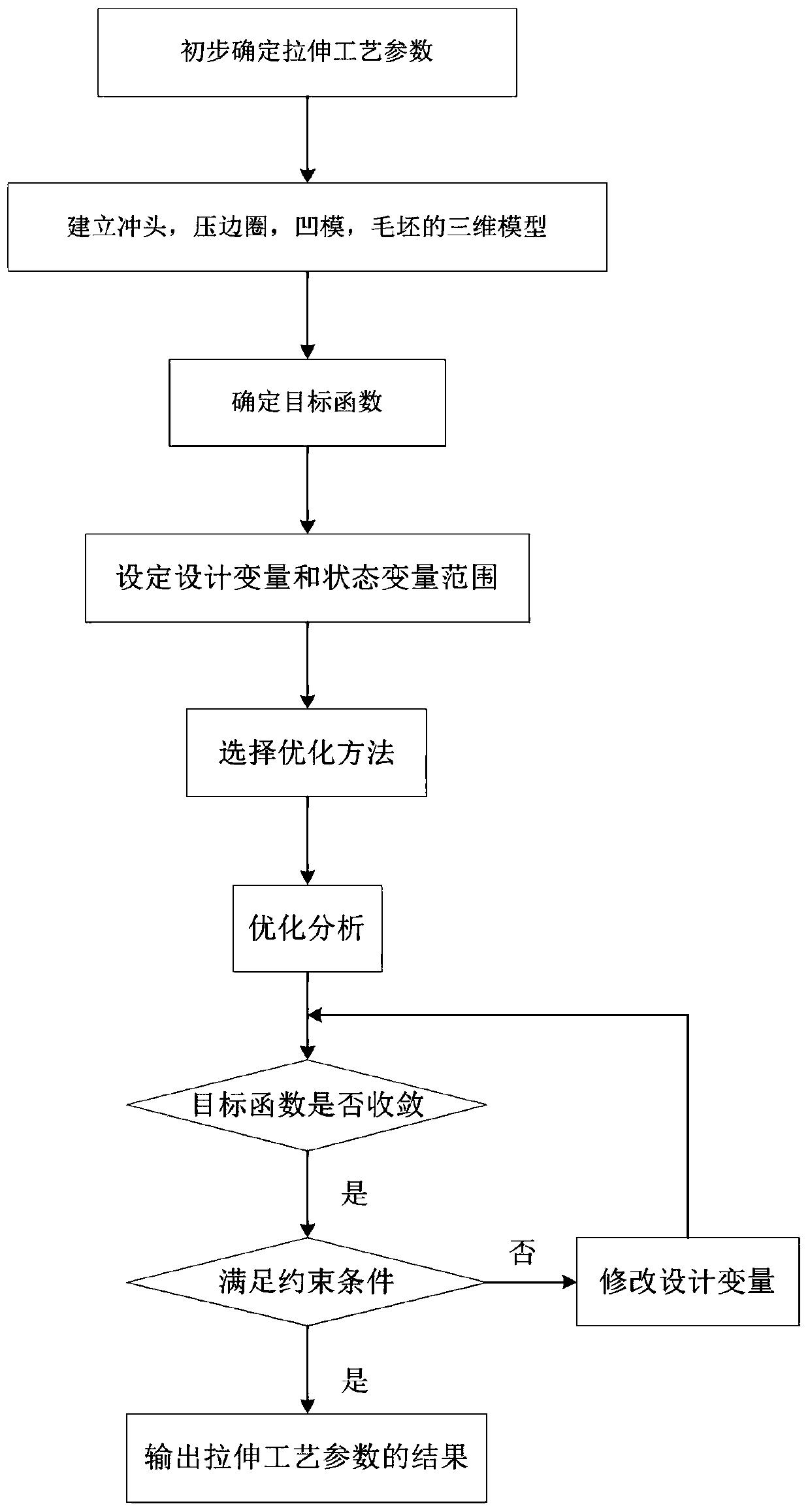

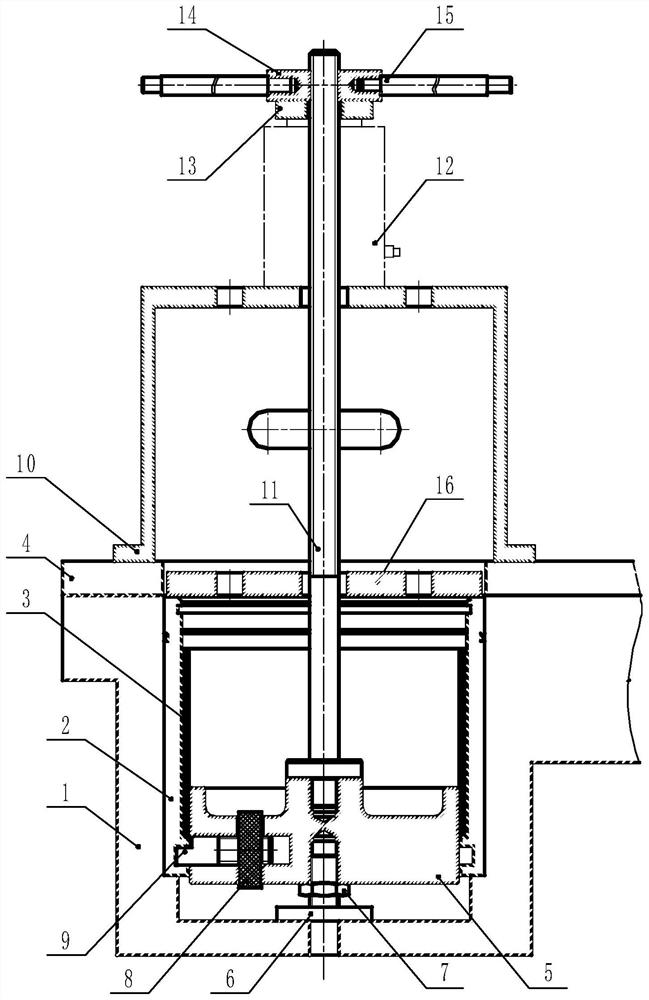

Deep drawing technology of deep-drawing-shaped simple pressure vessel

InactiveCN111299970AReduces the chance of weld damageReduce manufacturing costGeometric CADDesign optimisation/simulationFinite element techniqueEngineering

The invention provides a deep drawing technology of a deep-drawing-shaped simple pressure vessel. The deep drawing technology of the deep-drawing-shaped simple pressure vessel disclosed by the invention is characterized in that an end socket with a straight edge section, which is shaped by deep drawing, is directly used for docking circumferential welding, the technology breaks through a step of conducting circumferential welding on an upper end socket and a lower end socket and a cylinder body of a general simple pressure vessel, two circumferential welding joints are reduced to one circumferential welding joint, and a probability of welding damage is reduced. Meanwhile, the vessel does not have a cylindrical section which is shaped by a rolling plate and has a longitudinal welding joint,so that safety performance is greatly enhanced, production efficiency is increased, and production cost is reduced. Technological design is optimized with a finite element technology, and technologyparameters are optimized, so that the technology is more precise, generation of defective goods is avoided, a design cycle of a single product is reduced, equipment debugging time is reduced, and quality of deep-drawing shaping is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

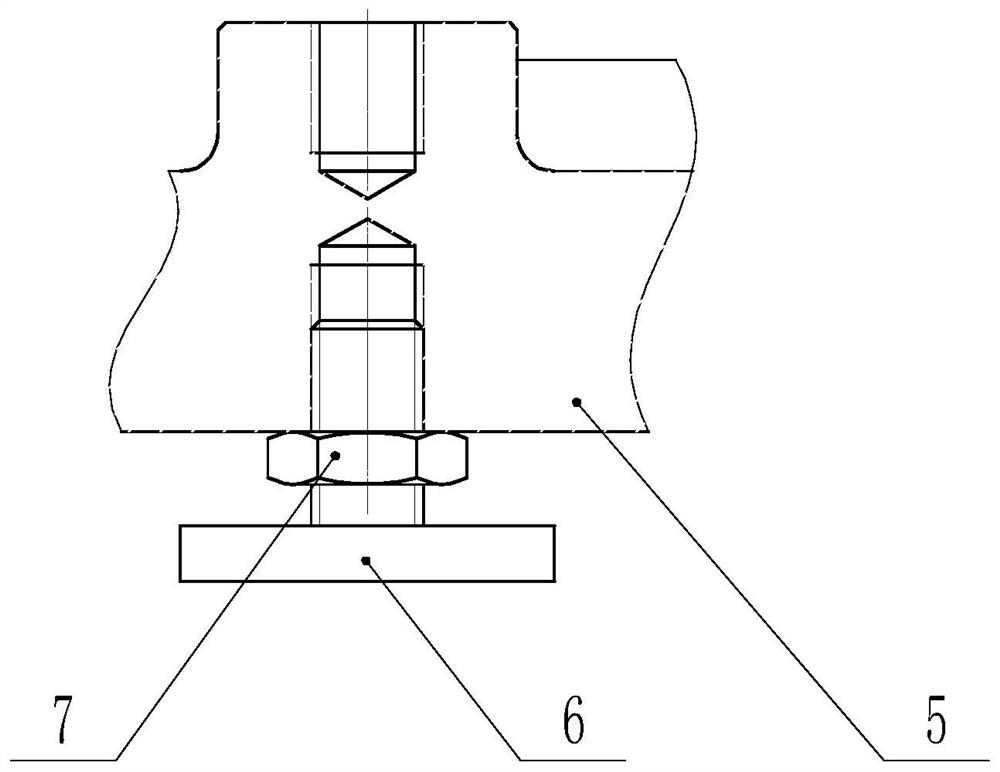

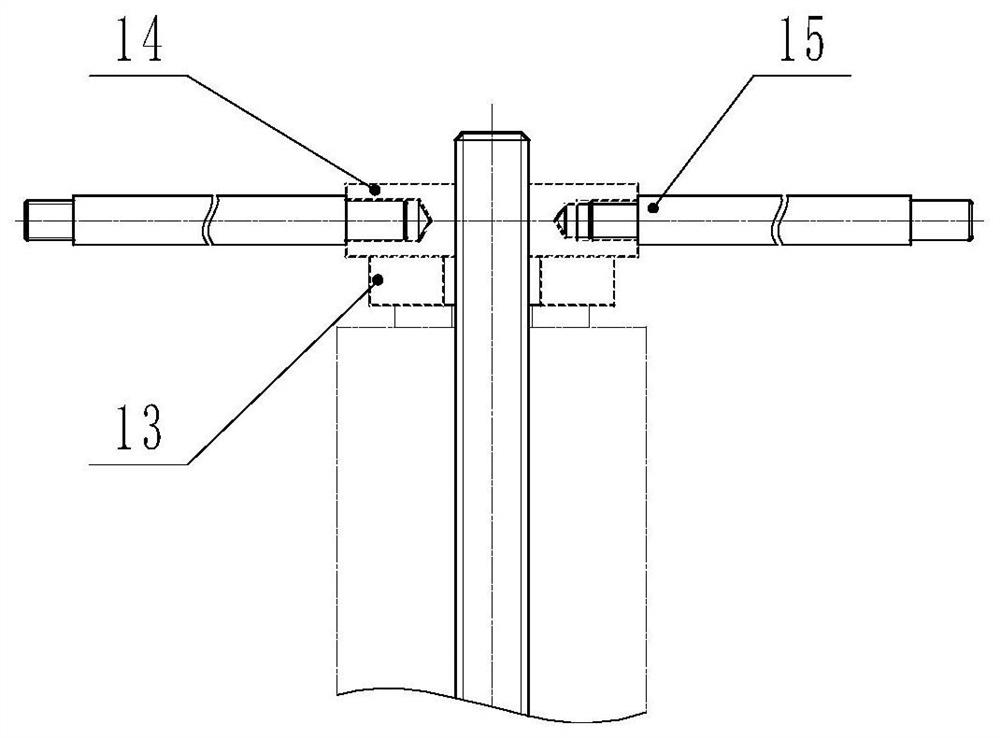

Guide blade shaft sleeve assembling and disassembling tool

InactiveCN111673670AReduce damageImprove securityMetal-working hand toolsStructural engineeringMechanical engineering

The invention provides a guide blade shaft sleeve assembling and disassembling tool. The guide blade shaft sleeve assembling and disassembling tool comprises a sleeve, a hollow jack, a lead screw anda chuck. The lower end of the sleeve is opened, the upper end of the sleeve is closed, the lower end of the sleeve abuts against a wear-resistant plate at the upper end of a bottom ring in a connection mode, and the sleeve comprises a holding space which is used for holding a shaft sleeve to be disassembled. The hollow jack and the sleeve are coaxially arranged, and the lower end of the hollow jack abuts against the top wall of the sleeve in a connection mode. The lead screw coaxially penetrates through the sleeve and the hollow jack, and the upper end of the lead screw is arranged above the hollow jack. A rotary twisting assembly which is used for driving the lead screw to move in the vertical direction is arranged at the upper end of the lead screw and abuts against the upper end of thehollow jack in a connection mode. The lower end of the lead screw is arranged below the hollow jack. The upper end of the chuck is connected with the lower end of the lead screw, and a clamping jaw assembly which can stretch out and draw back in the radial direction of the chuck is arranged on the periphery of the chuck and can be connected with an annular groove in the inner wall of the shaft sleeve in a clamped mode. The guide blade shaft sleeve assembling and disassembling tool is high in safety, accurate in technology and convenient and fast to operate, and the degree of the damage to theshaft sleeve is substantially reduced.

Owner:STATE GRID CORP OF CHINA +1

Flue-cured tobacco accurate intensive curing technology for tobacco high-temperature induced maturity

InactiveCN103271428BImprove qualityImprove appearance qualityTobacco preparationFlavorChemical composition

Owner:NANXIONG SCI RES INST OF GUANGDONG TOBACCO

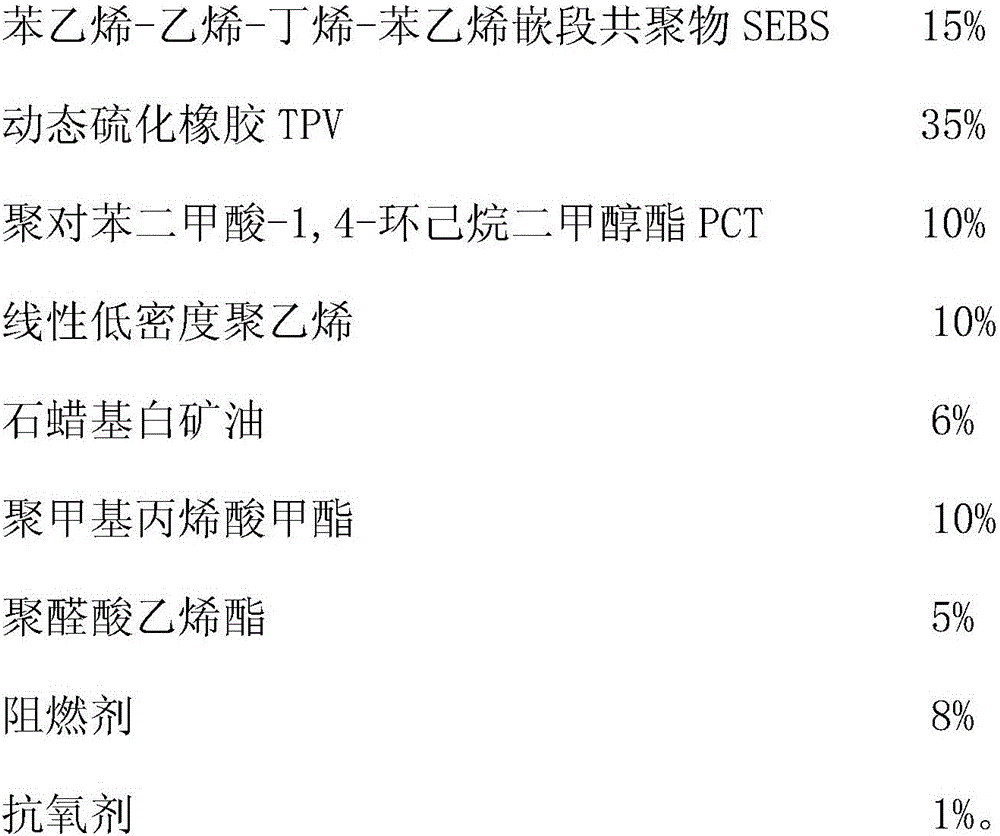

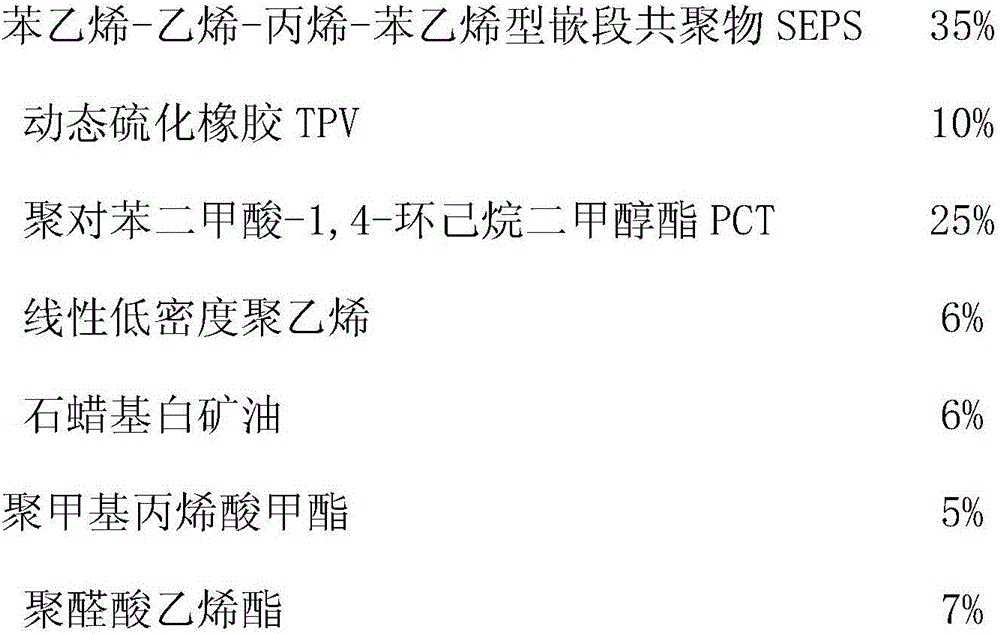

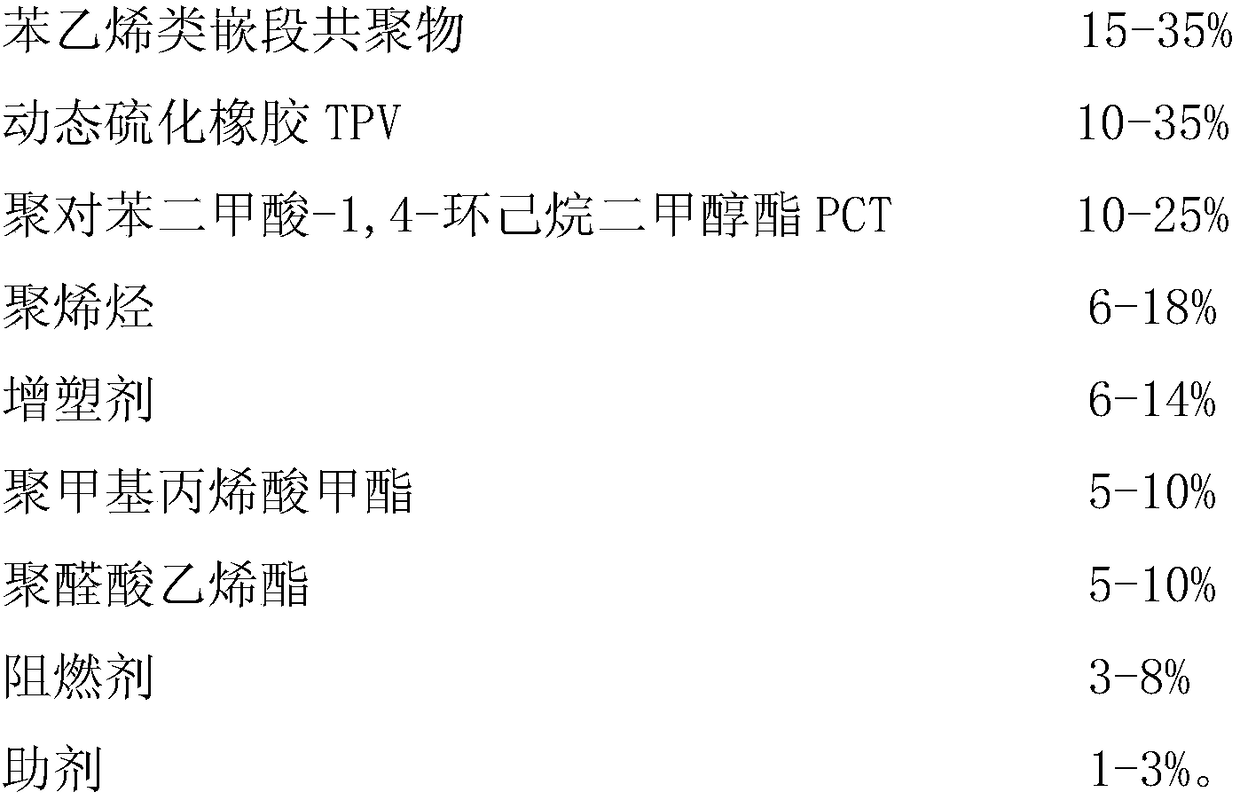

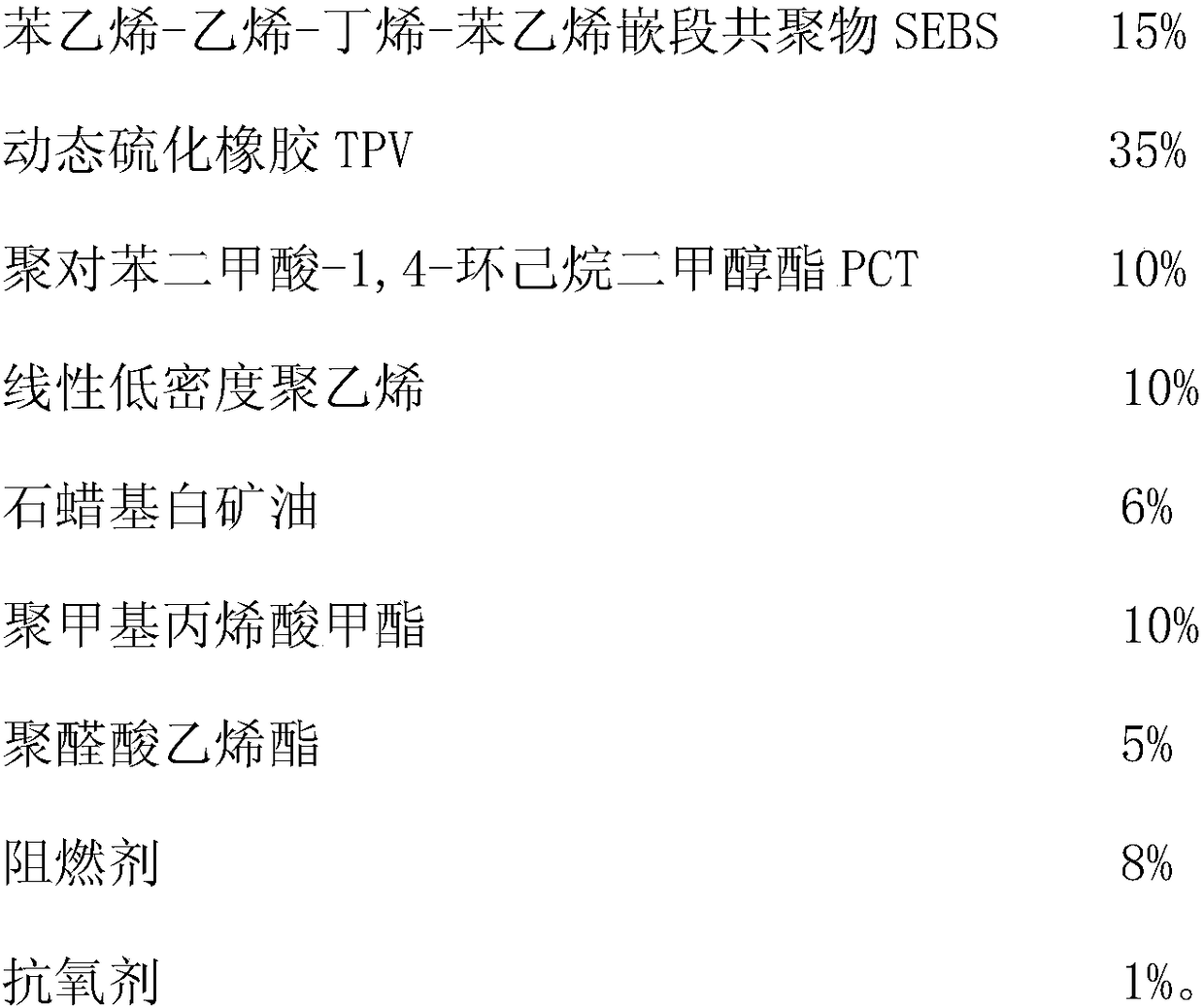

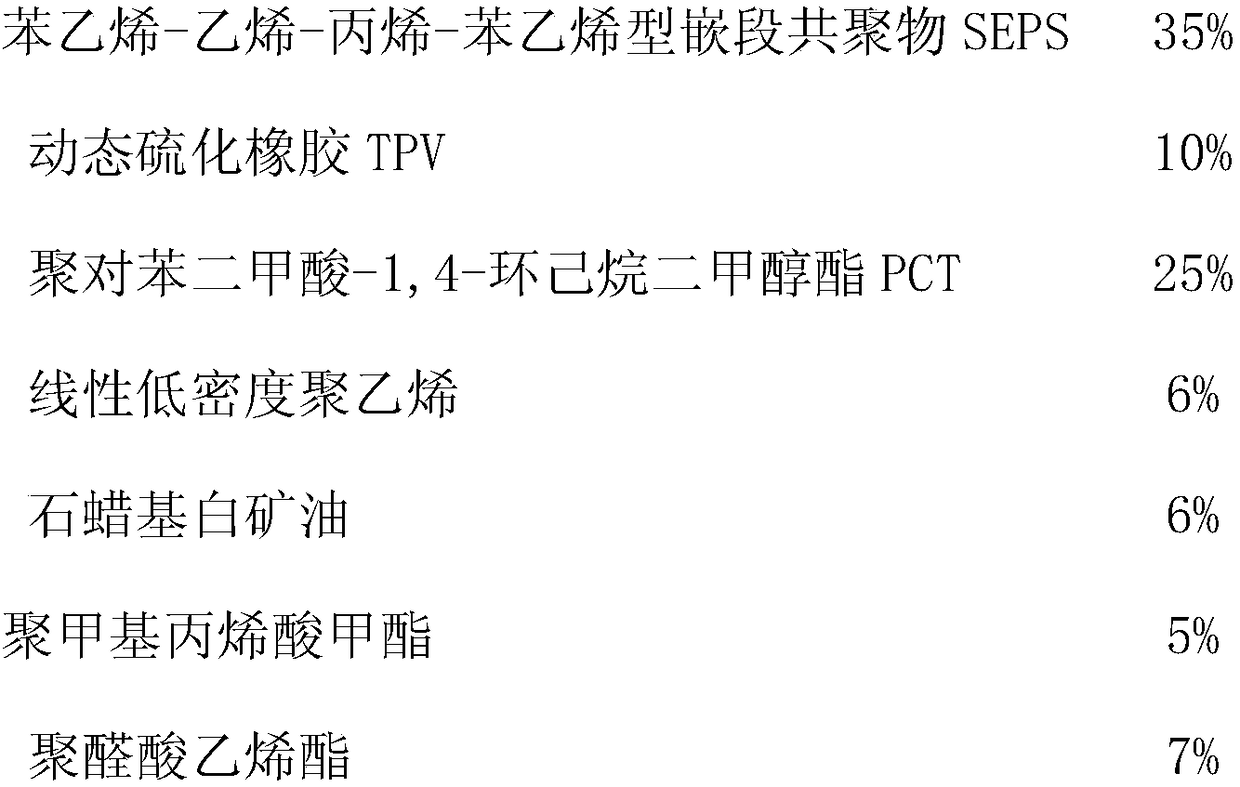

Thermoplastic elastomer for frosted-sense wire and preparation method of thermoplastic elastomer

The invention relates to the technical field of high polymer materials, and particularly discloses thermoplastic elastomer for a frosted-sense wire. The thermoplastic elastomer is prepared from, by weight, 15%-35% of styrene block copolymer, 10%-35% parts of dynamic vulcanized rubber TPV, 10%-25% of poly(ethylene-co-1,4-cyclohexylenedimethylene terephthalate) PCT, 6%-18% of polyolefin, 6%-14% of plasticizer, 5%-10% of polymethyl methacrylate, 5%-10% of poly aldehyde-acid vinyl ester, 3%-8% of fire retardant and 1%-3% of auxiliaries. The invention further discloses a preparation method of the thermoplastic elastomer for the frosted-sense wire. Compared with the prior art, the thermoplastic elastomer has the advantages of being good in frosted effect, good in resilience, low in cost, good in appearance, good in hand feeling and the like, and the comprehensive properties of good hardness, good strength, durability, shock resistance, tensile resistance and the like are achieved.

Owner:中广核高新核材集团(东莞)祈富新材料有限公司

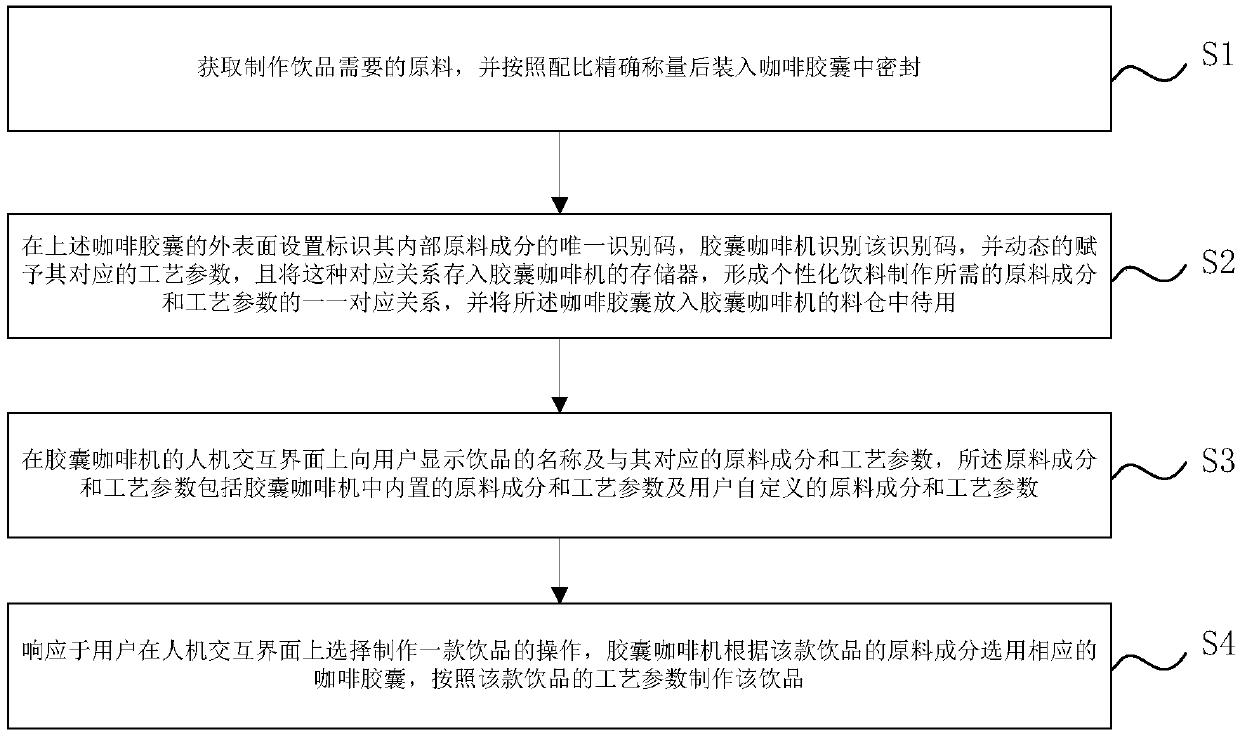

Making method of personalized beverage based on capsule coffee system

InactiveCN107822509AImprove success rateIncrease success rateBeverage vesselsEngineeringAdditive ingredient

The invention provides a making method of a personalized beverage based on a capsule coffee system. The making method comprises the following steps: acquiring raw materials needed for making the beverage, accurately weighing the raw materials according to the proportion, then putting the weighed raw materials into a coffee capsule, and carrying out sealing; arranging a unique identification code which identifies raw material ingredients inside the coffee capsule on the outer surface of the coffee capsule, endowing the raw material ingredients with the corresponding process parameters, storingthe correspondence relationship in a storage of a capsule coffee machine, and thus one-to-one correspondence relationship between the raw material ingredients needed for making the personalized beverage and the process parameters is formed; displaying the name of the beverage and the corresponding raw material ingredients and process parameters for a user on a human-computer interaction interfaceof the capsule coffee machine; and responding to the selection operation of making one beverage of the user on the human-computer interaction interface, thus preparing the beverage. According to the method disclosed by the invention, the making of the personalized beverage is finished based on the intelligent capsule coffee making system, so that the user can easily obtain the personalized beverage adopting the accurate formula and the accurate process and meeting the requirements of the user.

Owner:北京天材科技有限公司

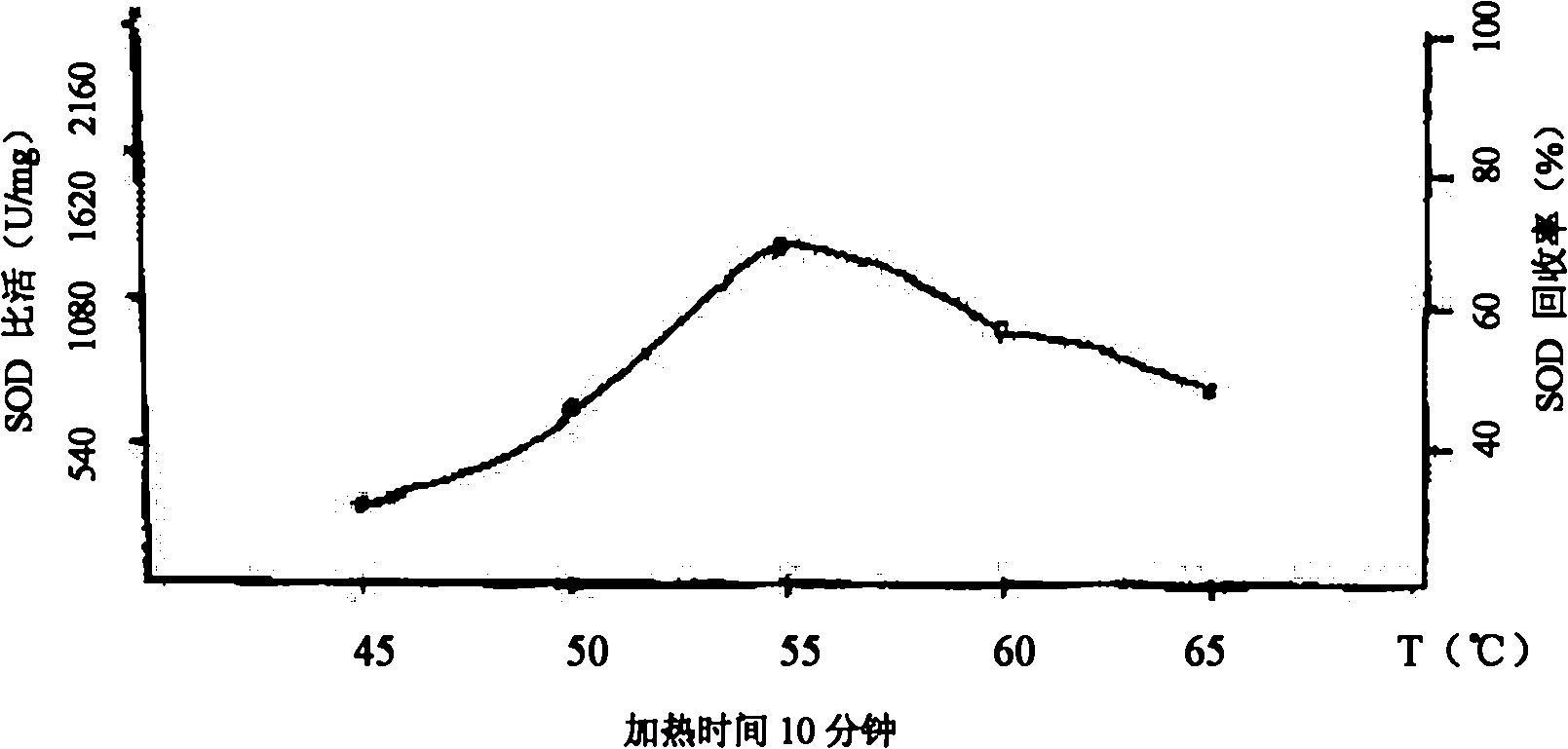

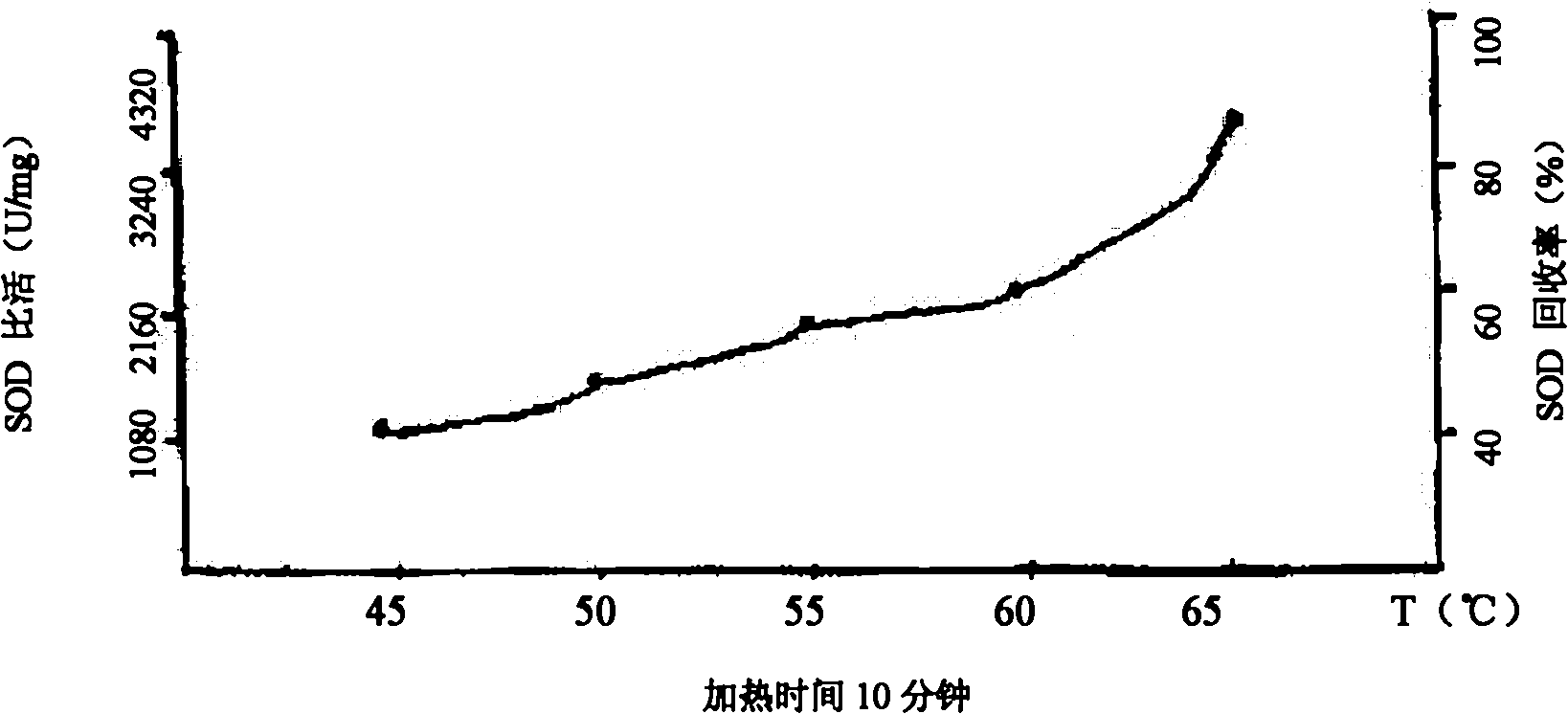

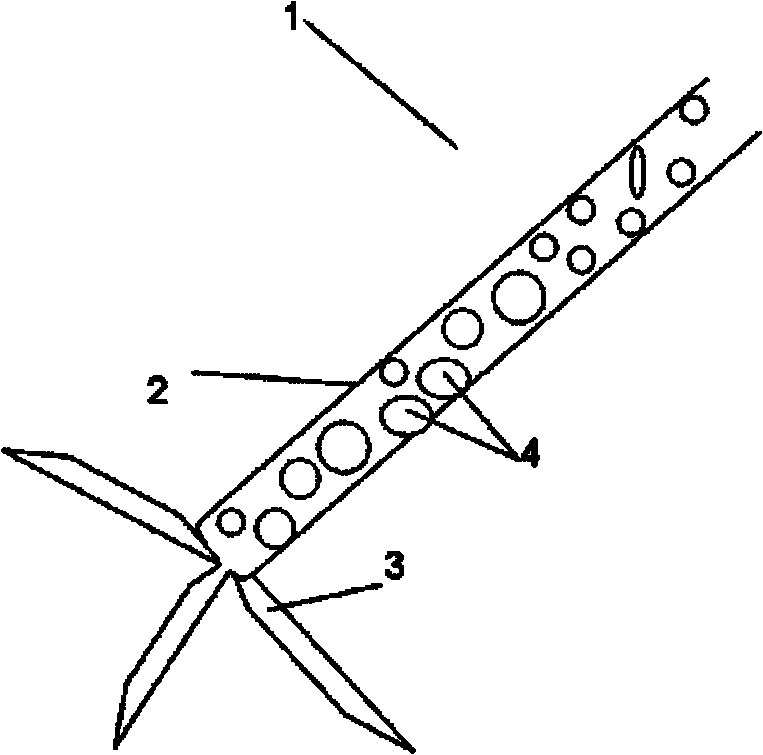

Method for extracting superoxide dismutase from cattle and sheep blood largly industrially and blade type agitator applied to same

InactiveCN101921736ASave heatReduce process costRotary stirring mixersMixer accessoriesUltrafiltrationChemistry

The invention discloses a method for extracting superoxide dismutase from cattle and sheep blood largly industrially, comprising the following steps of: carrying out the production steps of anticoagulation, hypotonic hemolysis, ultrafiltration, fast temperature rise and reduction, sedimentation, three-stage temperature treatment, salting-out, ultrafiltration, concentration, freeze drying, and the like on fresh cattle or sheep blood so as to simultaneously obtain two groups of superoxide dismutase finished products which are slightly different in specific activity and purity, wherein the fast temperature rise and reduction is realized through an agitator with a heat / cold source; the first-stage temperature treatment is carried out at 45-55 DEG C, the second-stage temperature treatment is carried out at 55-60 DEG C, and the third-stage temperature treatment is carried out at 60-65 DEG C. Compared with the prior art, the invention has the advantages of simple process, short production period, high yield coefficient and specific activity of the products, stable quality, low cost, excellent economic benefit, and the like.

Owner:云南光华亚南生物科技有限公司

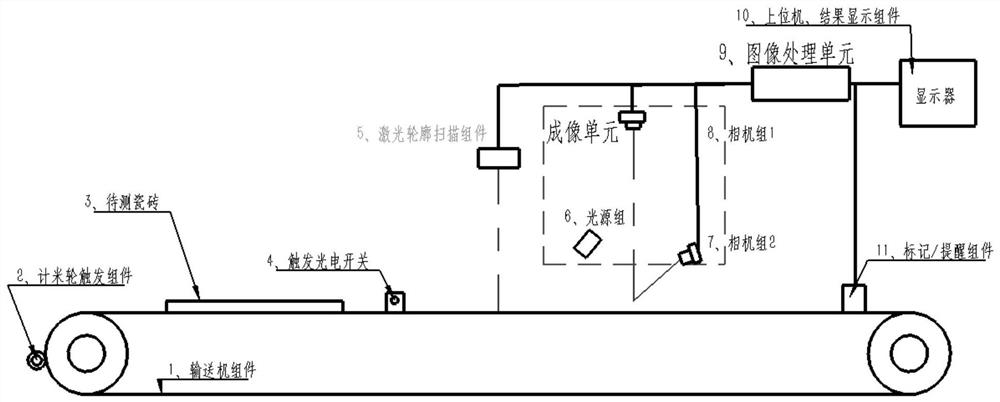

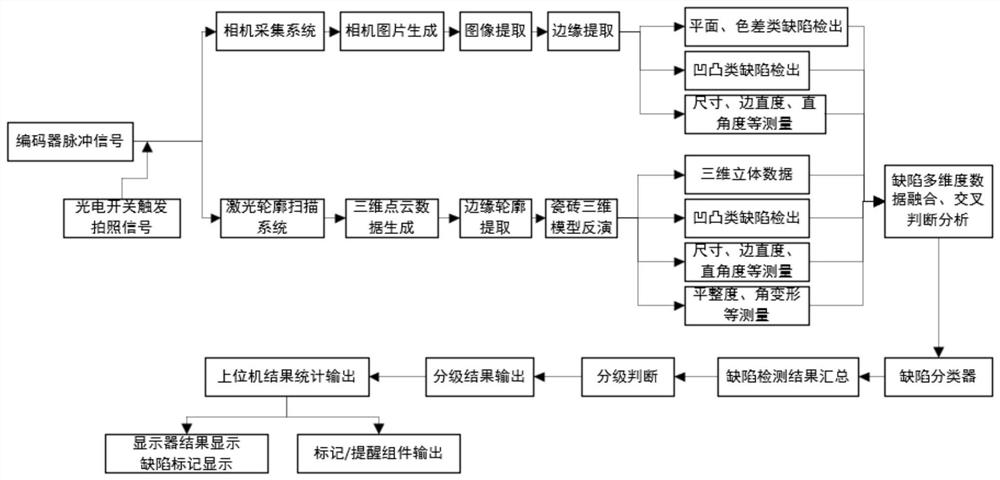

Ceramic tile defect detection device adopting laser and camera composite detection mode and classification method

InactiveCN114280073AGrade Information ExcellentAchieve integrated detection effectOptically investigating flaws/contaminationUsing optical meansImaging processingPoint cloud

The invention provides a ceramic tile defect detection device adopting a laser and camera composite detection mode. The ceramic tile defect detection device comprises a belt conveyor assembly, a photoelectric trigger assembly, a meter counting wheel trigger assembly, a camera acquisition system, a laser contour scanning assembly, an image processing unit, an upper computer display assembly and a marking / reminding assembly. The belt conveyor assembly conveys to-be-detected ceramic tiles for operation; the photoelectric triggering assembly is used for sending out a photoelectric triggering signal to start or stop working; the meter counting wheel triggering assembly is used for sending a scanning pulse triggering signal; and the image processing unit is used for processing the picture shot by the camera acquisition system and the point cloud data acquired by the laser contour scanning assembly, and transmitting a detection result to the upper computer display assembly and the marking / reminding assembly after completion. The invention further provides a method of the device, the ceramic tiles are detected in a laser and camera composite detection mode, complete ceramic tile defect detection can be achieved, and more accurate defect classification, qualitative analysis and quantitative analysis can be achieved on the defects.

Owner:南京光衡科技有限公司

A double-sided laser welding method controlled by powder metallurgy

ActiveCN105728944BImprove mechanical propertiesEvenly regulatedVehicle componentsMetal working apparatusAlloyLaser beams

The invention discloses a double-side laser welding method for powder metallurgy control, relates to a double-laser beam welding method, and solves the problem that welding wire elements cannot perform full alloy control for a welding line structure in the double-side laser welding process of a T-shaped structure. The method comprises the following steps: (1) a groove is mechanically milled in the center of a position to be welded on the upper surface of a cover in the welding direction; and the cover is chemically cleaned to remove an oxide film and machining stains; (2) alloy powder is prefilled in the groove to form a deposition layer; a laser cladding head is vertically placed rightly above the groove; the laser powder feeding material adding is performed on the surface of the groove to obtain the deposition layer by using a mode of coaxial feeding of laser beams and the alloy powder; and a deposition material higher than the surface of the cover is grinded off by using a grinding machine, so that a deposition surface is coplanar with the surface of the cover; and (3) the double-laser wire filling welding is performed for a long purlin and the cover to obtain symmetric welding lines on two sides. The method is used for double-laser beam welding of the T-shaped structure.

Owner:HARBIN INST OF TECH

Preparation method for producing amino acid through livestock blood bioconversion and product

InactiveCN104543390APromote degradationSmall molecular weightBio-organic fraction processingAnimal feeding stuffFiberBlood resource

The invention discloses a preparation method for producing amino acid through livestock blood bioconversion. The preparation method comprises the following steps: collecting and storing fresh livestock blood from a slaughter house; removing fat fiber from the livestock blood; producing friendly amino acid through secondary bioconversion of the livestock blood; performing post-treating and packaging and the like. The invention further discloses amino acid powder or amino acid solutions prepared by the preparation method. By using high-frequency and low-frequency ultrasonic, a bioconversion reaction tank and other technical equipment, and in combination with a special preparation method and optimized conditions, 18 types of main amino acid solutions or amino acid powder with the content of 18.66% or more are prepared, and the amino acids have smaller molecular weights, high internal absorptivity and high product yield; the equipment cost is reduced; livestock blood resources are recycled and wastewater pollution caused in production of blood powder is avoided, the preparation method is environment-friendly; the product is stable in quality and can realize industrialization easily.

Owner:东莞市双红生物技术有限公司 +1

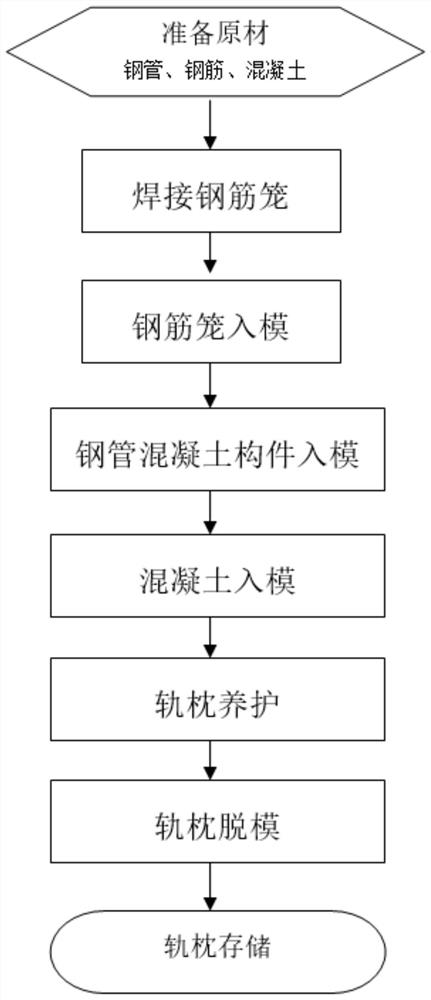

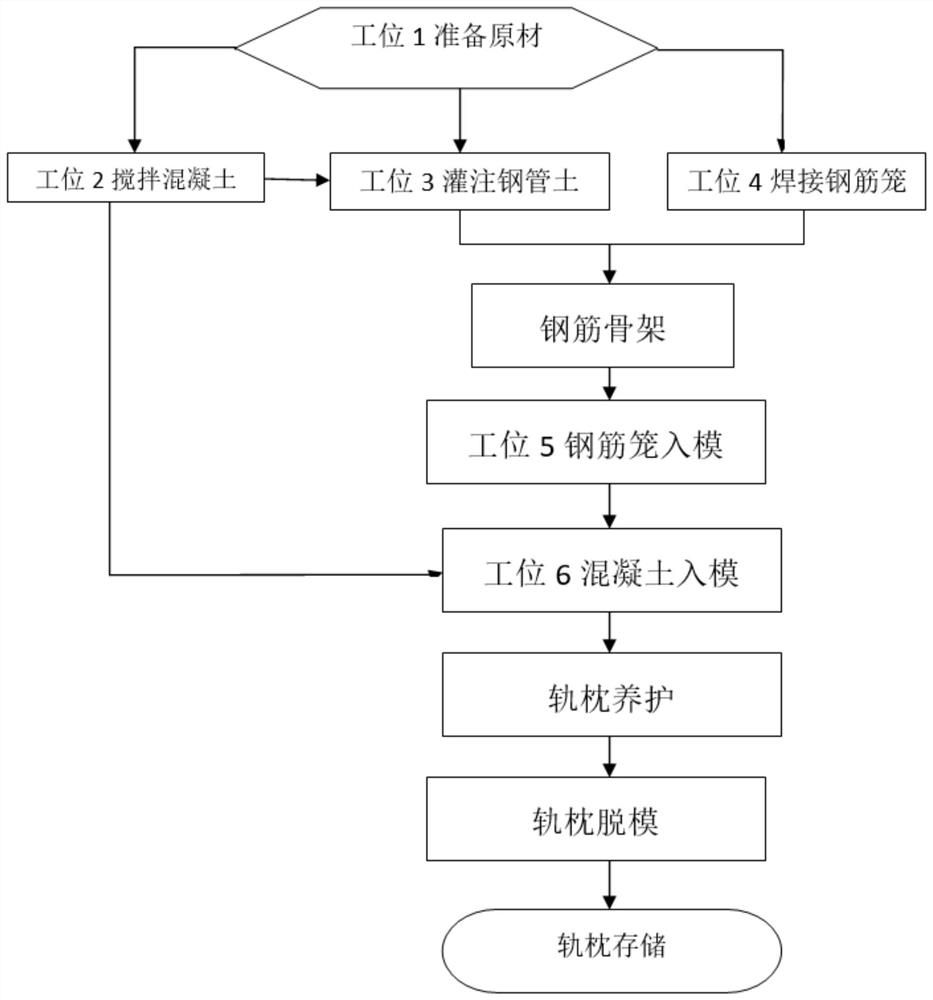

Steel pipe concrete sleeper production method

InactiveCN111993558ASolving Die-in DifficultiesQuality improvementDischarging arrangementShaping reinforcementsRebarRail transit

The invention discloses a steel pipe concrete sleeper production method. The steel pipe concrete sleeper production method comprises two production processes, namely, a low-cost manual operation steelpipe concrete sleeper production process and a high-efficiency robot operation steel pipe concrete sleeper production process. The steel pipe concrete sleeper production method comprises a mode of placing a steel pipe concrete component and a reinforcement cage separately into a mold and performing combining in the mold, and also comprises a process of combining the steel pipe concrete componentand the reinforcement cage to form an integrated structure and then placing the integrated structure into the mold. The difficulty of placing a framework of a steel pipe concrete sleeper into a mold is solved. Meanwhile, due to the automatic robot streamline production process, quality stability in the sleeper production process can be guaranteed, and the production efficiency is greatly improved.The technical guarantee is improved for high efficiency and stability in the sleeper production and manufacturing process. The batch production of sleepers can be realized, it is ensured that the sleeper manufacturing process is correct, and the process is smooth. At the same time, it is ensured that the produced sleepers are reliable in quality, good in durability and suitable for rail traffic construction.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +2

A kind of thermoplastic elastomer for frosted electric wire and preparation method thereof

The invention relates to the technical field of high polymer materials, and particularly discloses thermoplastic elastomer for a frosted-sense wire. The thermoplastic elastomer is prepared from, by weight, 15%-35% of styrene block copolymer, 10%-35% parts of dynamic vulcanized rubber TPV, 10%-25% of poly(ethylene-co-1,4-cyclohexylenedimethylene terephthalate) PCT, 6%-18% of polyolefin, 6%-14% of plasticizer, 5%-10% of polymethyl methacrylate, 5%-10% of poly aldehyde-acid vinyl ester, 3%-8% of fire retardant and 1%-3% of auxiliaries. The invention further discloses a preparation method of the thermoplastic elastomer for the frosted-sense wire. Compared with the prior art, the thermoplastic elastomer has the advantages of being good in frosted effect, good in resilience, low in cost, good in appearance, good in hand feeling and the like, and the comprehensive properties of good hardness, good strength, durability, shock resistance, tensile resistance and the like are achieved.

Owner:中广核高新核材集团(东莞)祈富新材料有限公司

Method of heating jacket of retaining ring of steam turbine generator rotor

ActiveCN102904394BHeating safetyHeating fastManufacturing stator/rotor bodiesEngineeringRetaining ring

The invention provides a method of a heating jacket of a retaining ring of a steam turbine generator rotor. Compared with the conventional method, the method has the advantages that firstly, a retaining ring sensing heating mode is adopted, compared with the conventional heating method, the mode is safer and rapider, and the temperature during the heating process is easier to master; secondly, compared with the conventional end part fixing mode, by adopting the fixing mode to the end part of a rotor, an end part coil can be relatively effectively fixed, the elastic swelling is reduced, the installation position of a center ring is relatively precise, so that the retaining ring is sleeved easily; thirdly, with the adoption of a hanging scheme of the retaining ring, the time spent on that the retaining ring is stopped being heated till being hung and transported to the rotor is shortened, the temperature loss is reduced, and moreover the hanging and transporting processes is safe, and meanwhile the problem of fixing a new tool retaining ring drawing pawl is solved simply and effectively; and fourthly, compared with the steps of the conventional retaining ring of the heating jacket, the steps of the method (provided by the scheme) of the retaining ring of the heating jacket are safer, rapider and more accurate.

Owner:HARBIN ELECTRIC MASCH CO LTD

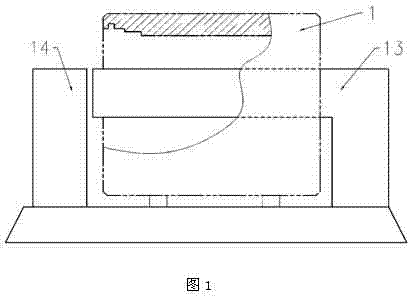

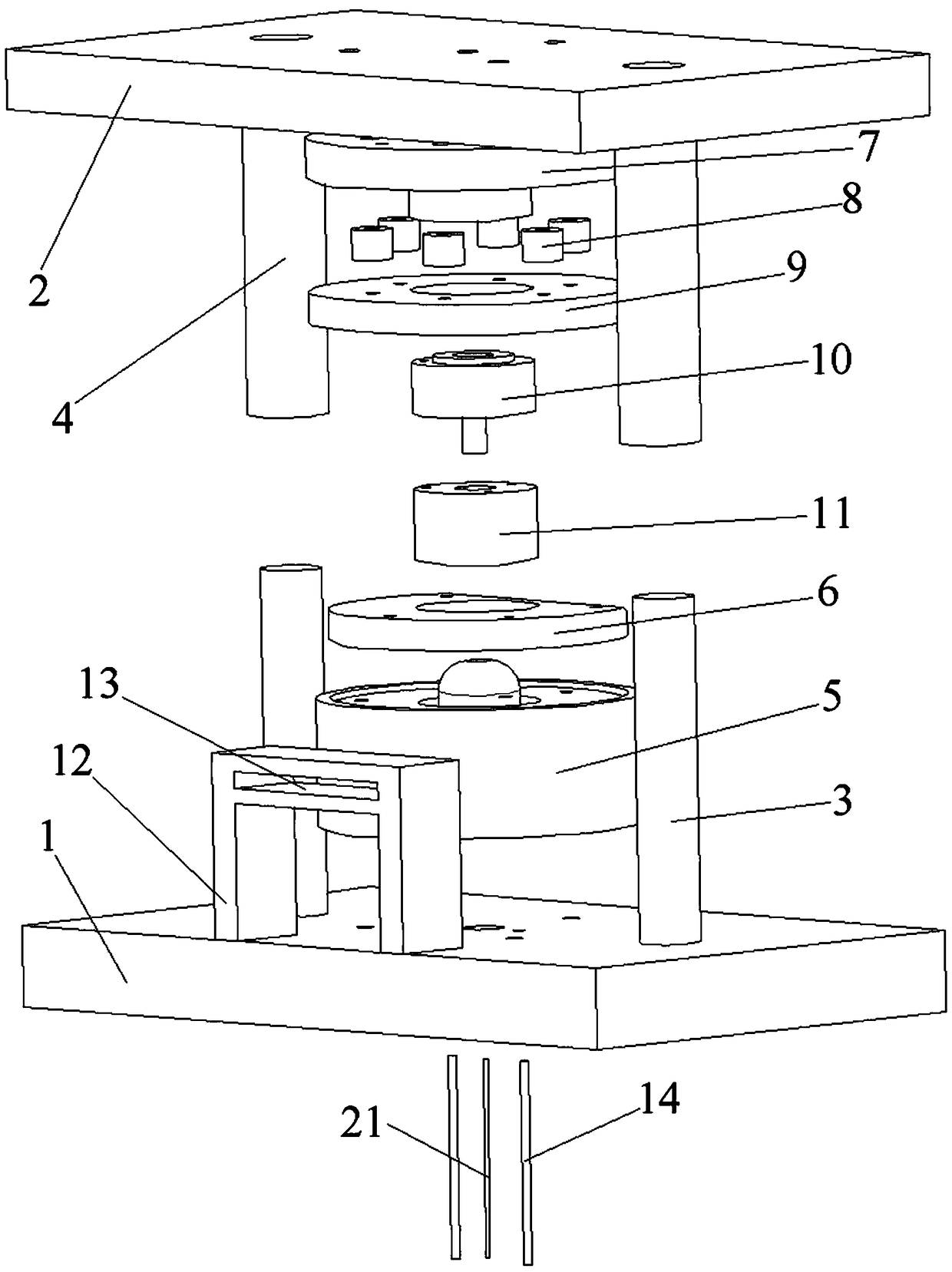

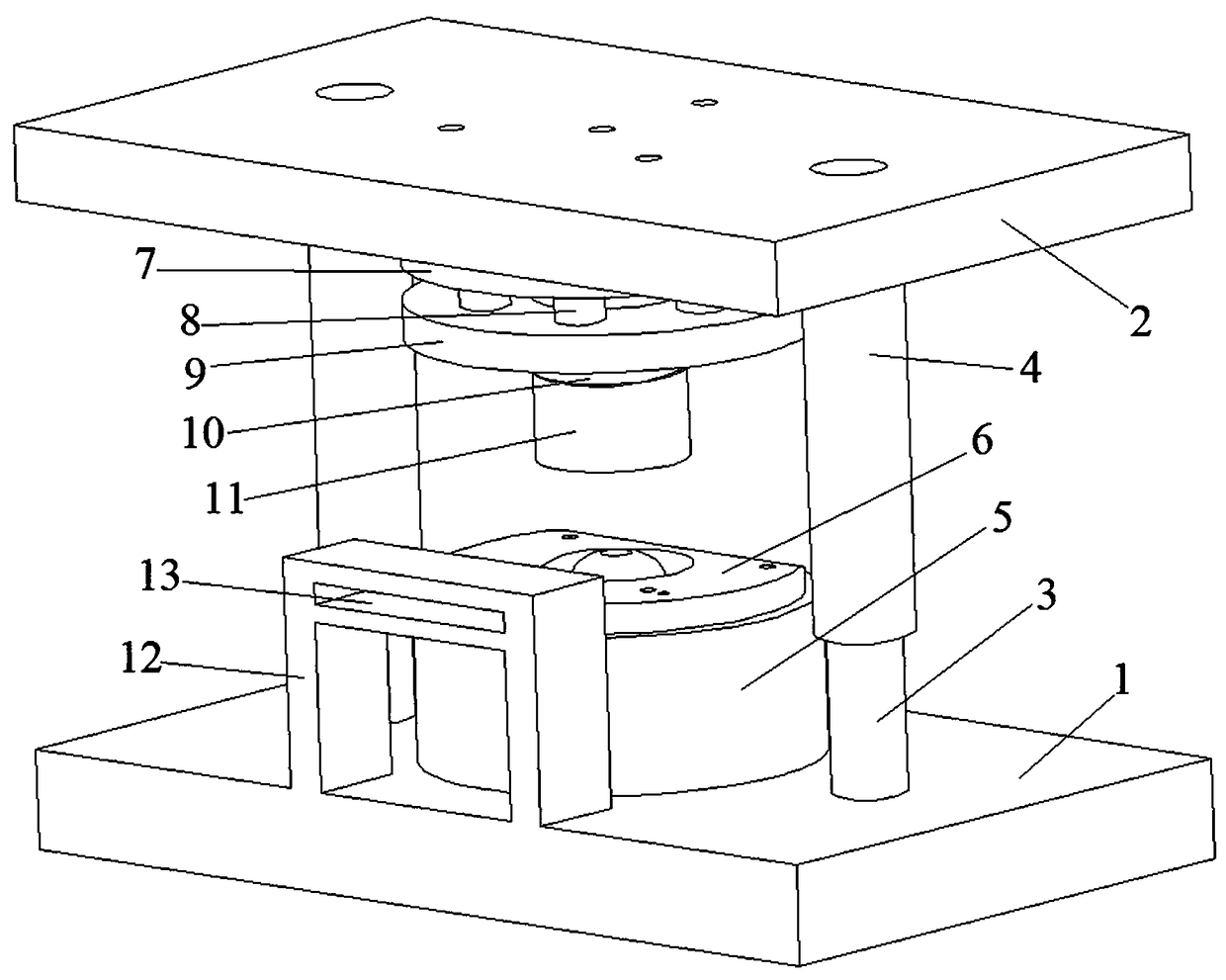

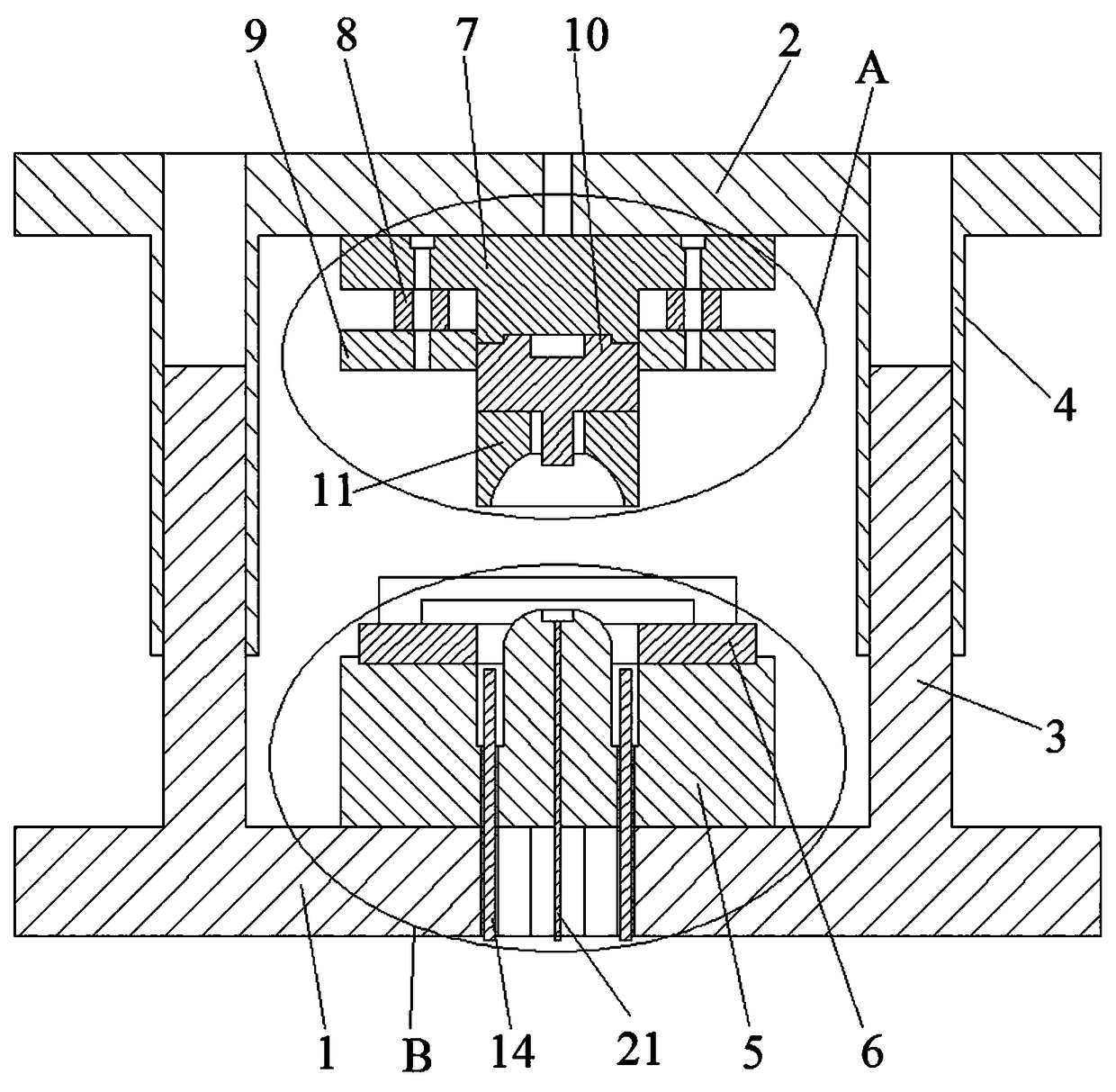

Anchor cable pressure bowl composite mould

The invention relates to an anchor cable pressure bowl composite mould and belongs to the field of anchor cable pressure bowl production. The anchor cable pressure bowl composite mould comprises a base and an upper seat; guide columns are fixed to the base; a lower mould is installed at the middle part of the base; a supporting seat is fixed to the lower mould; a cylindrical sinking groove is formed in the lower mould; a bulged shaft is integrally formed in the middle part of the sinking groove; the top surface of the bulged shaft is an arc-shaped surface; an inner ring groove is formed in thecenter of the top surface of the bulged shaft; sleeves fitting with the guide columns are fixed to the upper seat; an upper mould seat is fixed to the lower surface of the upper seat; an upper punching mould is fixed to the lower side of the upper mould seat; a punching rod is integrally formed in the upper punching mould; an upper sleeve mould is fixed to the lower side of the upper punching mould; a circular hole where the punching rod penetrates through is formed in the middle part of the upper sleeve mould; and a concave bowl-shaped cavity is formed in the lower surface of the upper sleeve mould. Through up-and-down squeezing and cutting, punching forming is carried out at one time; the anchor cable pressure bowl composite mould is concise in technology, low in labor intensity, safe,reliable, high in production efficiency and low in production-manufacturing cost; and the anchor cable pressure bowl composite mould is accurate in technology and high in finished product rate, so that the amount of waste pieces can be reduced substantially.

Owner:济宁落陵矿山支护材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com