Method for extracting superoxide dismutase from cattle and sheep blood largly industrially and blade type agitator applied to same

A superoxide, large-scale technology, applied in mixer accessories, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of long temperature gradient processing time, large equipment investment, long heating time, etc., and achieve uniform temperature. And fast, reduce process cost, and is conducive to the effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Embodiment 1: Large-scale industrialization extracts the method for superoxide dismutase from bovine blood

[0092] 1. Add 30g of sodium citrate anticoagulant to 10Kg of fresh bovine blood. Stand at a low temperature of 4° C. for 30 minutes, and remove most of the supernatant after the solution is separated.

[0093] 2. Add an equal volume of distilled water, stir, perform hypotonic hemolysis for 30 minutes, and place for another 40 minutes. After the solution is layered, perform ultrafiltration on the supernatant (using a polyacrylonitrile membrane with a pore size of 1 μm) to obtain 2000 ml of supernatant liquid and 6500ml precipitation;

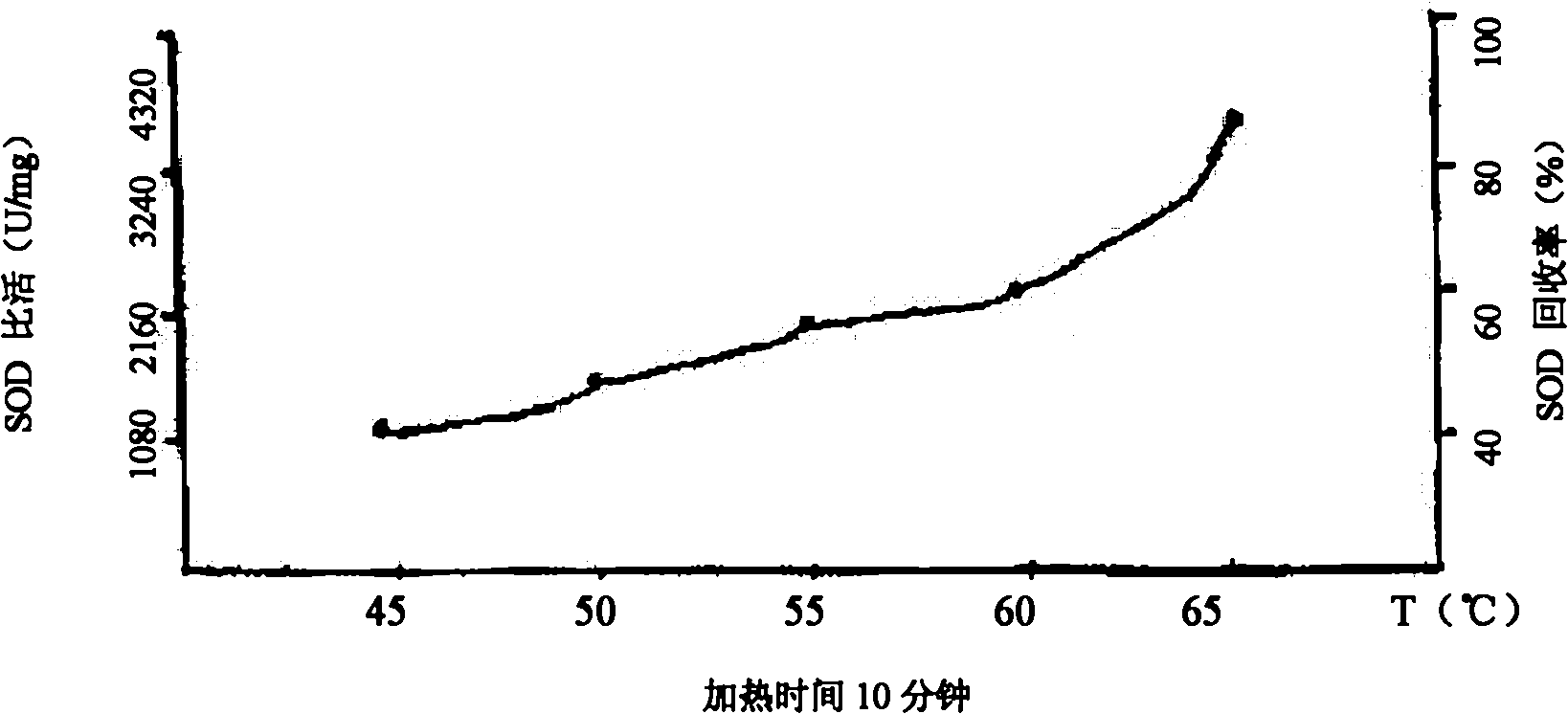

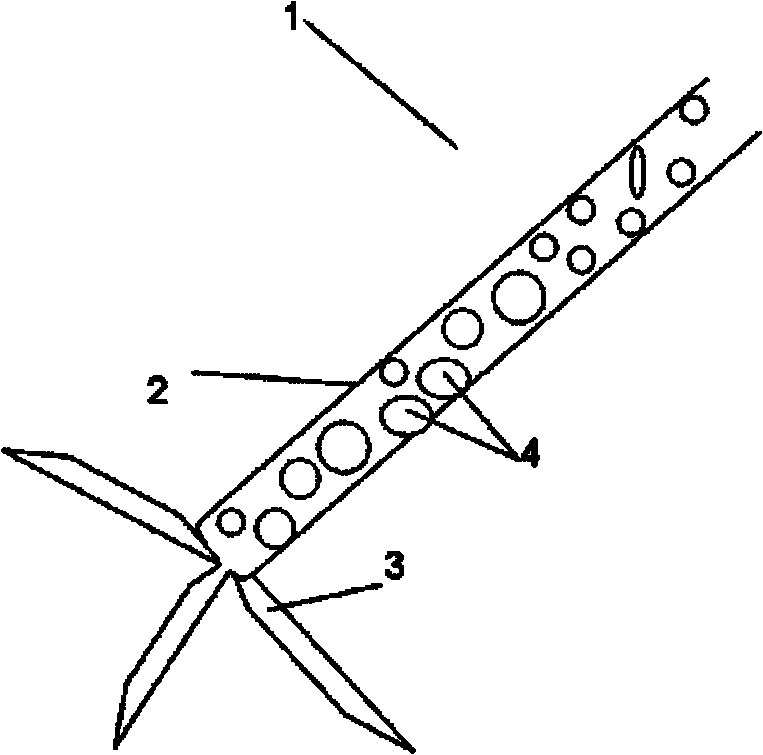

[0094] While heating the precipitate, stir it with a mixer with a heat source, so that it can be heated rapidly to 40°C within 8 minutes. After centrifugation at room temperature, 4000 rpm for 20 minutes, let stand at a low temperature of 4°C for 20 minutes, remove the precipitate, and obtain 3000ml supernatant;

[0095] 3. Mix t...

Embodiment 2

[0099] Embodiment 2: Large-scale industrialization extracts the method for superoxide dismutase from bovine blood

[0100] 1. Add 50g of sodium citrate anticoagulant to 10Kg of fresh bovine blood. Stand at a low temperature of 4° C. for 50 minutes, and remove most of the supernatant after the solution is separated.

[0101] 2. Add an equal volume of distilled water, stir, perform hypotonic hemolysis for 30 minutes, and place for another 50 minutes. After the solution is layered, perform ultrafiltration on the supernatant (using a polyacrylonitrile membrane with a pore size of 5 μm) to obtain 2500 ml of the supernatant solution and 6000ml precipitation;

[0102] While heating the precipitate, stir it with a mixer with a heat source, so that it can be heated rapidly to 45°C within 8 minutes. After centrifugation at room temperature, 5000 rpm for 15 minutes, let stand at a low temperature of 4°C for 10 minutes, remove the precipitate, and obtain 3000ml supernatant;

[0103] 3....

Embodiment 3

[0107] Embodiment 3: Large-scale industrialization extracts the method for superoxide dismutase from bovine blood

[0108] 1. Add 60g of sodium citrate anticoagulant to 10Kg of fresh bovine blood. Stand at a low temperature of 4° C. for 60 minutes, and remove most of the supernatant after the solution is separated.

[0109] 2. Add an equal volume of distilled water, stir, perform hypotonic hemolysis for 30 minutes, and place it for another 60 minutes. After the solution is layered, perform ultrafiltration on the supernatant (using a polyacrylonitrile membrane with a pore size of 5 μm) to obtain 3500 ml of the supernatant Liquid and 5800ml precipitation;

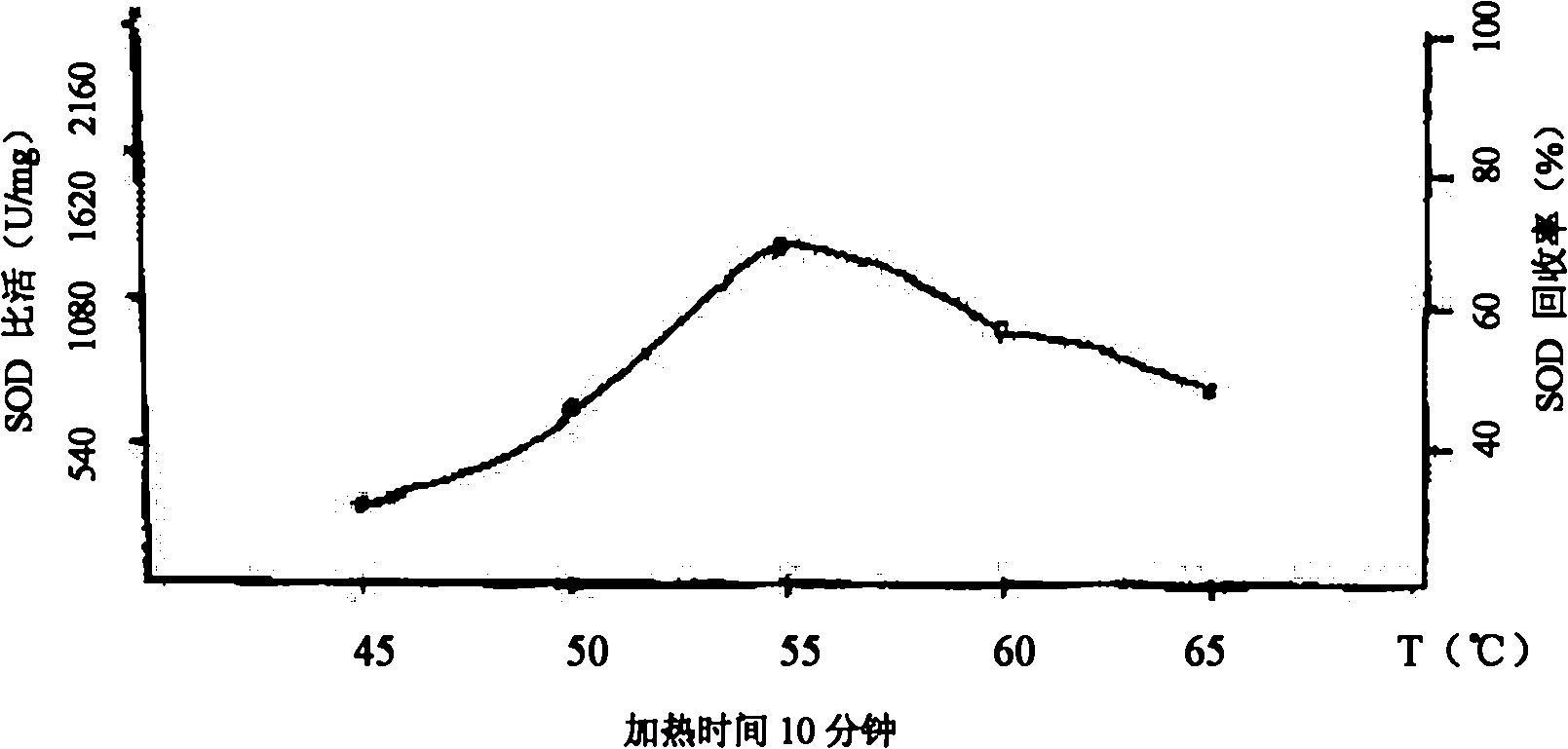

[0110] While heating the precipitate, stir it with a mixer with a heat source, so that it can be heated rapidly to 55°C within 10 minutes. After centrifugation at 6000 rpm for 20 minutes at room temperature, let stand at a low temperature of 4°C for 30 minutes to remove the precipitate and obtain 3000ml of supernatant;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com