Disperse dye composition, dyeing method and preparation method of disperse dye composition

A technology of disperse dyes and dyeing methods, applied in the field of disperse dye compositions, can solve the problems of high energy consumption and long process, and achieve the effects of improving dyeing fastness, improving desizing efficiency and excellent dyeing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

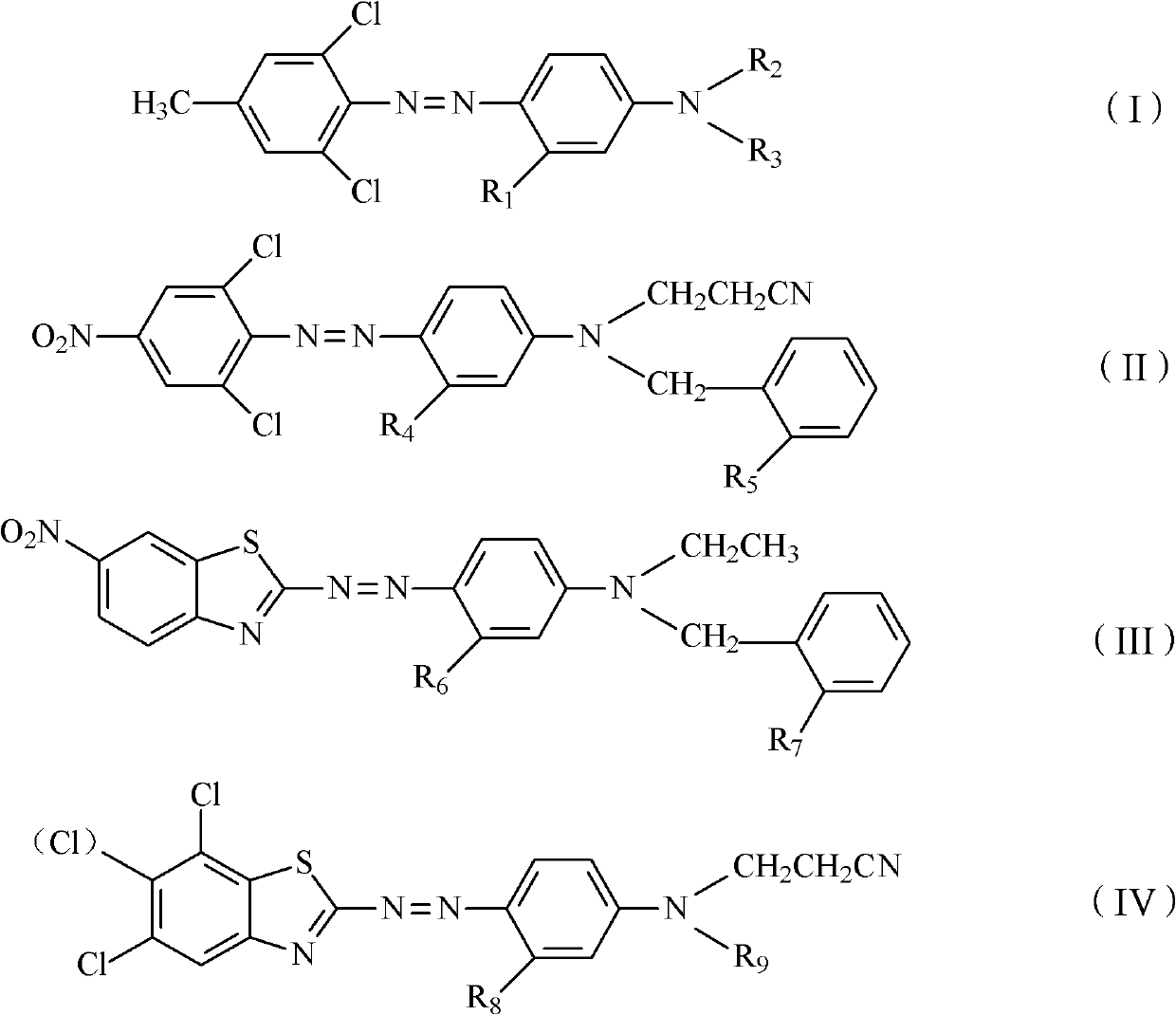

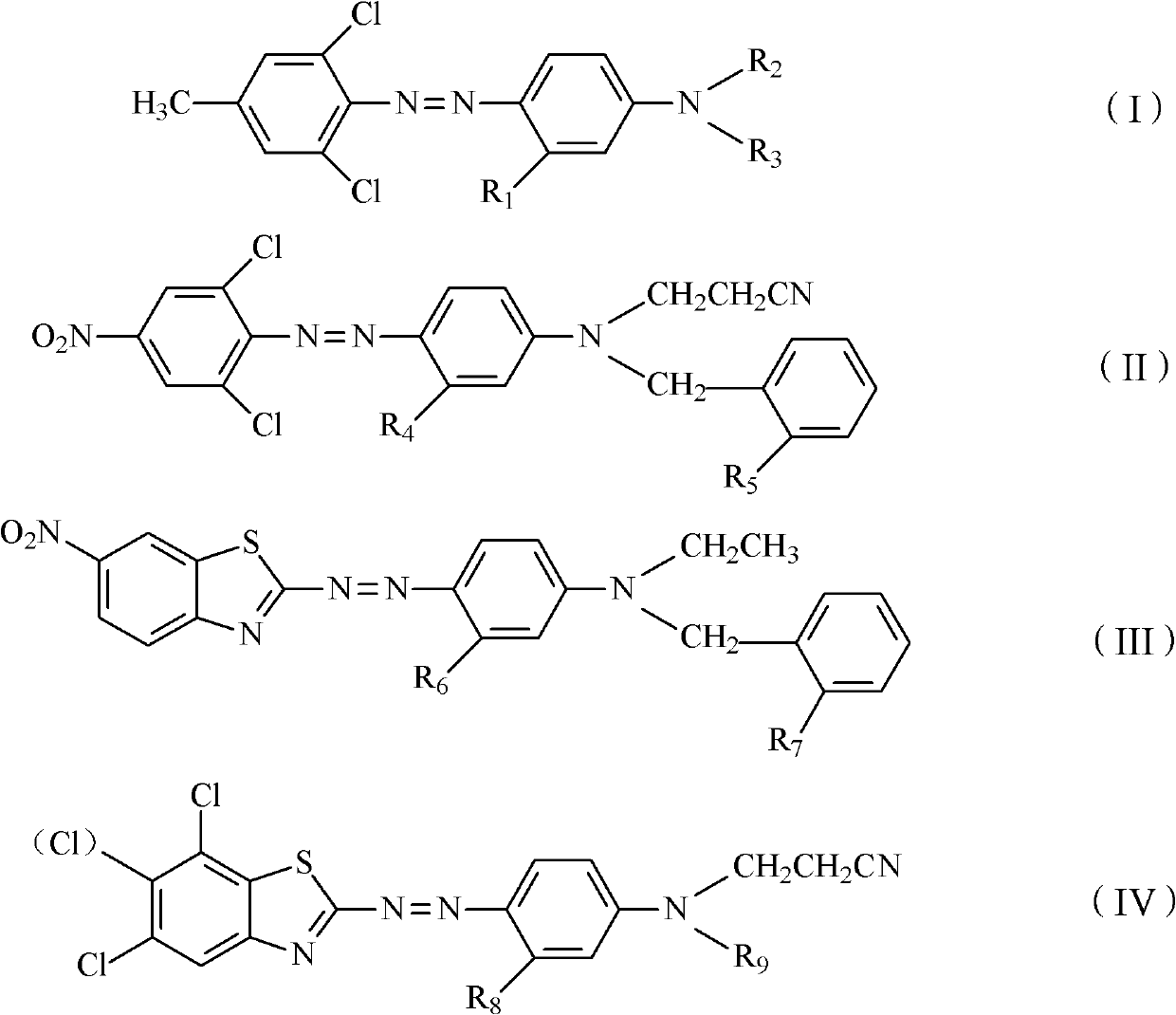

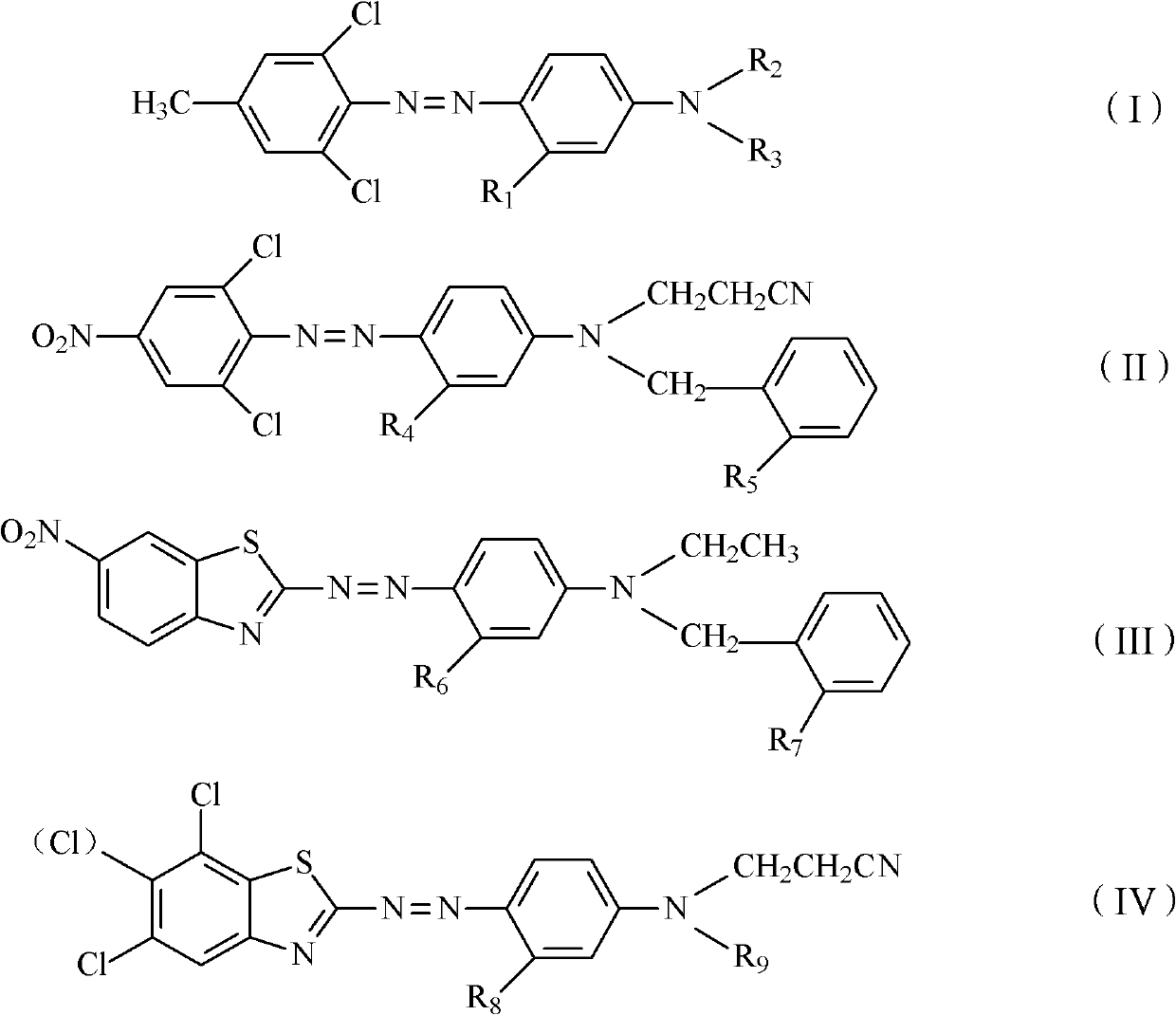

Image

Examples

Embodiment 1

[0066] 5 grams of yellow dye represented by general formula (I-A), 50 grams of yellow dye represented by general formula (I-C) and 82 grams of dispersant MF are mixed with water, and then ground and dispersed with a grinder until the particle size of disperse dye is When it is 1-3μm, stop grinding. Then, the yellow dye powder (disperse dye composition) was obtained by high-temperature spray drying.

Embodiment 2

[0068] 15 grams of yellow dye represented by general formula (I-B), 45 grams of yellow dye represented by general formula (I-E) and 120 grams of dispersant MF are mixed with water, and then ground and dispersed with a grinder until the particle size of disperse dye is When it is 1-3μm, stop grinding. Then, the yellow dye powder (disperse dye composition) was obtained by high-temperature spray drying.

Embodiment 3

[0070] 55 grams of yellow dye represented by general formula (I-E), 8 grams of orange dye represented by general formula (II-A) and 130 grams of dispersant MF are mixed with water and then ground and dispersed with a grinder until the disperse dye When the particle size is 1-3 μm, stop grinding. Then, the yellow dye powder (disperse dye composition) was obtained by high-temperature spray drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| soaping fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com