Patents

Literature

47results about How to "Improve desizing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

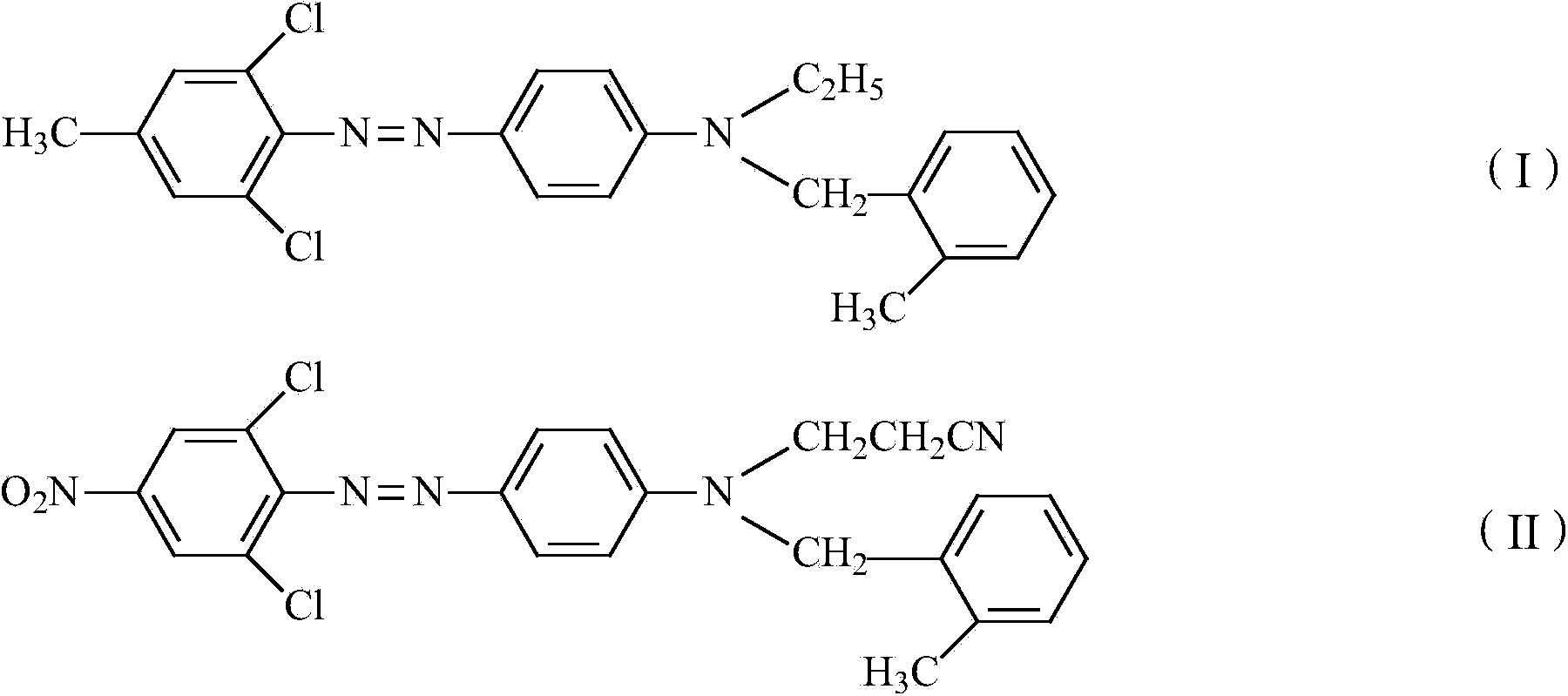

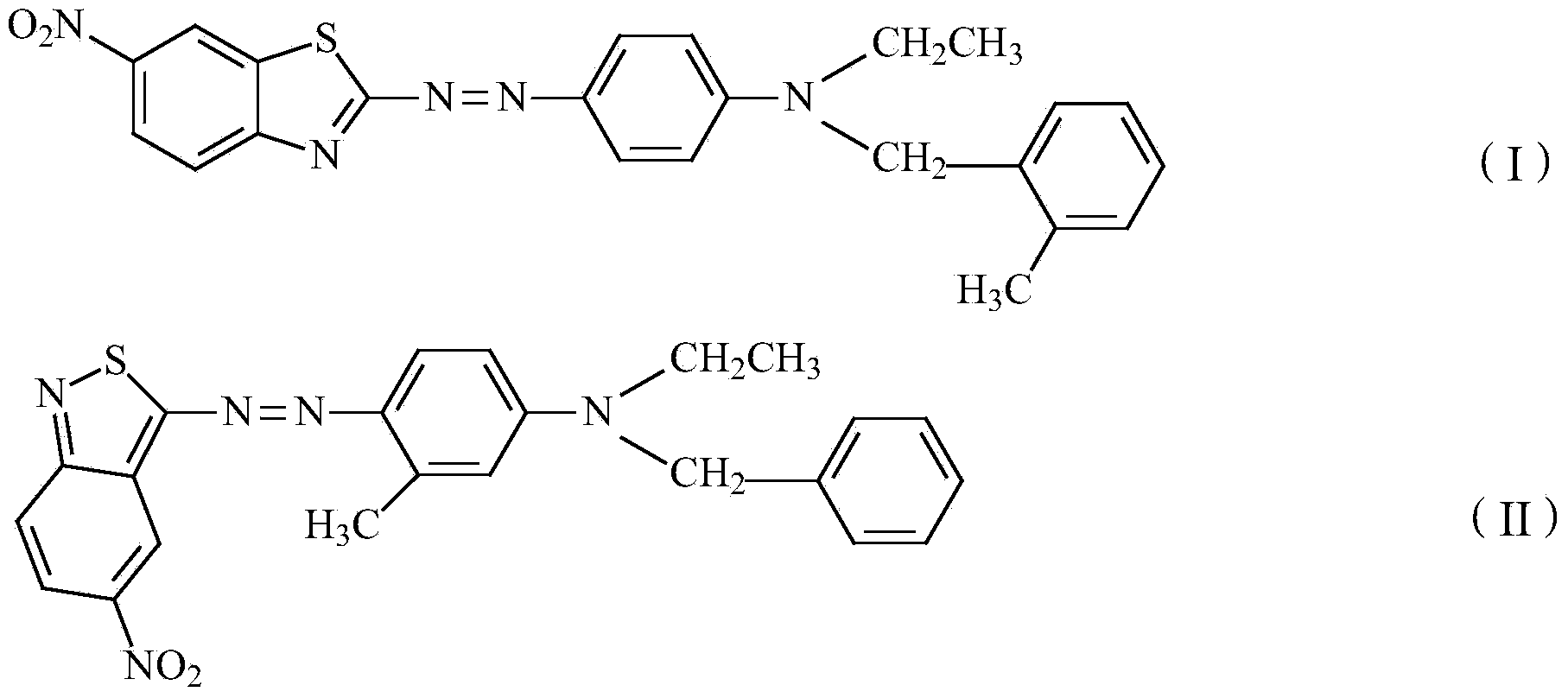

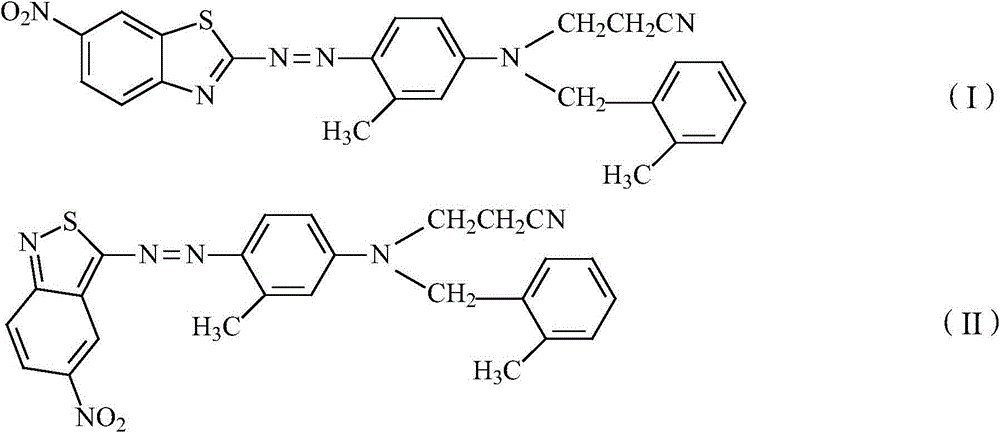

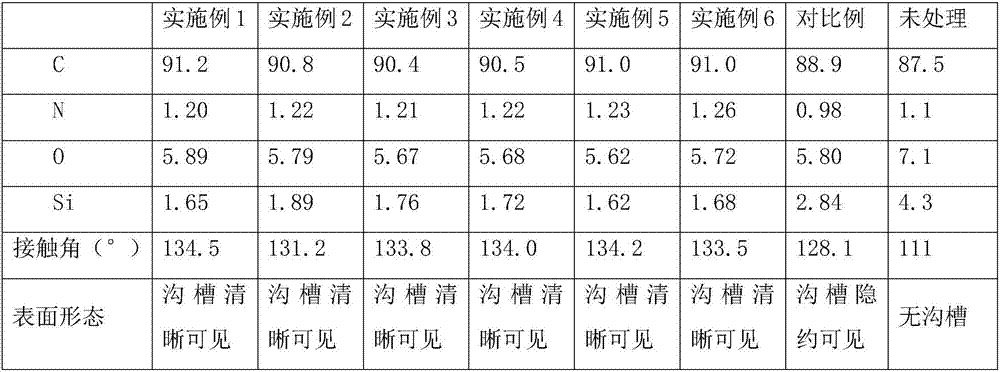

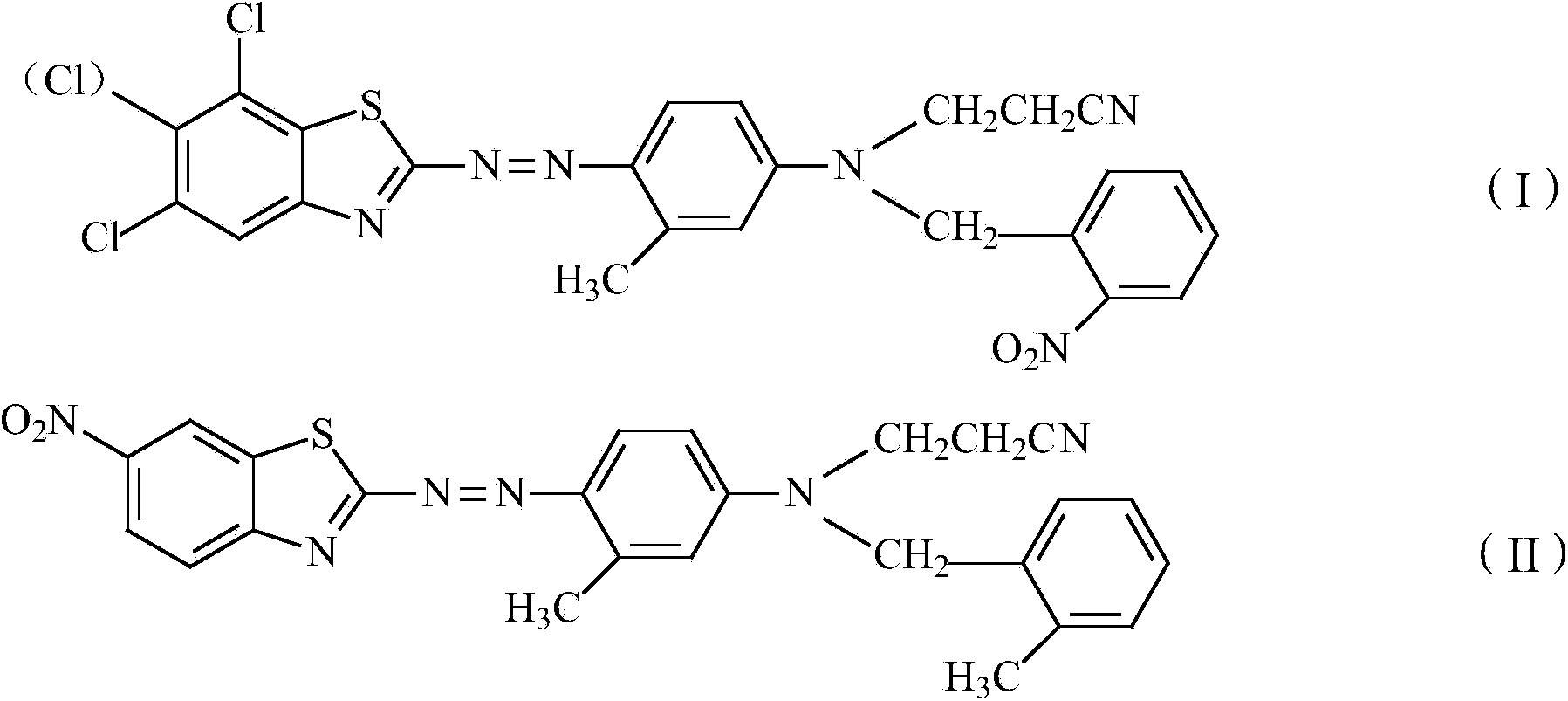

Disperse dye composition, dyeing method and preparation method of disperse dye composition

ActiveCN102618078AImprove oxidation resistanceGood alkali resistanceFibre treatmentOrganic dyesDisperse dyeHydrogen

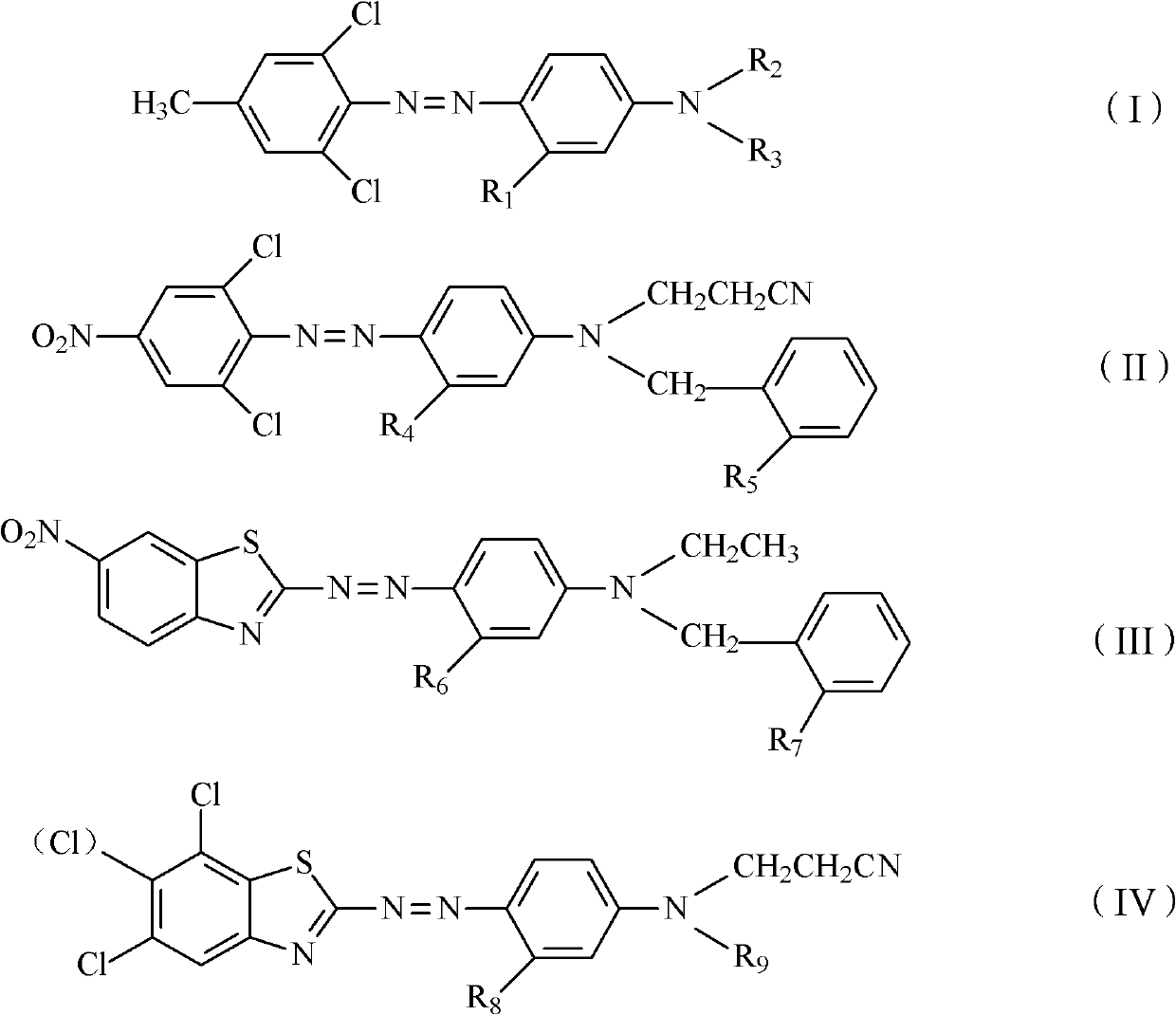

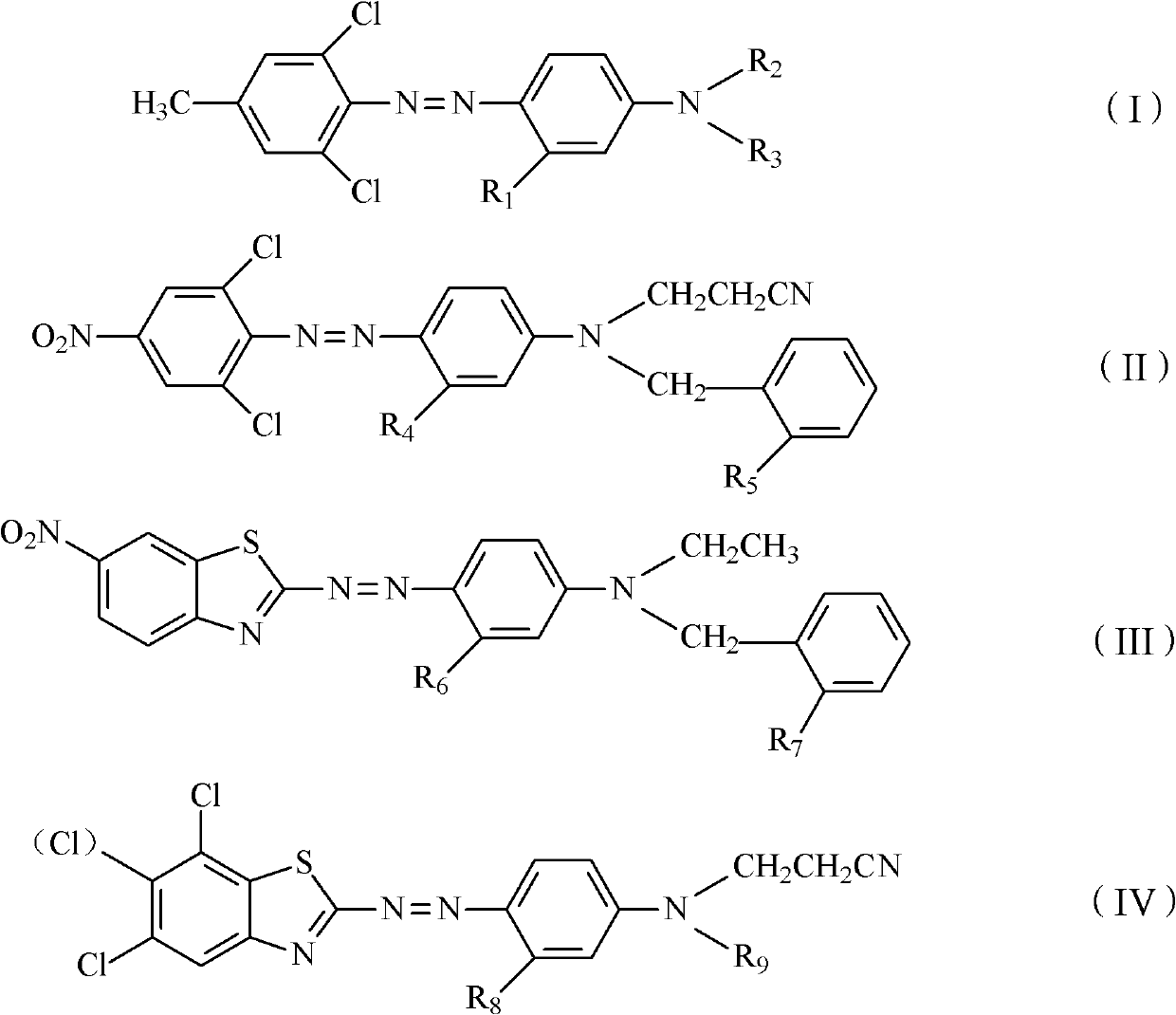

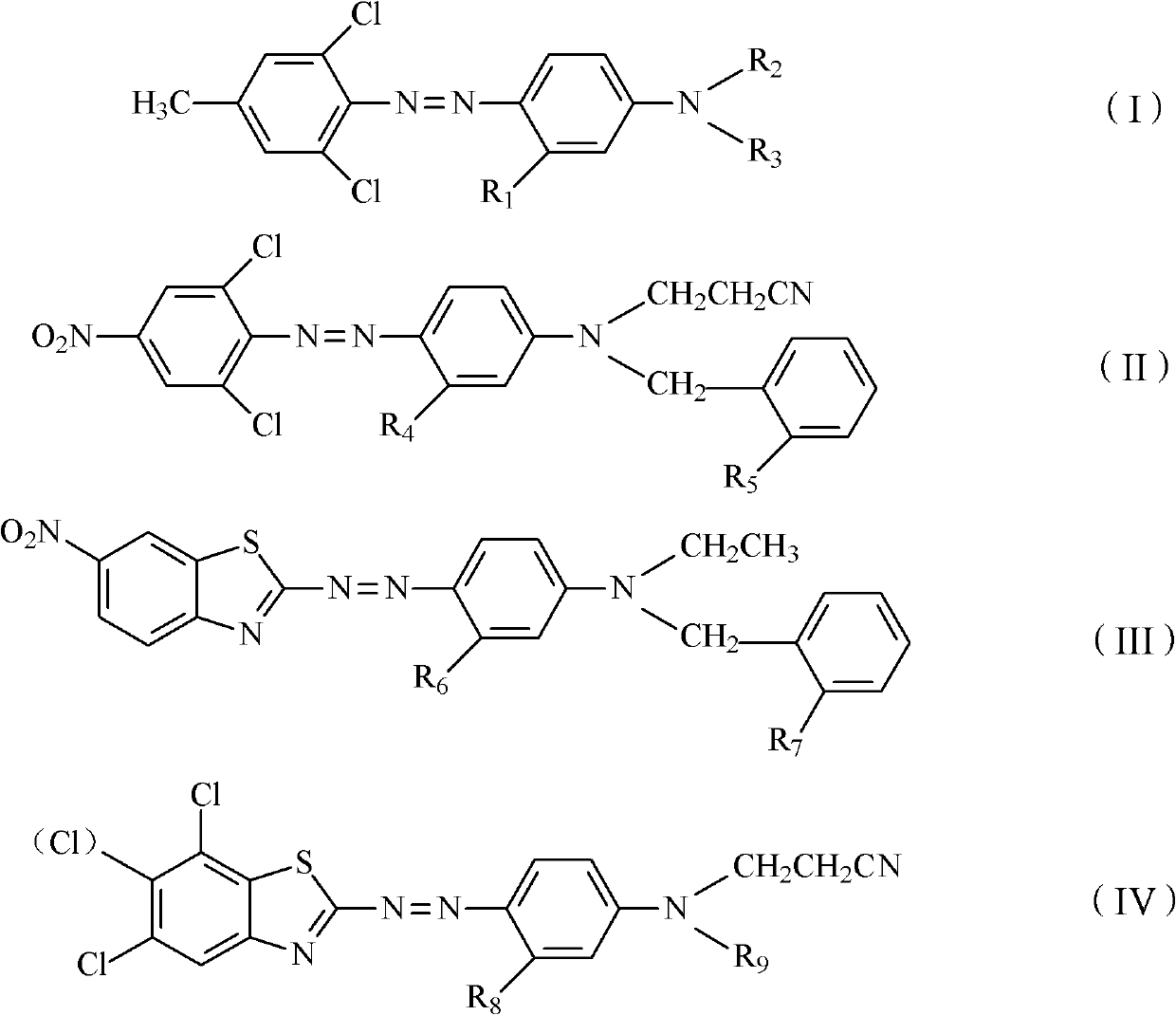

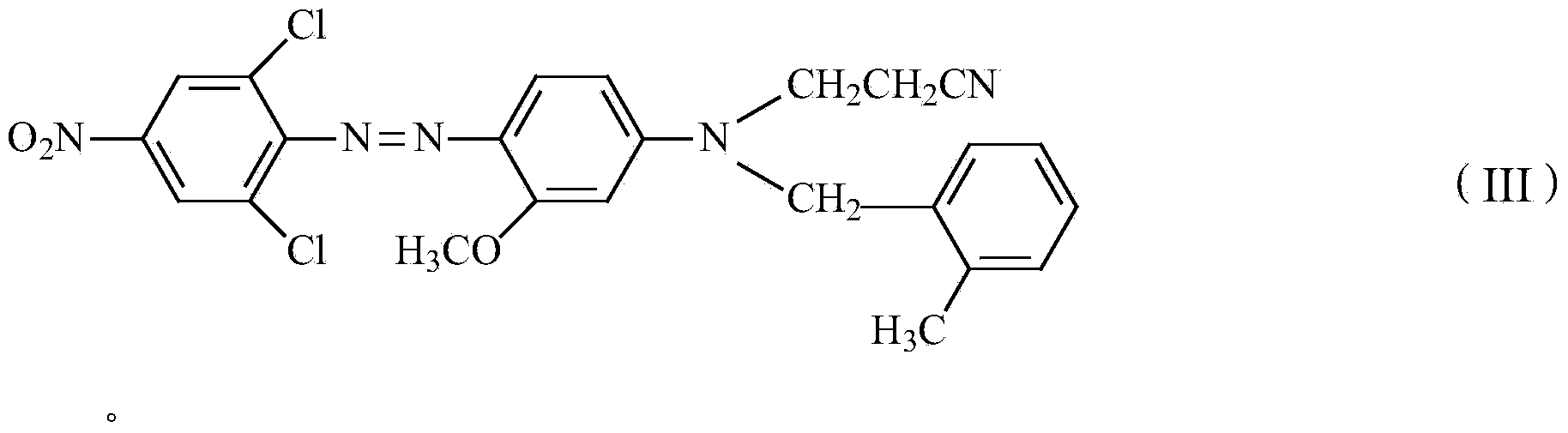

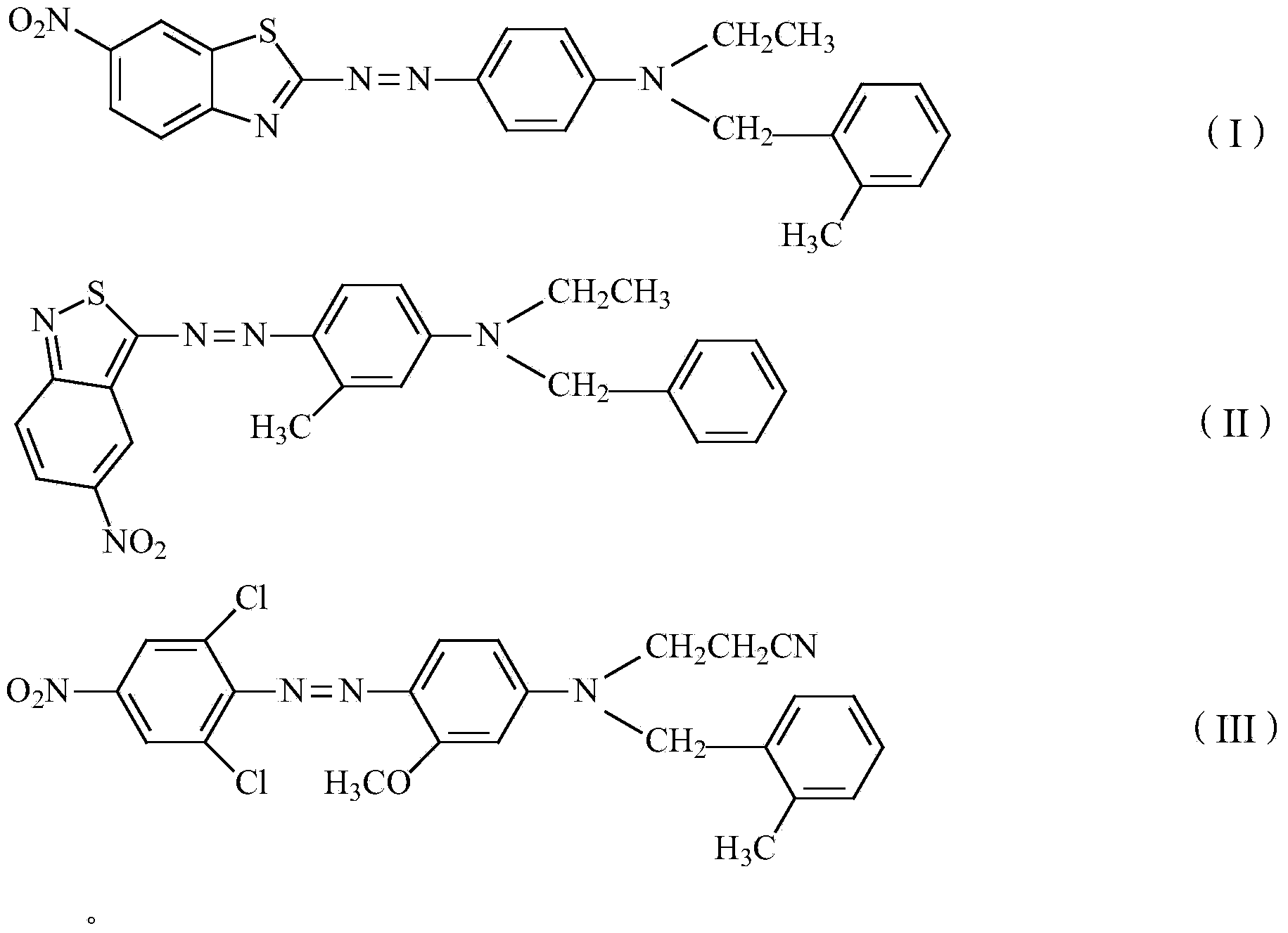

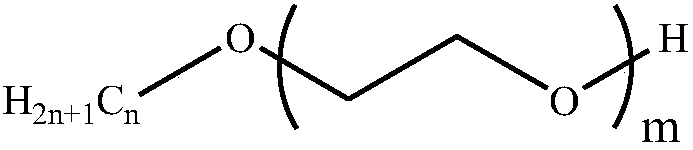

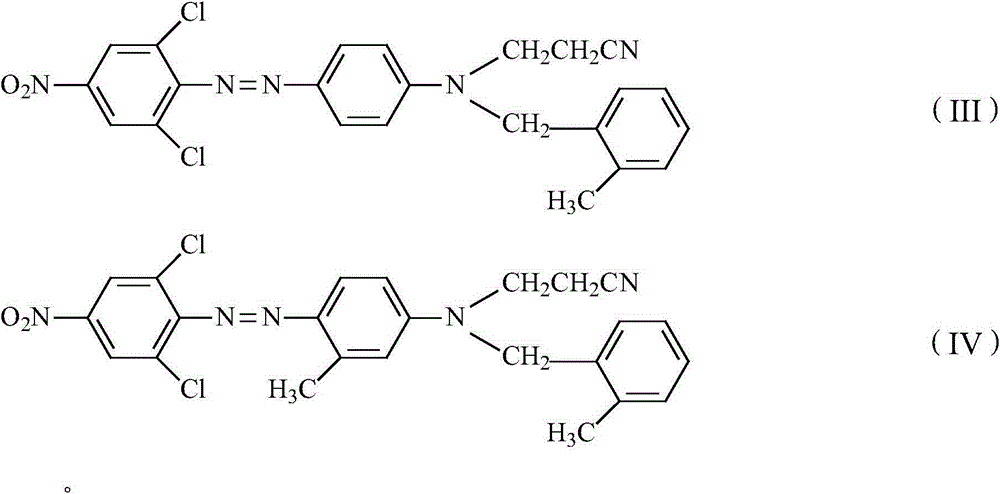

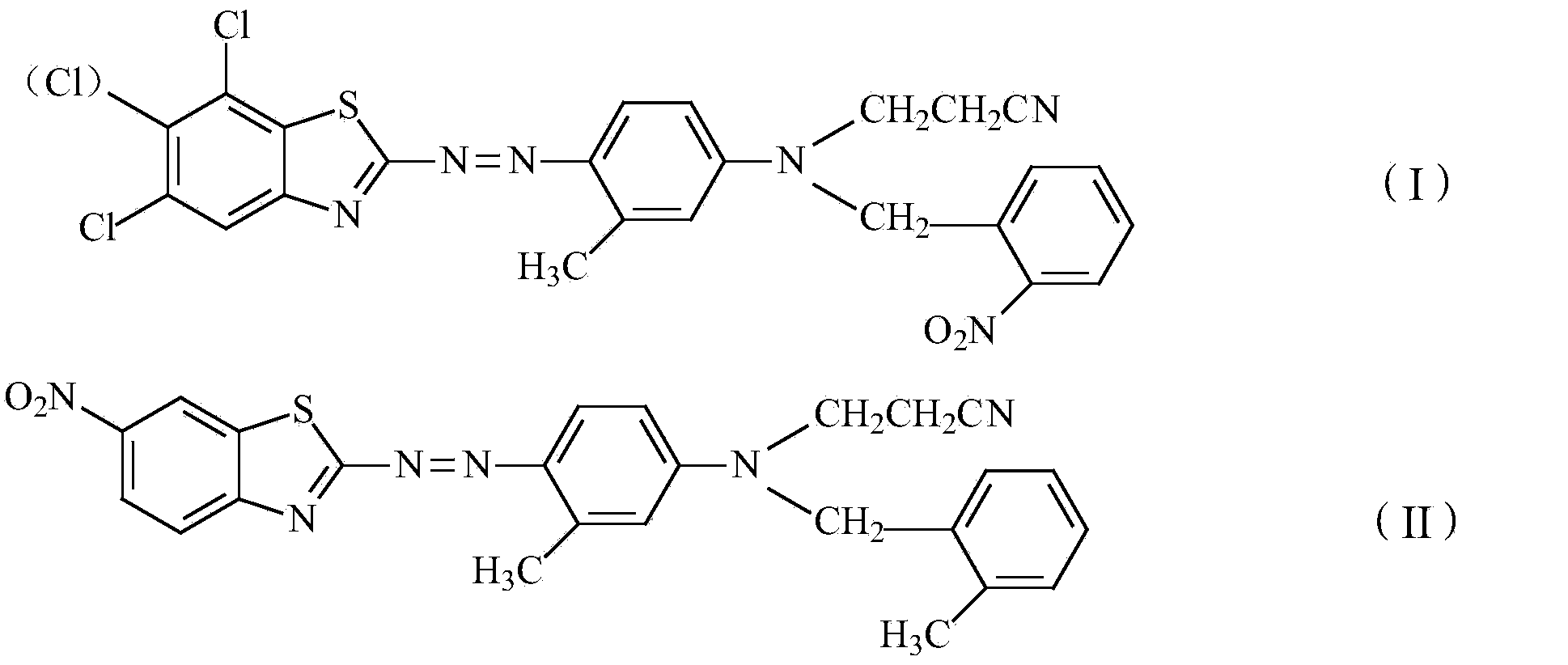

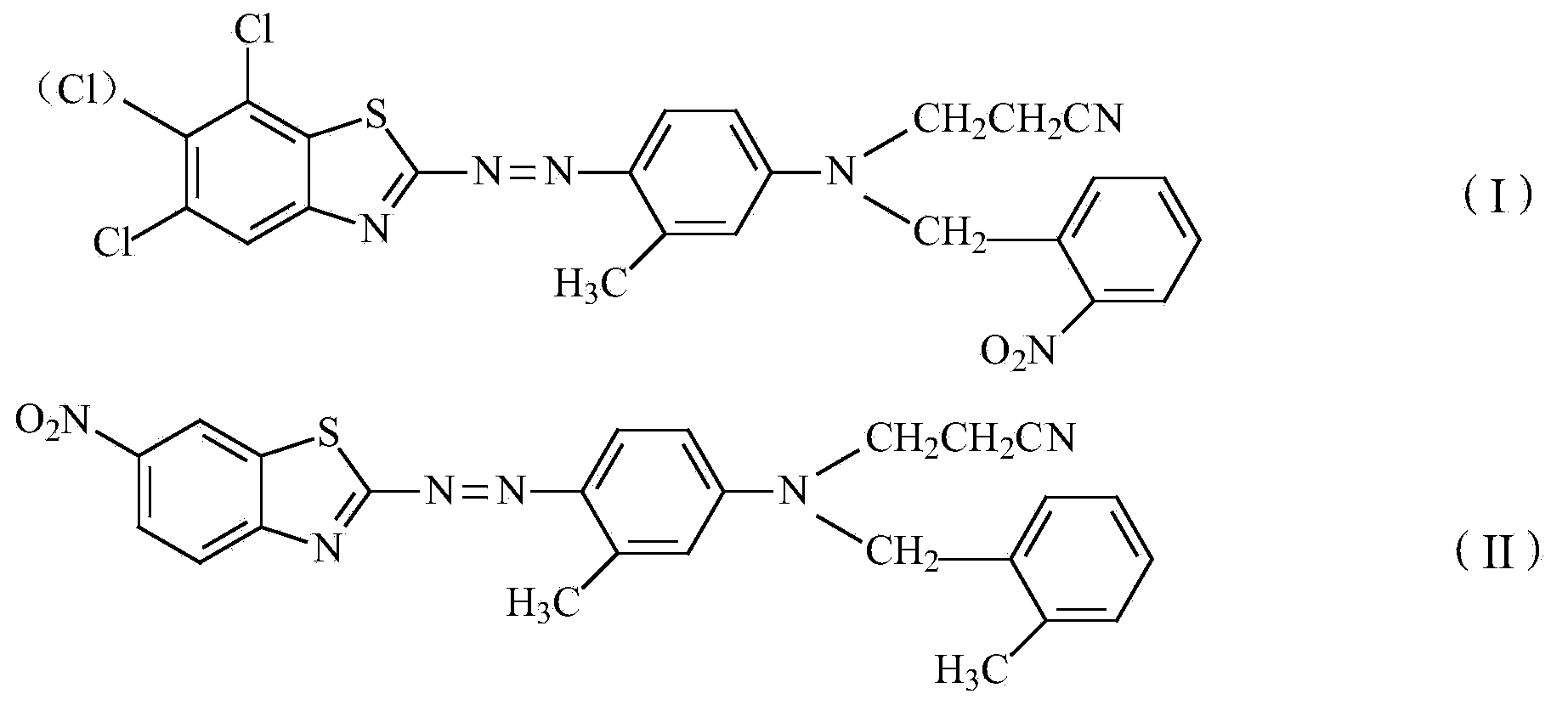

The invention discloses a disperse dye composition, which consists of an original dye and an aid, wherein the original dye consists of any 2-4 kinds of dyes selected from 0-2 kinds of dyes shown as a general formula (I), 0-2 kinds of dyes shown as a general formula (II), 0-2 kinds of dyes shown as a general formula (III) and 0-2 kinds of dyes shown as a general formula (IV), wherein R1, R4, R6 and R8 in the formula (I), formula (II), formula (III) and formula (IV) are independently hydrogen, methyl or methoxy; when R2 is hydrogen, R3 is 2-nitrobenzophenone or 2,4-dinitrophenyl; when R2 is methyl, ethide or cyanoethyl, R3 is benzyl or 2-methyl benzyl; R5 and R7 are independently hydrogen, nitryl, methyl or ethyl; and R9 is methyl, ethyl, benzyl, 2-methyl benzyl or 2-nitrobenzophenone. The invention further discloses a dyeing method for a dacron. The disperse dye composition provided by the invention has the advantages of high dispersing property and high oxygen resistance.

Owner:ZHEJIANG WANFENG CHEM

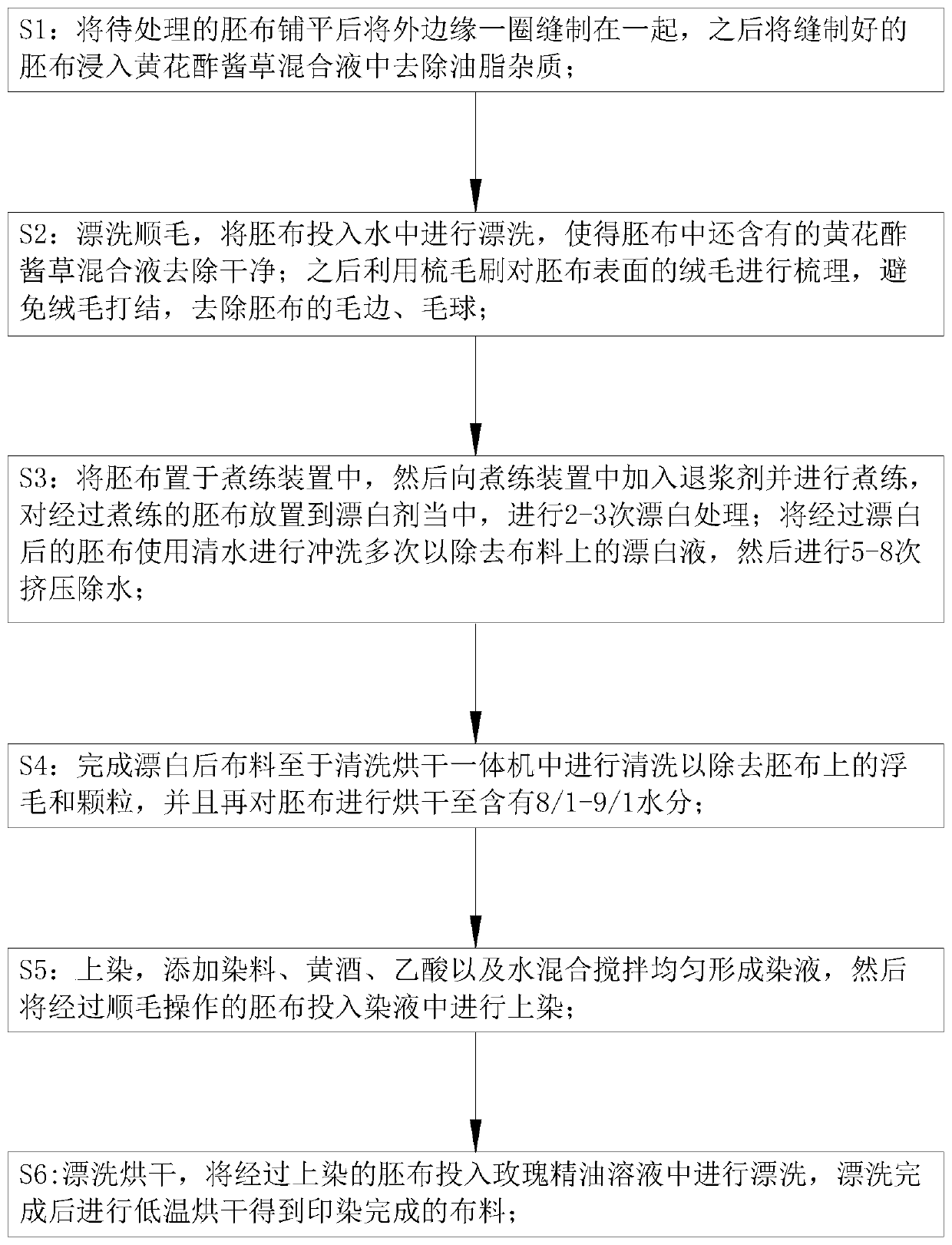

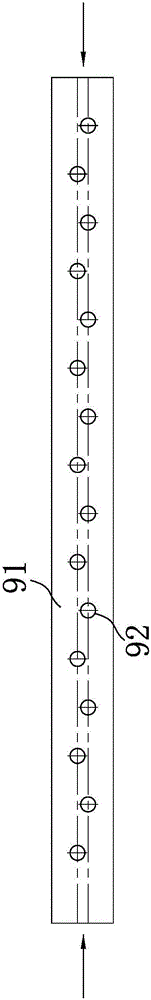

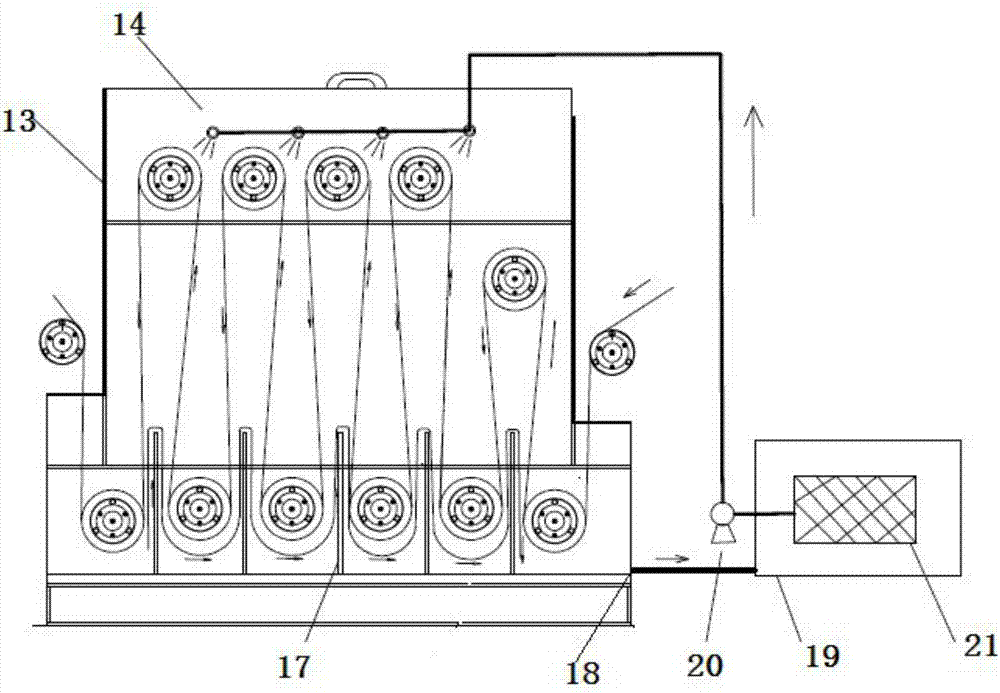

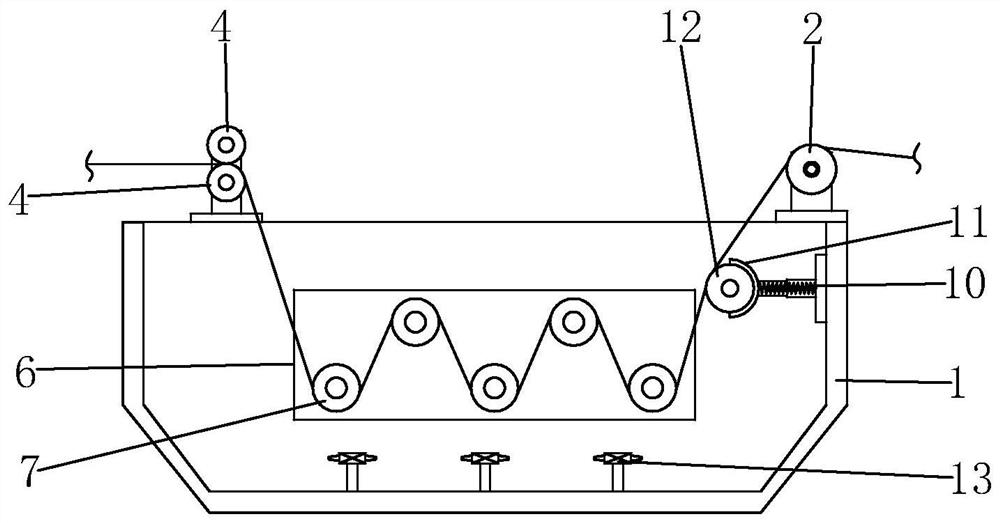

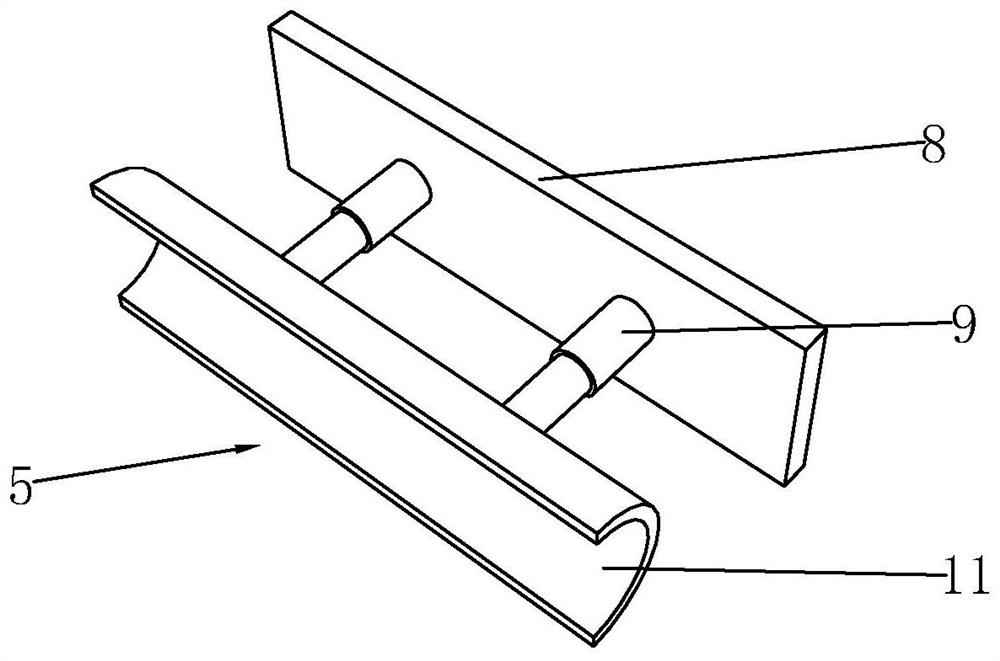

Environment-friendly energy-saving cloth printing and dyeing process

ActiveCN111304845APenetrate fastBig impactTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile printerMechanical engineering

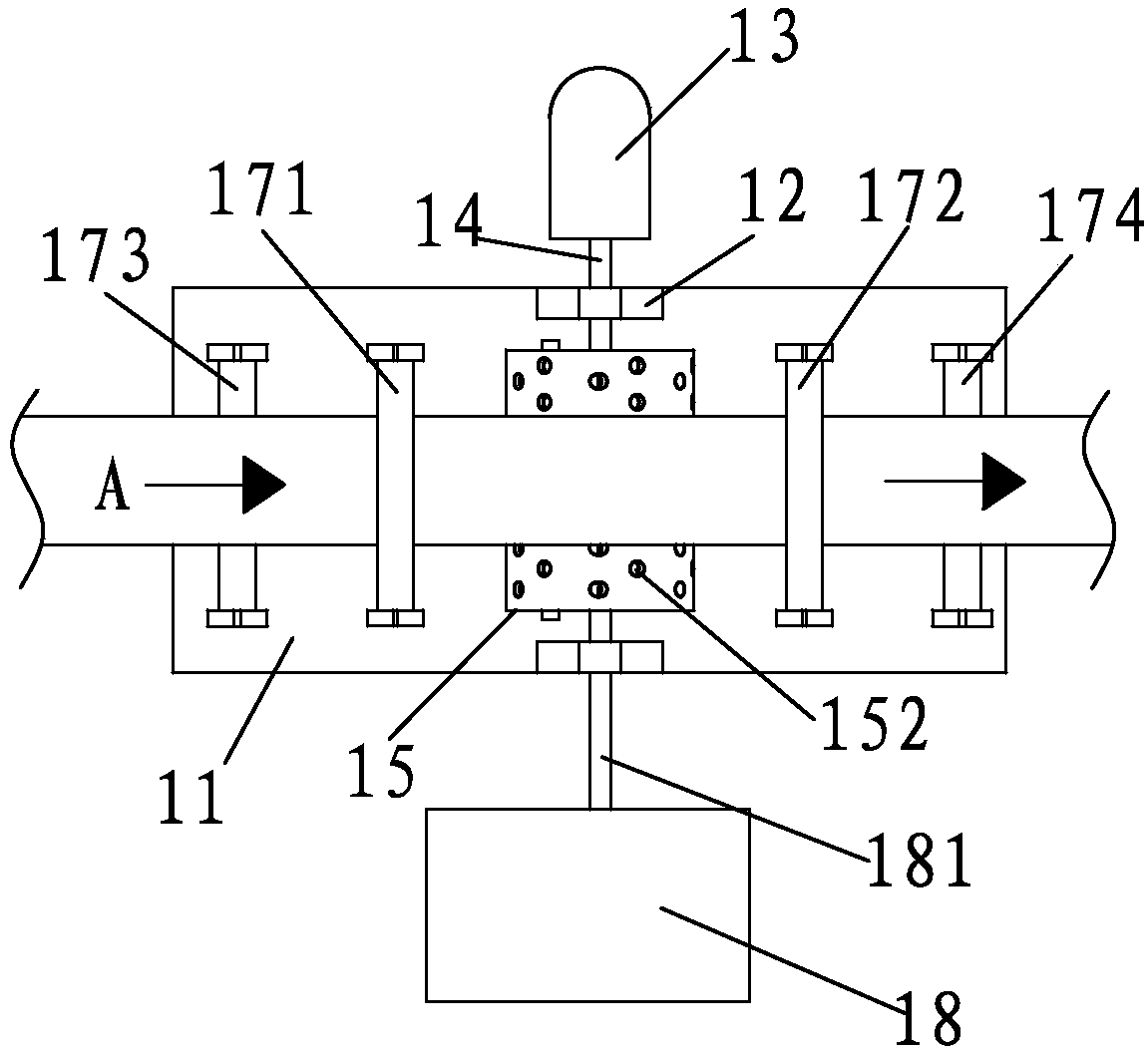

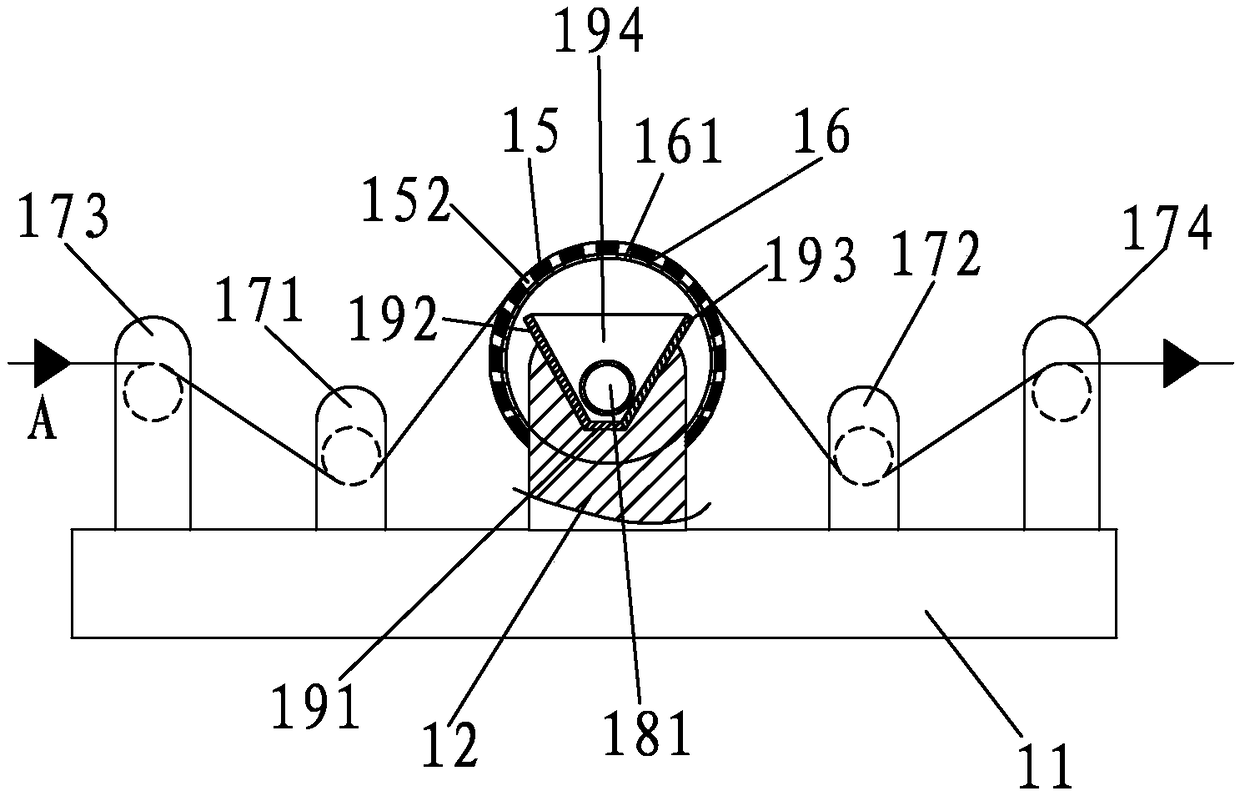

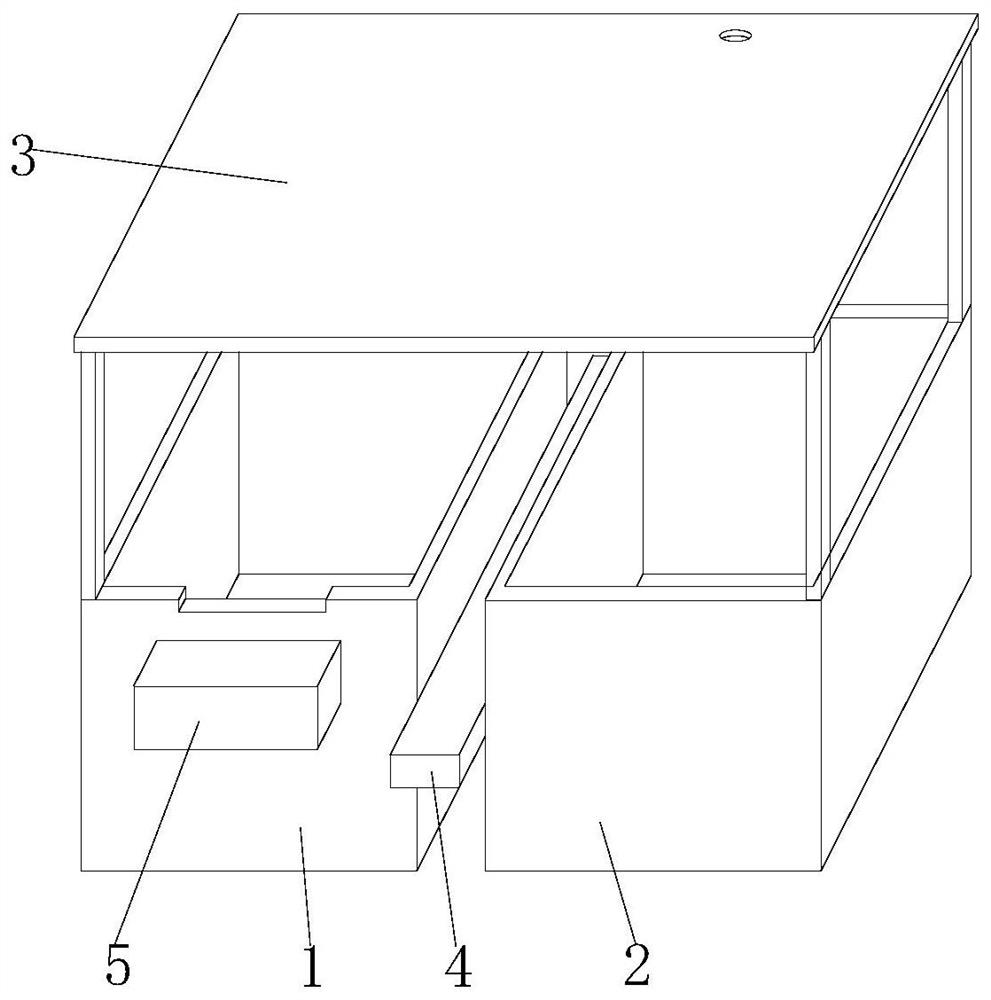

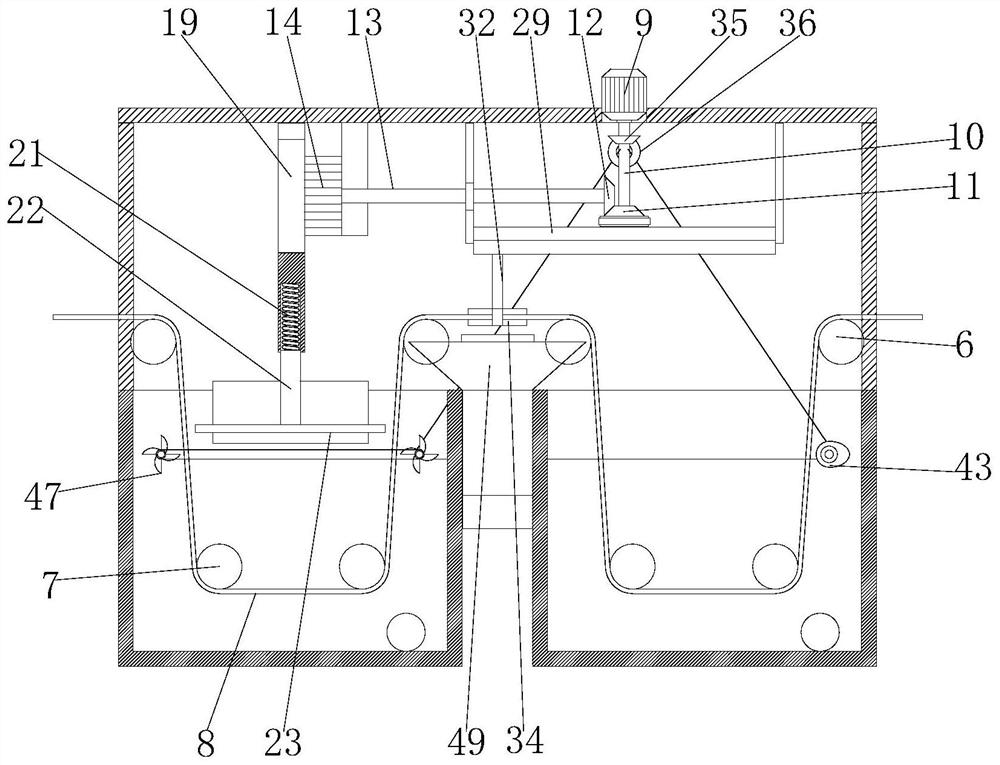

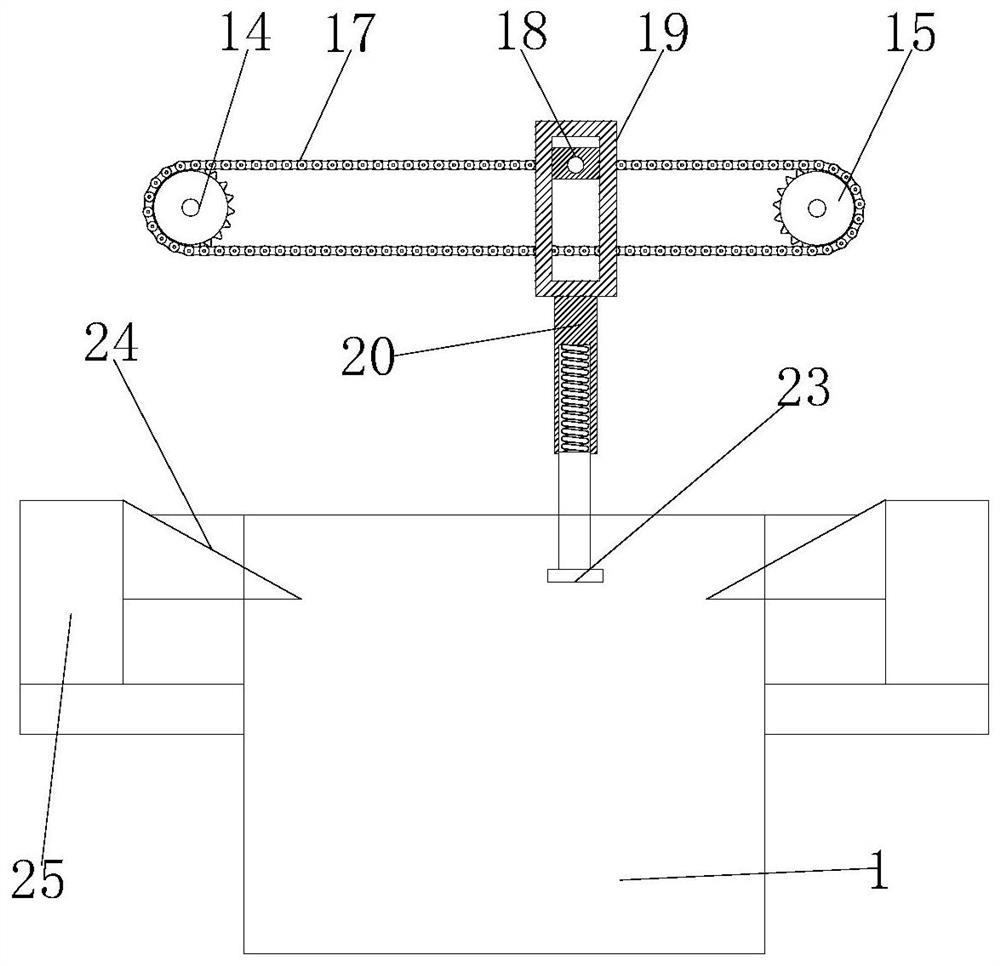

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to an environment-friendly energy-saving cloth printing and dyeing process. A boiling-off device used in the process comprises a pool body with an opening in the upper end; the position, close to the bottom, of the pool body is provided with a group of guide rollers, and one ends of the guide rollers are rotatably connected with the side walls of the pool body; the interior of the pool body between the adjacent guide rollers is fixedly connected with a sliding barrel, and the interior of the sliding barrel is in sliding connection with a sliding column; the top of the sliding column is fixedly connected with a rotating shaft, the rotating shaft is sleeved with a tensioning roller, and thetensioning roller is rotatably connected with the rotating shaft; a first hole formed in the rotating shaft in the axial direction communicates with a water pump through a pipeline and a valve; a second hole is reversely formed in the middle of the rotating shaft along the diameter of the cross section of the rotating shaft, and the second hole communicates with the first hole; and the position, corresponding to the second hole, of the tensioning roller is provided with an annular groove, and a group of spraying holes communicating with the annular groove are uniformly distributed in the outercircumference of the tensioning roller. A desizing agent is sprayed to grey cloth by the spraying holes, so that the desizing efficiency of the grey cloth is improved.

Owner:福懋兴业(中山)有限公司

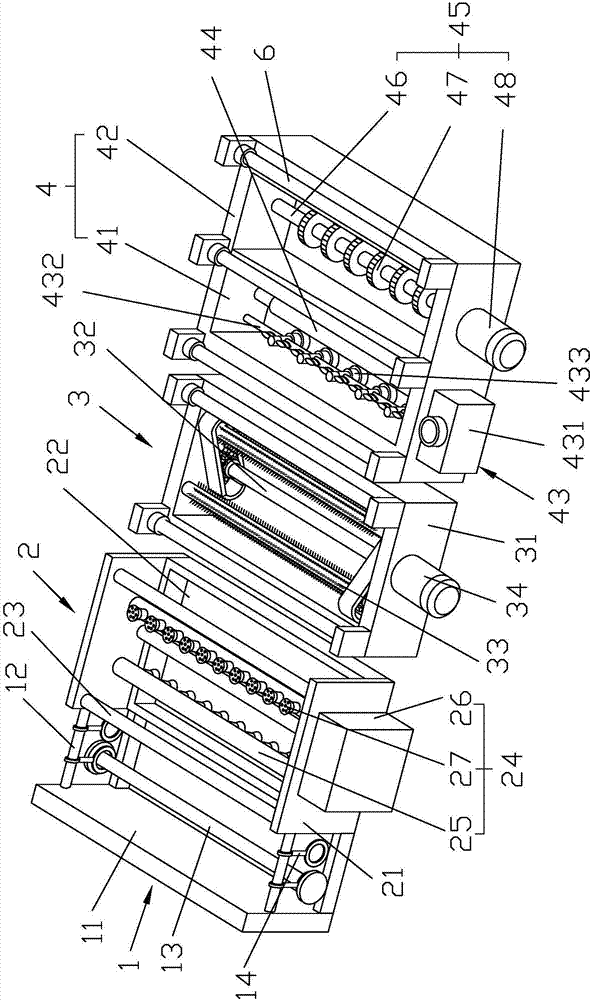

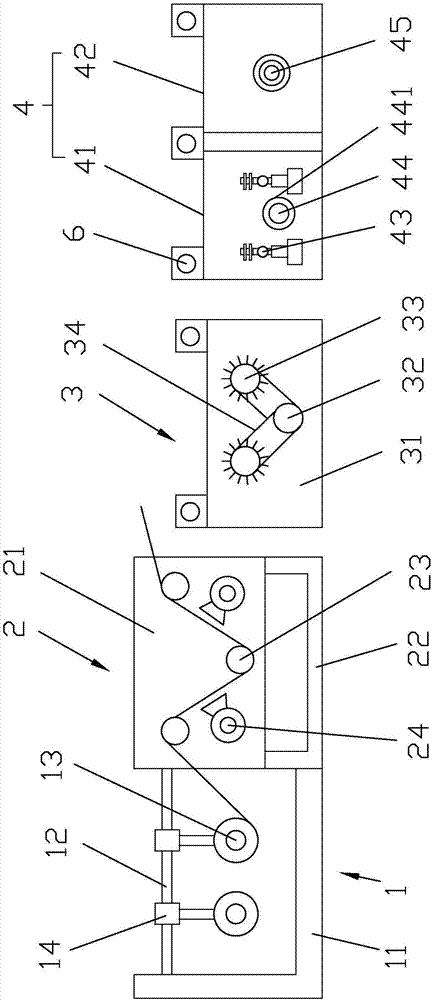

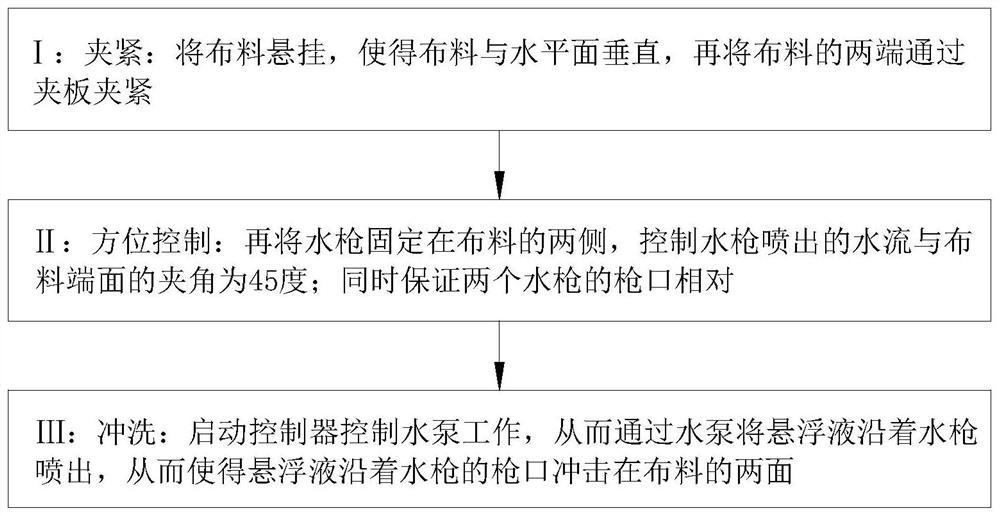

Desizing equipment for spinning fabric

InactiveCN107022860AEasy to feed the clothSave time changing clothMechanical cleaningPressure cleaningFiberPulp and paper industry

The invention mainly discloses a desizing equipment for textile fabrics. Its technical proposal includes a cloth laying rack, a pretreatment device, a scraping device and a desizing box. The pretreatment device includes a pretreatment rack, a water receiving tank, and a transmission roller. And the water spray device, the water receiving tank is located at the bottom of the pretreatment frame, the transmission rollers are distributed on the pretreatment frame in an inverted triangle, the water spray device is located between the adjacent transmission rollers, the scraping device includes a scraping box, the first cloth guide roller , brushing roller and driving device, the driving device respectively drives the first cloth guide roller and brushing roller to rotate, the desizing box includes a trough and an oscillating trough, and a feeding device and a second cloth guide with a heating pipe are arranged in the trough The roller has an oscillating device in the oscillating groove, and the oscillating device includes an oscillating roller, an oscillating wheel and an oscillating motor. The invention has fast desizing speed, high desizing efficiency, less damage to fabric fibers, removes pollutants and symbiotic impurities on fabrics, and is convenient for later processing of fabrics.

Owner:嵊州市靖洁纺织机械有限公司

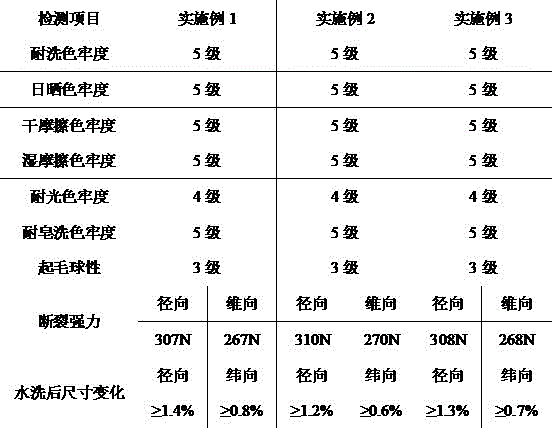

Method for processing yarn-dyed four-side stretch fabric garment

ActiveCN109097974AClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnEngineering

The invention discloses a method for processing a yarn-dyed four-side stretch fabric garment. The method comprises the following steps: (a) alkali soaking; (b) biological enzyme polishing; (c) dyeing;(d) air drying; (e) sizing; (f) weaving; (g) desizing; (h) scouring and bleaching; (i) padding; (j) drying; (k) finishing; and (l) pre-shrinking. The method is simple in process, saves energy and reduces consumption and is easy to control, and an obtained fabric is soft and comfortable in touch and has a fine and soft gloss, good non-ironing property, anti-wrinkle performance and anti-pilling performance and dimensional stability.

Owner:盛泰智造集团股份有限公司

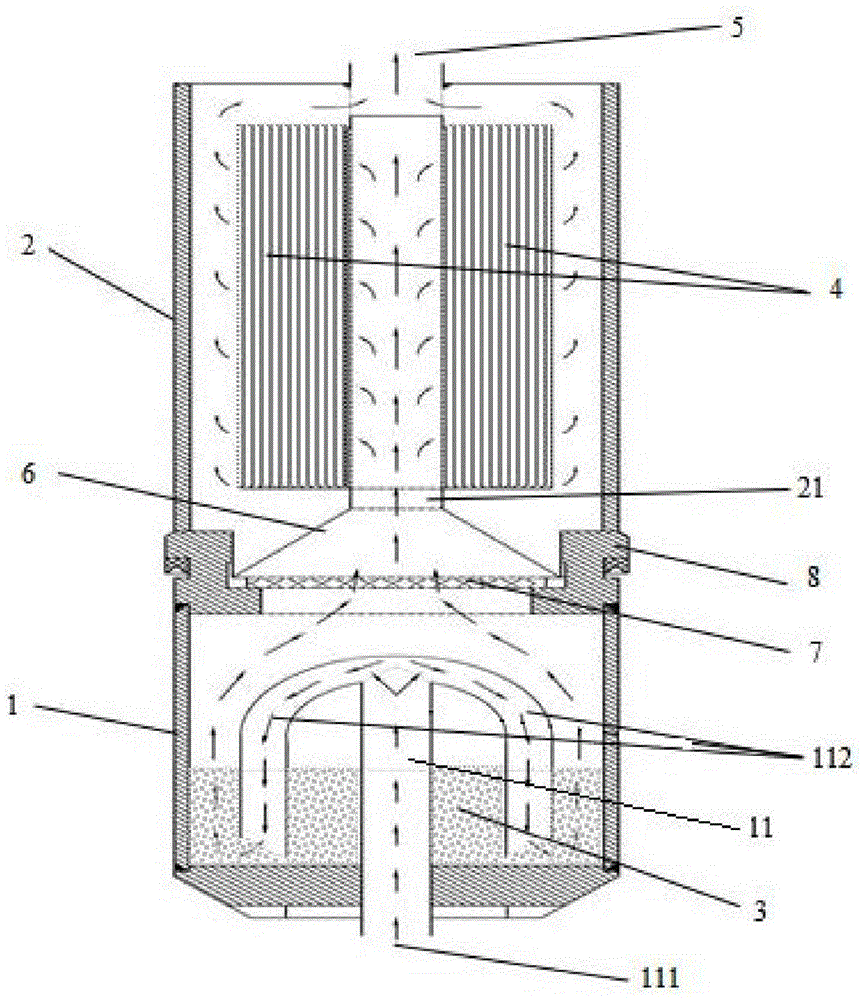

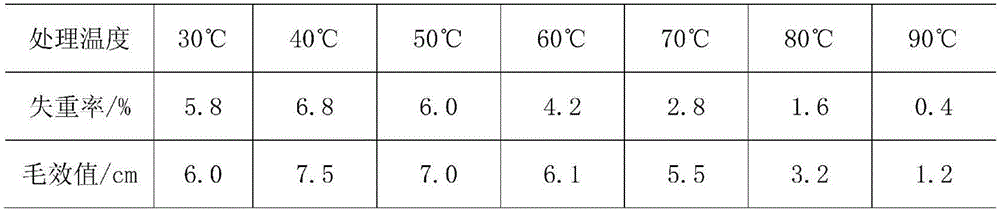

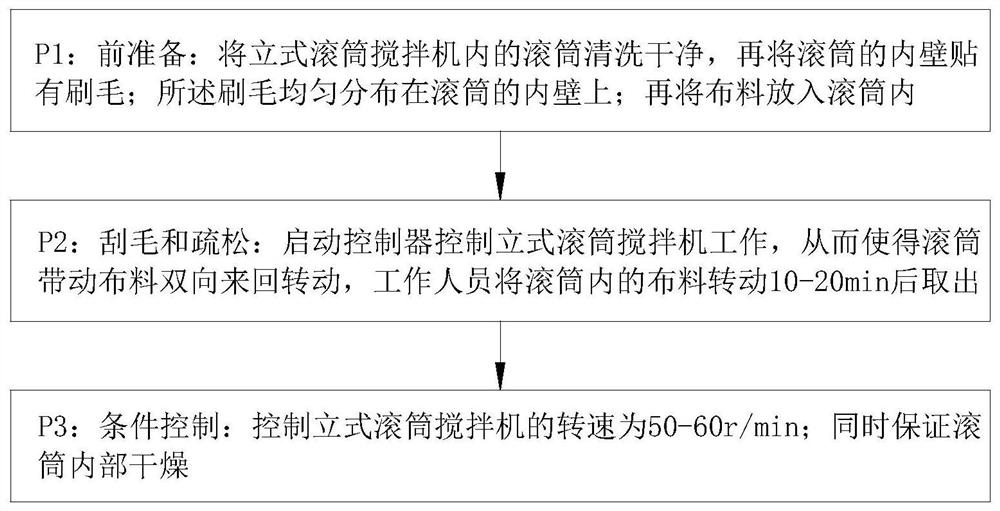

Desizing pretreatment method of textile

ActiveCN104452319AImprove desizing efficiencySimple processBiochemical fibre treatmentDry-cleaning apparatus for textilesPretreatment methodWater discharge

The invention discloses a desizing pretreatment method of textile, which belongs to the technical field of textile dyeing and finishing processing, and is designed for solving the problems of high water consumption, large waste water discharge amount, and the like in the traditional desizing technology. The method comprises the following steps: A. dissolving a surface active agent into a mixed solution of ethyl alcohol and water; B. feeding desizing enzyme into the mixed solution, and stirring until the system is clear to obtain desizing working liquid; C. putting the desizing working liquid into a supercritical carbon dioxide fluid treatment system; D. enabling the desizing working liquid to form microemulsion by a supercritical carbon dioxide medium, and carrying out desizing pretreatment on the textile under the conditions that the temperature is 30-95 DEG C, the pressure is 6-30 MPa, and the total pretreatment time is 0.5-24.0 hours. According to the desizing pretreatment method, the technology is simple, and the desizing pretreatment for the textile can be realized; the desizing efficiency of enzyme in the supercritical carbon dioxide medium can be improved by controlling the reaction parameters such as temperature, pressure and treatment time, so that the energy is saved, and the environment is protected.

Owner:SUZHOU UNIV

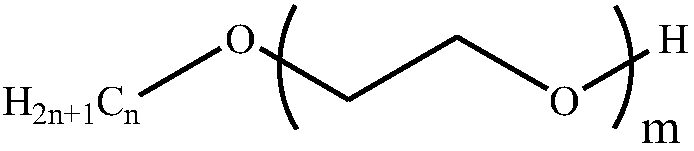

Multifunctional oxidizing desizing agent

InactiveCN102864622AImprove desizing effectImprove desizing efficiencyDry-cleaning apparatus for textilesPhosphorous acidALLYL SUCROSE

The invention discloses a multifunctional oxidizing desizing agent. The multifunctional oxidizing desizing agent is prepared by the following components in parts by weight: 3 to 5 parts of potassium peroxodisulfate, 1 to 3 parts of sodium bromite, 4 to 6 parts of sodium alkyl sulfate, 10 to 20 parts of fatty alcohol-polyoxyethylene ether, 1 to 3 parts of lauryl sodium sulfate, 1 to 3 parts of zinc stearate, 5 to 8 parts of polyacrylic acid, 1 to 3 parts of hydroxymethyl cellulose, 3 to 6 parts of phosphorous acid, and 80 to 100 parts of water. The multifunctional oxidizing desizing agent disclosed by the invention has a good effect of desizing, is suitable for various sizes, has a desizing effect on a plurality of mixing sizes, and is high in desizing efficiency; and the multifunctional oxidizing desizing agent has favorable stability to strong base bath.

Owner:WUJIANG YISHENG TEXTILE

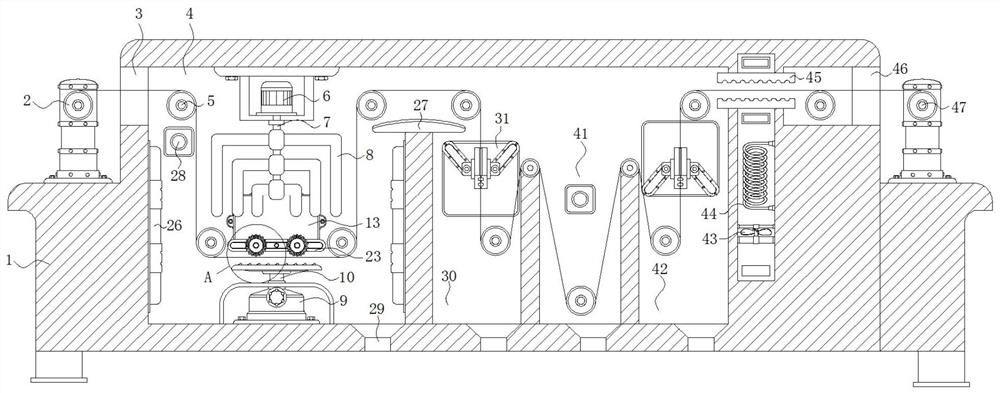

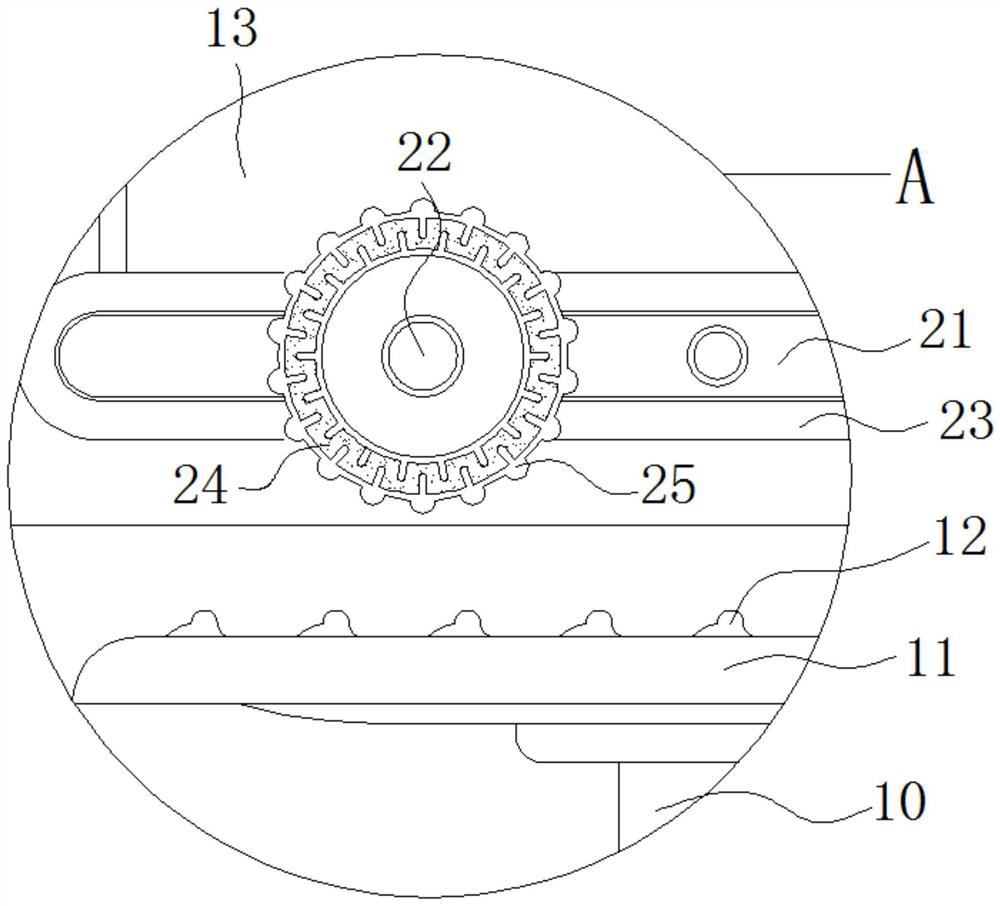

Printing and dyeing technology capable of realizing high efficiency desizing

ActiveCN108930118AImprove desizing efficiencyImprove desizing effectSingeingTextile treatment machine arrangementsTreatment useState of art

The invention discloses a printing and dyeing technology capable of realizing high efficiency desizing. The printing and dyeing technology capable of realizing high efficiency desizing comprises following steps: 1, cloth is place on a conveyer belt, is conveyed into a singeing machine for singeing so as to remove nap on the cloth through singeing; 2, after singeing treatment, the cloth is conveyedinto a desizing machine for desizing treatment using a desizing roller in the desizing machine; 3, after desizing treatment, the cloth is conveyed into a boiling off machine using the conveyer belt for high temperature boiling off using the boiling off machine; 4, after boiling off, the cloth is subjected to impurity removing treatment using an impurity removing device of the boiling off machine;5, after impurity removing, the cloth is subjected to water washing in a water washing tank; and 6, after water washing, the cloth is conveyed into a dyeing machine for dyeing treatment using the dyeing machine. Compared with the prior art, the advantages are that: cloth desizing efficiency is increased greatly, printing and dyeing effect is excellent, and labor intensity is low.

Owner:ASHFORD TEXTILE ZHANGZHOU

Cloth fabric with holes and preparation method thereof

ActiveCN106367960AIncrease elasticityWith tensionFibre treatmentHeating/cooling textile fabricsFiberPulp and paper industry

The invention relates to a cloth fabric with holes and a preparation method thereof, belonging to the technical field of cloth materials. The grey cloth of the cloth fabric with holes is formed by interweaving T / R fibers, and a plurality of evenly distributed holes are formed in the cloth fabric with holes. The preparation process of the cloth fabric with holes comprises the following steps: cloth batching, continuous desizing and water washing, perforating, dyeing, reduction washing, dewatering and cloth spreading, drying in a drum, in-process inspection and setting. The surface of the cloth fabric with holes disclosed by the invention has regular holes, brings a different visual effect to people, and has excellent elasticity and excellent air permeability.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

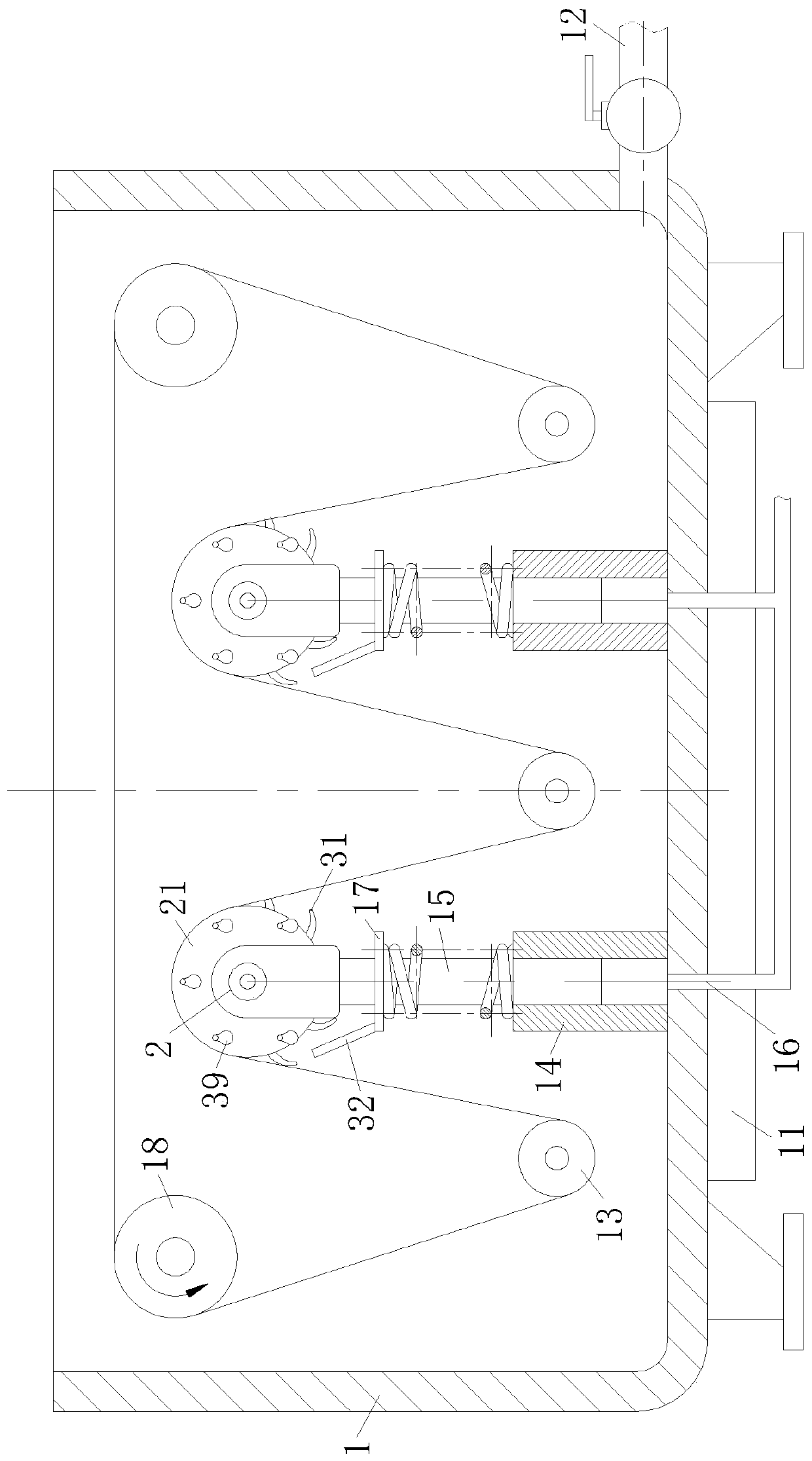

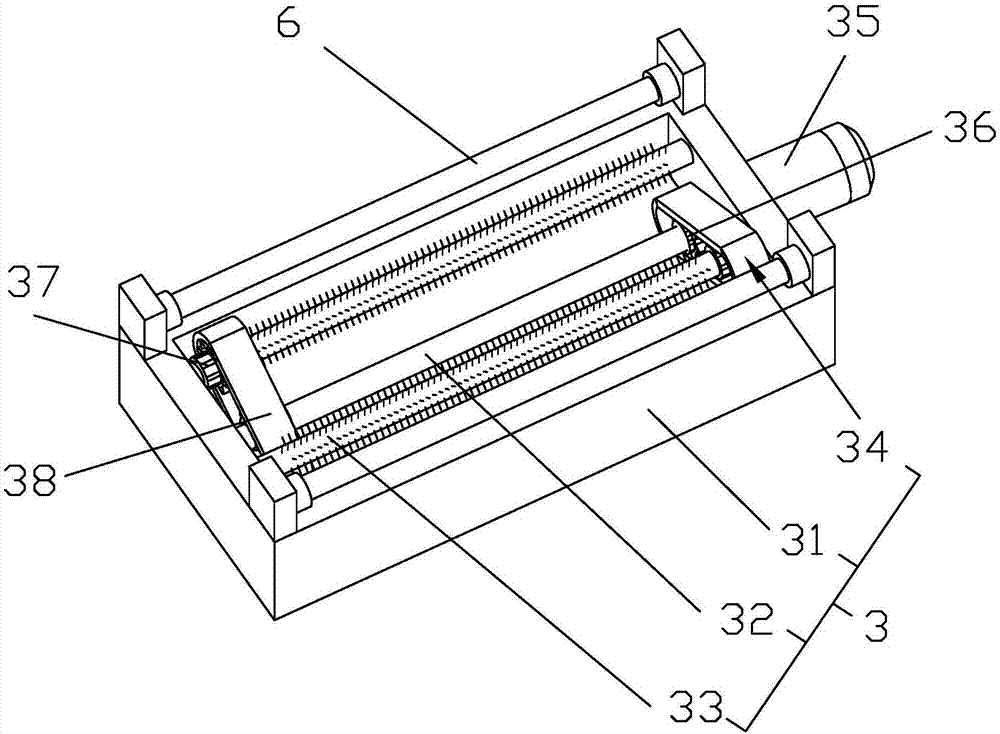

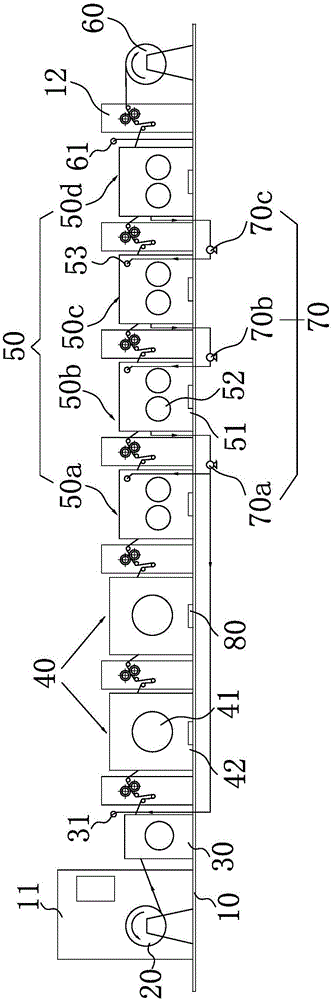

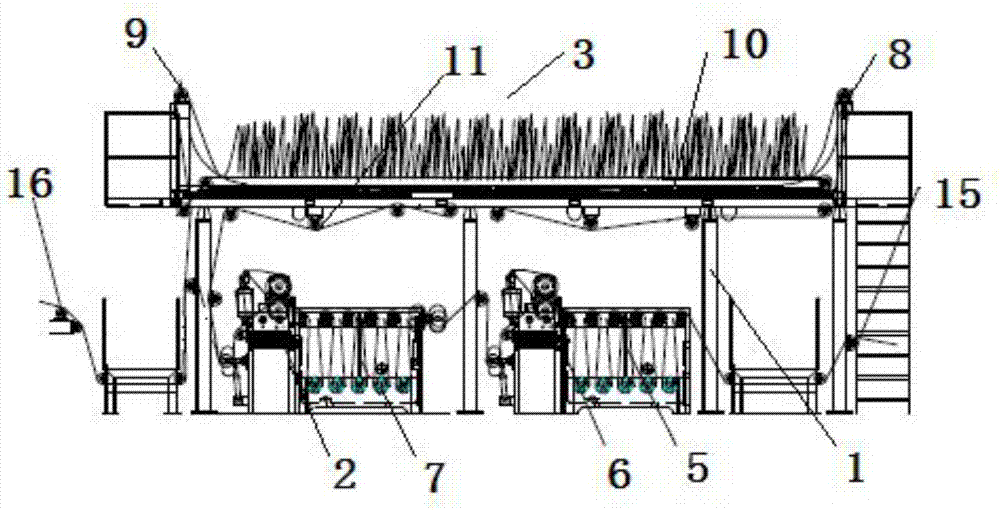

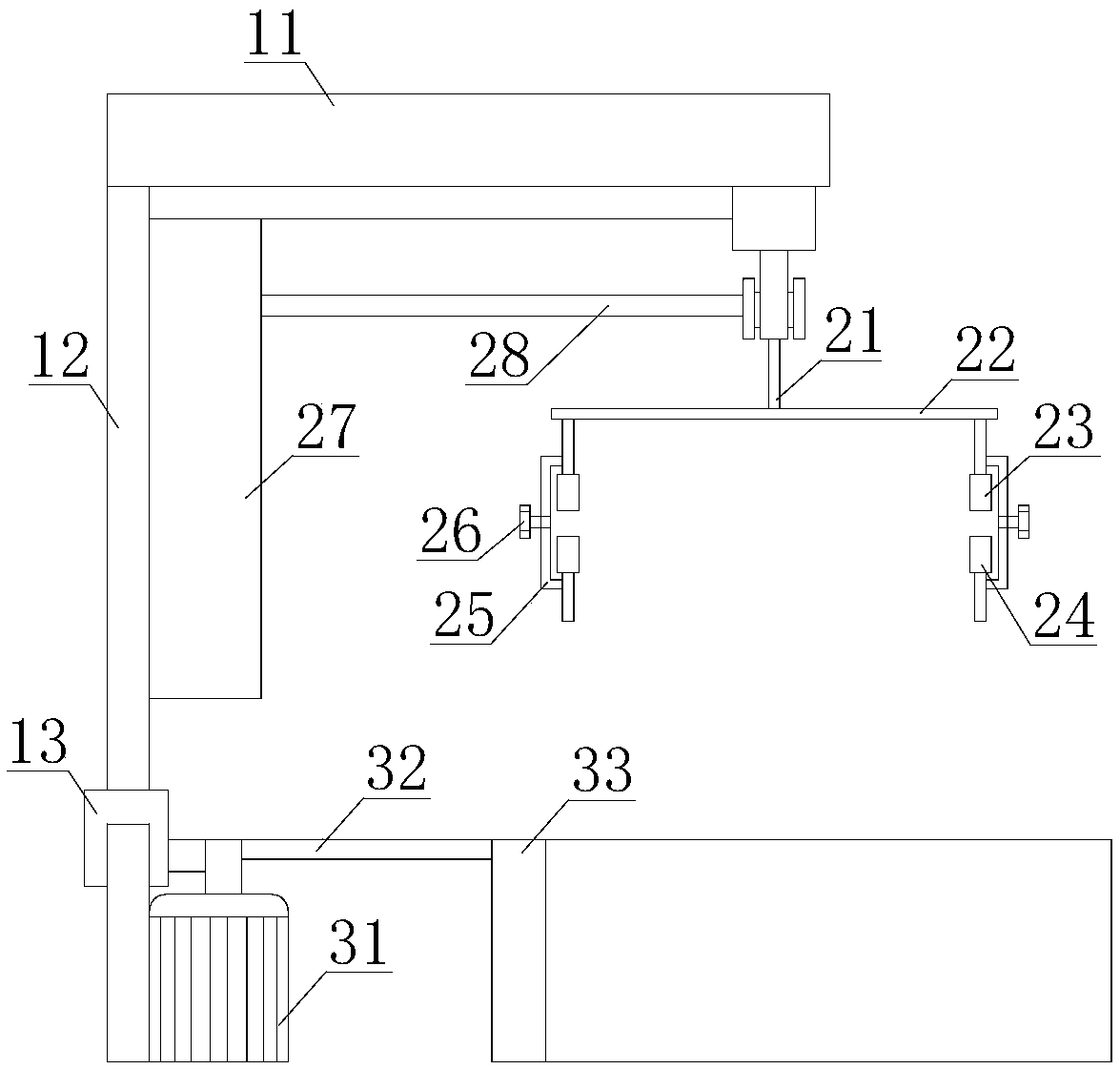

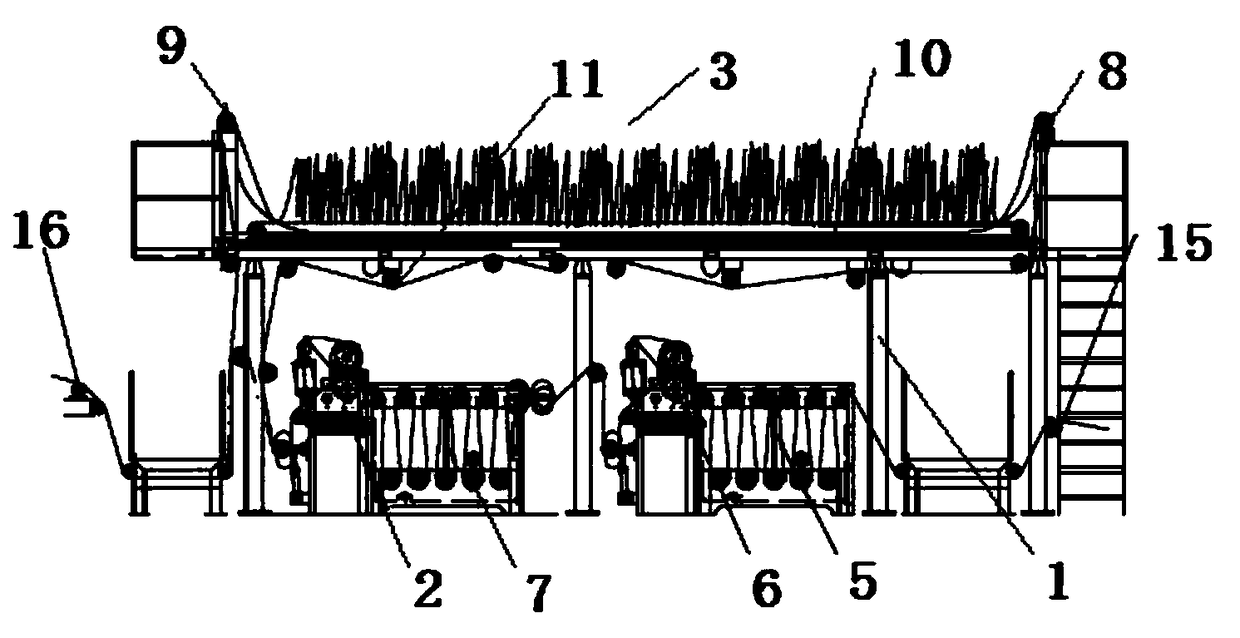

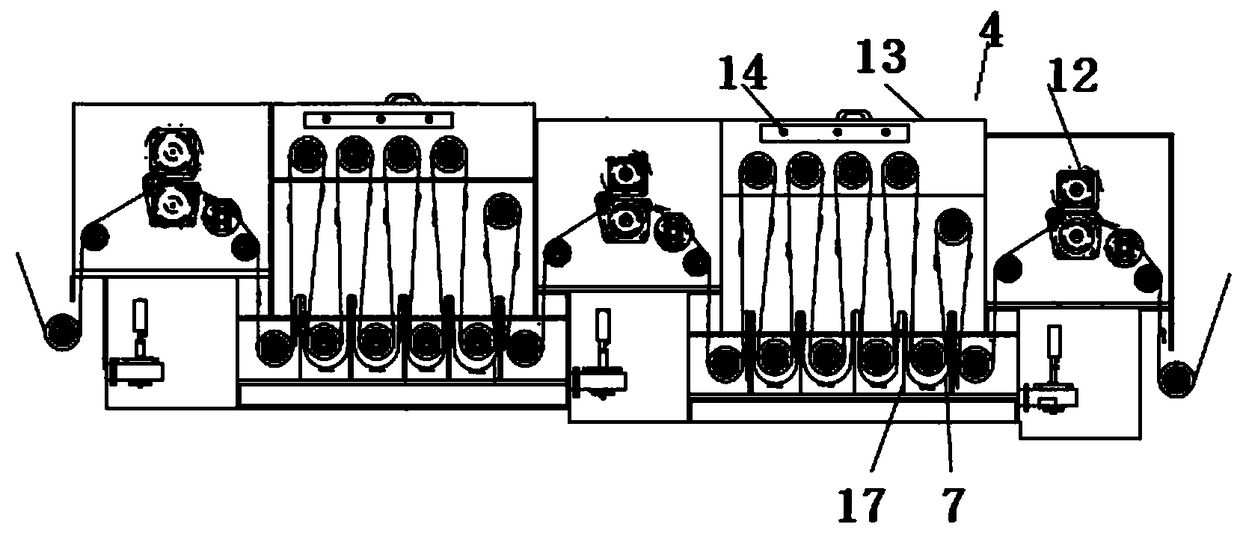

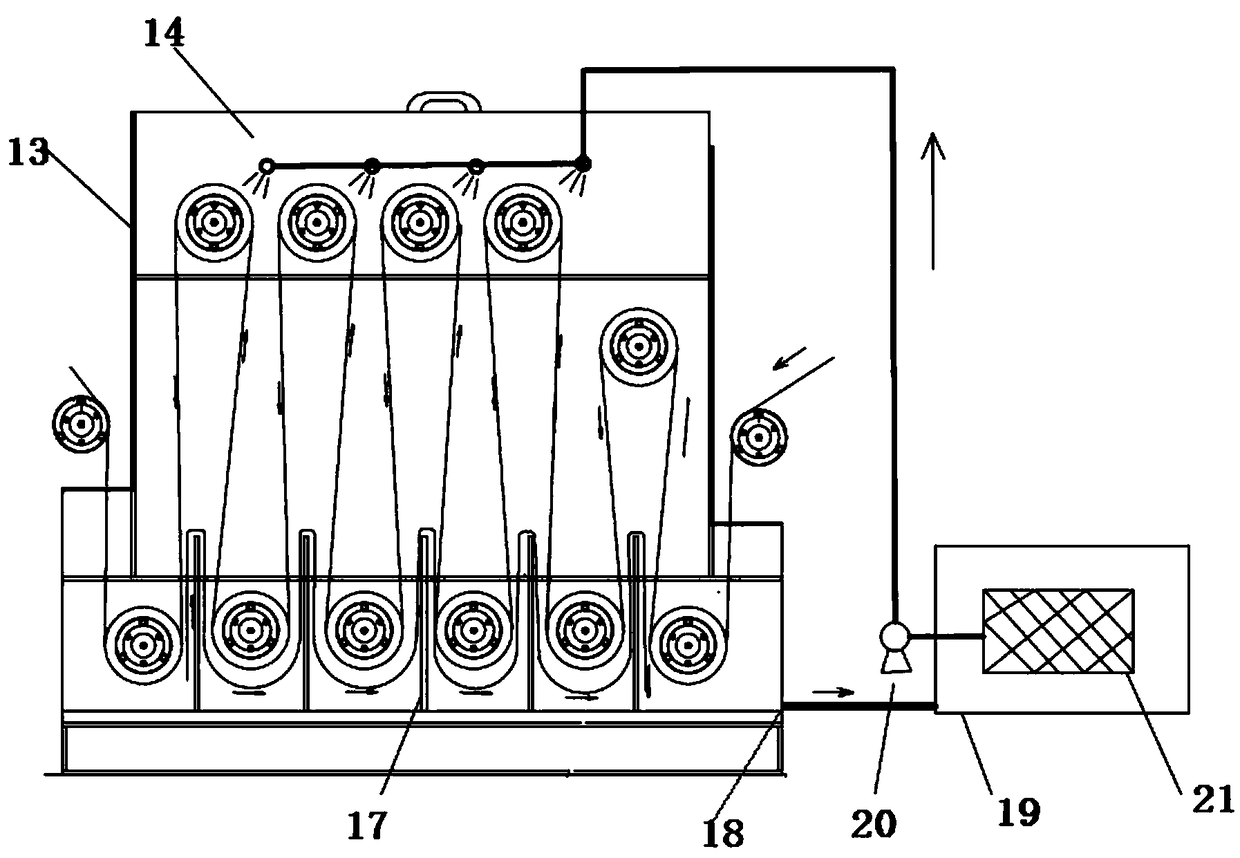

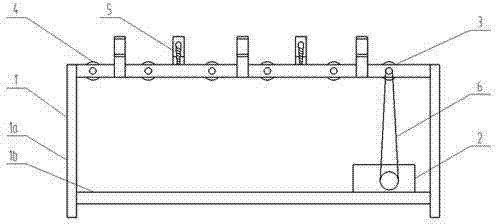

Efficient energy-saving desizing machine

InactiveCN105821612AAchieve cycleSave on cleanlinessSucessive textile treatmentsTextile treatment machine arrangementsWater circulationAutomatic control

The invention relates to the technical field of dyeing and weaving equipment, in particular to a desizing machine for removing sizing agent impurities obtained after cold stacking of nylon and polyester mixed fabrics. The desizing machine comprises a machine frame, a plurality of driving motors for providing power, a heating device for supplying heat to the whole machine and an automatic control system for controlling operation of the whole machine. A cloth feeding mechanism, a charging tank, a plurality of desizing mechanisms, a plurality of washing mechanisms and a cloth discharging mechanism are sequentially arranged on the machine frame in an assembly line mode. The charging tank, the desizing mechanisms and the washing mechanisms are connected with the heating device. Padders for performing squeezing and liquid pressing on cloth and keeping a certain cloth pick-up ratio are arranged between two adjacent desizing mechanisms, between two adjacent washing mechanisms, between the desizing mechanisms and the washing mechanisms, between the charging tank and the desizing mechanisms and between the washing mechanisms and the cloth discharging mechanism respectively. A circulating pump for achieving water circulation is arranged between every two adjacent washing mechanisms. The desizing machine is used for the desizing production technology in cloth dyeing and weaving.

Owner:晋江万兴隆染织实业有限公司

Dye composition (red brown) and preparation method thereof

InactiveCN103450706AImprove oxidation resistanceGood alkali resistanceDry-cleaning apparatus for textilesOrganic dyesPhotochemistryDyeing

The invention discloses a dye composition which is composed of dyes disclosed as general formulae (I), (II), (III) and (IV) and assistants. The invention also discloses a preparation method and dyeing method of the dye composition. The dye composition disclosed by the invention has the advantages of favorable oxidation resistance and short process when being used in a dyeing technique.

Owner:张家港市杨舍丝印工艺厂

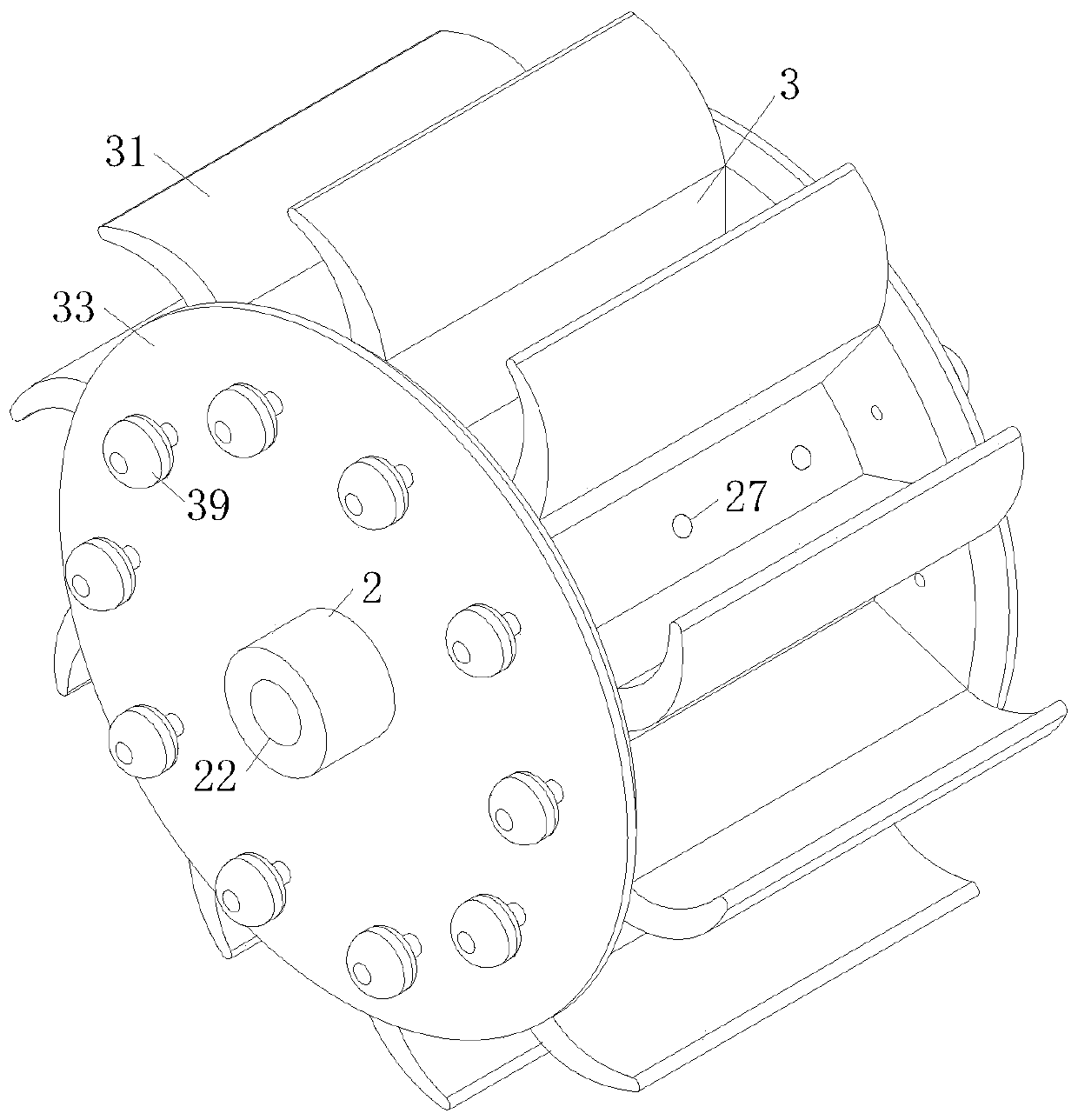

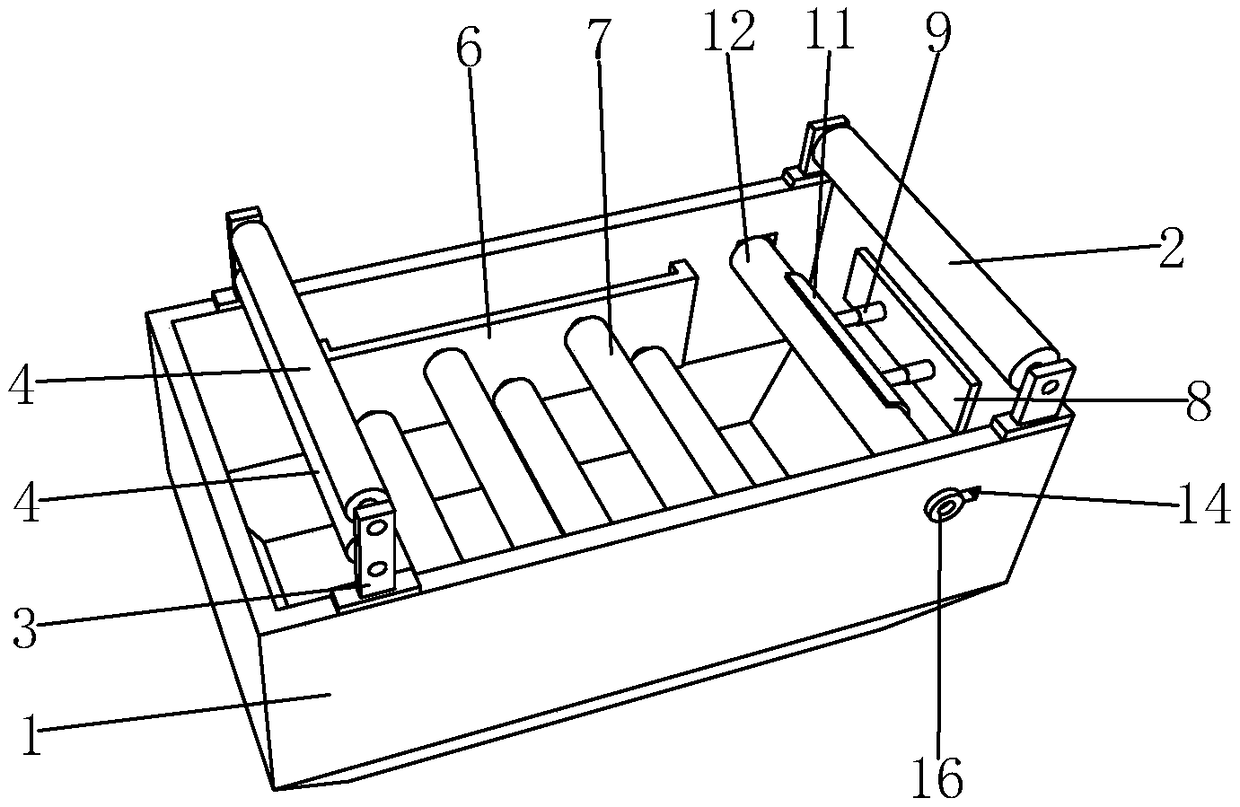

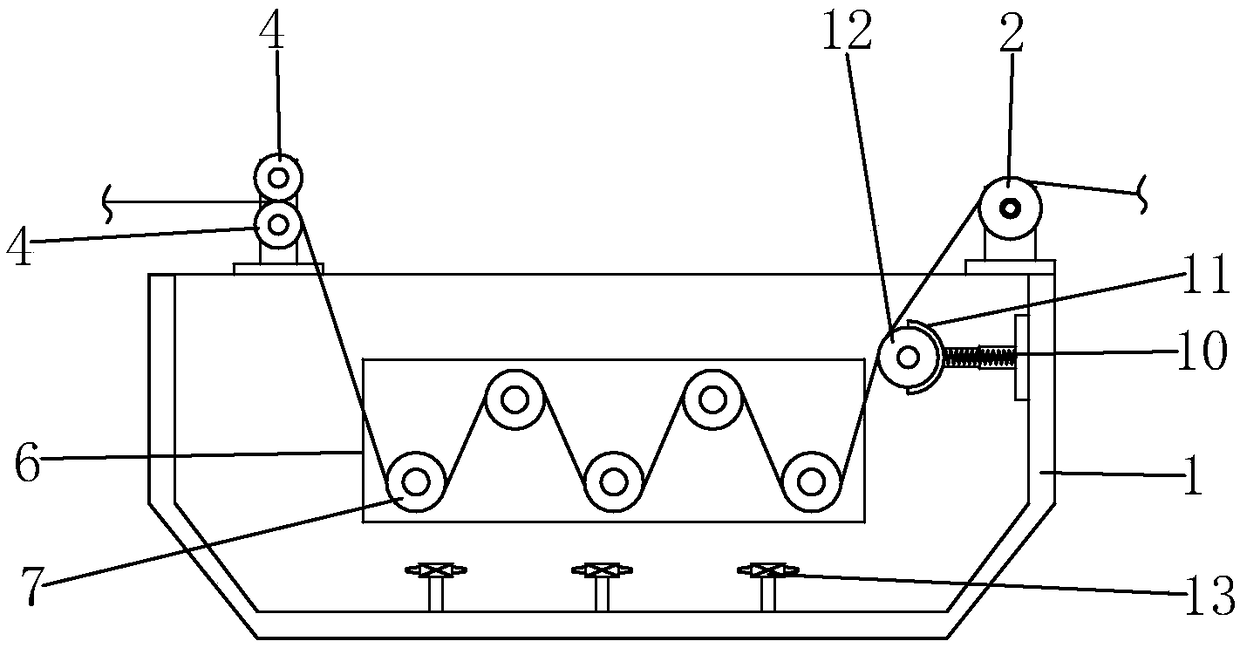

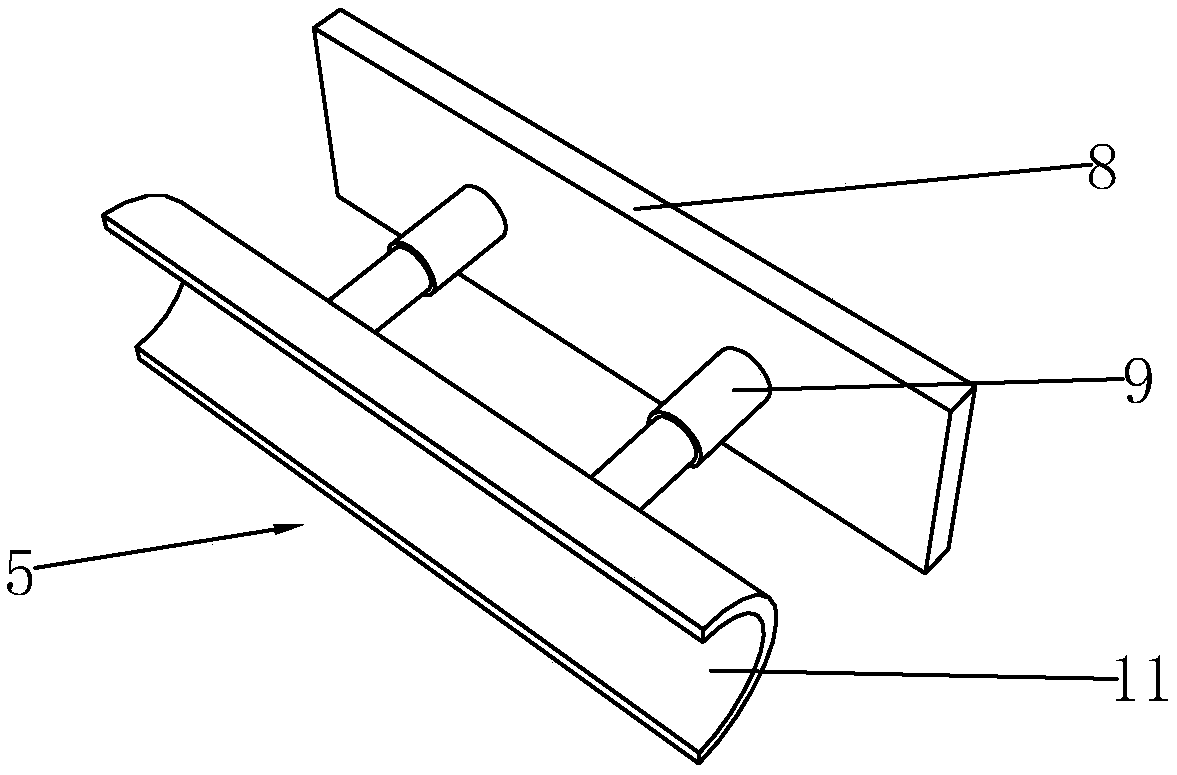

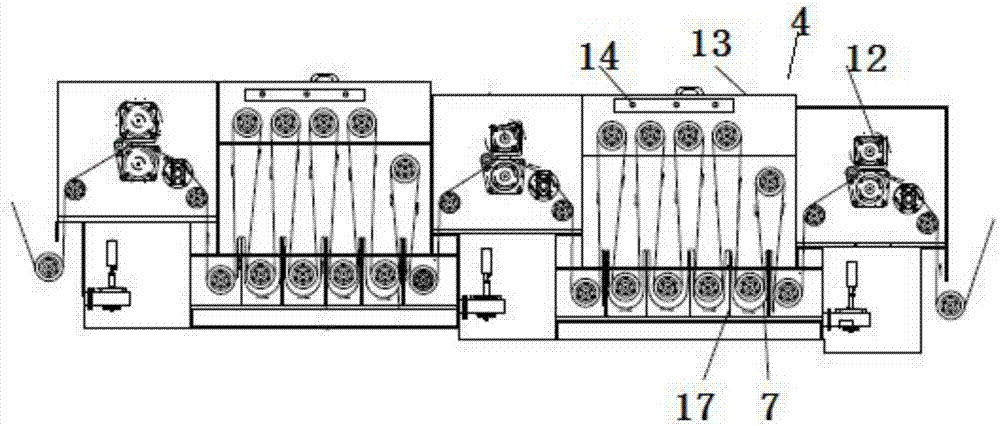

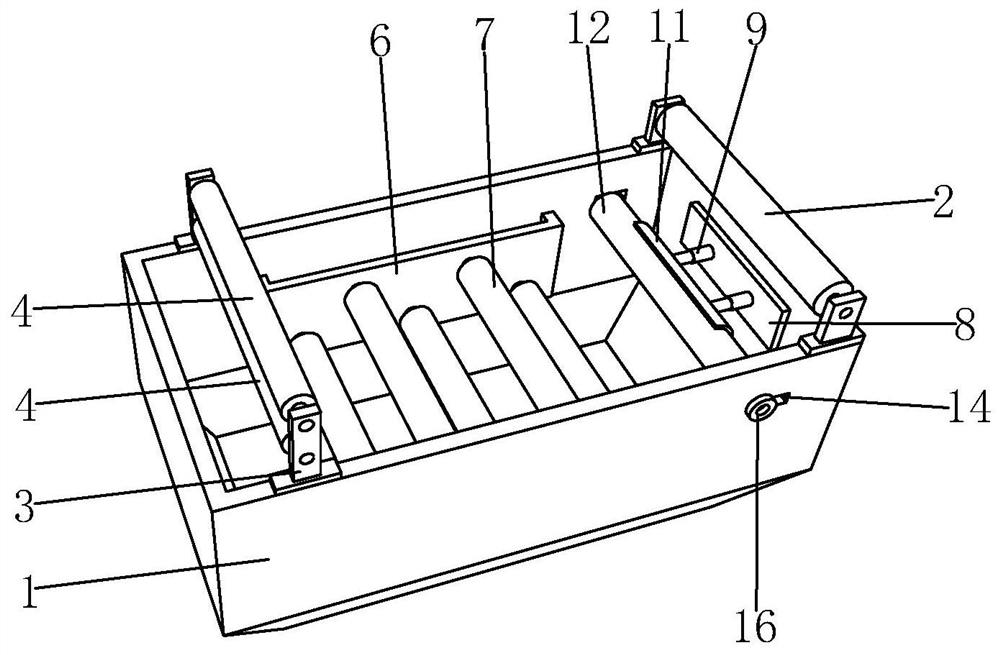

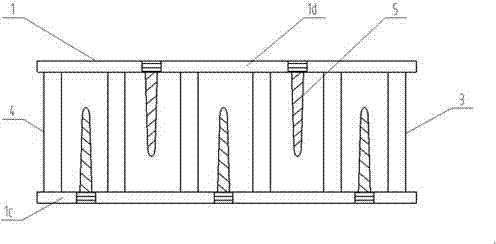

Efficient desizing machine

ActiveCN107313192AImprove desizing efficiencyExtend the decomposition timeTextile storage in superimposed formDry-cleaning apparatus for textilesDecompositionPulp and paper industry

The invention discloses an efficient desizing machine. The efficient desizing machine comprises a machine frame, a desizing region, a stacking region and a cleaning region. The desizing region comprises a desizing tank and a padder which are located at the lower end of the machine frame; the stacking region comprises a first variable-frequency roller, a second variable-frequency roller and a cloth conveying track, the first variable-frequency roller and the second variable-frequency roller are located on the machine frame, and the cloth conveying track is located between the first variable-frequency roller and the second variable-frequency roller; the cleaning region comprises a roll and a washing box; to-be-processed cloth is subjected to desizing enzyme padding in the desizing region, then decomposed in the stacking region and finally washed in the washing region, and then the desizing process is completed. According to the efficient desizing machine, the structure of a desizing machine is changed, desizing enzyme decomposition time is increased, the washing effect of the washing box is also improved, the desizing efficiency is improved, and the product quality is improved.

Owner:韶关市北纺智造科技有限公司

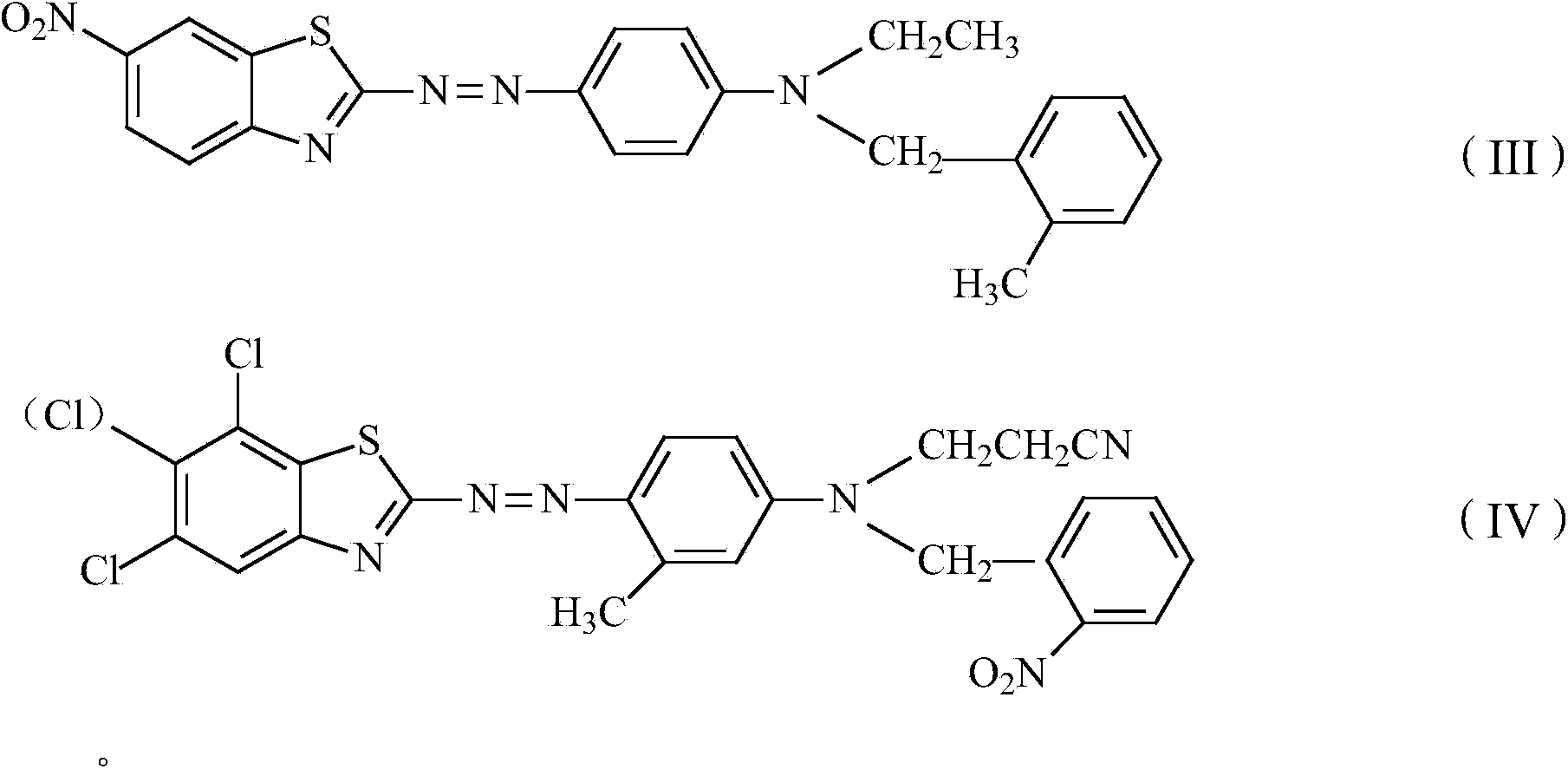

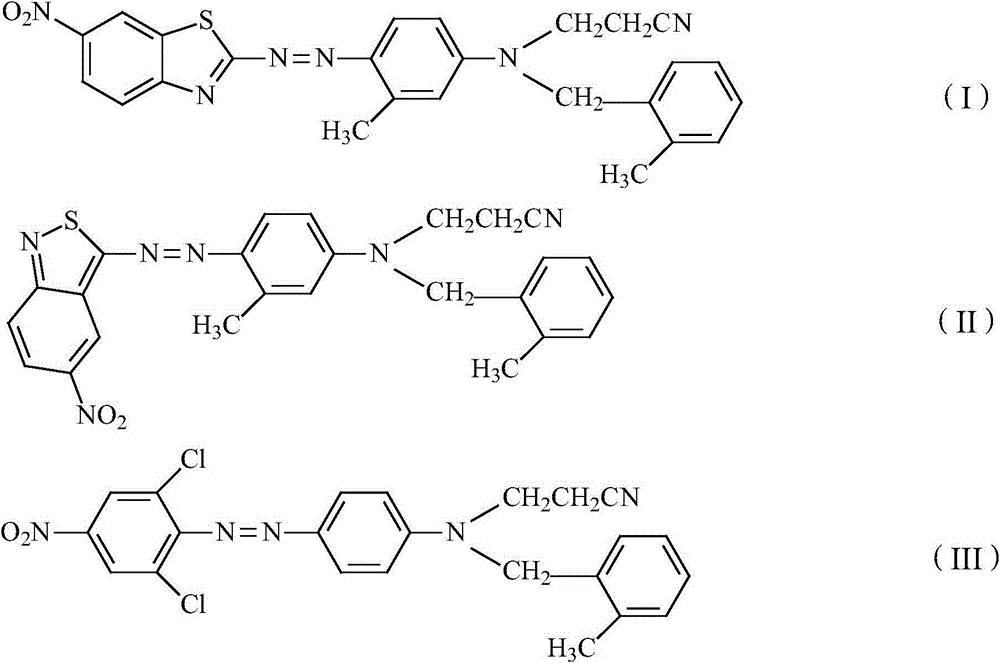

Blue dye composition and preparation method thereof

InactiveCN103509373AImprove oxidation resistanceGood alkali resistanceDry-cleaning apparatus for textilesOrganic dyesPhotochemistryDyeing

The invention discloses a blue dye composition. The blue dye composition comprises dyes shown in the general formulas (I), (II) and (III) and assistants. The invention also discloses a preparation method of the blue dye composition and a dyeing method adopting the blue dye composition. The blue dye composition has the advantages of good oxidation resistance and short dyeing process.

Owner:张家港市杨舍丝印工艺厂

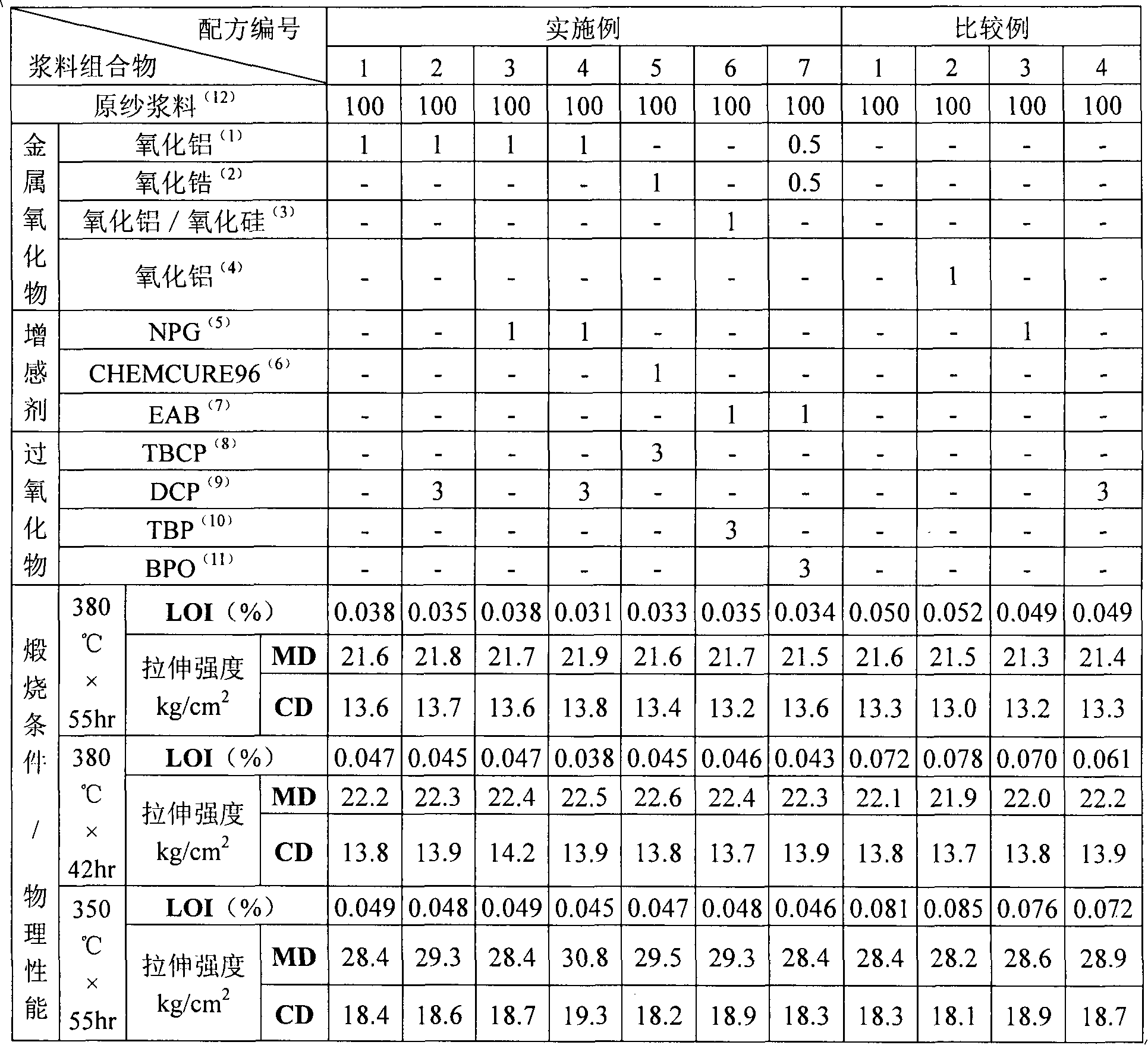

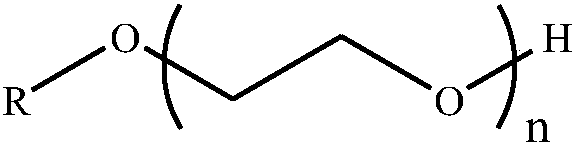

Cracking auxiliary agent-containing paste composition

The invention discloses a cracking auxiliary agent-containing paste composition. The past composition comprises 1.5 to 4.0 weight percent of paste, 1.0 to 3.0 weight percent of oiling agent, 0.2 to 0.5 weight percent of surfactant, 0.1 to 0.5 weight percent of softening agent, and 0.005 to 5.0 weight percent of cracking auxiliary agent. Compared with the formula of conventional glass fiber yarn paste, the cracking auxiliary agent is added into the paste composition, which can improve the desizing efficiency of a glass fiber fabric, reduce a secondary desizing temperature, reduce desizing time and reduce ignition loss and improve the strength of the glass fiber fabric.

Owner:NANYA PLASTICS CORP

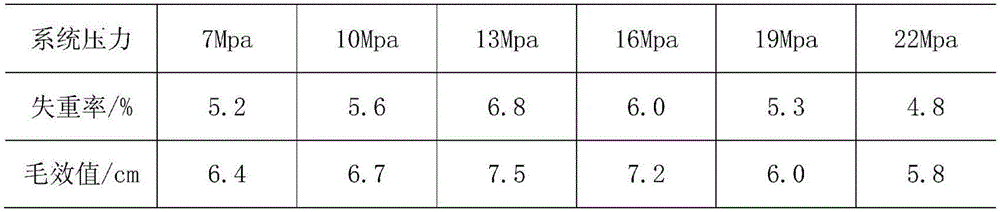

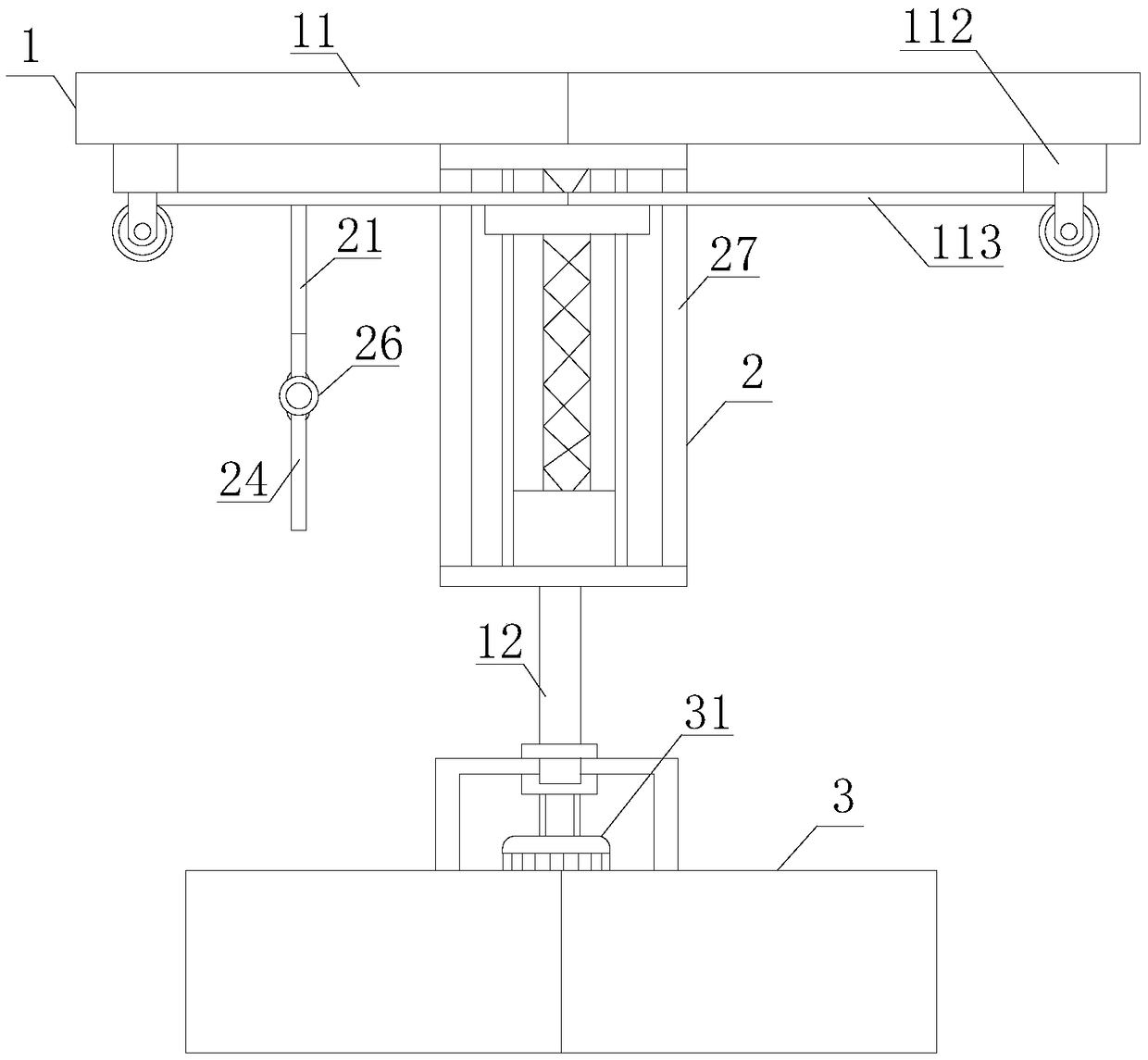

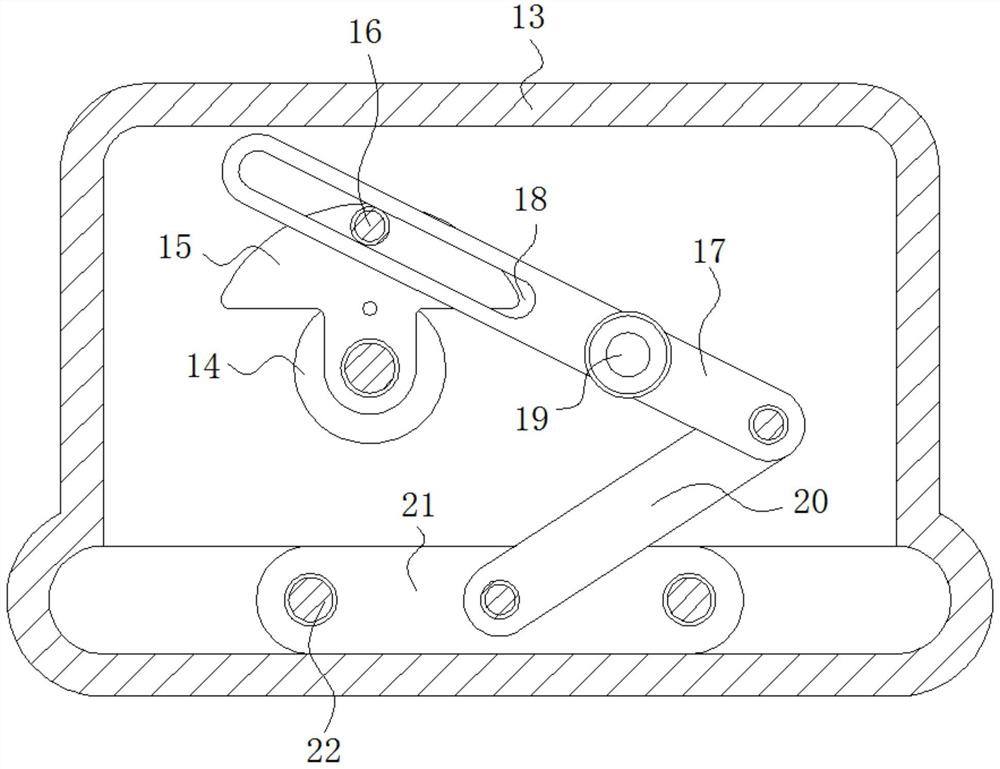

Chemical fiber fabric rapid desizing device and using method thereof

InactiveCN109056229AAvoid reworkImprove desizing efficiencyTextile treatment carriersLiquid/gas/vapor textile treatmentFiberEngineering

The invention discloses a chemical fiber fabric rapid desizing device and a using method thereof. The device comprises a fixed mechanism, a moving mechanism and a desizing mechanism. A produced chemical fiber fabric is placed between an upper clamping arm and a lower clamping arm, so that the chemical fiber fabric is clamped, the stability of the position of the chemical fiber fabric is guaranteed, the chemical fiber fabric is prevented from falling off, and the desizing efficiency of the chemical fiber fabric is improved. A lifting control box controls a lifting shaft to move downwards. Whenthe clamped chemical fiber fabric is immersed in an alkali solution washing tank, desizing is carried out on the chemical fiber fabric by using an alkaline solution in the alkaline solution washing tank, a motor is started, a rotating shaft drives the chemical fiber fabric to rotate in the alkali solution washing tank, and therefore complete desizing of the chemical fiber fabric is guaranteed. A movable connecting block is pushed, so that the clamped chemical fiber fabric is immersed into a clear water tank; the rotating shaft drives the chemical fiber fabric to rotate in the clear water tank,so that the alkaline solution attached to the chemical fiber fabric is removed, and the desizing process is completed. The chemical fiber fabric fast desizing device has the advantages of being highin desizing efficiency and good in desizing effect, avoiding manual operation and reducing the labor cost.

Owner:马鞍山市金毫厘纺织有限公司

A Rope Pretreatment Process Based on Low Alkali Scouring Agent

ActiveCN105803799BImprove gross effectImprove desizing effectBiochemical treatment with enzymes/microorganismsVegetal fibresWastewaterOxygen

The invention relates to a rope-form pretreatment process based on a low-alkaline scouring agent. The process comprises steps of batching, singeing, enzyme desizing, rope-form low-alkaline scouring with a two-step method and rope-form oxygen bleaching. The enzyme desizing efficiency is improved by the aid of an efficient penetrant, a sizing agent on fabric is effectively removed by using the low-alkaline scouring agent, and the use amount of alkali in the scouring process is reduced. The use amount of caustic soda is reduced while the pretreatment effect is guaranteed, the pH value of wastewater is reduced, and the biodegradability of the wastewater is improved.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment

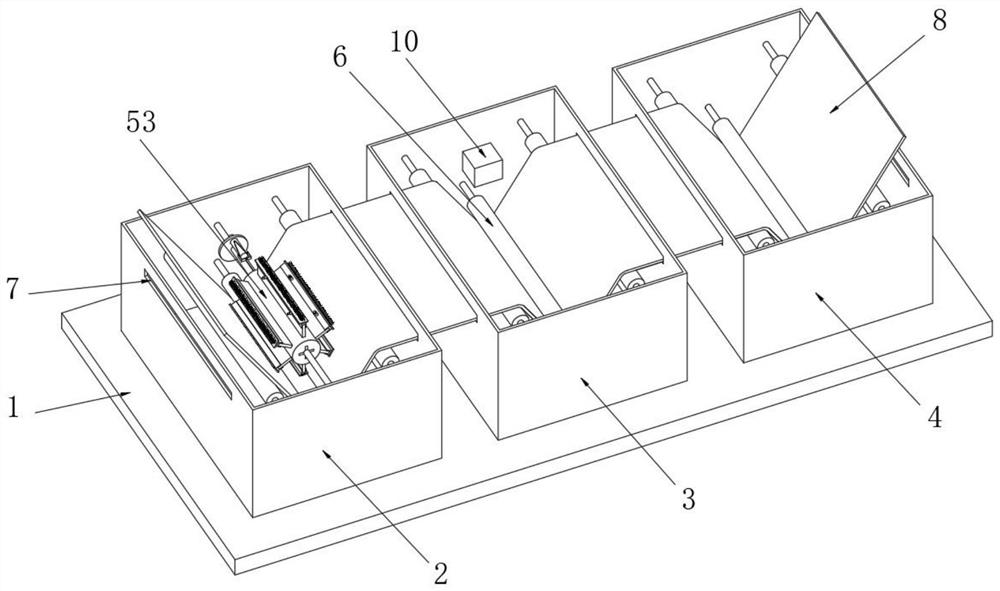

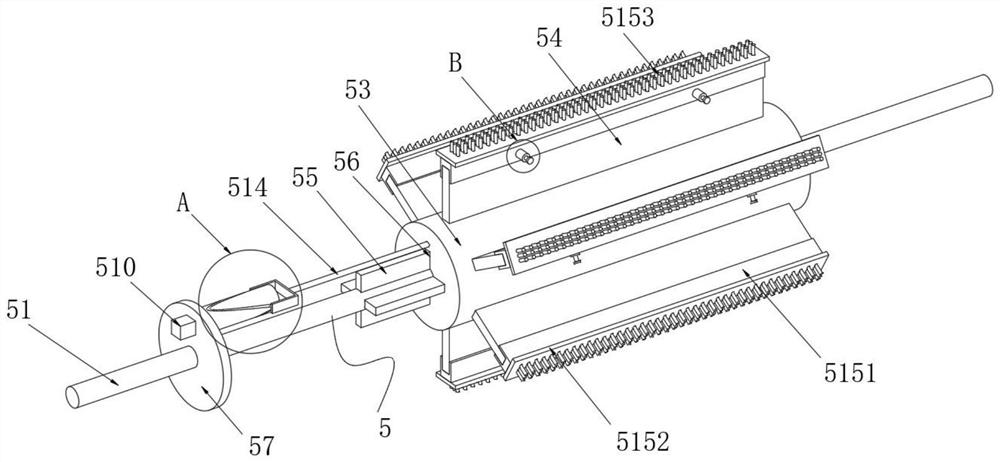

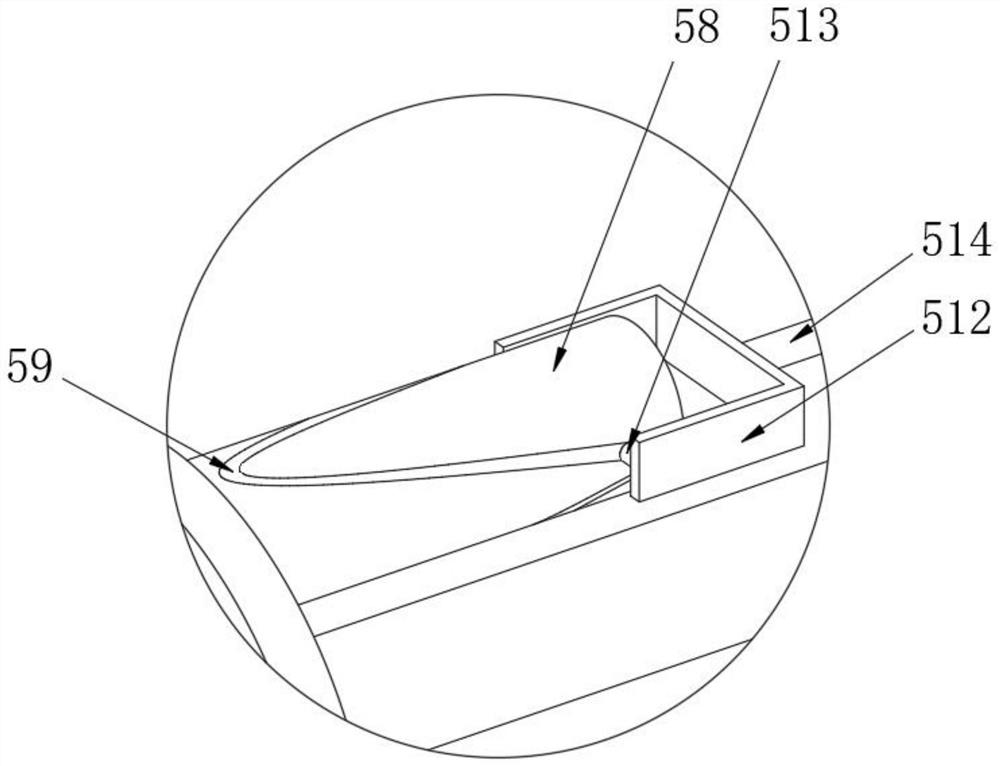

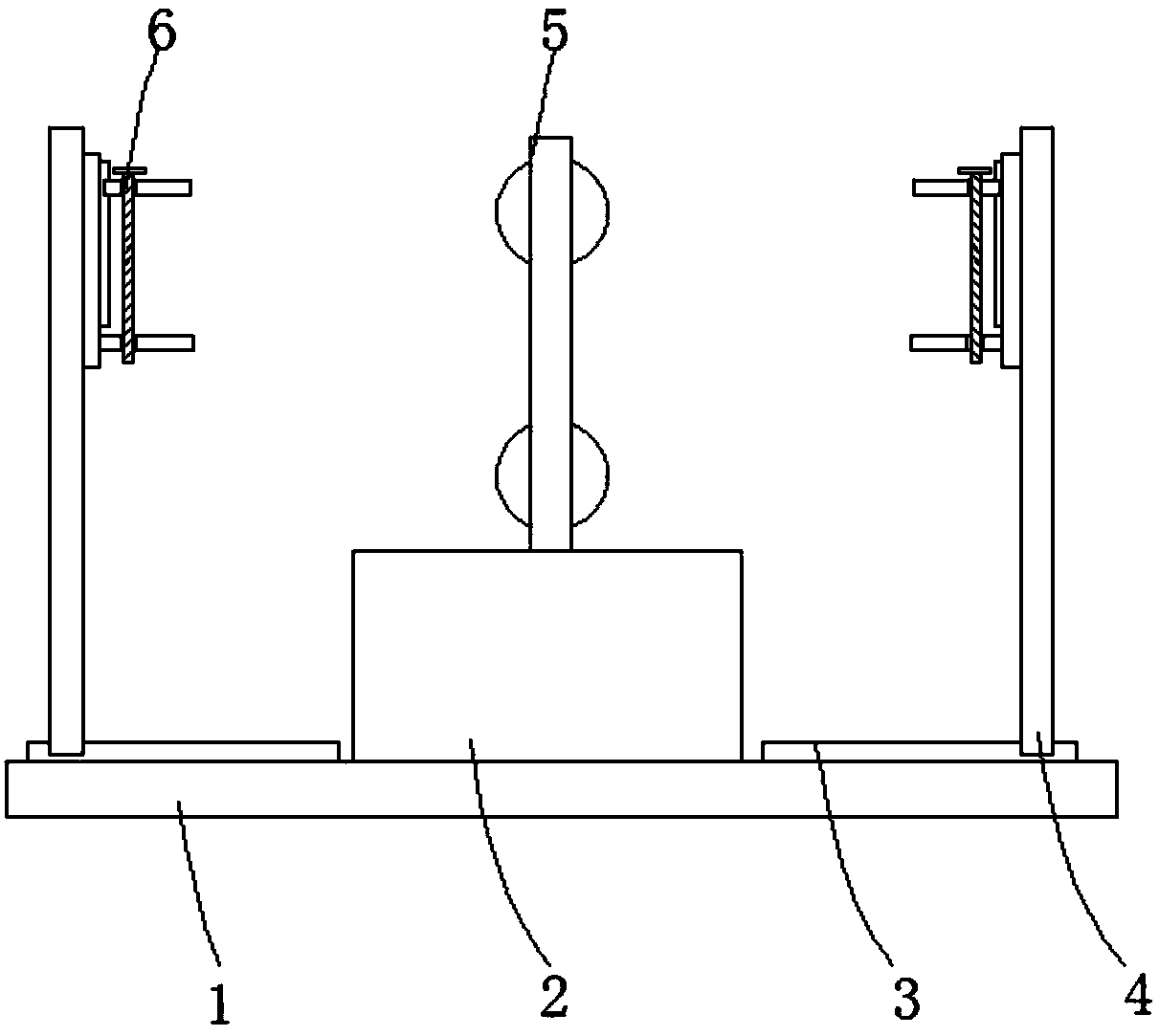

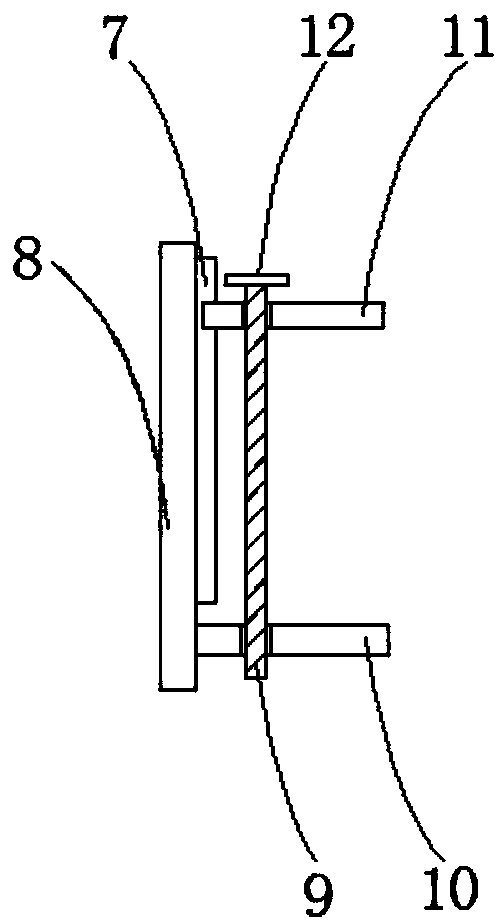

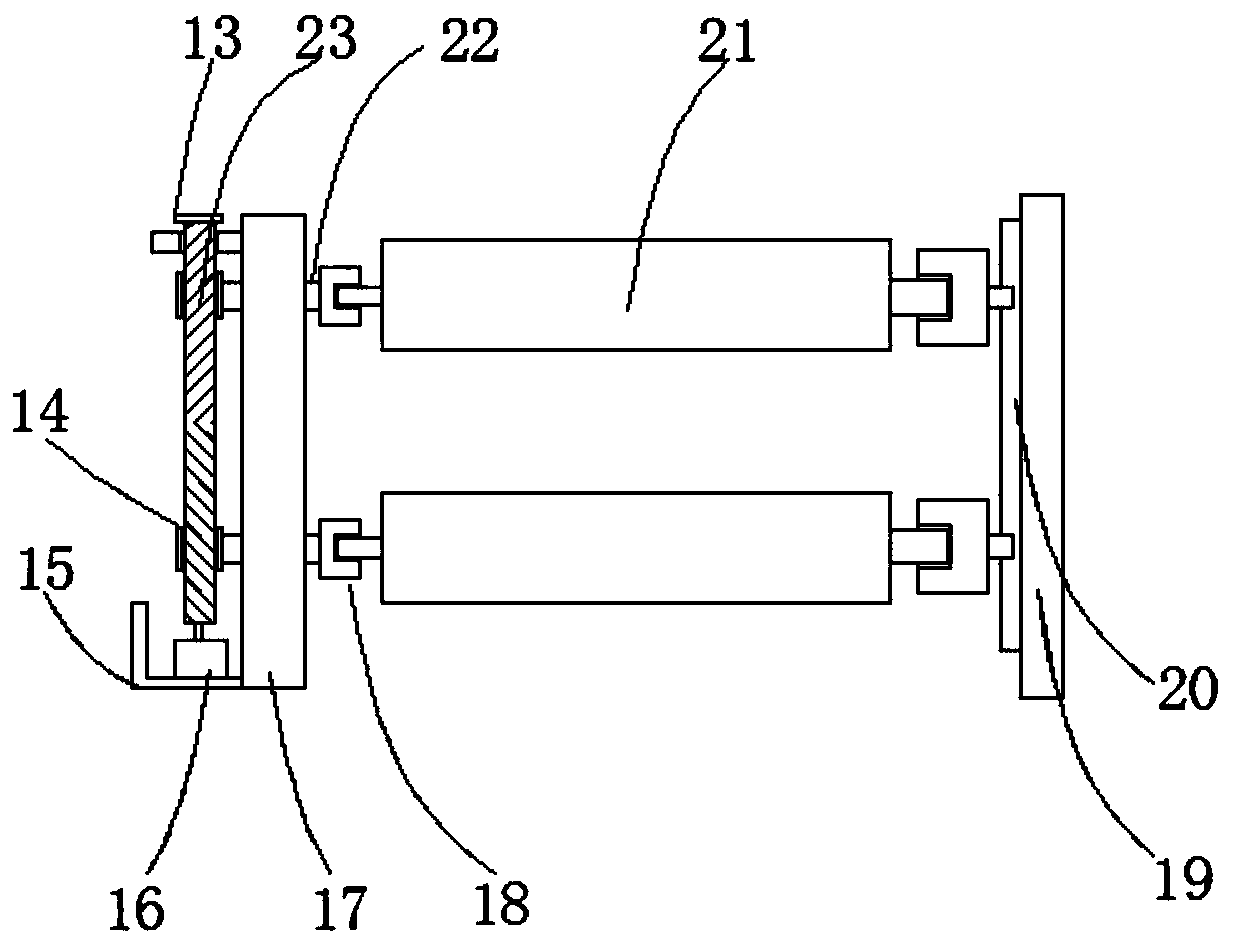

PendingCN113914045AMeet clean upImprove efficiencyLiquid/gas/vapor treatment machines driving mechanismsSucessive textile treatmentsProcess engineeringWoven fabric

The invention discloses a desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment, and relates to the technical field of cloth production. The desizing, scouring and bleaching one-bath process system comprises a bottom plate, a desizing bin, a scouring bin and a bleaching bin are fixedly connected with the top of the bottom plate in sequence from left to right, and a reciprocating stirring mechanism is arranged in the desizing bin; and the reciprocating stirring mechanism comprises a rotating rod rotationally connected between the front side and the rear side of the inner wall of the desizing bin, and the rear end of the rotating rod penetrates through the desizing bin and extends to the rear side of the desizing bin. According to the desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment, by arranging the reciprocating stirring mechanism, desizing liquid is stirred and mixed by a stirring paddle, full desizing of the desizing liquid on the surface of the fabric is facilitated, through the front-back-side reciprocating motion of a stirring wheel, the stirring wheel drives the stirring paddle and bristles to movably clean the surface of the cloth, cleaning of the surfaces of the cloth with different widths is met, and the desizing efficiency of the cloth is greatly improved.

Owner:佛山市顺德金纺集团有限公司

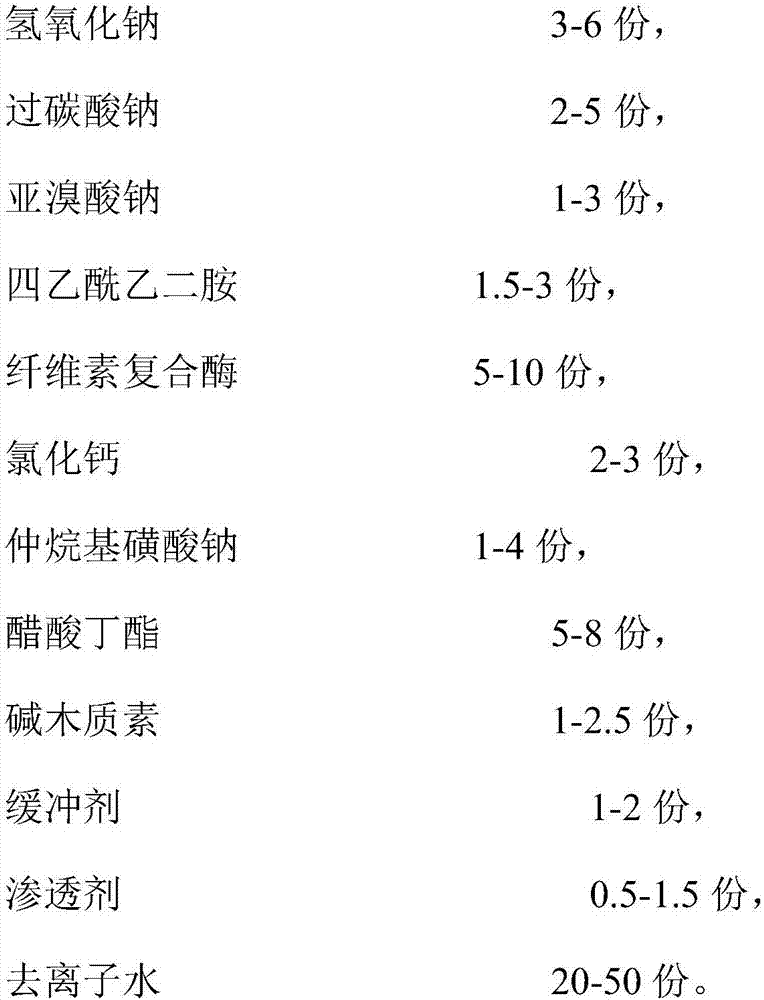

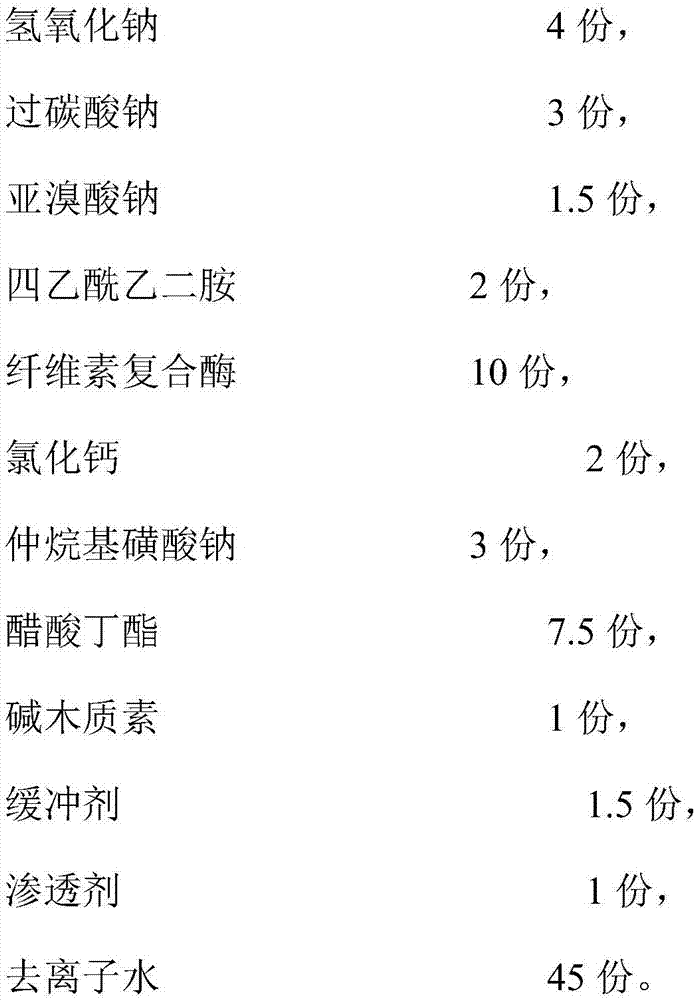

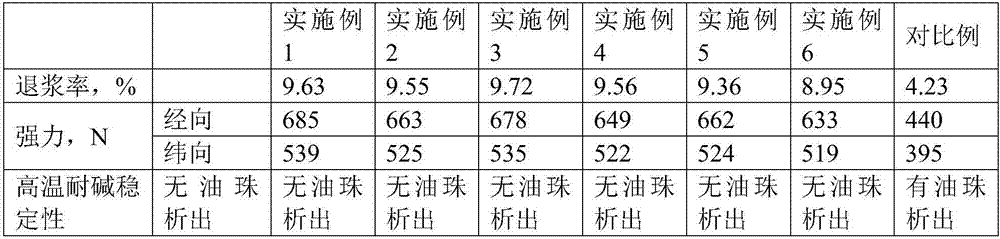

A kind of environment-friendly desizing agent for high-density polyester fabric and preparation method thereof

InactiveCN105603710BImprove high temperature and strong alkali resistanceImprove diffusion abilityDry-cleaning apparatus for textilesEthylenediaminePolyester

The invention discloses an environmentally-friendly desizing agent used for high-density polyester fabric. The environmentally-friendly desizing agent is prepared from, by weight, 3-6 parts of sodium hydroxide, 2-5 parts of sodium percarbonate, 1-3 parts of sodium bromite, 1.5-3 parts of tetraacetyl ethylenediamine,5-10 parts of cellulose compound enzyme, 2-3 parts of calcium chloride, 1-4 parts of secondary alkyl sodium sulfonate, 5-8 parts of n-butyl acetate, 1-2.5 parts of alkali lignin, 1-2 parts of a buffering agent, 0.5-1.5 parts of a penetrating agent and 20-50 parts of deionized water. The invention further discloses a preparation method of the environmentally-friendly desizing agent. The desizing agent is good in desizing effect, excellent in acid and alkali resistance, free of damage to the fabric and small in usage quantity, cleaning is easy, the yield of waste water is low, and no pollution is generated; the preparation method is simple, the raw materials are easy to obtain, the price is low, and the production cost is low.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

Red-light navy blue dye composition and preparation method thereof

InactiveCN103554986AImprove oxidation resistanceGood alkali resistanceDry-cleaning apparatus for textilesOrganic dyesPhotochemistryRed light

The invention discloses a dye composition. The dye composition is composed of dyes having structures represented by general formula (I), general formula (I), general formula (II), general formula (III) and general formula (IV) respectively, and assistants. The invention also discloses a preparation method of the dye composition, and a dyeing method of the dye composition. The dye composition obtained in the invention has a good oxidation resistance, and the dyeing method using the dye composition has a short flow.

Owner:广东华博知识产权运营有限公司

Desizing agent for viscose-based wood carbon fibers and preparation and use method of desizing agent

InactiveCN106978713AImprove surface activityReduce surface damageCarbon fibresDry-cleaning apparatus for textilesCarbon fibersAlpha-amylase

The invention provides a desizing agent for viscose-based wood carbon fibers and a preparation and use method of the desizing agent. The desizing agent for viscose-based wood carbon fibers comprises alkali lignin, sodium carbonate alkaline substances, cellulase, pectase, alpha-amylase, alkaline protease desizing enzyme, lecithin, disecoctylmaleate sodium sulfonate, a cetyl trimethylammonium bromide surfactant, isopropyl alcohol and water which are ultrasonically stirred and prepared into microemulsion. The use method comprises the following steps: dipping the viscose-based wood carbon fibers in the desizing agent for viscose-based wood carbon fibers; after fully wetting the viscose-based wood carbon fibers, transferring the viscose-based wood carbon fibers into a supercritical carbon dioxide fluid device; carrying out heating and pressurizing reaction; taking out the viscose-based wood carbon fibers; cleaning the viscose-based wood carbon fibers repeatedly; and drying the viscose-based wood carbon fibers under vacuum to obtain the desized viscose-based wood carbon fibers. The prepared desizing agent is prepared according to characteristics of the viscose-based wood carbon fibers, a microemulsification technology and a supercritical carbon dioxide technology are combined, the purpose of desizing gently and efficiency is achieved, and active groups and microstructures on surfaces of the carbon fibers are seldom injured.

Owner:苏州凯邦生物技术有限公司

Red dye composition and preparation method thereof

InactiveCN103509374AImprove oxidation resistanceGood alkali resistanceDry-cleaning apparatus for textilesOrganic dyesPhotochemistryDyeing

The invention discloses a red dye composition. The red dye composition comprises dyes shown in the general formulas (I) and (II) and assistants. The invention also discloses a preparation method of the red dye composition and a dyeing method adopting the red dye composition. The red dye composition has the advantages of good oxidation resistance and short dyeing process.

Owner:张家港市杨舍丝印工艺厂

A high-efficiency desizing machine

ActiveCN107313192BImprove desizing efficiencyExtend the decomposition timeTextile storage in superimposed formTextile treatment machine arrangementsDecompositionPulp and paper industry

The invention discloses an efficient desizing machine. The efficient desizing machine comprises a machine frame, a desizing region, a stacking region and a cleaning region. The desizing region comprises a desizing tank and a padder which are located at the lower end of the machine frame; the stacking region comprises a first variable-frequency roller, a second variable-frequency roller and a cloth conveying track, the first variable-frequency roller and the second variable-frequency roller are located on the machine frame, and the cloth conveying track is located between the first variable-frequency roller and the second variable-frequency roller; the cleaning region comprises a roll and a washing box; to-be-processed cloth is subjected to desizing enzyme padding in the desizing region, then decomposed in the stacking region and finally washed in the washing region, and then the desizing process is completed. According to the efficient desizing machine, the structure of a desizing machine is changed, desizing enzyme decomposition time is increased, the washing effect of the washing box is also improved, the desizing efficiency is improved, and the product quality is improved.

Owner:韶关市北纺智造科技有限公司

Manufacturing method for carbon dioxide desized mucilage glue/copper ammonia fiber blended yarn weaved fabric

InactiveCN104674431AQuality improvementAvoid lightBiochemical fibre treatmentWarping machinesPolyesterCuprammonium rayon

The invention discloses a manufacturing method for a carbon dioxide desized mucilage glue / copper ammonia fiber blended yarn weaved fabric. A warp and weft yarn material selected by the manufacturing method comprises the following components in parts by mass: 40-90 parts of mucilage glue fiber, 36-45 parts of copper ammonia fiber, 24-28 parts of cocoon silk, 20-40 parts of combed cotton and 8-18 parts of superfine denier polyester; the manufacturing method for the fiber fabric comprises the following steps: scutching, cotton carding, drawing, roving, spinning and weaving; the weaving process comprises the following operations, such as beam warping, poaching for shaping, slashing and air injection; in the beam warping step, the beam warping is carried out in batch at the beam warping tension of 20-22dN, the beam warping speed of 400r / min, the environment temperature of 24 DEG C, the relative humidity of 68%, the winding density 0.53-0.56g / cm<3> and the yarn end breaking delay of 1s. According to the manufacturing method for the carbon dioxide desized mucilage glue / copper ammonia fiber blended yarn weaved fabric, the integral performance of the fiber spun fabric is improved through performance complementation among different fibers, and meanwhile, the manufacturing method is pollution-free and environment-friendly.

Owner:SUZHOU CHENHENG WEAVING

A non-ironing processing method for yarn-dyed four-way stretch fabric garments

ActiveCN109097974BClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnProcess engineering

Owner:盛泰智造集团股份有限公司

Textile fabric desizing equipment

InactiveCN114606679AReduce contaminationAvoid affecting workSucessive textile treatmentsTextile treatment machine arrangementsElectric machinerySlurry

The invention belongs to the technical field of textile equipment, and particularly relates to textile fabric desizing equipment which comprises a desizing pool and a clean water pool, a support is arranged on the desizing pool and the clean water pool, a transverse plate is arranged on the desizing pool and the clean water pool, two placing plates are arranged on the desizing pool, a plurality of feeding rollers are arranged on the support, and the feeding rollers are arranged on the transverse plate. Auxiliary rollers are arranged in the desizing pool and the clean water pool, desizing fabric is arranged on the multiple feeding rollers and the auxiliary rollers, a motor is arranged on the support, a rotating rod is fixedly installed on an output shaft of the motor, a first bevel gear is fixedly installed on the rotating rod, a second bevel gear is meshed with the first bevel gear, and a rotating rod is fixedly installed on the second bevel gear; a slurry cleaning mechanism is arranged on the support, two inclined plates are arranged on the desizing pool, first collecting boxes are arranged on the two placing plates, and a first belt wheel is fixedly installed on the rotating rod. The desizing device can automatically clean slurry blocks, reduce the possibility that the slurry blocks are stained on fabrics, clean the fabrics and improve the desizing efficiency, and is simple to use and convenient to operate.

Owner:江先庆

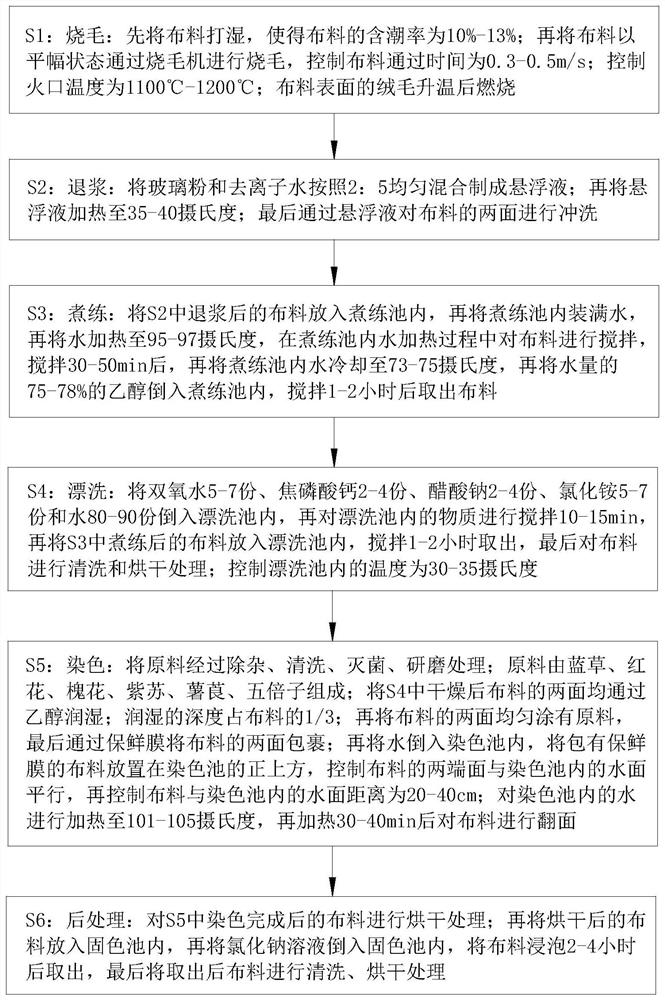

Environment-friendly and energy-saving cloth printing and dyeing process

InactiveCN112391768ASave energyAvoid wastingMechanical cleaningPressure cleaningTextile printerHazardous substance

The invention relates to the technical field of textile printing and dyeing, in particular to an environment-friendly and energy-saving cloth printing and dyeing process. The environment-friendly andenergy-saving cloth printing and dyeing process comprises the following steps: singeing, desizing, scouring, rinsing, dyeing and post-processing. In the dyeing process, raw materials are subjected toimpurity removal, cleaning, sterilization and grinding treatment; the raw materials comprise bluegrass, safflower carthamus, flos sophorae, purple perilla, rhizoma dioscoreae cirrhosae and gallnut; the two sides of the dried cloth are wetted with ethyl alcohol; the wetting depth accounts for 1 / 3 of the cloth; the two sides of the cloth are uniformly coated with the raw materials, and finally the two sides of the cloth are wrapped with a preservative film; water is poured into a dyeing pool, and the cloth wrapped with the preservative film is placed right above the dyeing pool. According to thecloth printing and dyeing process, water vapor is used for heating the cloth, ethyl alcohol is used for extracting pigments in the raw materials, the process of dyeing the cloth through plant dyes isachieved, harmful substances are not generated in the cloth dyeing process, meanwhile, a large amount of energy is saved, and the cloth printing and dyeing process has the advantages of being environmentally friendly and capable of saving energy.

Owner:胡玉

A kind of textile fabric desizing equipment for textile

ActiveCN112726068BIncrease temperatureHigh activityLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsProcess engineeringMechanical engineering

The invention discloses a textile fabric desizing equipment for textiles, which comprises a desizing box body, a discharge drum is fixed above the left end of the desizing box, and a feeding port is arranged on the right end of the unloading drum. A hydrolysis zone is arranged on the left inner side of the slurry box, and a limit roller is installed on the upper left of the hydrolysis zone, a stirring motor is fixed above the center of the hydrolysis zone, and a stirring shaft is fixed at the lower end of the stirring motor. Compared with the existing textile fabric desizing equipment, the textile fabric desizing equipment for textiles is provided with a heating plate and a stirring rod, and heating plates are arranged on the left and right sides of the hydrolysis zone. Increasing the temperature of the solution increases the activity of amylase in the solution, thereby accelerating the efficiency of equipment desizing, and a stirring rod is also provided inside the hydrolysis box, and the solution can be stirred more fully through the n-shaped stirring rod. Sufficient contact of the solution to the cloth further increases the efficiency of hydrolysis.

Owner:JIHUA 3509 TEXTILE

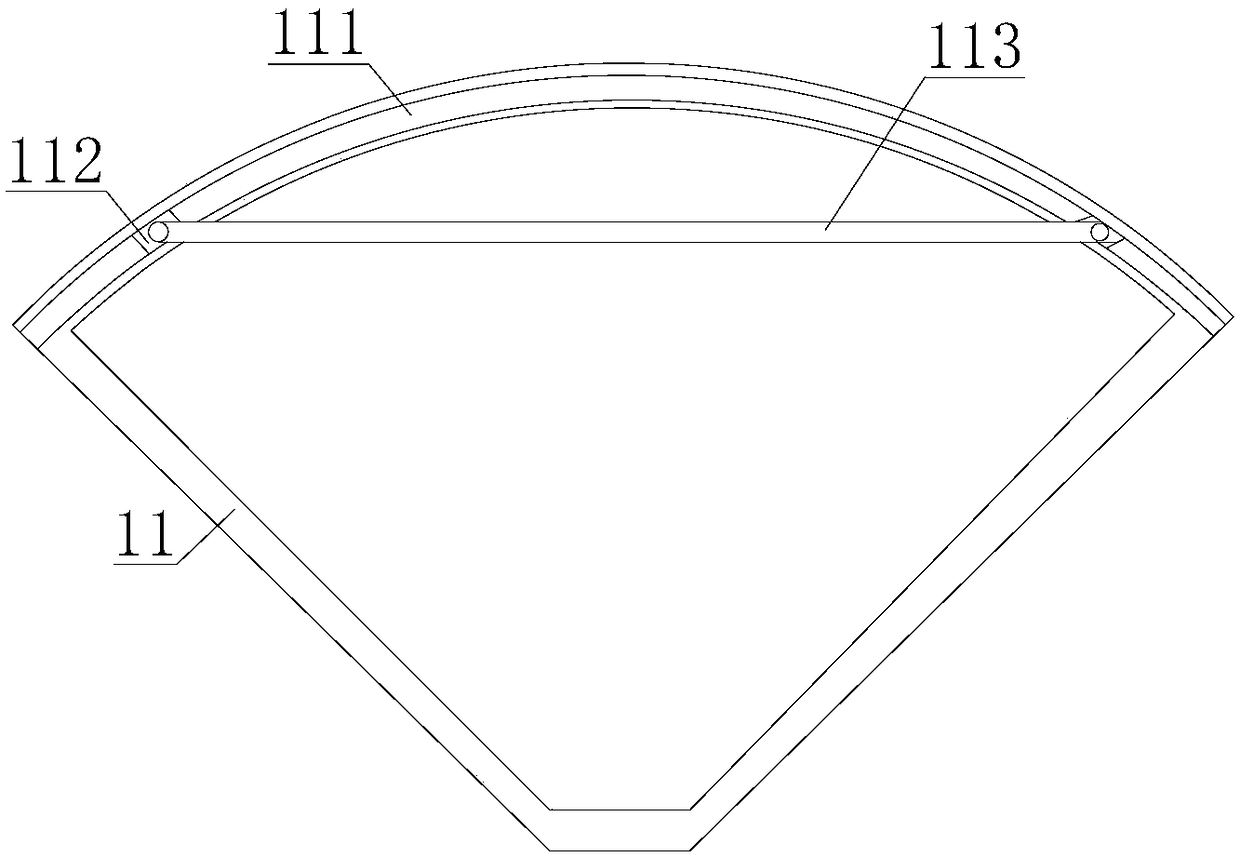

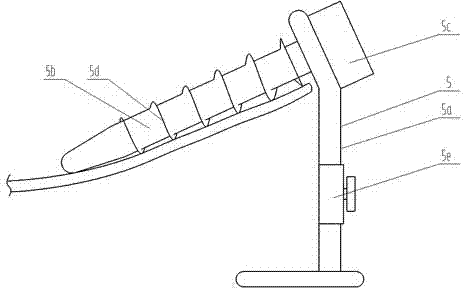

Starch removing device special for blue print cloth

ActiveCN104723665AGuaranteed qualityGuarantee the same qualityRotary pressesElectric machineryMaterials science

The invention discloses a starch removing device special for blue print cloth. According to the device, through the cooperation of a support, a main motor, driving rollers, driven rollers and starch removing tools, traditional manual blue print cloth starch removal is replaced with an industrial automation scheme, the quality of blue print cloth is unchanged, and production efficiency is improved greatly. According to the device, the top end of each tool body is a spherical end face, so that damage to the surface of blue print cloth caused by edges and corners is reduced compared with an angular top end of a blade; a certain inclination angle is formed between each tool body and the horizontal plane to be adapted to the characteristic of softness of a blue print cloth body, so that the tool bodies are better attached to the surface of the blue print cloth body, and the problem of incomplete starch removal caused by gaps formed between the tools and the blue print cloth body is solved; due to the fact that blades incline towards the side, close to the support, of the tool bodies, the blades can enter blue print cloth surface starch gently, damage to the surface of blue print cloth is reduced, and starch removal efficiency is not affected.

Owner:IANGSU COLLEGE OF ENG & TECH

Textile desizing refiner

InactiveCN108589131AIncrease contact areaImprove desizing efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentTextileArchitectural engineering

The invention discloses a textile desizing refiner. The refiner comprises a base plate; a collecting box and two horizontal sliding rails are fixedly installed at the top of the base plate, and a desizing device is fixedly installed at the top of the collecting box and comprises a first vertical plate and a second vertical plate; a metal plate and an L-shaped placement plate are fixedly installedat one side of the first vertical plate, a motor is arranged at the top of a horizontal supporting arm of the L-shaped placement plate, a two-way screw rod is fixedly installed on an output shaft of the motor, a circular through hole is formed in the plate body of the metal plate, the rod body of the two-way screw rod is rotatably connected with the metal plate at the circular through hole, the outer side of the two-way screw rod is in threaded connection with two threaded sleeves, and a guide rod is welded to one end of each threaded sleeve. Compared with existing devices, the textile desizing refiner has the advantages that textiles different in specification and size can be well clamped and fixed, in the desizing process, the contact area of the textiles is well enlarged, and the desizing efficiency is improved.

Owner:CHANGXING BAOFU WEAVING

Hole fabric and method for making same

ActiveCN106367960BIncrease elasticityWith tensionFibre treatmentHeating/cooling textile fabricsFiberPulp and paper industry

The invention relates to a cloth fabric with holes and a preparation method thereof, belonging to the technical field of cloth materials. The grey cloth of the cloth fabric with holes is formed by interweaving T / R fibers, and a plurality of evenly distributed holes are formed in the cloth fabric with holes. The preparation process of the cloth fabric with holes comprises the following steps: cloth batching, continuous desizing and water washing, perforating, dyeing, reduction washing, dewatering and cloth spreading, drying in a drum, in-process inspection and setting. The surface of the cloth fabric with holes disclosed by the invention has regular holes, brings a different visual effect to people, and has excellent elasticity and excellent air permeability.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

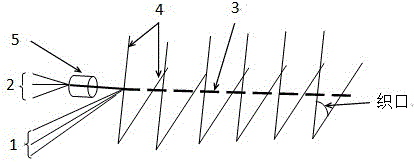

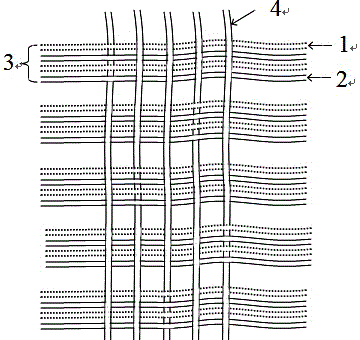

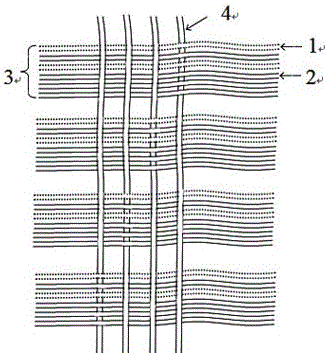

Method for weaving fabrics with high moisture absorption and free styles

InactiveCN107177975AImprove hydrophilicityOvercoming mechanical lawsAuxillary apparatusGrip property fibresWater dispersibleAir-jet loom

The invention relates to a method for weaving fabrics with high moisture absorption and free styles. The method includes that warp yarns are cellulose fiber yarns which are already subjected to sizing treatment, and sizing agents comprise water dispersible polyester and acidic starch mixed size during sizing; weft yarns are made of cellulose fiber yarns and polyester filament yarns, and the warp yarns and the weft yarns are interwoven by the aid of different-surface weave on looms to obtain grey cloth; each weft yarn at least comprises the corresponding single polyester filament yarn and the corresponding single cellulose fiber yarn; the polyester filament yarn and the cellulose fiber yarn of each weft yarn are distributed on different cheeses before being woven and are wound on different weft accumulators during weaving, the water dispersible polyester is sprayed on the polyester filament yarns when the polyester filament yarns are transmitted through spray devices, then the polyester filament yarns and the cellulose fiber yarns of the weft yarns are led in via water or air jet looms, and the multiple weft yarns are freely wound in the air and are led into cloth fell; boiling, bleaching, dyeing, soaping and soft type approval are carried out on the grey cloth. The method has the advantages that one surface of each fabric is soft, fine and smooth and is high in moisture absorption, the other surface of each fabric is smooth and moisture-absorption and has printing styles, and accordingly the fabrics can be widely applied to home textile products and garment products.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com