A Rope Pretreatment Process Based on Low Alkali Scouring Agent

A scouring agent and pre-treatment technology, applied in enzyme/microbial biochemical treatment, fiber treatment, biochemical fiber treatment, etc., can solve the problems of fabric damage, pollute the environment, affect the appearance and feel of fabrics, and reduce the alkali content , high capillary effect, enhanced desizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

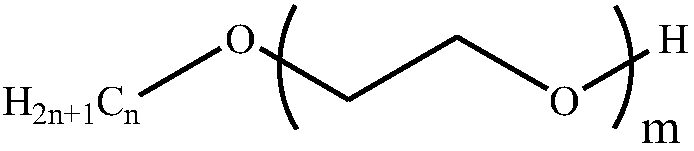

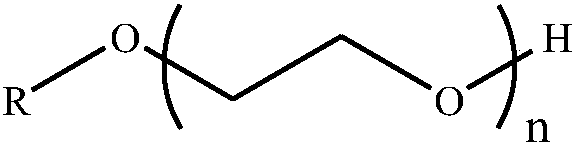

[0034] The high-efficiency penetrating agent is composed of the following mass percentages: sodium bis[(2-ethylhexyloxy)ethyl] phosphate 10%, isomeric alcohol polyoxyethylene ether 30%, and distilled water 60%.

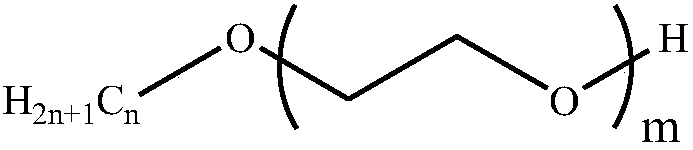

[0035] The low alkali scouring agent is composed of the following mass percentages, fatty alcohol polyoxyethylene ether 15%, ethylene-bis(N-ethanesulfonic acid-dodecamide) sodium salt 10%, fatty acid methyl ester ethoxylate 10%, distilled water 65%.

[0036] Technological process: seam turning → singeing → enzyme desizing → rope two-step low-alkali scouring → rope oxygen bleaching.

[0037]Specific process conditions and additive dosage: the gray cloth is directly padded with enzyme solution to extinguish the fire after seam turning and singeing, the vehicle speed is 140m / min, the temperature of the enzyme solution is 50°C, the liquid carrying rate of gray cloth is 85%, and it is piled up in a rope shape at 20°C 3h, low-temperature amylase dosage 1.5g / L, high-efficie...

Embodiment 2

[0039] The high-efficiency penetrating agent is composed of the following mass percentages: sodium bis[(2-ethylhexyloxy)ethyl] phosphate 10%, isomeric alcohol polyoxyethylene ether 30%, and distilled water 60%.

[0040] The low alkali scouring agent is composed of the following mass percentages, fatty alcohol polyoxyethylene ether 15%, ethylene-bis(N-ethanesulfonic acid-dodecamide) sodium salt 10%, fatty acid methyl ester ethoxylate 10%, distilled water 65%.

[0041] Technological process: seam turning → singeing → enzyme desizing → rope two-step low-alkali scouring → rope oxygen bleaching.

[0042] Specific process conditions and additive dosage: the gray cloth is directly padded with enzyme solution to extinguish the fire after seam turning and singeing, the vehicle speed is 140m / min, the temperature of the enzyme solution is 60°C, the liquid carrying rate of gray cloth is 90%, and it is piled up in a rope shape at 30°C 2h, the amount of low-temperature amylase 2g / L, high-e...

Embodiment 3

[0044] The high-efficiency penetrating agent is composed of the following mass percentages: sodium bis[(2-ethylhexyloxy)ethyl] phosphate 15%, isomeric alcohol polyoxyethylene ether 40%, and distilled water 45%.

[0045] The low alkali scouring agent is composed of the following mass percentages, fatty alcohol polyoxyethylene ether 20%, ethylene-bis(N-ethanesulfonic acid-dodecamide) sodium salt 10%, fatty acid methyl ester ethoxylate 15%, distilled water 55%.

[0046] Technological process: seam turning → singeing → enzyme desizing → rope two-step low-alkali scouring → rope oxygen bleaching.

[0047] Specific process conditions and additive dosage: the gray cloth is directly padded with enzyme solution to extinguish the fire after seam turning and singeing, the vehicle speed is 140m / min, the temperature of the enzyme solution is 50°C, the liquid carrying rate of gray cloth is 85%, and it is piled up in a rope shape at 20°C 3h, low-temperature amylase dosage 1.5g / L, high-effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com