Patents

Literature

88results about How to "Improve desizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

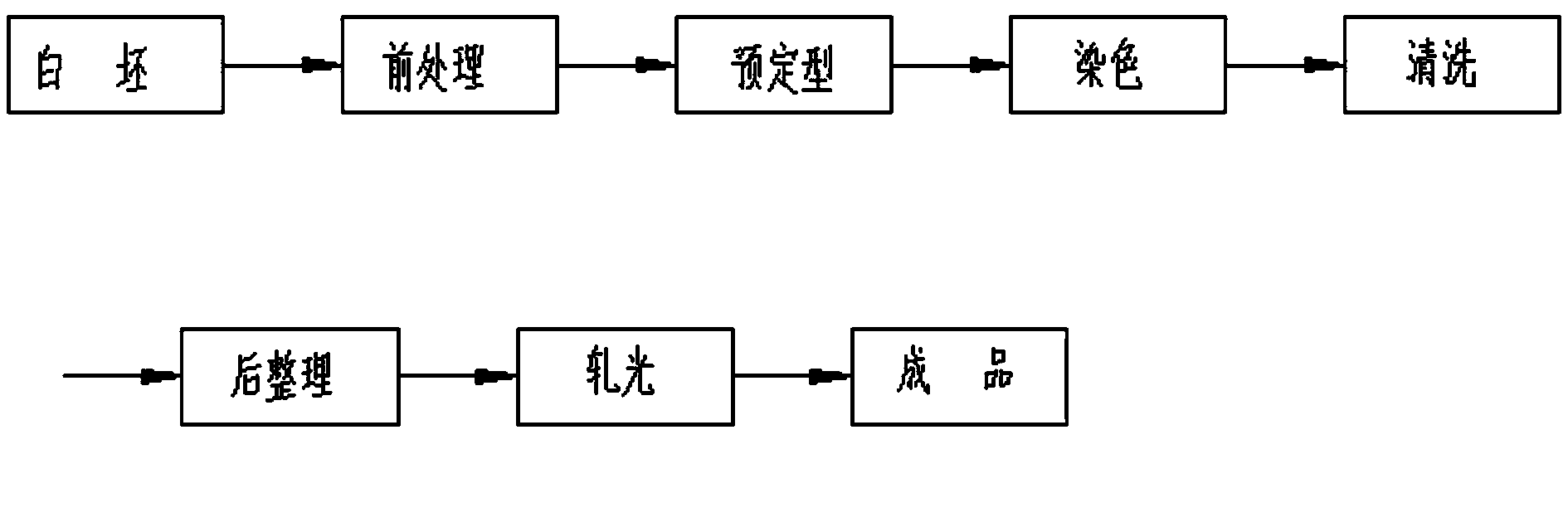

Novel dyeing and finishing processing technology of micro polyester fabric

ActiveCN102628211AReduce wrinklesReduce staining and chafingHeating/cooling textile fabricsDry-cleaning apparatus for textilesEnvironmental resistanceDisperse dye

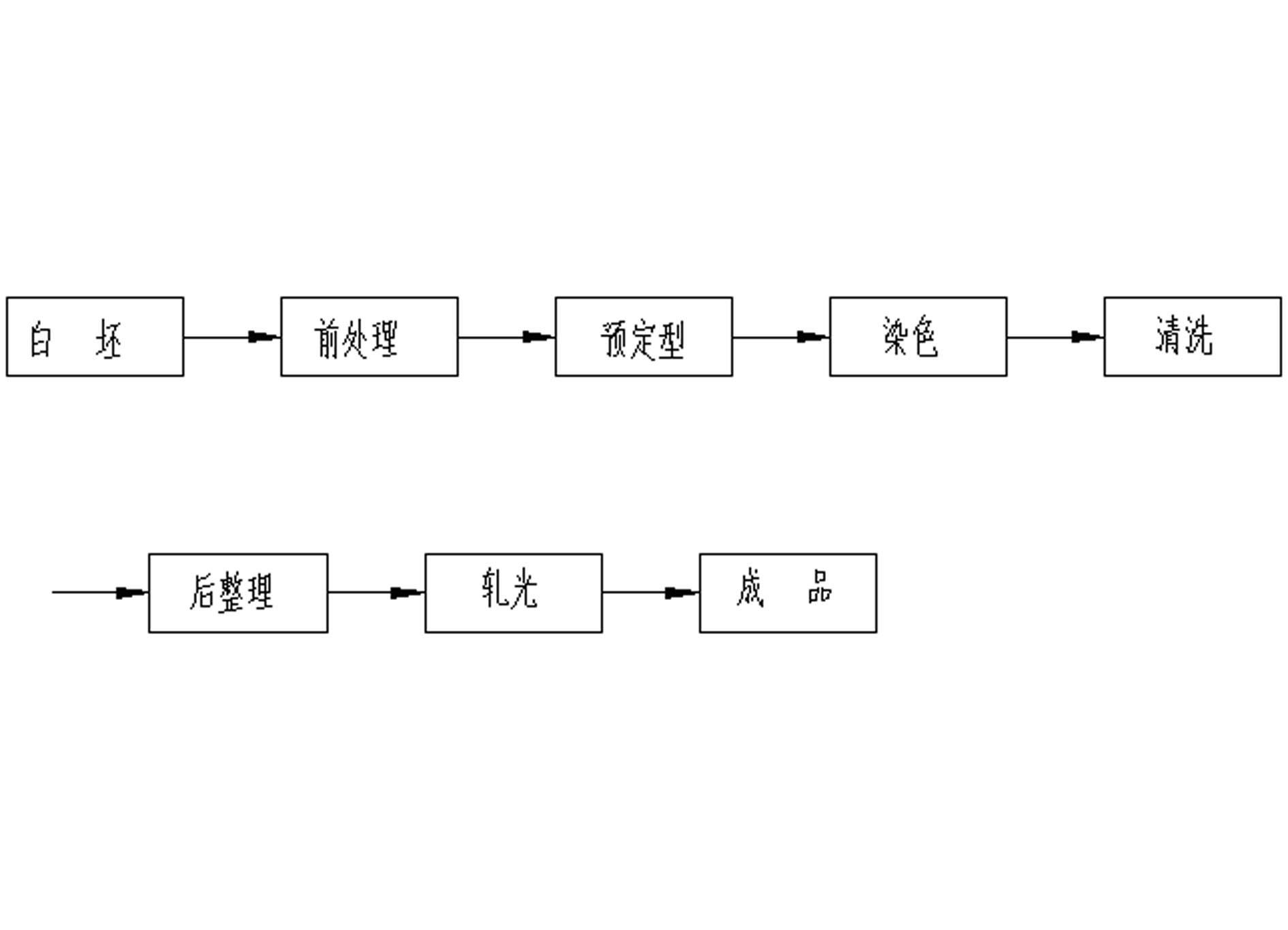

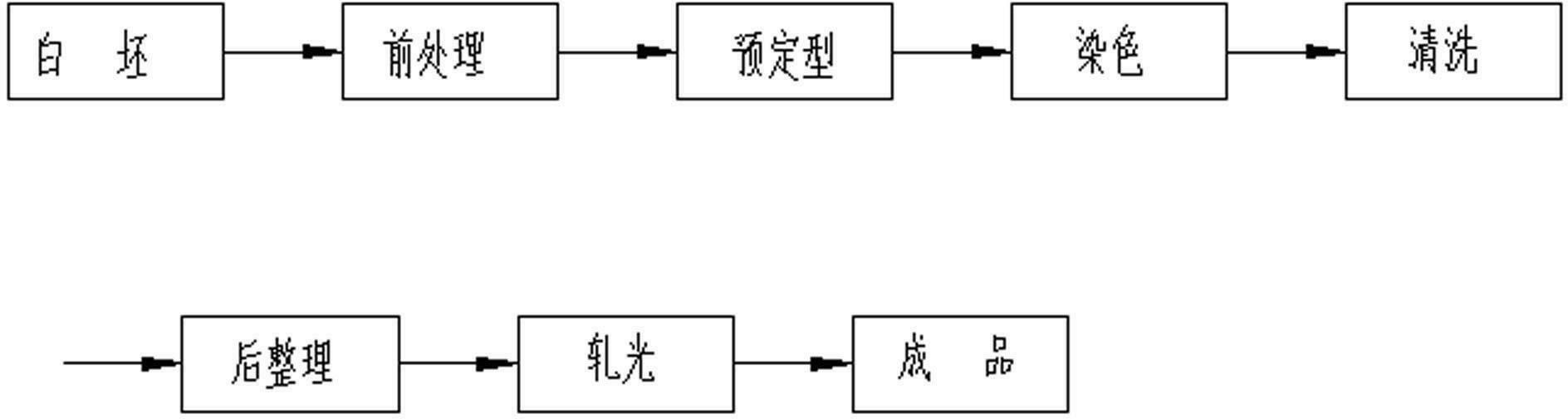

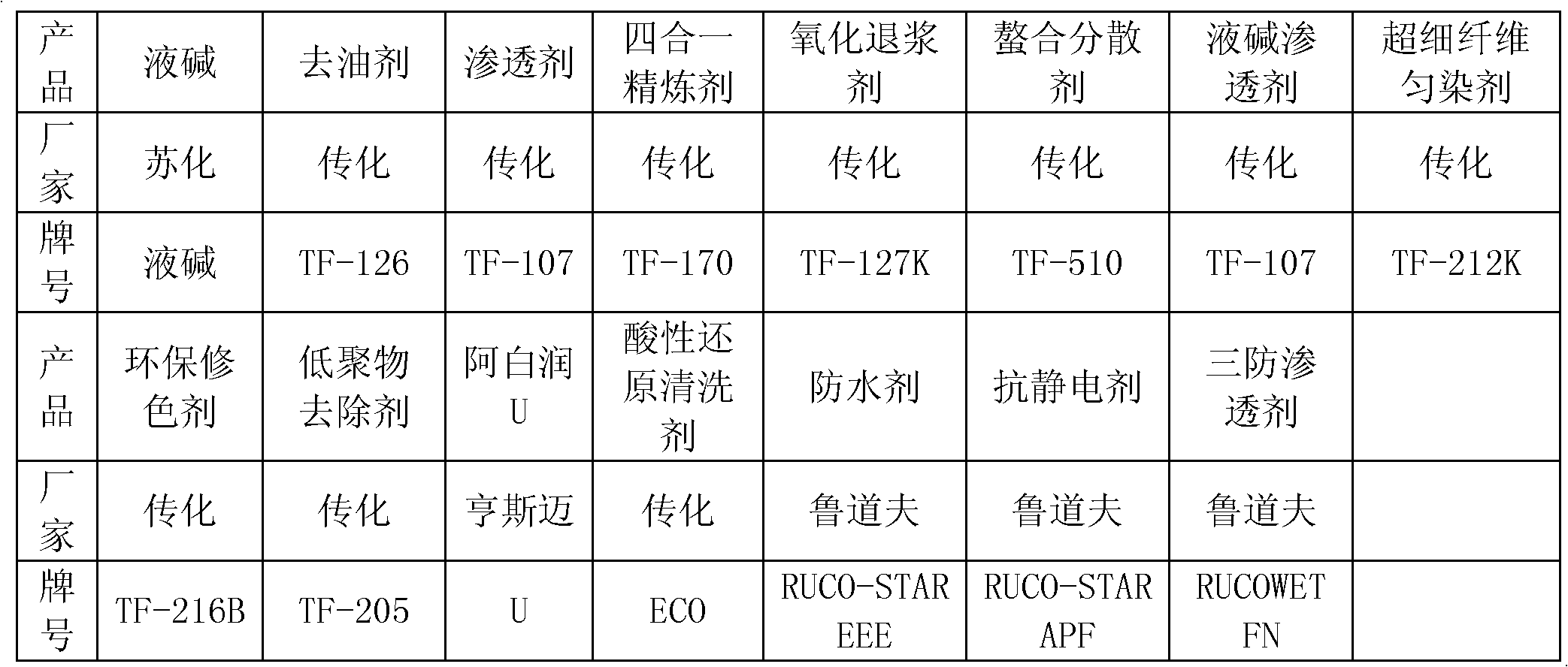

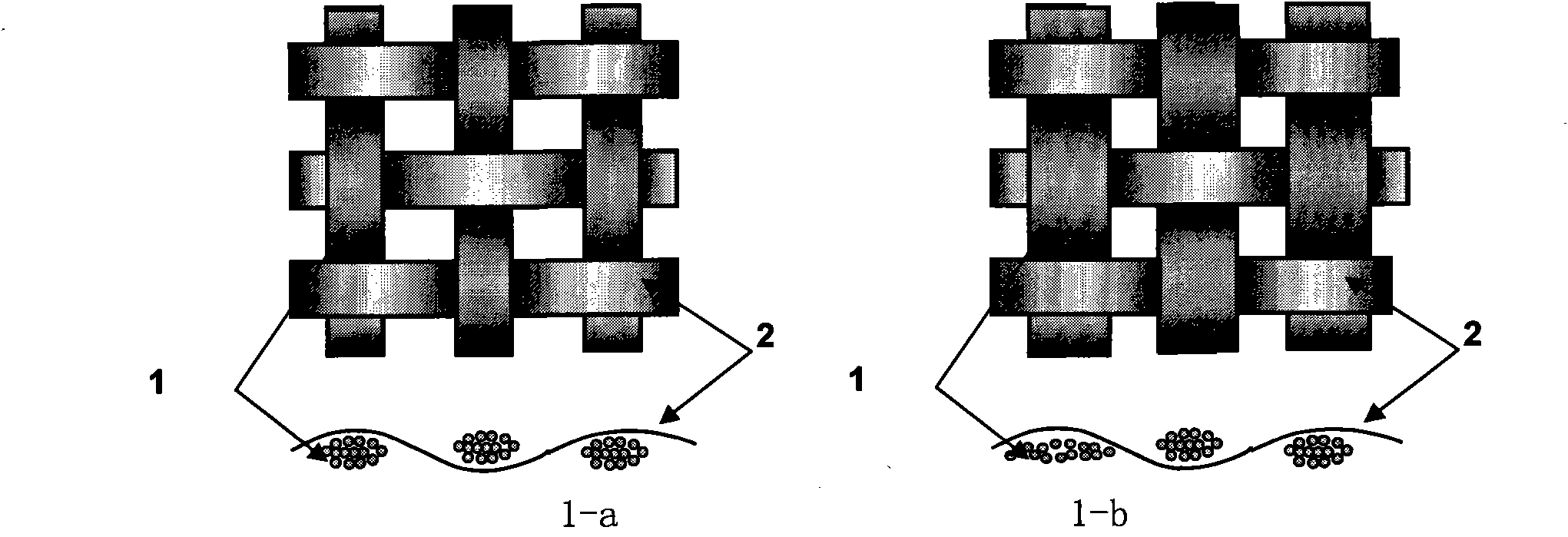

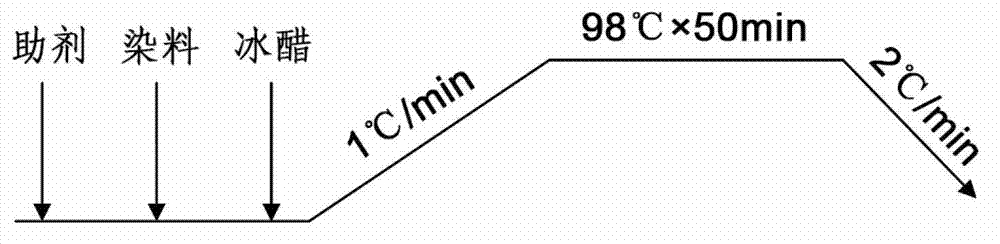

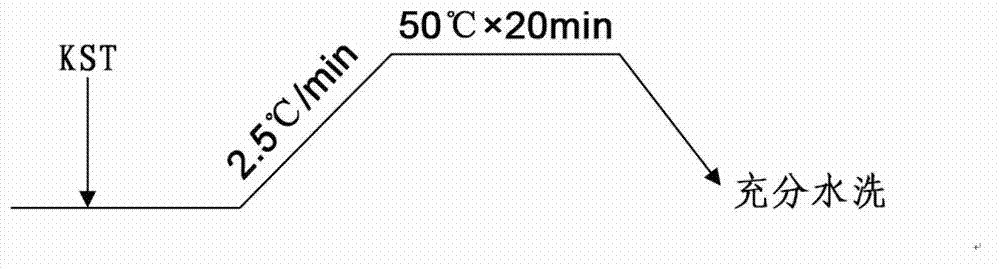

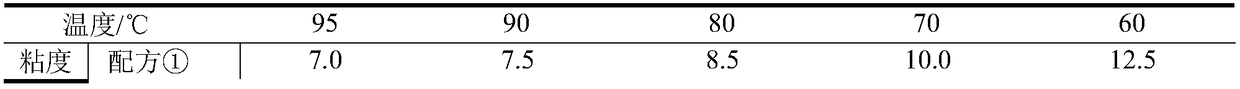

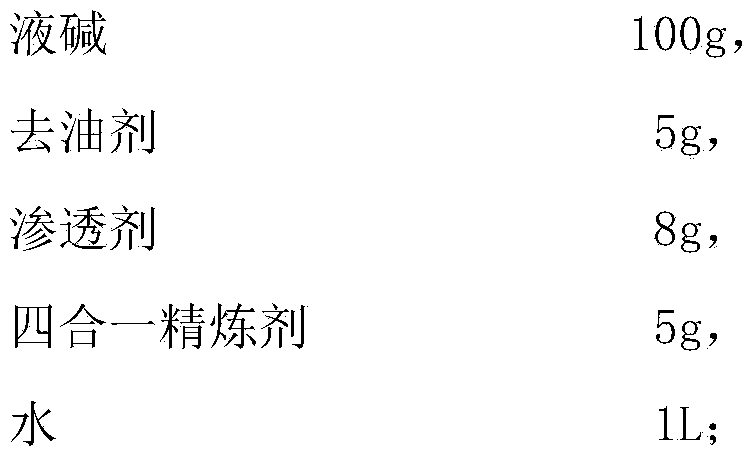

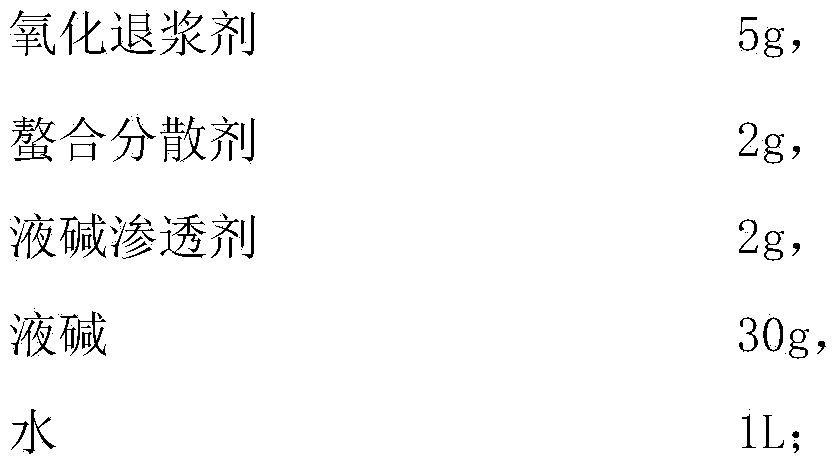

The invention relates to a novel dyeing and finishing processing technology of a micro polyester fabric. The novel dyeing and finishing process disclosed by the invention is characterized by comprising the following steps of: (1) pretreatment, namely carrying out cold rolling and stacking processing comprising three stages, namely cold stacking, hot alkali treatment and high efficiency washing, on polyester gray fabric; (2) presetting, namely carrying out high temperature tentering and presetting on a pretreated fabric white body by utilizing a setting machine; (3) dyeing, namely dyeing the preset fabric white body by adopting superfine fiber leveling agent; and (4) cleaning, namely carrying out cleaning post-processing on the dyed fabric to remove disperse dyes which are not set after fibres are dyed. According to the novel dyeing and finishing processing technology disclosed by the invention, an environment-friendly and low-energy-consumption cold rolling and stacking pretreatment technology is used for carrying out pretreatment on the micro polyester fabric, on one hand, desizing effect is good and good dyeing and finishing processing conditions are provided for dyeing, and on the other hand, crease mark of the fabric can be effectively reduced; meanwhile, a formula of a dyeing process additive can be adjusted, albafluid U is added to reduce fabric dyeing scratch, and dyeing defects can be prevented from being caused.

Owner:SHENGHONG GRP CO LTD

Fabric desizing agent

InactiveCN102965902AHigh whitenessImprove water absorptionDry-cleaning apparatus for textilesFiberAmylase

The invention discloses a fabric desizing agent. The fabric desizing agent consists of the following components in parts by weight: 10-20 parts of amylase, 3-5 parts of sodium persulfate, 2-6 parts of methyl cellulose, 0.2-0.6 part of sodium hydroxide, 10-20 parts of butyl acetate, 20-40 parts of isopropyl alcohol, 1-3 parts of butyl phthalate and 100-160 parts of water. Compared with the prior art, the fabric desizing agent has the following beneficial effects of (1) being good in desizing effect and enabling size to be fully hydrolyzed without damaging a fabric, and (2) removing impurities and minerals on the fiber, and improving the whiteness and hydroscopicity of a semi-finished product of the fabric.

Owner:吴江红蔷薇纺织有限公司

Fabric desizing agent

The invention relates to a fabric desizing agent. The fabric desizing agent is characterized by comprising the following components in parts by weight: 10-20 parts of amylase, 3-5 parts of sodium persulfate, 2-6 parts of methylcellulose, 15-25 parts of sodium chloride, 10-20 parts of n-butyl acetate, 10-20 parts of isopropanol, 1-3 parts of phthalic acid dibutyl ester, 10-25 parts of 12% hydrogen peroxide, 4-6 parts of argon sodium bromate, 5-10 parts of talcum powder, 5-8 parts of polyvinyl alcohol, and 100-160 parts of water. Compared with the prior art, the fabric desizing agent has the beneficial effects of having good desizing effect, fully hydrolyzing sizing agent without damaging the fabric, being capable of removing impurities and mineral substances on fibers, and improving whiteness and water absorption of half-finished product of the fabric.

Owner:HUZHOU JINTADI TEXTILE MILL

Environment-friendly and green secondary slurry of electronic-grade glass fiber cloth

InactiveCN101880964AGuaranteed tensile strengthImprove protectionFibre treatmentGlass fiberMetallurgy

The invention relates to secondary warp slurry used in the technical field of electronic-grade glass fiber cloth. The secondary slurry comprises the following components by weight percentage: 5-10 percent of main slurry starch, 0.5-1 percent of smoothing agent, 0.5-1 percent of binder, 0.01-0.05 percent of surfactant, and the balance of deionized water. The invention is warp slurry of electronic-grade glass fiber cloth for a printed circuit board with high-precision, high-uniformity and high-performance, the electronic-grade glass fiber cloth produced by the slurry formula has the advantages of excellent fabric appearance quality, smaller fabric thickness and energy saving and environment-friendly production process. The glass fiber cloth is applicable for insulation enhancing material of the printed circuit board, and is widely used in high-end products such as mobile phone boards, notebook computers, automotive sheets, digital cameras, digital players, navigation devices and the like.

Owner:SHANGHAI GRACE FABRIC

Desizing method for pure cotton fabrics sized by starch and PVA (Polyvinyl Acetate) mixing pulp

ActiveCN104018337AAvoid damageImprove qualityBiochemical fibre treatmentDry-cleaning apparatus for textilesSewage treatmentChemistry

The invention discloses a desizing method for pure cotton fabrics sized by a starch and PVA (Polyvinyl Acetate) mixing pulp and belongs to the pretreatment technology field of pure cotton fabrics. The pure cotton fabrics are subjected to bio-enzyme desizing treatment dip-padding after being pretreated by using hot water and subjected to stacking treatment, active enzyme remaining in the fabrics is removed by an enzyme deactivation treatment, and then the pure cotton fabrics are washed and dried. According to desizing method provided by the invention, the fiber damage is less, the treated fabrics are high in quality and soft in hand feel; particularly, the chromaticity, pH value and COD value of wastewater treated by the desizing method are greatly lower than that of a conventional process, thus the desizing method is in favor of protection of ecological environment, and the load of sewage treatment is greatly reduced. Because dip-padding-stacking continuous treatment processes are used, the desizing method has characteristics of high production efficiency and low labor intensity, and saves energy and water.

Owner:JIANGSU LIANFA TEXTILE +1

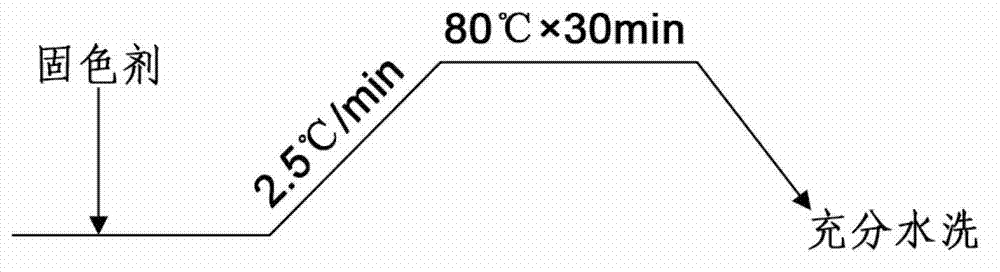

Preparation method of non-lining down-proof fabric

The invention is applicable to the fabric processing field, and provides a preparation method of non-lining down-proof fabric. The method comprises the following step of: performing cold batch treatment, open-width desizing treatment, presetting treatment, freshening treatment, dyeing treatment, fixation treatment, resin finishing, setting treatment and calendering treatment to chinlon fabric. The preparation method realizes the purpose that a final finished product has smooth, light and soft feeling, air permeability and faddish light sensation, down prevention and other features of fabric of cold protective clothing, is applied to down coat manufacture, is used for people to get rid of heavier mode for passing the winter, and produces a new consumption concept.

Owner:SHENGHONG GRP CO LTD

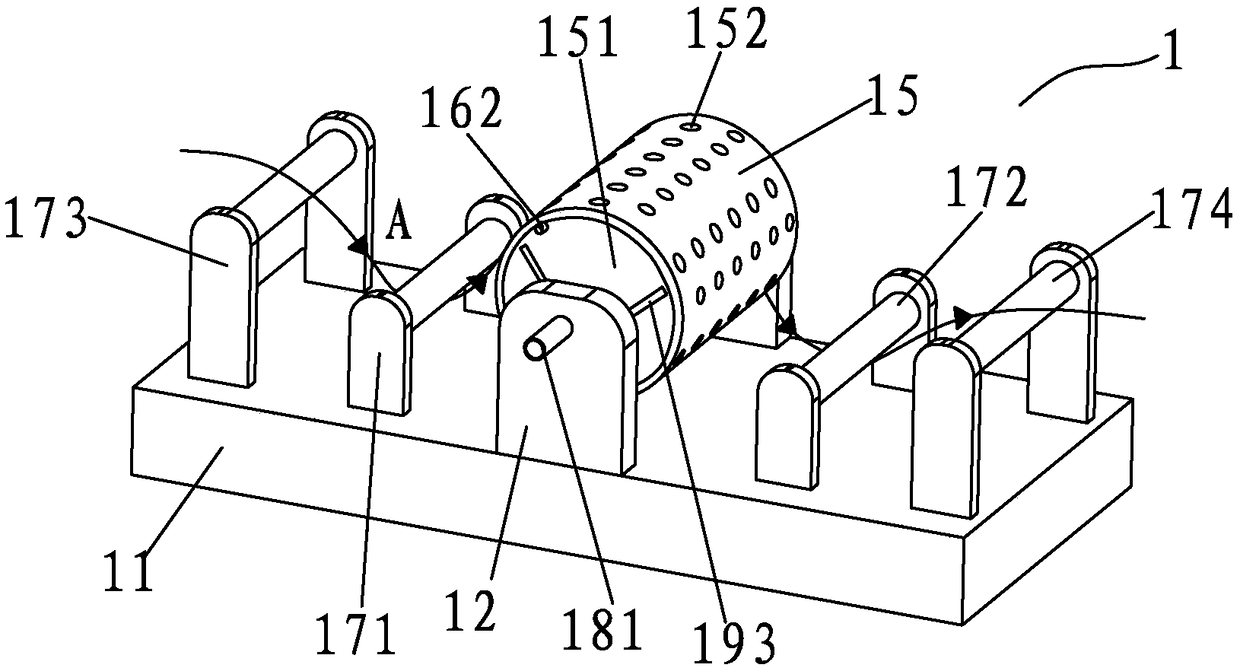

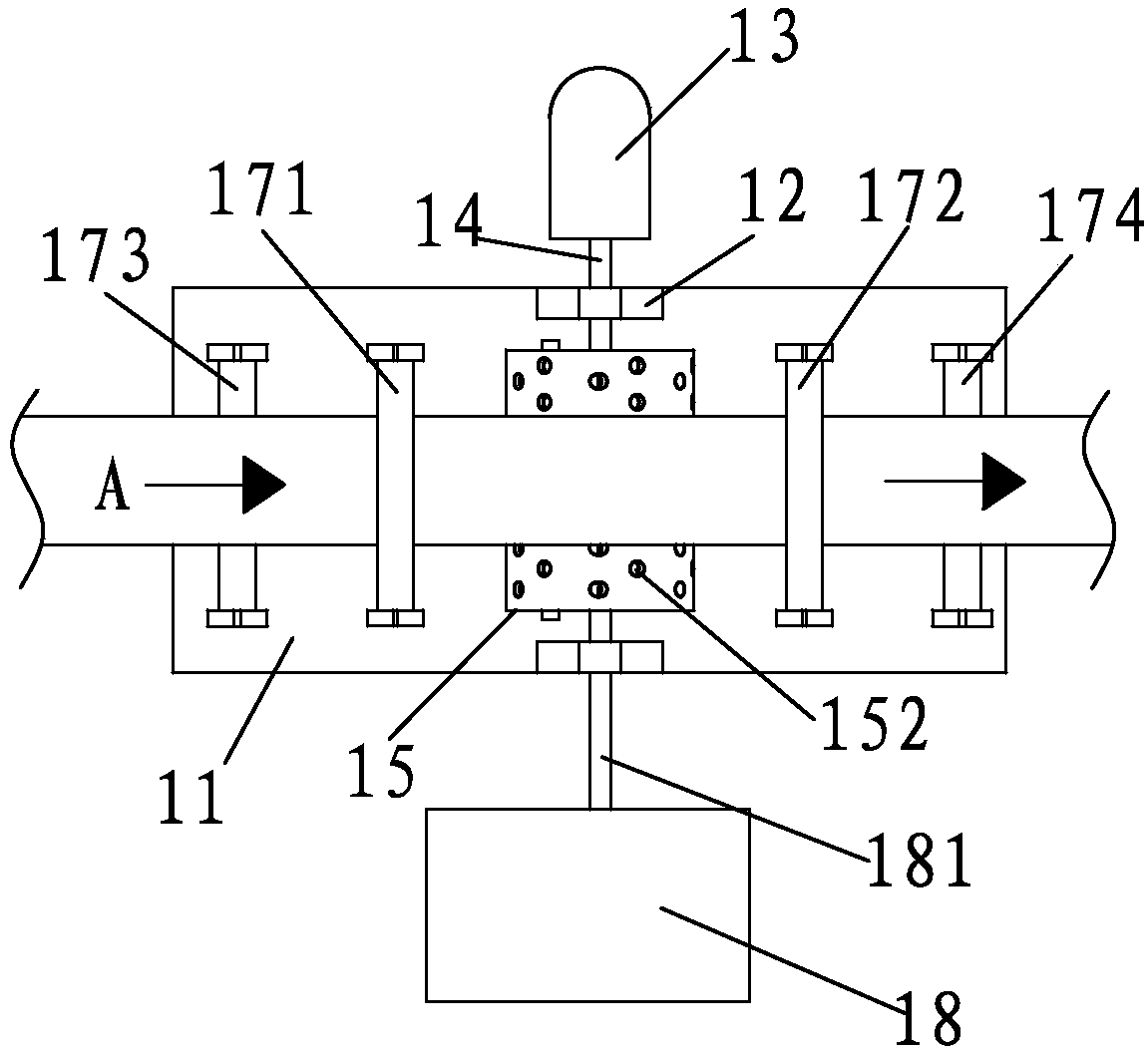

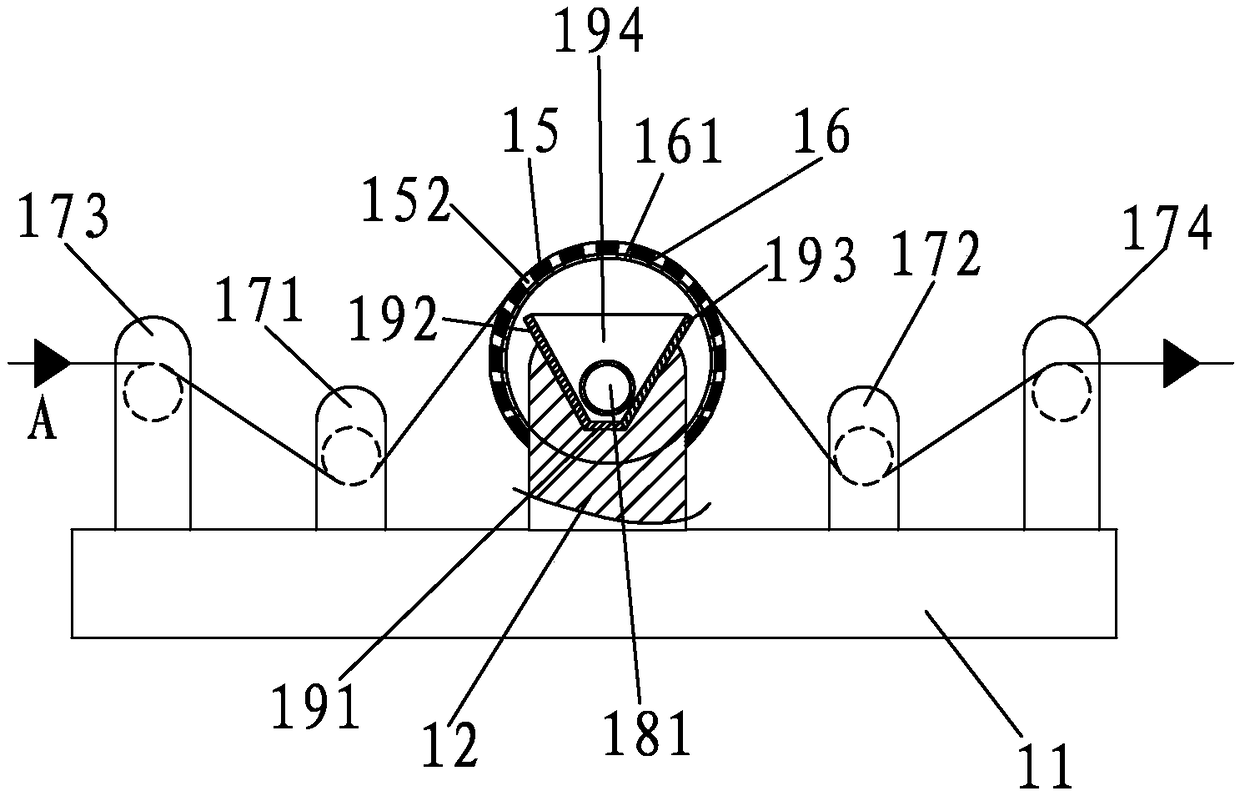

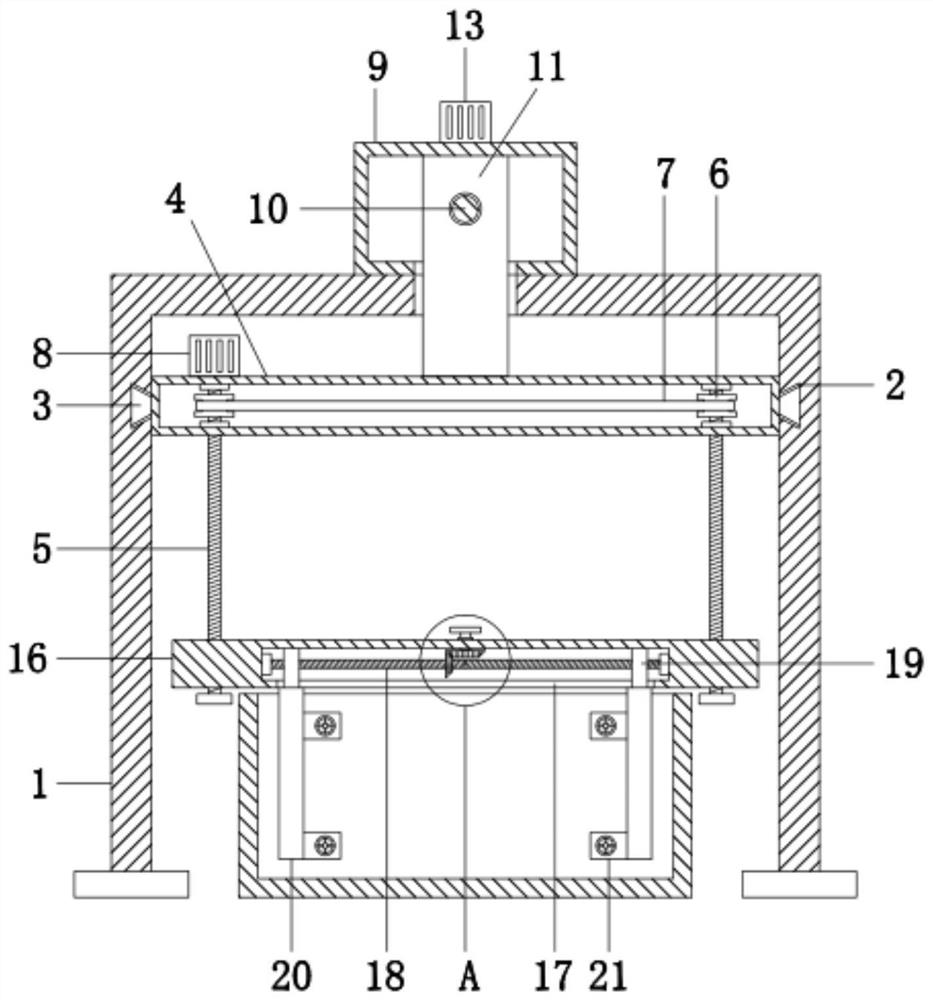

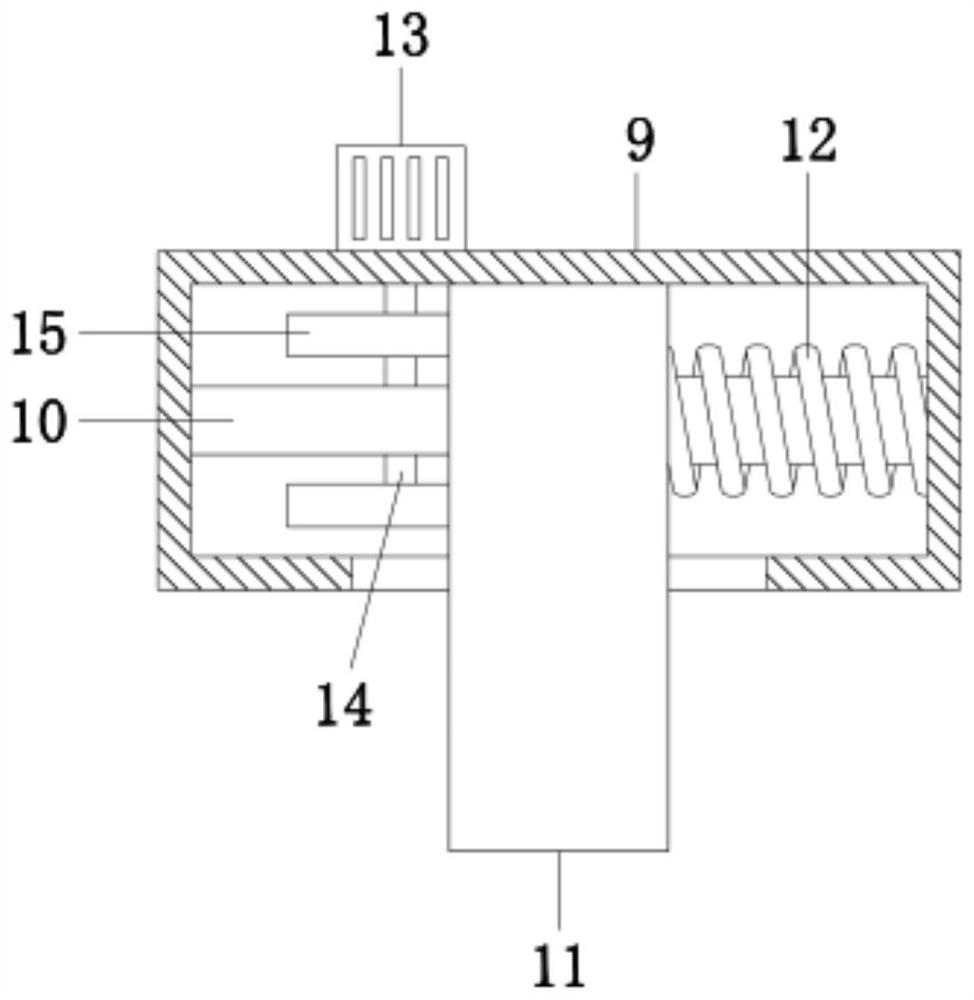

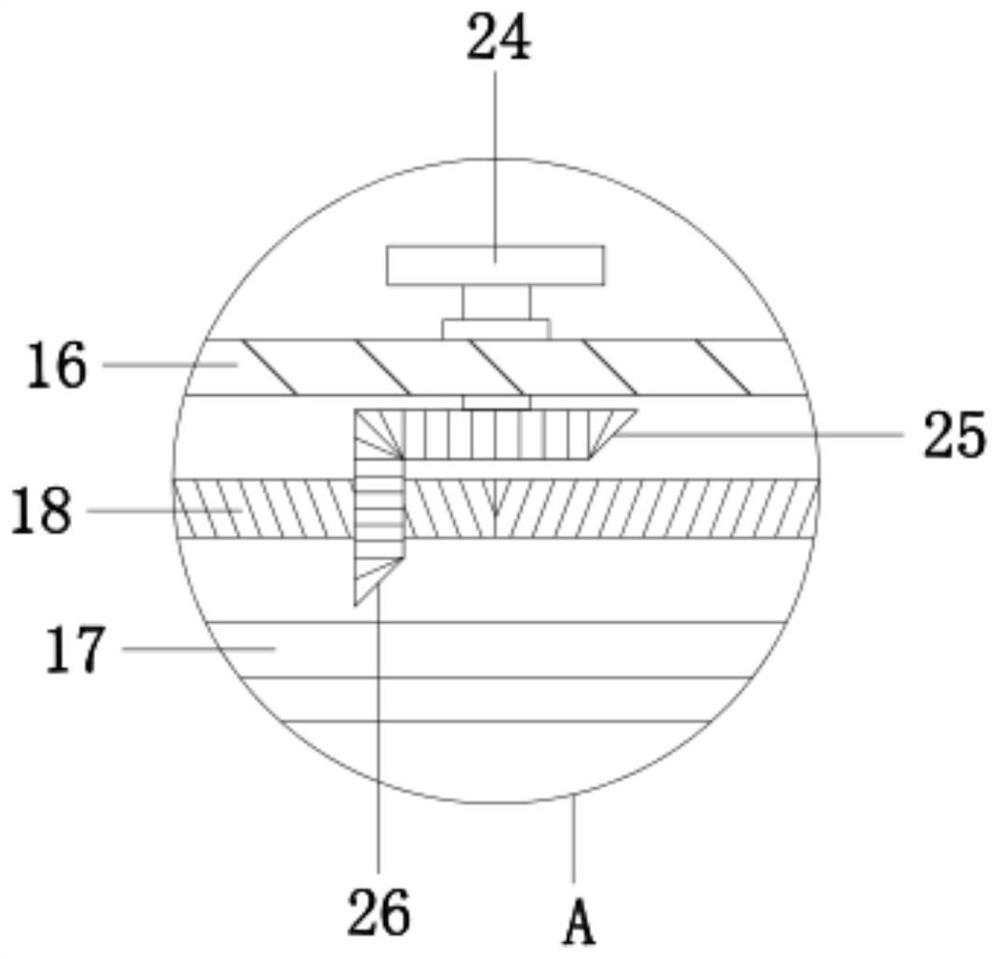

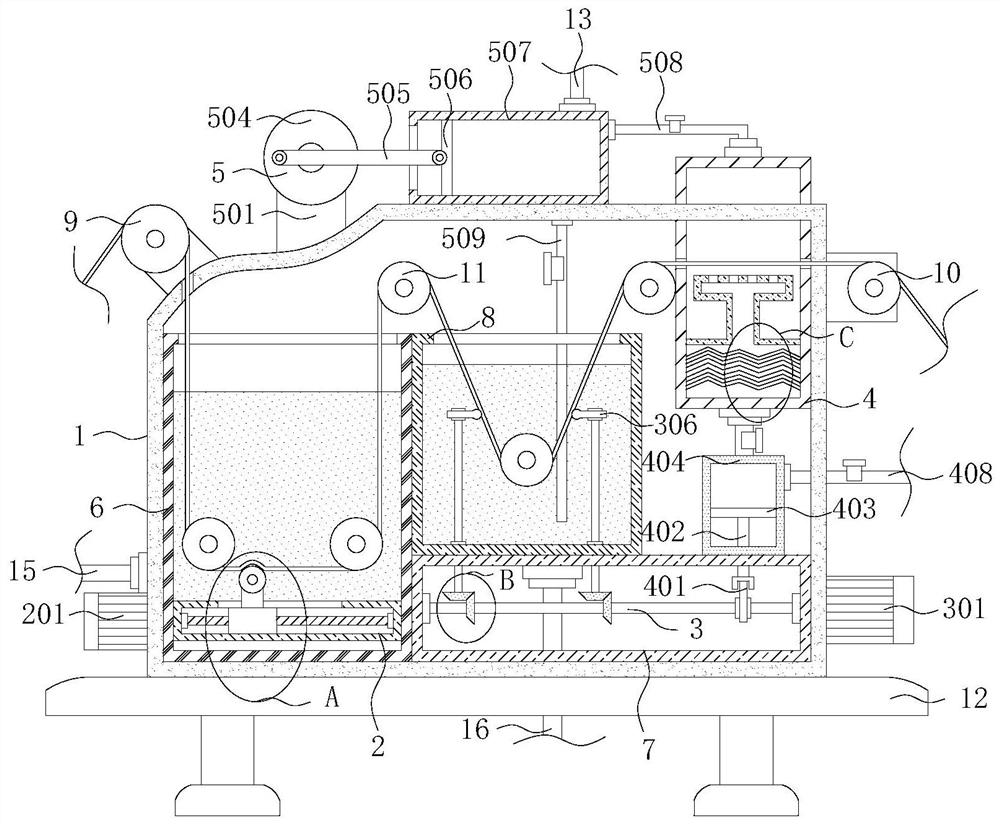

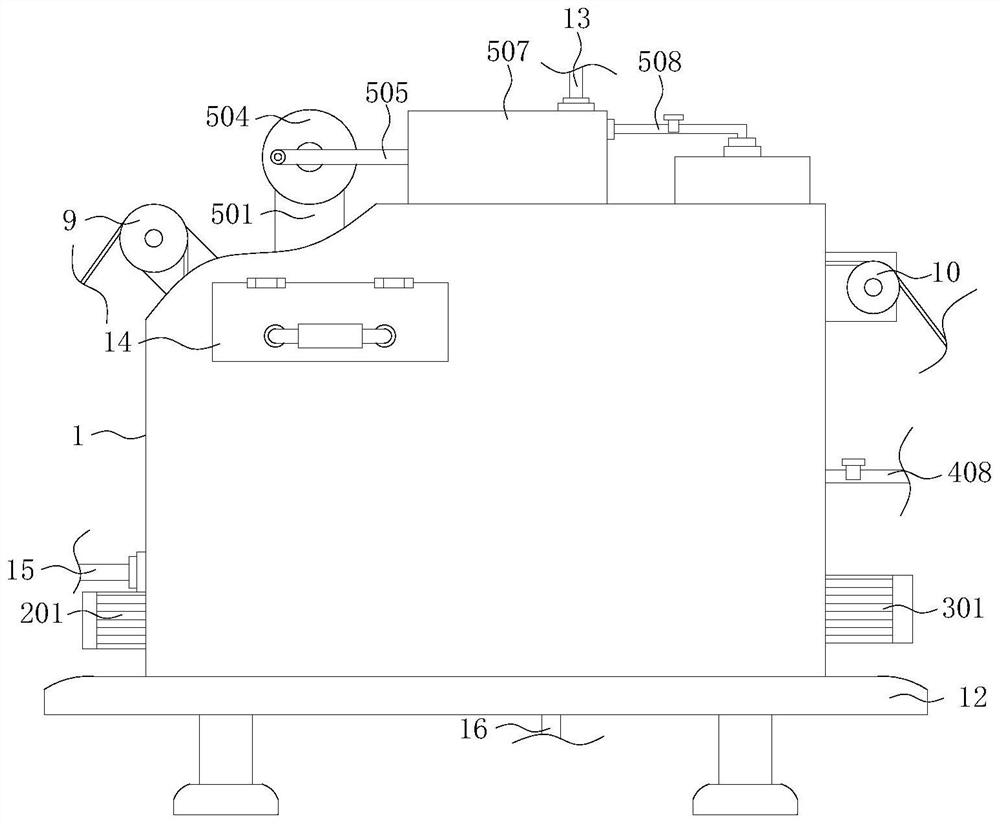

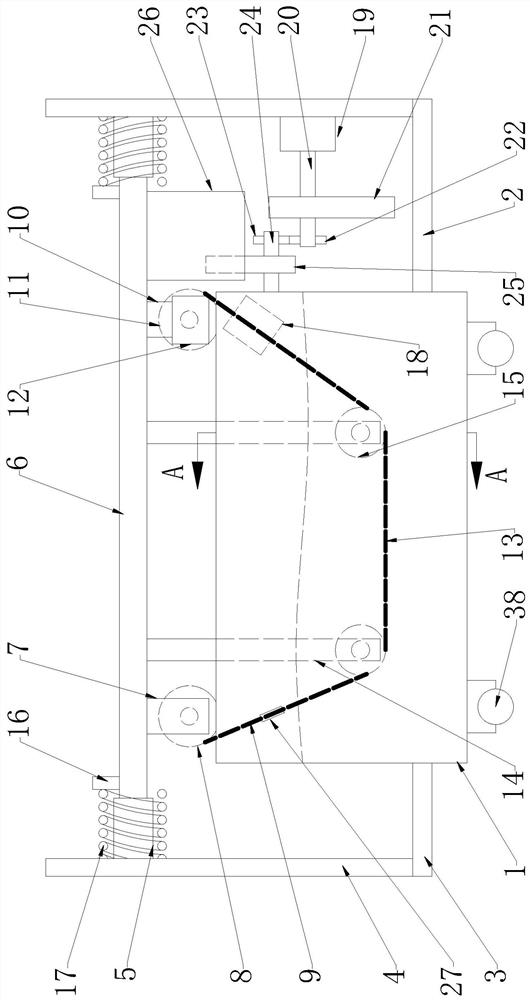

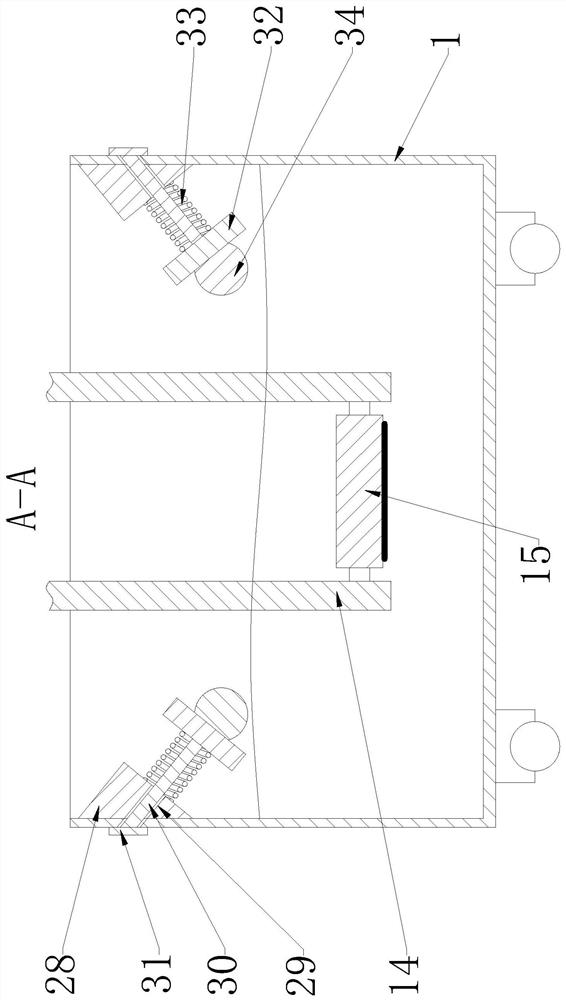

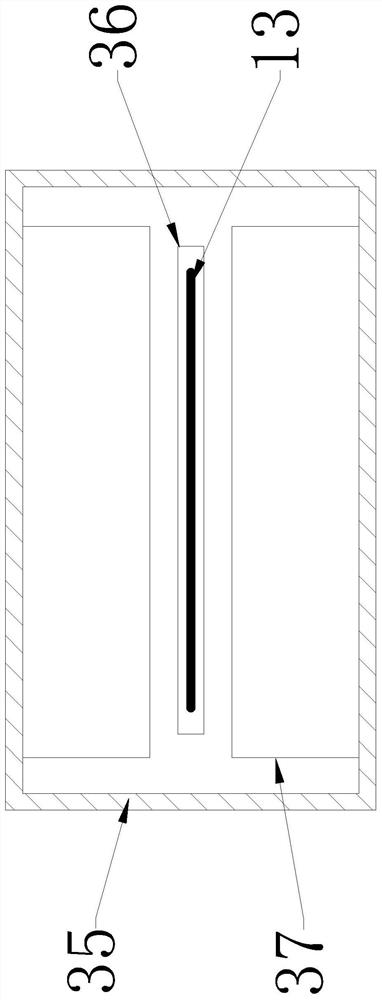

Efficient desizing machine

InactiveCN105887393AImprove desizing effectImprove efficiencySucessive textile treatmentsLiquid/gas/vapor removalAutomatic controlDrive motor

The invention relates to the technical field of dyeing and weaving equipment, in particular to an efficient desizing machine. The machine comprises a machine frame, a plurality of driving motors used for providing power, a water vapor supplying device for providing heat for the whole machine, and an automatic control system used for controlling the whole machine to operate, wherein the machine frame is provided with a cloth feeding mechanism, a wetting tank, a plurality of desizing mechanisms, a plurality of washing mechanisms and a cloth discharging mechanism in sequence into a production line, the wetting tank, the desizing mechanisms and the washing mechanisms are all connected with the water vapor supplying device, and a wetting and sprinkling pipe used for directly sprinkling cloth is arranged at the output end of the wetting tank; each desizing mechanism comprises a desizing roller, a desizing box and a desizing and cloth guiding roller, wherein the desizing roller and the desizing and cloth guiding roller are installed in the desizing box; each washing mechanism comprises a washing box, a washing roller, a plurality of washing and cloth guiding rollers and circulating pumps installed at the two ends of the washing box to enable hot water in the washing box to circulate. The machine is used for desizing in cloth dyeing and weaving.

Owner:晋江万兴隆染织实业有限公司

Enzyme oxygen-bath-low-temperature bleach process for fibre pretreatment

ActiveCN101509197AImprove qualityAvoid damageBiochemical fibre treatmentBleaching apparatusFiberGram

The invention discloses an oxidizing, bathing and low-temperature bleaching process for fiber pretreatment enzyme, which comprises the following steps: dissolving 1 to 2 grams per liter of osmotic agent in a treatment bath at a temperature of between 20 and 30 DEG C, putting textile into the treatment bath, and keeping the treatment bath flowing evenly and circularly; heating the temperature to 55 DEG C, adding 1 gram per liter of biological refining enzyme and 3 grams per liter of hydrogen peroxide into the treatment bath, adjusting the pH to be 7 to 9, and processing the treatment bath for 40 minutes; and heating the temperature to 80 DEG C, adding 3 grams per liter of low-temperature bleaching agent, treating the treatment bath at the temperature, then water washing, and entering the following processes. The process achieves low-temperature refining and low-temperature bleaching, and reaches the aim of low-temperature, environment-friendly, energy-saving and efficient preliminary treatment.

Owner:QINGDAO VLAND BIOTECH GRP

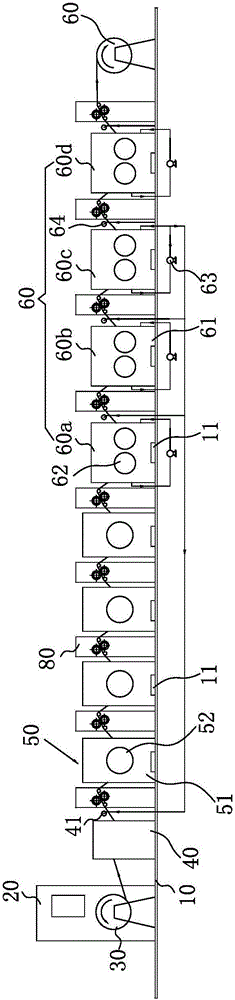

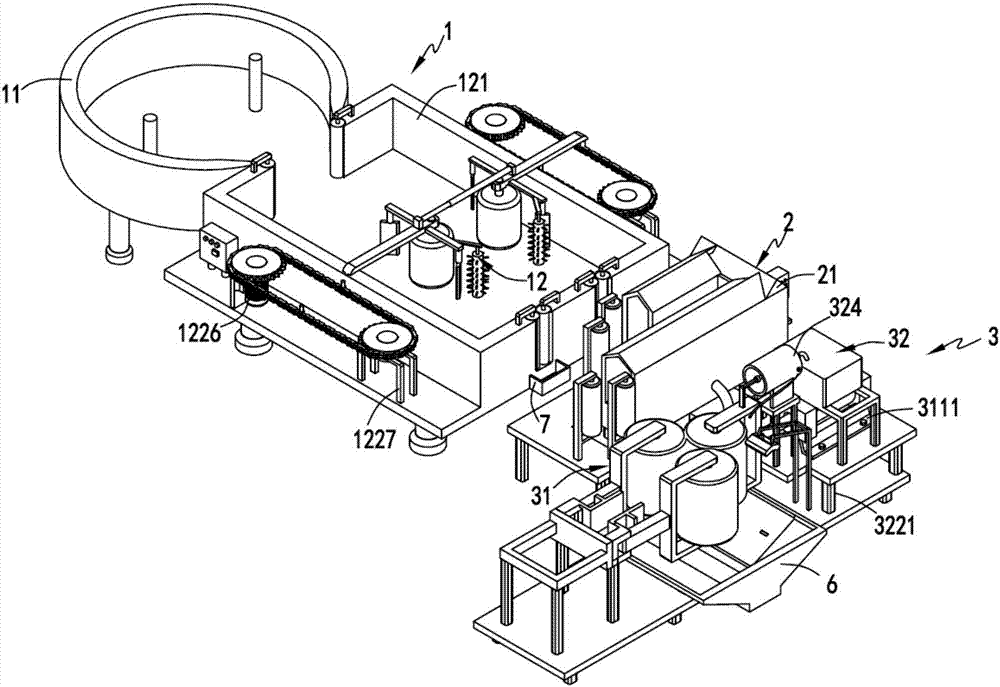

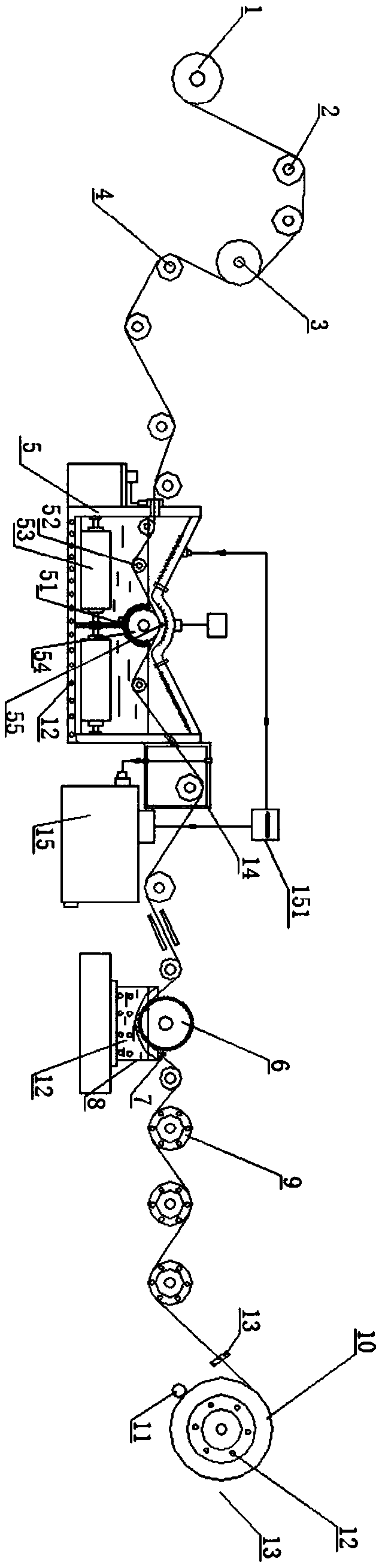

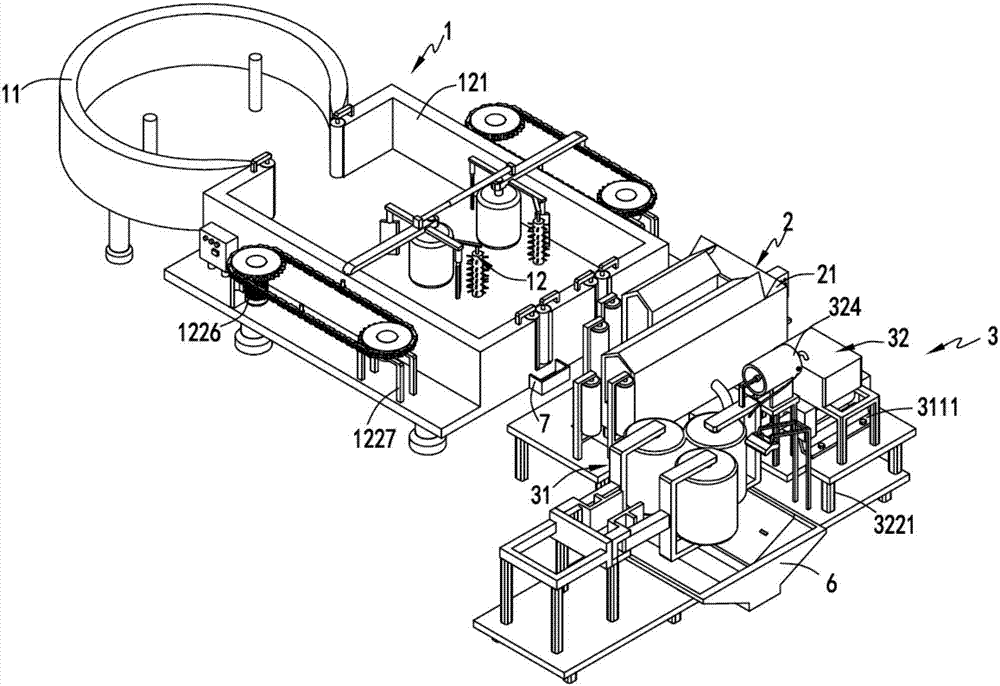

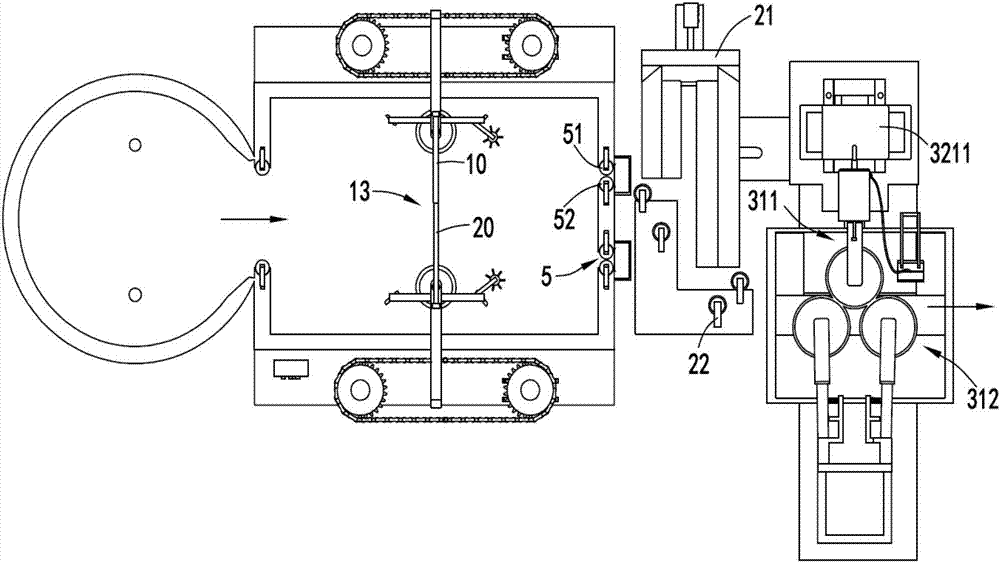

Textile fabric aftertreatment production line

InactiveCN107313194AIncrease reaction ratePromote decompositionSucessive textile treatmentsTextile treatment machine arrangementsProduction lineEngineering

The invention relates to a textile fabric post-processing production line, comprising a desizing part, the desizing part includes a soaking pool for releasing amylase and the fabric to be desized, and a soaking pool set at the rear end of the soaking pool The finishing mechanism for sorting the fabrics that are transported backwards; the steaming part, the steaming part is set at the rear end of the finishing mechanism, and the steaming part is used to steam the fabrics that have been sorted by the finishing mechanism while being transported; the rubbing and washing part The rubbing and washing part is arranged at the rear end of the steaming part. The rubbing and washing part includes a rubbing mechanism and a water washing mechanism. Under the drive of the kneading mechanism, the rolled fabric is sprayed and rinsed; the invention overcomes the problems of poor desizing effect of the fabric, uneven output of the desizing fabric and removal of stickers on the surface of the fabric .

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

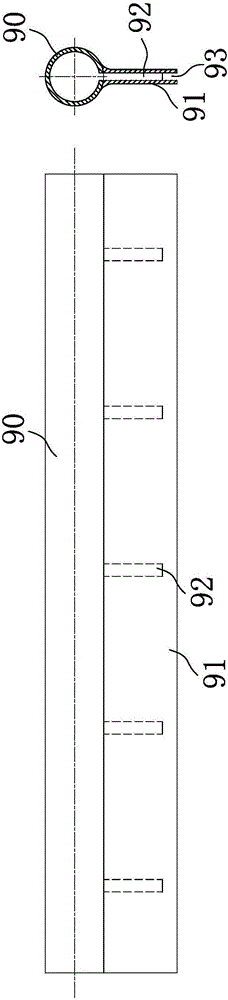

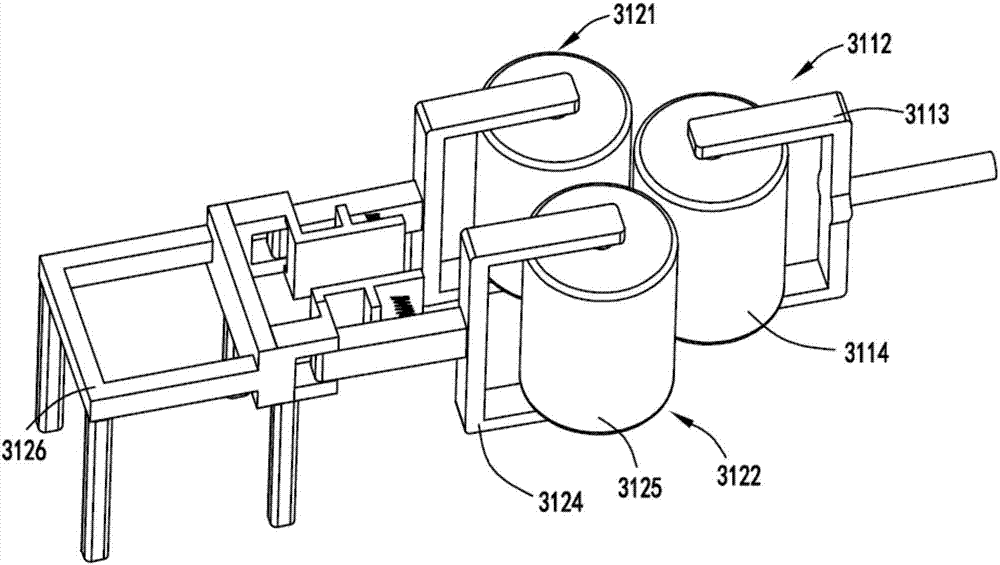

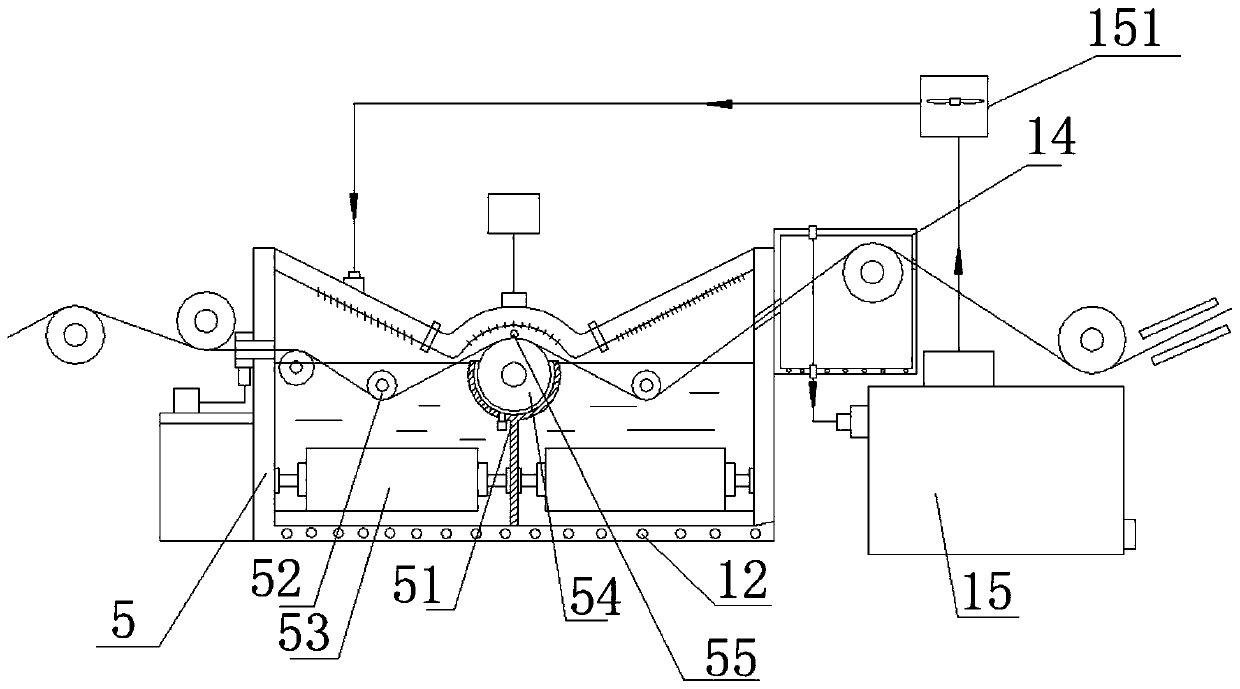

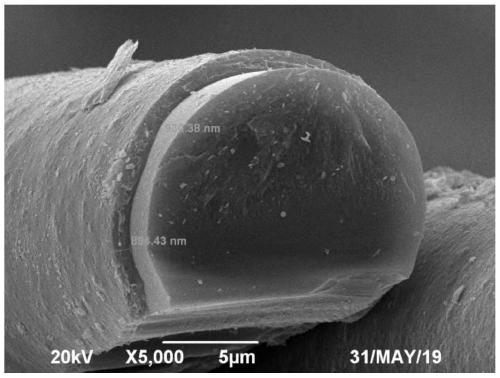

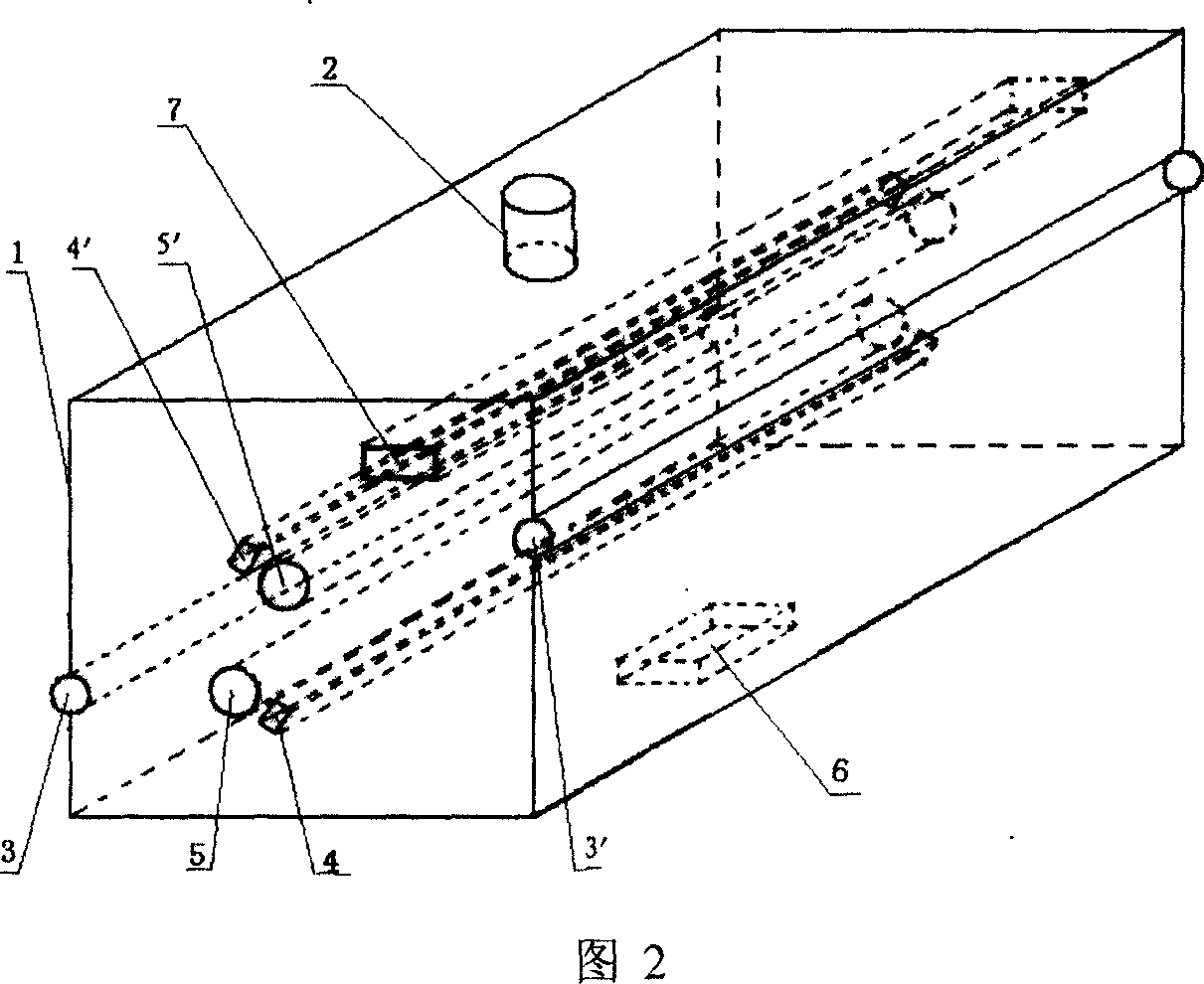

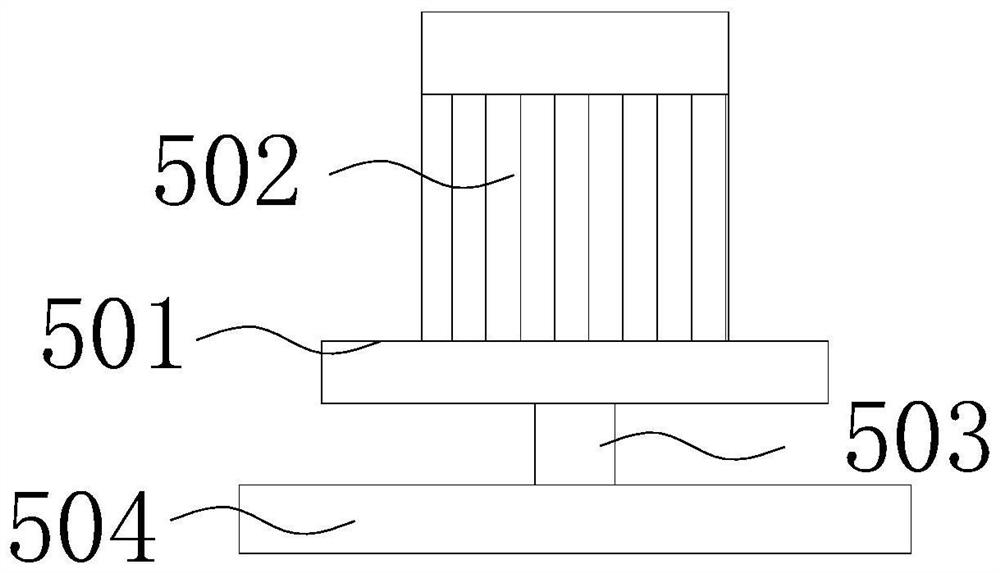

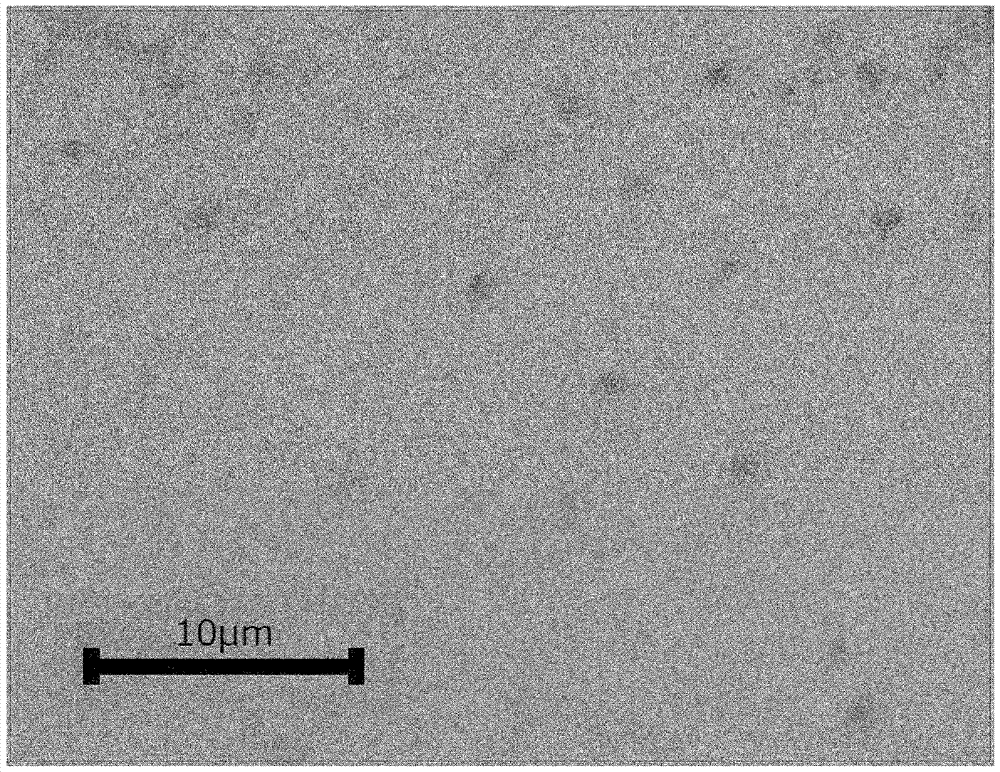

Preparation method and equipment of SiC fiber prepreg tape with attached interface layer

ActiveCN111058187AImprove toughnessAvoid wire breakageTextile treatment containersFibre treatmentSic fiberFiber bundle

The invention provides a preparation method of a SiC fiber prepreg tape with an attached interface layer. The preparation method comprises the following steps of introducing a continuous silicon carbide fiber bundle onto a tension pulley after being unwound through a godet roller and a guide wheel, sending the continuous silicon carbide fiber bundle straightly into a desizing device to expand thecontinuous silicon carbide fiber bundle; introducing the continuous silicon carbide fiber bundle onto a gluing device, so that glue fully infiltrates the continuous silicon carbide fiber, after that,introducing the continuous silicon carbide fiber bundle to a silk spreading device, and fully spreading and sizing the continuous silicon carbide fiber bundle by a drawing-in roller in the silk spreading device; and enabling the fully spread and sized continuous silicon carbide fiber bundle to enter a winding roller to obtain the flat and uniform prepreg tape. The prepreg tape prepared by the invention not only can greatly improve the toughness of the silicon carbide fiber, but also a deposited interface layer is uniform, meanwhile, the overlapped parts of two adjacent fiber bundles in the prepreg tape are few, the fiber bundle is good in flatness and thin in thickness, in addition, the preparation equipment can control parameters in real time, and full automation and complete controllability can be realized.

Owner:CENT SOUTH UNIV

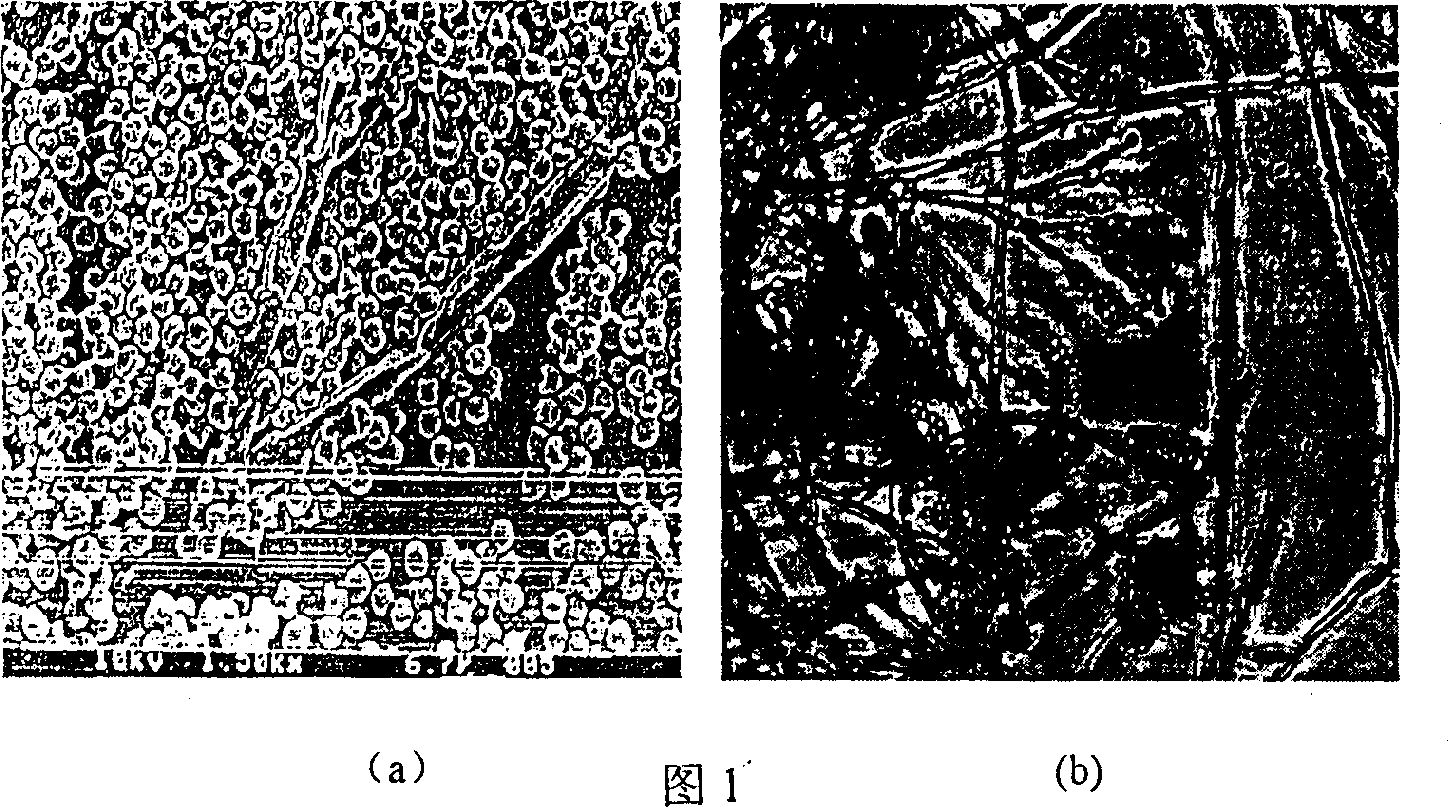

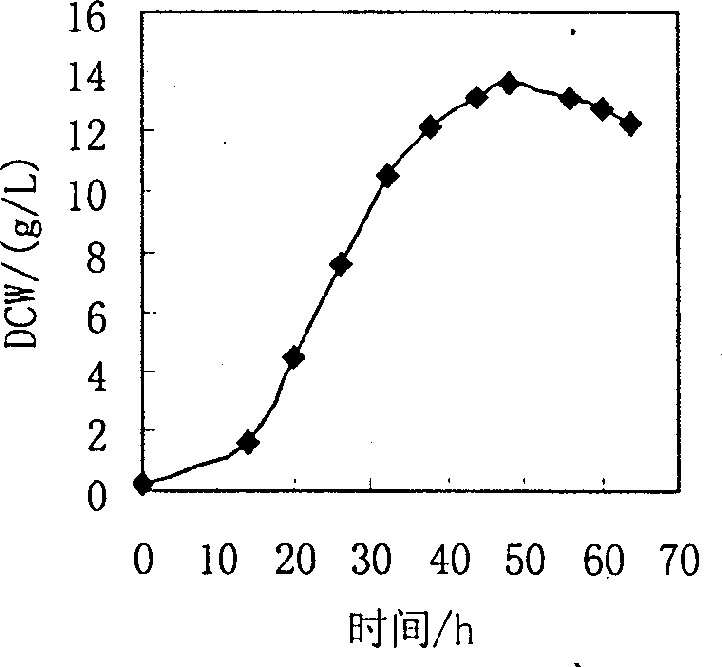

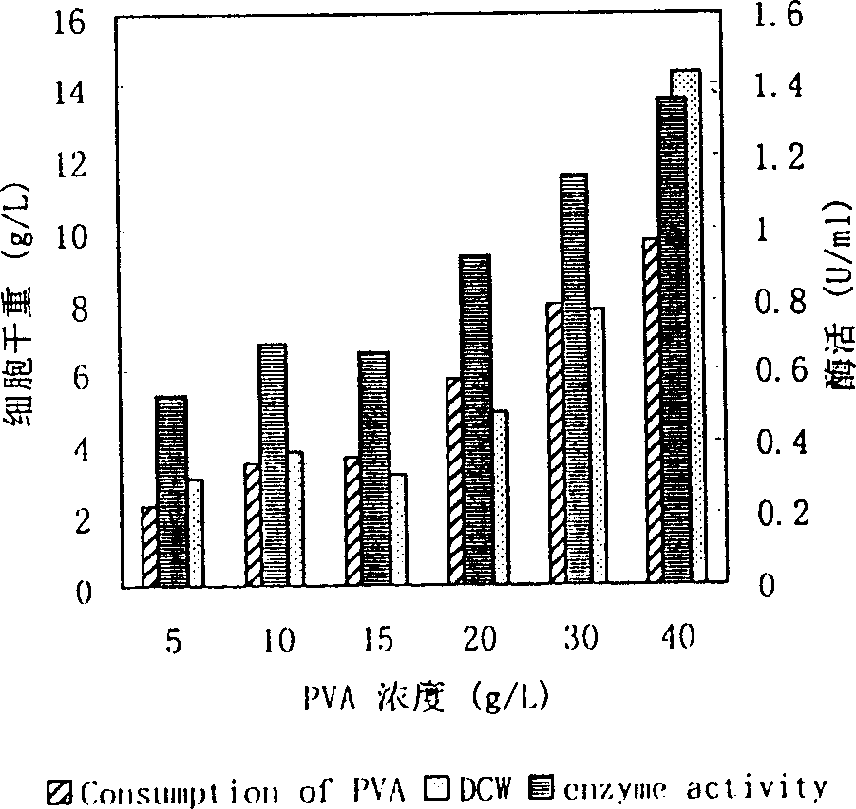

Polyninylalcohol degradative enzyme high productive bacteria and method of its seed selection and uses said bacteria to produce polyving/alcoho/ degradation enzyme by fermentation method

InactiveCN1513974AImprove desizing effectReduce energy consumptionFungiBiochemical fibre treatmentPenicilliumBio engineering

A Penicillium sp. (CCTCC No.M203035) for generating the degradative enzyme of PVA with high output is selectively cultured from the textile sewage through shake-flask culture. Its advantage is high and stable activity to degradate PVA.

Owner:JIANGNAN UNIV

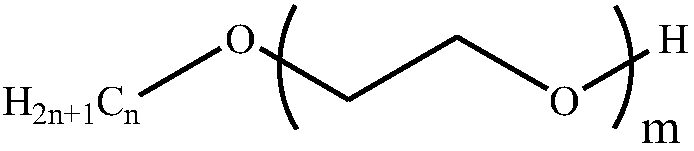

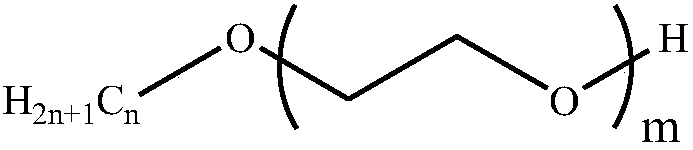

Multifunctional oxidizing desizing agent

InactiveCN102864622AImprove desizing effectImprove desizing efficiencyDry-cleaning apparatus for textilesPhosphorous acidALLYL SUCROSE

The invention discloses a multifunctional oxidizing desizing agent. The multifunctional oxidizing desizing agent is prepared by the following components in parts by weight: 3 to 5 parts of potassium peroxodisulfate, 1 to 3 parts of sodium bromite, 4 to 6 parts of sodium alkyl sulfate, 10 to 20 parts of fatty alcohol-polyoxyethylene ether, 1 to 3 parts of lauryl sodium sulfate, 1 to 3 parts of zinc stearate, 5 to 8 parts of polyacrylic acid, 1 to 3 parts of hydroxymethyl cellulose, 3 to 6 parts of phosphorous acid, and 80 to 100 parts of water. The multifunctional oxidizing desizing agent disclosed by the invention has a good effect of desizing, is suitable for various sizes, has a desizing effect on a plurality of mixing sizes, and is high in desizing efficiency; and the multifunctional oxidizing desizing agent has favorable stability to strong base bath.

Owner:WUJIANG YISHENG TEXTILE

Printing and dyeing technology capable of realizing high efficiency desizing

ActiveCN108930118AImprove desizing efficiencyImprove desizing effectSingeingTextile treatment machine arrangementsTreatment useState of art

The invention discloses a printing and dyeing technology capable of realizing high efficiency desizing. The printing and dyeing technology capable of realizing high efficiency desizing comprises following steps: 1, cloth is place on a conveyer belt, is conveyed into a singeing machine for singeing so as to remove nap on the cloth through singeing; 2, after singeing treatment, the cloth is conveyedinto a desizing machine for desizing treatment using a desizing roller in the desizing machine; 3, after desizing treatment, the cloth is conveyed into a boiling off machine using the conveyer belt for high temperature boiling off using the boiling off machine; 4, after boiling off, the cloth is subjected to impurity removing treatment using an impurity removing device of the boiling off machine;5, after impurity removing, the cloth is subjected to water washing in a water washing tank; and 6, after water washing, the cloth is conveyed into a dyeing machine for dyeing treatment using the dyeing machine. Compared with the prior art, the advantages are that: cloth desizing efficiency is increased greatly, printing and dyeing effect is excellent, and labor intensity is low.

Owner:ASHFORD TEXTILE ZHANGZHOU

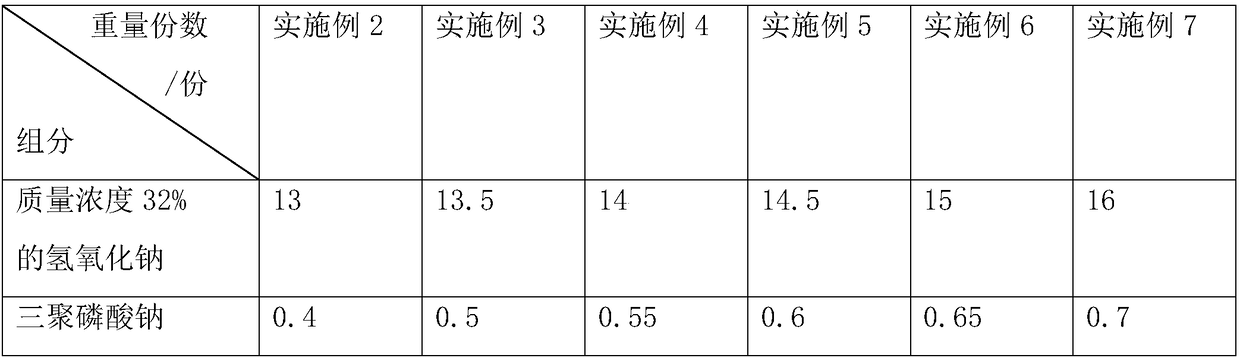

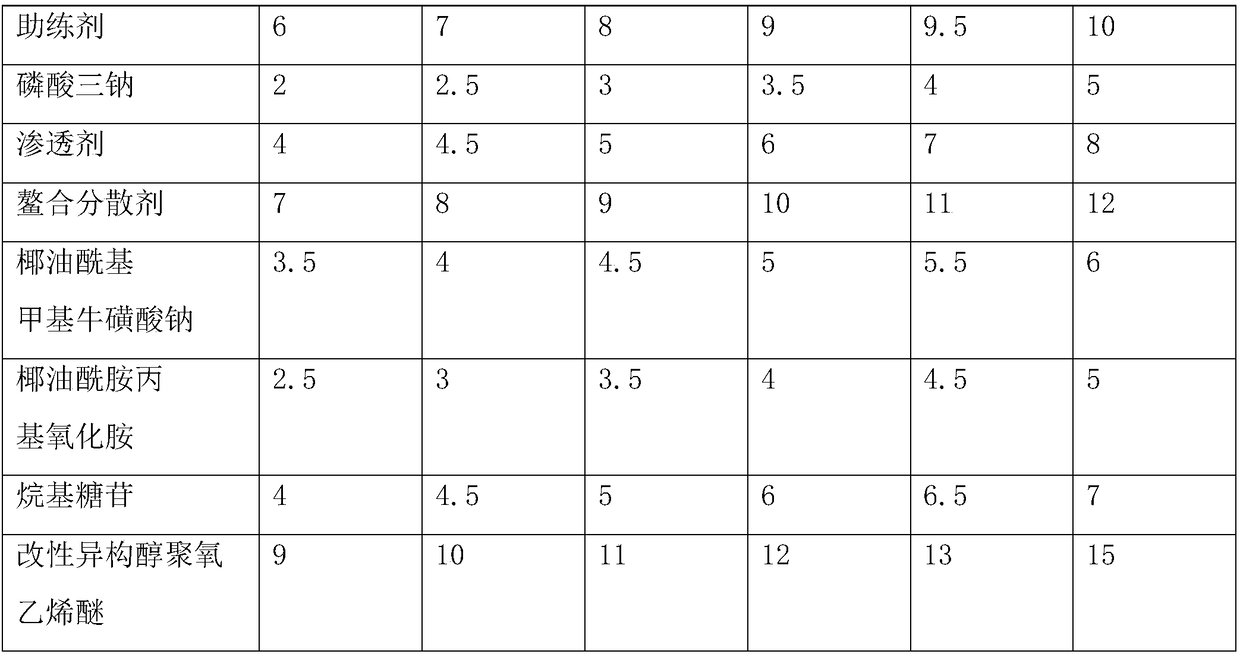

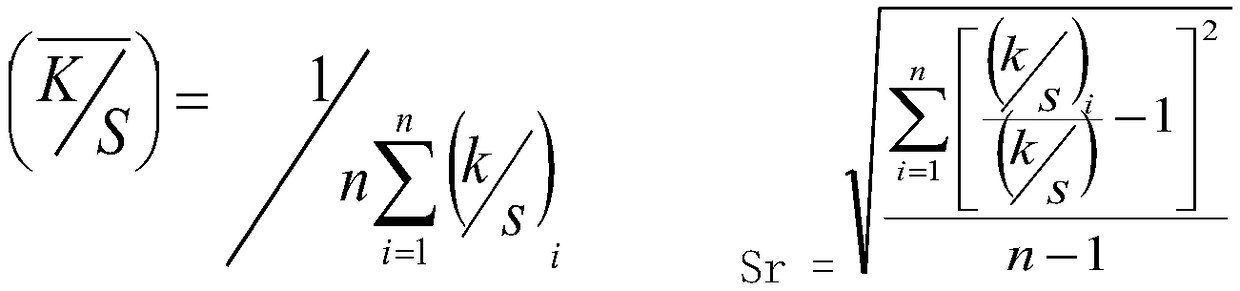

Refining desizing process for chemical fiber fabric

The invention discloses a refining desizing process for a chemical fiber fabric, and relates to the technical field of textile printing and dyeing pretreatment, and the refining desizing process comprises the following steps: (1) pre-shrinking; (2) refining, wherein a refining liquid is composed of the components, by weight, of 12-16 parts of sodium hydroxide with the mass concentration of 32%, 0.3-0.7 part of sodium tripolyphosphate, 5-10 parts of a refining aid, 1-5 parts of trisodium phosphate, 3-8 parts of a penetrating agent, 6-12 parts of a chelating dispersant, 3-6 parts of sodium cocoyl methyl taurate, 2-5 parts of cocamidopropyl amine oxide, 3-7 parts of alkyl glycoside and 8-15 parts of isomeric alcohol polyoxyethylene ether; wherein the grinding aid comprises the components of sodium hydrogen sulfite, sodium silicate and alkyl sulfate in a mass ratio of 2: 3: 3; (3) water washing; (4) steaming; (5) enzyme water washing; and (6) shaping. According to the invention, the problems that the desizing effect of the chemical fiber fabric is poor, and the dye uptake and the dyeing uniformity are poor are solved; a refining agent is used for refining and desizing the chemical fiber fabric, the desizing rate is high, and the dye uptake and the leveling property are good.

Owner:嘉兴市嘉盛印染有限公司

Textile fabric desizing equipment for textile use

InactiveCN111648074AEasy to clamp limitMeet the needs of useTextile treatment machine arrangementsTextile treatment carriersStructural engineeringDesizing

The invention discloses textile fabric desizing equipment for textile use. The textile fabric desizing equipment for textile use comprises a concave rack, two chutes, slide blocks, a hollow plate, first screws, a belt wheel, a belt, a first motor, a reciprocating mechanism and a clamping mechanism, wherein a port is formed in the top end of the concave rack; the two chutes are separately formed inthe top ends of the left and right sides of an inner cavity of the concave rack in a front-back direction; the slide blocks are embedded into the inner cavities of the chutes and the inner sides of the slide blocks extend outside the chutes; a hollow plate is fixedly mounted inside the slide blocks and connects the two slide blocks; and the two first screws are separately mounted on the left andright sides of the top end of the inner cavity of the hollow plate through a bearing, and the bottom ends of the first screws extend outside the hollow plate. According to the textile fabric desizingequipment for textile use, a textile fabric impregnated in a desizing liquid moves in a reciprocating manner, so that the desizing effect is improved and the desizing time is shortened. The textile fabric desizing equipment for textile use can be convenient to clamp and limit textile fabrics of different widths, so that the using demand of an enterprise is met, and the textile fabric desizing equipment for textile use is widely popularized favorably.

Owner:新昌县才珏纺织机械有限公司

Pretreating equipment for improving yarn sizing performance

The present invention relates to a pretreatment equipment capable of on-line improving yarn sizing performance for sizing machine. Said pretreatment equipment can be mounted between the warping beam frame of sizing machine and size box, and is formed from the following several portions: box body, guiding roller, high-voltage discharge heads, ozonator, UV irradiation device and sealing rubber-covered roll. Said invention also provides the working principle of said pretreatment equipment and its operation method.

Owner:WUHAN TEXTILE UNIV

Cold-batching and open-width desizing process for chemical fiber fabric

InactiveCN109306619AImprove desizing effectGuaranteed uniformityDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsFiberTextile printer

The invention discloses a cold-batching and open-width desizing process for a chemical fiber fabric, and relates to the technical field of textile printing and dyeing pretreatment. According to the technical scheme, the process comprises the following steps: S1, padding of a cold-batching treatment solution placing the chemical fiber fabric in a padding groove for padding, and padding the cold-batching treatment solution with an evenness padder, wherein the padding groove is filled with the cold-batching treatment solution, and the bath ratio of the cold-batching treatment solution and the chemical fiber fabric is 1 to (1.5 to 1.8); S2, cold-batching treatment; S3, water washing; S4, first open-width desizing; S5, second open-width desizing; S6, unwinding and water washing. By adopting thecold-batching and open-width desizing process, the problems of low dyeing percentage and poor dyeing evenness caused by a poor desizing effect of the chemical fiber fabric are solved. A cold-batchingprocess and an open-width process are combined, so that the chemical fiber fabric can be desized completely, and higher dyeing percentage and dyeing evenness are achieved.

Owner:新天地纺织印染(嘉兴)有限公司

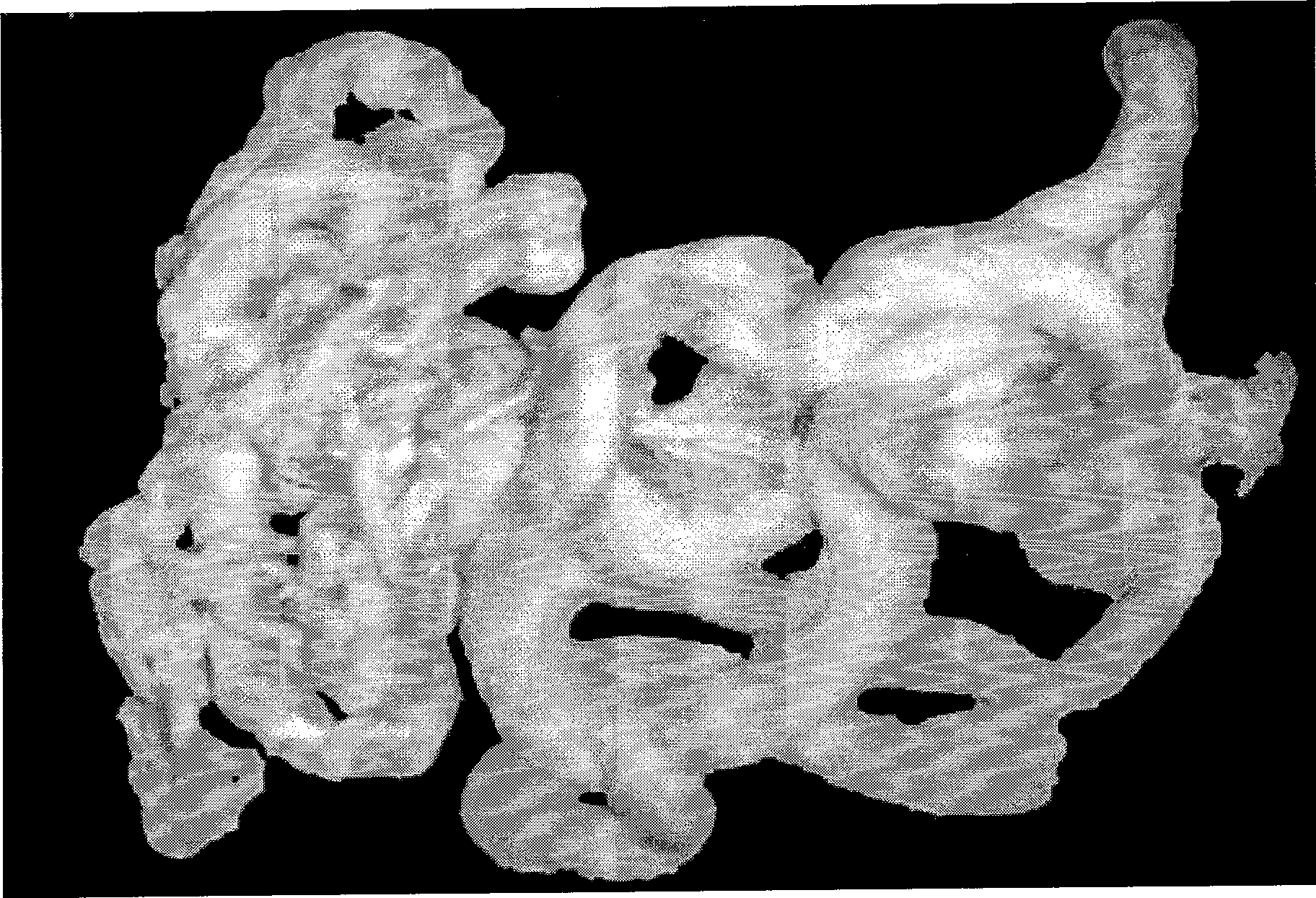

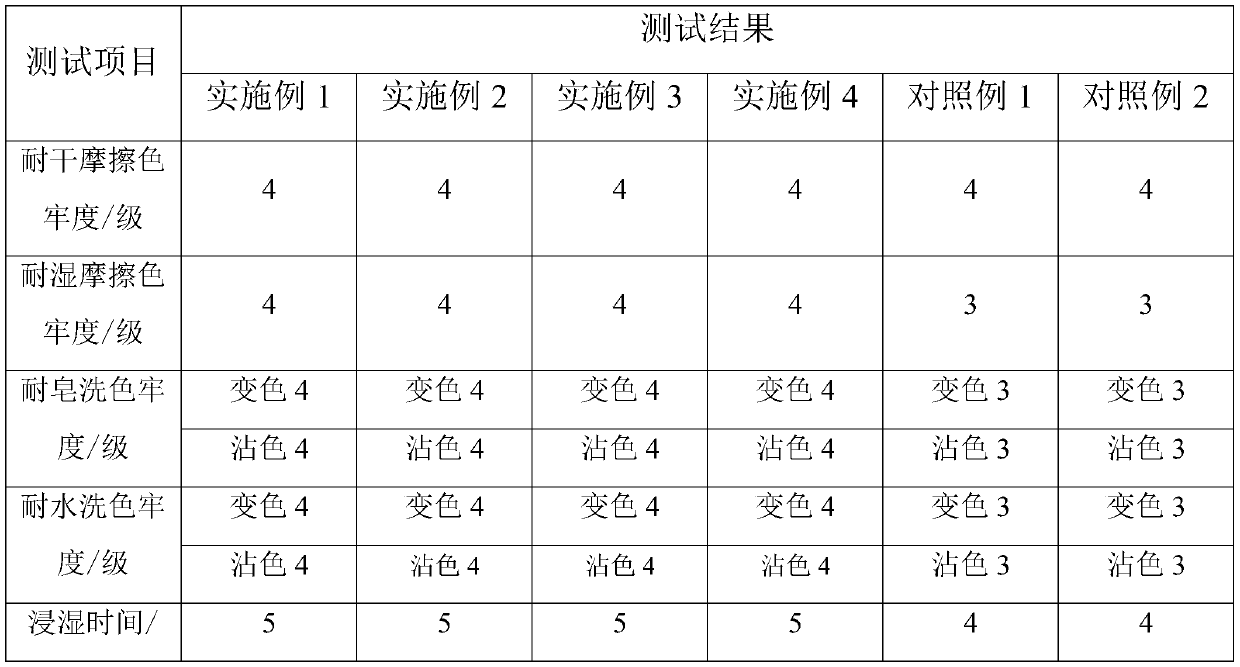

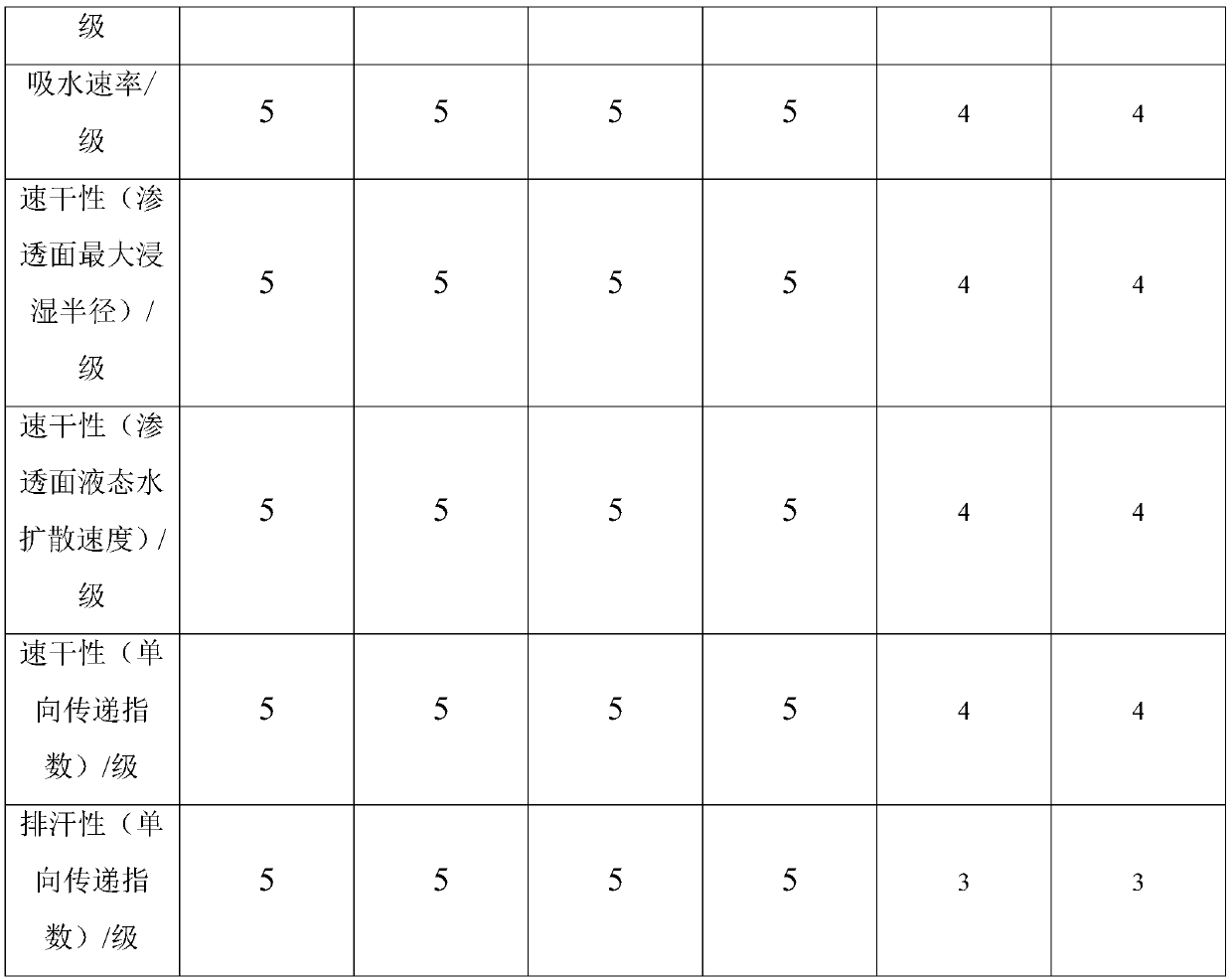

Preparing method of chamois-imitation fabric

InactiveCN109868664AEfficient removalGood desizing effectFibre typesDry-cleaning apparatus for textilesPolyesterMoisture absorption

The invention discloses a preparing method of a chamois-imitation fabric, and belongs to the technical field of fabrics. The preparing method includes the following step of conducting desizing, alkali-peeling splitting, presetting, sanding, dyeing and postprocessing to obtain a polyester sea-island filament gray fabric so as to prepare the chamois-imitation fabric. The prepared chamois-imitation fabric is wide in application range, good in moisture absorption and sweat releasing performance, excellent in antistatic effect, high in softness and excellent in color fastness.

Owner:晋江市维丰织造漂染有限公司

Biological enzyme airflow dyeing process of soybean protein/modal fiber fabric

ActiveCN107190527AImprove permeabilityFully dispersedDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsFiberPre treatment

The invention discloses a biological enzyme airflow dyeing process of a soybean protein / modal fiber fabric. The process is characterized by comprising the following specific steps: (1) carrying out desizing pre-treatment by a biological enzyme; (2) carrying out shortened steaming and oxygen bleaching treatment; (3) carrying out steam flow biological enzyme polishing treatment; (4) carrying out airflow dyeing treatment; (5) carrying out drying treatment; (6) carrying out finishing, softening and pre-shrinking to obtain a finished product. By adopting the biological enzyme airflow dyeing process disclosed by the invention, the soybean protein / modal fiber fabric can be effectively subjected to dyeing pre-treatment operation, so that two types of different fiber substances react moderately in a biological enzyme desizing treatment process, and the fiber substances are not damaged; meanwhile, the process has the advantages of environment friendliness, energy saving and high efficiency; a production process adopts an improved airflow dyeing process, so that the soybean protein / modal fiber fabric can be used for solving the problems that the coloring degree is not uniform, the coloring speed is rapid and a fabric is easily dyed unevenly; an active dyestuff can smoothly and stably enter two fibers and is combined with a basic bond, so that the aims of permeable dyeing and even dyeing are realized.

Owner:SHISHI LONGXINGLONG TEXTILE IND CO LTD

Desizing agent for synthetic fiber

InactiveCN102839532AGood desizing effectDesizing fitDry-cleaning apparatus for textilesAlkylphenolChloride

The invention discloses a desizing agent for a synthetic fiber. The desizing agent consists of the following components in parts by weight: 3-6 parts of sodium hydroxide, 10-20 parts of alkylphenol polyoxyethylene, 10-20 parts of ethanol, 1-3 parts of sodium hexametaphosphate, 1-3 parts of potassium chloride, 10-20 parts of fatty alcohol, 5-8 parts of polyvinylpyrrolidone, 1-3 parts of methylcellulose and 120-160 parts of water. Compared with the prior art, the desizing agent has the beneficial effects of good desizing effect, suitability for desizing under various conditions, ready availability of raw materials, simple preparation process and low cost.

Owner:WUJIANG YISHENG TEXTILE

Desizing fluid for pretreatment of cotton woven fabric

InactiveCN102817246AAvoid damageImprove desizing effectBiochemical fibre treatmentVegetal fibresStarch breakdownNaCl - Sodium chloride

The invention discloses desizing fluid for pretreatment of cotton woven fabric. The desizing fluid comprises, by weight, 12-25 parts of 12% hydrogen peroxide, 4.5-6 parts of argon sodium bromate, 30-50 parts of amylolytic enzyme, 15-25 parts of sodium chloride, 2-6 parts of penetrant, and 100 parts of water. Effective desizing and reduced damage of the cotton woven fabric by desizing can be achieved by organic combination of enzymes, oxidants and the like. In addition, pollution discharge can be reduced as the desizing fluid is improved.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

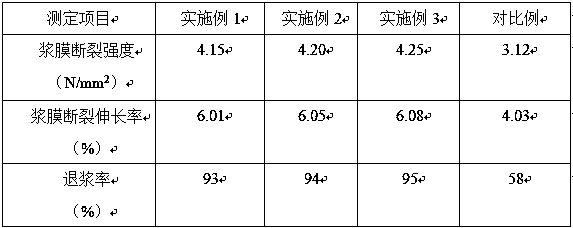

Preparation method of starch-grafted composite glutin sizing

InactiveCN110016808ACatalytic hydrolysisReduce the degree of polymerizationFibre typesFiberMonoglyceride

The invention relates to a preparation method of starch-grafted composite glutin sizing, and belongs to the technical field of textile materials. By adding hydrogenated sheep oil and hydrogenated castor oil, composite sizing is prepared, and hydrogenated sheep oil and hydrogenated castor oil have emulsifying properties under the action of tridecanol polyoxyethylene ether and monoglyceride, can beevenly mixed in the sizing, play roles in plasticizing and improve the sizing percentage of the sizing. When grease is added in an adhesive containing polar groups, grease molecules can destroy physical crosslinking points of adhesive macromolecules and make it impossible for the polar groups of the macromolecules to establish interaction and hydrogen bonds, original non-moving chain segments begin to move, the vitrification temperature of serosas is reduced, and the serosas become softer. Besides, intervals between grease molecules make cohesive force between adhesive molecules reduced, a serosa structure thus relaxes, the strength is reduced, meanwhile the adhesive molecules are kept from fully moving close to fiber due to isolation of the grease molecules, and the desizing percentage ofthe sizing can be effectively improved.

Owner:常州市泰英物资有限公司

Textile size for PVA-free sizing of medium-and-high-count pure cotton fabric warps

ActiveCN109295718AStrong adhesionGood film formingAbrasion resistant fibresVegetal fibresYarnCellulose fiber

The invention discloses a textile size for PVA-free sizing of medium-and-high-count pure cotton fabric warps, and belongs to the field of textiles. The size comprises 30-50 wt% of starch and 50-70 wt%of assistants, and the assistants comprise 30-60 wt% of Arabic gum, 20-40 wt% of pectin, 10-20 wt% of polyacrylic acid-acrylamide and 4-10 wt% of botanical oil. The size has strong adhesion to cottonfiber, viscose glue and other cellulose fiber yarns, makes yarns be soft and smooth and have few reborn fluffs, less size falling and good desizing performance, can completely replace PVA sizing in sizing of 30 to 60 medium-and-high-count pure cotton fabric warps, and obtained sized yarns are soft and smooth, and have few reborn fluffs, less size falling, good weavability and a high blooming efficiency reaching 92% or above.

Owner:JIANGNAN UNIV

Textile fabric desizing device for textile operation

InactiveCN112251955AFully desizingImprove desizing effectLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsElectric machineryProcess engineering

The invention discloses a textile fabric desizing device for textile operation, and relates to the technical field of fabric desizing. The textile fabric desizing device for textile operation comprises a box body, wherein a sliding mechanism, a beating mechanism, a drying mechanism and a backflow mechanism are arranged in the box body, a desizing box is fixedly mounted at the bottom of the inner side of the box body, an opening is formed in the outer surface of the top of the desizing box, a mounting box is fixedly mounted at the bottom of the inner side of the box body, a hot water tank is fixedly mounted on the outer surface of the top of the mounting box, and an opening is formed in the outer surface of the bottom of the hot water tank. According to the textile fabric desizing device for textile operation, through cooperative use of a first motor, a mounting plate, a sliding groove, a threaded rod, a sliding block and a peristaltic cam, the surface of cloth during desizing is flattened, the contact area between the cloth and desizing liquid during desizing is increased, the cloth is desized more sufficiently, the cloth desizing effect is improved, and the efficiency of the device is improved.

Owner:湖州恒晨纺织品有限公司

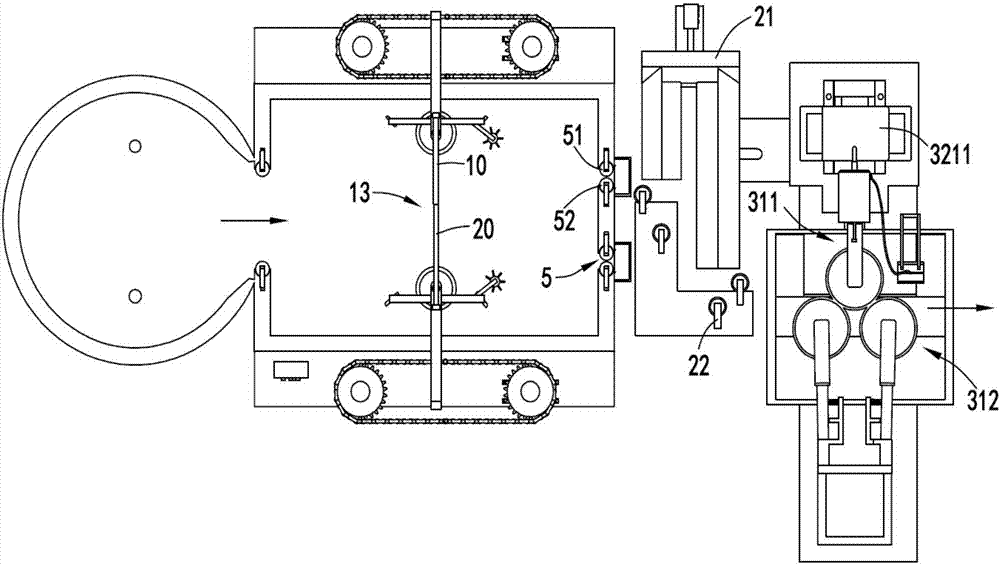

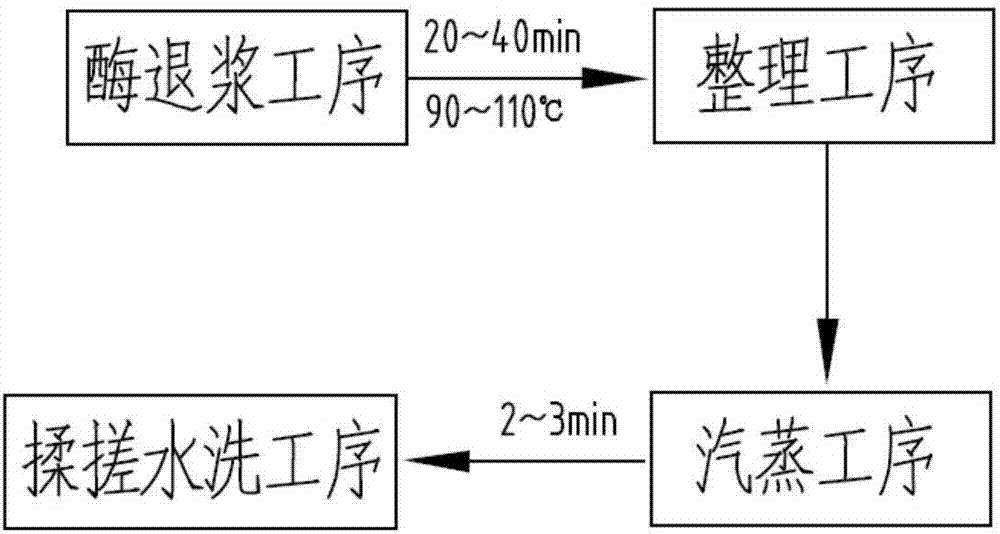

Textile fabric aftertreatment production technology

InactiveCN107313240AEasy to transportIncrease reaction rateFabric breaking/softeningDry-cleaning apparatus for textilesEngineeringMechanical engineering

The invention relates to a textile fabric aftertreatment production technology. The textile fabric aftertreatment production technology comprises the following processing steps: a, an enzyme desizing process, soaking to-be-desized fabric into amylase; b, a finishing process, backwards transporting textile fabric which is soaked in the amylase and is desized in the step a, smoothening the fabric during a transportation process through the matching of two smoothening devices, and removing sundries around the fabric during a smoothening process; c, a steaming process, carrying out steaming treatment while backwards transporting the fabric which is smoothened and in which the sundries are removed in the step b; d, a twisting and washing process, carrying out bidirectional rolling and twisting on the fabric along a forward direction and a reverse direction of a transportation direction of the fabric while transporting the fabric of which the steaming treatment is completed in the step c, softening the fabric, and spraying water to wash impurities on the surface of the fabric of which the bidirectional rolling and twisting is completed by a washing mechanism. According to the textile fabric aftertreatment production technology disclosed by the invention, the problems that desizing and washing technological effects are poor and the processes are incompact are solved.

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

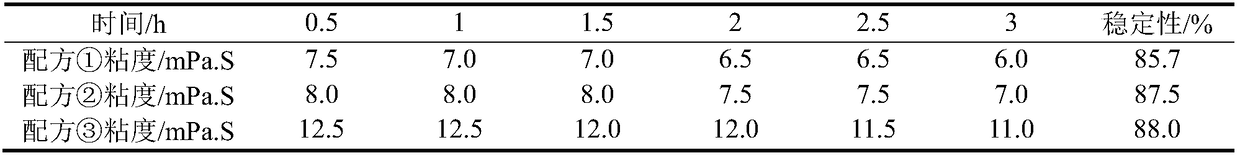

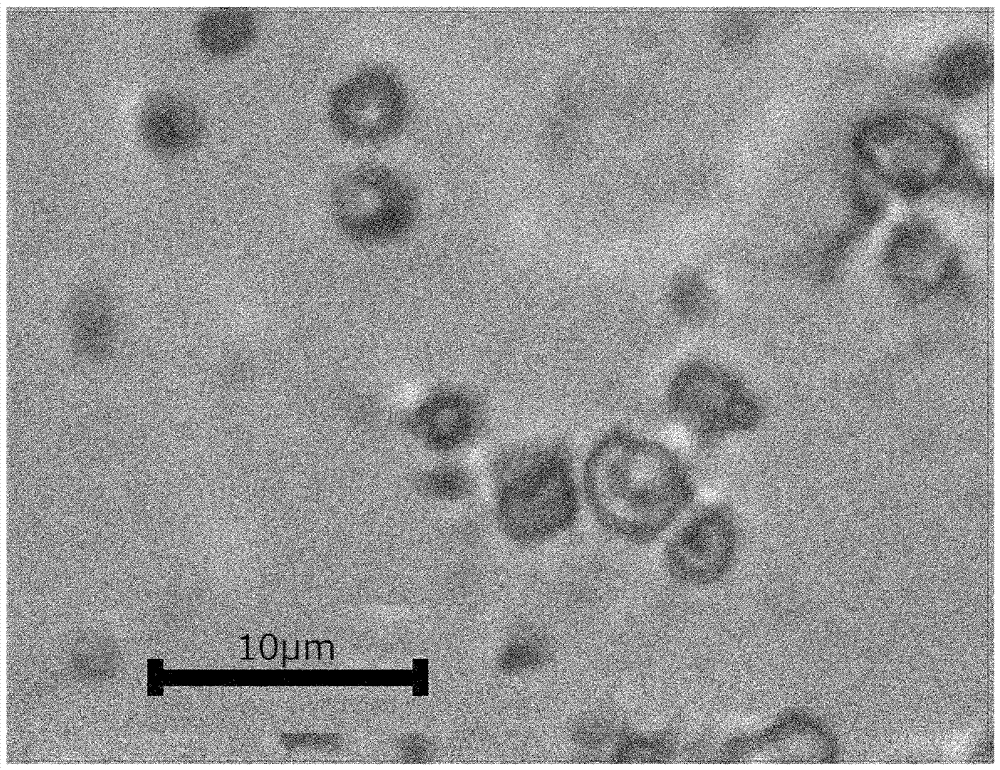

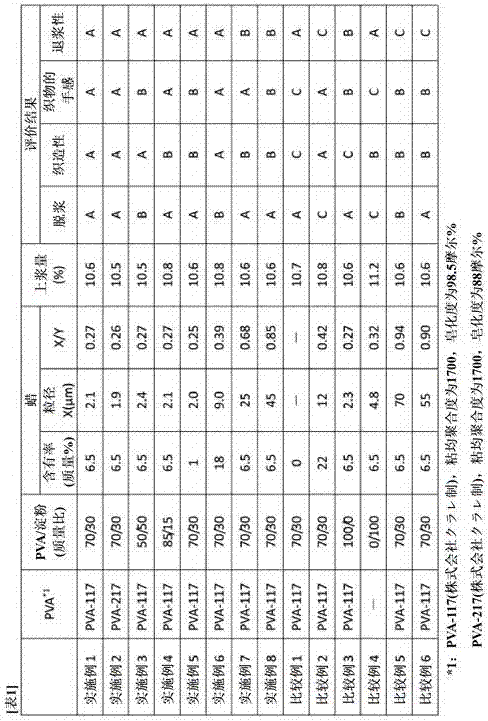

Fibre sizing agent

A fibre sizing agent containing polyvinyl alcohol, starch, and wax, said fibre sizing agent being characterised in that: the viscosity average polymerisation degree of the polyvinyl alcohol is 200-5000; the saponification degree of the polyvinyl alcohol is 70-99.5 mol%; the mass ratio of the polyvinyl alcohol and the starch is 90 / 10-1 / 99; the wax content is 0.5-20 mass% relative to the total solid content; the concentration of solid content included in the fibre sizing agent is 10 mass%; and the average particle size (X) of the wax in an aqueous dispersion prepared at 70 DEG C is 0.1-50 mum. Thus, provided is a fibre sizing agent with which desizing when dividing can be reduced and which has excellent weavability, fabric texture, and desizing properties.

Owner:KURARAY CO LTD

Textile fabric desizing equipment for textiles

PendingCN112176591AEasy desizingImprove desizing effectLiquid/gas/vapor removalTextile treatment carriersEngineeringPower apparatus

The textile fabric desizing equipment for textiles comprises a desizing box, rotating columns, a fourth supporting plate, a fabric, sixth supporting plates, a second power device, a first rotating shaft, a first cam, a first gear, a second gear, a second rotating shaft and a second cam, wherein third supporting plates are arranged on a first supporting plate and a second supporting plate; the rotating columns are arranged on the third supporting plate; the fourth supporting plate is arranged on the two groups of rotating columns; the fabric is wound on holding rollers; winding rollers are arranged on the two groups of sixth supporting plates; guide rollers are arranged at the bottoms of two groups of seventh supporting plates; the second power device is in transmission connection with thefirst rotating shaft; the first cam is in key connection with the first rotating shaft; the second gear is meshed with the first gear; the second cam is in key connection with the second rotating shaft; and a baffle is arranged at the bottom of the fourth supporting plate. According to the desizing equipment, the fabric swings back and forth in desizing liquid, and the desizing effect of two facesof the fabric is guaranteed; meanwhile, through connection between a standby fabric and the fabric, desizing can be conveniently carried out on the starting end of the fabric.

Owner:SUZHOU BABEL TEXTILE TECH CO LTD

A Rope Pretreatment Process Based on Low Alkali Scouring Agent

ActiveCN105803799BImprove gross effectImprove desizing effectBiochemical treatment with enzymes/microorganismsVegetal fibresWastewaterOxygen

The invention relates to a rope-form pretreatment process based on a low-alkaline scouring agent. The process comprises steps of batching, singeing, enzyme desizing, rope-form low-alkaline scouring with a two-step method and rope-form oxygen bleaching. The enzyme desizing efficiency is improved by the aid of an efficient penetrant, a sizing agent on fabric is effectively removed by using the low-alkaline scouring agent, and the use amount of alkali in the scouring process is reduced. The use amount of caustic soda is reduced while the pretreatment effect is guaranteed, the pH value of wastewater is reduced, and the biodegradability of the wastewater is improved.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Novel dyeing and finishing processing technology of micro polyester fabric

ActiveCN102628211BReduce wrinklesReduce staining and chafingHeating/cooling textile fabricsDry-cleaning apparatus for textilesDisperse dyeThree stage

Owner:SHENGHONG GRP CO LTD

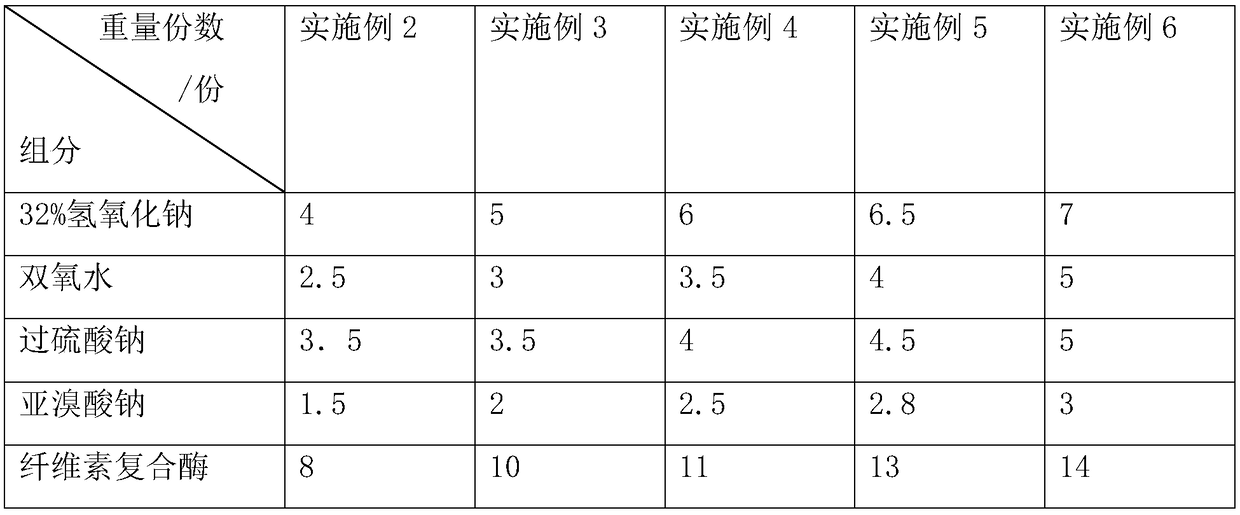

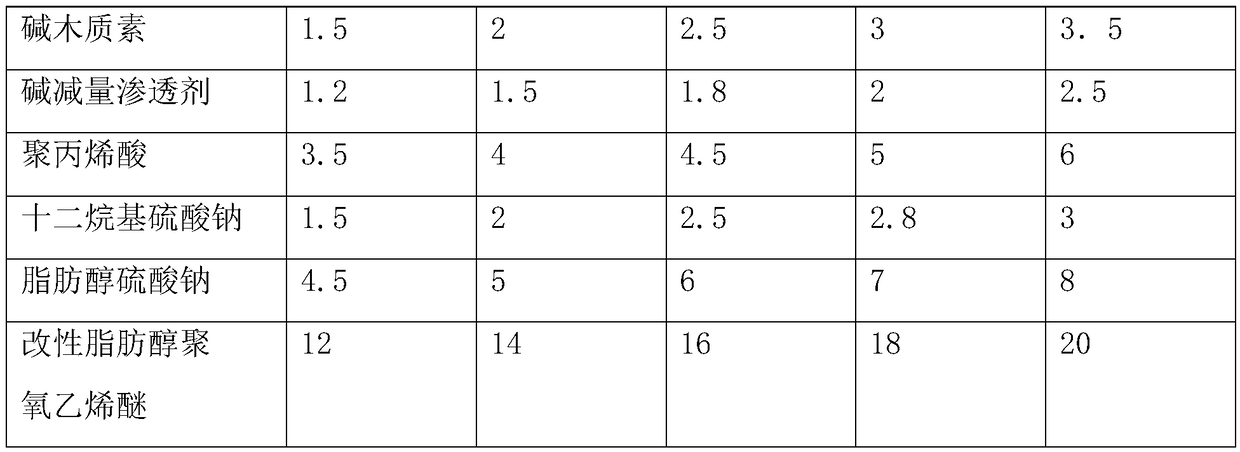

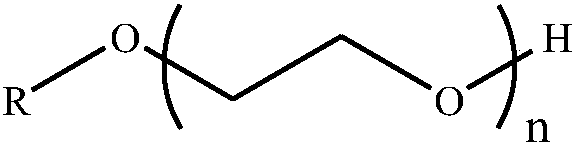

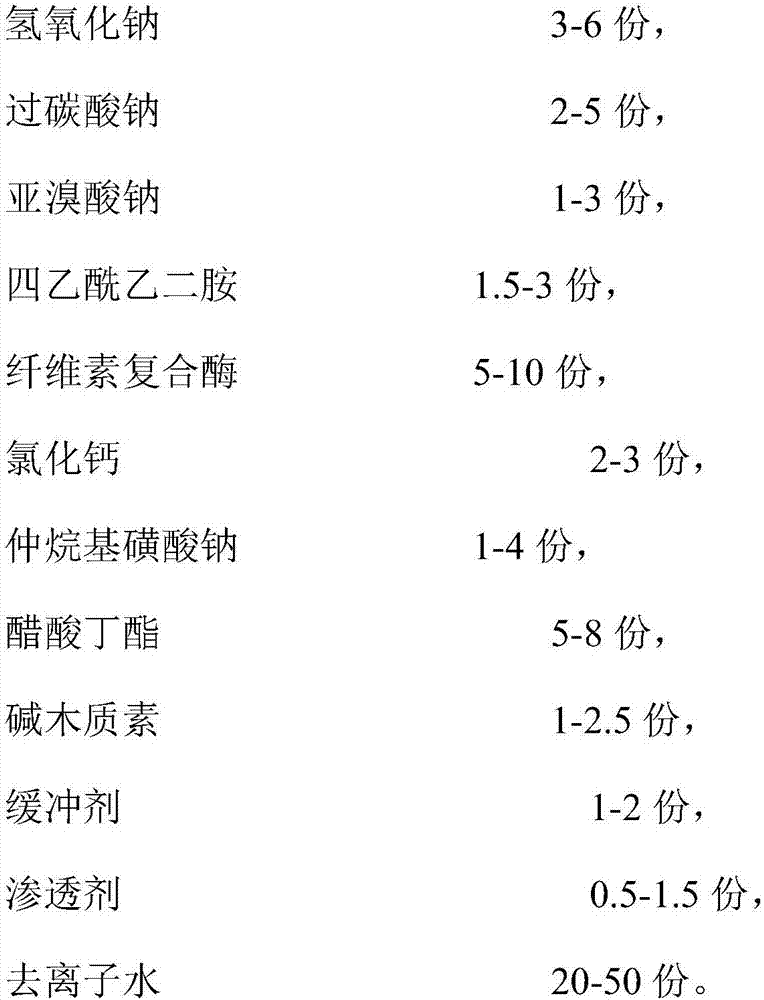

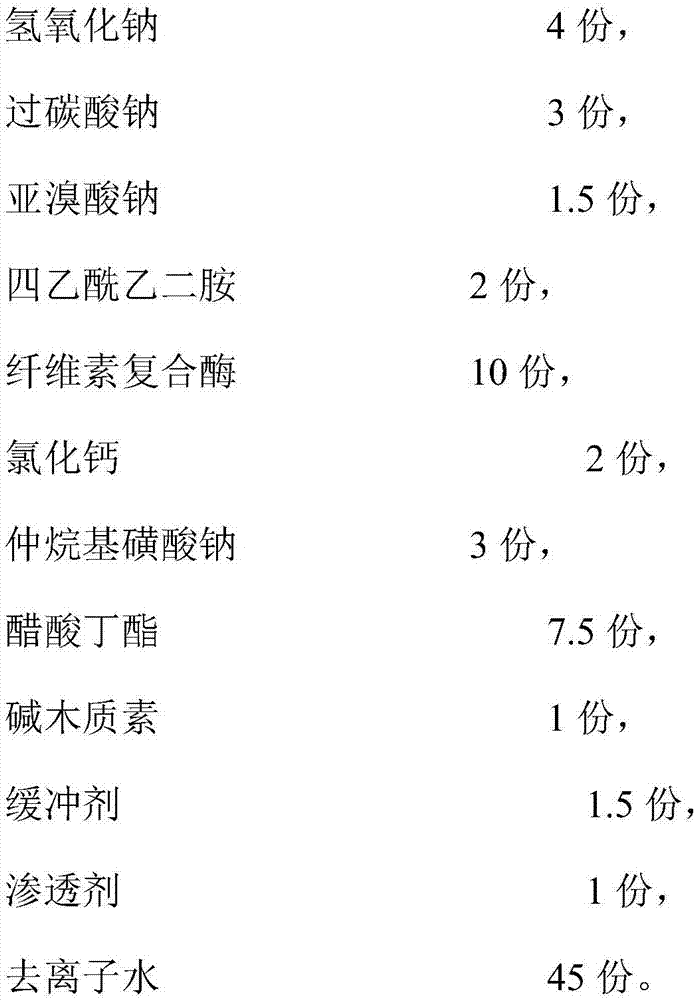

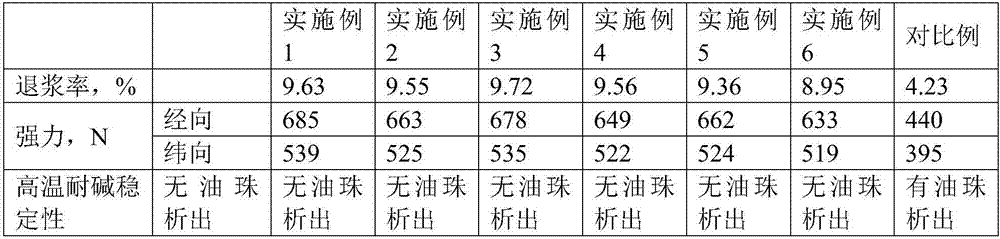

A kind of environment-friendly desizing agent for high-density polyester fabric and preparation method thereof

InactiveCN105603710BImprove high temperature and strong alkali resistanceImprove diffusion abilityDry-cleaning apparatus for textilesEthylenediaminePolyester

The invention discloses an environmentally-friendly desizing agent used for high-density polyester fabric. The environmentally-friendly desizing agent is prepared from, by weight, 3-6 parts of sodium hydroxide, 2-5 parts of sodium percarbonate, 1-3 parts of sodium bromite, 1.5-3 parts of tetraacetyl ethylenediamine,5-10 parts of cellulose compound enzyme, 2-3 parts of calcium chloride, 1-4 parts of secondary alkyl sodium sulfonate, 5-8 parts of n-butyl acetate, 1-2.5 parts of alkali lignin, 1-2 parts of a buffering agent, 0.5-1.5 parts of a penetrating agent and 20-50 parts of deionized water. The invention further discloses a preparation method of the environmentally-friendly desizing agent. The desizing agent is good in desizing effect, excellent in acid and alkali resistance, free of damage to the fabric and small in usage quantity, cleaning is easy, the yield of waste water is low, and no pollution is generated; the preparation method is simple, the raw materials are easy to obtain, the price is low, and the production cost is low.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com