Efficient desizing machine

A desizing machine and desizing technology are applied in the directions of vibration treatment, continuous treatment of textile materials, treatment of textile material carriers, etc., which can solve problems such as affecting the washing effect of the subsequent washing mechanism, affecting the dyeing process of fabrics, and hard hand feeling of fabrics. Save spraying cold water and steam resources, reduce slippage, and have the effect of soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below in conjunction with specific examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

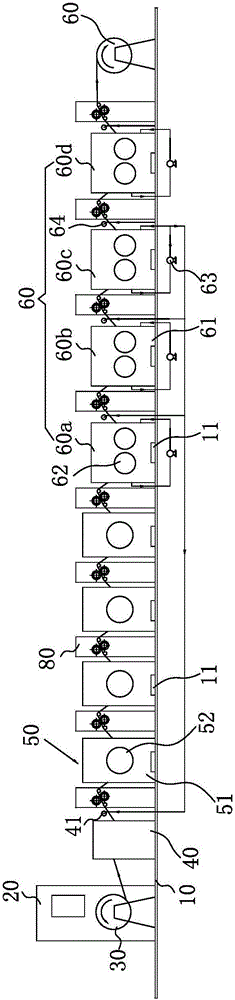

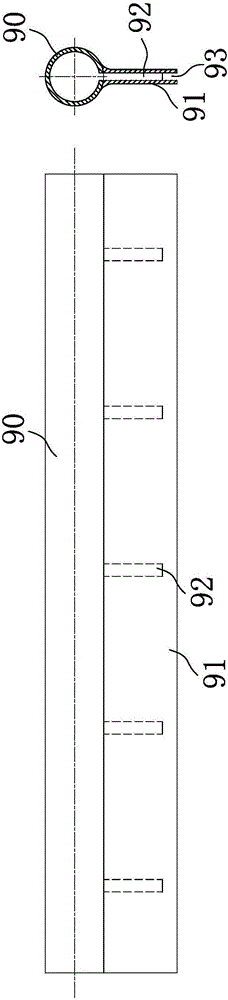

[0017] refer to figure 1 , a high-efficiency desizing machine, including a frame 10, a plurality of driving motors for providing power, a water vapor supply device for heating the whole machine, and an automatic control system 20 for controlling the operation of the whole machine, the automatic The control system 20 is a PLC automatic control system. The frame 10 is sequentially provided with a cloth feeding mechanism 30, a wetting tank 40, four desizing mechanisms 50, four washing mechanisms 60 and a cloth outlet mechanism 70, arranged in an assembly line, the wetting tank 40, the desizing mechanism 50 , the water washing mechanism 60 is connected with the steam supply device, the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com