Patents

Literature

713results about "Vibration treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FET-based sensor for detecting ionic material, ionic material detecting device using the FET-based sensor, and method of detecting ionic material using the FET-based sensor

ActiveUS7859029B2Reduce concentrationHigh sensitivityDrying solid materials without heatSolid-state devicesEngineeringElectric current

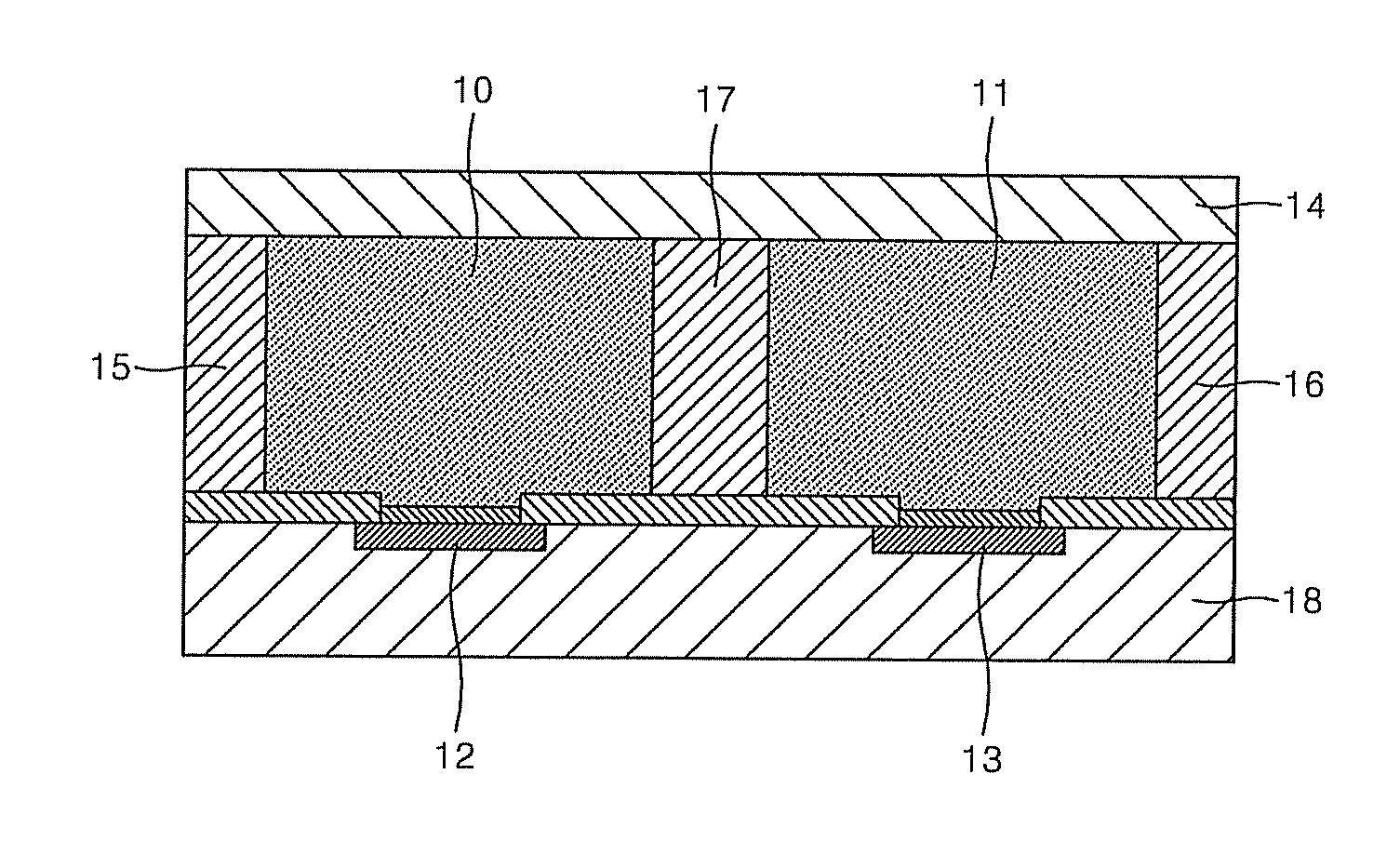

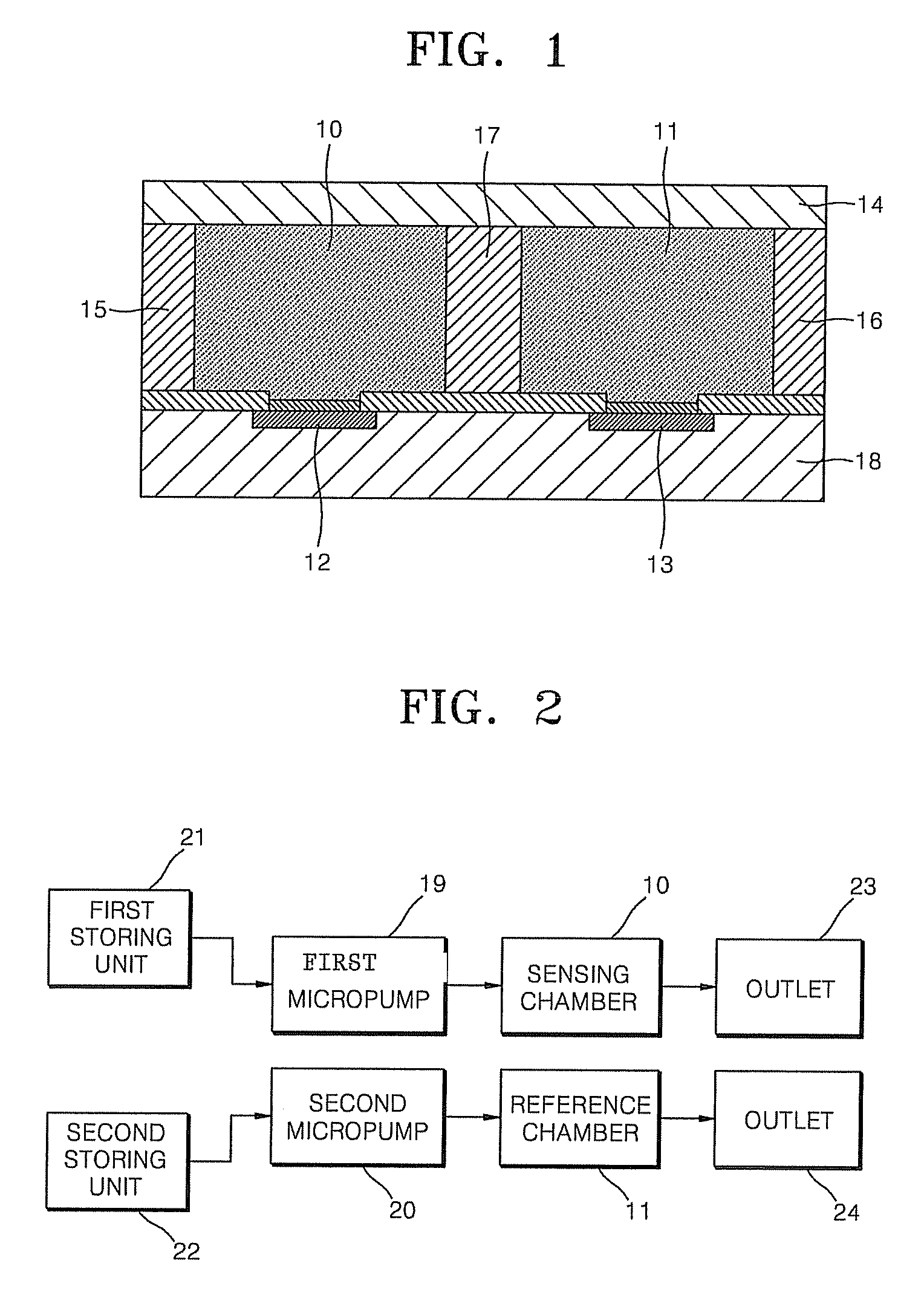

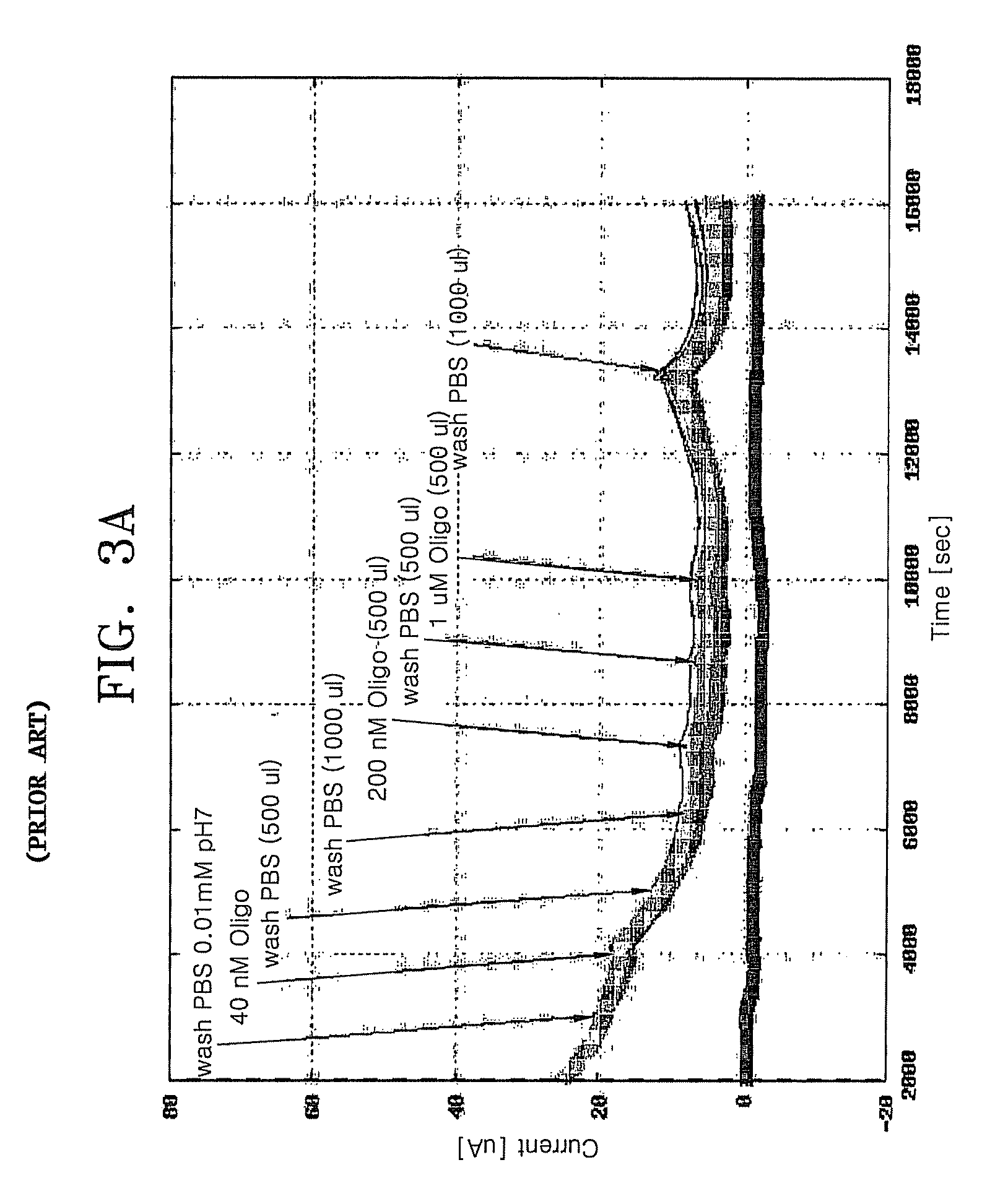

Provided are a FET-based sensor for detecting an ionic material, an ionic material detecting device including the FET-based sensor, and a method of detecting an ionic material using the FET-based sensor. The FET-based sensor includes: a sensing chamber including a reference electrode and a plurality of sensing FETs; and a reference chamber including a reference electrode and a plurality of reference FETs. The method includes: flowing a first solution into and out of the sensing chamber and the reference chamber of the FET-based sensor; flowing a second solution expected to contain an ionic material into and out of the sensing chamber while continuously flowing the first solution into and out of the reference chamber; measuring a current in a channel region between the source and drain of each of the sensing and reference FETs; and correcting the current of the sensing FETs.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

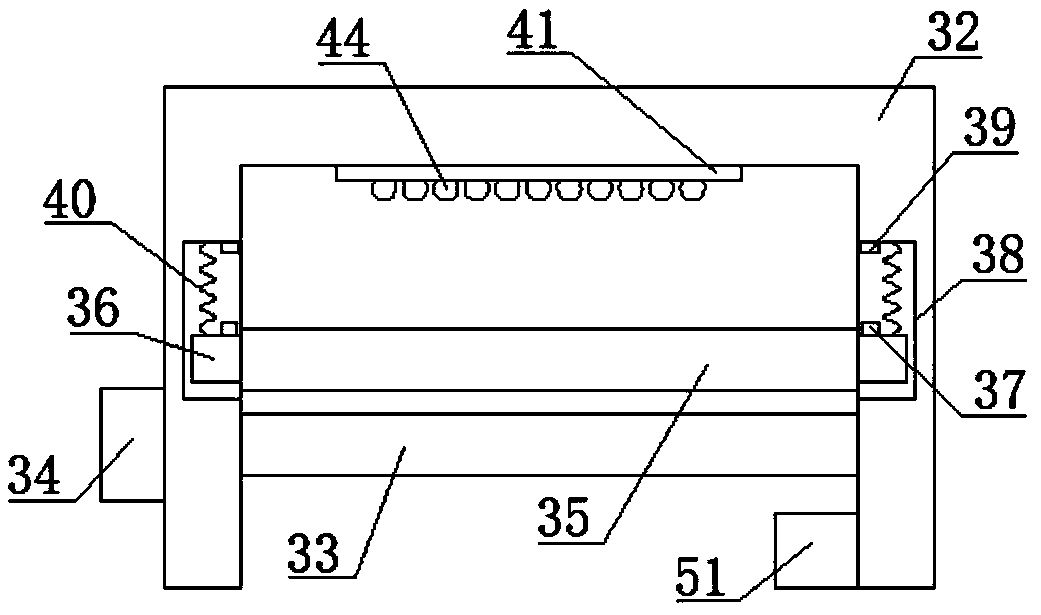

Wrinkle removal equipment for synthetic leather machining

InactiveCN104264402AReasonable structureLow costHeating/cooling textile fabricsStretchingElectricityWrinkle skin

The invention discloses wrinkle removal equipment for synthetic leather machining. The wrinkle removal equipment for the synthetic leather machining comprises a coating machine; the wrinkle removal equipment is installed before the coating machine; the wrinkle removal equipment comprises heating rollers, impression rollers and a humidification box; the heating rollers compress the impression roller; a first steam inlet and a second steam inlet are formed inside the humidification box; cloth is conveyed to the coating machine through the heating rollers and the impression rollers after penetrating the humidification box; the first steam inlet and the second steam inlet are communicated with an ultrasonic wave water atomization generator; water mist output from the first steam inlet and the second steam inlet can wet two sides of the cloth; the heating rollers are provided with at least three electric heating bodies which are connected with an electric control controller, first temperature sensors and second temperature sensors; the heating rollers in the middle and at two ends allow setting of different temperature and are specifically used for removing wrinkle at two ends of the cloth. The wrinkle removal equipment for the synthetic leather machining has the advantages of being reasonable in structure, low in cost, saving electricity and water, saving sites and removing winkles on the cloth in a fixed form mode under high temperature, high humidity and high pressure.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

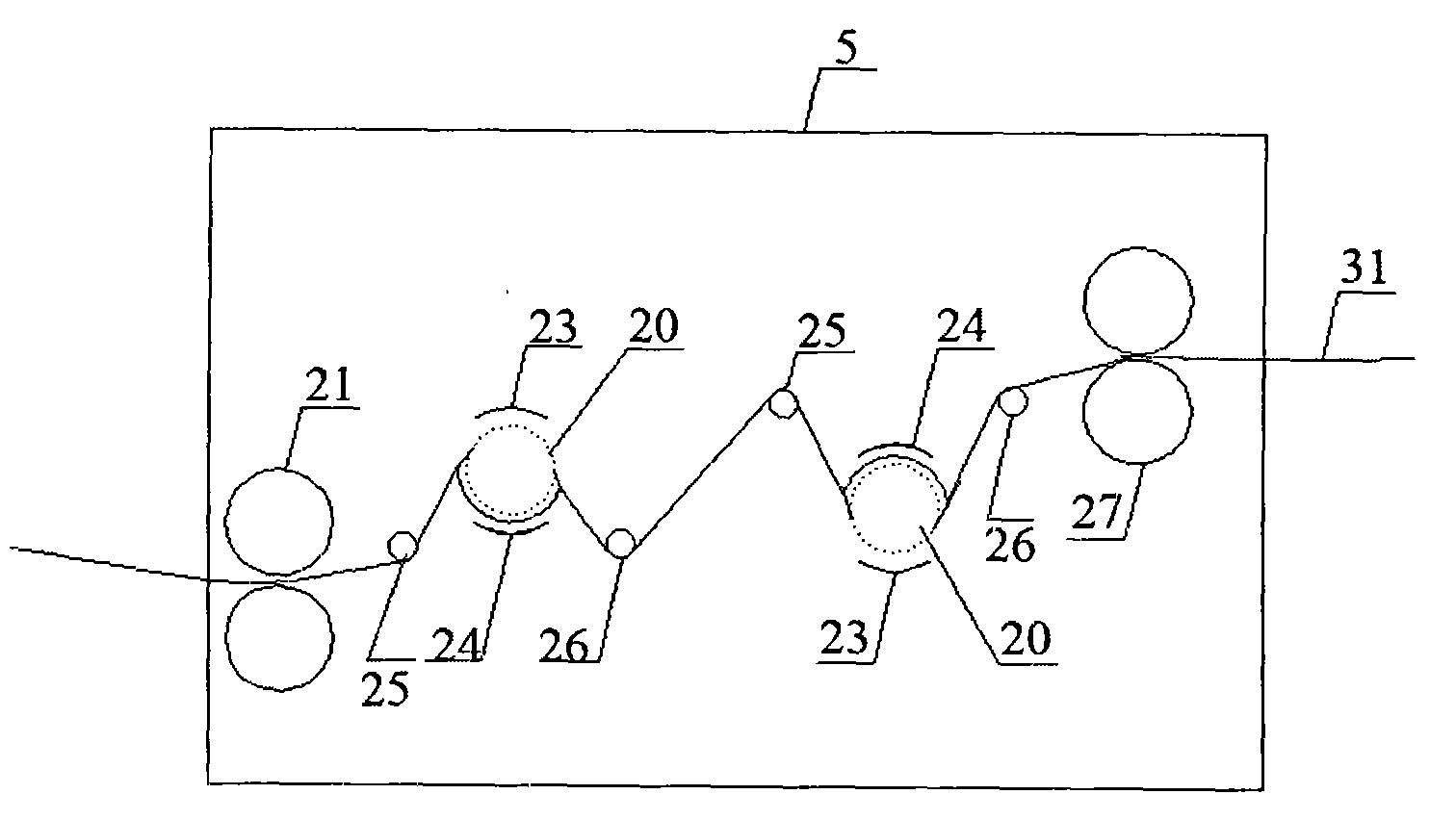

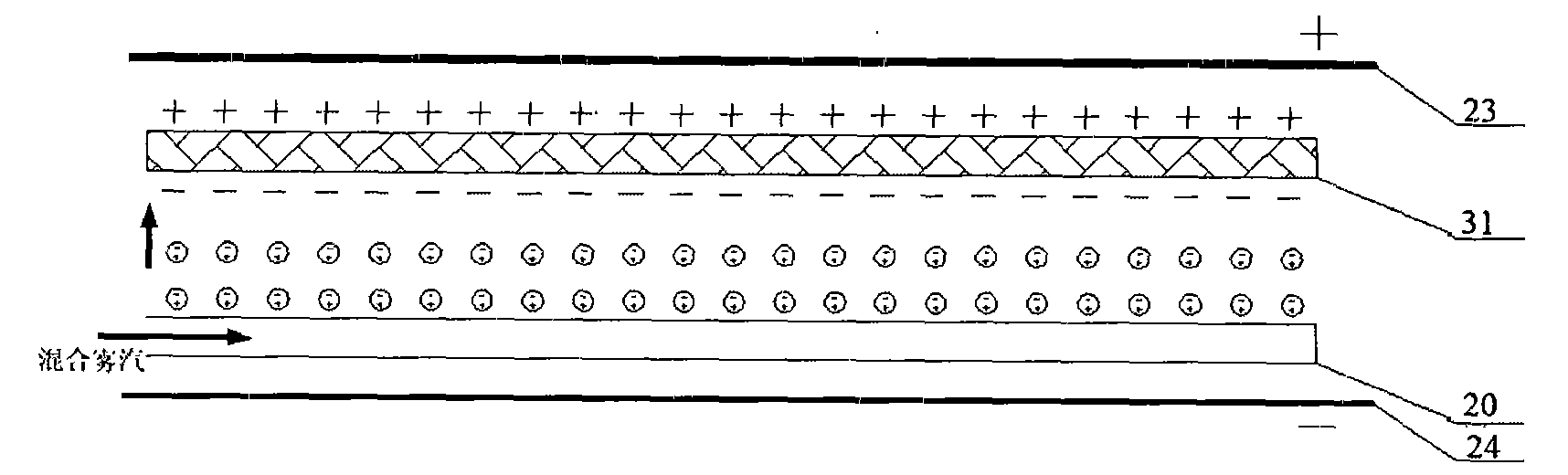

Textile dyeing method

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

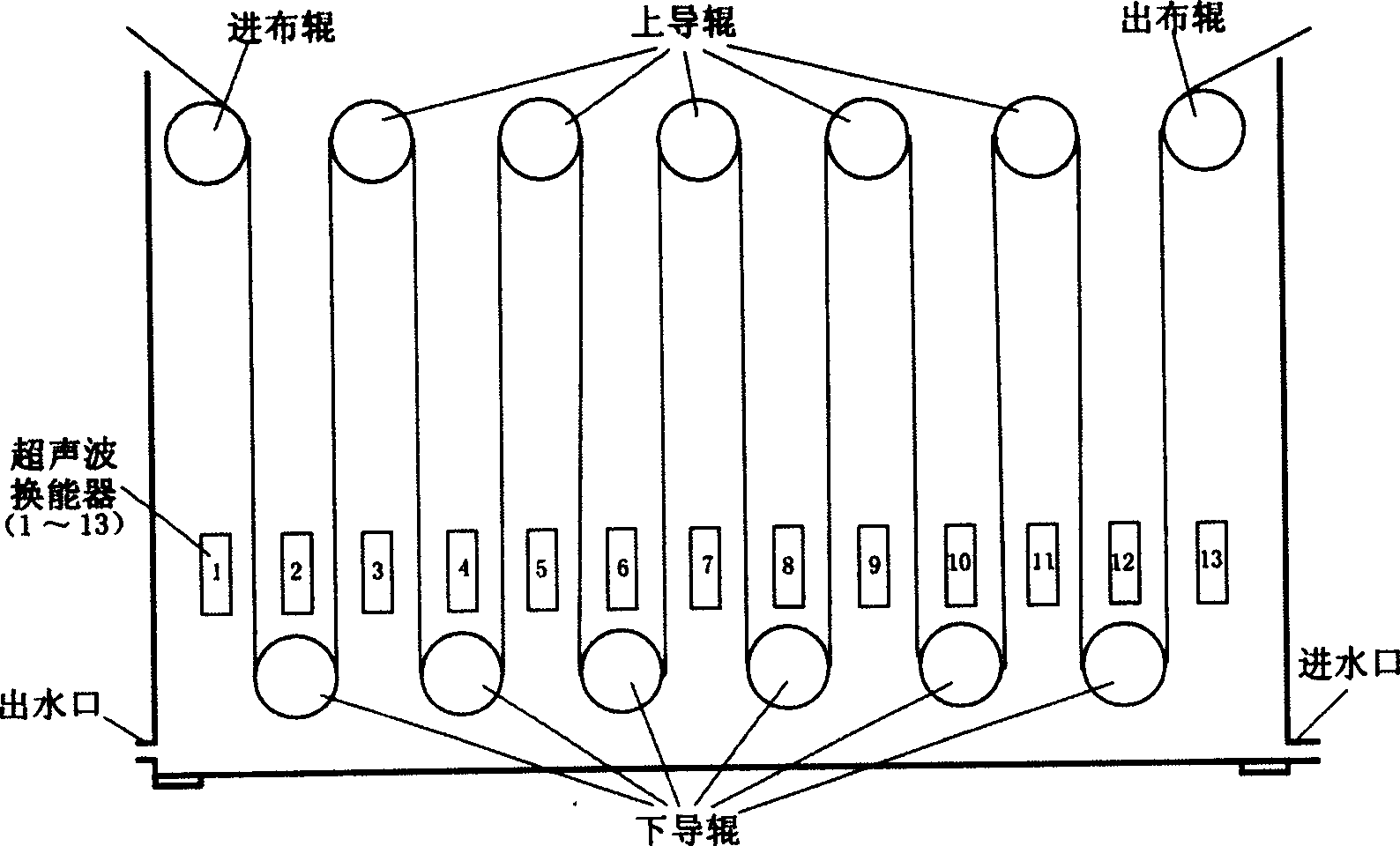

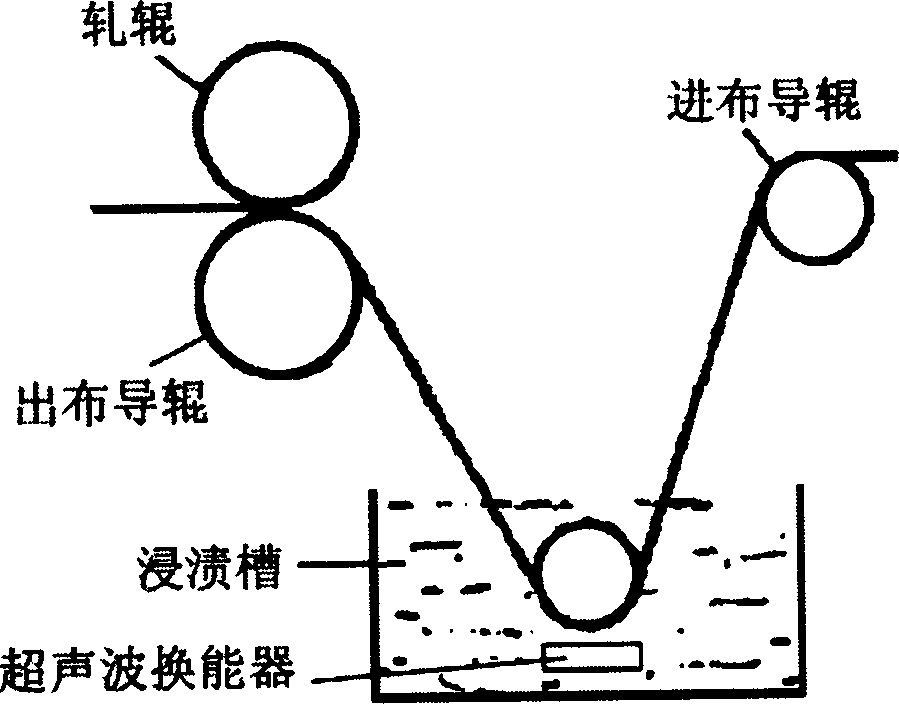

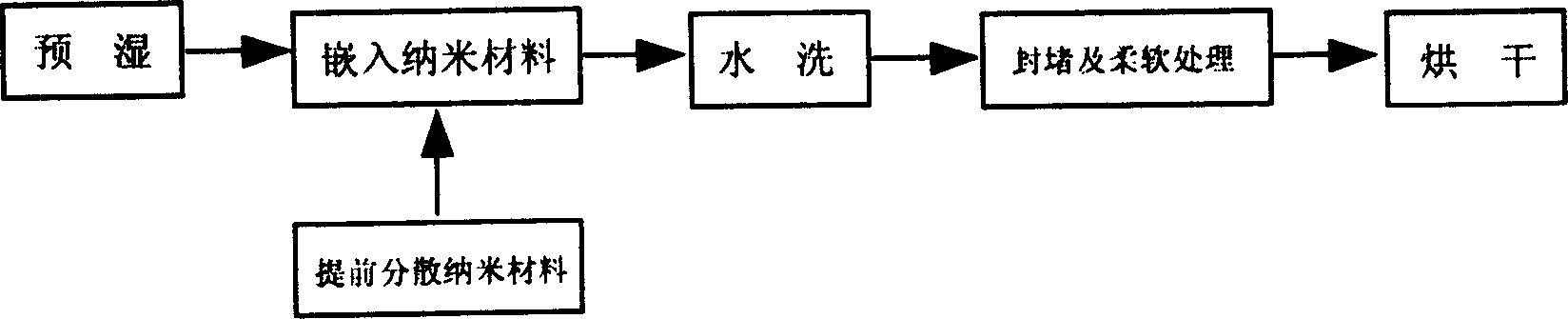

Nano functional textile finishing method

The nanometer functional fabric processing method is mainly to utilize ultrasonic technology in adding nanometer functional material to fabric to prepare nanometer functional fabric. The fabric, which may be pre-humidified, is fed to finishing machine and treated under the action of ultrasonic wave field inside treating bath with nanometer functional material dispersed in water in advance, so that the nanometer functional material is embedded into fine cracks, furrows and holes of fabric and fiber owing to the cavitaion effect and other physical and mechanical effects of ultrasonic wave inside liquid. Through further water washing, mounting, softening and stoving, firm and soft nanometer functional fabric is ultimately prepared.

Owner:DONGHUA UNIV +1

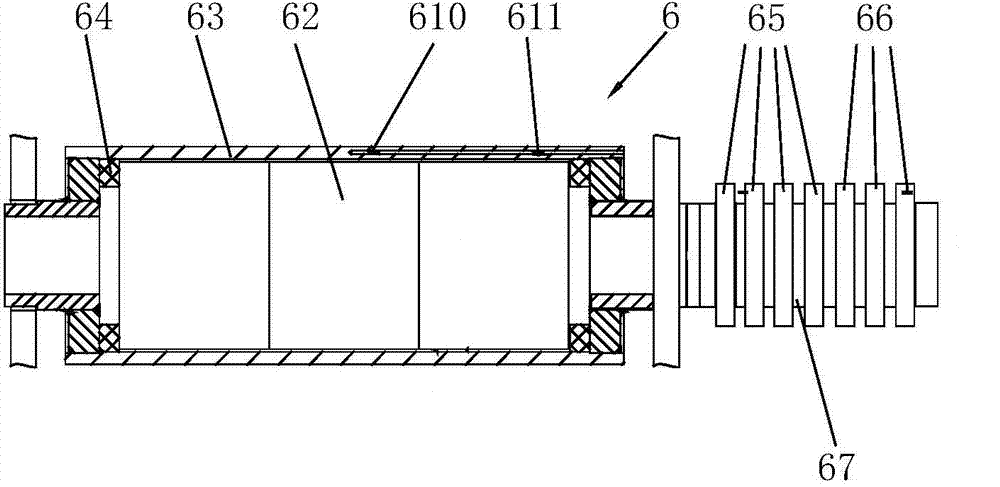

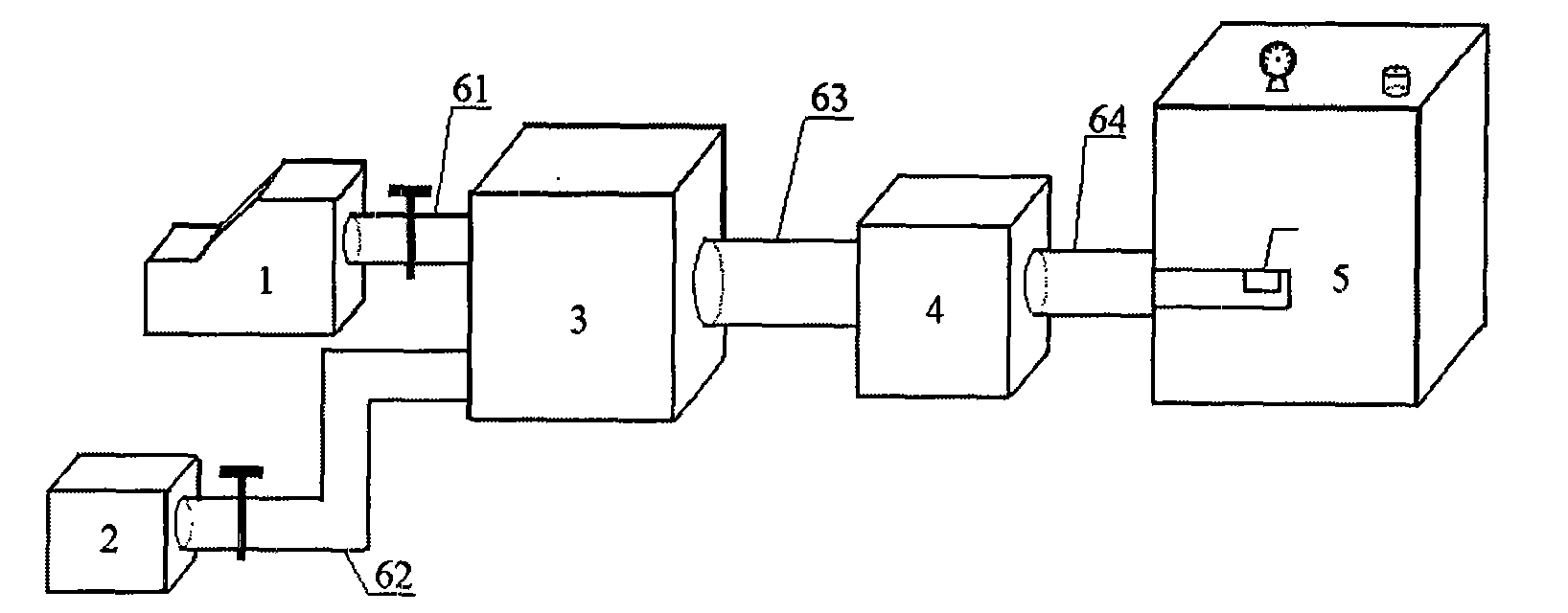

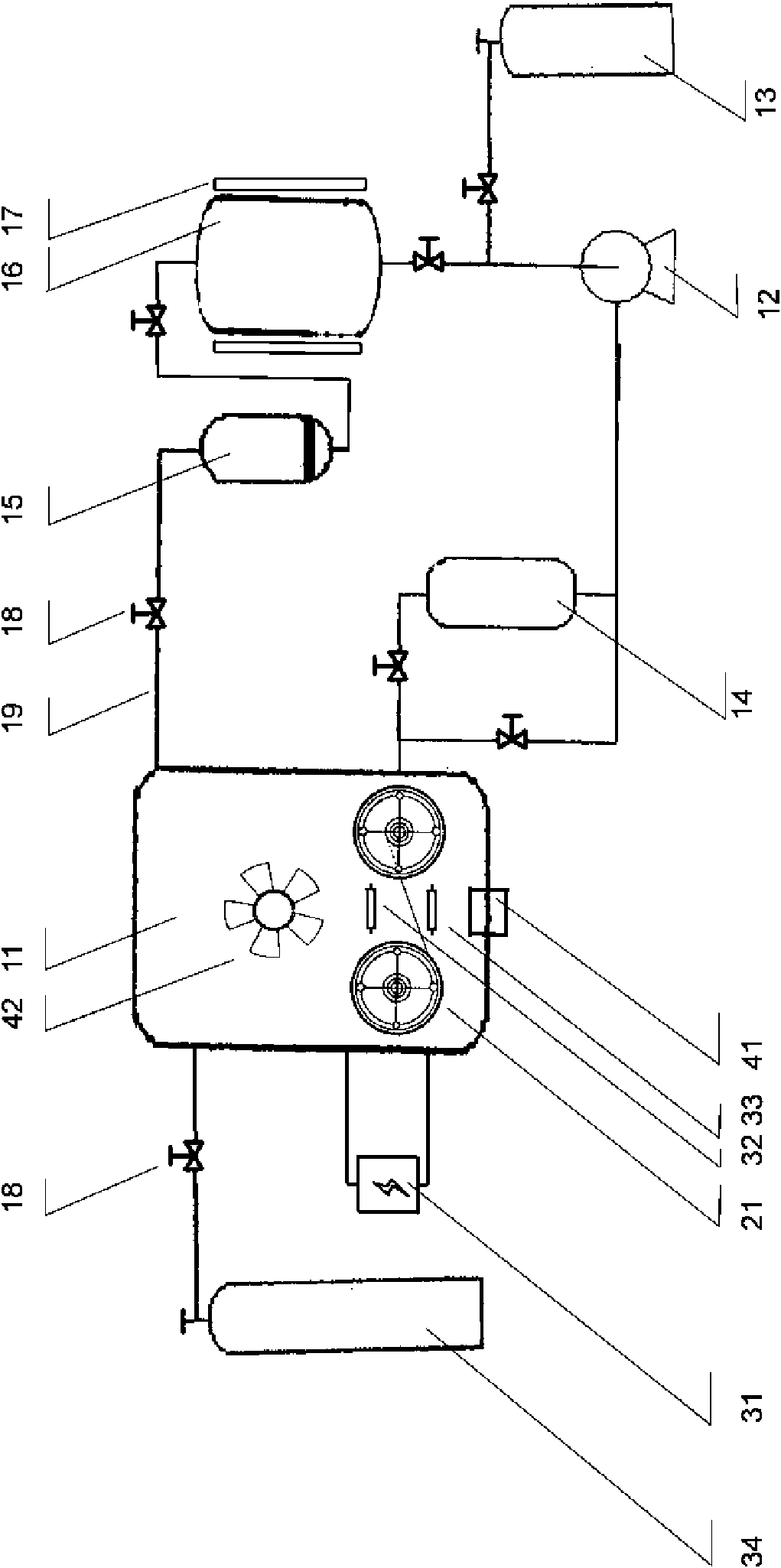

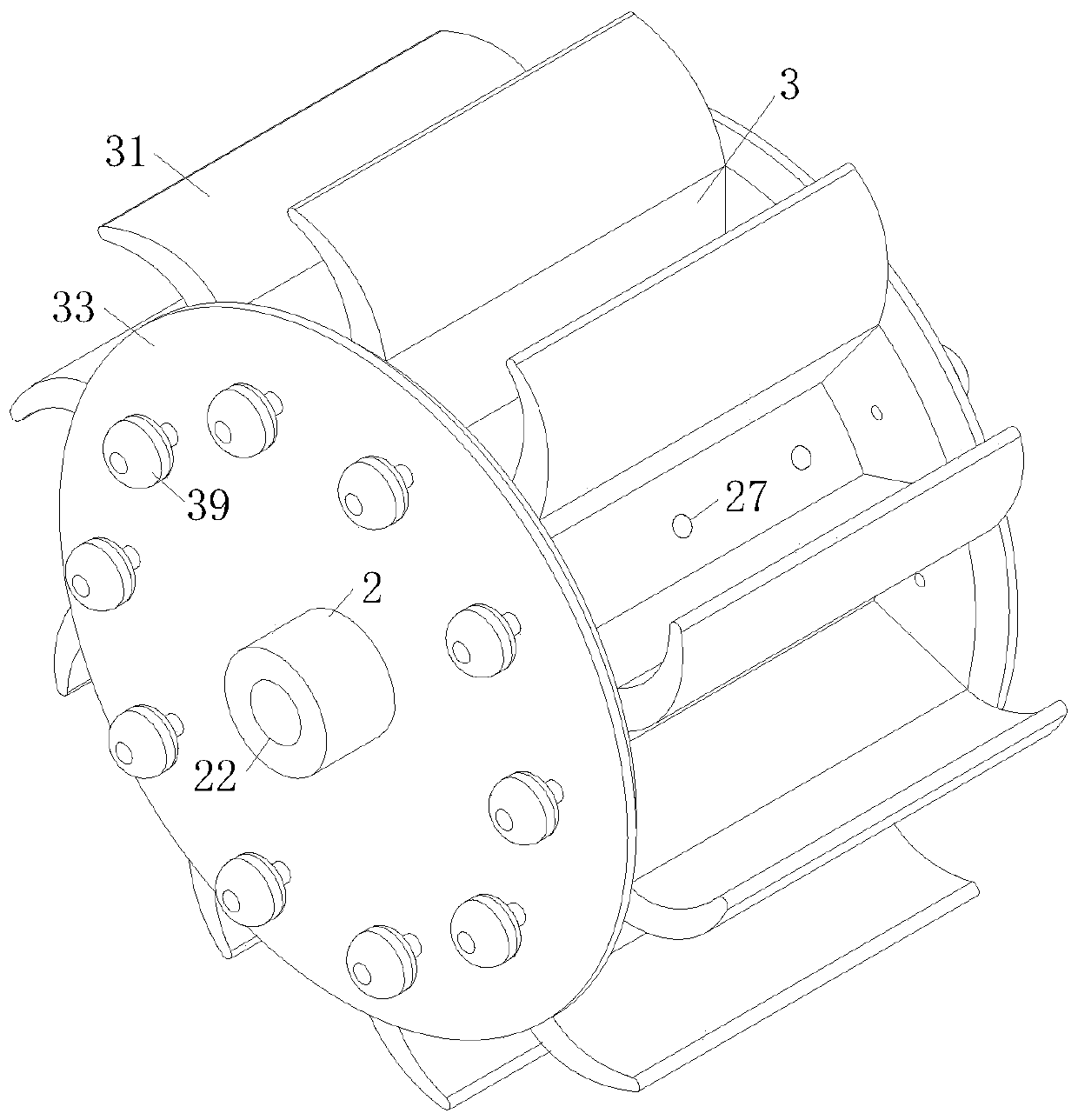

Identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing

InactiveCN101555665AFast anhydrous dyeing rateImprove solubilityTextile treatment containersPhysical treatmentUltrasonic sensorExhaust valve

The invention discloses an identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing system, comprising a general control console, a carbon dioxide storage bottle, a high-pressure pump, a dye tank, a heat exchange device, a reaction kettle, a dye recycling tank, a filter, a condenser, a liquid carbon dioxide storage tank, a flow meter, a valve and a pipeline, and characterized in that the reaction kettle is provided with an upper electrode and a lower electrode of a plasma generator, an exhaust valve and a vacuum pump, is internally provided with one or a plurality of groups of reel-to-reel or axis-to-axis wind and relative motors, is also internally provided with one or a plurality of groups of agitating devices and relative motors, and is embedded with an ultrasonic transducer connected with an ultrasonic wave generation device. The plasma realizes the modification for the surface of material, the ultrasonic wave disperses the dyes uniformly, the supercritical carbon dioxide realizes non-aqueous dyeing, and the reel-to-reel way realizes non-intermittent continuous industry production. The invention can meet the most rigorous environment-friendly demand and product safety demand.

Owner:冷博

Method and device for dyeing by utilizing ultrasonic wave and microwave

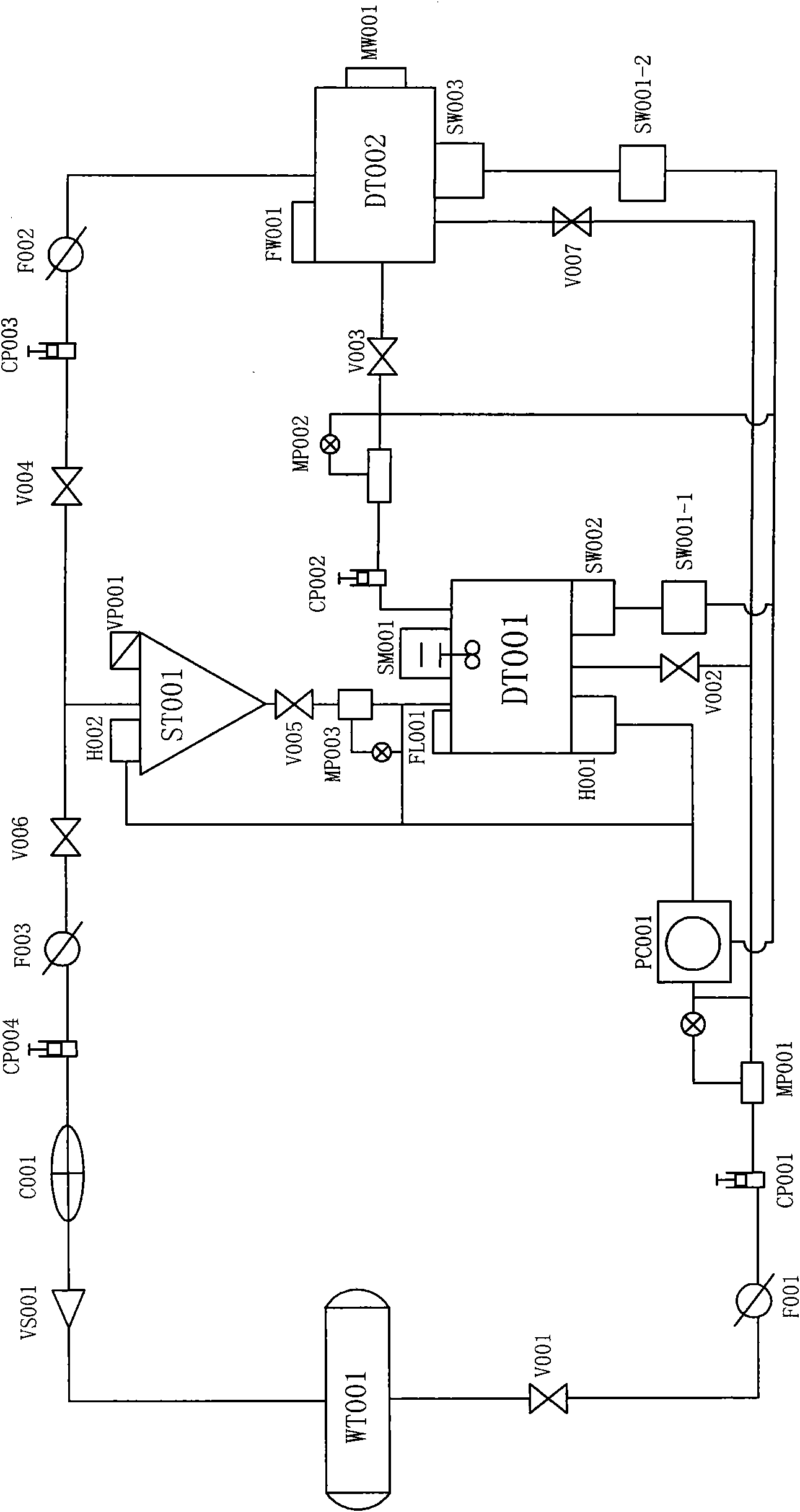

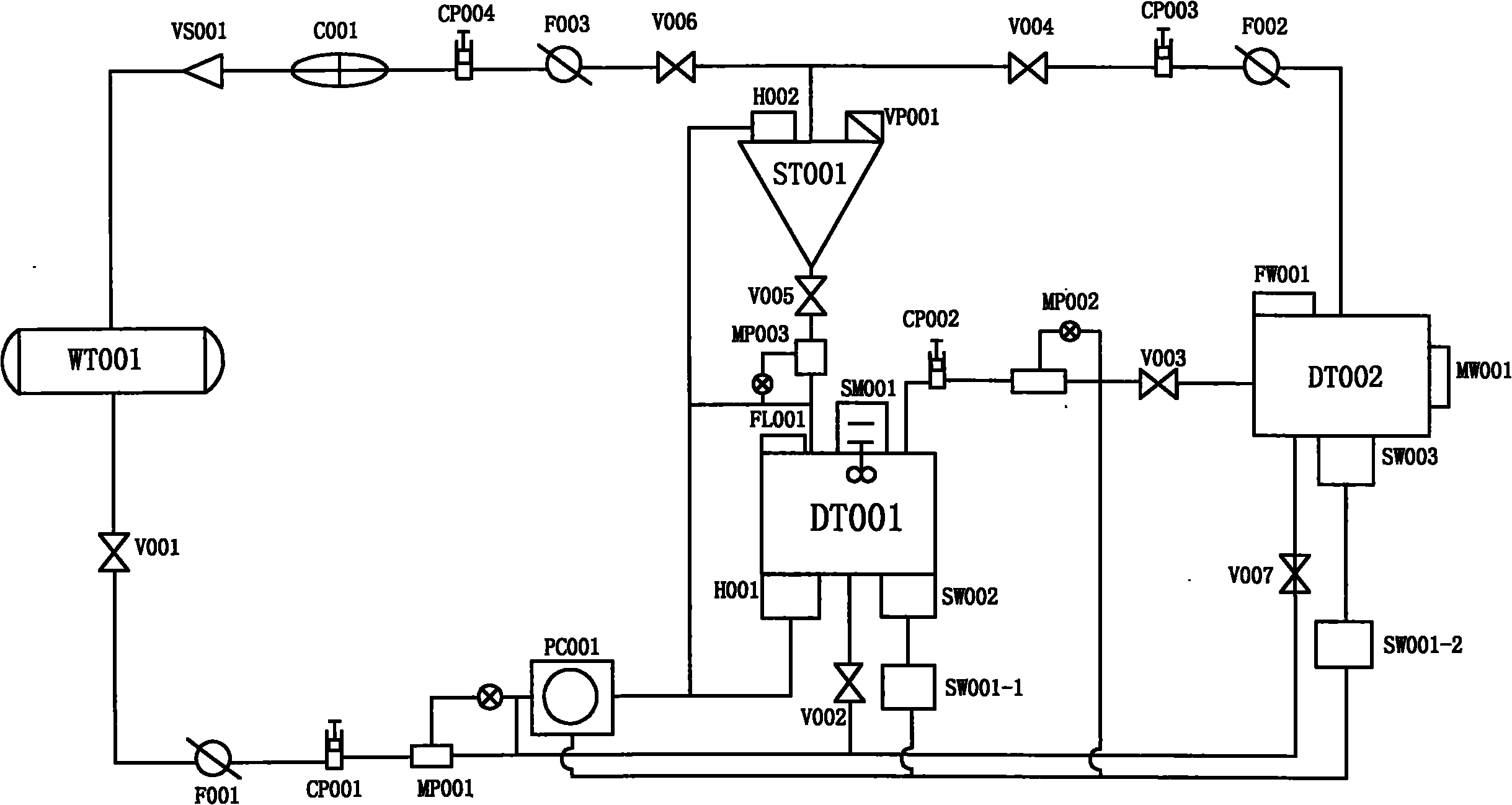

InactiveCN102080315ASimple structureEasy to controlTextile treatment machine arrangementsVibration treatmentUltrasound - actionMicrowave

The invention provides a method and device for dyeing by utilizing ultrasonic waves and microwaves. The dyeing device comprises a water storage tank WT001, a dye kettle DT001, a dyeing kettle DT002, a separator ST001, an ultrasonic generator SW001-1, an ultrasonic generator SW001-2, an ultrasonic transducer SW001, an ultrasonic transducer SW002 and a microwave generator MW001. The dyeing method comprises the steps of: preparing dye liquor under the action of ultrasonic waves, dyeing fabric under the action of ultrasonic waves and microwaves, treating the dye liquor after dyeing, and recycling the recovered water and dye. The method and device for dyeing has the following benefits: the dyeing efficiency and the dyeing effect are effectively improved without using assistants, and the dye can be recycled; and simultaneously, the dyeing device has simple structure, is convenient to control, reduces energy consumption and saves water resources.

Owner:YANCHENG INST OF IND TECH

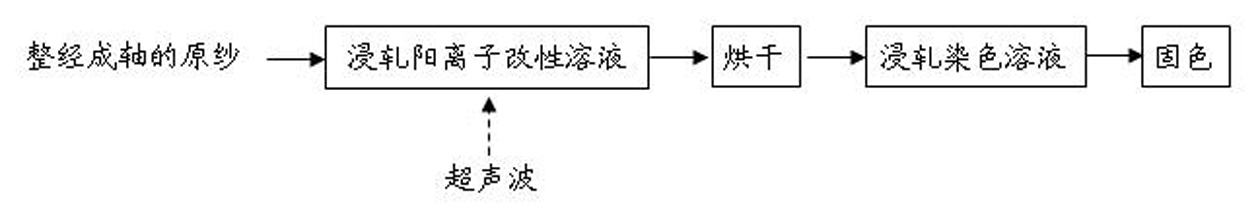

Equipment for dying cotton-containing yarn

ActiveCN101994219ASolve the color fastnessSolve the core penetrationTextile treatment machine arrangementsVibration treatmentYarnBiomedical engineering

The invention relates to equipment for dying a cotton-containing yarn. The equipment comprises an ultrasonic padding device which comprises a padding tank used for containing a cationic modified solution, a yarn guide roller and a drawing padding roller, wherein the padding roller is internally provided with an ultrasonic vibrating box used for cavitating the cationic modified solution, and the ultrasonic vibrating box is connected with an ultrasonic generator. In the continuous pad dyeing of the cotton-containing yarn, the problems of poor dyeing firmness, poor transparency and low dye-uptake of the continuous pad dyeing technology of the cotton-containing yarn are solved through additionally arranging the ultrasonic padding device, and a boiling off procedure before or in the dyeing process or a pretreatment procedure having a boiling off effect can be saved.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

Dyeing and finishing process of polyester-nylon composite fiber fabric

InactiveCN105019237AHigh whitenessAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsPolyesterInorganic salts

The invention discloses a dyeing and finishing process of polyester-nylon composite fiber fabric. The dyeing and finishing process of the polyester-nylon composite fiber fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the dyeing and finishing process of the polyester-nylon composite fiber fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, the modification treatment is conducted before dyeing, modification is conducted on performance of the polyester-nylon fabric radically, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent, substitution alkali, migration inhibitor and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; self-cleaning treatment is added in finishing, and the self-cleaning capacity, crease resistant property and fastness to washing of the fabric are improved; the whole process is environmentally friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

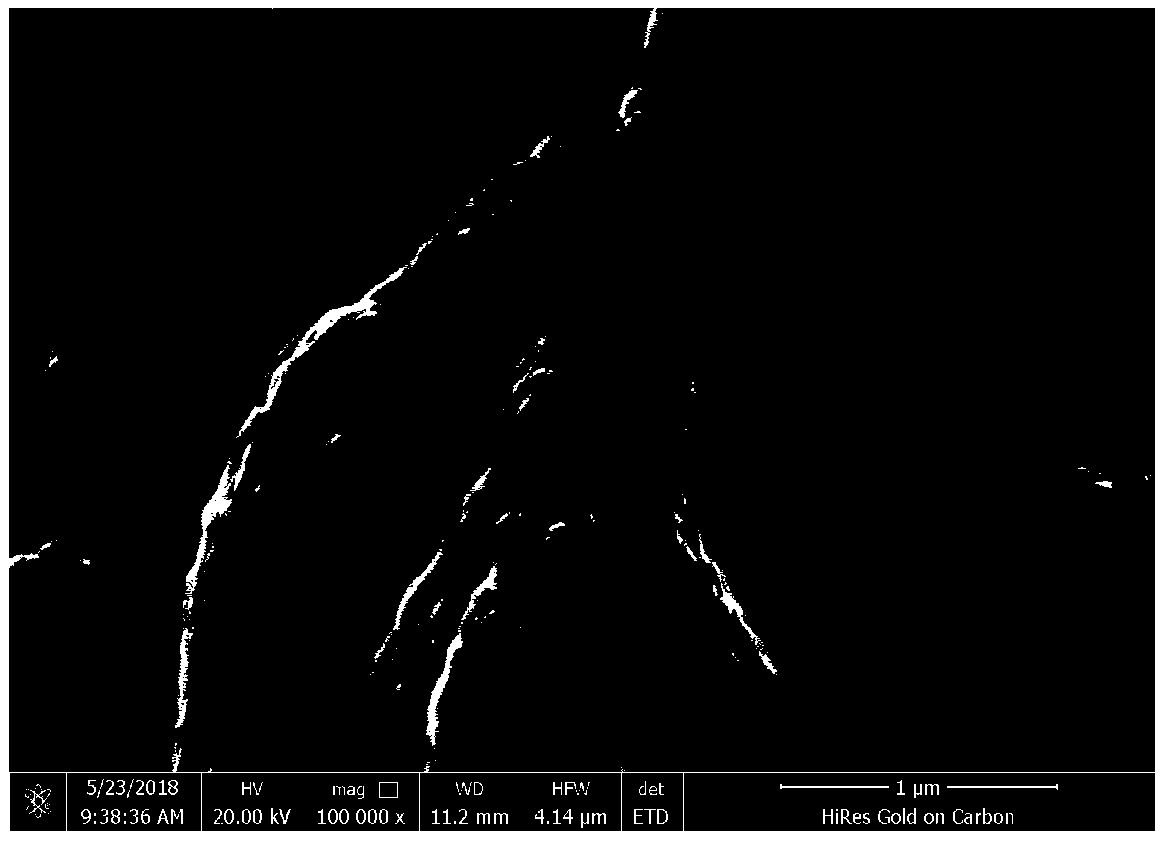

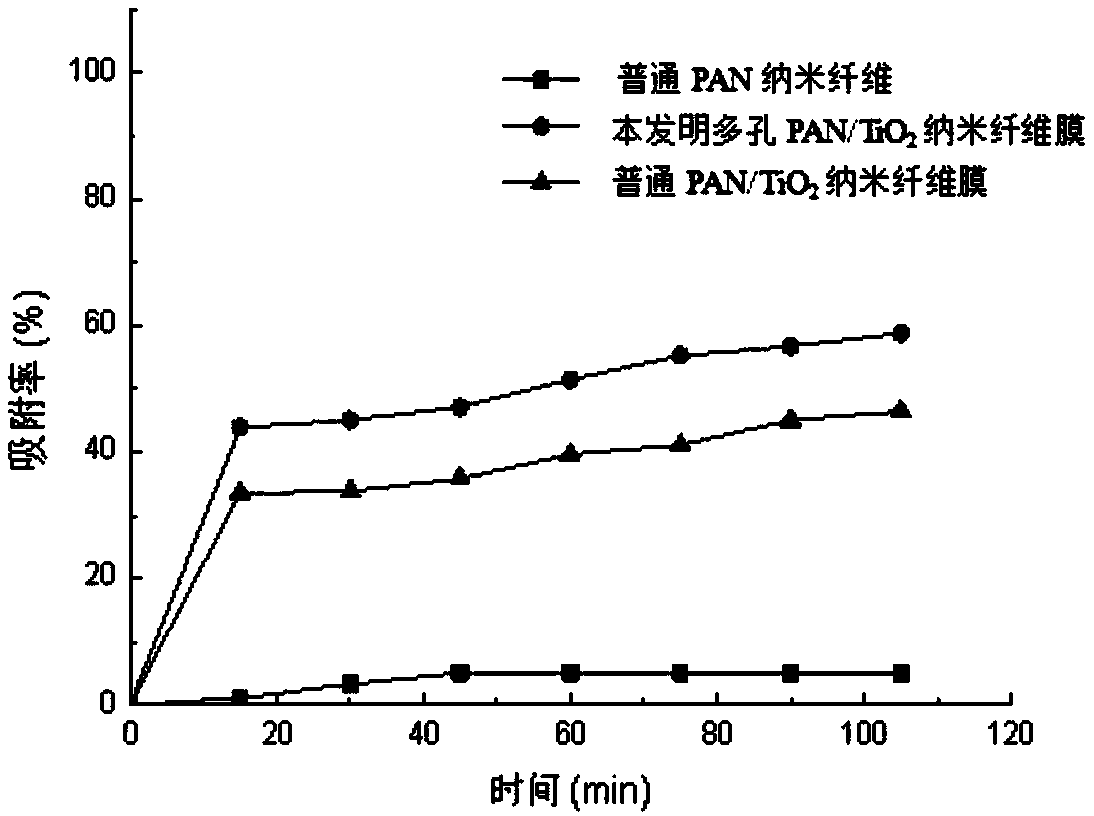

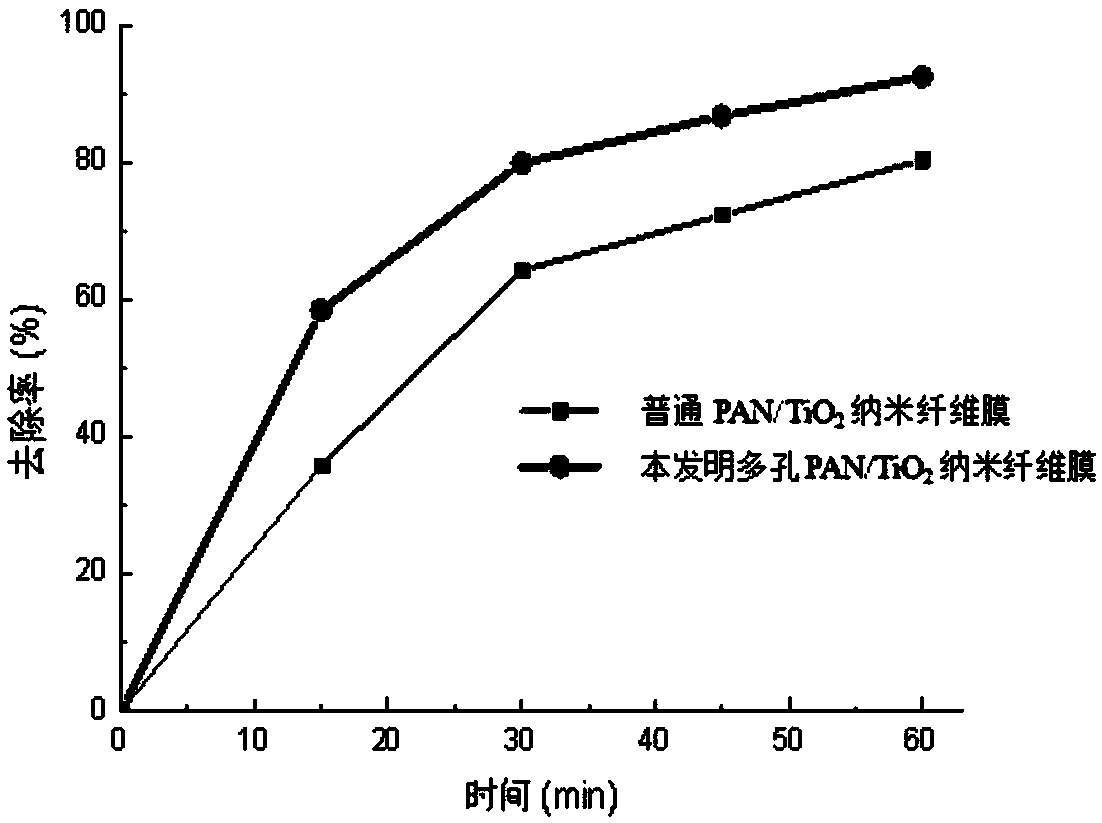

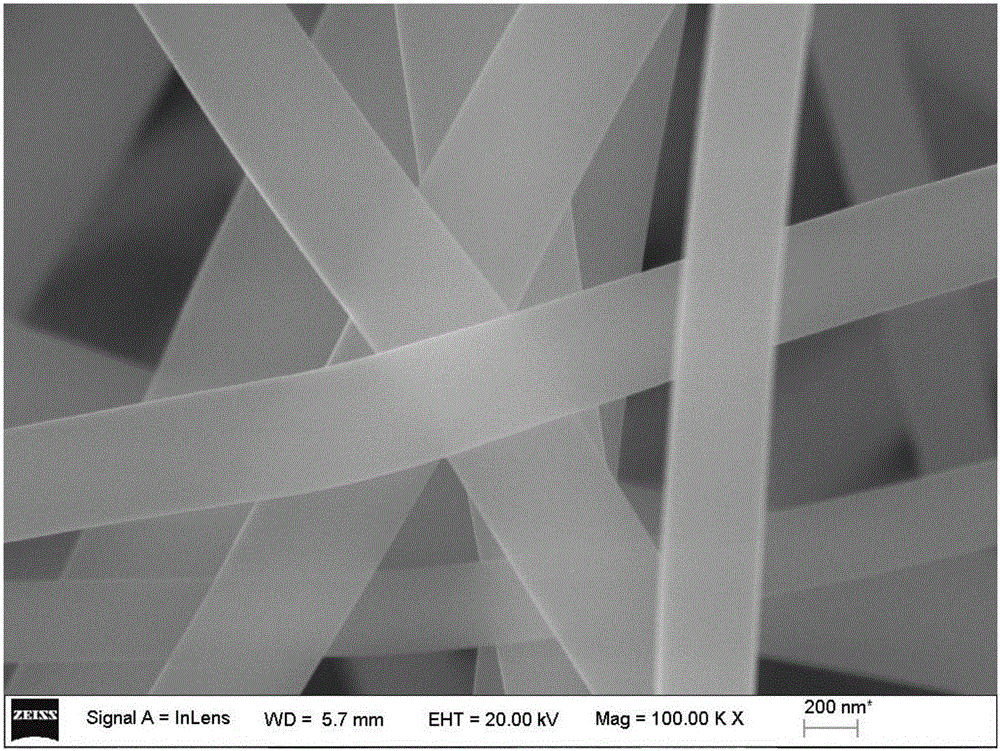

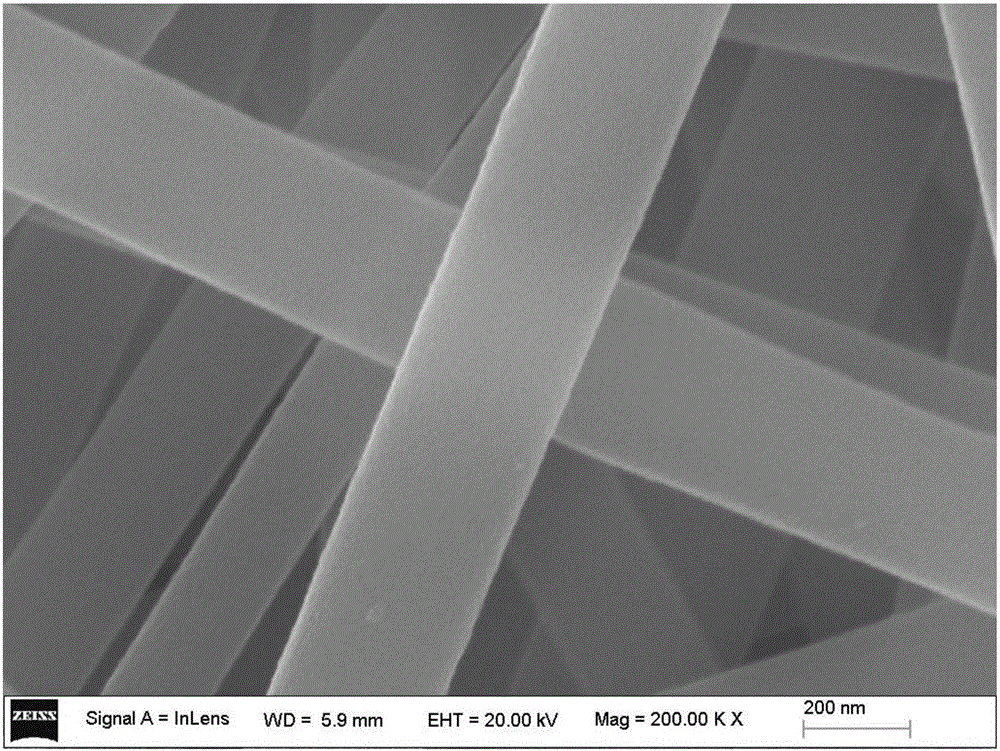

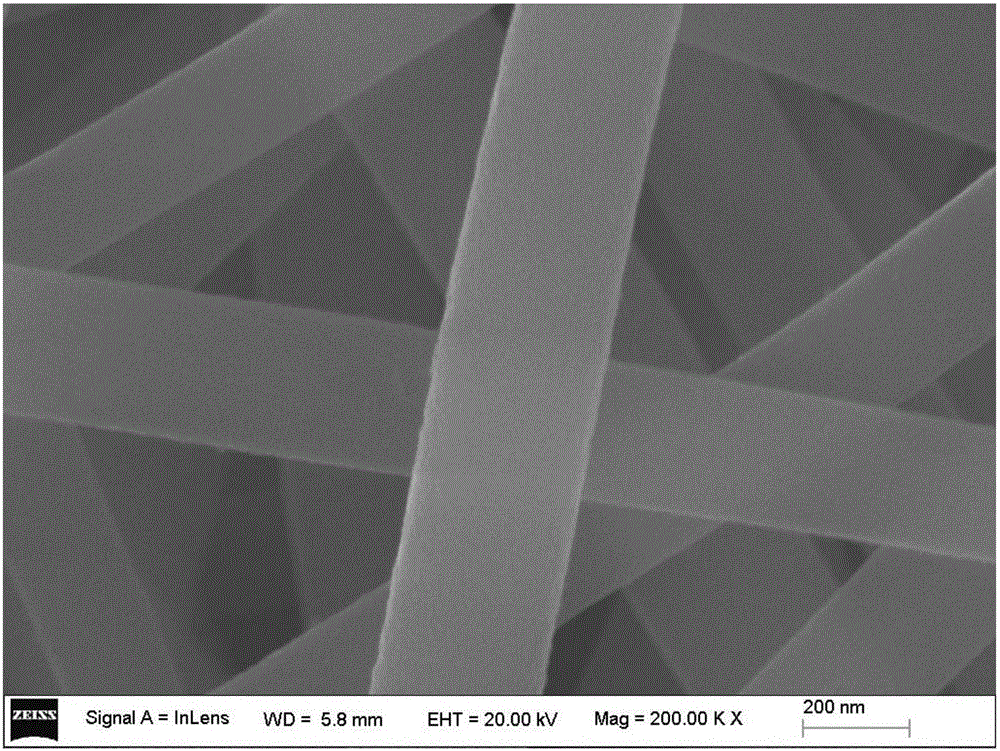

Porous supported electrospun nano photocatalytic fiber membrane and preparation method thereof

ActiveCN108842304ASolve the adsorption problemSolve removalLiquid/gas/vapor removalMonocomponent synthetic polymer artificial filamentPorosityElectrospinning

The invention relates to a porous supported electrospun nano photocatalytic fiber membrane and a preparation method thereof. According to the preparation method, nano titanium dioxide, polyacrylonitrile (PAN) and polyvinylpyrrolidone (PVP) are dissolved in a solvent to obtain an electrospinning solution, a nano photocatalytic fiber membrane loaded with the nano titanium dioxide is obtained throughelectrospinning, and after water treatment is carried out on the nano photocatalytic fiber membrane, the PVP is dissolved out to obtain the porous supported electrospun nano photocatalytic fiber membrane. The porous supported electrospun nano photocatalytic fiber membrane and the preparation method thereof have the advantages that the method is simple, the operation is easy, the cost is low, theprepared photocatalytic fiber membrane has the characteristics of high porosity and large specific surface area, the contact area between the photocatalytic fiber membrane and reactant is effectivelyincreased, the photocatalytic degradation efficiency is increased, the photocatalytic efficiency reaches up to 90% or above, the removal rate of methylene blue can reach up to 93% or above, electrospun nanofiber serves as a carrier to fix the photocatalyst titanium dioxide, thereby preventing the catalyst from being lost and recycling the catalyst, and the photocatalytic effect is permanent.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

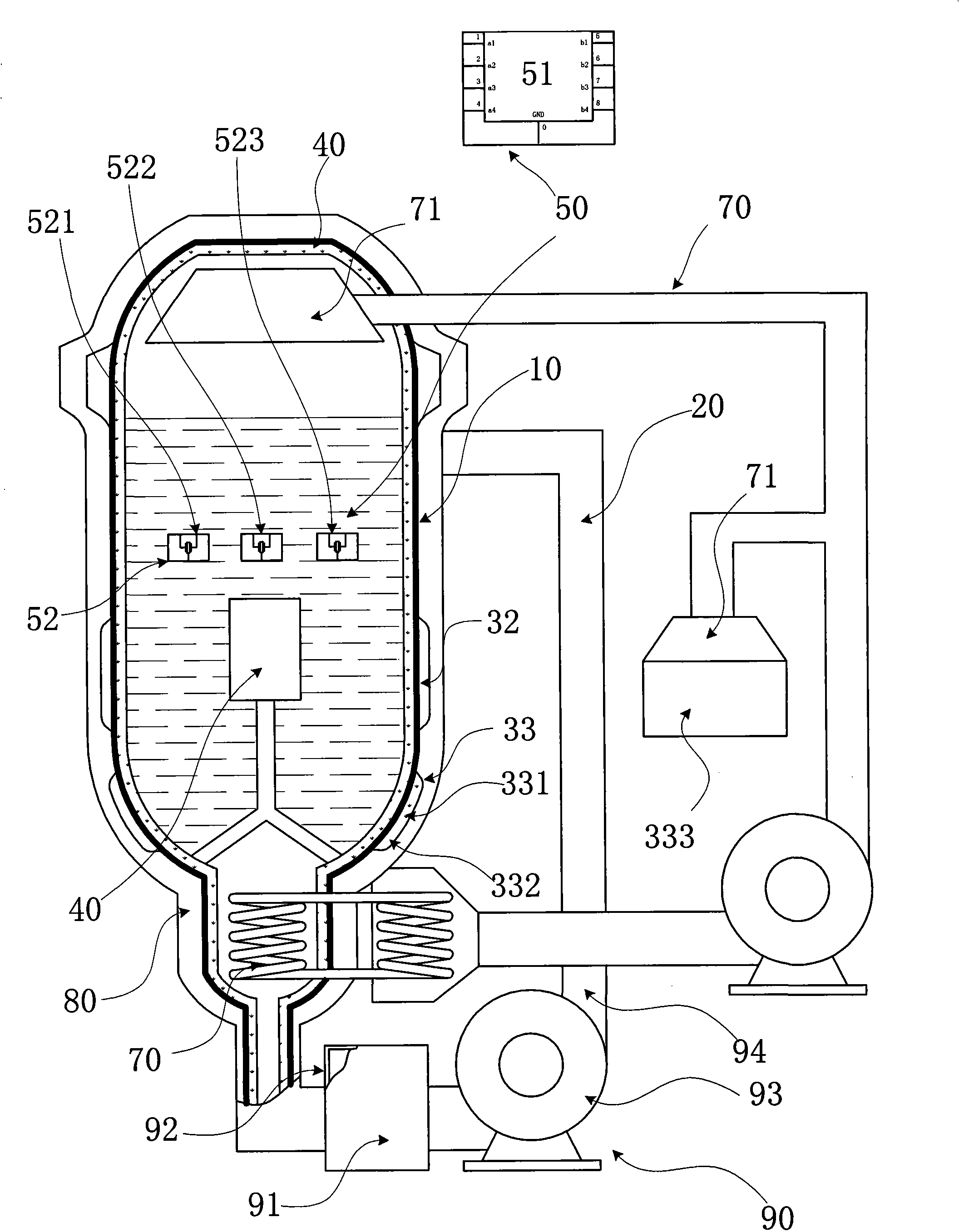

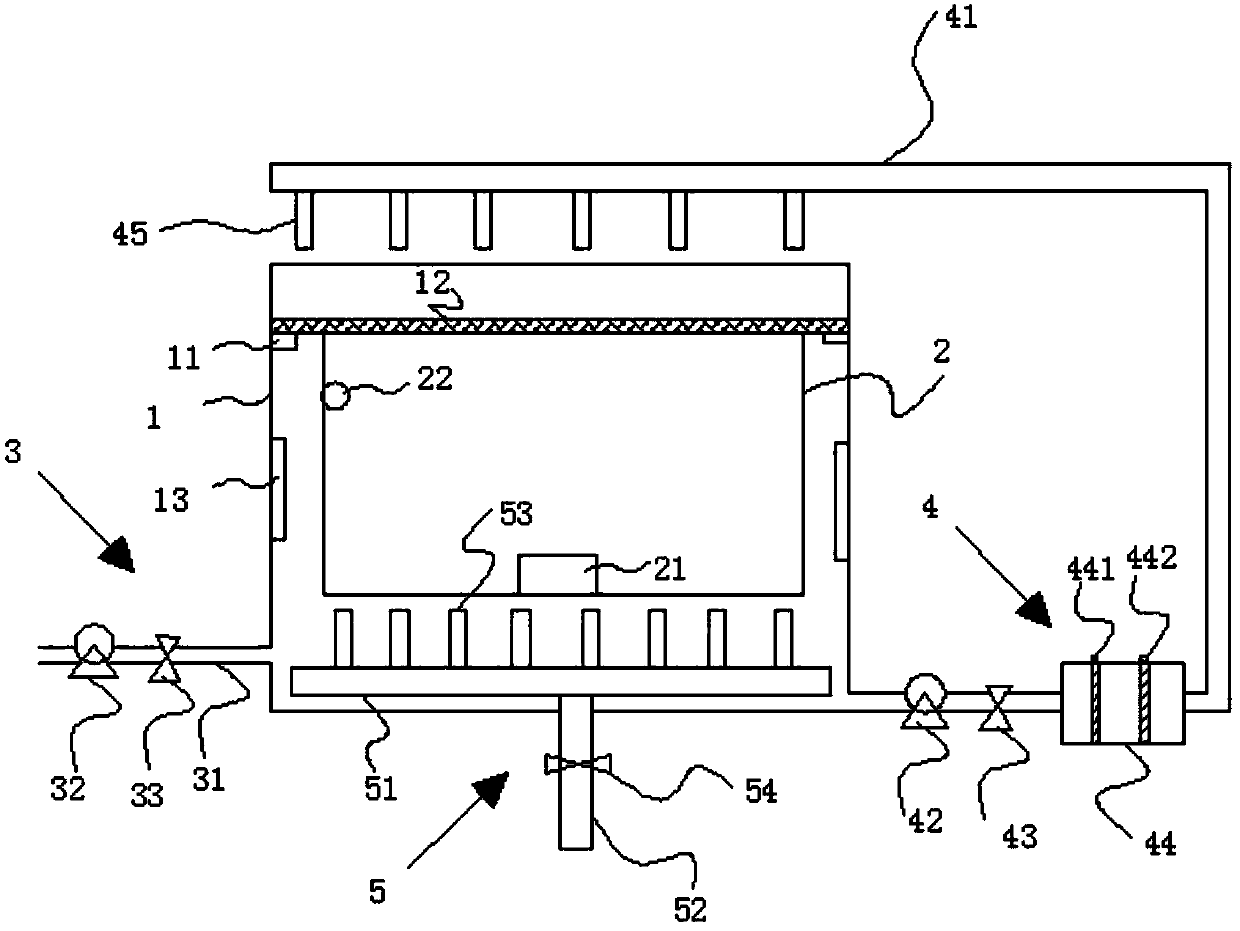

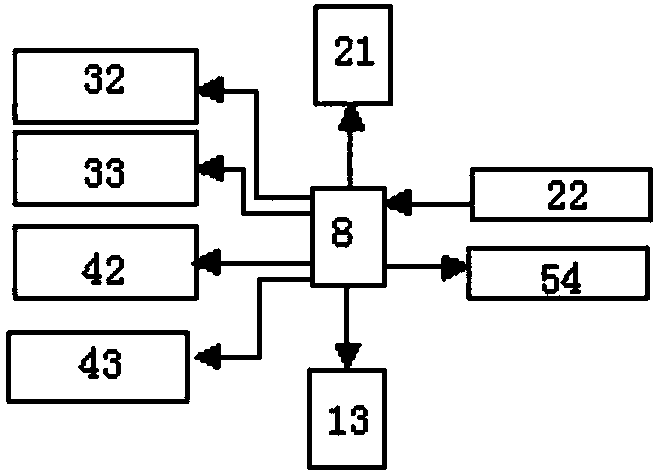

Energy-saving dyeing apparatus for textile

InactiveCN101294339AImprove thermal efficiencySave electricityTextile treatment containersTextile treatment machine arrangementsUltrasonic sensorLow voltage

An energy-conserving textile dyeing device comprises a metal dye vat (10) and liquid transport pipes (20), wherein a heat pump heating unit (31), an electromagnetic heating unit (32) and a low-voltage electric heating unit (33) of a heating device (30) are arranged on the dye vat (10); and an inorganic anticorrosive coating (40) is applied on the inner surfaces of the dye vat (10) and the liquid transport pipes. An ultrasonic transducer (60) is also arranged in the dye vat (10), and a heat insulating layer (80) is applied on the outer surfaces of dye vat (10) and the liquid transport pipes (20). By adopting the above technical scheme, the novel dyeing device has the advantages of high heat efficiency, reduced power consumption, less heat loss and good dyeing effect, thus reducing the production cost and protecting the environment.

Owner:杨栋 +1

Silk fabric dyeing and finishing method

InactiveCN105113300AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsPolymer science

The invention discloses a silk fabric dyeing and finishing method. The silk fabric dyeing and finishing method comprises pre-treatment, pre-setting, modification treatment, dyeing, soaping, dye fixation, finishing, drying, setting, calendering and rolling. The method utilizes supersonic wave to carry out pretreatment and utilizes a modification treatment process. In dyeing, a large amount of alkaline substances and inorganic salts are avoided, natural dye is adopted, and colophony powder is used as a dye-fixing agent so that dye-fixing effects are obtained, environmental pollution is avoided and environmental protection requirements are satisfied. Through the silk fabric dyeing and finishing method, the silk fabric with high crockfastness and high dye fixation is obtained.

Owner:太仓市宝明化纤有限公司

Method for covering polyimide nanofiber surface with titanium dioxide nano-layer

The invention discloses a method for covering the polyimide nanofiber surface with a titanium dioxide nano-layer. The method comprises steps as follows: firstly, a polyamide acid nanofiber membrane is prepared from a polyamic acid solution with an electrostatic spinning technology; then, the nanofiber membrane is immersed in an aqueous solution of a titanium compound for processing, then washed with water, dried and subjected to thermal imidization at gradient rising temperature, and accordingly, the polyimide nanofiber surface is covered with a titanium dioxide nano-layer, and a polyimide fiber membrane with the surface covered with the titanium dioxide nano-layer is prepared. The method has the advantages that the implementation process is simple, the coating efficiency is high, the cost is low, the thickness of the titanium dioxide nano-layer is adjustable and controllable, and the application prospect is good.

Owner:启鼎技术(北京)有限公司

Ultrasonic implement

Owner:THE PROCTER & GAMBLE COMPANY

Treatment method for glass fiber cloth

ActiveCN102817245AOvercome limitationsImprove mechanical propertiesBiochemical fibre treatmentTextile treatment by spraying/projectingGlass fiberWear resistance

The present invention relates to a treatment method for a glass fiber cloth. According to the method, an amylase solution with a temperature of 30-100 DEG C is adopted to wash a glass fiber cloth applied with a starch type sizing agent; after rolling is performed to remove water, a surface treatment agent is adopted to carry out an impregnation treatment on the glass fiber cloth; and finally drying and baking are performed to obtain the treated glass fiber cloth. The glass fiber cloth treated by the treatment method of the present invention has characteristics of excellent mechanical property, folding and wear resistance, excellent product appearance, soft hand feeling, and substantially prolonged service life.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

Cleaning device for textile fabric

InactiveCN107904827AEasy to cleanSolve the problem of unsatisfactory cleaning effect and reduce the quality of fabric productionTextile treatment machine partsLiquid/gas/vapor removal by squeezing rollersEngineeringUltrasonic generator

The invention discloses a textile cloth cleaning device, which comprises a shell, an ultrasonic generator is fixedly installed at the middle end of the bottom of the inner cavity of the shell, an electric telescopic rod is fixedly connected to the bottom of the inner cavity of the shell and located outside the ultrasonic generator, and the electric The top of the telescopic rod is fixedly connected with a movable plate, the inner surface of the movable plate is movably installed with a second cleaning roller, and the right end of the outer surface of the movable plate is fixedly installed with a third motor, and the output shaft of the third motor is fixedly connected with the second cleaning roller . In the present invention, cleaning brushes are fixedly connected to the outer surfaces of the first cleaning roller and the second cleaning roller, and through the effects of bubblers, pipelines and ultrasonic generators, the cleaning effect on the cloth can be improved, and at the same time, the electric telescopic rod can Adjusting the horizontal position between the second cleaning roller and the first cleaning roller enhances the cleaning strength of the cloth, and solves the problem that the cleaning effect of the existing cleaning device is not satisfactory and the production quality of the cloth is reduced.

Owner:吴江市恒达纺织整理有限公司

Graphene heating fabric and production method and system

ActiveCN105922669AIncrease contentImprove conductivityLayered productsFibre treatmentFiberAcrylic resin

The invention discloses a graphene heating fabric, and provides the graphene heating fabric mainly for the problem that an existing heating fabric is low in conductivity. The graphene heating fabric comprises a conducting layer, two insulating layers arranged on the two sides of the conducting layer, a temperature measuring layer arranged on the outer side of one insulating layer and a covering layer arranged on the outer side of the temperature measuring layer in a covering mode; the conducting layer comprises warp yarns and weft yarns which are mutually weaved together in a floating and sinking mode, wherein the warp yarns and the weft yarns are both conductive graphene fibers, or the warp yarns are the conductive graphene fibers, and the weft yarns are the conductive graphene fibers and metal wires; each conductive graphene fiber comprises a linear substrate material and a conductive coating arranged on the outer surface of the linear substrate material in a wrapping mode, wherein the conductive coating is prepared from, by mass, 1-1.8 parts of graphene, 7-25 parts of conductive carbon black and 40-50 parts of acrylic resin; one side of the temperature measuring layer is provided with a plurality of sensors in an array mode. The graphene heating fabric has the good conductivity.

Owner:BEIJING AIKALIFE LNNOVATIVE TECH CO LTD

Dyeing and finishing method for tencel/bamboo pulp fiber blended fabric

ActiveCN105483904ASoft touchMercerising of indefinite length fabricsFabric breaking/softeningFiberYarn

The invention provides a dyeing and finishing method for tencel / bamboo pulp fiber blended fabric. Gray fabric is sequentially subjected to singeing, enzyme rolling and cold piling, washing, cold piling, mercerizing, tentering and whitening, printing, ageing, washing, softening and shaping, calendaring and pre-shrinking, and then the tencel / bamboo pulp fiber blended fabric is obtained, wherein the caustic soda concentration in the mercerizing process ranges from 80 g / L to 90 g / L. The dyeing and finishing method is mainly used for dyeing and finishing the tencel / bamboo pulp fiber blended fabric, and warp and weft of the fabric are tencel / bamboo pulp fiber blended yarn. The shrinkage rate of the obtained tencel / bamboo pulp fiber blended fabric is within the range from +2% to -4%, and the fabric is soft in hand feeling, smooth in fabric cover and free of deformation.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Environmental-friendly dyeing and finishing process of real silk fabric

InactiveCN105040485AHigh whitenessAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsPulp and paper industry

The invention discloses an environmental-friendly dyeing and finishing process of a real silk fabric. The environmental-friendly dyeing and finishing process of the real silk fabric comprises pretreatment, presetting, cryogenic freezing treatment, dyeing, mordant removal, soaping, color fixing, post-finishing, drying, setting, calendering and winding. By performing pretreatment with helicase and alpha-amylase and by adopting cryogenic freezing treatment before dyeing, the performance of the real silk fabric is fundamentally modified and the dye uptake rate of the fabric is improved; a great amount of alkali substances and inorganic salt are not used in the dyeing process and leveling agent and dispersing agent are added, the dyeing uniformity is improved, the environmental pollution is avoided by using natural dyes and the requirements on the environmental protection are satisfied; since self-cleaning treatment is added during post-treatment, the self-cleaning ability, the wrinkling resistance and the water washing fastness of the fabric are improved; the entire process is environmental-friendly and pollution-free.

Owner:TAICANG CHENGLE CHEM FIBER

Environment-friendly energy-saving cloth printing and dyeing process

ActiveCN111304845APenetrate fastBig impactTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile printerMechanical engineering

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to an environment-friendly energy-saving cloth printing and dyeing process. A boiling-off device used in the process comprises a pool body with an opening in the upper end; the position, close to the bottom, of the pool body is provided with a group of guide rollers, and one ends of the guide rollers are rotatably connected with the side walls of the pool body; the interior of the pool body between the adjacent guide rollers is fixedly connected with a sliding barrel, and the interior of the sliding barrel is in sliding connection with a sliding column; the top of the sliding column is fixedly connected with a rotating shaft, the rotating shaft is sleeved with a tensioning roller, and thetensioning roller is rotatably connected with the rotating shaft; a first hole formed in the rotating shaft in the axial direction communicates with a water pump through a pipeline and a valve; a second hole is reversely formed in the middle of the rotating shaft along the diameter of the cross section of the rotating shaft, and the second hole communicates with the first hole; and the position, corresponding to the second hole, of the tensioning roller is provided with an annular groove, and a group of spraying holes communicating with the annular groove are uniformly distributed in the outercircumference of the tensioning roller. A desizing agent is sprayed to grey cloth by the spraying holes, so that the desizing efficiency of the grey cloth is improved.

Owner:福懋兴业(中山)有限公司

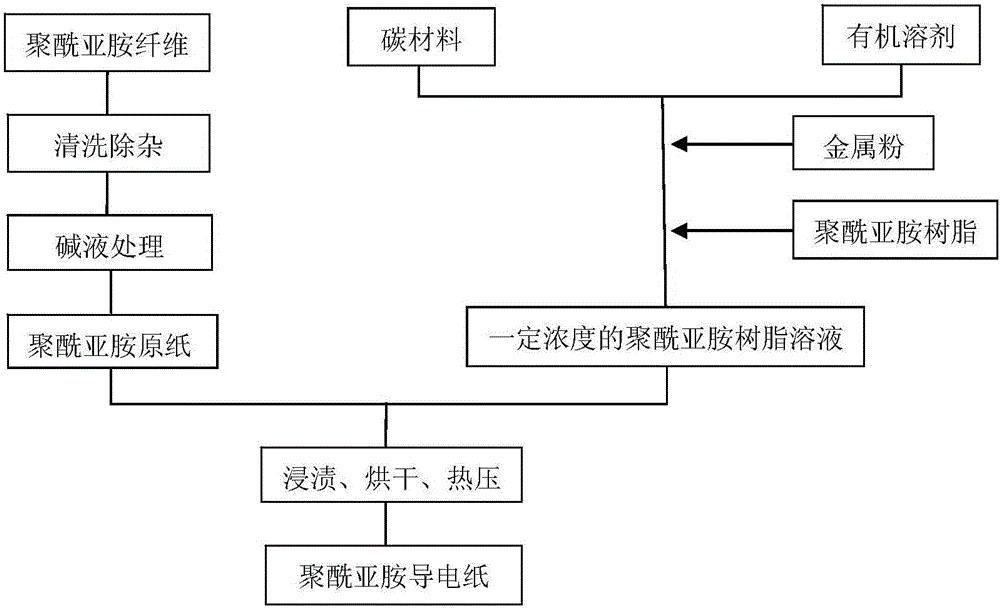

Preparation method of polyimide conductive paper

InactiveCN106120458AImprove conductivityImprove high temperature resistanceNon-fibrous pulp additionSpecial paperPaper basedElectromagnetic shielding

The invention relates to a preparation method of polyimide conductive paper, and belongs to the technical field of high-temperature-resistance and high-conductivity paper base materials. The final product is prepared through the pretreatment of polyimide fiber, the preparation of polyimide fiber crude paper, the configuration of a polyimide resin solution and the preparation of the polyimide conductive paper. The prepared polyimide conductive paper has good conductivity and high temperature resistance, mechanical performance and flexibility and can replace a polyimide conductive thin film and aramid fiber conductive paper to be used for the fields of electromagnetic shielding, electrostatic adsorbing and the like.

Owner:JIANGNAN UNIV +2

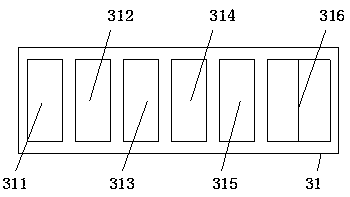

Production process of wool terylene blended smooth double-faced woolen goods

ActiveCN108456965AEasy to organizeHair to smoothLiquid/gas/vapor treatment of propelled fabricsDyeing processYarnPulp and paper industry

The invention provides a production process of wool terylene blended smooth double-faced woolen goods. The production process of the smooth double-faced woolen goods includes the steps: sufficiently mixing wool fibers and terylene fibers; spinning the mixed wool fibers and terylene fibers into yarns of 13 / 1 metric number by an open-end spinning frame; weaving the spun yarns on a rapier loom; performing edge sewing, fulling, scouring, dewatering, drying, decating, teasel raising, drying, anti-shrinking finishing, dyeing, softening finishing, scalding, cutting, decating and the like on a woven gray fabric to prepare a finished product. The total number of warp yarns is 6100-6300, the acting reed width is 195-200cm, porter / permeating number is 35 / 9, weft density is 285-290 yarns / 10cm, and theweight of a fabric billet is 930-950g / m<2>. The fabric is fine, smooth and soft in hand feeling, compact in texture, bright in color and high in color fastness and does not easily felt after being washed with water.

Owner:江阴市长泾花园毛纺织有限公司

Textile product cleaning machine

InactiveCN107558044AGuaranteed cleaning effectSave human effortTextile treatment machine arrangementsTextile treatment by spraying/projectingElectricityInjection port

The invention discloses a textile cleaning machine, which comprises a main body of the cleaning machine, a cleaning room is arranged in the main body, and a water supply system and a return water system connected with the cleaning room; the return water system includes a return water pipe, a return water pump, a return water electromagnetic Valve, filter cavity and water spray pipe; the cleaning room is hollowed out, and there is an ultrasonic vibration device in the cleaning room; a blowing unit is installed in the body and below the cleaning room, and the blowing unit includes a main ventilation pipe, a compressed air pipe, a ventilation branch pipe, an air jet and a blower Electromagnetic valve; also includes a PLC controller and a liquid level sensor, the liquid level sensor is located in the cleaning room, the return water pump, the return water solenoid valve, the ultrasonic vibration device, the blowing solenoid valve and the liquid level sensor are respectively electrically connected or signal connected to the PLC controller. The invention can use mechanical equipment to clean textiles such as cloth and ready-made clothes, which saves manpower and improves efficiency; at the same time, water resources are recycled, water resources are saved, and production costs are also saved.

Owner:SUZHOU SISHAN NANO TECH CO LTD

Conductive graphene fiber and production method and system

The invention discloses a conductive graphene fiber and a production method and system in order to solve the problem that conductive fibers in the prior art are weak in conductivity. The conductive graphene fiber comprises a linear base body material and a graphene conductive coating wrapping the base body material. The graphene conductive coating is prepared from, by mass, 1-1.8 parts of graphene, 7-25 parts of conductive carbon black and 40-50 parts of acrylic acid resin. The production method includes the steps that spinning is conducted through a spinning machine, graphene printing ink and conductive carbon black printing ink are alternately sprayed on long monofilament fibers through a yarn spraying machine, doubling is conducted through a doubling machine to form piled yarn, and conductive carbon black printing ink and graphene printing ink are alternately sprayed on the piled yarn through a piled yarn spraying machine to form the conductive graphene fiber. The conductive graphene fiber is good in conductivity and good in folding and processing performance.

Owner:BEIJING AIKALIFE LNNOVATIVE TECH CO LTD

Dyeing process and dyeing apparatus for collagen fiber regenerated leather

ActiveCN103255653AEffective penetrationUniform dyeing effectTextile treatment machine partsDyeing processFiberHigh concentration

The invention relates to a dyeing process for collagen fiber regenerated leather. The process successively comprises at least two dyeing treatment, at least one fixation treatment, at least one handfeel modification and drying treatment, wherein dyeing, fixation and handfeel modification are all carried out in an supersonic sound field, so a coloring agent, a fixing agent and a handfeel modifier can effectively penetrate into collagen fiber bundles so as to obtain a more uniform dyeing effect. The concentration of the coloring agent in sequentially used bath liquids increasingly decreases, temperatures of the bath liquids gradually increase, the power of the supersonic sound field increasingly decreases, so bath liquids with high concentration can infiltrate into a leather blank at first, and flooding which is serious in the process of filtration can be eliminated in subsequent dipping in liquids with low concentration; thus, flooding generated in subsequent procedures increasingly decreases, and uniform dyeing of the leather blank is realized. Moreover, surface flooding is eliminated in virtue of a brush of a brush roller in the invention. The invention also relates to a dyeing apparatus capable of realizing continuous uniform dyeing of cloth and leather.

Owner:JIANGYIN JUNHUA TEXTILE TECH

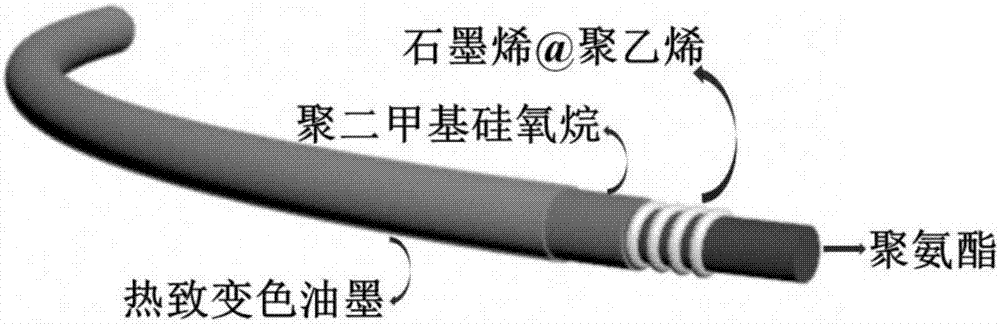

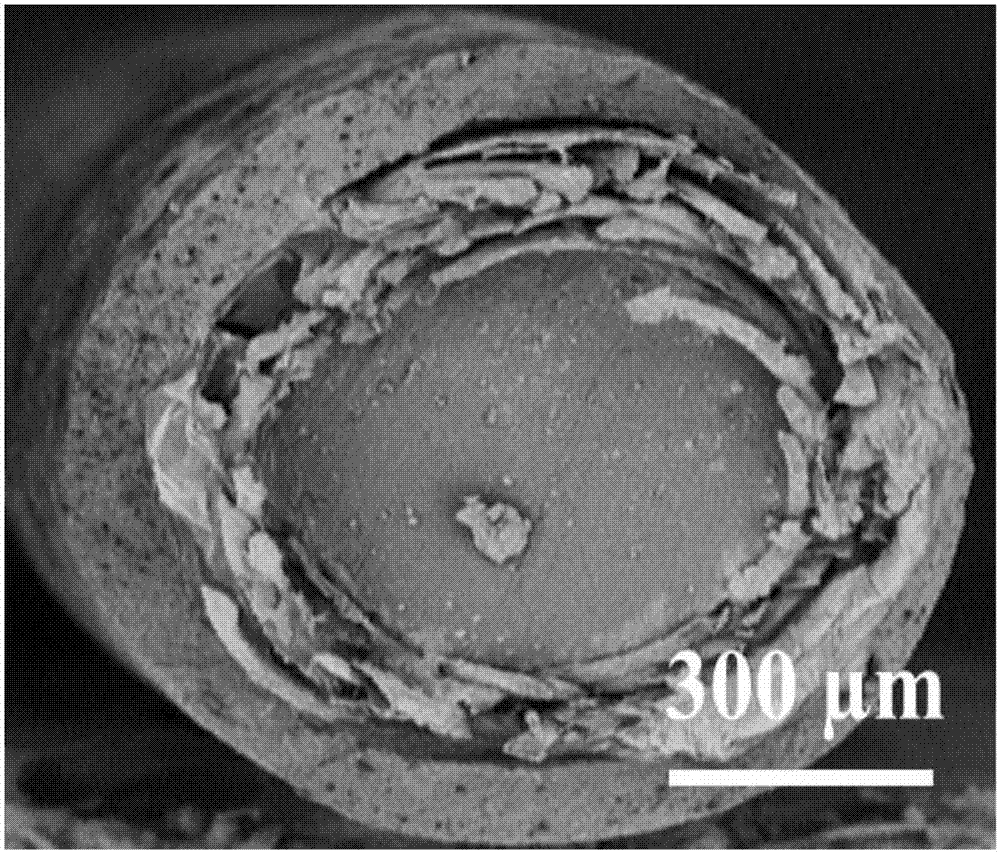

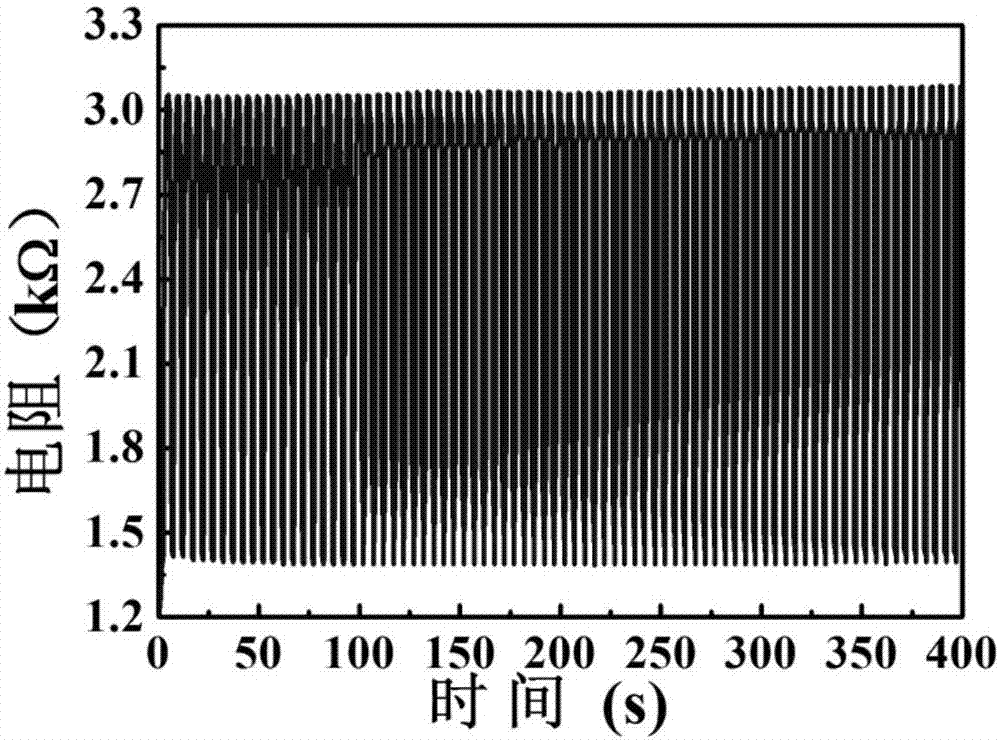

Stretchable electric-heating-induced chameleon fiber and preparing method thereof

The invention relates to stretchable electric-heating-induced chameleon fiber. Core-spun yarn serves as an elastic substrate, and a conducting layer, a protection layer and a chameleon layer are prepared on the surface of the substrate in sequence. A preparing method comprises the steps of pre-treatment of the core-covering yarn, synthesis of the core-spun yarn modified by multilayer graphene oxide, synthesis of the core-spun yarn modified by multilayer graphene, and synthesis of stretchable electric-heating-induced chameleon fiber. According to the stretchable electric-heating-induced chameleon fiber and the preparing method thereof, the method is simple, the condition is mild, the cost is low, and thus the stretchable electric-heating-induced chameleon fiber is suitable for scale production. The obtained stretchable electric-heating-induced chameleon fiber can be changed into multiple colors, has good electroconductivity and cycling stability, and meanwhile shows excellent stretchable performance; basis is provided for functionalization and intellectualization of fiber, and the stretchable electric-heating-induced chameleon fiber has high application value in the aspect like military camouflage, intelligent wearability and visual sensors.

Owner:DONGHUA UNIV

Curcumin-loaded collagen-PCL-PVP composite micro-nano fiber membrane and preparation method thereof

ActiveCN106049026APromote proliferationPromote migrationSurgical adhesivesSynthetic fibresFiberMicro nano

The invention discloses a curcumin-loaded collagen-PCL-PVP composite micro-nano fiber membrane and a preparation method thereof. The preparation method is characterized by comprising the steps that firstly, dichloromethane and ethyl alcohol which have the certain volume ratio are mixed to be prepared into an electrostatic spinning solvent; secondly, curcumin, PCL and PVP which have the certain mass proportion are mixed to be added into the electrostatic spinning solvent and stirred at room temperature until the mixture is transparent, spinning mother liquid with the concentration of 6%-12% is prepared, the spinning mother liquid is injected into electrostatic spinning equipment to be spun, and then a curcumin-loaded PCL-PVP composite micro-nano fiber membrane is obtained; thirdly, the composite membrane is placed in an ultrasonic generator to be subjected to intermittent ultrasonic treatment; lastly, the composite membrane is steeped into an I type collagen solution and naturally aired, and then the curcumin-loaded collagen-PCL-PVP composite micro-nano fiber membrane is prepared. The material has the good biocompatibility and biodegradability, can promote cell growth, proliferation and adhesion, has the effects of resisting inflammations and oxidization, promoting wound healing and the like and can be used as a tissue engineering scaffold, high-grade dressings, a hemostatic material and the like.

Owner:SICHUAN UNIV

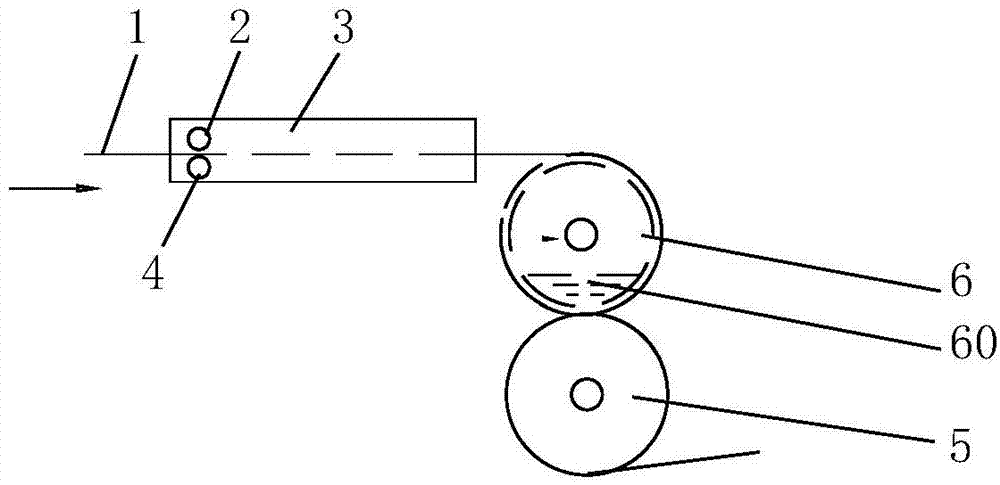

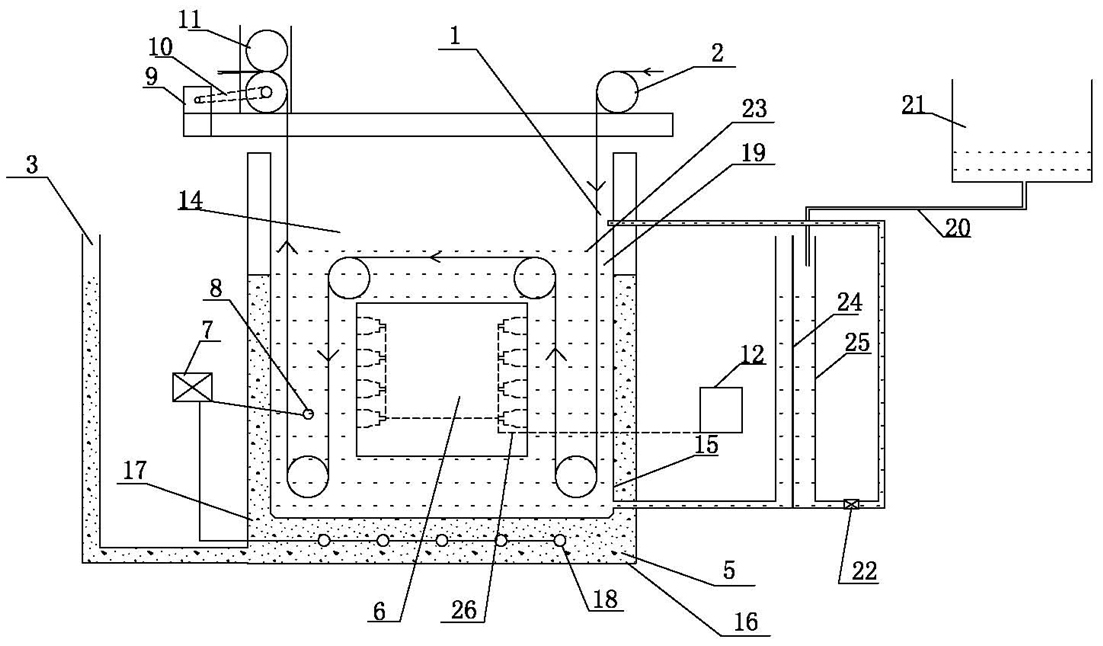

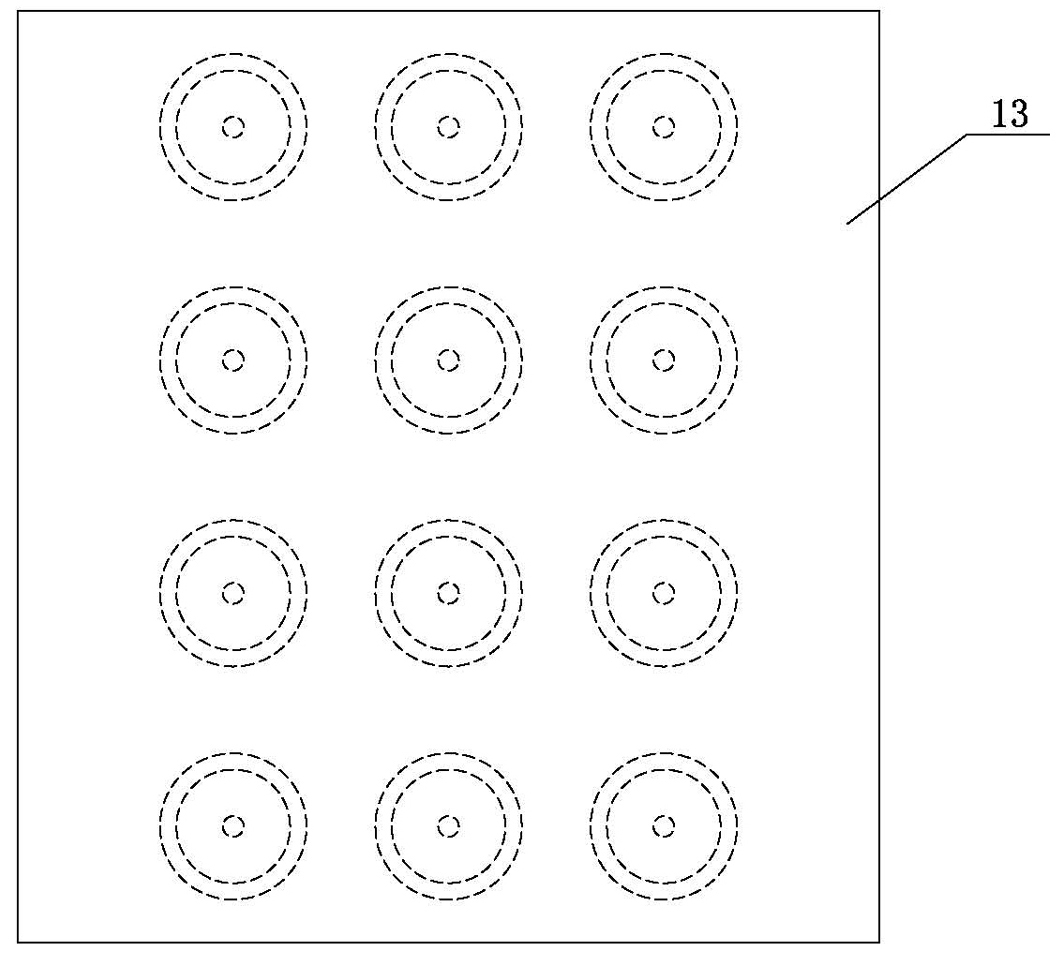

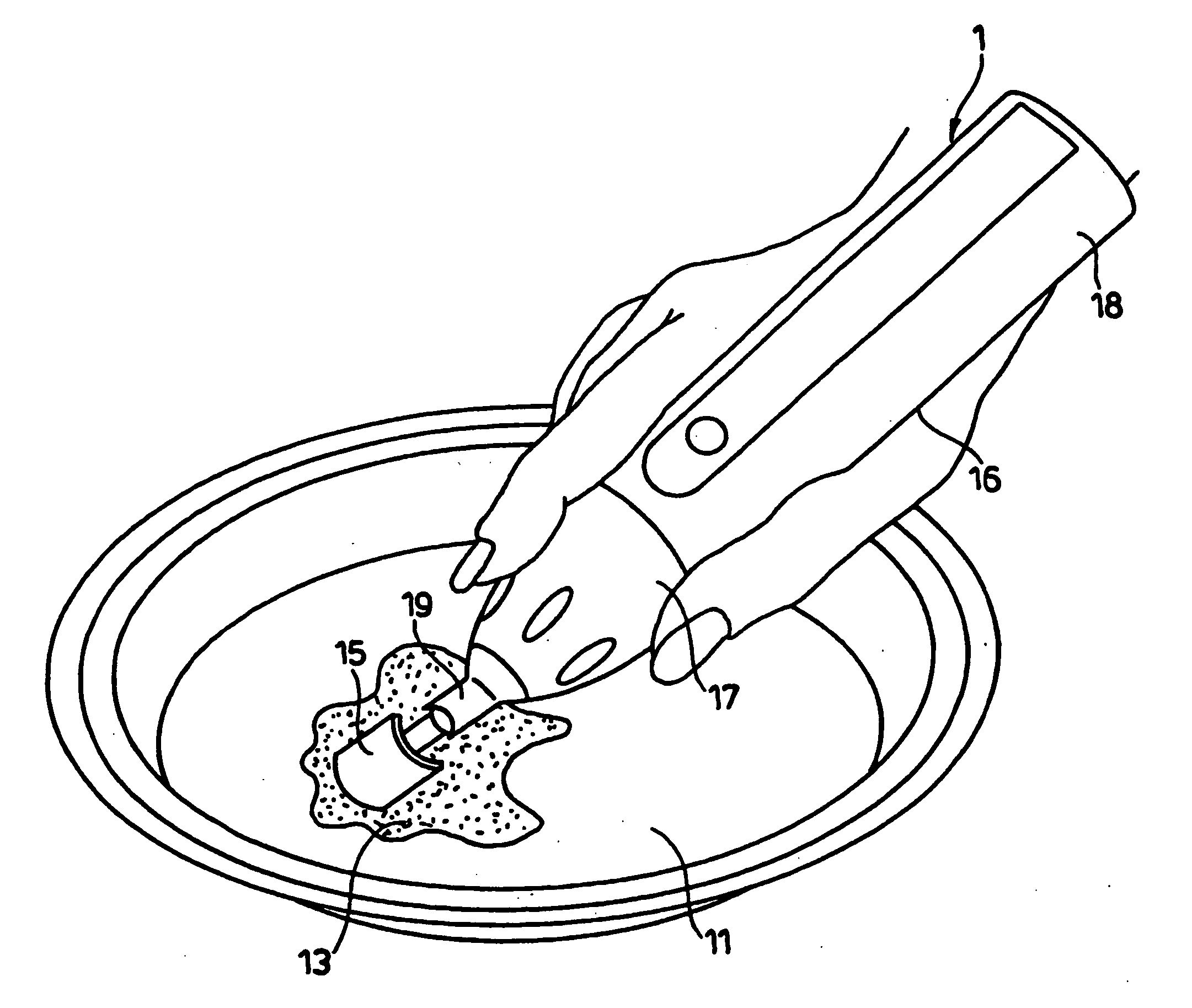

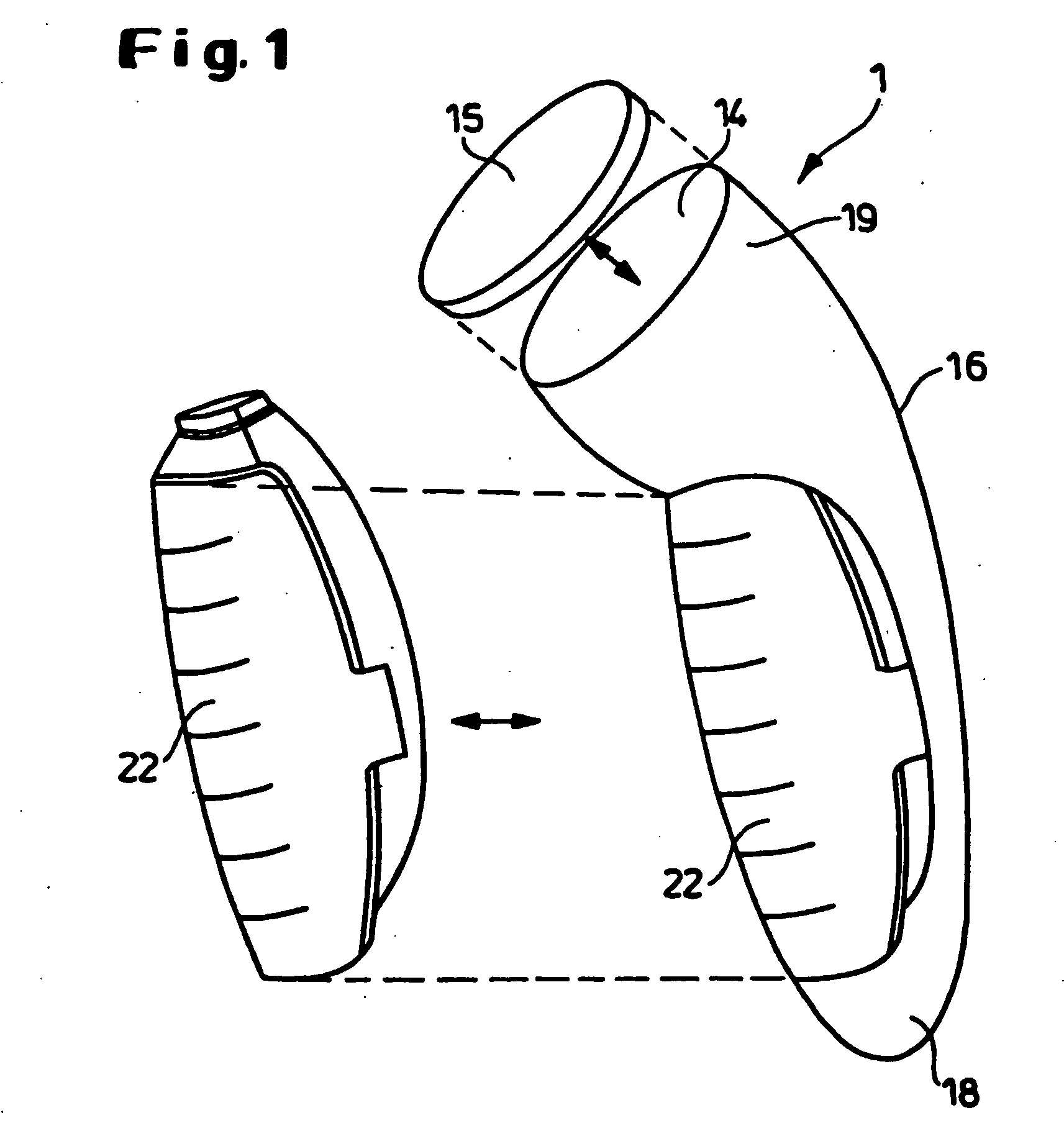

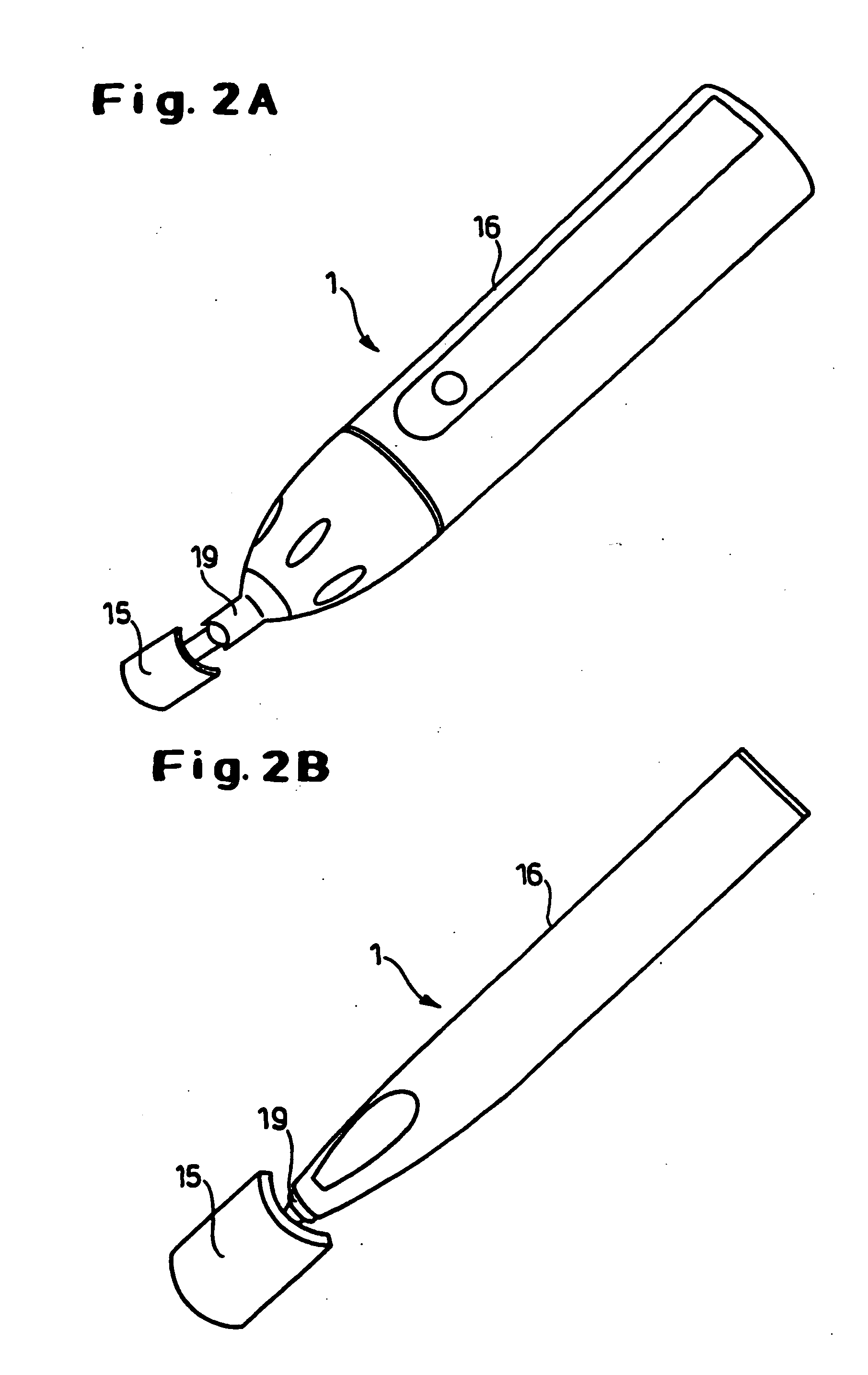

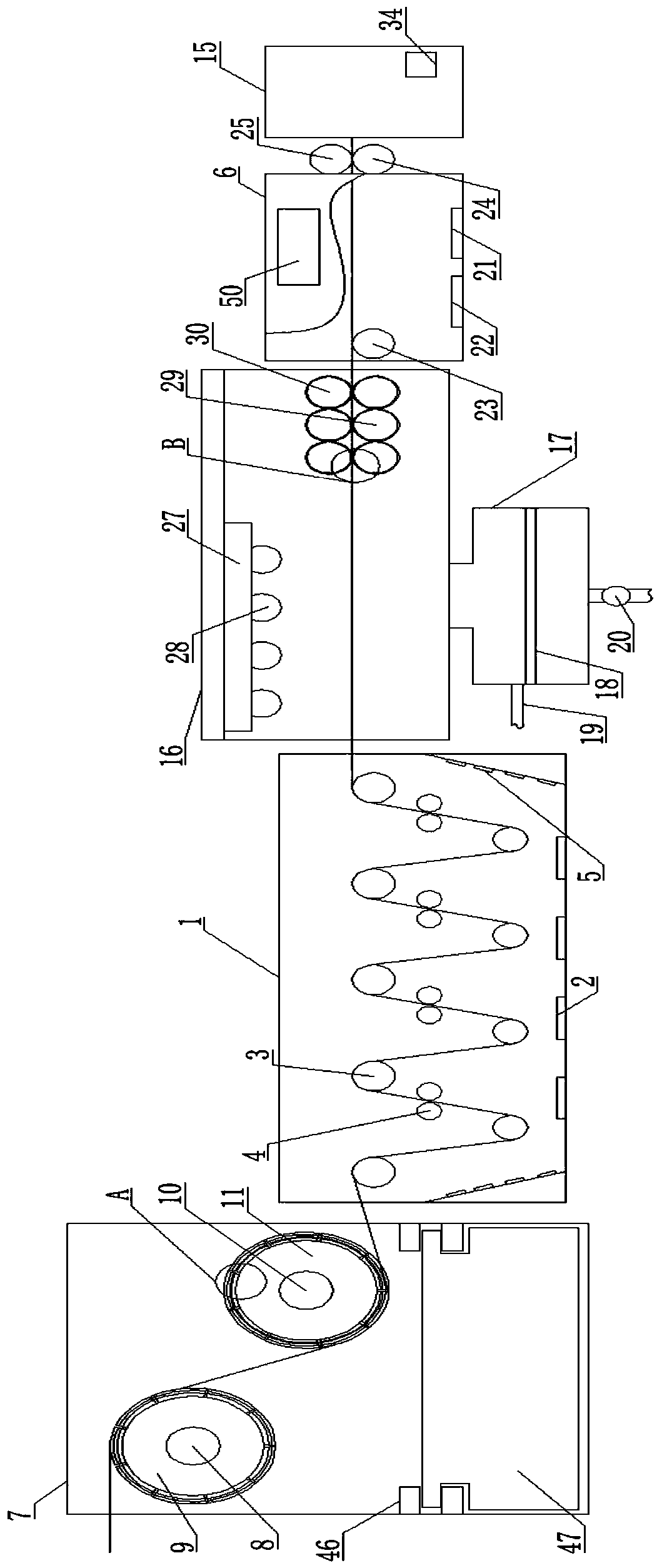

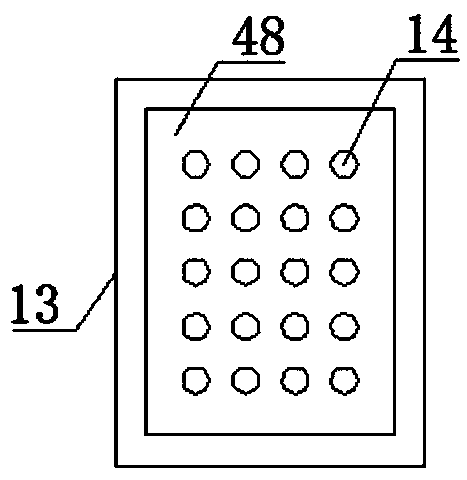

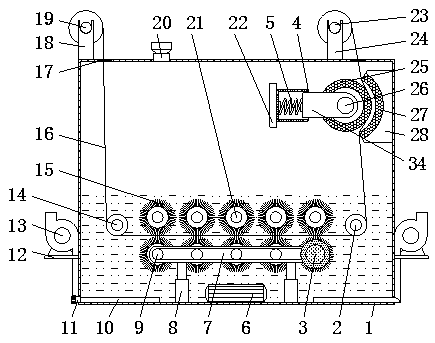

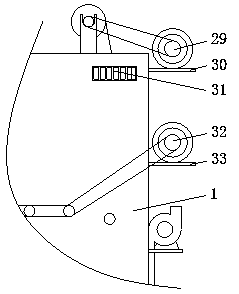

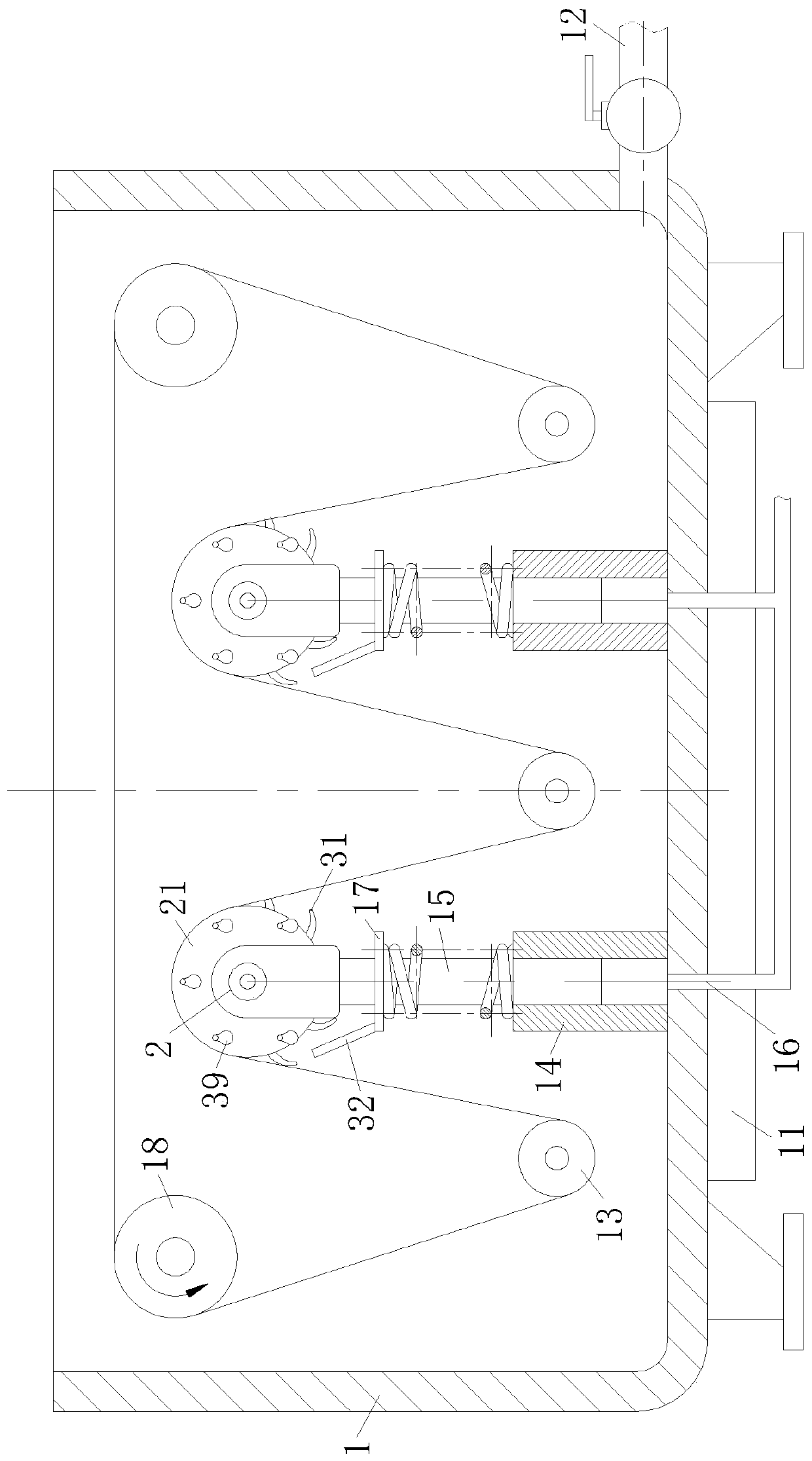

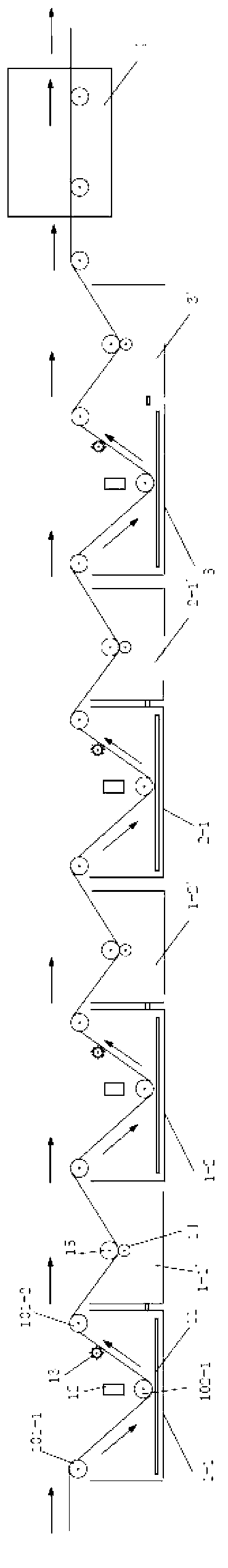

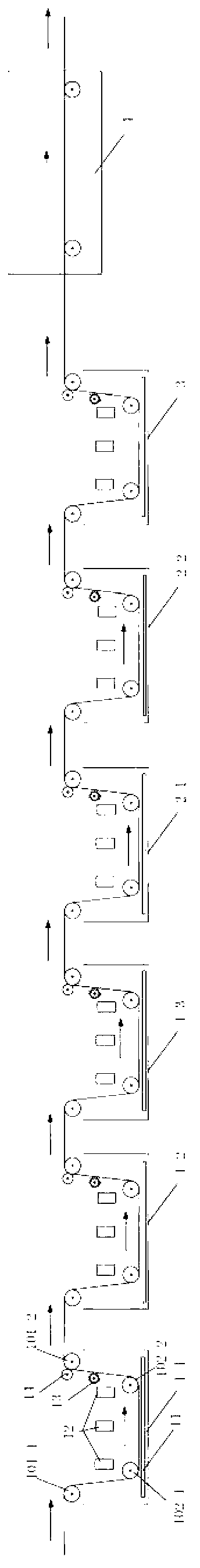

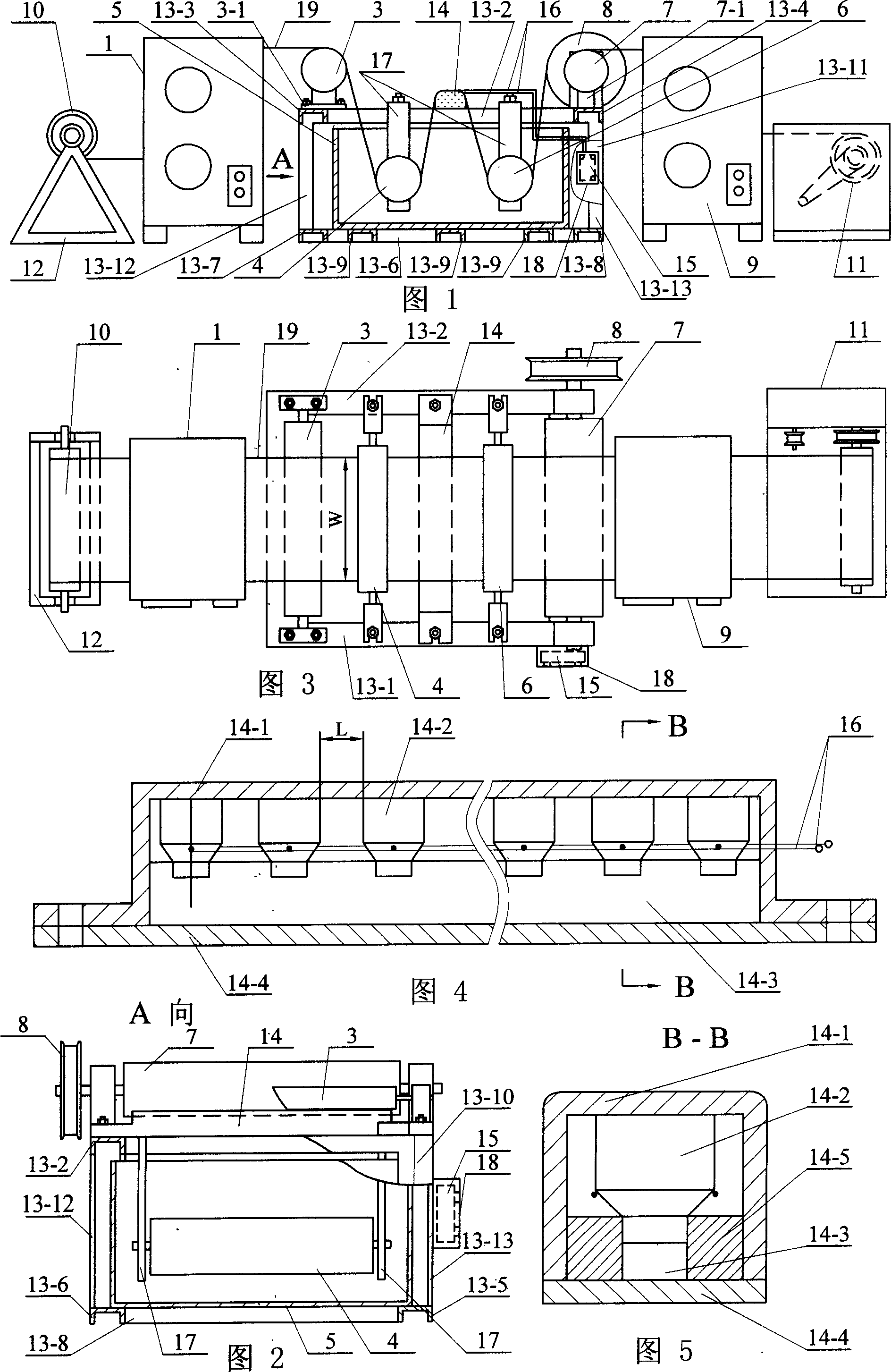

Method and device for improving wettability of broad width presoaking material

ActiveCN1734003ALow viscositySpeed up molecular motionUltrasonic/sonic fibre treatmentVibration treatmentFiberTransformer

A process and apparatus for improving the width prepreg soakage property relates to a process and apparatus for improving the prepreg soakage property. This invention solves the following problems in the prepeg production, using the fiber improved technology can't improve the soakage property of the prepreg; using the ultrasonic vibration technology can't fit for the thermosetting tar; using the ultrasonic soakage narrowband technology can't realize the width fiber soakage disposal. The method of this invention as follows: digging the dried fiber cloth 19 into the thermosetting tar, then going through the compound transformer 14 which is under the control of the ultrasonic power 15, and then drying, rolling and bundling, wherein the width of the fiber cloth 19 W is 0.1-1.5m; the device of this invention as follows: the first drying stove 1 and the rolling roller 10 are mounted at the left of the frame, the second drying stove 9 and the curling machine 11 are mounted at the right of the frame, the upper face of the frame fixes with the compound transformer 14, and the ultrasonic power 15 fixes on the frame. Using this device and the method of this invention can improve the width prepreg soakage property greatly.

Owner:HARBIN INST OF TECH

Popular searches

Material analysis by electric/magnetic means Digital storage Liquid/gas/vapor removal by gas jets Semiconductor devices Current/voltage measurement Microbiological testing/measurement Drying machines with progressive movements Differential amplifiers Dc-amplifiers with dc-coupled stages Liquid/gas/vapor textile treatment

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com