Preparation method of polyimide conductive paper

A technology of polyimide and polyimide fiber, which is applied in the field of preparation of polyimide conductive paper to achieve good high temperature resistance and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

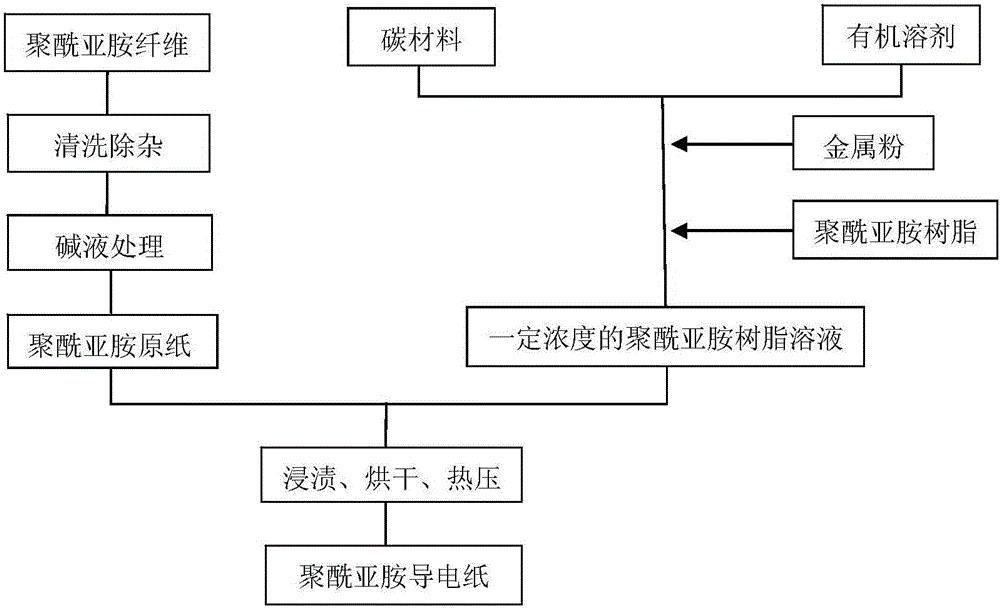

Method used

Image

Examples

Embodiment 1

[0021] (1) Pretreatment of polyimide fibers: put an appropriate amount of polyimide fibers in a sodium hydroxide solution with a temperature of 20°C and a mass fraction of 20%, adding 0.5 g / L sodium lauryl sulfate , assisted by ultrasonic treatment for 2 min, and the ultrasonic treatment conditions are as follows: the temperature is 20° C., and the ultrasonic frequency is 50 kHz; then, it is washed with deionized water.

[0022] (2) The treated polyimide fiber is used to prepare polyimide fiber base paper by a wet method.

[0023] (3) Configuration of polyimide resin solution: 15 parts of carbon black were added to 65 parts of N,N-dimethylacetamide, and ultrasonically treated at 20° C. and 30 kHz for 2 hours. Then, 20 parts of nano-silver powder was added, stirred for 5 minutes, and then ultrasonically treated at 50° C. and 20 kHz for 2 hours. Disperse carbon black and silver powder evenly in N,N-dimethylacetamide. Use this N,N-dimethylacetamide solution to configure a polyi...

Embodiment 2

[0026] (1) Pretreatment of polyimide fibers: put an appropriate amount of polyimide fibers in a potassium hydroxide solution with a temperature of 40°C and a mass fraction of 10%, adding 0.5g / L sodium lauryl sulfate , assisted by ultrasonic treatment for 5 min, and the ultrasonic treatment conditions are as follows: the temperature is 40° C., and the ultrasonic frequency is 100 kHz; then, it is washed with deionized water.

[0027] (2) The treated polyimide fiber is used to prepare polyimide fiber base paper by a wet method.

[0028] (3) Configuration of polyimide resin solution: Add 10 parts of carbon black to 70 parts of N,N-dimethylformamide, sonicate at 20°C and 50 kHz for 1 hour, then add 20 parts of nano Silver powder, stirred for 10 minutes, and then ultrasonically treated at 40°C and 50 kHz for 15 minutes, so that carbon black and silver powder were uniformly dispersed in N,N-dimethylformamide. Use this N,N-dimethylformamide solution to configure a polyimide resin sol...

Embodiment 3

[0031] (1) Pretreatment of polyimide fibers: put an appropriate amount of polyimide fibers in a sodium hydroxide solution with a temperature of 20°C and a mass fraction of 20%, adding 1g / L sodium lauryl sulfate, Ultrasonic assisted treatment for 8 min, the ultrasonic treatment conditions are as follows: the temperature is 20-60 °C, the ultrasonic frequency is 30 kHz; then, wash with deionized water.

[0032] (2) The treated polyimide fiber is used to prepare polyimide fiber base paper by a wet method.

[0033] (3) Configuration of polyimide resin solution: 20 parts of carbon nanotubes were added to 60 parts of N-methylpyrrolidone, and ultrasonically treated at 30° C. and 50 kHz for 1 hour. Then, 20 parts of nano-nickel powder were added, stirred for 10 minutes, and ultrasonically treated for 10 minutes under the conditions of 30° C. and 20 kHz, so that carbon nanotubes and nickel powder were uniformly dispersed in N-methylpyrrolidone. Use this N-methylpyrrolidone solution to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com