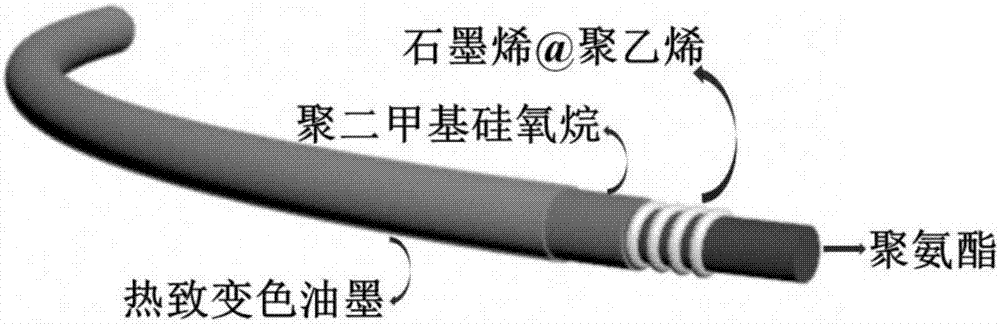

Stretchable electric-heating-induced chameleon fiber and preparing method thereof

A thermochromic and color-inducing technology, applied in fiber type, fiber treatment, vibration treatment, etc., can solve the problems of restricting the development of wearable field, difficult preparation of color-changing fibers, unstretchable fibers, etc., and achieve excellent stretchability. , huge application value, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

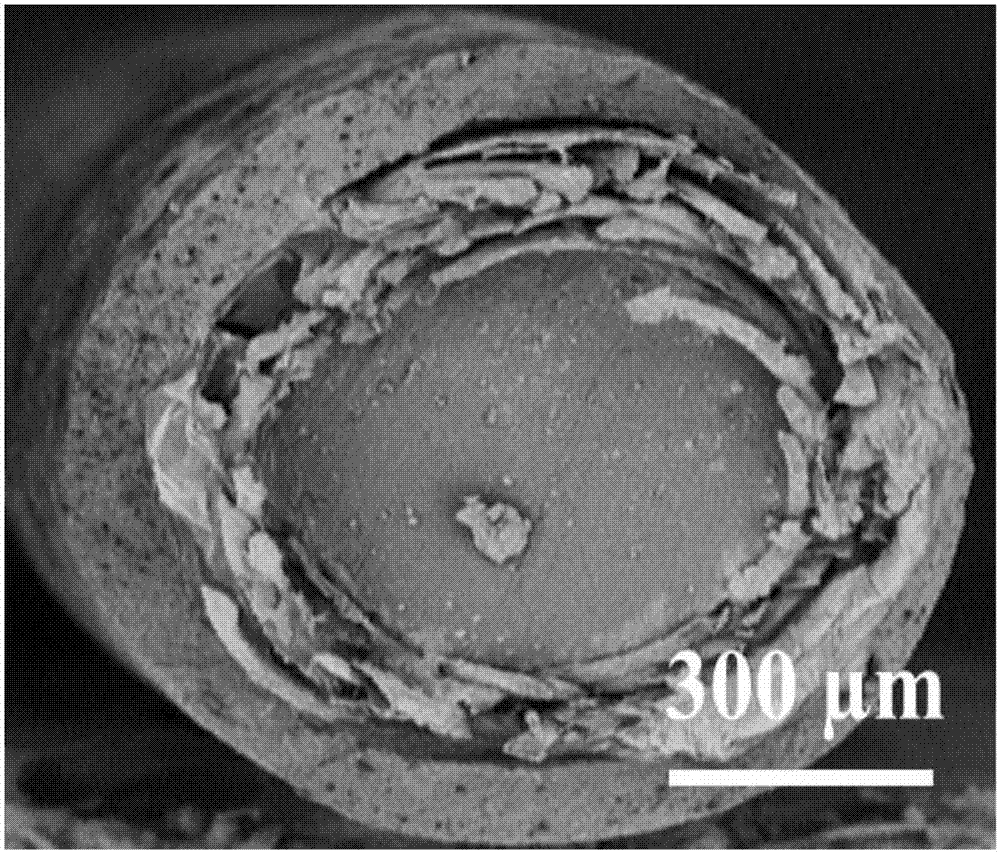

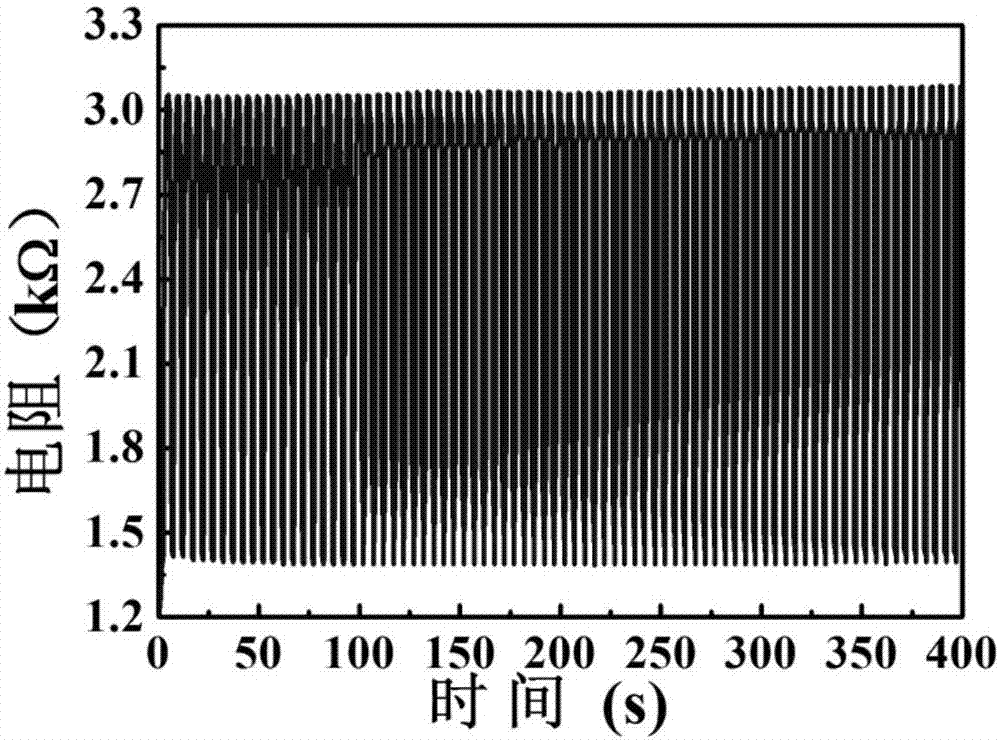

Method used

Image

Examples

Embodiment 1

[0033] (1) 500 mg of graphene oxide powder was dissolved in 100 mL of deionized water, and ultrasonicated for 1 h with an ultrasonic cell pulverizer to obtain a brown graphene oxide dispersion.

[0034] (2) The core-spun yarn (0.0226 g) was ultrasonically placed in deionized water, acetone and ethanol for 15 minutes, dried, and pre-stretched by 40% after plasma treatment for 15 minutes to obtain the treated core-spun yarn.

[0035] (3) Put the core-spun yarn (0.0227g) treated in step (2) into the graphene oxide dispersion in step (1) and soak for 8s, take it out and dry it with a hair dryer to obtain a single-layer graphene oxide-modified bag core yarn.

[0036] (4) Repeat step (3) 30 times with the core-spun yarn modified by single-layer graphene oxide in step (3), to obtain the core-spun yarn modified by multilayer graphene oxide, the core-spun yarn modified by multilayer graphene oxide After the yarn (0.02335g) is released and pre-stretched, it is placed in hydroiodic acid...

Embodiment 2

[0045] (1) 500 mg of graphene oxide powder was dissolved in 100 mL of deionized water, and ultrasonicated for 1 h with an ultrasonic cell pulverizer to obtain a brown graphene oxide dispersion.

[0046] (2) The core-spun yarn (0.0226 g) was ultrasonically placed in deionized water, acetone and ethanol for 15 minutes, dried, and then pre-stretched by 10% after plasma treatment for 15 minutes to obtain the treated core-spun yarn.

[0047] (3) Put the core-spun yarn (0.0227g) treated in step (2) into the graphene oxide dispersion in step (1) and soak for 8s, take it out and dry it with a hair dryer to obtain a single-layer graphene oxide-modified bag core yarn.

[0048] (4) Repeat step (3) 30 times with the core-spun yarn modified by single-layer graphene oxide in step (3), to obtain the core-spun yarn modified by multilayer graphene oxide, the core-spun yarn modified by multilayer graphene oxide After the yarn (0.02326g) is released and pre-stretched, it is placed in hydroiodic...

Embodiment 3

[0051] (1) 500 mg of graphene oxide powder was dissolved in 100 mL of deionized water, and ultrasonicated for 1 h with an ultrasonic cell pulverizer to obtain a brown graphene oxide dispersion.

[0052] (2) The core-spun yarn (0.0226 g) was ultrasonically placed in deionized water, acetone and ethanol for 15 minutes, dried, and pre-stretched by 50% after plasma treatment for 15 minutes to obtain the treated core-spun yarn.

[0053] (3) Put the core-spun yarn (0.0227g) treated in step (2) into the graphene oxide dispersion in step (1) and soak for 8s, take it out and dry it with a hair dryer to obtain a single-layer graphene oxide-modified bag core yarn.

[0054] (4) Repeat step (3) 30 times with the core-spun yarn modified by single-layer graphene oxide in step (3), to obtain the core-spun yarn modified by multilayer graphene oxide, the core-spun yarn modified by multilayer graphene oxide After the yarn (0.02354g) was released and pre-stretched, it was placed in hydroiodic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com