Method and device for dyeing by utilizing ultrasonic wave and microwave

A dyeing method, ultrasonic technology, applied in the field of dyeing using ultrasonic waves and microwaves and its devices, can solve the problems of low dye utilization rate, affecting dyeing efficiency, and high water consumption, so as to improve dyeing effect, improve dyeing efficiency, and save water resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

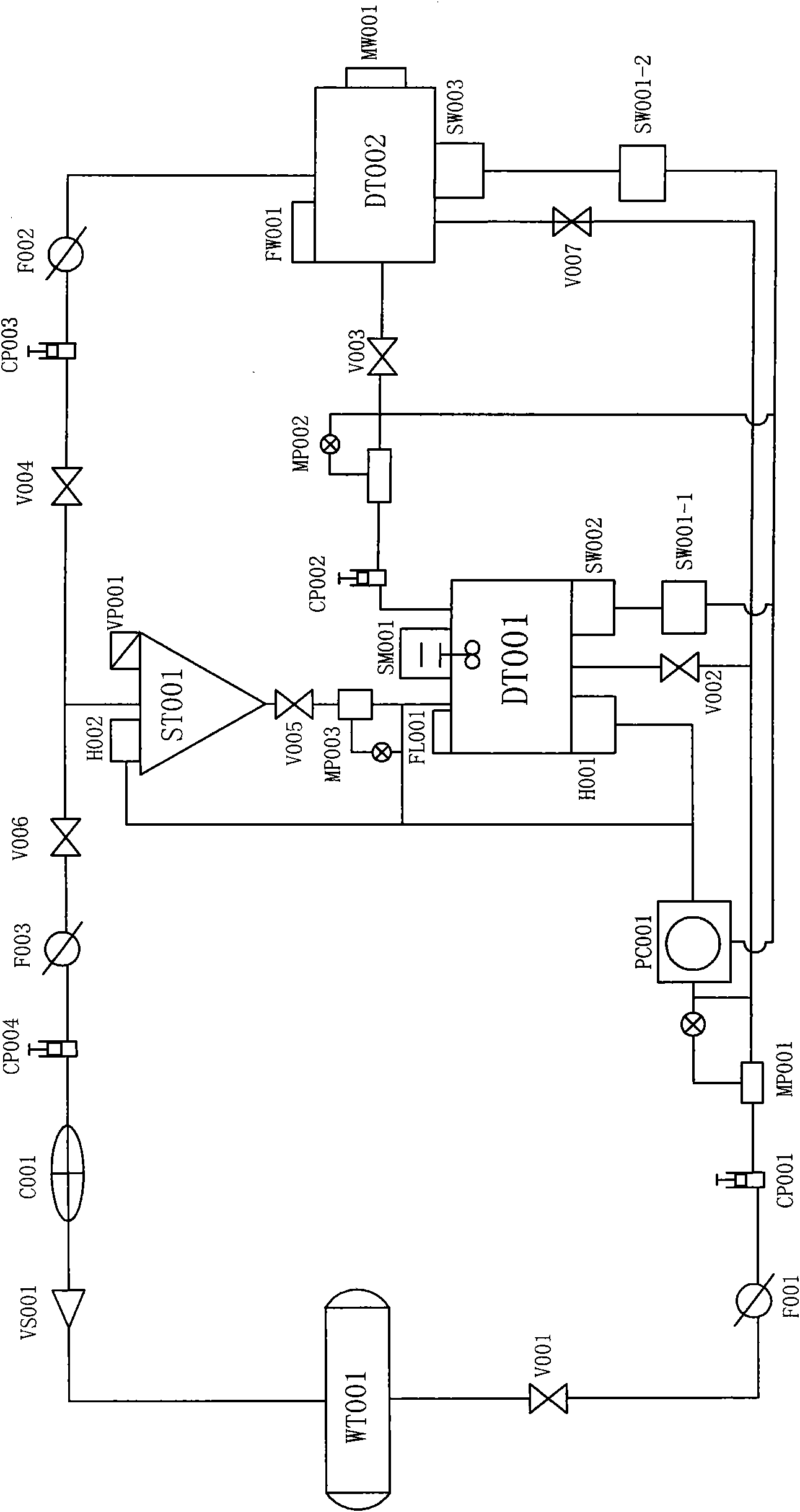

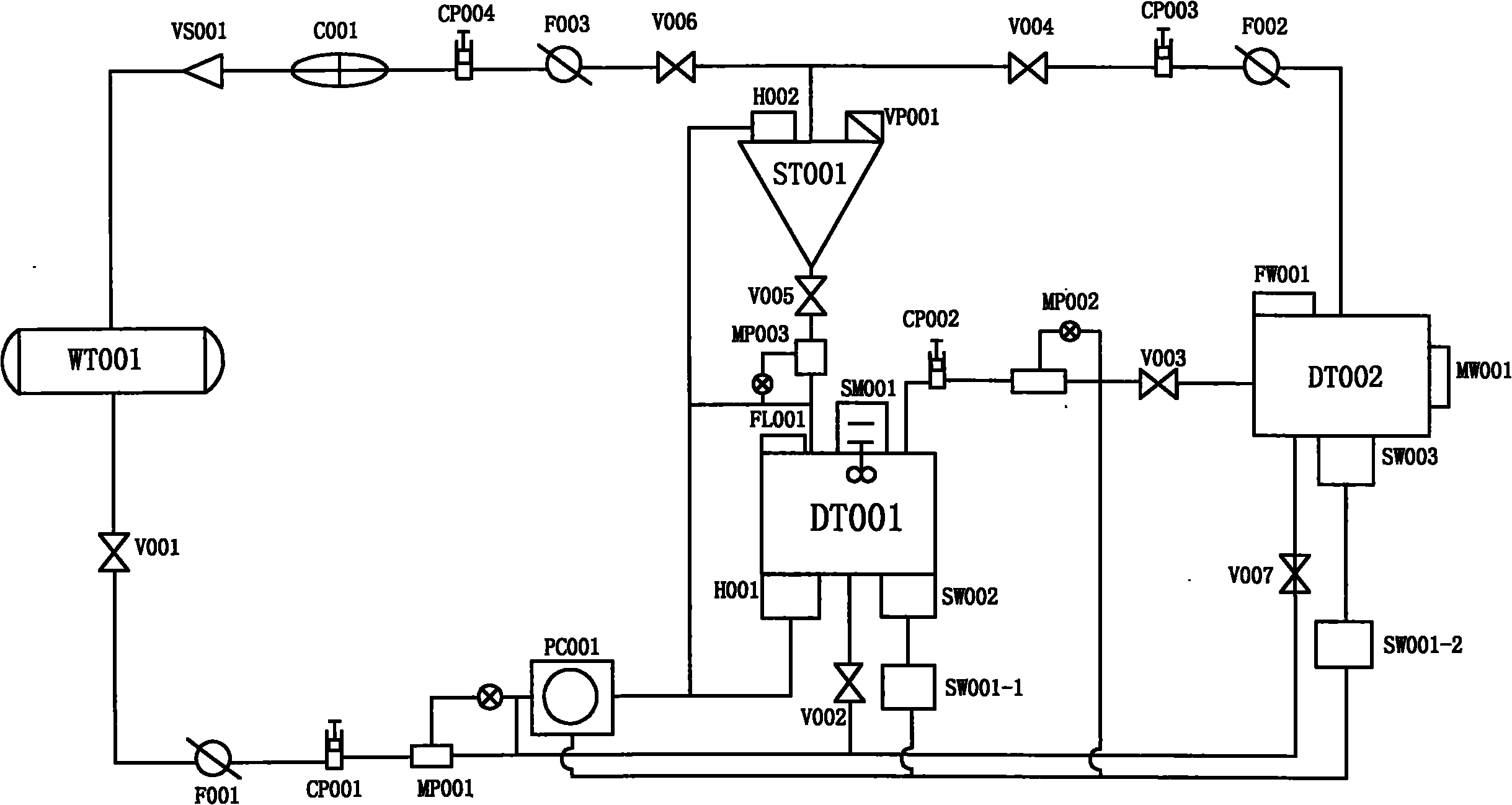

[0022] The dyeing device using ultrasonic waves and microwaves used in the embodiment of the present invention includes a water storage tank WT001, a dye kettle DT001, a dyeing kettle DT002, a separator ST001, an ultrasonic generator SW001-1, an ultrasonic generator SW001-2, and an ultrasonic transducer Device SW001, ultrasonic transducer SW002, microwave generator MW001 and control unit PC001; said water storage tank WT001 passes through the valve V001, filter F001, circulation pump CP001, metering pump MP001 and valve V002 connected in sequence, and is connected with the dye kettle DT001 is connected. Dye kettle DT001 is equipped with heater H001, agitator SM001 and ultrasonic transducer SW001, and dye kettle DT001 is connected to dye kettle DT002 through circulation pump CP002, metering pump MP002 and valve V003 connected in sequence. Dyeing kettle DT002 is equipped with ultrasonic transducer SW002 and microwave generator MW001, ultrasonic transducer SW002 is connected with...

Embodiment 2

[0030] The dyeing device utilizing ultrasonic waves and microwaves adopted in this embodiment is the same as that in Embodiment 1.

[0031] The dyeing method that utilizes ultrasonic wave and microwave described in the embodiment of the invention, for adopting above-mentioned device, be 100 to specification with neutral black S-GL dyestuff S ×80 S / 150×13088″, 5kg silk fabric dyeing as an example:

[0032] 1) Preparation of dye solution, open the valve V001, the water in the water storage tank WT001 is filtered by the filter F001, and then under the action of the circulation pump CP001, the 60L water measured by the metering pump MP001 enters the dye kettle DT001, and passes through the dye kettle DT001 Add 25g of neutral black S-GL dye to the upper discharge port FL001, then close the valves V001 and V002, and the heater H001 will heat the dye kettle DT001 at a constant temperature at a fixed time, and the temperature is 50°C; the stirrer SM001 starts to stir at a constant s...

Embodiment 3

[0038] The dyeing device utilizing ultrasonic waves and microwaves adopted in this embodiment is the same as that in Embodiment 1. The dyeing method utilizing ultrasonic wave and microwave described in the embodiment of the invention, for adopting above-mentioned device, be 80 to specification with disperse blue BGL S ×80 S / 120×10058″, 5kg polyester poplin fabric dyeing as an example:

[0039] 1) Preparation of dye liquor, open the valve V001, the water in the water storage tank WT 001 is filtered by the filter F001, and then under the action of the circulation pump CP001, 100L of water measured by the metering pump MP001 enters the dye kettle DT001, and passes through the dye kettle Add 25g of disperse blue BGL to the discharge port FL001 on DT001, and then close the valves V001 and V002. The heater H001 heats the dye kettle DT001 at a constant temperature at a fixed time, and the temperature is 50°C; the agitator SM001 starts stirring at a constant speed, and the speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com