Textile dyeing method

A dyeing method and technology for textiles, applied in the field of textile printing and dyeing, can solve the problems of shortened dyeing time, lack of versatility, unstable foam, etc., and achieve the effects of good dyeing effect, fine dyeing effect and less liquid carrying amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] 1 adopt the present invention to dye cotton fabric with reactive dyestuff

[0028] (1) Preparation of dye solution. According to the ratio of reactive red B-3BF 5g / L, Yuanming powder 20g / L, and high-efficiency penetrant Leophen M 0.1g / L, dissolve the above dyes in water, and adjust the pH value to 10-11 with soda ash;

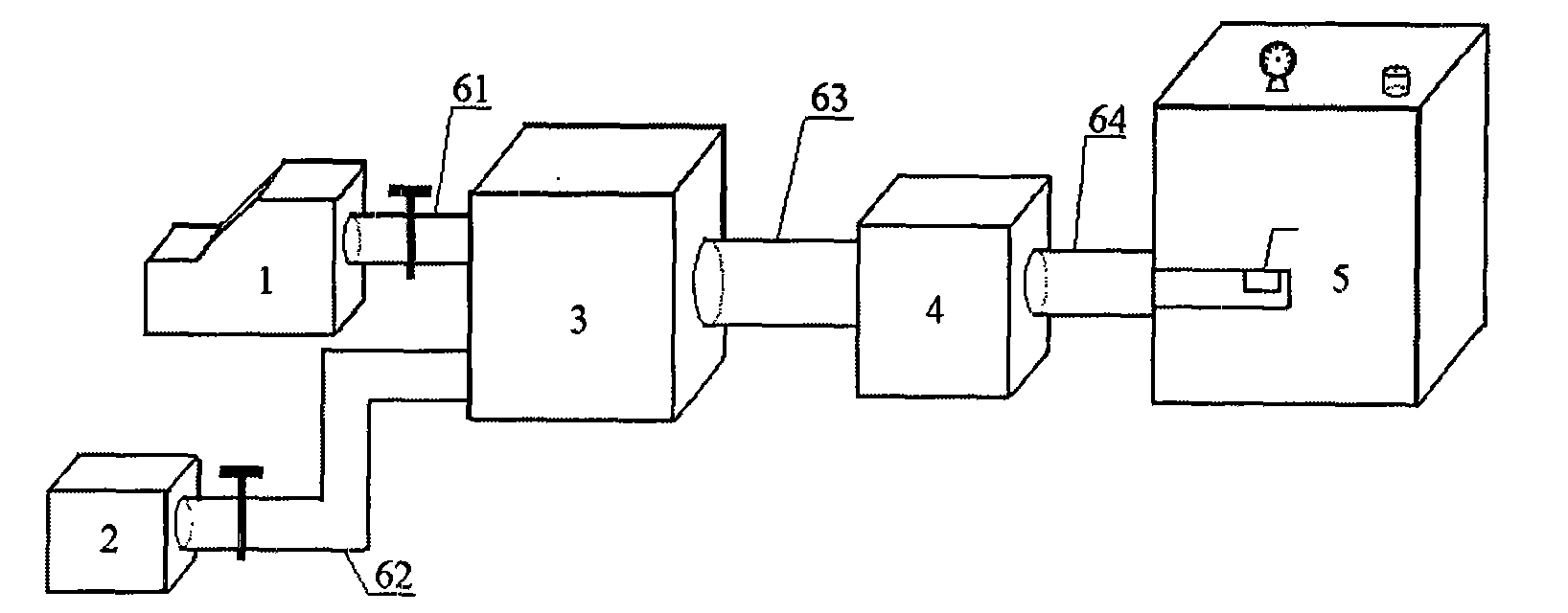

[0029] (2) Atomization of the dye solution, the configured solution is atomized in the high-frequency ultrasonic generator 1 to generate dye particles with a particle size of 50 μm;

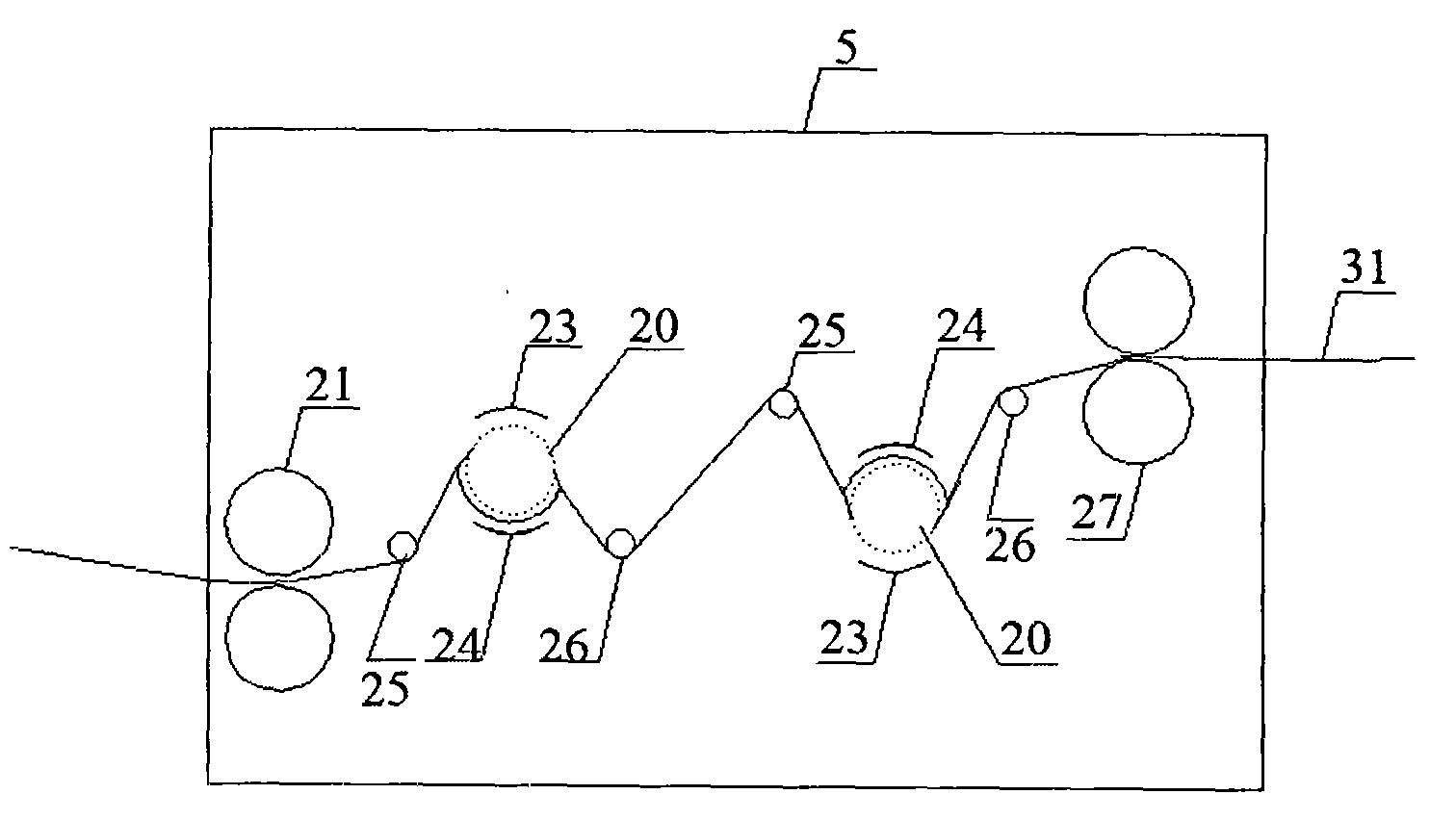

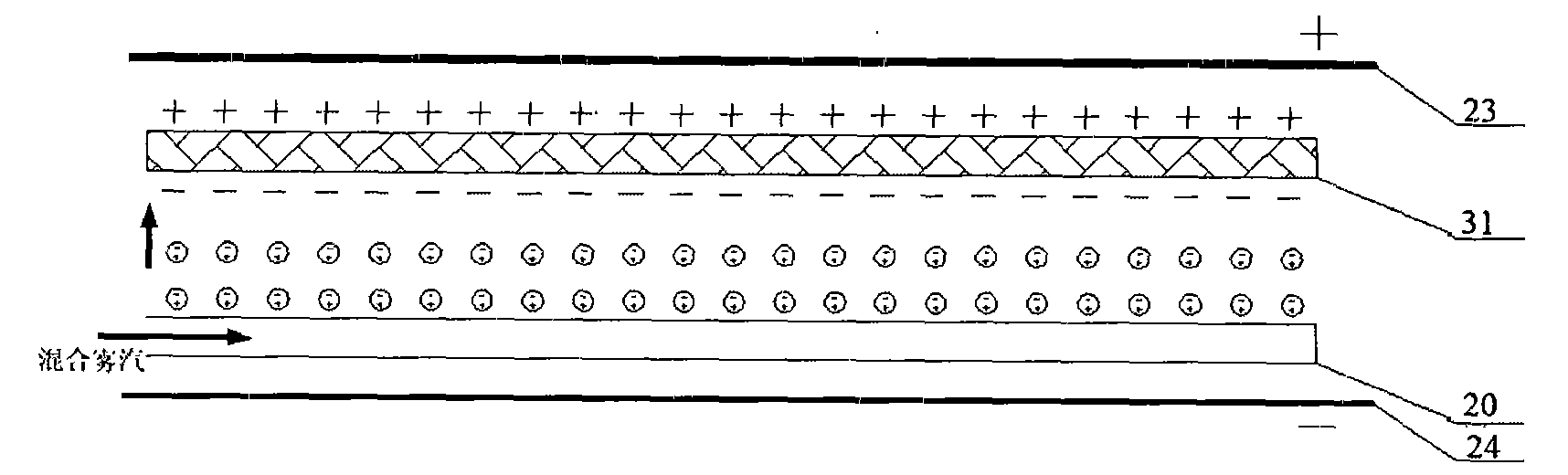

[0030] (3) mixing pressurization, the dye liquor beads are transported to the constant temperature gas mixing chamber 3 through the pipeline 61, and the temperature generated from the high temperature steam generator 2 and sent to the constant temperature gas mixing chamber 3 through the pipeline 62 is 80 ℃. The water vapor is evenly mixed according to the weight ratio of 1:1, and the mixed mist of the dye solution microbeads and water vapor is pressurized to 0.1Mpa by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com