Wrinkle removal equipment for synthetic leather machining

A synthetic leather and equipment technology, which is applied in the direction of fabric elongation, textile material processing, heating/cooling fabric, etc., can solve the problems of wrinkling, increase tensile power, increase energy consumption, etc., and achieve reasonable structure and low cost. , good effect of setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention will be further described:

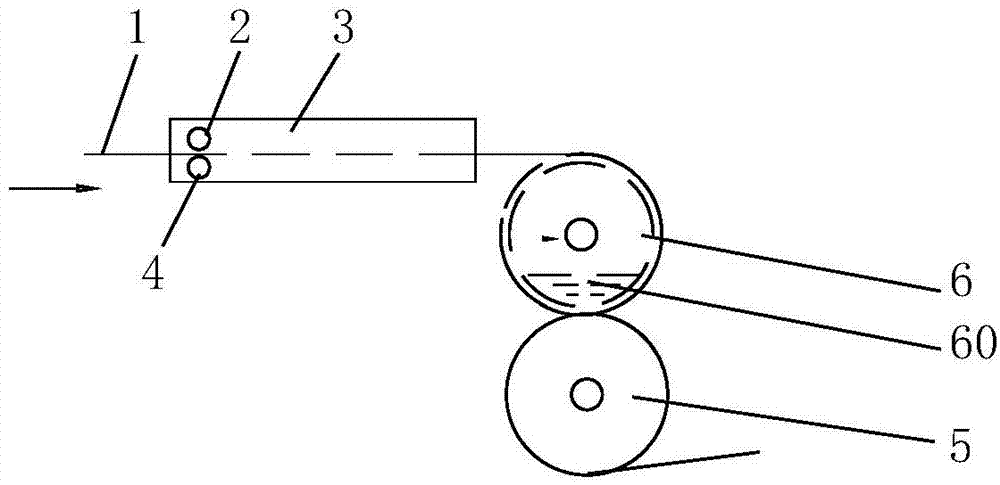

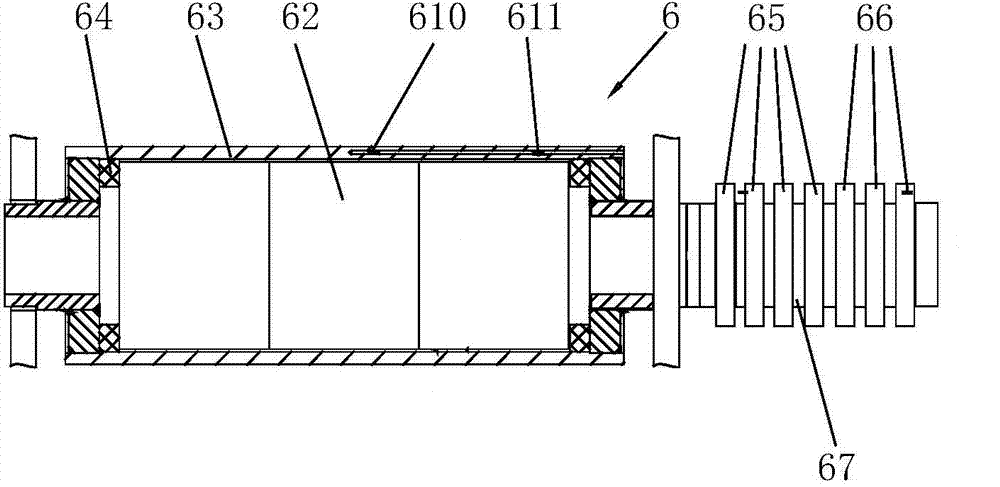

[0022] As shown in the figure, a kind of wrinkle-removing equipment for synthetic leather processing includes: a coating machine, which is equipped with wrinkle-removing equipment before coating, and the wrinkle-removing equipment includes heating roller 6, pressure roller 5 and humidifying box 3, The heating roller 6 presses the pressure roller 5 tightly, and the first steam inlet 2 and the second steam inlet 2 are arranged in the humidification box 3. After passing through the humidification box 3, the cloth 1 is transported to the coating by the heating roller 6 and the pressure roller 5. Cloth machine, the first steam inlet 2 and the second steam inlet 2 are connected with the ultrasonic water atomization generator, the first steam inlet 2 and the second steam inlet 2 are aligned with the two surfaces of the cloth 1, and the spray The water mist can wet the cloth 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com