Nano functional textile finishing method

A technology of nano-function and processing method, applied in textile and papermaking, textile material processing, fiber processing and other directions, can solve the problems of difficult to control product quality, difficult to last and stabilize, and poor stability of dispersion liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

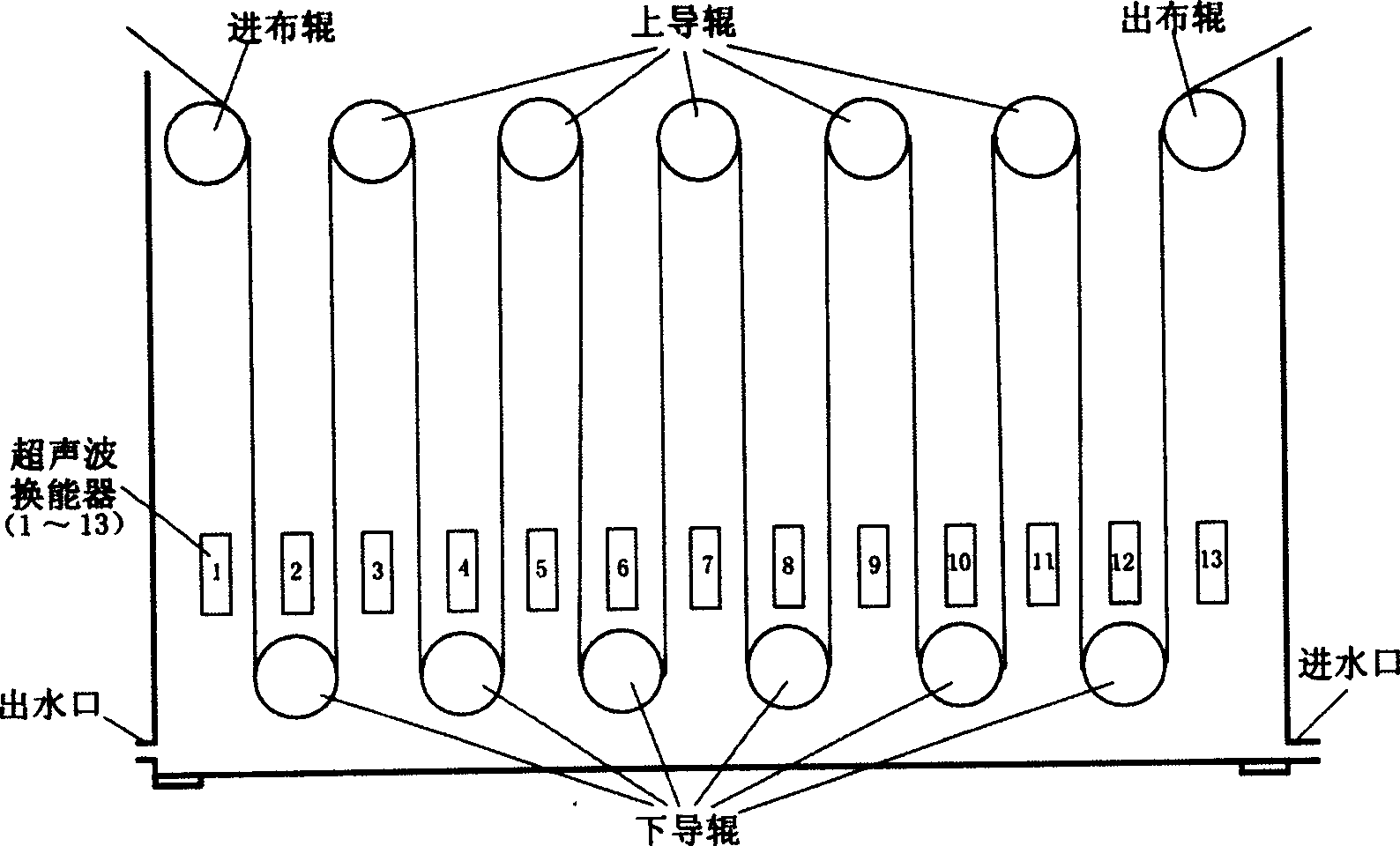

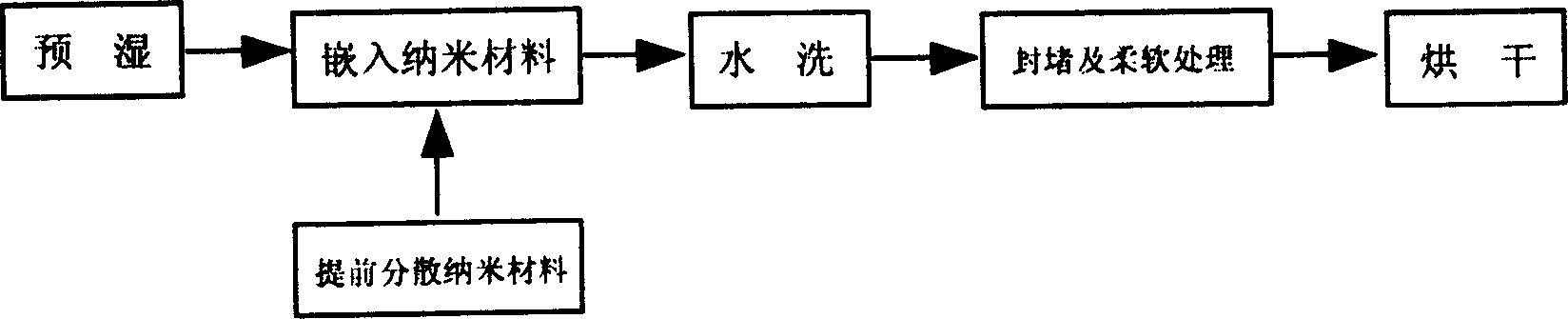

[0038] The preparation of embodiment 1 nano antibacterial textile

[0039] 1. Textile specifications

[0040] Black 100% pure ramie plain cloth; Weight: 140g / m 2 ; Yarn special number: 21×21; Warp and weft density: 236×236; Width: 140cm.

[0041] 2. Selection of nano antibacterial agent

[0042] There are many kinds of nanomaterials that can be used in antibacterial textiles, such as nano-titanium oxide, nano-zinc oxide, nano-silicon oxide, and nano-zirconia. In order to improve the antibacterial properties of these nanomaterials, these nanoantibacterial agents are often compounded with silver or rare earths to make composite antibacterial agents, such as rare earth-activated nano-zinc oxide antibacterial agents and nano-titanium oxide composite silver antibacterial agents.

[0043] Considering the cost performance, this embodiment selects a commercially available rare earth-activated nano-zinc oxide antibacterial agent, the main component of which is nano-ZnO pa...

Embodiment 2

[0064] Preparation of other nano functional textiles of embodiment 2

[0065] 1. Material selection

[0066] See Table 1 for the selection of raw materials for nano-anti-ultraviolet and anti-static textiles.

[0067] Table 1 Selection of Raw Materials for Nano Anti-ultraviolet and Anti-static Textiles

[0068]

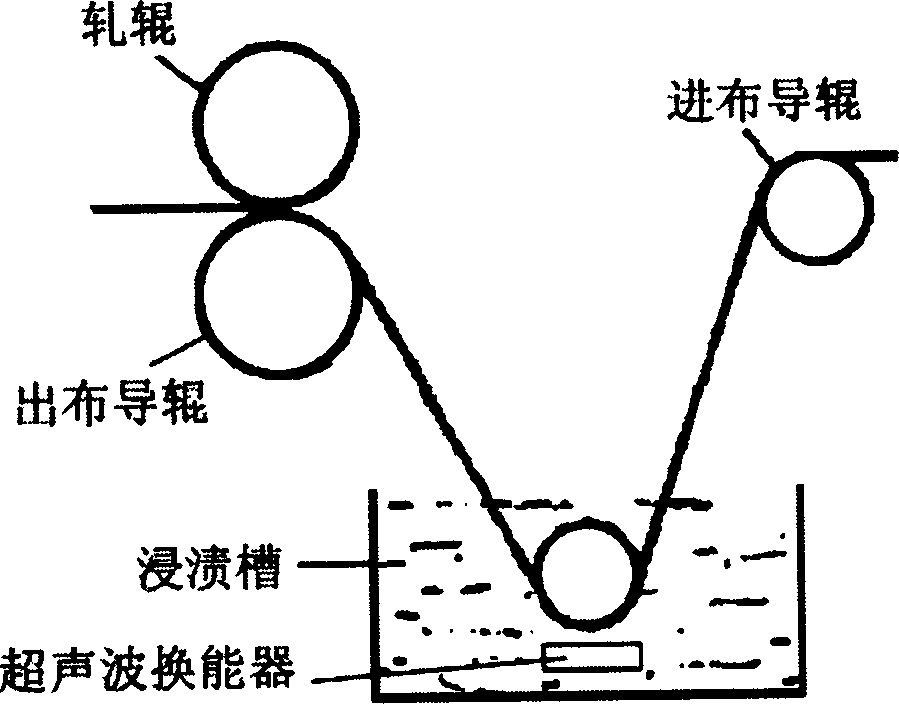

[0069] 2. Processing technology

[0070] Prewetting and washing are the same as in Example 1. See Table 2 for other process parameters.

[0071] Table 2 Main preparation process of nano-anti-ultraviolet and anti-static textiles

[0072]

[0073] 0.1~2%:

In this embodiment, the dispersion concentration is 1%.

antistatic

Dispersion temperature is 45~55℃;

Dispersion time is 10-20 minutes:

The suitable dispersion frequency is 28~51kH,

This embodiment selects 40kH.

The suitable concentration of nanomaterials is 0.1-2%

The dispersion concentration of this embodiment is 3%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com