Energy-saving dyeing apparatus for textile

A technology for dyeing equipment and textiles, applied in textiles and papermaking, equipment configuration for processing textile materials, accessories of textile processing machines, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

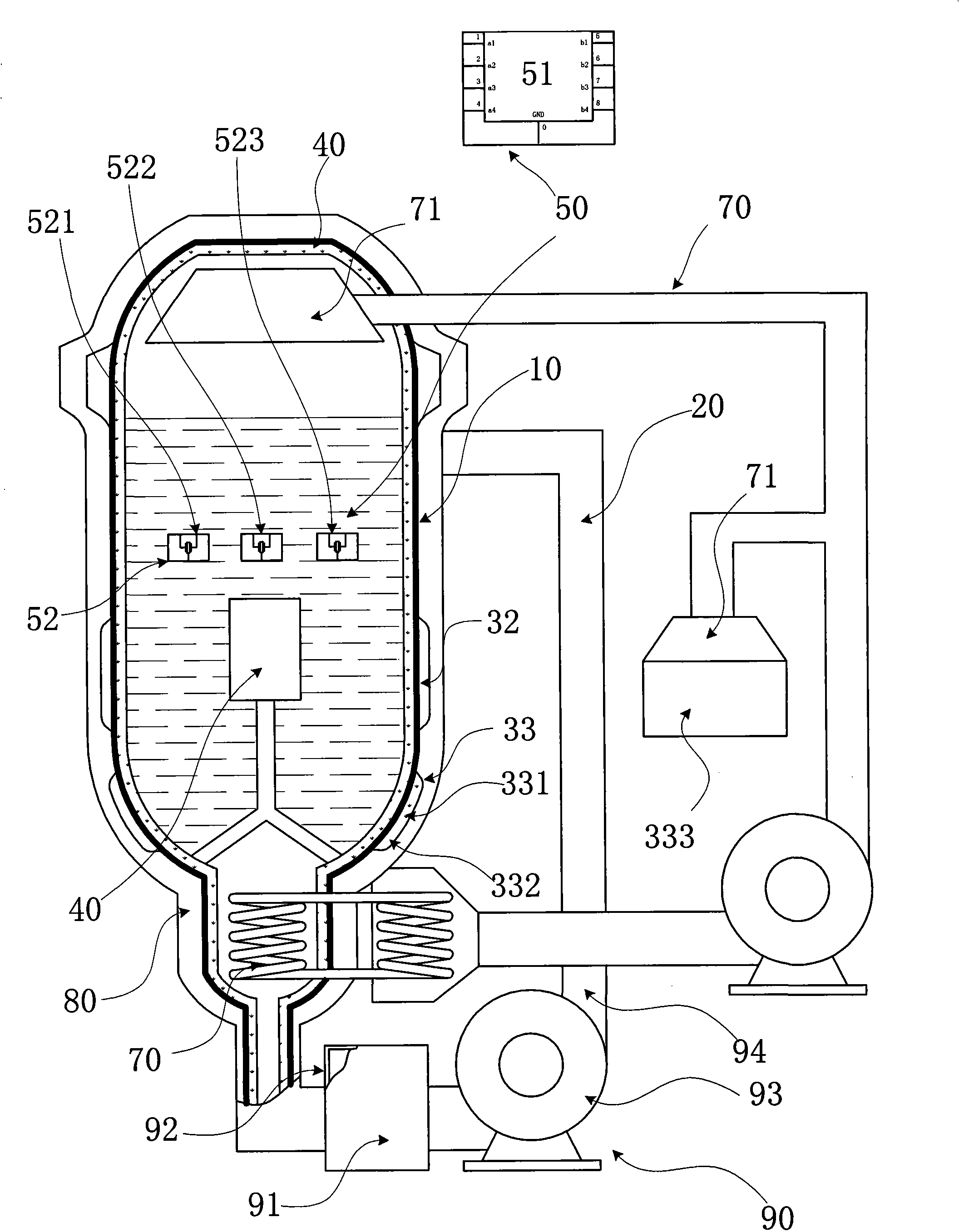

[0013] combined with figure 1 Specific embodiments of the present invention will be described.

[0014] An energy-saving dyeing device for textiles, the dyeing device includes a metal dye vat 10 and an infusion pipeline 20, and a heating device 30 is arranged on the dye vat 10; Coating 40. In the present invention, the anti-corrosion coating 40 is laid on the dyeing vat 10 and the infusion pipeline 20, so that the cylinder body can be made of ordinary metal, which can not only reduce the cost, but also improve the manufacturability, and the inner and outer surfaces of the cylinder body can be made to dissipate heat. The shape of the sheet provides a heat dissipation area and improves thermal efficiency.

[0015] The heating device 30 includes at least three different types of heating units 31-33, the dyeing device further includes a control system 50, the control system 50 controls the heating device 30, the control system 40 includes a controller 51 and a temperature Relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com