Dyeing and finishing method for tencel/bamboo pulp fiber blended fabric

A technology of bamboo pulp fiber and blended fabrics, which is applied in liquid/gas/steam textile material processing, textile material processing, textile and other directions, which can solve the problems of poor dimensional stability of fabrics and difficult control of shrinkage rate, and achieve the effect of soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

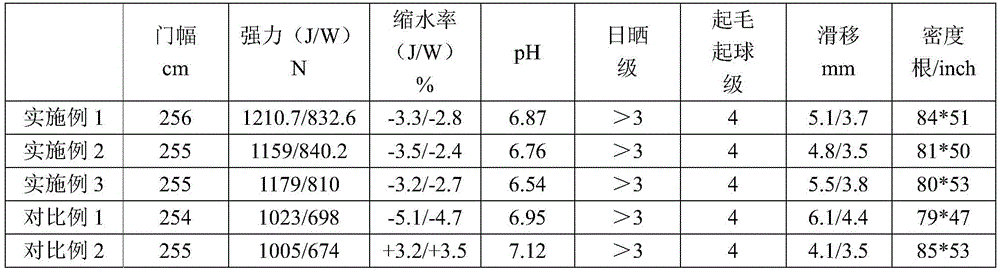

Examples

Embodiment 1

[0021] Specification: 106.5' / (Tencel LF / bamboo pulp fiber 50 / 50) 21s / 2*(Tencel LF / bamboo pulp fiber 50 / 50) 21s / 2 / 80*45, 3 / 1 left twill.

[0022] The above fabrics go through the following steps in turn:

[0023] 1. Singeing: gas singeing, vehicle speed 110m / min, two positive and two reverse, through burning, rolling enzyme to extinguish the fire, stacking for 6-7 hours, the dosage of amylase is 15g / L.

[0024] 2. Washing water: oxalic acid 5g / L, 5 bars of hot water washing, drying, cloth bed fall cloth.

[0025] 3. Cold stack: 10g / L, concentration of hydrogen peroxide is 12g / L, 80% of the liquid is carried, and the stacking time is 24h.

[0026] 4. Mercerizing: Mercerizing is carried out on a straight roller mercerizing machine, including 30 alkali soaking rollers in the cold alkali zone, 18 alkali soaking rollers in the hot alkali zone, 5 grids of hot water washing, caustic soda 80g / L, and alkali soaking time 30s.

[0027] 5. Stenter whitening: Stenter finishing is carried ...

Embodiment 2

[0033] Specification: 106.5' / (Tencel LF / bamboo pulp fiber 50 / 50) 21s / 2*(Tencel LF / bamboo pulp fiber 50 / 50) 21s / 2 / 78*48, 3 / 1 right twill.

[0034] The above fabrics go through the following steps in turn:

[0035] 1. Singeing: gas singeing, vehicle speed 110m / min, two positive and two reverse, through burning, rolling enzyme to extinguish the fire, stacking for 6-7 hours, the dosage of amylase is 15g / L.

[0036] 2. Washing water: oxalic acid 5g / L, 5 bars of hot water washing, drying, cloth bed fall cloth.

[0037] 3. Cold pile: 15g / L, the concentration of hydrogen peroxide is 15g / L, the amount of liquid is 70%, and the stacking time is 20h.

[0038] 4. Mercerizing: Carry out mercerizing on a straight roller mercerizing machine, including 30 alkali soaking rollers in the cold alkali zone and 18 alkali soaking rollers in the hot alkali zone, washing with 5 grids of hot water, caustic soda 90g / L, and alkali soaking time 20s.

[0039] 5. Stretching and whitening: Stretching is ca...

Embodiment 3

[0045] Specification: 106.5' / (Tencel LF / bamboo pulp fiber 50 / 50) 21s / 2*(Tencel LF / bamboo pulp fiber 50 / 50) 21s / 2 / 76*50, 3 / 1 left twill.

[0046] The above fabrics go through the following steps in turn:

[0047] 1. Singeing: gas singeing, vehicle speed 110m / min, two positive and two reverse, through burning, rolling enzyme to extinguish the fire, stacking for 6-7 hours, the dosage of amylase is 15g / L.

[0048] 2. Washing water: oxalic acid 5g / L, 5 bars of hot water washing, drying, cloth bed fall cloth.

[0049] 3. Cold stack: 13g / L, concentration of hydrogen peroxide is 13g / L, 70% of liquid, stacking time 24h.

[0050] 4. Mercerizing: Carry out mercerizing on a straight roller mercerizing machine, including 30 alkali soaking rollers in the cold alkali zone, 18 alkali soaking rollers in the hot alkali zone, 5 grids of hot water washing, caustic soda 85g / L, and alkali soaking time 26s.

[0051] 5. Stretching and whitening: Stretching is carried out on the Monforts setting mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com