Textile product cleaning machine

A textile and washing machine technology, applied in the field of textile processing, can solve problems such as large water consumption, efficiency not keeping up with the production rhythm, and reduced textile quality, so as to achieve the effects of ensuring cleaning effect, saving water resources, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

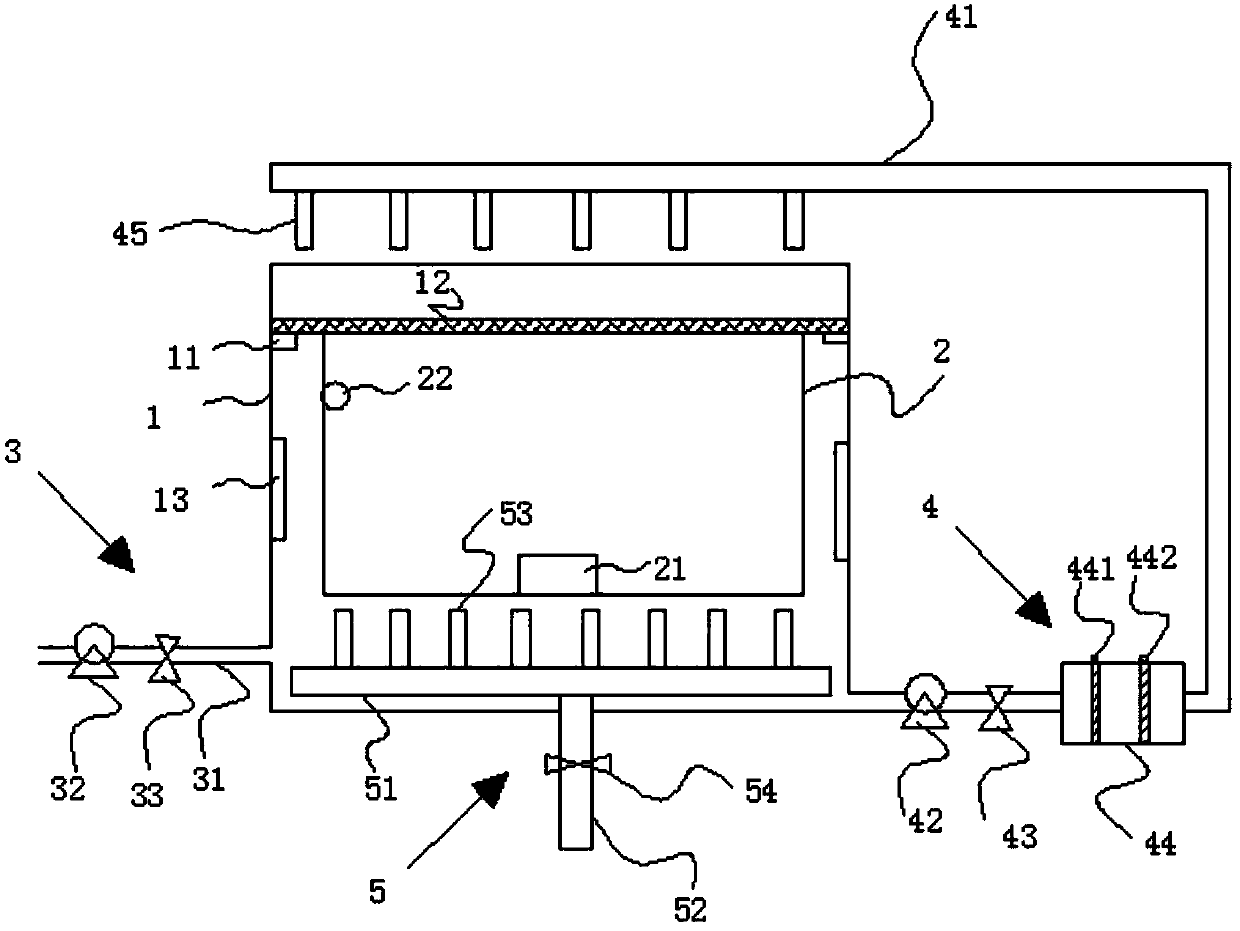

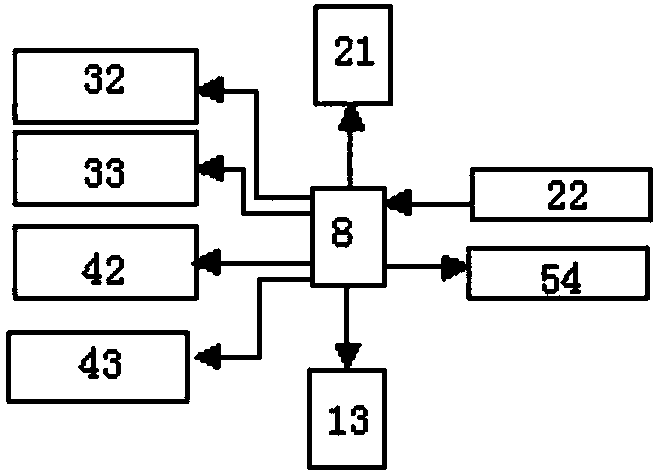

[0028] Embodiment: a kind of textile cleaning machine, as figure 1 and figure 2 As shown, it includes a main body 1 of the cleaning machine, a cleaning chamber 2 is arranged in the body, and a water supply system 3 and a return water system 4 connected to the cleaning chamber are also included;

[0029] The return water system 4 includes a return water pipe 41, a return water pump 42, a return water solenoid valve 43, a filter cavity 44 and a water spray pipe 45, one end of the return water pipe is connected with the cleaning chamber, and the other end is connected with the spray water spray pipe. Water pipe connection, the return water pump, the return water solenoid valve and the filter chamber are arranged on the return water pipe, and the inside of the filter chamber is provided with a primary filter 441 and a secondary filter in sequence according to the direction of water flow 442. Both the primary filter and the secondary filter are detachably connected to the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com