Acidic reduction cleaner

A cleaning agent and acidic technology, applied in the field of printing and dyeing auxiliaries, can solve the problems of waste of resources, cumbersome steps, strong damage to polyester, etc., and achieve the effect of saving pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

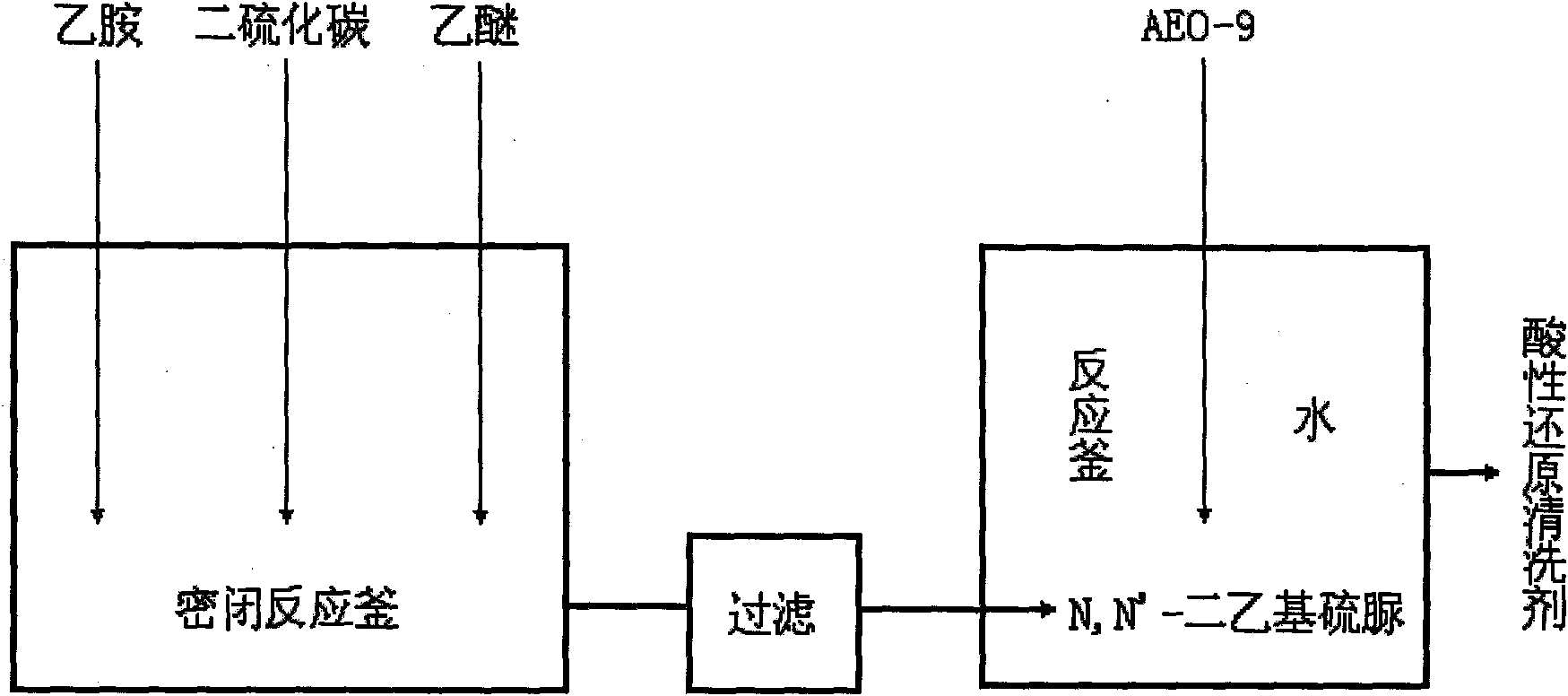

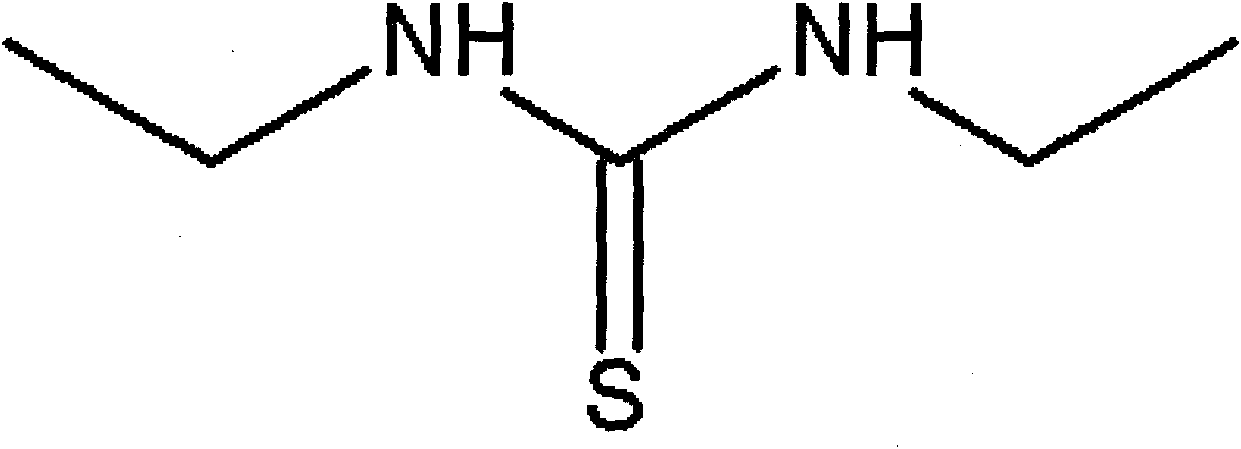

[0007] 1.N, N'-diethylthiourea / (C 2 h 5 NH) 2 Synthesis of CS

[0008] Prepare 45Kg ethylamine / C 2 h 5 NH 2 , 38Kg carbon disulfide / CS 2 , 115Kg ether / (CH 3 ) 2 O.

[0009] In the airtight reaction kettle, first add 115Kg ether. Open stirrer, add 38Kg carbon disulfide. After stirring evenly, 45Kg of ethylamine was added. React at room temperature (20-25° C.) for 12 hours, and stop stirring. The reaction product is filtered through a filter device to obtain N,N'-diethylthiourea.

[0010] 2. Compounding of acid reduction cleaning agent

[0011] Prepare 75Kg N,N'-diethylthiourea, 12Kg AEO-9 / C 12 h 25 O(CH 2 CH 2 O) 9 H, 288Kg water.

[0012] In the reactor, add 288Kg of water, 12Kg of AEO-9, 75Kg of N,N'-diethylthiourea in turn, and stir until uniform to obtain an acidic reducing cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com