Patents

Literature

99 results about "Backwater valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A backwater valve is a backflow prevention device used to prevent outbound water through a dwelling's drain pipes from re-entering -- "back flowing"—into a home. The valve contains a flap that allows water to exit the home, but closes to prevent the back flow into the home.

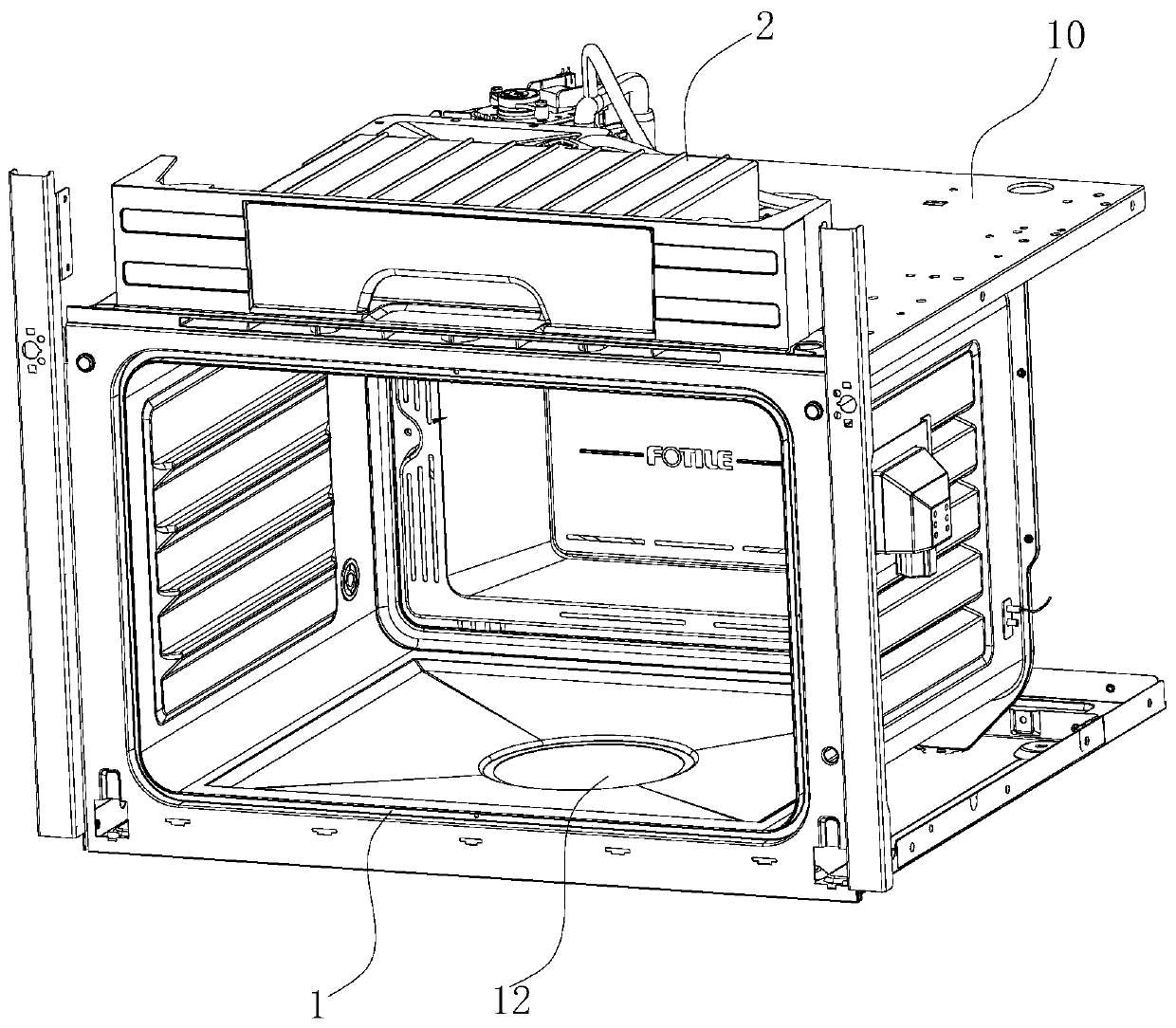

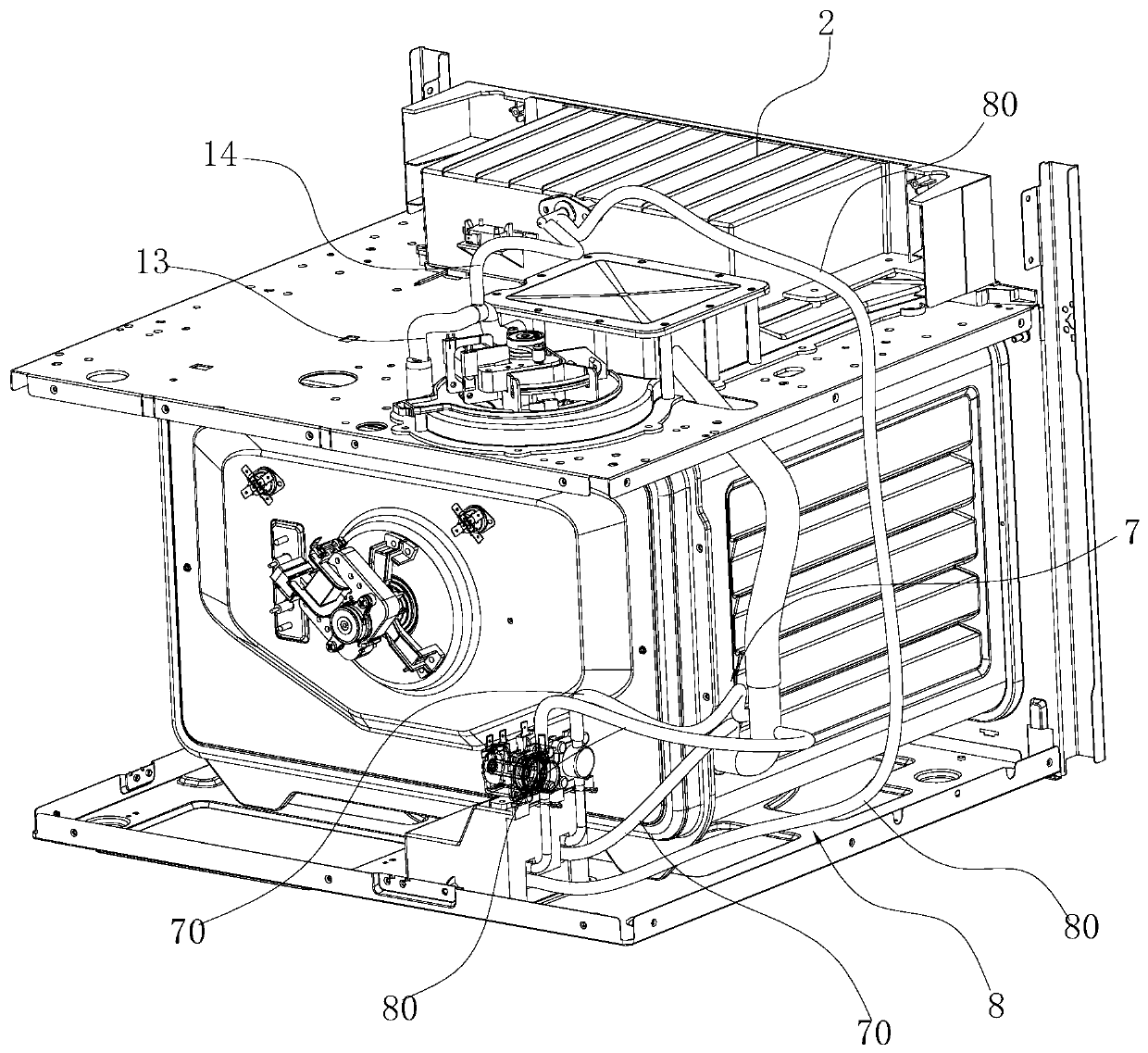

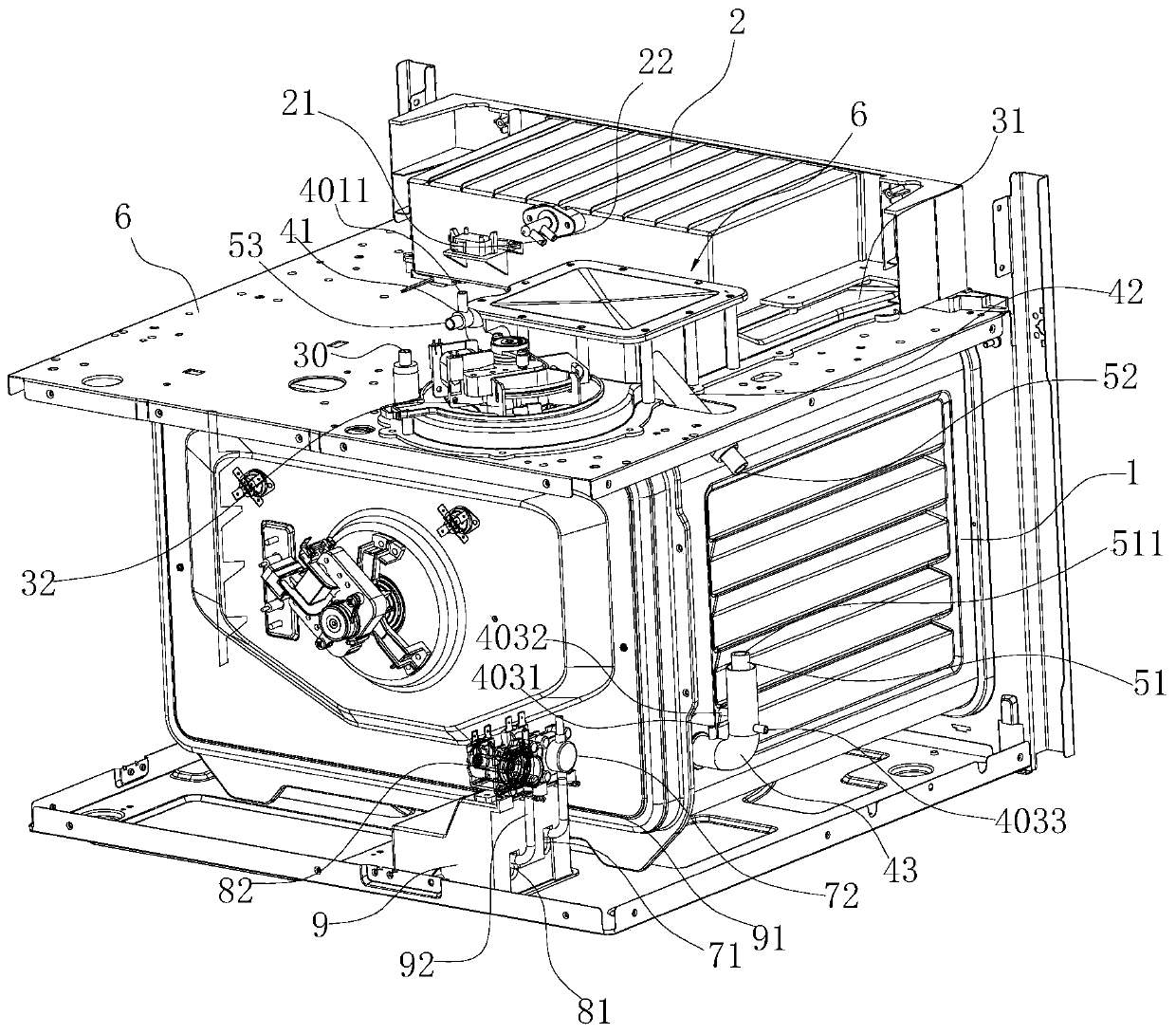

Steam low-displacement steam box

ActiveCN111557587AAchieve condensationShorten warm-up timeSteam cooking vesselsThermodynamicsInlet valve

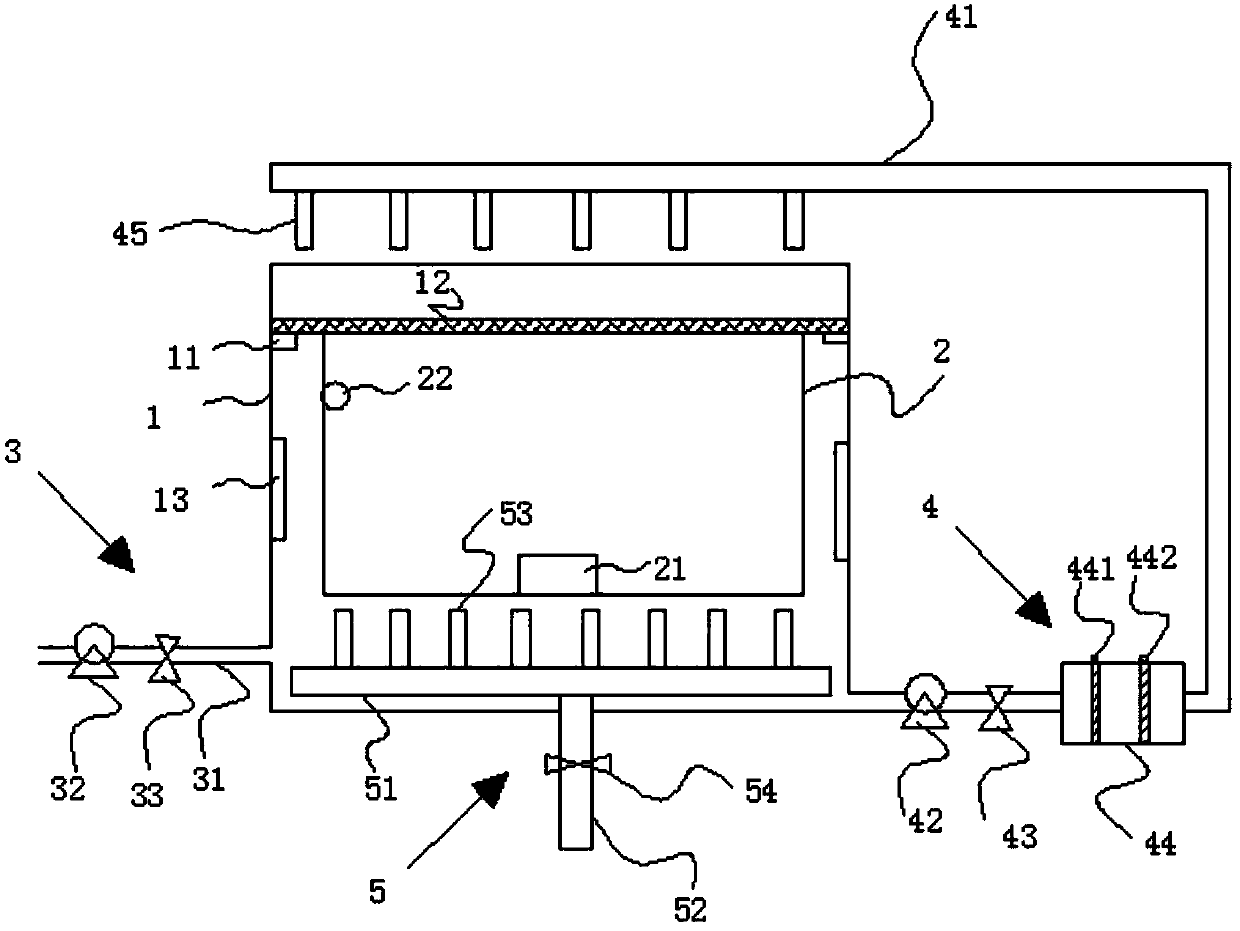

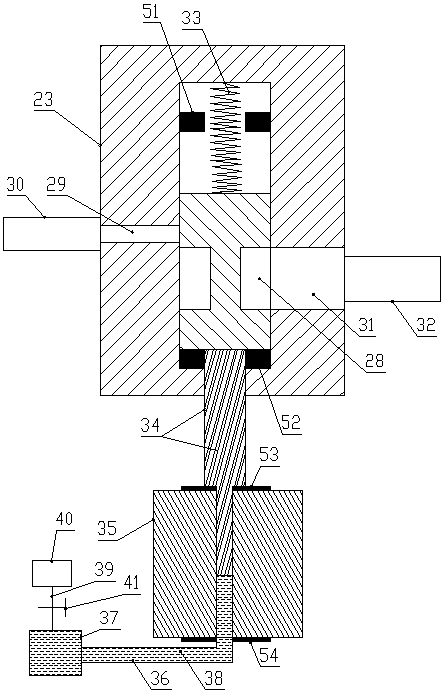

The invention relates to a low-displacement steam box. The low-displacement steam box comprises an inner container, a water tank and an exhaust channel, and an exhaust port and a water inlet are formed in the side wall of the inner container. The water tank is provided with a water outlet connector and a water return connector. The low-displacement steam box also comprises a water inlet pipeline and an exhaust pipeline. The water inlet pipeline and the exhaust pipeline are adjacent to each other. One end of the water inlet pipeline is communicated with the water outlet interface. The other endof the exhaust pipeline is provided with a first water inlet branch and a second water inlet branch, a water inlet valve is arranged on the first water inlet branch, a water return valve is arrangedon the second water inlet branch, one end of the exhaust pipeline is communicated with the water return connector, the other end of the exhaust pipeline is communicated with an air inlet of the exhaust channel, and water in the water inlet pipeline can exchange heat with steam in the exhaust pipeline. Compared with the prior art, the amount of discharged steam can be reduced, the use experience ofa user is improved, meanwhile, the water in the water inlet pipeline can be preheated through the steam, and therefore the preheating time of the steam box is shortened, the time for heating water through a heating disc to generate steam is shortened, and the energy consumption of the steam box is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

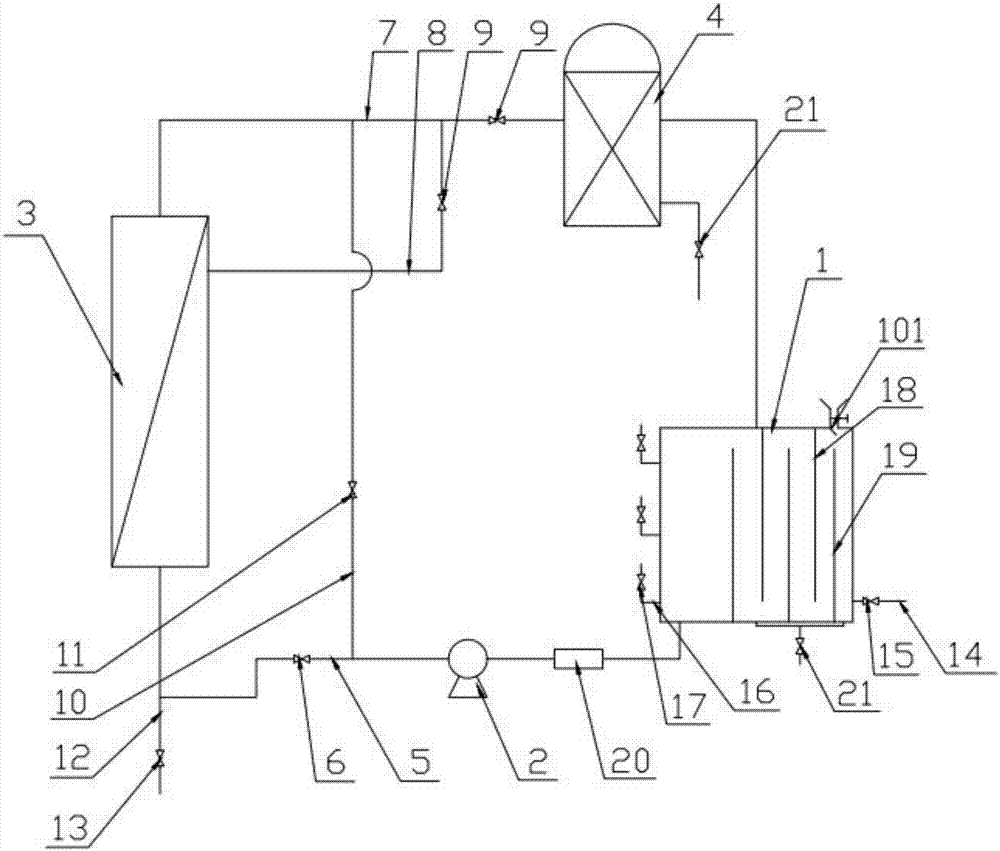

New method for controlling secondary side temperature of thermal substation

InactiveCN101608812ALighting and heating apparatusSpace heating and ventilation detailsThermodynamicsEngineering

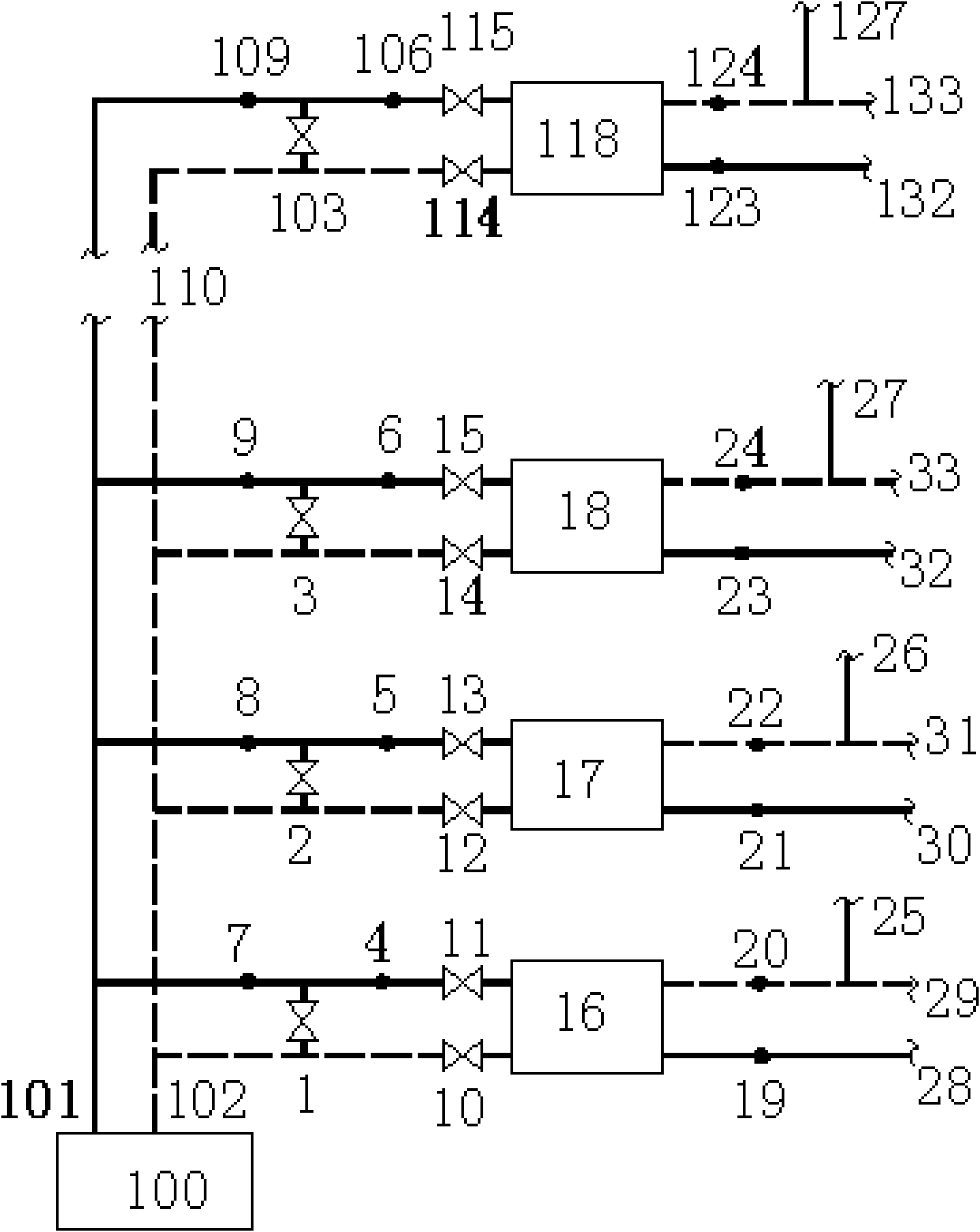

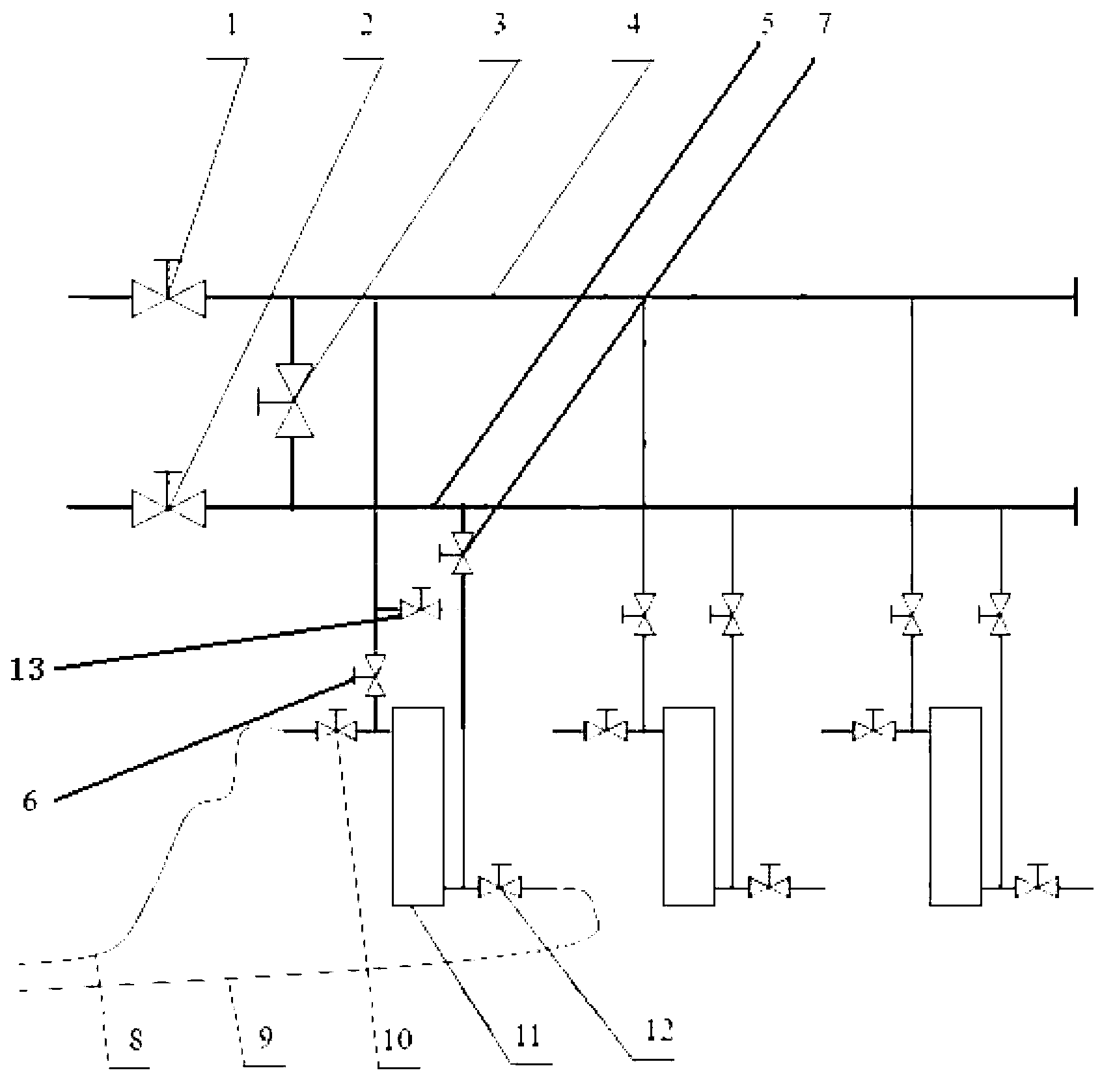

The invention relates to a new method for controlling secondary side temperature of a thermal substation. The control method used currently is very easy to cause increase and decrease of the pressure of a primary network trunk line in the practical operation and further directly cause instable pressure at a heat source (thermal power plants or boiler houses). When controlling the secondary side temperature, the method not only needs to adjust a primary network water supply / back-water valve of a heat exchanging unit to control secondary side temperature, but also needs to adjust a valve of a primary network communication pipe of the heat exchanging unit, which is used as one part for controlling the secondary side temperature operation. In the practical operation of controlling the secondary side temperature, the pressure change of a heat source 100 and main trunk lines 101 and 102 in a central heat-supplying network is basically zero or greatly smaller than that of the method used currently.

Owner:李凯

Textile product cleaning machine

InactiveCN107558044AGuaranteed cleaning effectSave human effortTextile treatment machine arrangementsTextile treatment by spraying/projectingElectricityInjection port

The invention discloses a textile cleaning machine, which comprises a main body of the cleaning machine, a cleaning room is arranged in the main body, and a water supply system and a return water system connected with the cleaning room; the return water system includes a return water pipe, a return water pump, a return water electromagnetic Valve, filter cavity and water spray pipe; the cleaning room is hollowed out, and there is an ultrasonic vibration device in the cleaning room; a blowing unit is installed in the body and below the cleaning room, and the blowing unit includes a main ventilation pipe, a compressed air pipe, a ventilation branch pipe, an air jet and a blower Electromagnetic valve; also includes a PLC controller and a liquid level sensor, the liquid level sensor is located in the cleaning room, the return water pump, the return water solenoid valve, the ultrasonic vibration device, the blowing solenoid valve and the liquid level sensor are respectively electrically connected or signal connected to the PLC controller. The invention can use mechanical equipment to clean textiles such as cloth and ready-made clothes, which saves manpower and improves efficiency; at the same time, water resources are recycled, water resources are saved, and production costs are also saved.

Owner:SUZHOU SISHAN NANO TECH CO LTD

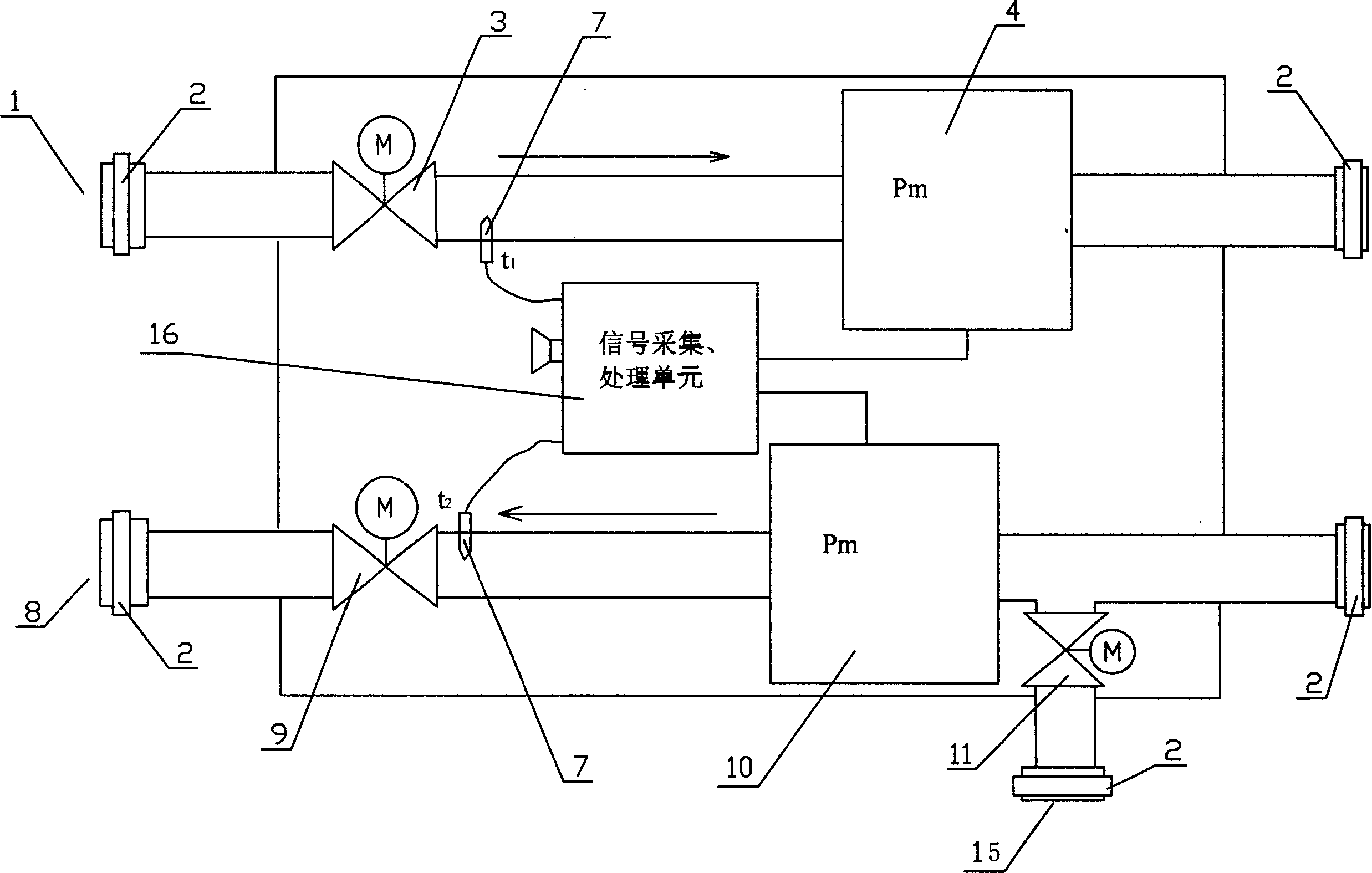

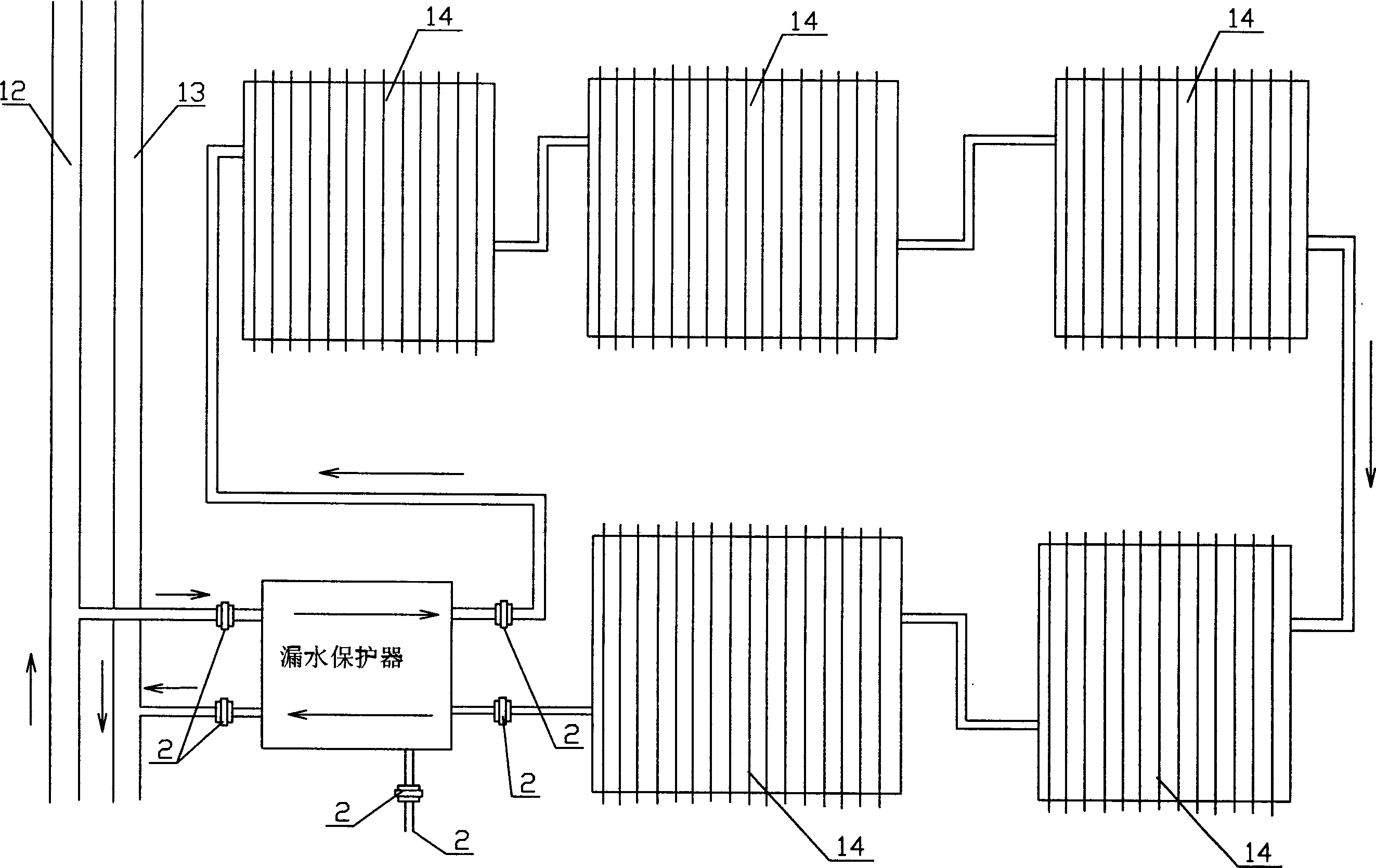

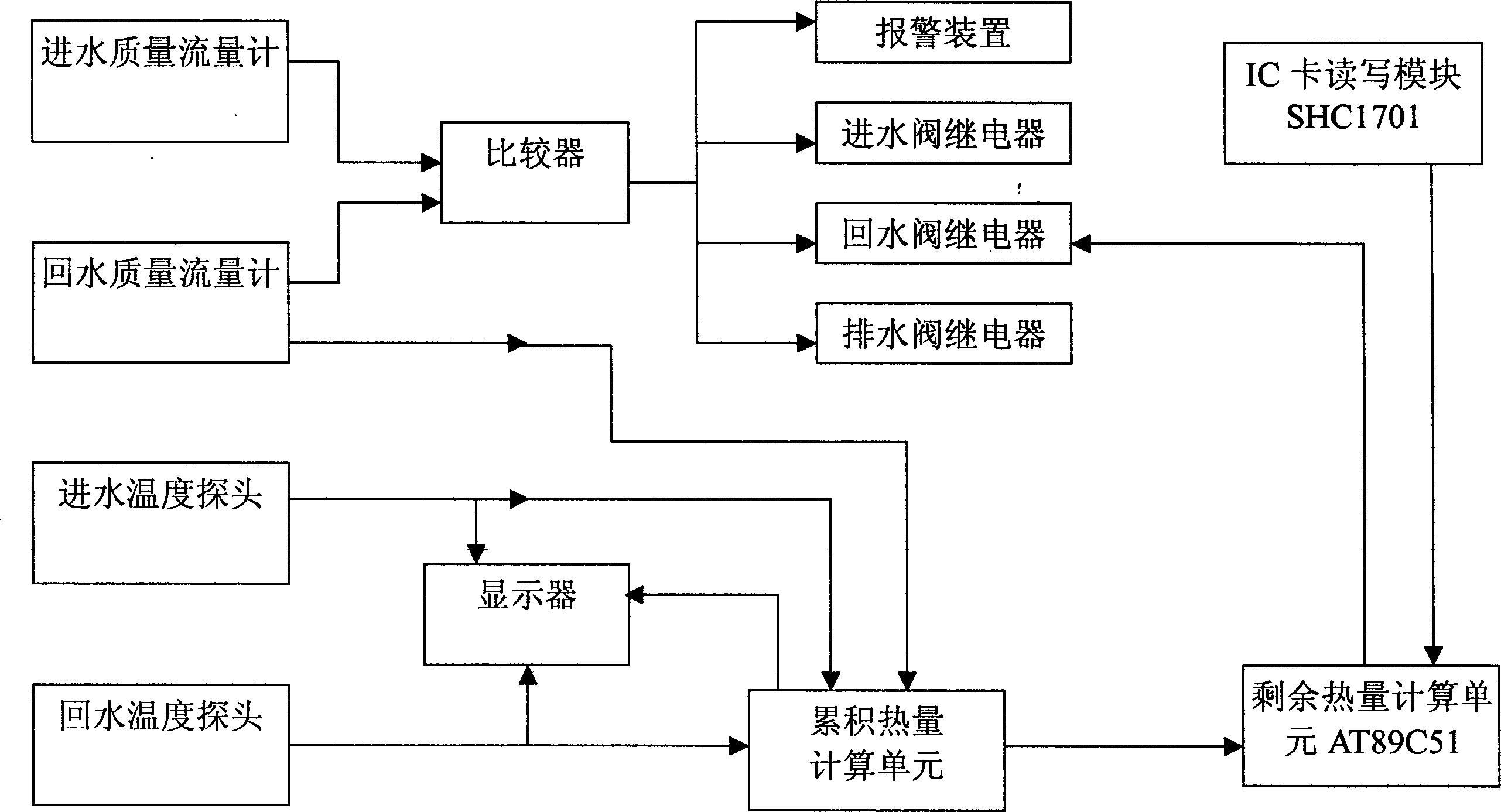

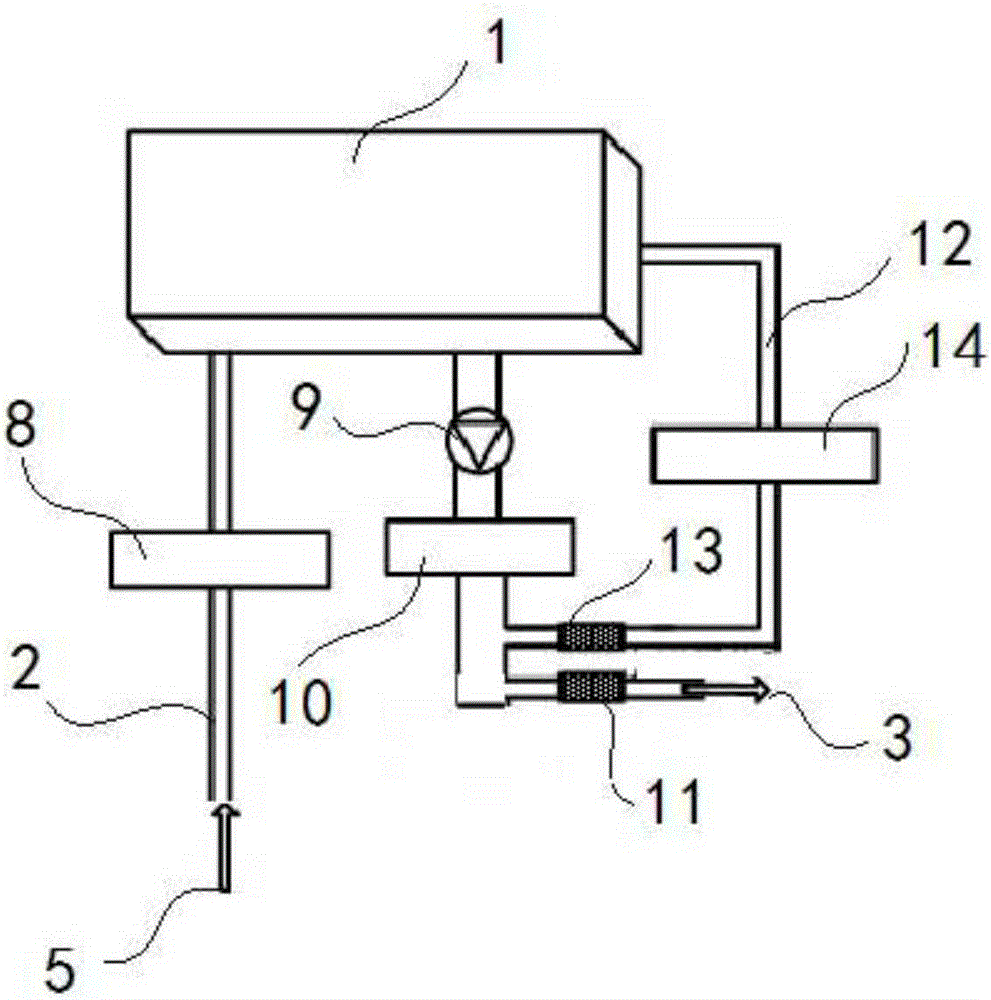

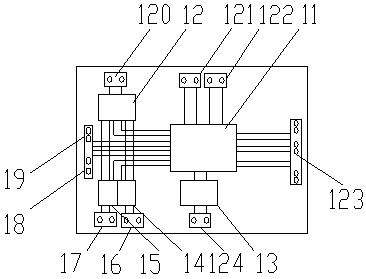

Leak protector for sealed circulation system

A leakage protector for use in a sealed circulation system includes water inlet and return pipes for connecting the circulation system. In the water inlet pipe are disposed a water intake valve, a mass flow meter and a temperature probe and in the water return pipe are disposed a water return valve, a mass flow meter and a temperature probe. The mass flow meter and the temperature probe collect processing units by a wire connection signal. The water return pipe is in communication with the discharge pipeline via a three-way connecting piece and a draw-off valve is set at the water outlet.

Owner:王超

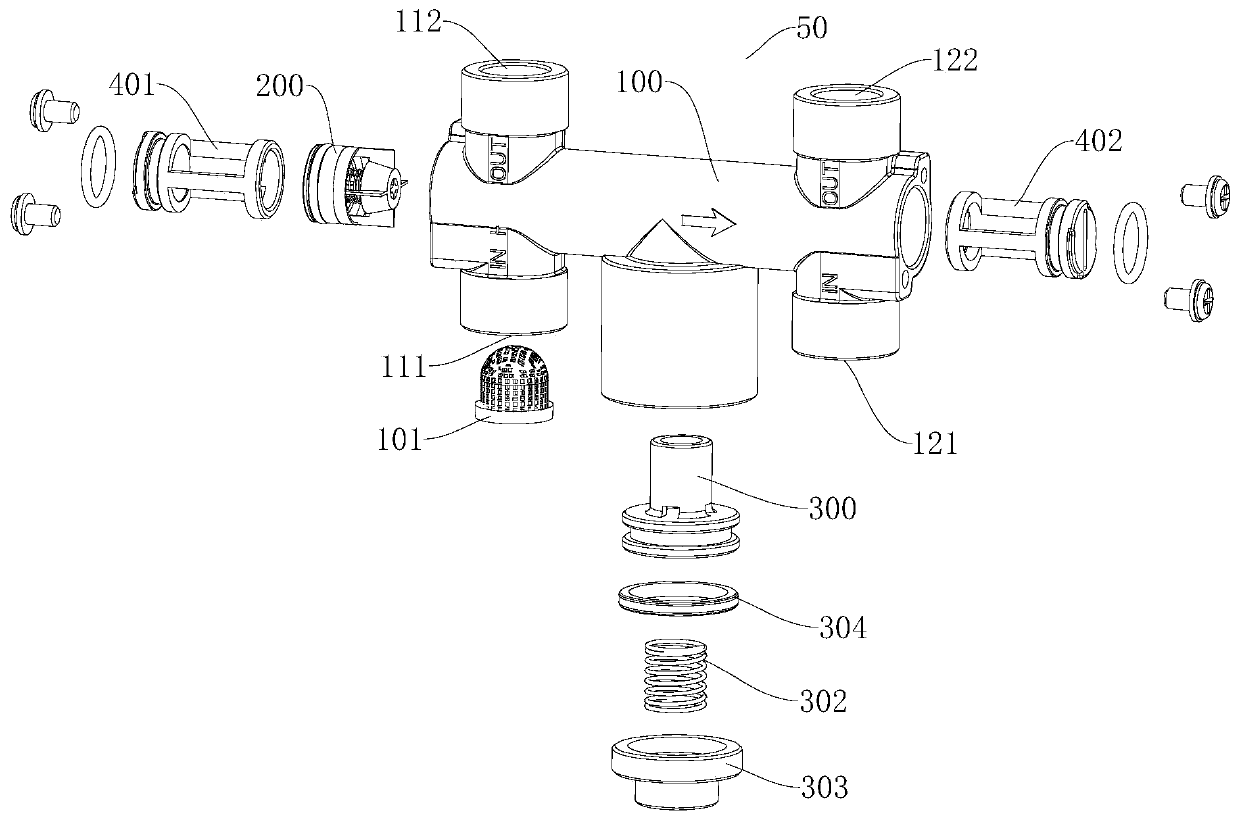

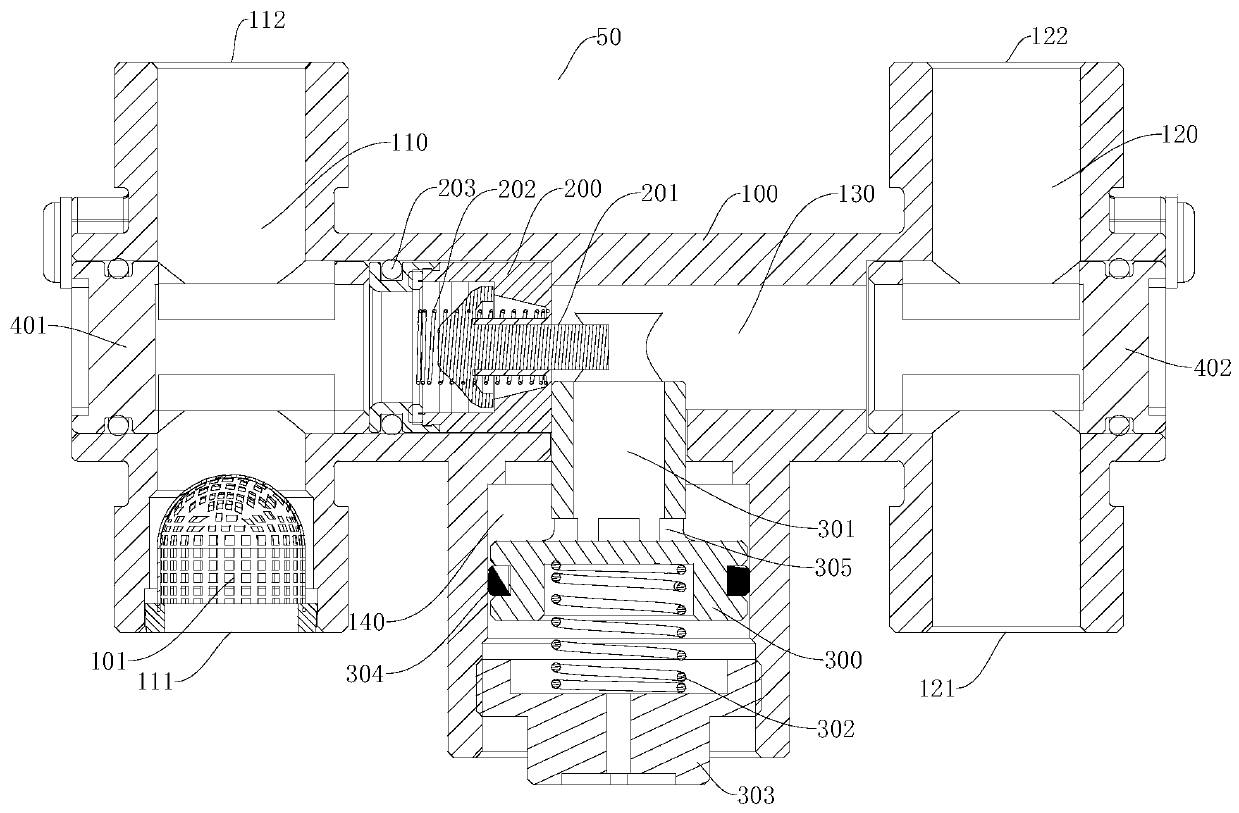

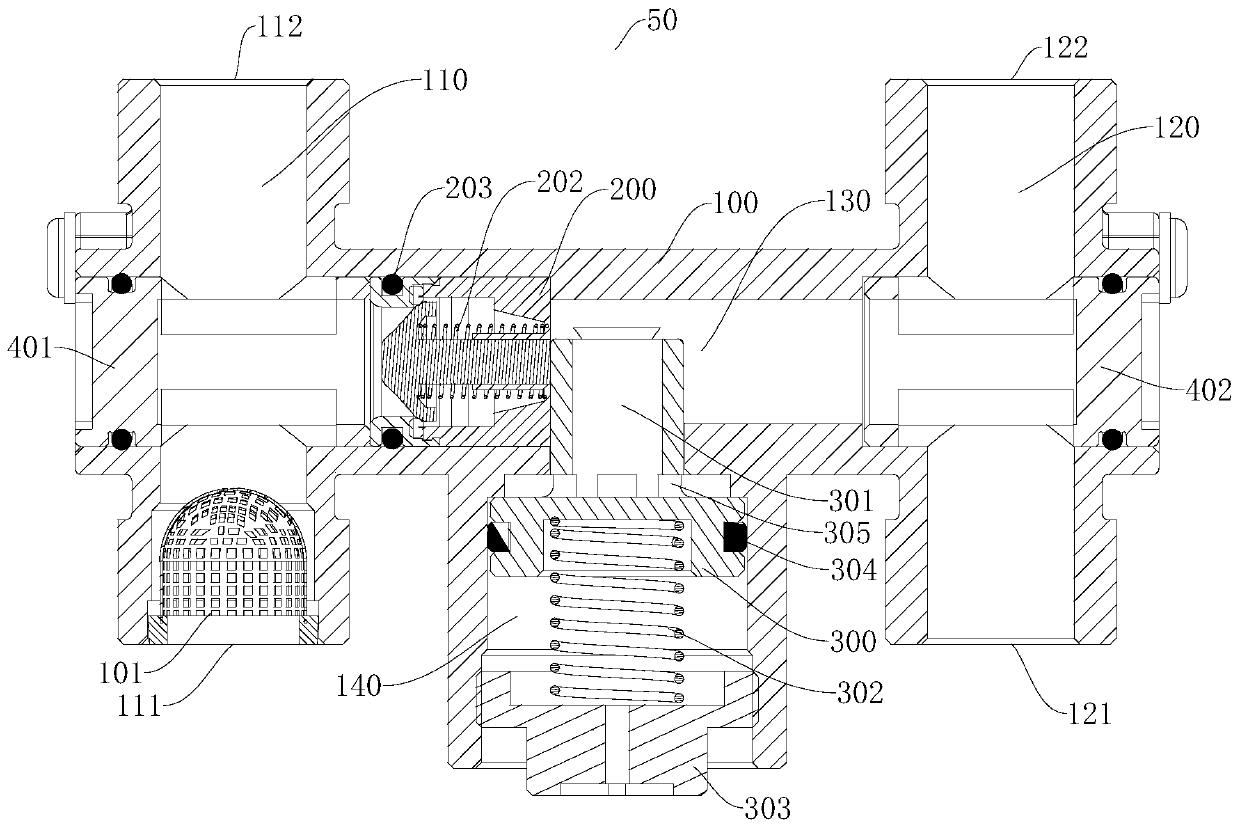

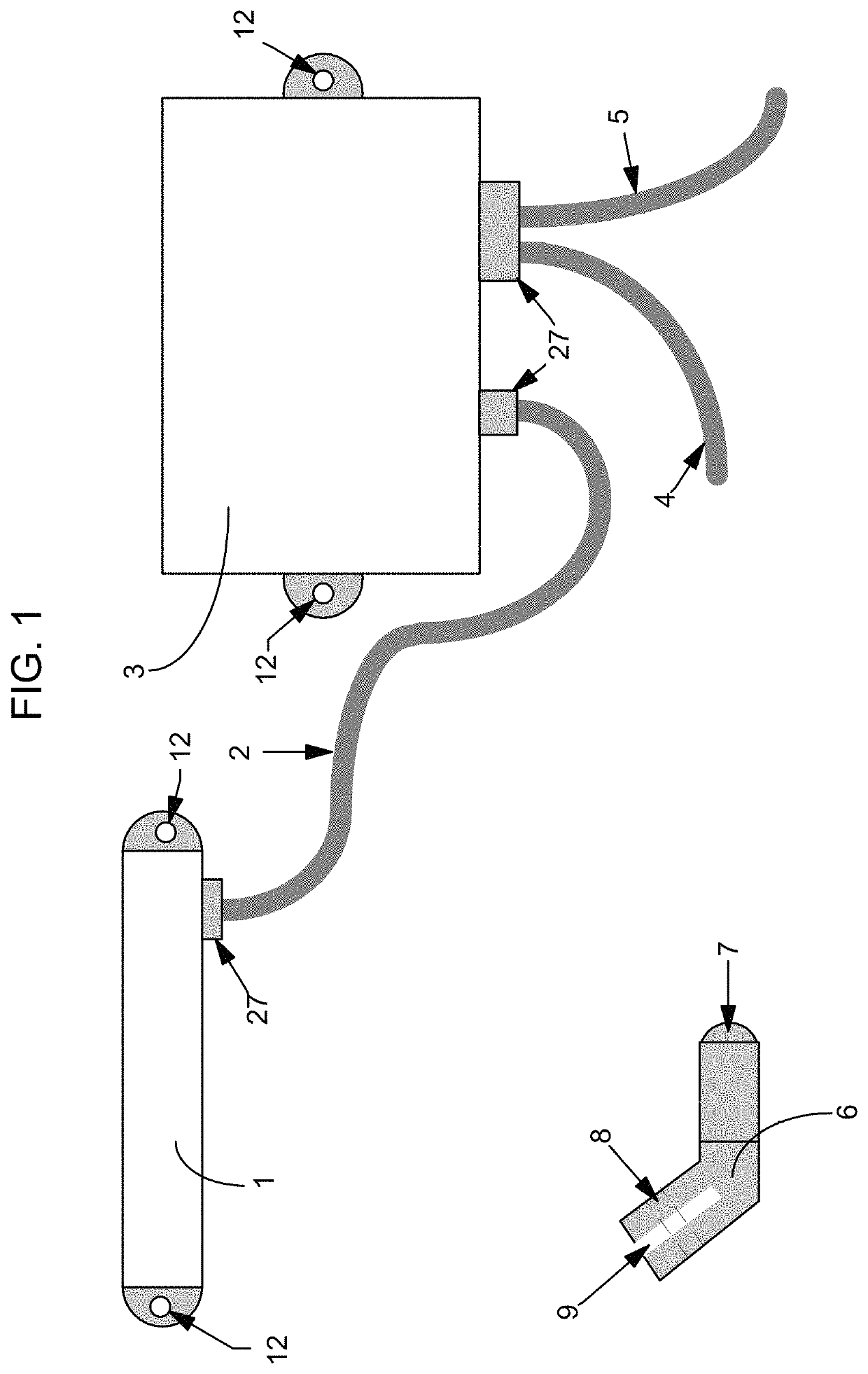

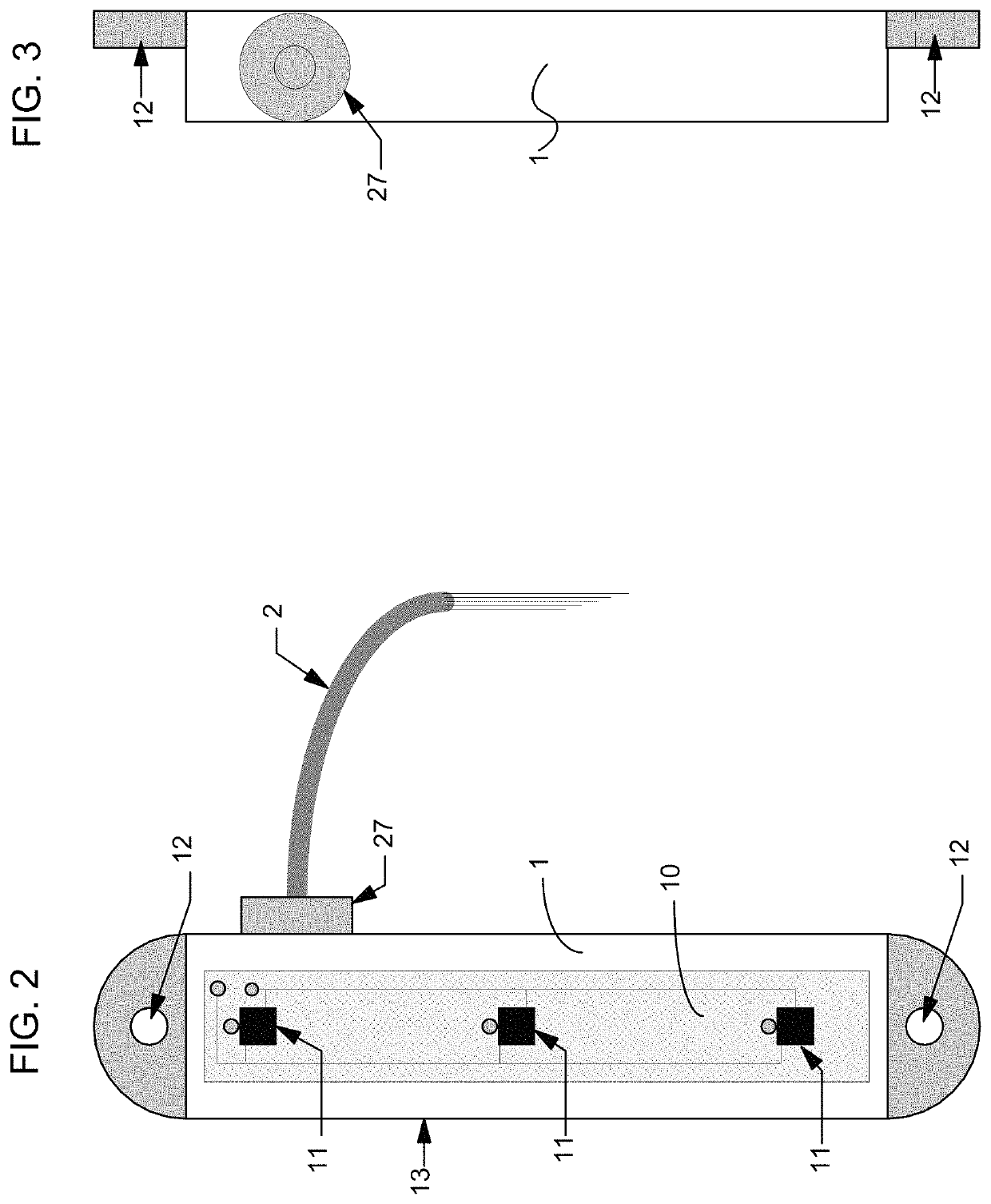

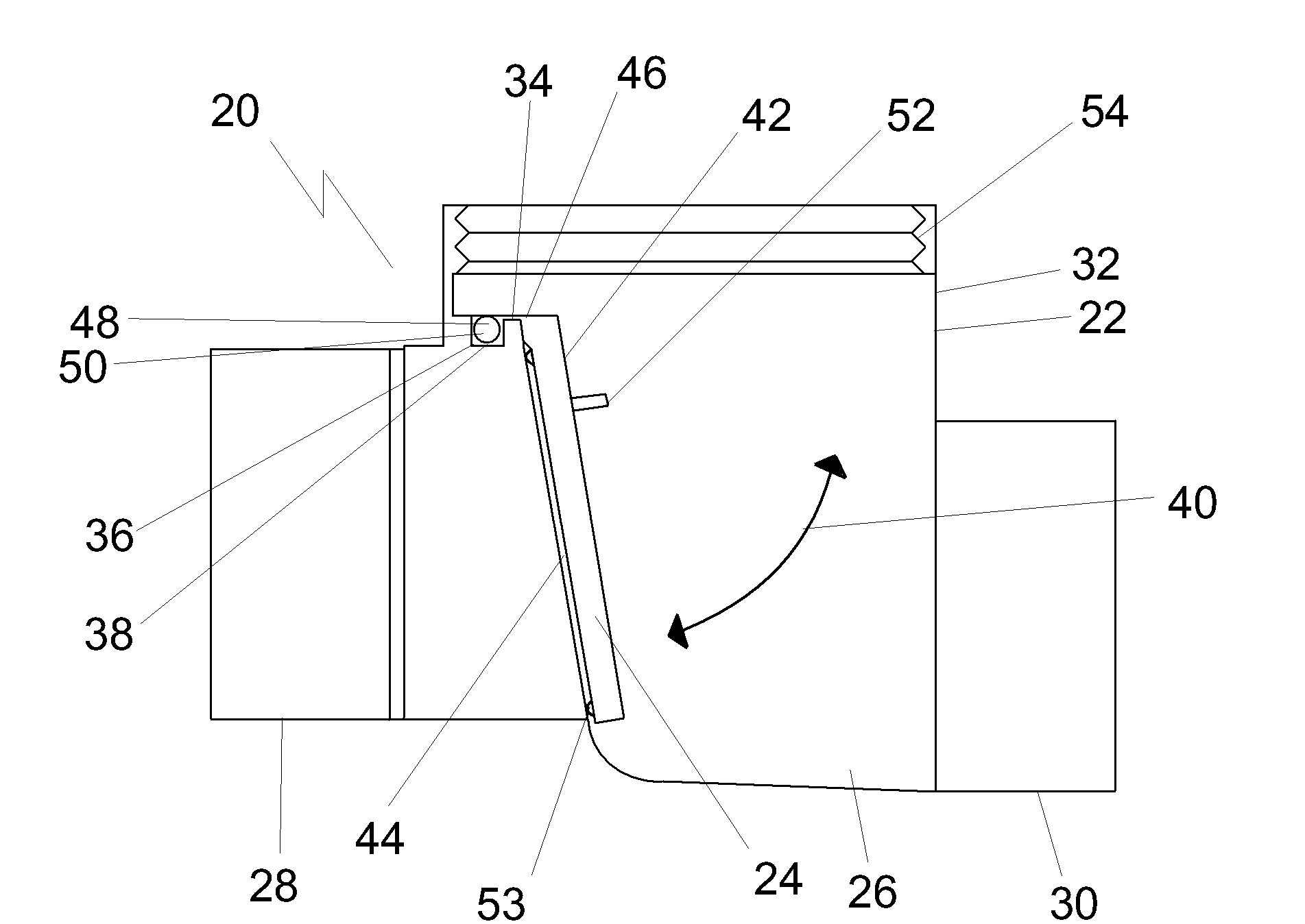

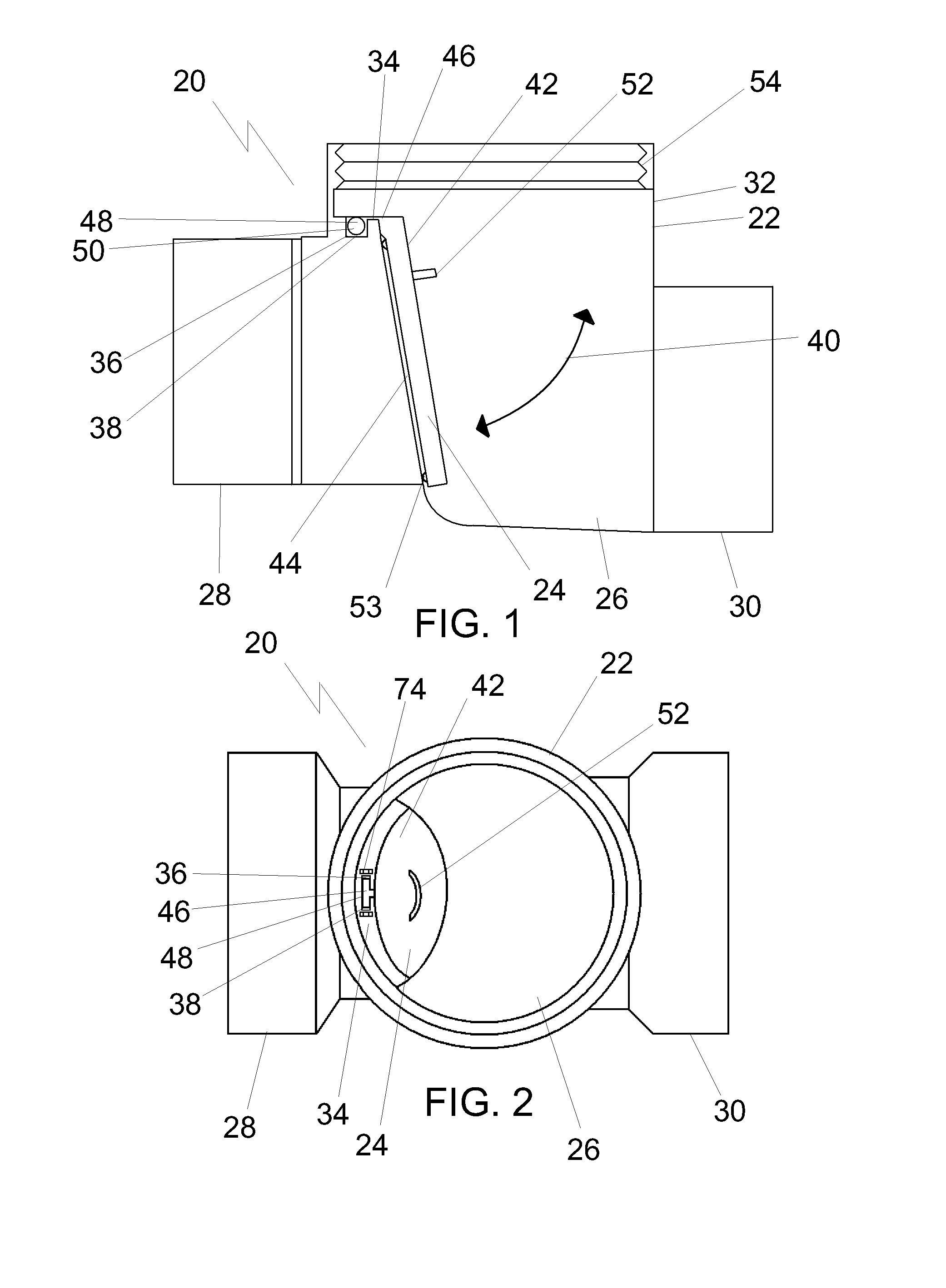

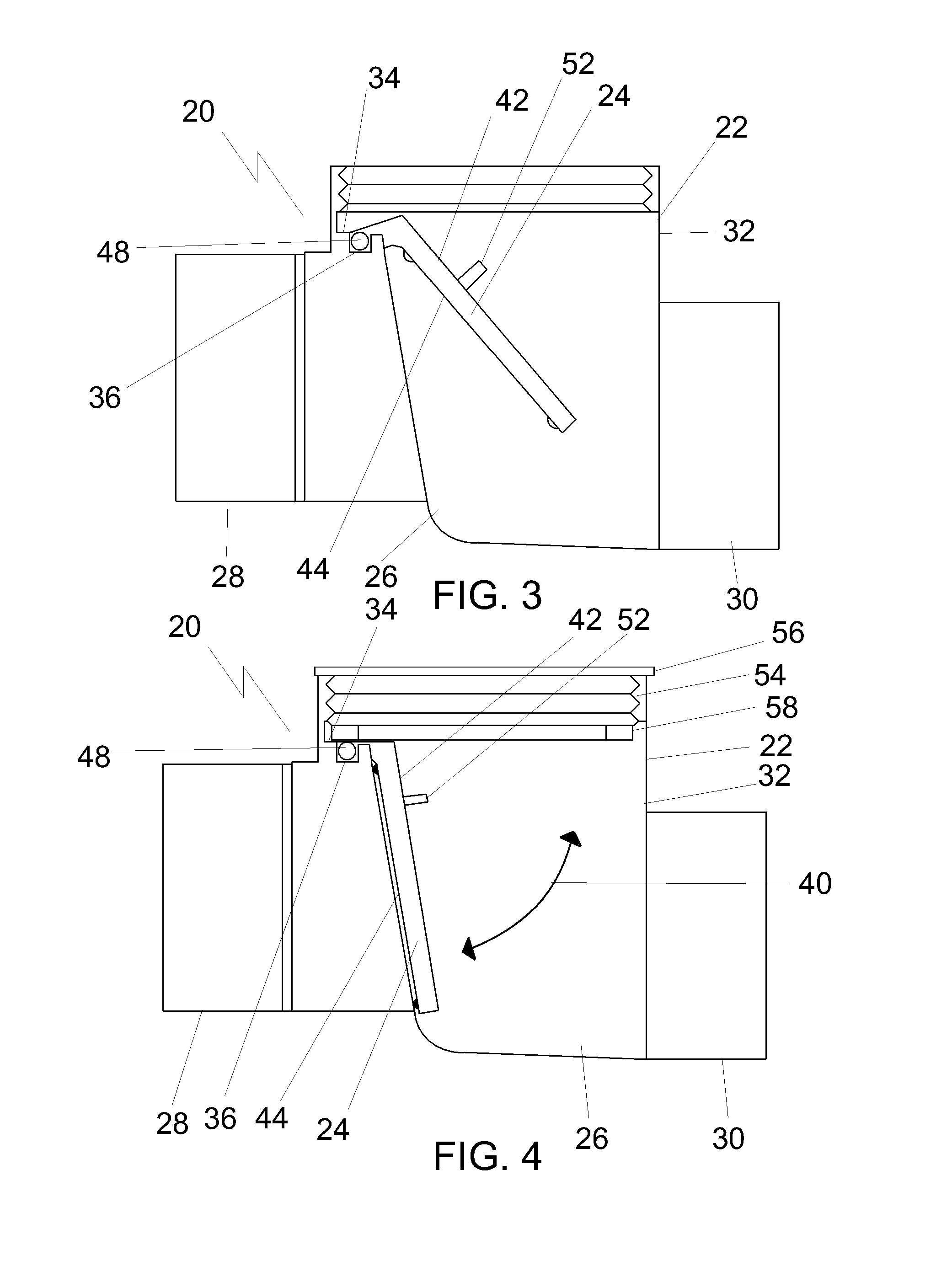

Backwater valve assembly with removable valve member

ActiveUS7757706B2Operating means/releasing devices for valvesCheck valvesVertical alignmentBackwater valve

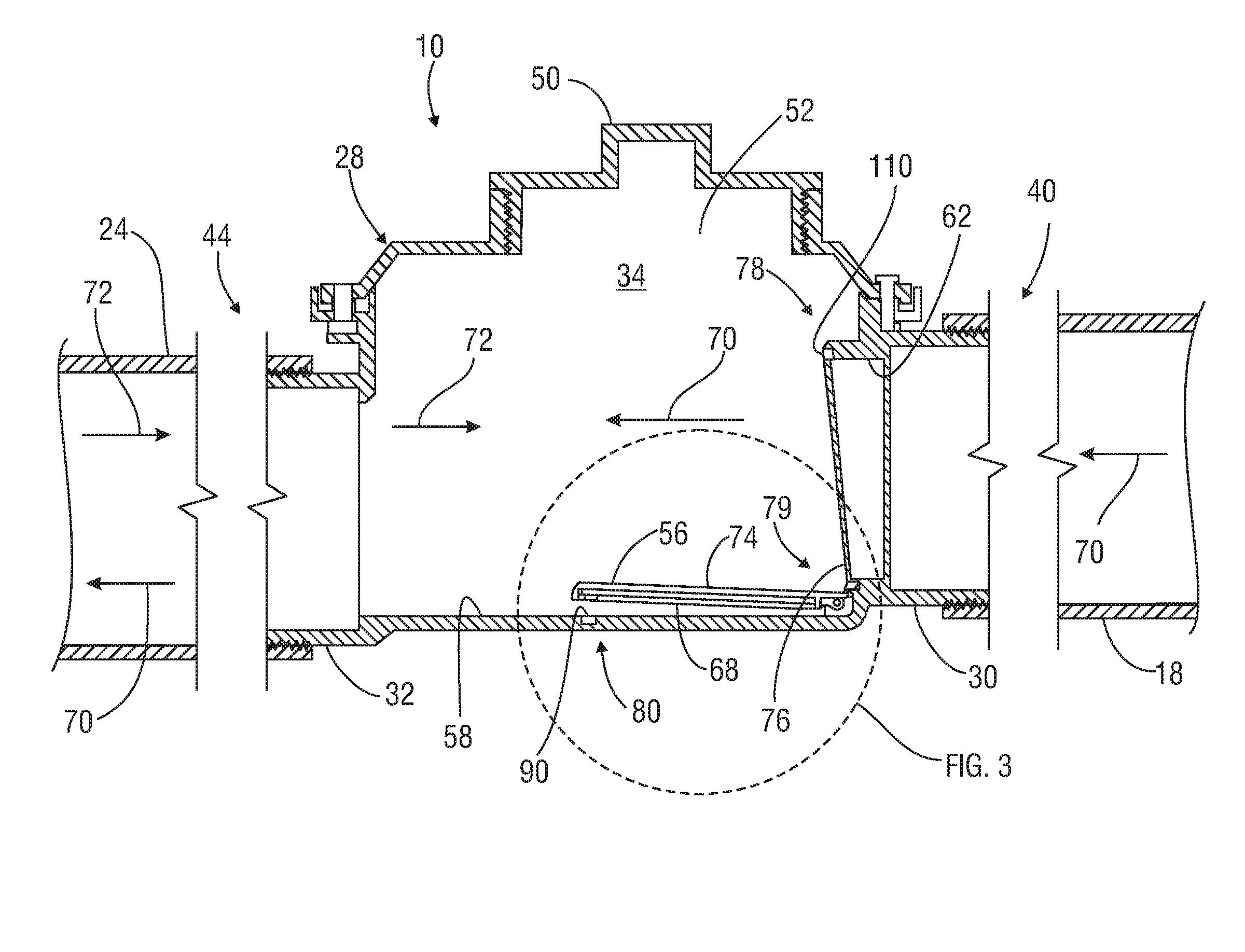

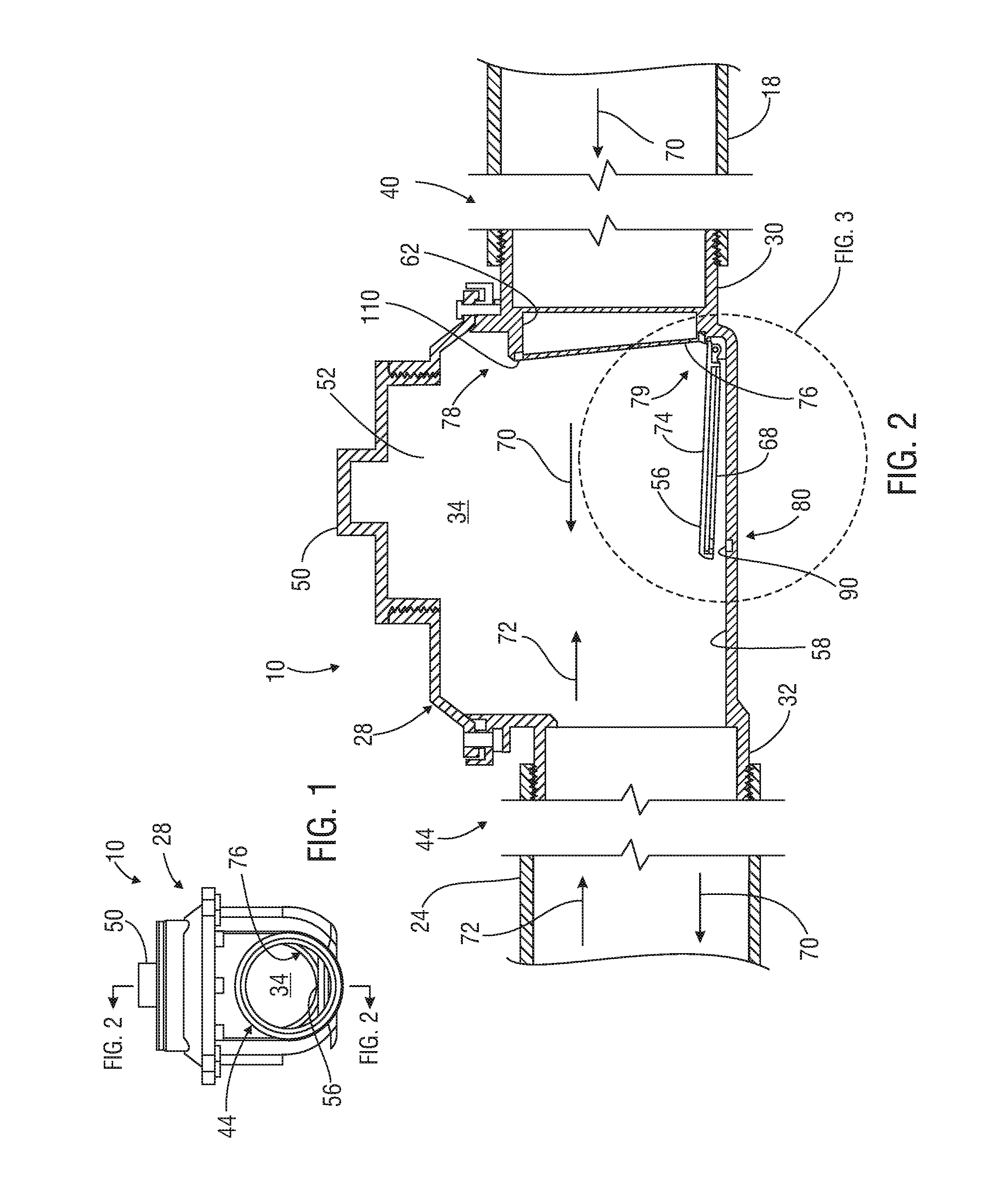

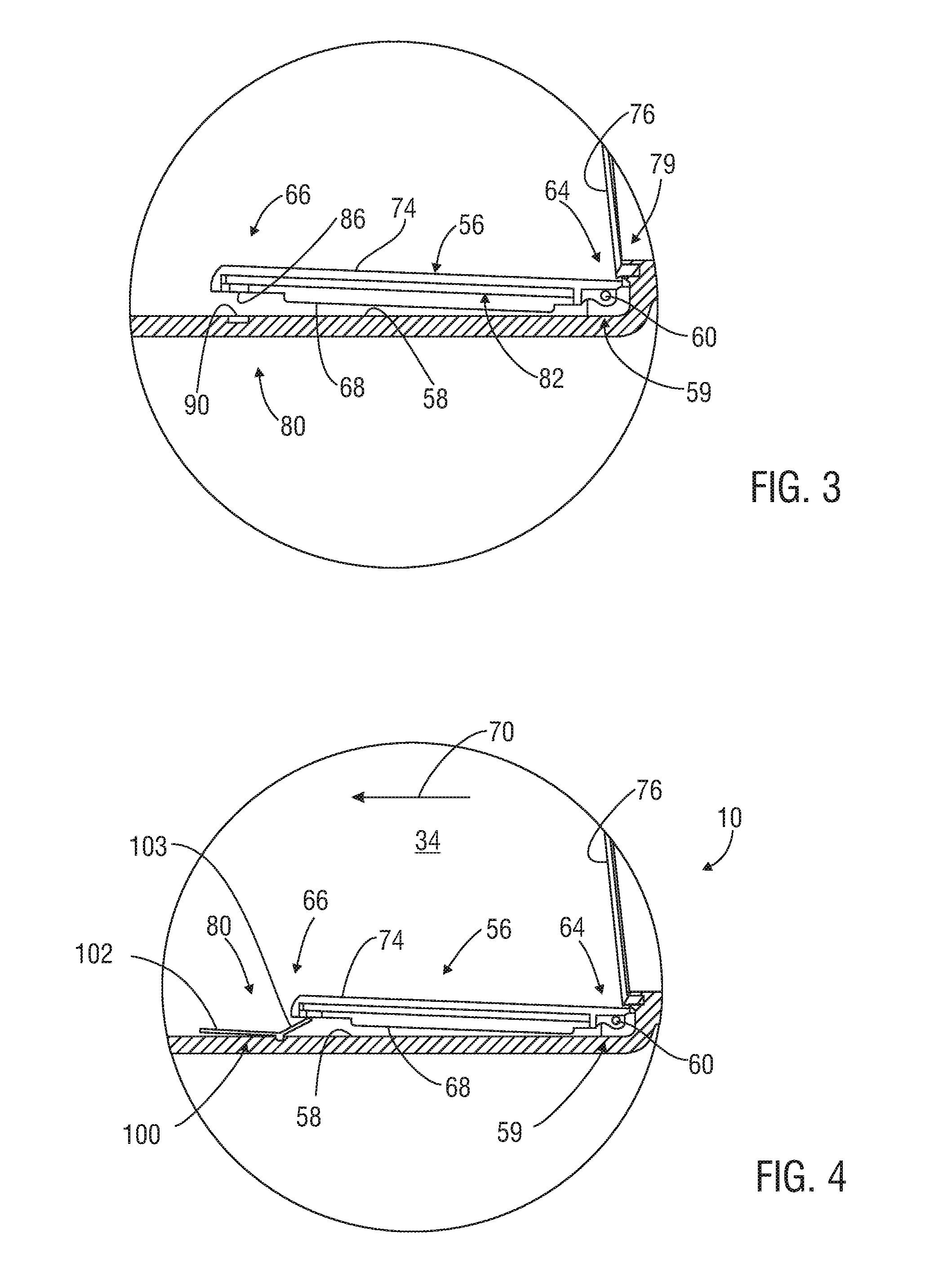

A backwater valve assembly includes a valve housing, a valve member and a servicing tool. The valve housing has an internal ledge within its interior on which is positioned a retainer clip oriented in vertical alignment with a riser. The valve member has a first engagement of a two part engagement on one face and a mounting along a peripheral edge which includes transverse pins adapted to engage the retainer clip. The servicing tool includes a second engagement of the two part engagement at a working end of a shaft. The hook engages the hook receiver of the valve member during insertion and removal.

Owner:COSCARELLA GABE

Water saving temperature control backwater valve

InactiveCN101050829ANo energy consumptionOperating means/releasing devices for valvesWater savingTemperature control

A return water valve of water-saving and temperature control type consists of shell, core body, shaft body, water inlet interface, and water outlet interface and temperature control element. It is featured as surrounding a seal cavity by shell, leading hot water pipe from shell external to cavity, leading cold return water pipe from shell external to cavity and connecting cold return water pipe to single-way valve through U form channel outlet on core body and connecting pressure converter set with conical opening to single-way valve then to U form channel outlet by passing through shell.

Owner:王存

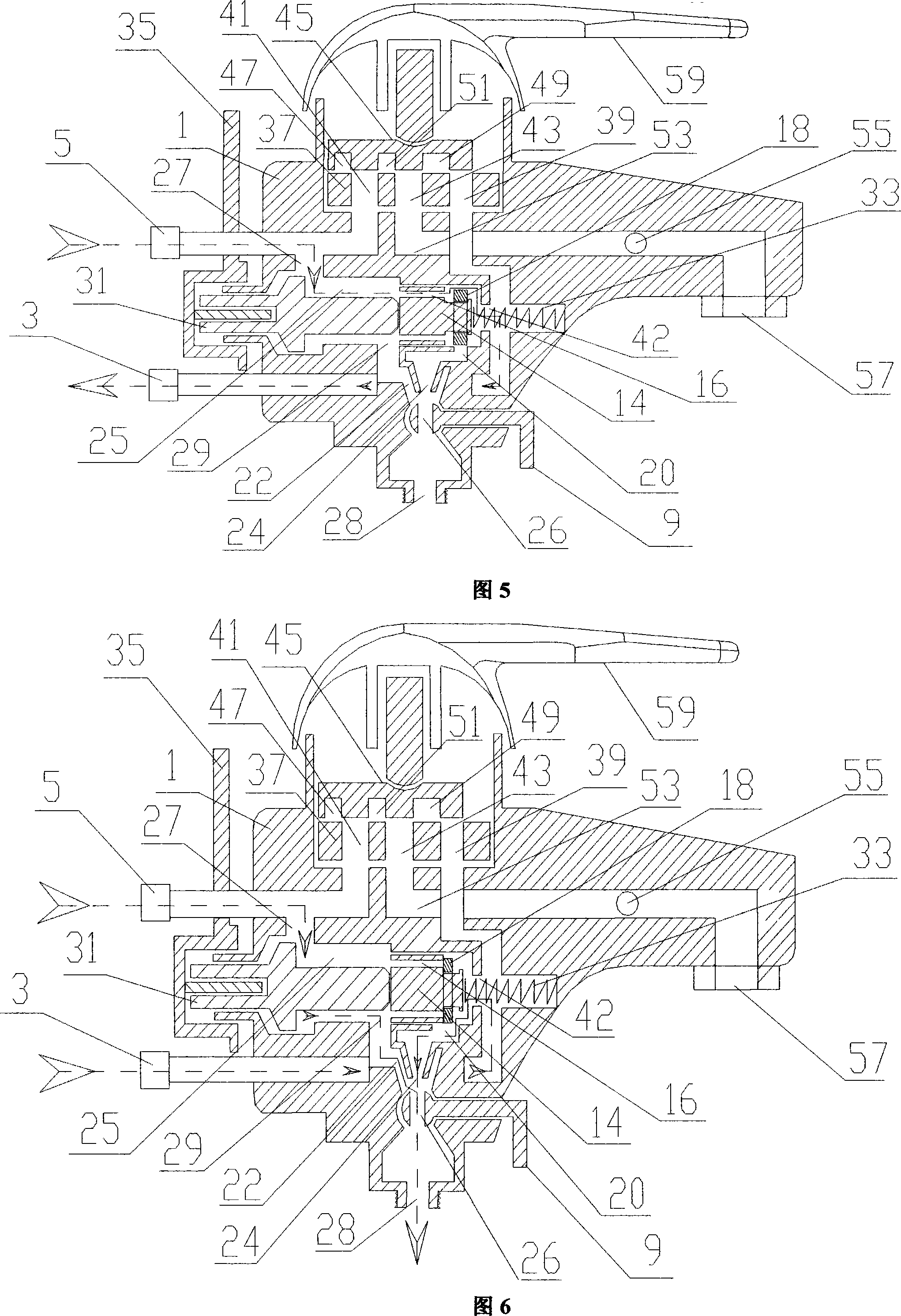

Temperature control differential pressure backwater tap

InactiveCN101205982AReduce the amount of waterPromote incomeOperating means/releasing devices for valvesTemperatue controlTemperature controlWater saving

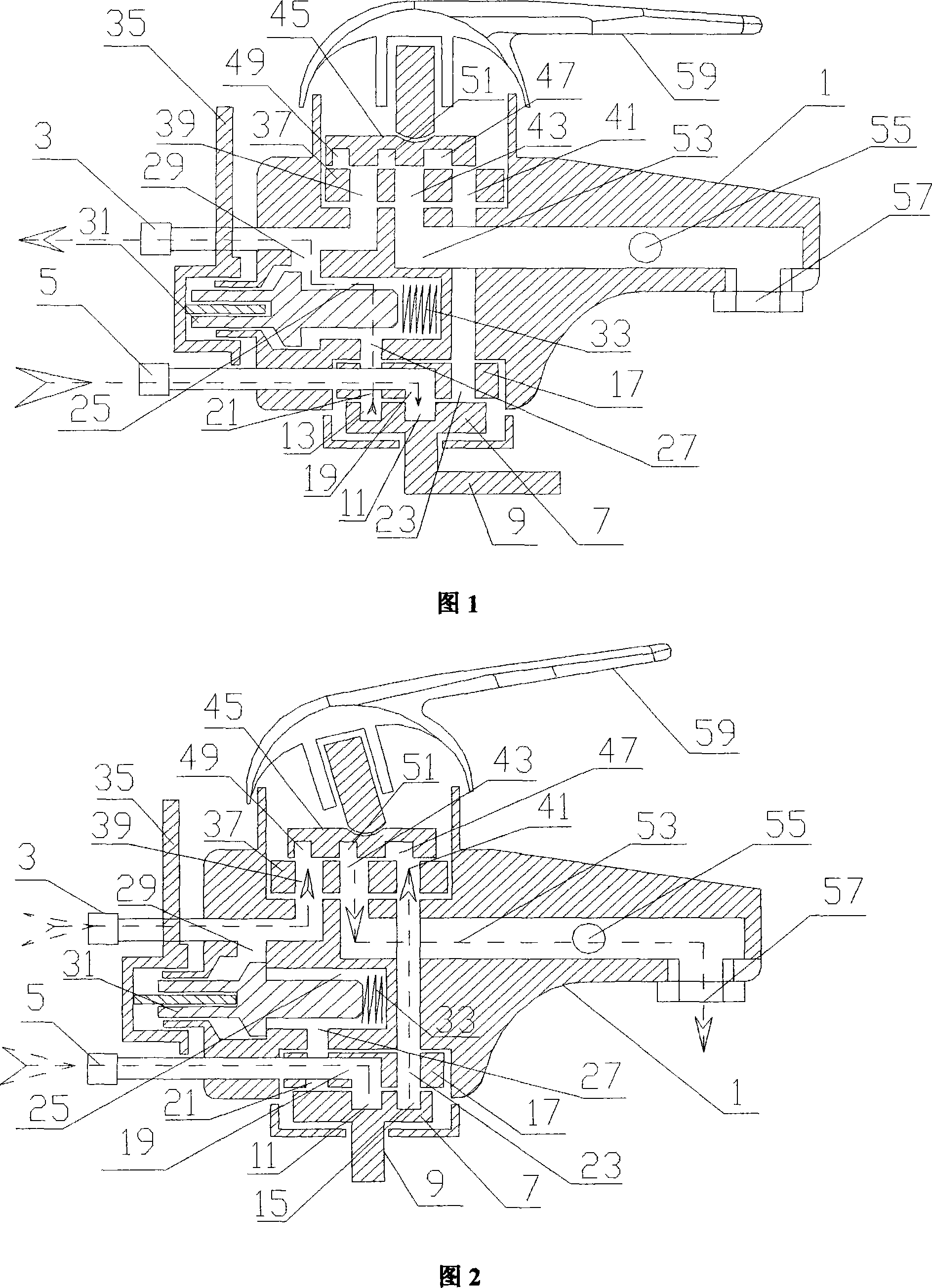

A temperature control differential pressure backwater tap with water saving function comprises a valve mechanism capable of realizing pressure sensing, temperature sensing and interlocking. When a user turns a backwater handle to open a backwater valve, residual cold water in a hot water pipe enters a temperature control cavity from the lower valve plate of the backwater valve. When the water temperature fails to reach a preset temperature, the valve mechanism formed by a temperature control member and the temperature control cavity is in an open status, and a cold water pipe and the hot water pipe are enabled to be communicated with each other. The cold water in the hot water pipe enters continuously the cold water pipe under the action of pressure. With the backwater process, the water temperature in the temperature control cavity increases gradually, and the temperature control member displaces due to thermal expansion. When the water temperature reaches the preset temperature, the displacement of the temperature control member 31 finally cuts off the connection between the water inlet of the temperature control cavity and the water outlet of the temperature control cavity, thereby completing the backwater process. At that time, the can uplift a water handle to get water of desired temperature.

Owner:王存

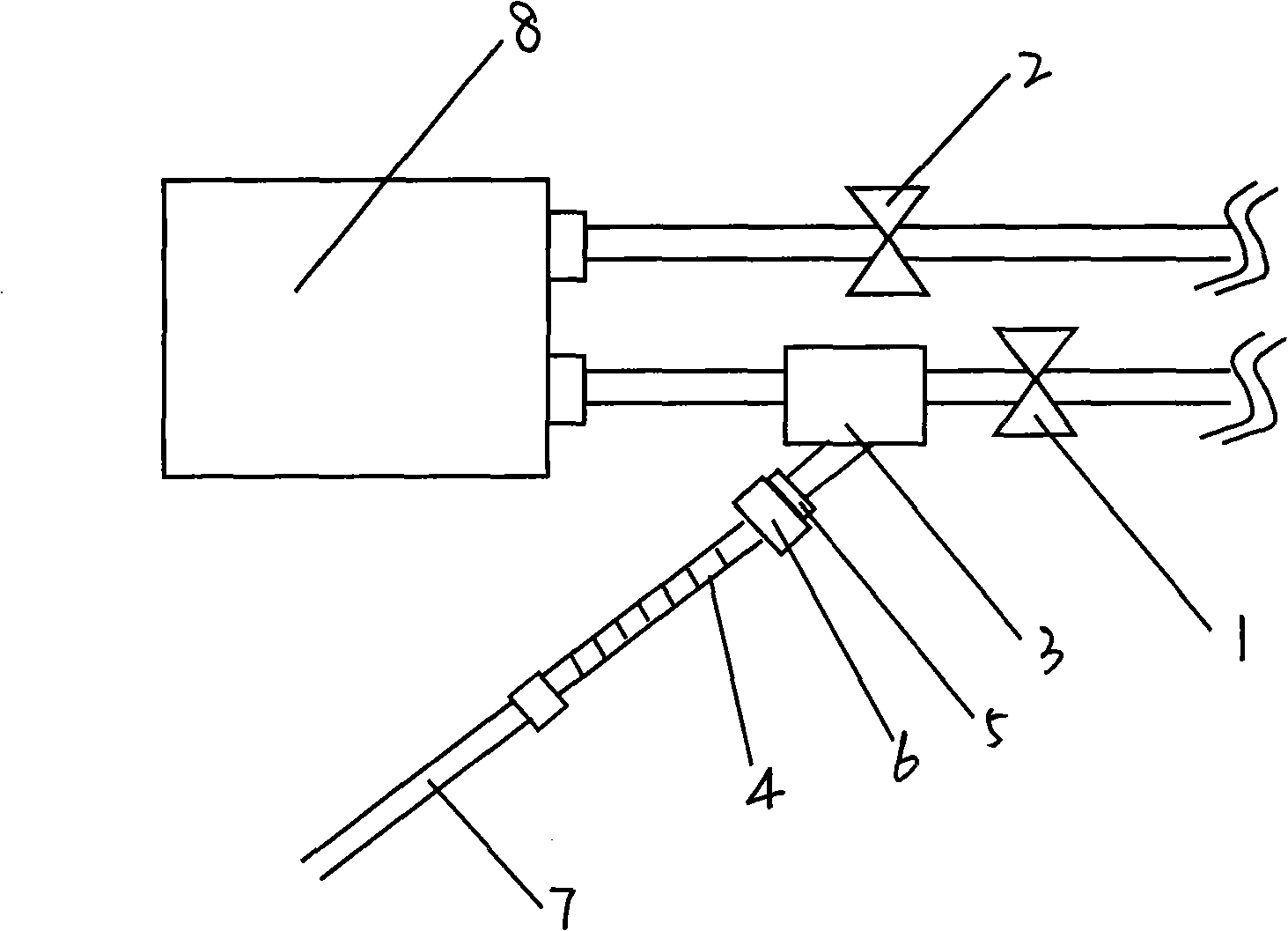

Central air-conditioning fan coiler cleaner and method thereof

The invention discloses a cleaning device and a cleaning method thereof for a fan coil pipe of a central air conditioning which comprises a water inlet valve, a back water valve, a filter and a special tube for cleaning; the special tube for cleaning consists of a metal soft tube and a connector; one end of the connector is connected with the metal soft tube; the other end is provided with a connecting screw thread matched with the filter and is screwed tightly and fixed by a fixing bolt; the other end of the metal soft tube is connected with a water draining soft tube. The cleaning method is that the aim of reverse flushing is realized by utilizing the pressure of the water in a pipeline and adjusting the water inlet valve as well as the back water valve. As the special tube for cleaning is arranged on the filter, the special tube for cleaning can be dismounted at any time and can rotate 360 degrees freely, thus being capable of meeting the requirements of different directions and cleaning the filter, a water inlet pipeline and flushing silt and rust dirt of the fan coil pipe reversely under the situation that the air conditioning is not stopped. Compared with the prior art, the cleaning device of the invention has the advantages of simple structure, convenient operation and low cost, etc.

Owner:董海涛

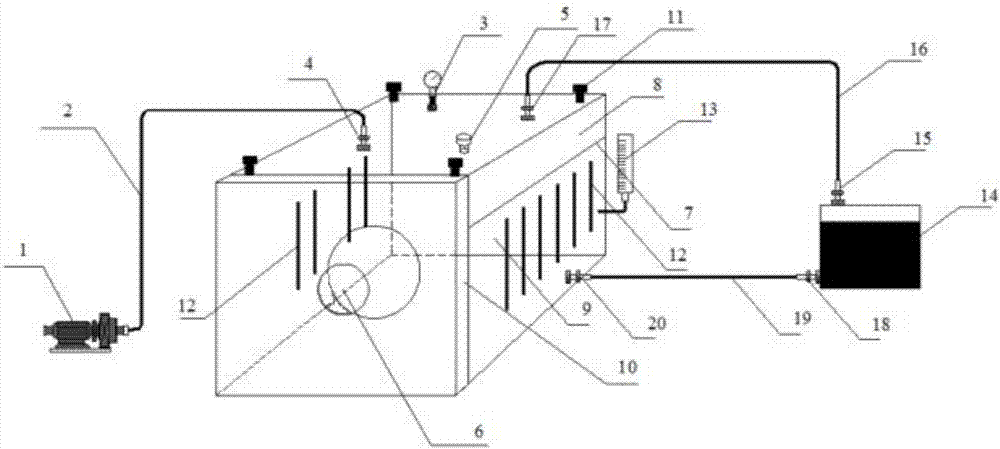

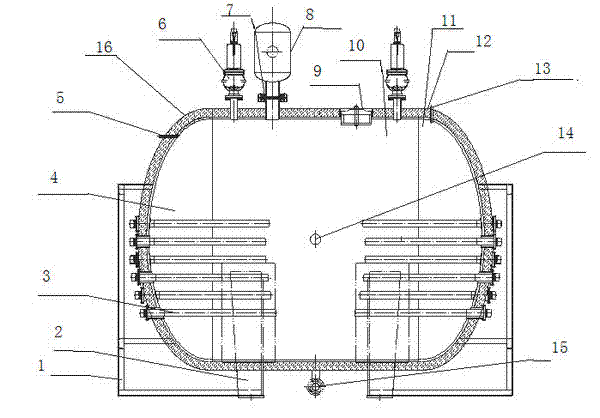

Device for testing hydrostatic seepage pressure of concrete under temperature-variable condition

PendingCN107356512AImprove test accuracyTest pressure adjustmentPermeability/surface area analysisNuclear energy generationInlet valveHeater Rod

The invention provides a device for testing hydrostatic seepage pressure of concrete under a temperature-variable condition. A pressure valve, a pressure meter and a reduced pressure valve are arranged at the top end of a testing tank, the pressure valve is connected with an external air pressure machine through a high-pressure air pipe, one side wall of the testing tank is a steel sealed test board, a conical bore is formed in the steel sealed test board, and a big end of the conical bore is located in the testing tank; and an air bin and a water bin are arranged in the testing tank, the air bin is located at the upper part of the water bin and is communicated with the water bin, heating bars are arranged in the water bin, a thermometer is arranged on the outer wall of the water bin, a water return valve is arranged on the side wall of the bottom of the water bin and is connected with a first water inlet valve on an external cold water circulating tank through a water return pipe, and a water outlet valve on the cold water circulating tank is communicated with a second water inlet valve at the top of the air bin. The device can be used for testing the seepage pressure of the concrete in a temperature-variable environment and is simple in structure and convenient to operate.

Owner:重庆卡勒斯通科技有限公司

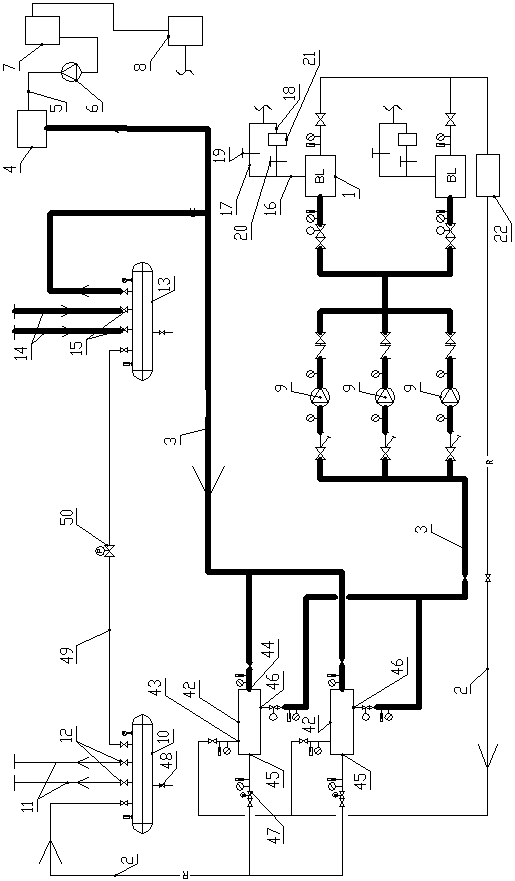

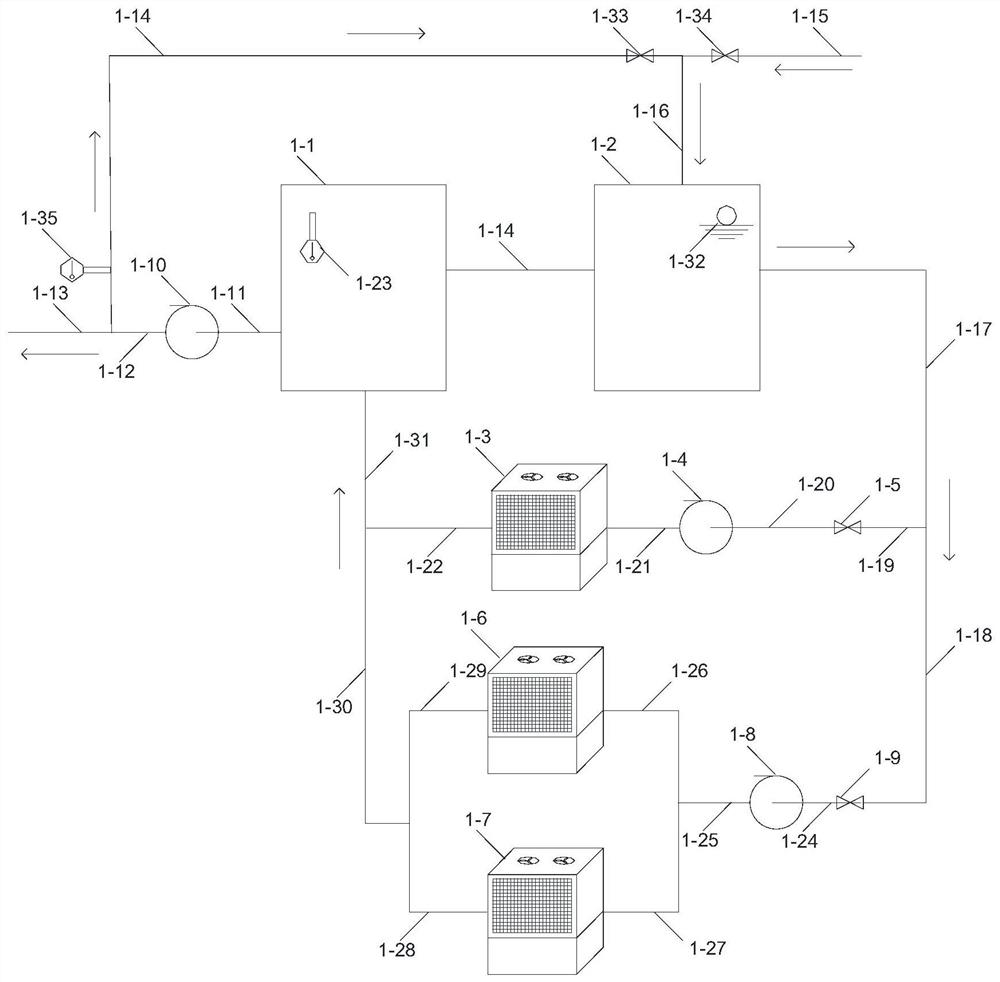

Cooling system capable of on-line cleaning heat exchanger and cleaning method thereof

ActiveCN102798317ARealize online cleaningAvoid Offline CleaningFlush cleaningInlet valveCleaning methods

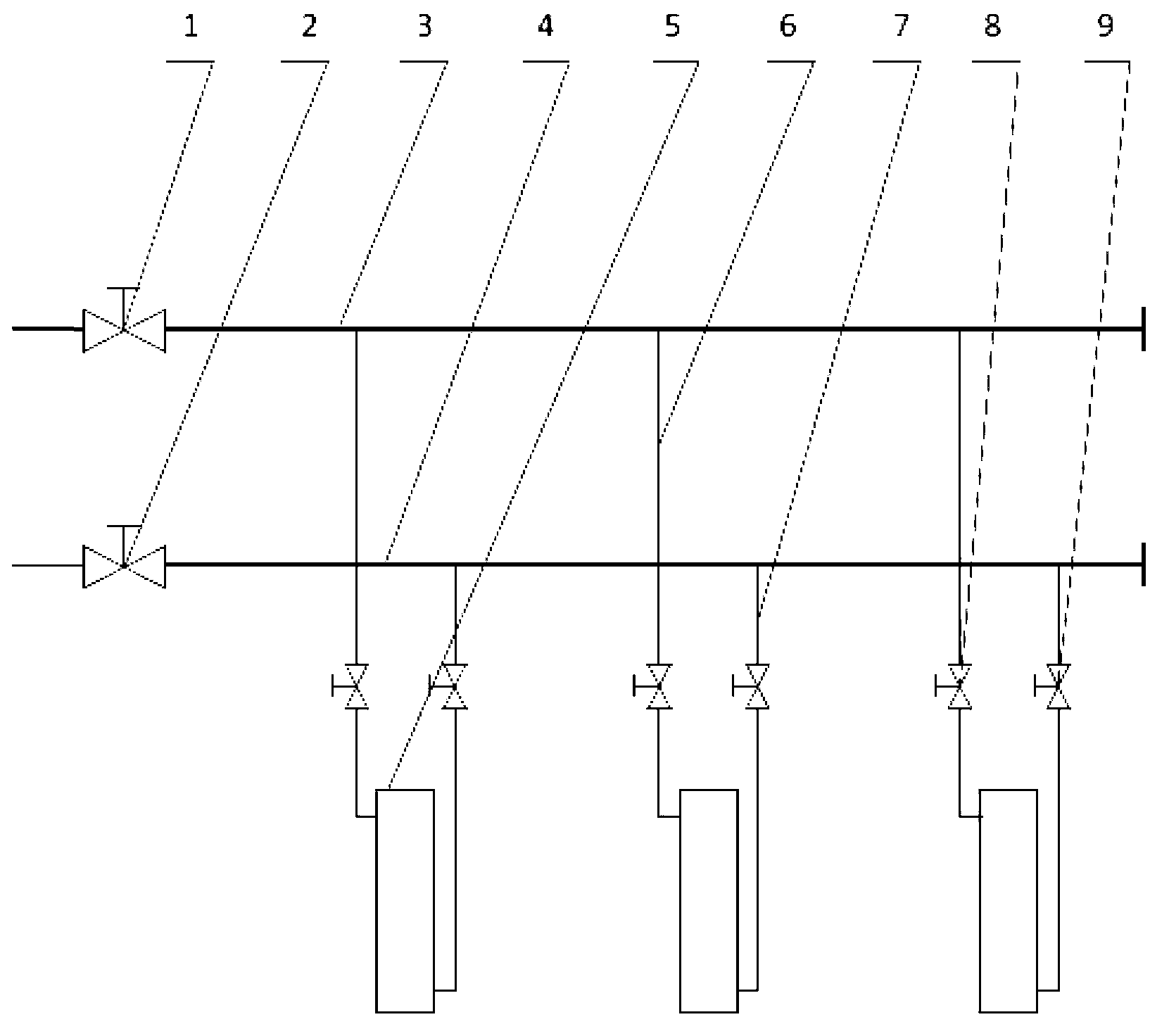

The invention discloses a cooling system capable of on-line cleaning a heat exchanger, which comprises at least two branches. Each branch comprises a heat exchanger and a water inlet drain valve. Both ends of the heat exchanger are respectively connected with a trunk water inlet pipeline and a trunk backwater pipeline through branch pipes, the trunk backwater pipeline is provided with a trunk backwater valve, and branch pipes on both sides of the heat exchanger are respectively provided with a water inlet valve and a backwater valve; the water inlet drain valve is arranged on the branch pipe between the heat exchanger and the water inlet valve; and the water inlet drain valve is connected with a drain pipe. According to the invention, the drain pipe and the drain valve are arranged on the branch pipeline, so that the cooling system capable of on-line cleaning the heat exchanger can on-line clean the heat exchanger by utilizing the original pipeline and valve of the cooling system so as to avoid offline cleaning, which is labor-consuming and time-consuming. In addition, the cleaning manner with the complicated water inlet or backwater pipeline switch equipment or the cleaning manner of adding a cleaning pipeline pump in the prior art is not required.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

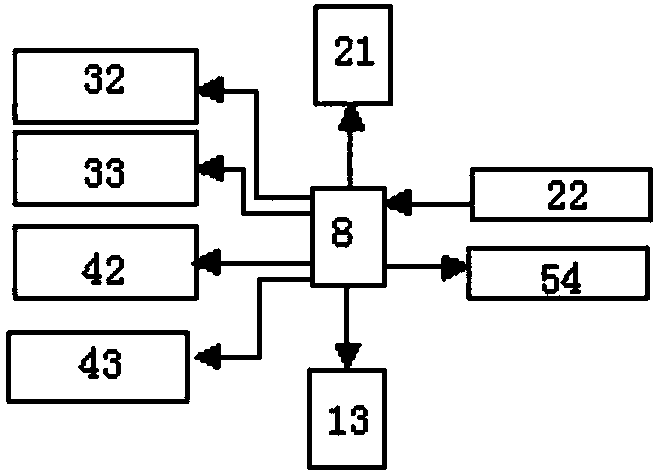

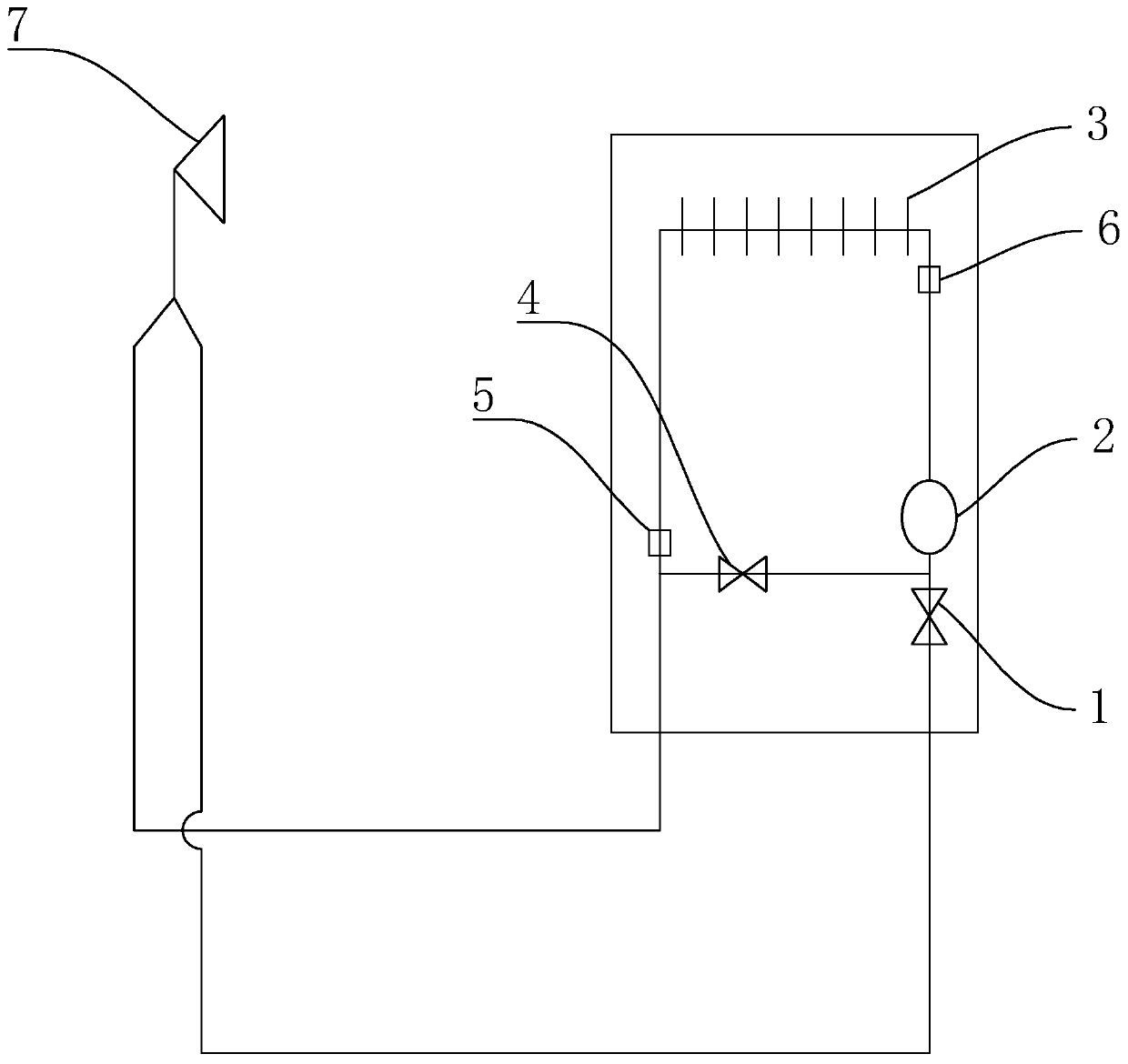

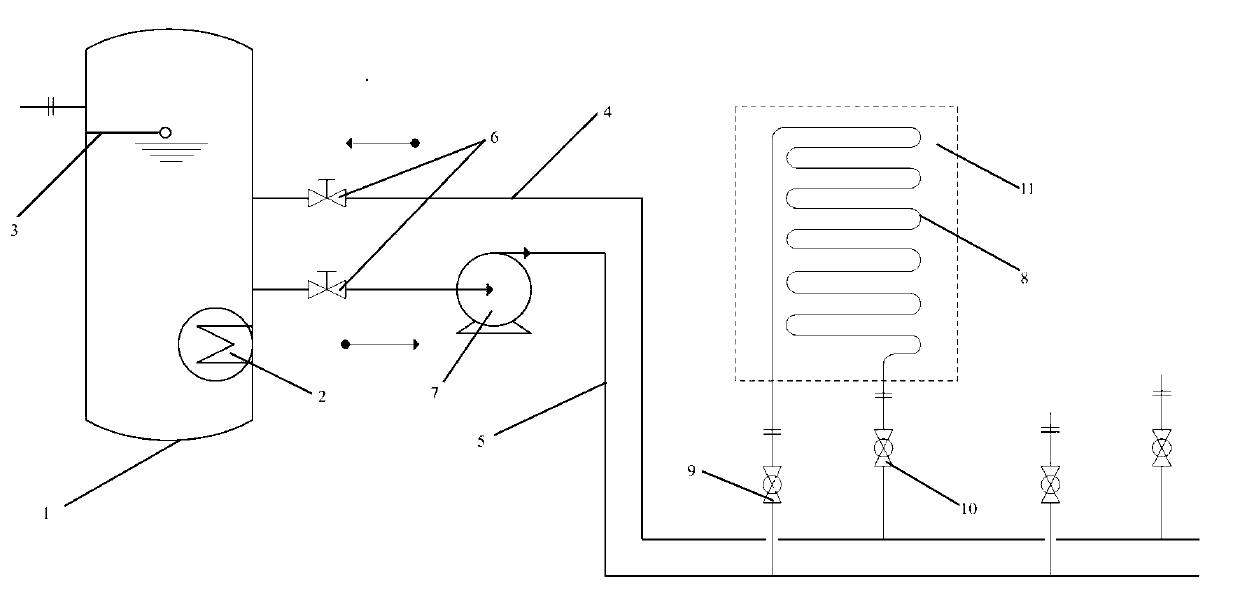

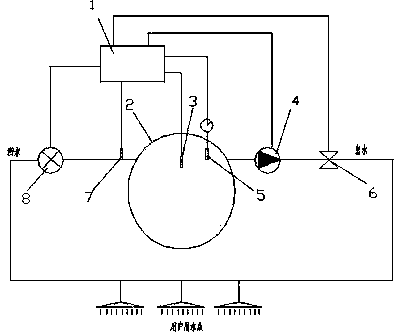

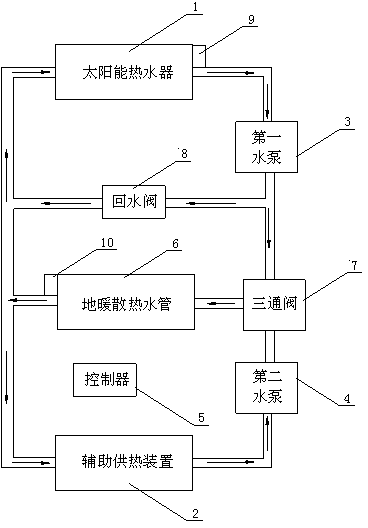

Solar water heater control system

InactiveCN105258368ARealize start-stop controlRealize automatic water replenishmentSolar heat devicesSolar thermal energy generationElectricityControl system

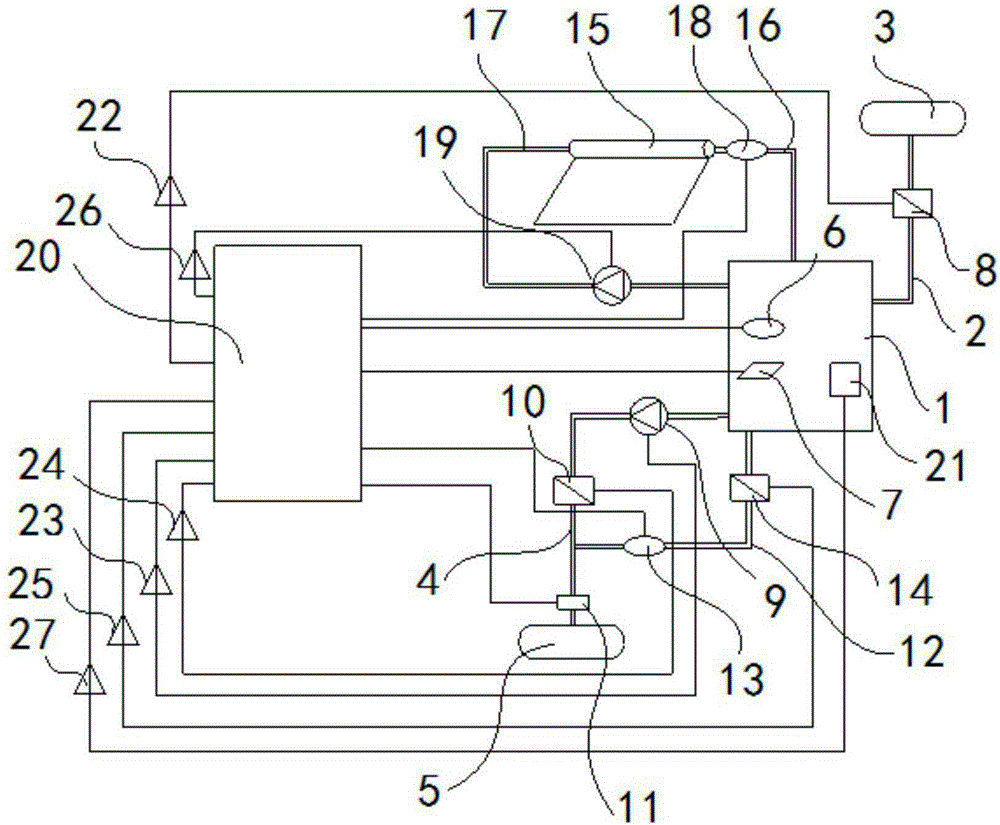

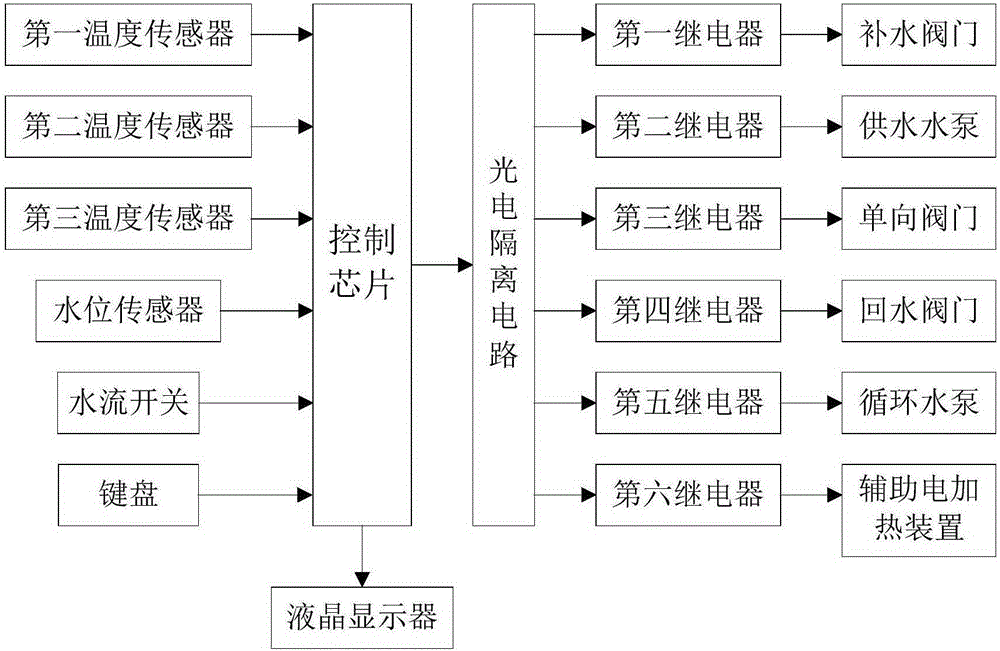

The invention discloses a solar water heater control system which comprises a heat storage water tank, a heat collector and a controller. A first temperature sensor, a water level sensor and an auxiliary electric heating device are arranged in the heat storage water tank. A water filling valve is arranged on a water inlet pipeline. A water supply pump, a one-way valve and a water flow switch are arranged on a water supply pipeline. A second temperature sensor and a backwater valve are arranged on a backwater pipeline. A third temperature sensor is arranged on a hot water outlet pipeline of the heat collector, and a circulating water pump is arranged on a hot water inlet pipeline. The controller receives signals collected by the temperature sensors, the water level sensor and the water flow switch so as to achieve the starting and stopping control over the water filling valve, the water supply pump, the one-way valve, the backwater valve and the circulating water pump and the on-off control over the auxiliary electric heating device, thereby achieving the functions of automatic water filling, automatic heating, auxiliary electric heating, instant heating and the like of a solar water heater. The solar water heater control system can be convenient to use, accurate in controlling and high in automatic degree.

Owner:SUZHOU SIKABO COMM TECH

Resistance type electric heating hot water boiler

InactiveCN102788418ASolve the problem of low thermal efficiency and energy savingReduce labor intensityWater heatersBlowoff valveEngineering

The invention relates to a resistance type electric heating hot water boiler, belonging to the technical field of a boiler. A boiler cylinder body is formed by welding a boiler cylinder, a front seal head, and a rear seal head; a gas collecting pot is connected with a water outlet valve by a flange; an electric heating pipe protecting cover and a boiler supporting base are welded at the outer part of the boiler cylinder; an electric heater is connected to an electric heating pipe interface by bolts, a safety valve is fixed on a safety valve pipe base by bolts; a pressure gage interface, an electric heating pipe interface, the safety valve base, a water outlet valve base, a manhole, a temperature meter interface, a water returning valve, and a blowoff valve base are welded to the boiler cylinder and are communicated with one another; the outer part of the boiler cylinder is provided with a boiler to preserve temperature. The resistance type electric heating hot water boiler has the following beneficial effects that: 1. the problems of low heat efficiency of the boiler is solved to save energy; 2, the environment-friendly problem is solved; 3. the labor is saved and the labor intensity of an operator is lightened; 3. the history of 4.2 MW / h of the evaporation capacity of a resistance type electric heating steam boiler is broken through.

Owner:大连船舶重工集团装备制造有限公司

Gas boiler constant-temperature operation method

InactiveCN107843004AAchieve constant temperature controlEasy to controlOperating means/releasing devices for valvesSlide valveTemperature controlTemperature monitoring

The invention discloses a gas boiler constant-temperature operation method. The gas boiler constant-temperature operation method comprises the following steps that firstly, the normal operation process comprises the steps that water shunting valves, a backwater valve and a first gas valve are opened, a second gas valve and an adjusting valve are closed, and gas passes through the first gas valve,a first gas branch pipe and a gas inlet pipe and then is supplied to a gas boiler; the gas boiler and a circulating pump are started, hot water formed after heating enters a water supply main to be supplied to all heating units; backwater passes through the circulating pump and a backwater main to enter the gas boiler, and complete waterway circulation is formed; when a temperature monitoring andcontrolling mechanism of the gas boiler breaks down, the second gas valve is opened immediately, the first gas valve is closed, and the gas is supplied to the gas boiler through a gas boiler hot waterthermostatic valve; and the opening degree of the adjusting valve is controlled to control the water outlet temperature of the gas boiler. Operators do not need specialized training, and constant-temperature control can be achieved through operation of valve opening and closing. By controlling the opening degree of the adjusting valve, the set water outlet temperature of the gas boiler can be controlled.

Owner:HUANGHE S & T COLLEGE

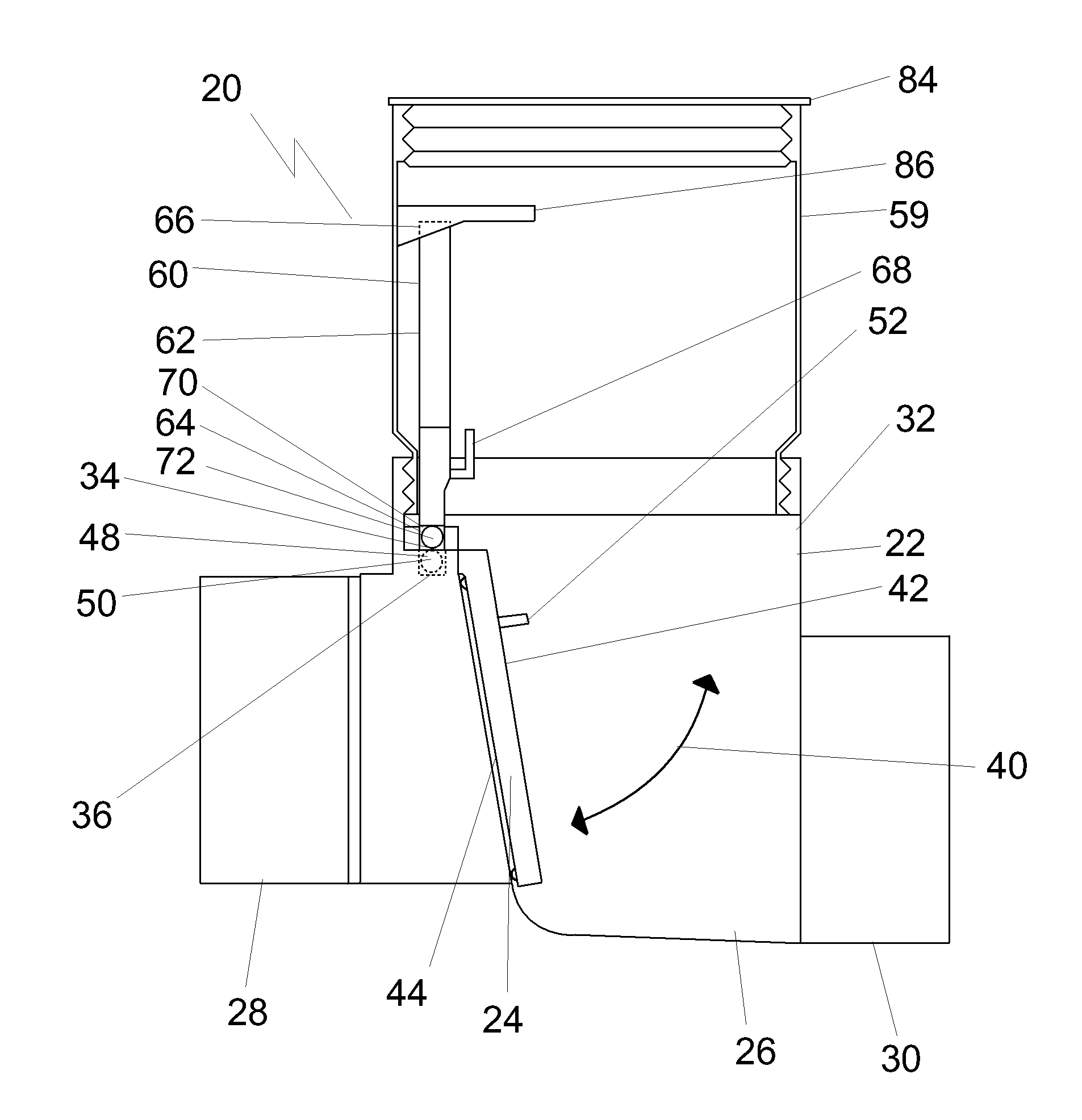

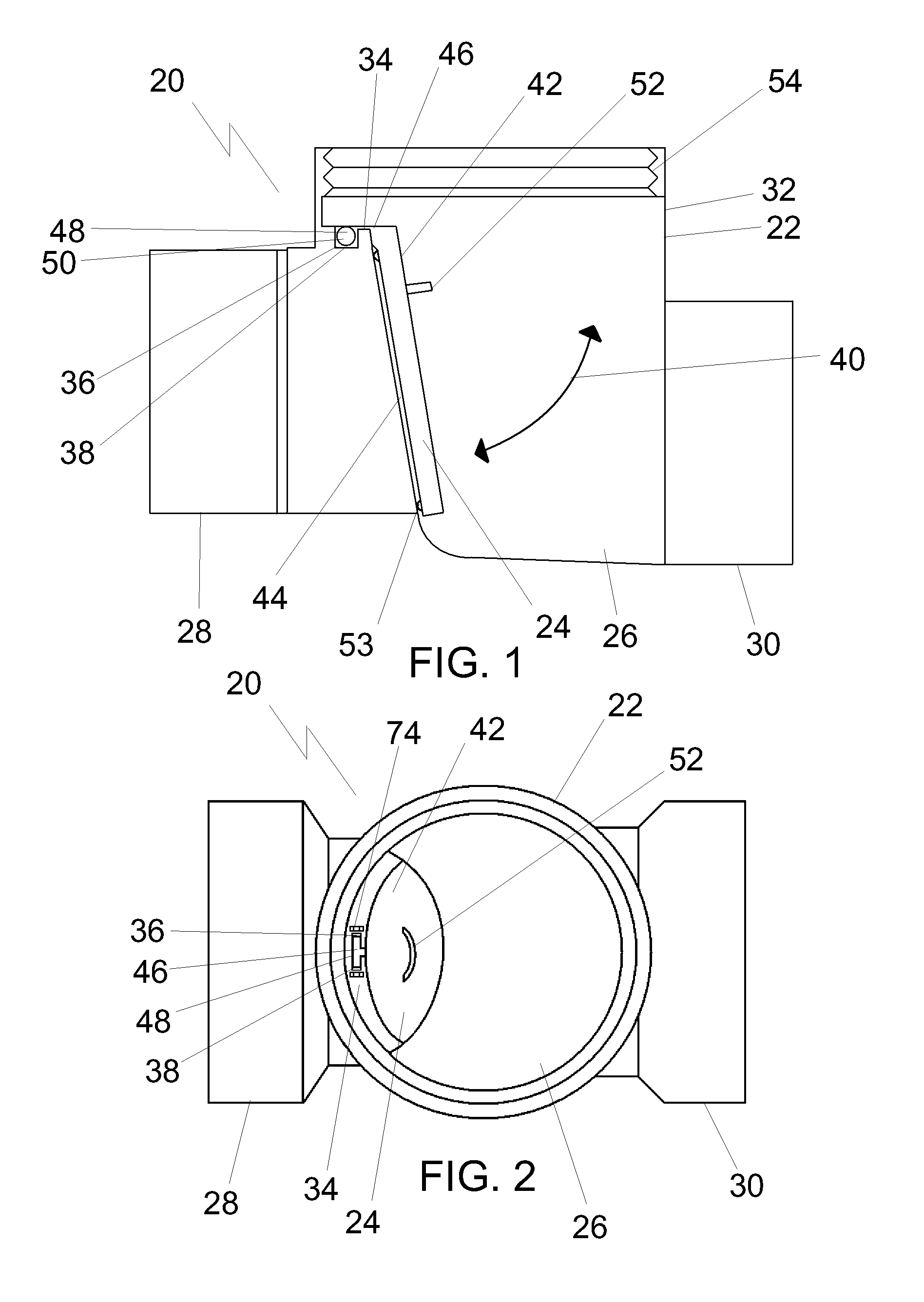

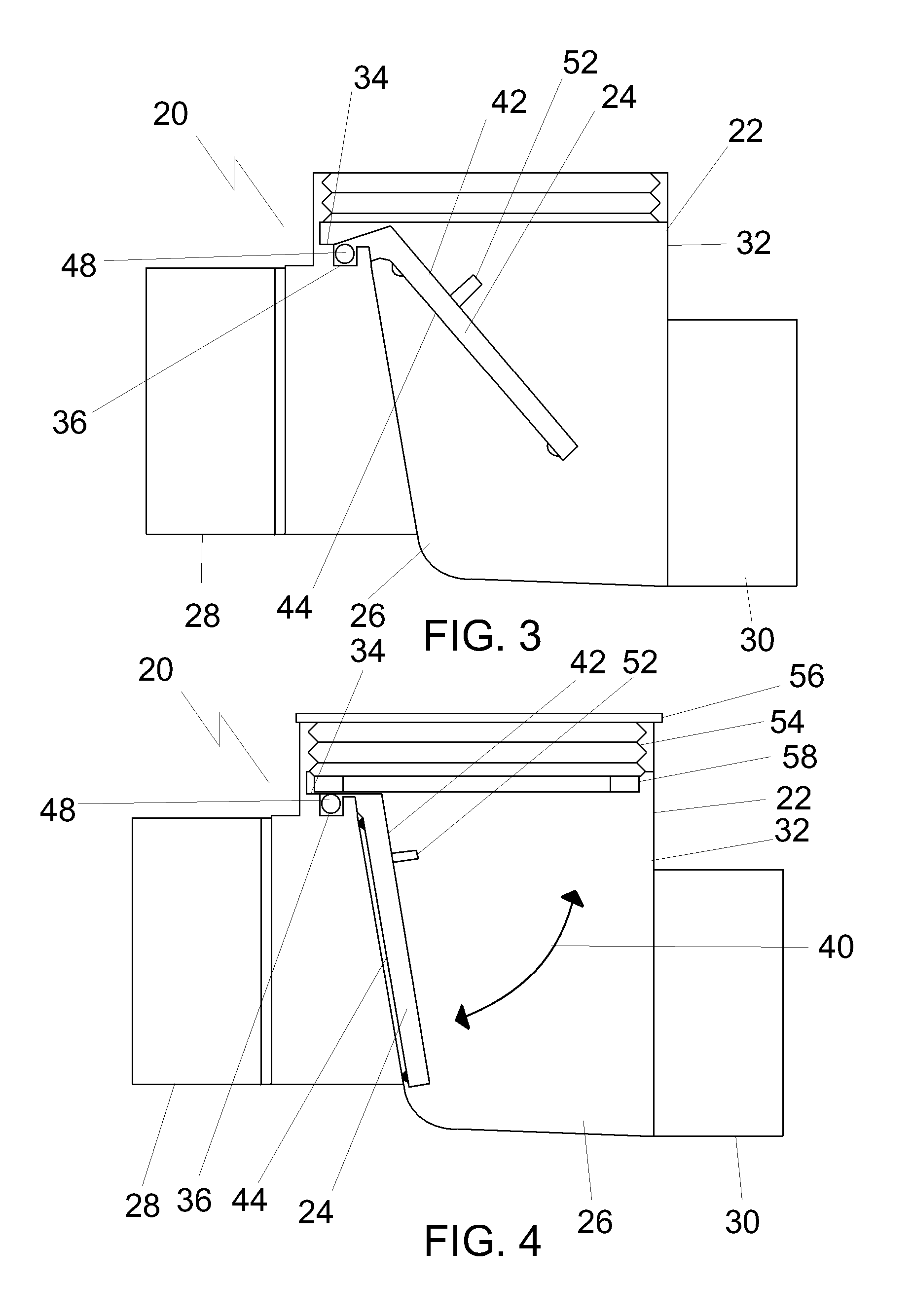

Normally-open backwater valve with suspended flapper

A normally-open backwater valve fluidly coupled between one or more discharge conduits of a building, or other location, and a sewage, or drainage, system includes a valve body having a horizontally-oriented fluid flow passageway, a flapper pivotably moveable therein and at least one spacer configured to position the flapper above the lower interior surface of the valve body in the passageway when the flapper is in an open position.

Owner:RECTORSEAL LLC

Water return valve for water heater and water heater

ActiveCN111397213AGuaranteed backwater flowGuaranteed supercharging effectFluid heatersWater useMechanical engineering

The invention discloses a water return valve for a water heater and the water heater. The water return valve can be switched between a first working state and a second working state and comprises a valve body and a flow limiting valve, the valve body is provided with a first flow channel, a second flow channel and a flow limiting flow channel, and the flow limiting flow channel is in communicationwith the first flow channel and the second flow channel; at least one part of the flow limiting valve is movably arranged in the flow limiting flow channel between a full flow position and a flow limiting position, and in the first working state, the flow limiting valve moves to the full flow position so as to control the opening degree of the flow limiting flow channel to be maximum; and in thesecond working state, the flow limiting valve moves to the flow limiting position so as to control the opening degree of the flow limiting flow channel to be minimum. According to the water return valve, by controlling the opening degree of the flow limiting flow channel, the water return flow can be guaranteed during circulating preheating, the pressurization effect can be guaranteed during low-water-pressure water using, and the water return valve is also suitable for a water heater with a water return pipeline and a water heater without a water return pipeline.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Operation flushing device for general surgery department

InactiveCN105435323ASimple structureImprove protectionCannulasEnemata/irrigatorsSurgical operationCatheter

The invention discloses an operation flushing device for the general surgery department. The device comprises a flushing chamber and a recycling chamber which are formed integrally, the flushing chamber and the recycling chamber are internally provided with a T-branch pipe, the top of the T-branch pipe is connected with a guide pipe, the top, located in the flushing chamber, of the T-branch pipe is provided with a water outlet valve, the top, located in the recycling chamber, of the T-branch pipe is further provided with a backwater valve, the top of the guide pipe is connected with a pressure regulating air bag, a liquid inlet is formed in the top of the flushing chamber, a seal cover is arranged at the top of the liquid inlet, a heating device is arranged at the outer side of the flushing chamber, the bottom of the flushing chamber is connected with a water spraying head, the surface of a liquid outlet pipe is provided with a one-way valve, the bottom of the recycling chamber is connected with a water sucking head through a liquid returning pipe, and a water outlet is formed in the bottom of the recycling chamber. The operation flushing device for the general surgery department is simple in structure, by arranging the recycling chamber, waste water generated in the flushing process can be recycled, and operation proceeding is facilitated.

Owner:夏周阳

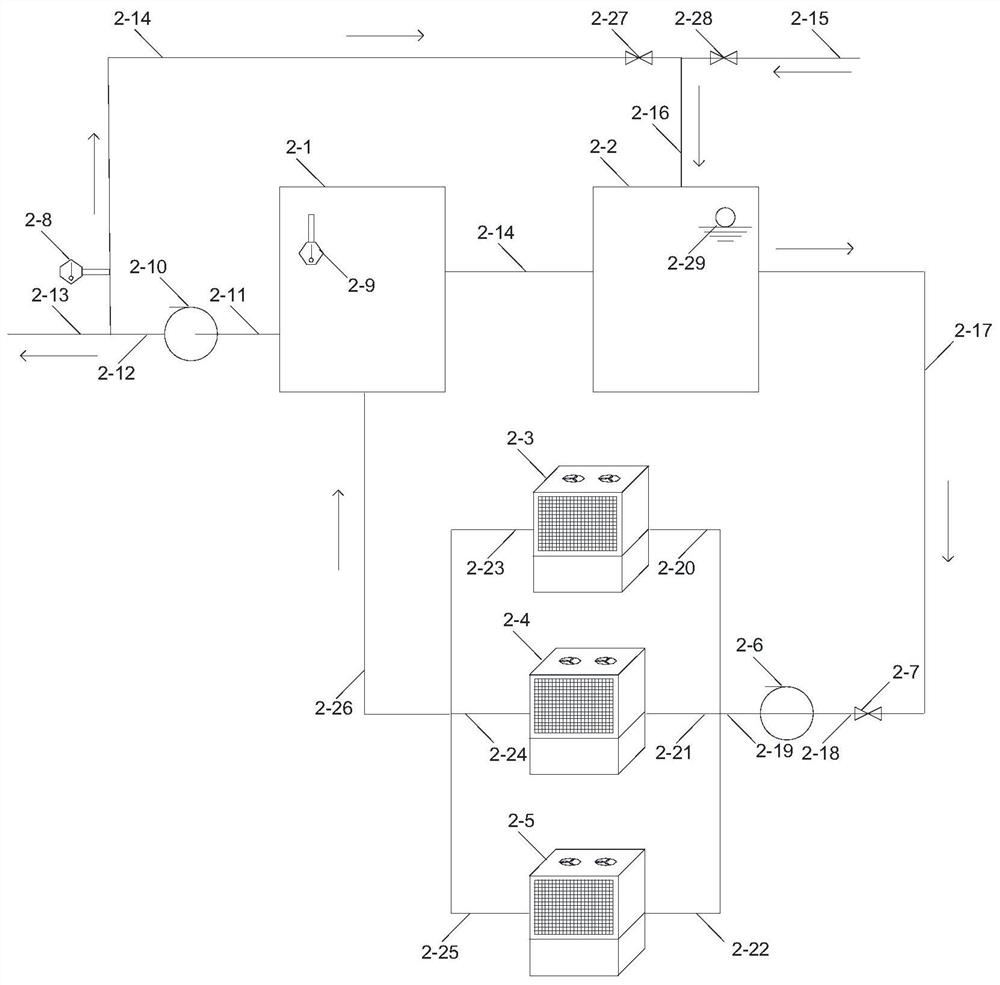

Air source heat pump double-water-tank hot water system and control method thereof

The invention relates to an air source heat pump double-water-tank hot water system and a control method. The air source heat pump double-water-tank hot water system comprises a variable-frequency water supply pump, a hot water tank, a warm water tank and a parallel host which are connected in sequence, and further comprises a water return valve and a water replenishing valve which are connected with the warm water tank; the hot water tank, the warm water tank and the parallel host are sequentially connected to form host-water tank circulation; the warm water tank, the hot water tank, the variable-frequency water supply pump and the water return valve are sequentially connected to form water tank-tail end circulation; and the parallel host comprises a plurality of parallel branches which are independently controlled or not independently controlled, and different heat supply modes are achieved by opening a specific number of parallel branches, so that different tail end load requirements are met. Compared with the prior art, the double-water-tank scheme is adopted, so that the mixing loss among return water, replenished water and hot water is reduced; and meanwhile, the water inlet temperature and the water outlet temperature of the heat pump are reduced, the condensation temperature of the heat pump can be well reduced, and the energy efficiency of the heat pump unit is improved while water consumption of a user is guaranteed.

Owner:TONGJI UNIV

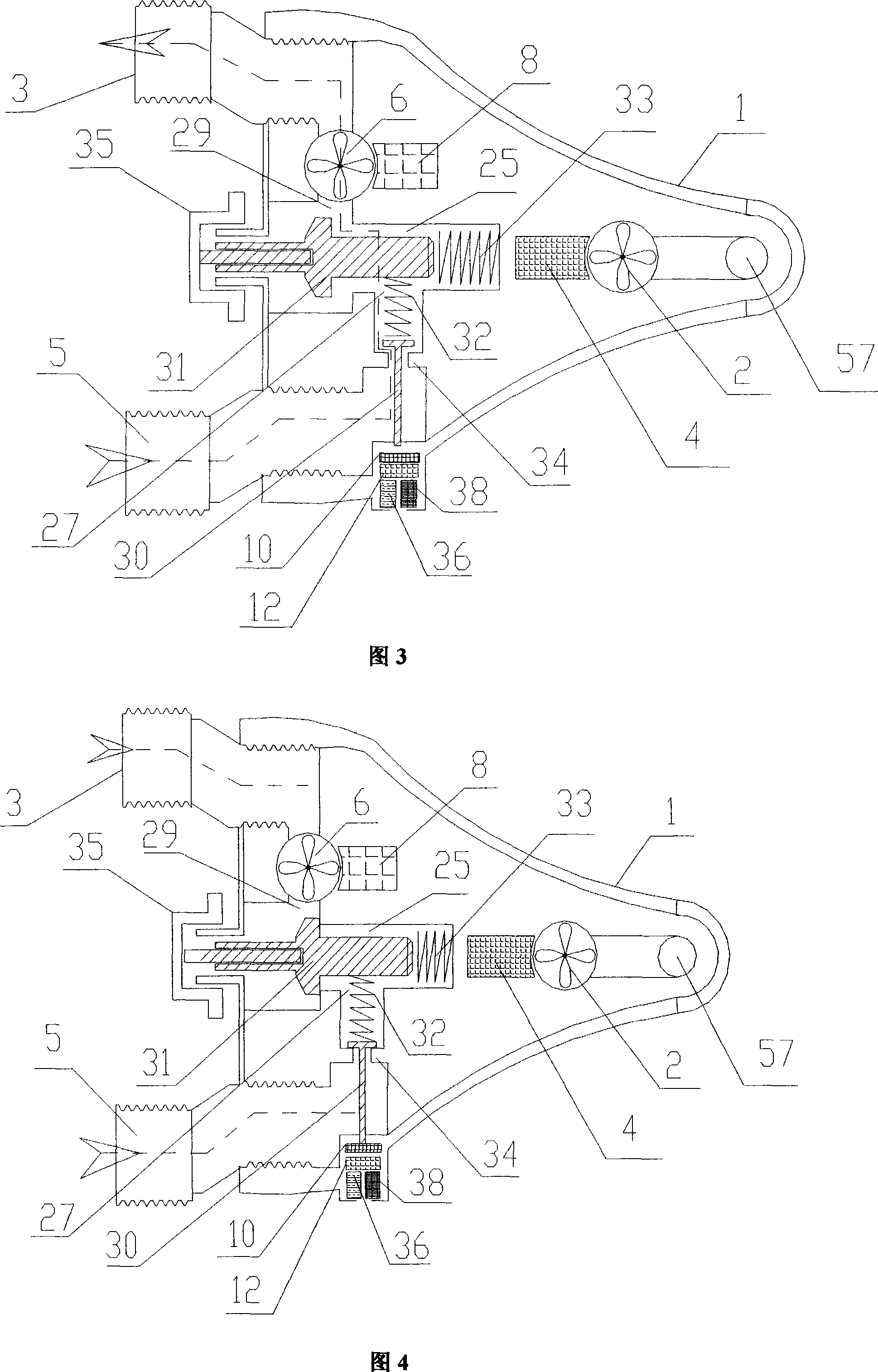

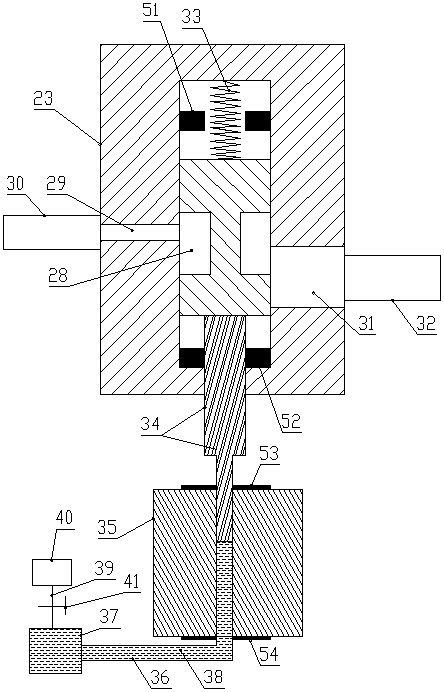

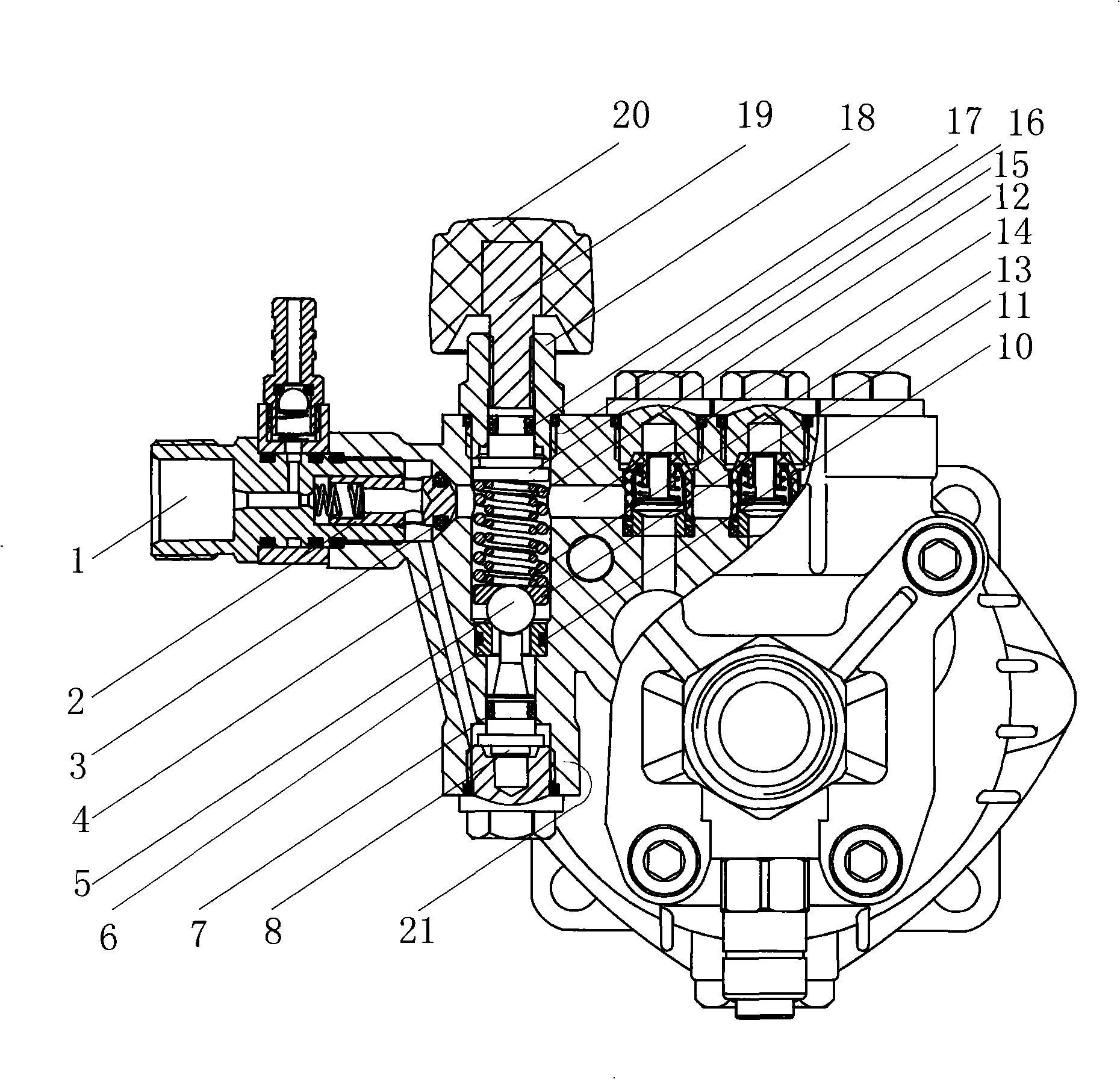

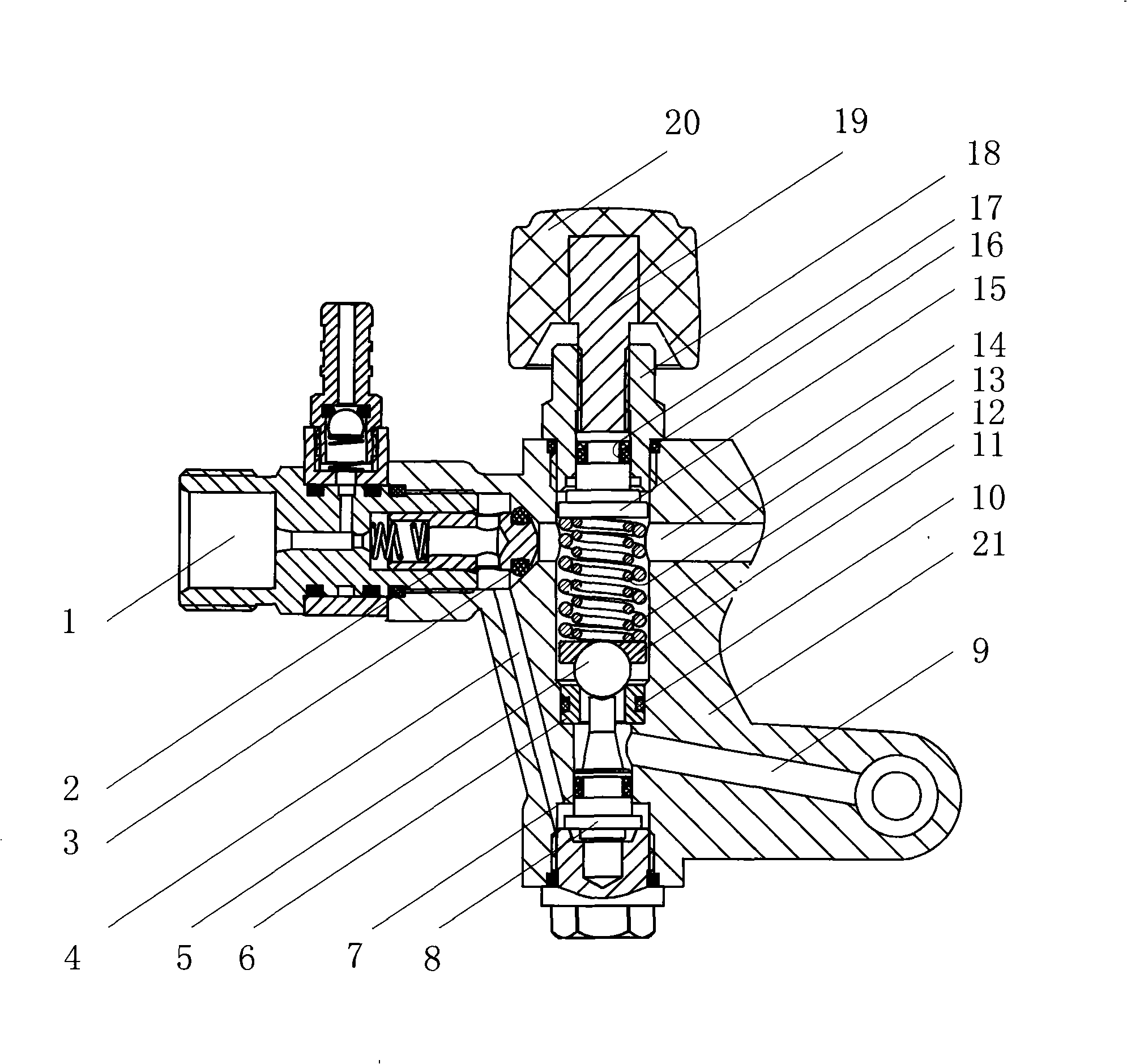

Pressure-regulating device of high-pressure water pump

ActiveCN101403395ACompact structureImprove sealingPositive displacement pump componentsPump controlWater channelEngineering

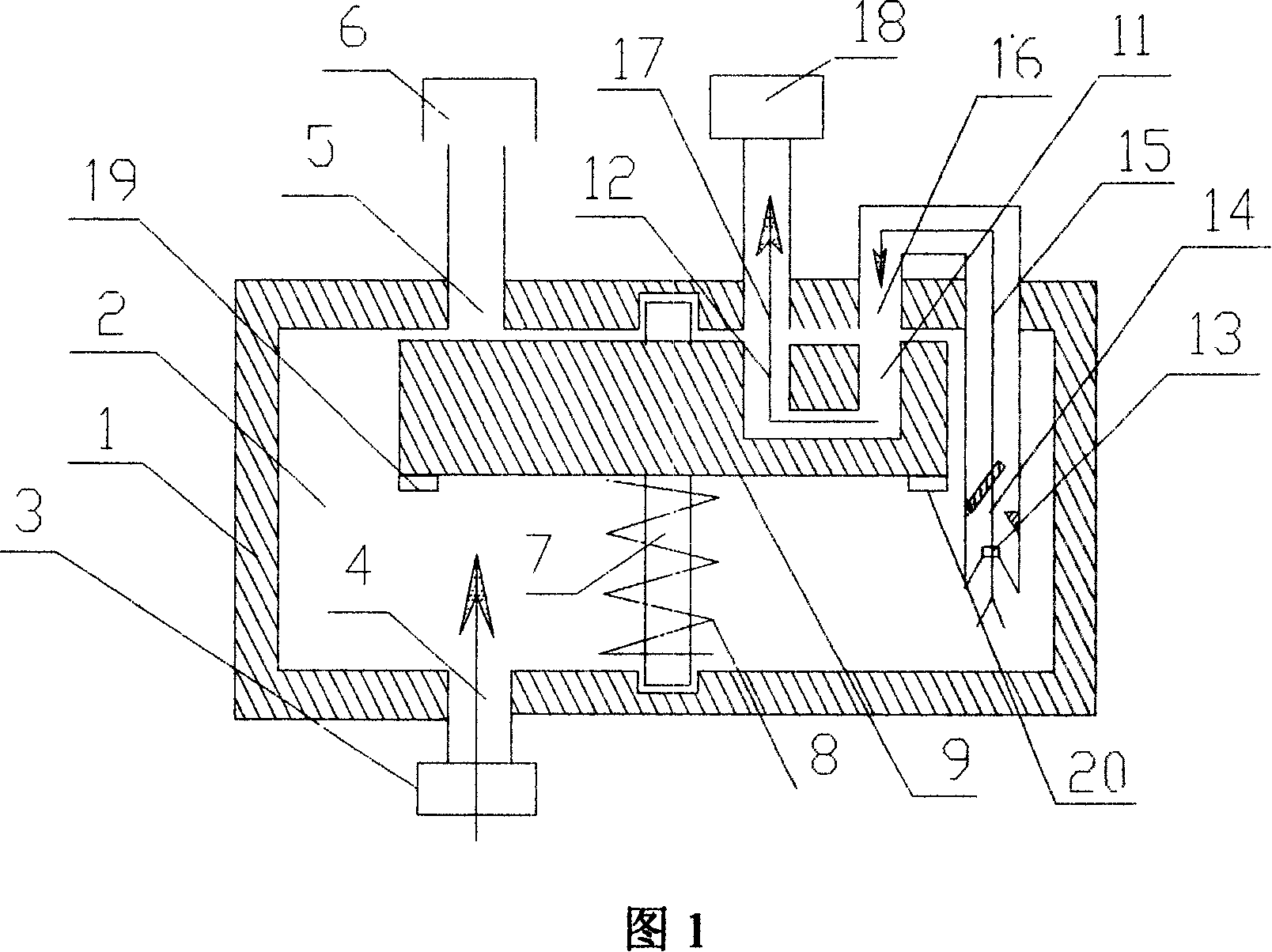

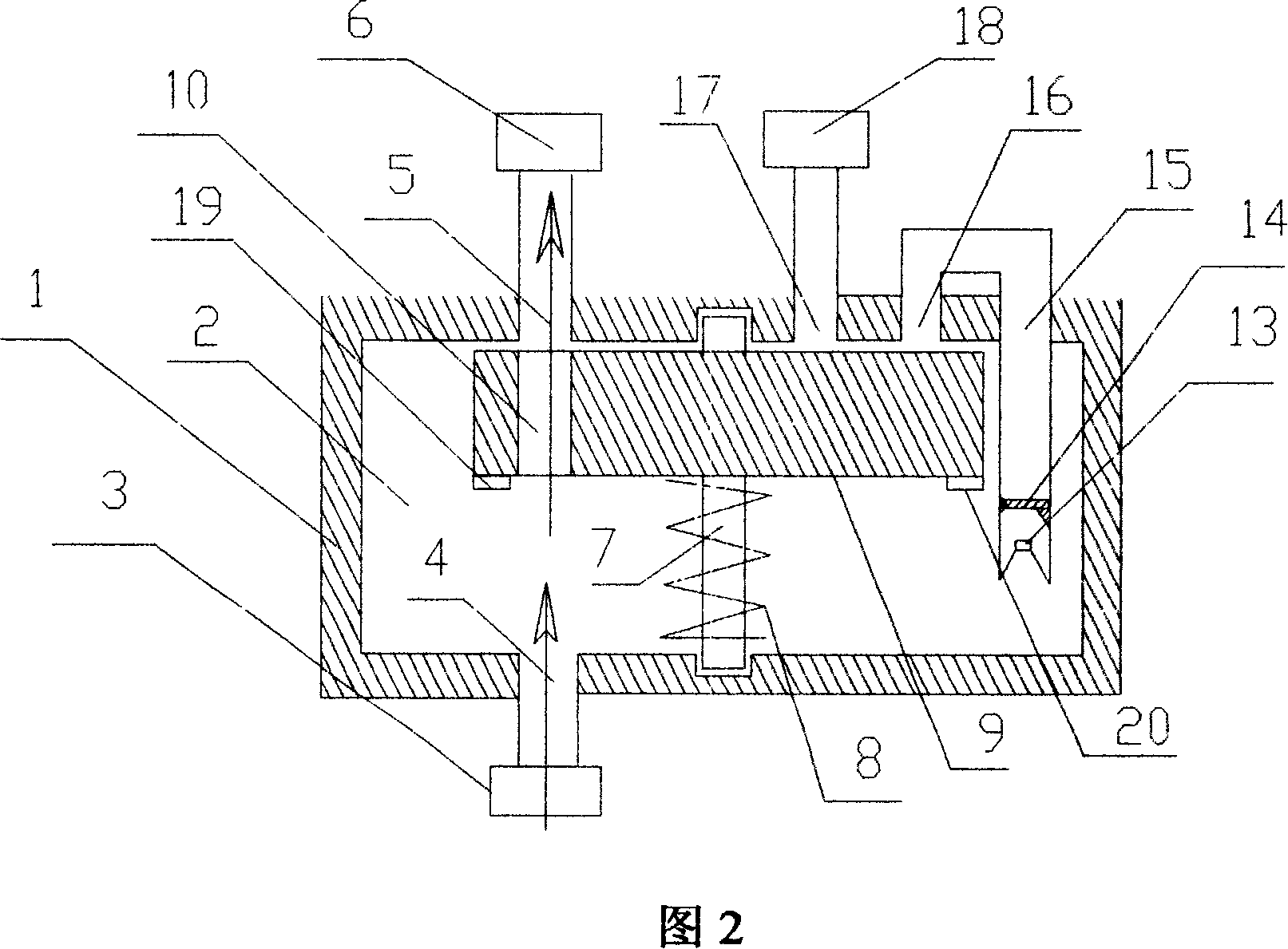

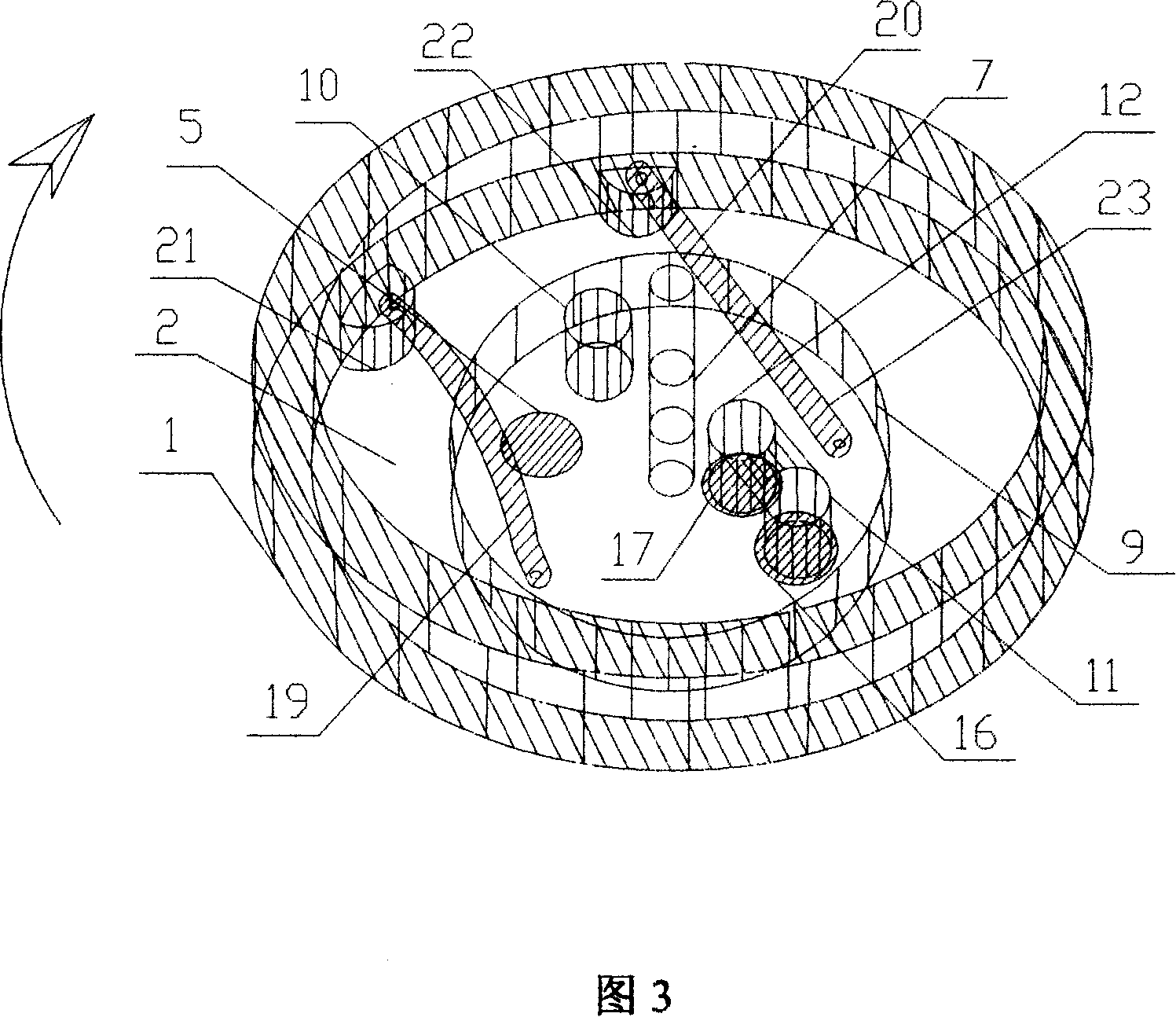

The invention belongs to the technology field of pumps, more particularly relates to a pressure regulating mechanism of a high-pressure pump; the pressure regulating mechanism of the high-pressure pump is provided with a water inlet pipeline and a high-pressure pipeline on a pump shell; an water channel of an opening valve, which is communicated with the bottom of a backwater valve core is arranged on the high-pressure pipeline at the back of a water outlet valve; a top rod on the upper part of the backwater valve core supports the bottom of a backwater valve; the upper part of the backwater valve is communicated with the high-pressure pipeline; the lower part of the backwater valve is pressed on a backwater valve seat; after the backwater valve is opened, the high-pressure pipeline can be communicated with the water inlet pipeline; a lower spring seat, a big pressure regulating spring and a small pressure regulating spring which are sleeved inside and outside, and an upper spring seat, a pressure regulating bolt and a pressure regulating handle are arranged on the upper part of the backwater valve in sequence. The mechanism uses the big pressure regulating spring and the small pressure regulating spring which are sleeved inside and outside, and therefore causes the pump body structure to be compact, greatly enhances the sealing performance of the pump as gaps among each part are provided with sealing rings, improves the convenience of the operation and use of the pump, has quite strong creativity and practicality, and is suitable to be popularized in and applied to the pump-typed products.

Owner:ZHEJIANG DA NONG IND CO LTD

Strong anti-block automatic pollution discharge breast wall type backflow device

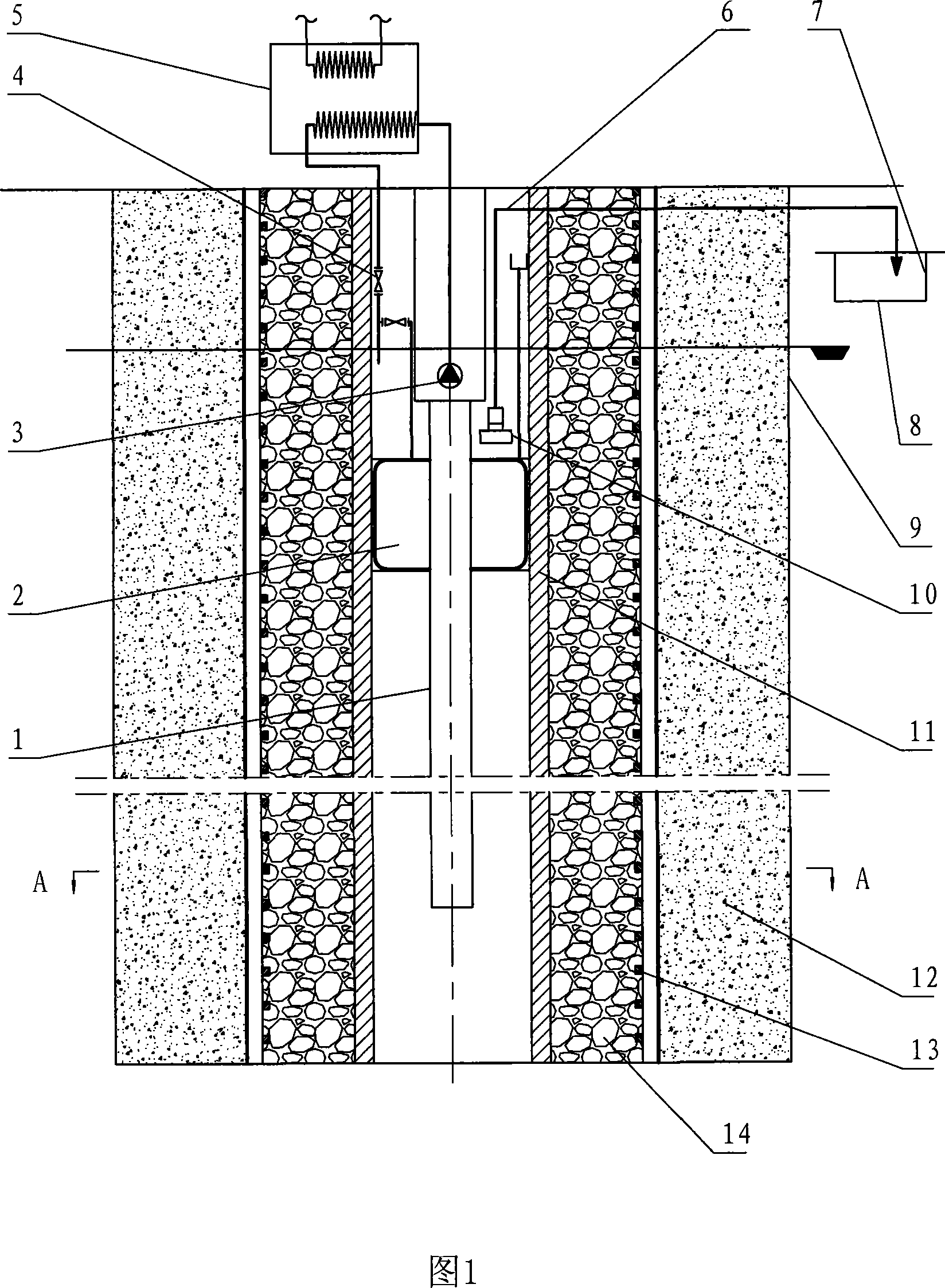

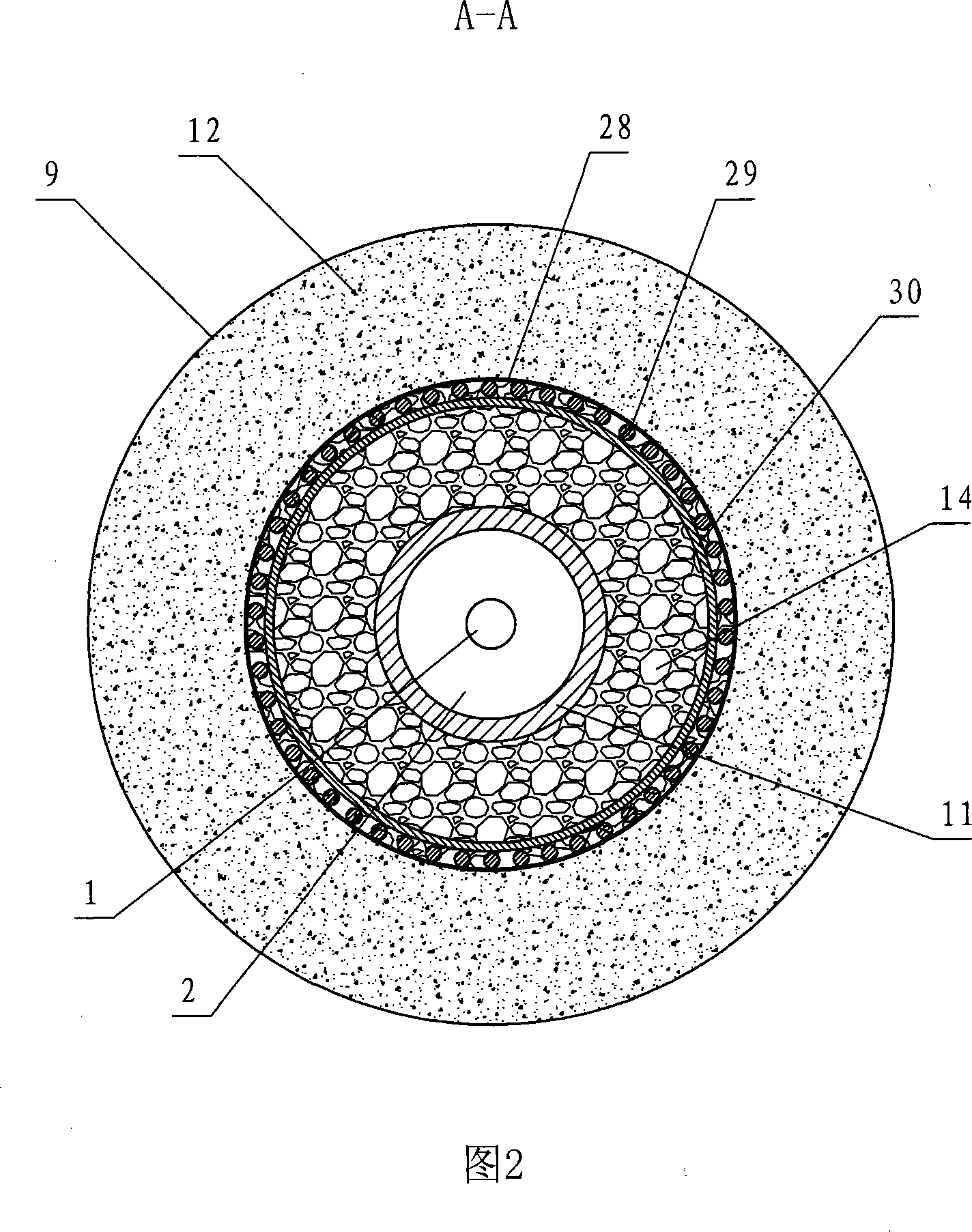

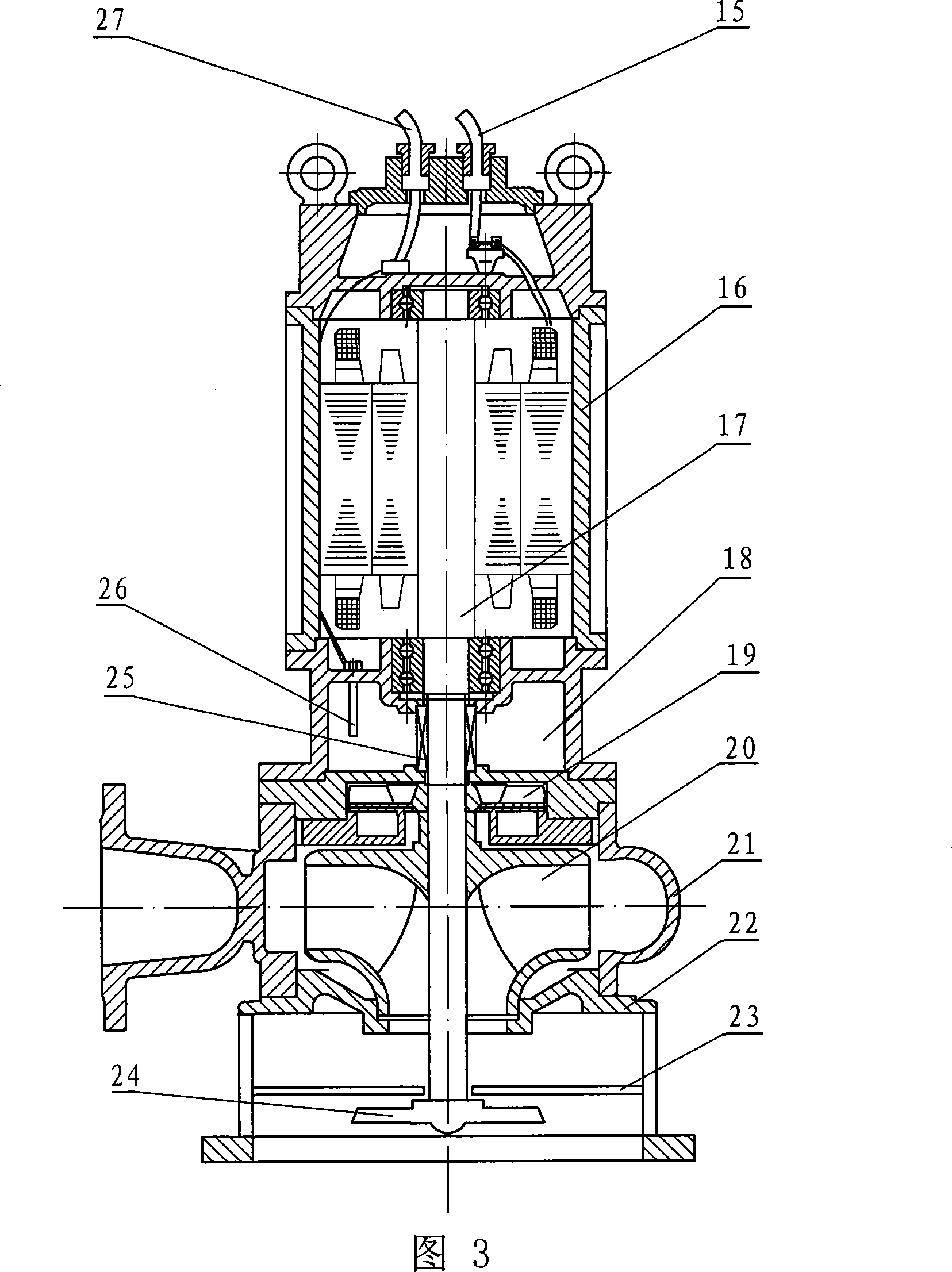

InactiveCN101158515AAvoid enteringExtended service lifeOther heat production devicesGeothermal energy generationWater source heat pumpImpeller

A strong anti-fouling automatic pollution discharge breast wall type recirculation device comprises a well pipe, a recirculation water pipe which is assembled in the well pipe, is communicated with a water source heat pump and is controlled by a backwater valve, a double channel non-clogging impeller which is integrated in a pump body arranged at the bottom of a recirculation water layer in the well pipe and consists of a master impeller and an assisted impeller and the automatic control strong sewage pump of a mixer; the outlet end of the pump body is connected with a catch basin arranged outside the well pipe. The technical points are that an interlayer decompression breast wall is arranged at the external circumference of the well pipe, and the coarse gravels are filled between the well pipe and the interlayer decompression breast wall, and the fine filling gravels are filled between the interlayer decompression breast wall and the external well pipe. The invention can fundamentally solve the problems that the sand is moved at the bottom of the pumping well of the single-pipe well or multi-pipe well and the well wall collapses to cause a dead well, etc., and further has the advantages of more reasonably designed structure and more stable and reliable running besides the advantages of the effect of completely desilting and timely recirculation, and further prolongs the service life of the heat collecting well, improves the effects of preventing the fouling and recirculation, and effectively avoids the pumping well of the single-pipe or multi-pipe well from being caused to be a dead well.

Owner:靖洪铭 +1

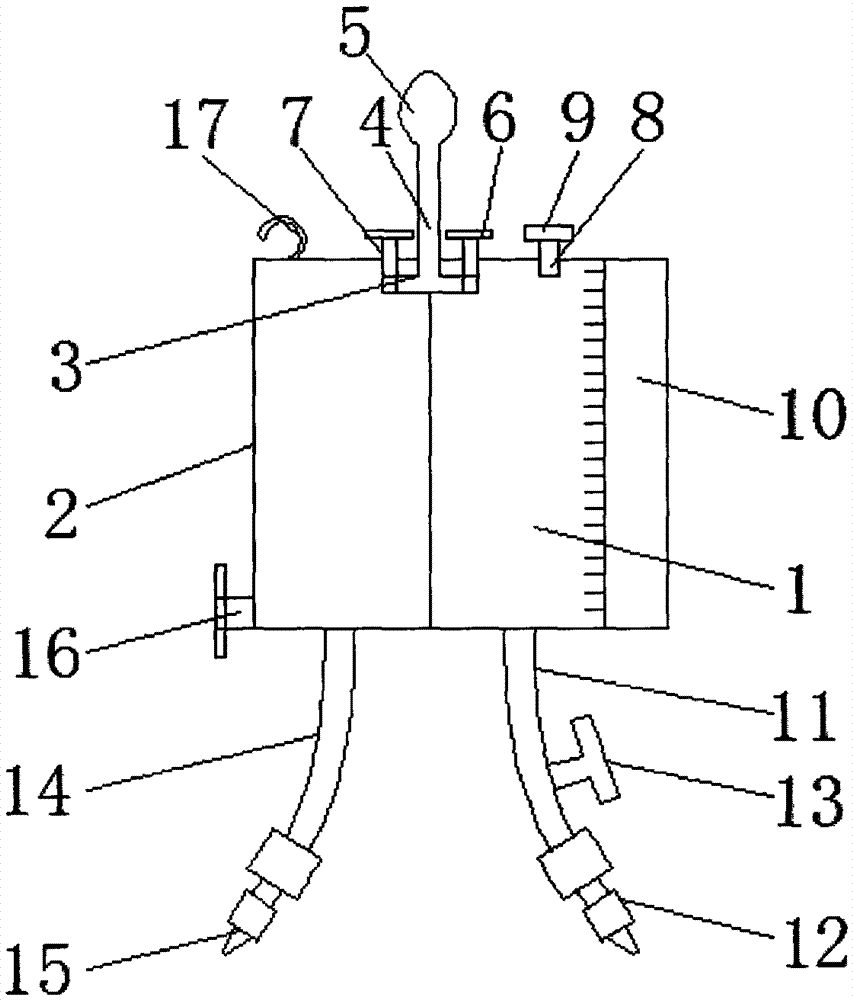

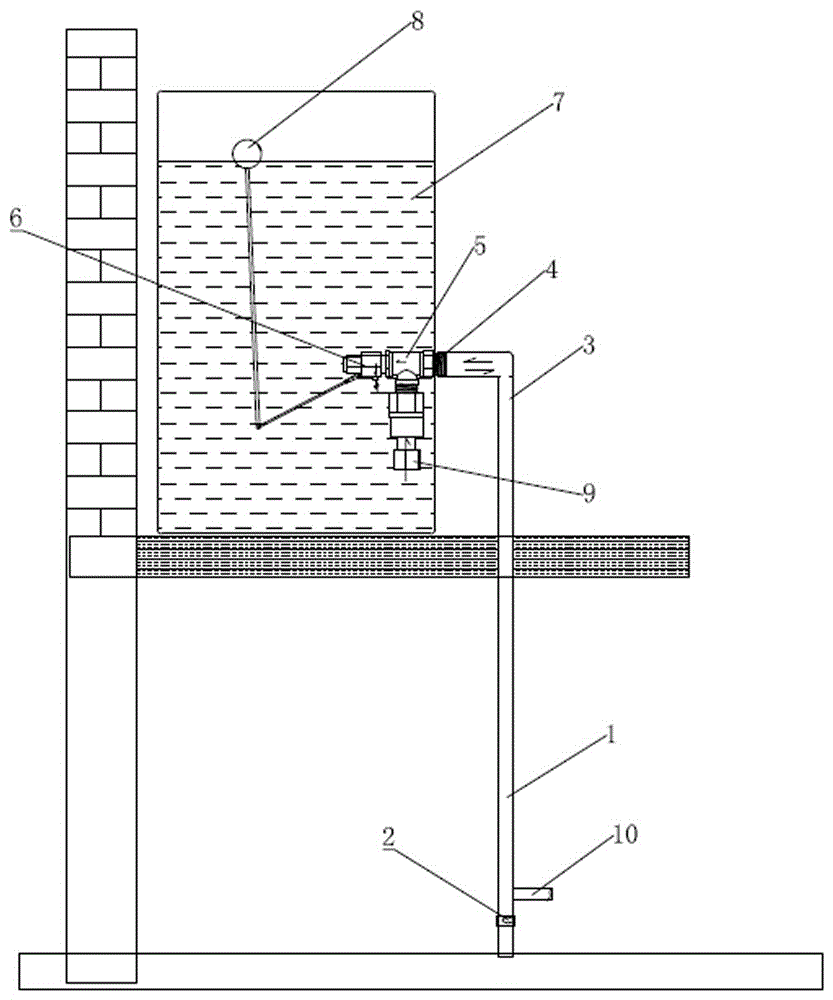

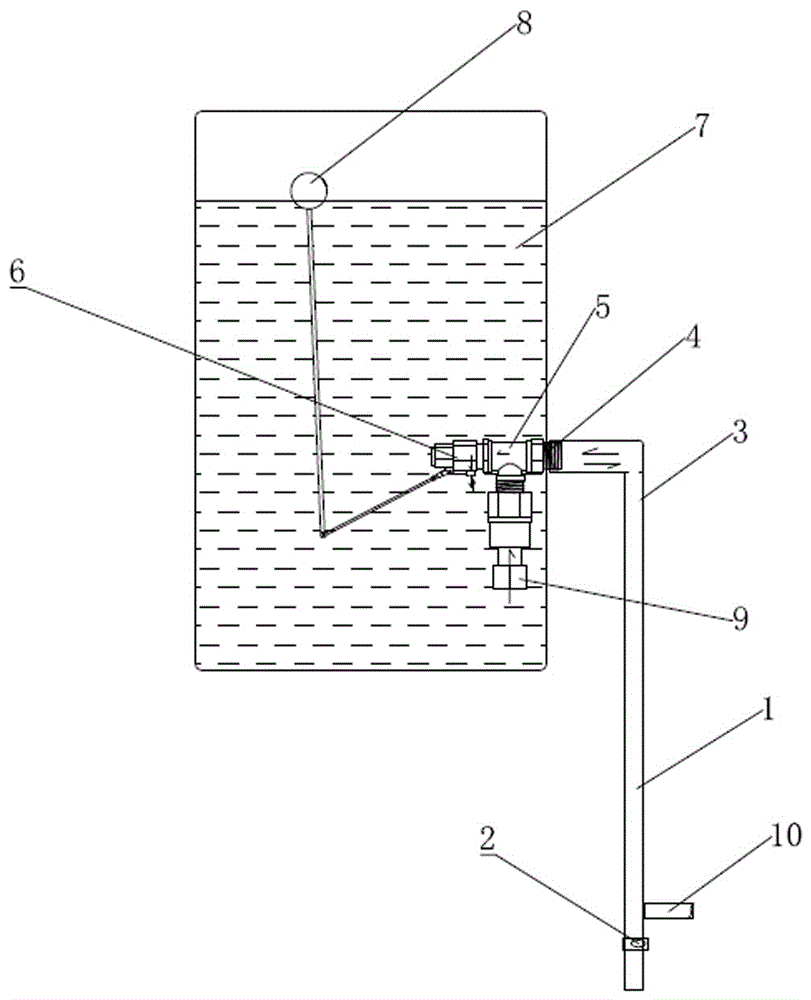

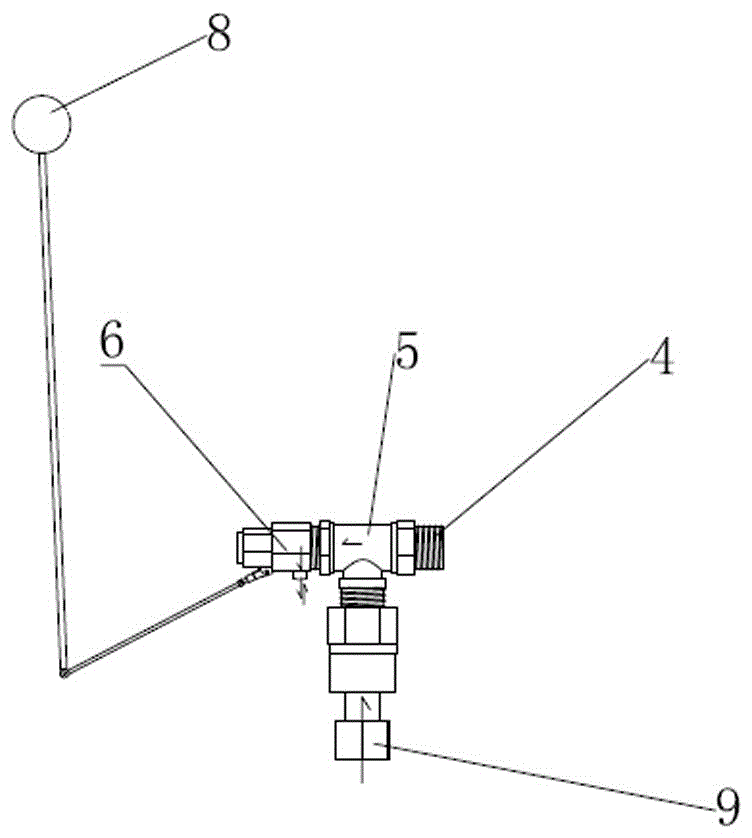

Full-automatic non-electric water storage control device for water cut-off emergency meeting and using method thereof

InactiveCN105756139ANo precision partsSimple structureService pipe systemsWater mainsWater useAutomatic control

The invention relates to domestic water, in particular to a full-automatic non-electric water storage control device for water cut-off emergency meeting.The device comprises a main water pipe, a water tank and a water tank common water inlet and outlet pipe, a water tank water inlet and outlet control device is arranged in the water tank, is of a T-shaped structure and comprises a water tank interior and exterior connector of which one end is arranged on the inner wall of the water tank, the other end of the water tank interior and exterior connector is provided with a floating ball control valve, the lower end of a floating ball connecting rod is provided with a water inlet and outlet, the lower end of the water inlet and outlet control device is provided with a one-way water return valve, and the one-way water return valve is switched on in the direction from the water tank to the water tank common water inlet and outlet pipe and switched off in the opposite direction; the front end of a service pipe of the main water pipe is provided with a check valve, and when water of the main water pipe is cut off, the water in the water tank does not flow back to enter a main pipe network.According to the device, automatic control is achieved by utilizing the physical principle, power is saved, no precise part is needed, the structure is simple, maintenance is easy, the cost is low, the economical and practical properties are achieved, and the water cut-off emergency meeting problem is effectively solved.

Owner:黄宏伦

Iron pollution micro-filtration/ultra-filtration film cleaning equipment and cleaning method

PendingCN107261852AEfficient removalSmall footprintWater treatment parameter controlSpecific water treatment objectivesManganeseMicrofiltration

The invention discloses iron pollution micro-filtration / ultra-filtration film cleaning equipment and a cleaning method. The equipment comprises a cleaning water tank, a cleaning water pump, a film module region and a manganese sand filter which circularly communicate with one another successively through pipes, wherein a chemical agent feeding opening is formed in the top end of the cleaning water tank; cleaning water inlet valves are arranged on water inlet pipes of the cleaning water pump and the film module region; a water producing end of the film module region is connected with a water inlet of the manganese sand filter through a water producing pipe; a concentrated water end of the film module region is connected with the water inlet of the manganese sand filter through a concentrated water pipe; and water returning valves are respectively arranged on the water producing pipe and the concentrated water pipe. The cleaning method comprises the steps of circular soaking and backwashing and backflushing. According to the cleaning equipment, the cleaning water tank, the cleaning water pump, the film module region and the manganese sand filter communicate with one another circularly, a film module is soaked circularly and subjected to backwashing and backflushing treatment by liquor, iron pollution can be removed effectively, and the equipment occupies small space and can move, is low in energy consumption, and is economical, practical, safe and reliable.

Owner:BEIJING BODA WATER

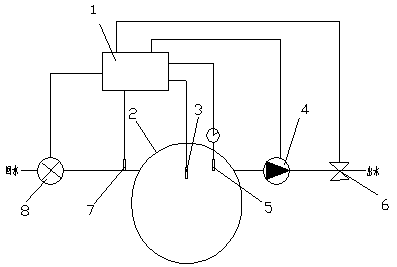

Water temperature control method and device

ActiveCN110657583AControl water temperatureControl the outlet water temperatureFluid heatersWater flowInlet valve

The invention discloses a water temperature control method and device. A water inlet valve on a water inlet pipe is turned on; a water pump is operated, and water currents are heated by a heat exchanger to reach a temperature detecting point; the water temperature of the temperature detecting point is a water outlet temperature; the water outlet temperature is compared with a first set temperatureand a second set temperature; when the water outlet temperature is lower than the first set temperature or higher than the second set temperature, the water inlet valve is turned off, a water returnvalve is turned on, and the water currents are continuously circulated among the water pump, the water inlet valve, the heat exchanger and the water return valve until the water outlet temperature ishigher than the first set temperature and lower than the second set temperature; the water return valve is turned off, the water inlet valve is turned on, and the water currents flow out from a wateroutlet pipe; and when the water outlet temperature is higher than the first set temperature and lower than the second set temperature, the water currents are discharged from the water outlet pipe. Thewater outlet temperature can be effectively controlled to prevent the problem of hot and cold feelings.

Owner:GUANGDONG MACRO GAS APPLIANCE

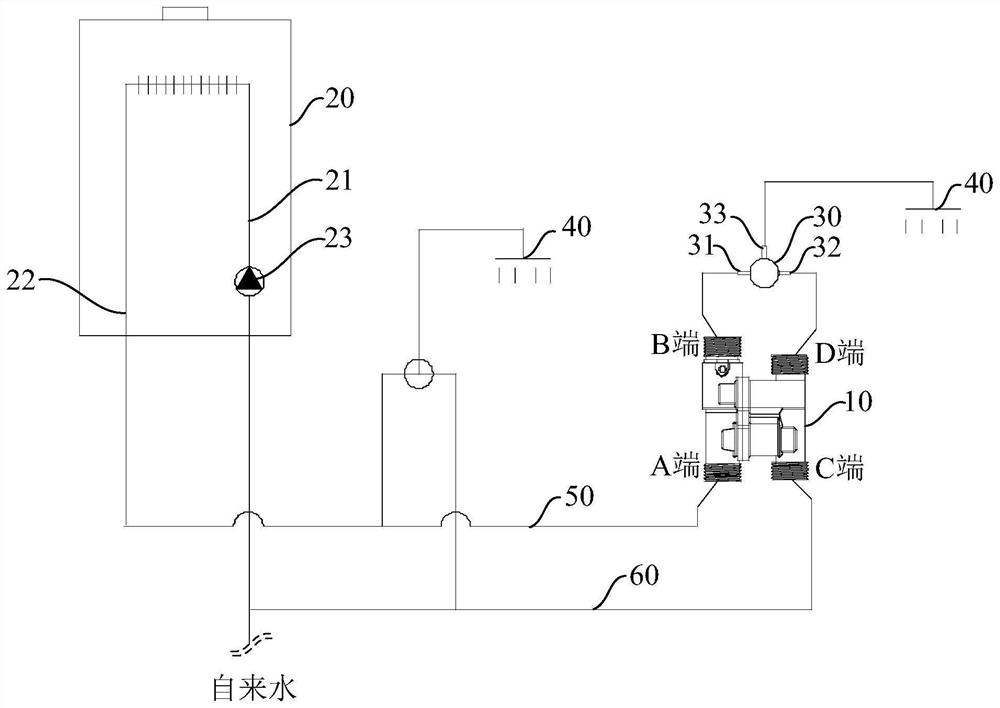

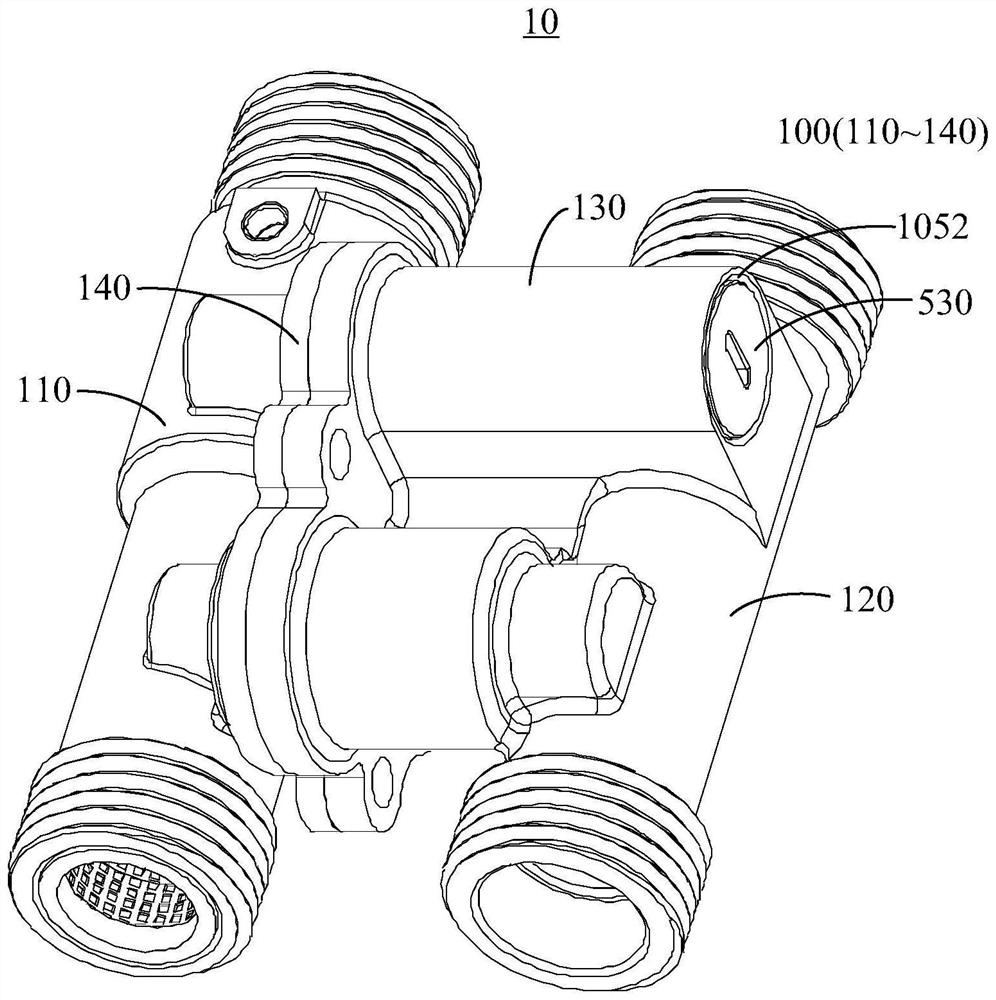

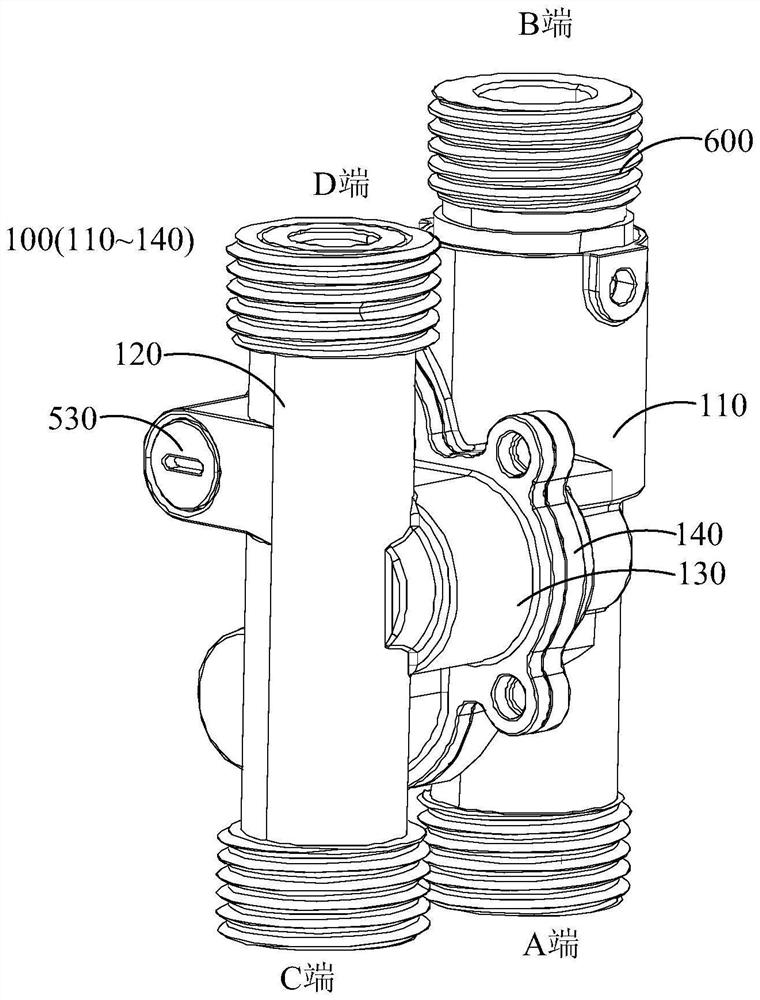

Water return valve and water supply system

PendingCN114135695AWith backwater functionReduced output of cold waterFluid heatersCheck valvesHot runnerHeat flow

The invention discloses a water return valve and a water supply system. The water return valve comprises a valve body and a circulating valve; wherein the valve body is provided with a hot runner, a cold runner and a circulating runner; a circulating inlet is formed between the water inlet end and the water outlet end of the hot runner; a circulating outlet is formed between the water inlet end and the water outlet end of the cold runner; the circulating inlet is communicated with the circulating outlet through the circulating flow channel; the circulating valve is arranged in the circulating runner, and the circulating valve is provided with an initial position for closing the circulating inlet and a circulating position for opening the circulating inlet under the action of fluid pressure in the hot runner. The water return valve can have the water return function, cold water remaining on the tail end pipeline of the water supply system flows back to the water heater through the water return valve to be preheated and then supplied to a user, and cold water output at the initial stage of starting of the water supply system is reduced.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

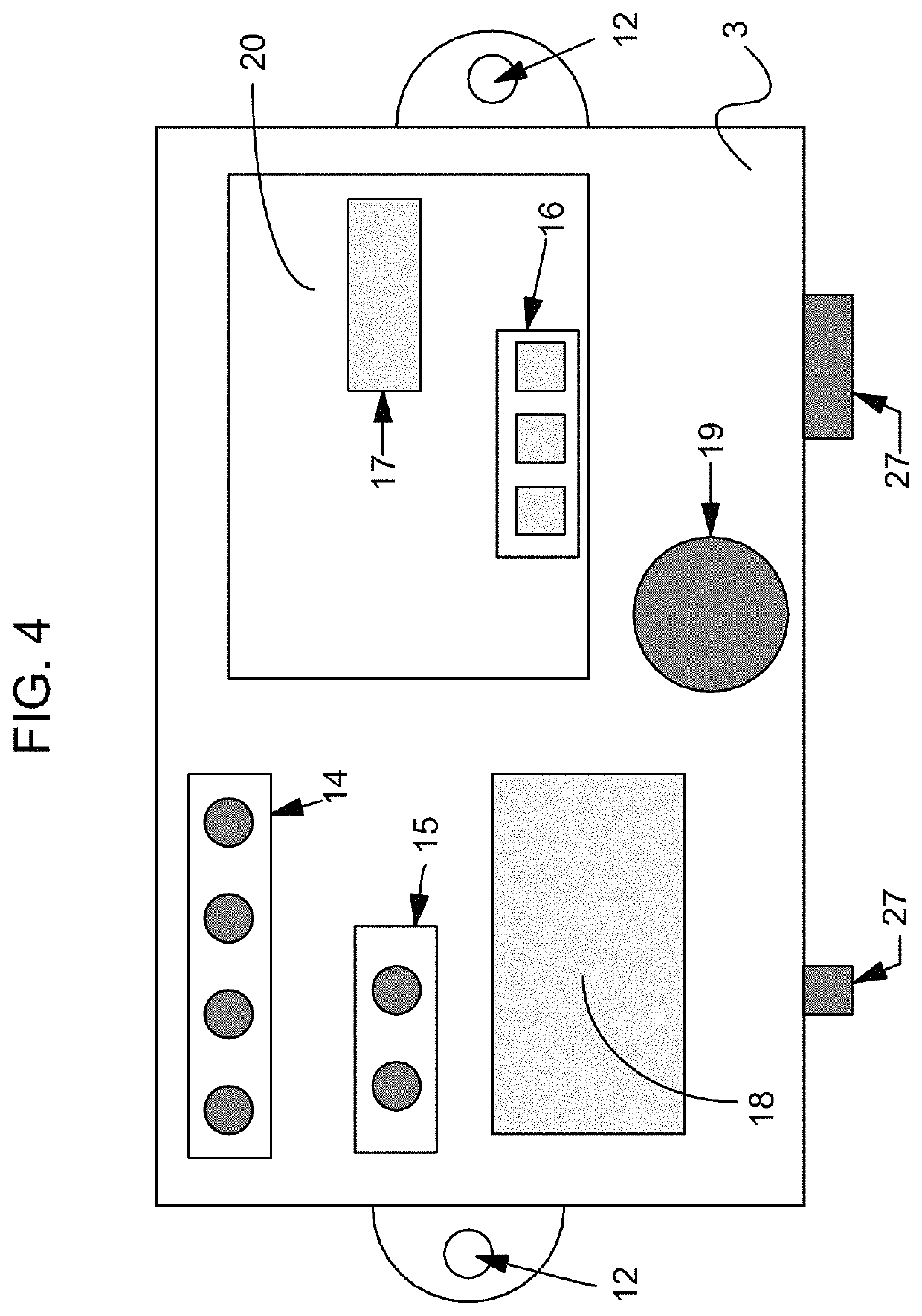

Sewer back-flow preventer monitor

ActiveUS10626585B1Creates calmOperating means/releasing devices for valvesCheck valvesReflux valveMarine engineering

The Sewer Back-flow Preventer Monitor is a device designed to be an add-on to a sewer back-flow preventer valve, otherwise known as a backwater valve. It offers a higher level of protection against flood than that which is offered by a sewer backwater valve without any such device. It uses digital and / or analog electrical sensors, magnetically linked to the flapper, to determine the precise flapper position of a backwater valve and will warn a user of a municipal sewer backup and or back-flow. As well, it will provide an alert when a cleaning is necessary and informs users when a sewer backwater valve has successfully closed during an event. It is a cost effective solution.

Owner:SULLIVAN AARON DALE

Heating apparatus enabling convenience for winter concrete construction

InactiveCN105507603AImprove utilization efficiencyReduce lossesService pipe systemsWater mainsAnti freezingEngineering

A heating apparatus enabling convenience for winter concrete construction comprises a water tank, a heater and an automatic water supplement valve are arranged inside the water tank, a water outgoing line and a water return line are mounted outside the water tank, both connections of the water outgoing line and water return line with the water tank are fitted with check valves, the connection of the water outgoing line with the water tank is further provided with a water pump, at least one branch pipe is mounted between the water outgoing line and the water return line, one end of every branch pipe is connected to the water outgoing line through a water incoming valve, the other end of every branch pipe is connected to the water return line through a water return valve, and the middle of each branch pipe is bent into a position where concrete will be poured. In the pre-curing period of concrete, cement hydration is accelerated by heating the inside of the concrete, hydration heat of the concrete is maintained, concrete strength is promoted to rise above anti-freezing critical strength quickly, and the concrete is protected from freezing damage; early strength of the concrete is effectively improved, a forceful guarantee is provided for engineering quality, maintenance time is shortened, construction progress is quickened, and maintenance cost is saved.

Owner:HUBEI GEZHOUBA TESTING

Water outlet automatic pressurization and water return linkage integrated intelligent control device for air energy water heater

The invention provides a water outlet automatic pressurization and water return linkage integrated intelligent control device for an air energy water heater, relates to the field of air energy water heaters, and particularly relates to the technical field of a water outlet automatic pressurization and water return linkage integrated intelligent control device for the air energy water heater. The technical problems of unhooking between pressurization and water return of an existing air energy water heater such as insufficient water outlet pressure required by a user using the air energy water heater, long-time non-heated water, unstable water temperature are effectively solved. A method solving the problems is that through an intelligent pressurization and water return linkage controller, according to a detected temperature of water in a water tank, a pressure on a water outlet, a water flow signal on the water outlet, a set water outlet time and the like, a booster pump is started, a water return valve is started according to a detected water temperature on the water outlet, the booster pump and the water return valve are flexibly and effectively started, an RS485 to Ethernet server is connected with a computer, and real-time monitoring is realized.

Owner:江苏美力格环境科技有限公司

Backwater valve assembly with removable valve member

A backwater valve assembly includes a valve housing, a valve member and a servicing tool. The valve housing has an internal ledge within its interior on which is positioned a retainer clip oriented in vertical alignment with a riser. The valve member has a first engagement of a two part engagement on one face and a mounting along a peripheral edge which includes transverse pins adapted to engage the retainer clip. The servicing tool includes a second engagement of the two part engagement at a working end of a shaft. The hook engages the hook receiver of the valve member during insertion and removal.

Owner:COSCARELLA GABE

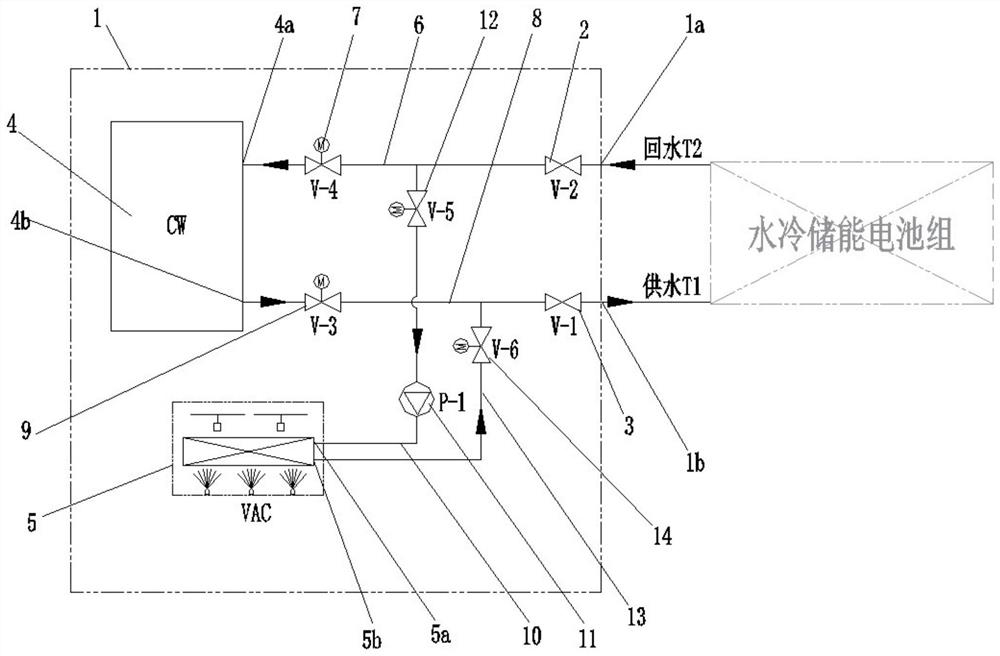

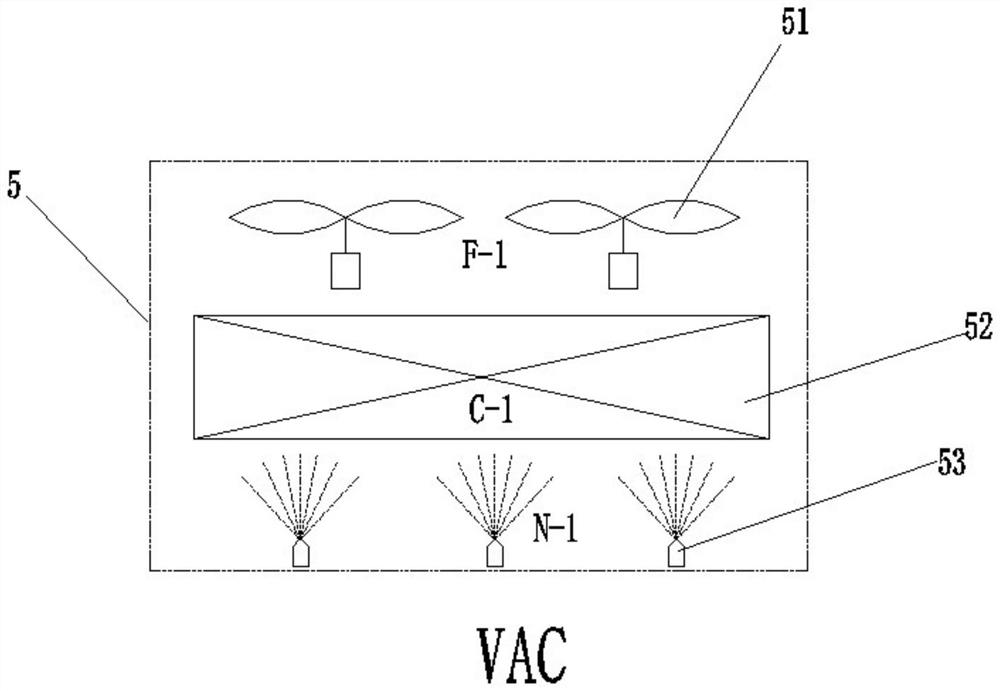

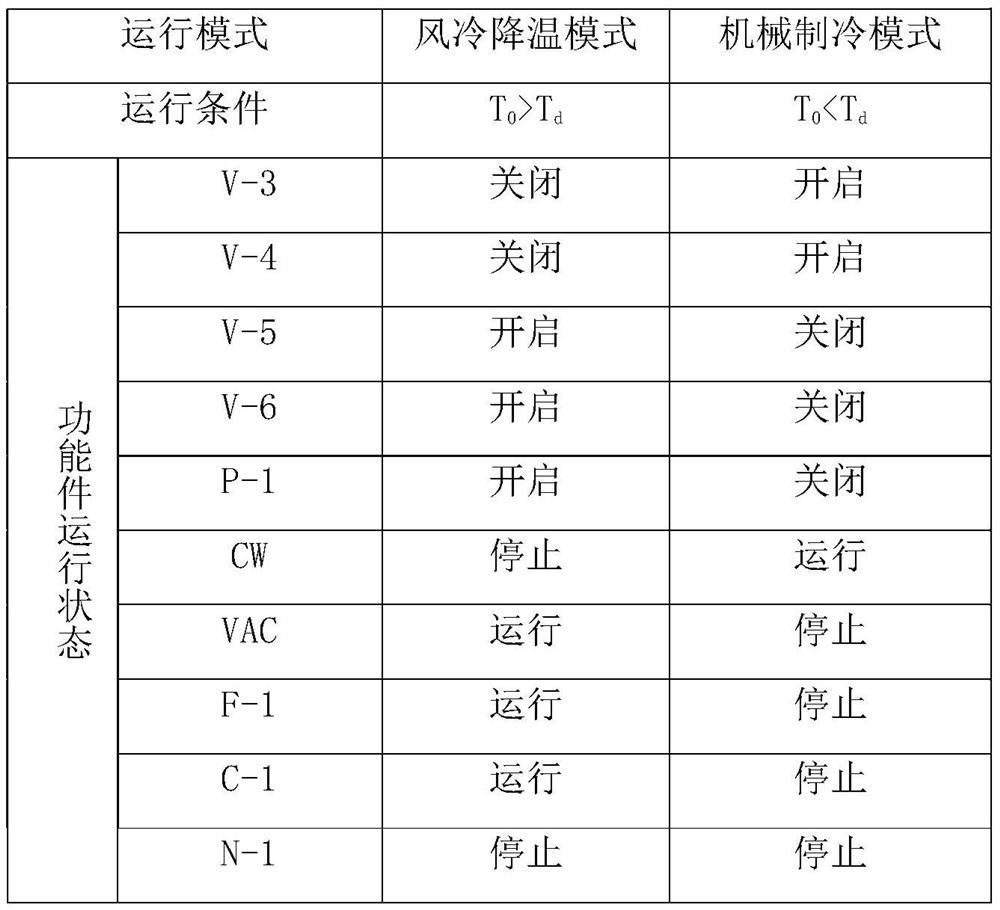

Cooling device of water-cooled energy storage battery and control method thereof

PendingCN112086712AAchieve smooth switchingBroaden the scope of natural conditionsCells cooling/heatingSecondary cellsProcess engineeringCooling energy

The invention relates to a cooling device of a water-cooled energy storage battery cooling device. The device comprises a body (1). A main water return port (1a), a main water supply port (1b), a mainwater return valve (2) and a main water supply valve (3) are arranged on the body (1), a high-temperature water chilling unit (4) and an evaporation air cooling module (5) are arranged in the body (1), and first water return ports (4a) and second water return ports (5a) are connected with the main water return port (1a). The first water supply port (4b) and the second water supply port (5b) are respectively connected with the main water supply port (1b), and a first water return valve (7), a first water supply valve (9), a water return pump (11), a second water return valve (12) and a secondwater supply valve (14) are respectively arranged on pipelines which are connected in pairs. The device has the advantages that the natural cold source is used for cooling the water-cooled battery cooling water, so that the energy consumption of battery cooling is greatly reduced.

Owner:江苏华强新能源科技有限公司

Frozen-blocking prevention solar natural ventilation system

InactiveCN102798171ASimple structureLow costLighting and heating apparatusSpace heating and ventilation detailsNatural ventilationSolar water

The invention provides a frozen-blocking prevention solar natural ventilation system used for room heating and solving the problems of frozen blocking in winter and switch-over of a heat source. The solar natural ventilation system comprises a solar water heater, an auxiliary heating device, a first water pump, a second water pump, a controller, a floor heating cooling water pipe, a three-way valve and a return valve, wherein a water outlet of the solar water heater is connected with a first input end of the three-way valve through the first water pump; a water outlet of the auxiliary heating device is connected with a second input end of the three-way valve through the second water pump, and an output end of the three-way valve is connected with a water inlet end of the floor heating cooling water pipe; a water outlet end of the floor heating cooling water pipe is connected with the water inlet of the solar water heater and a water inlet of the auxiliary heating device through independent pipes; a water outlet of the first water pump is connected with a water inlet of the solar water heater through a water return valve; and the first water pump, the second water pump, the three-way valve and the water return valve are respectively connected with the controller and are controlled by the controller.

Owner:TAIZHOU HUAYUAN HEAT SUPPLY ENG

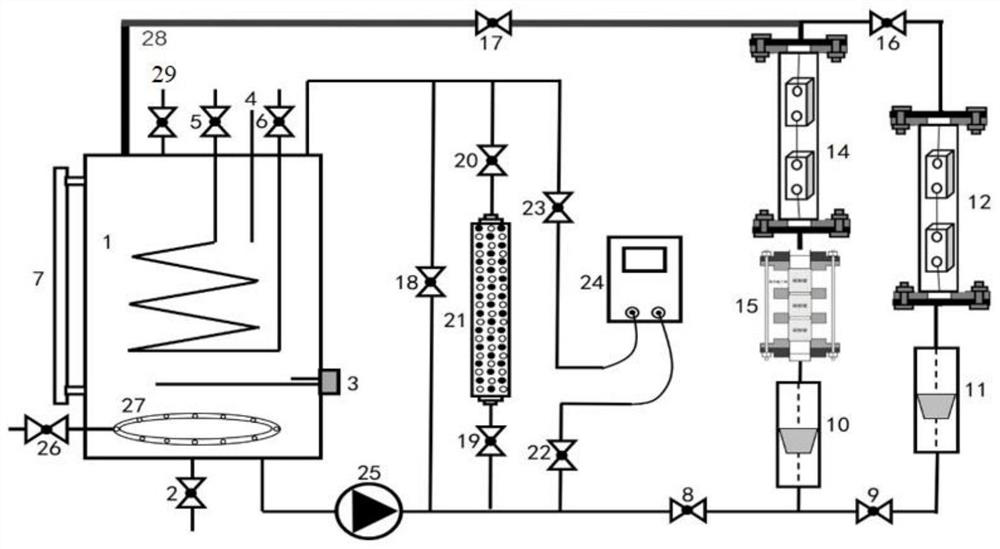

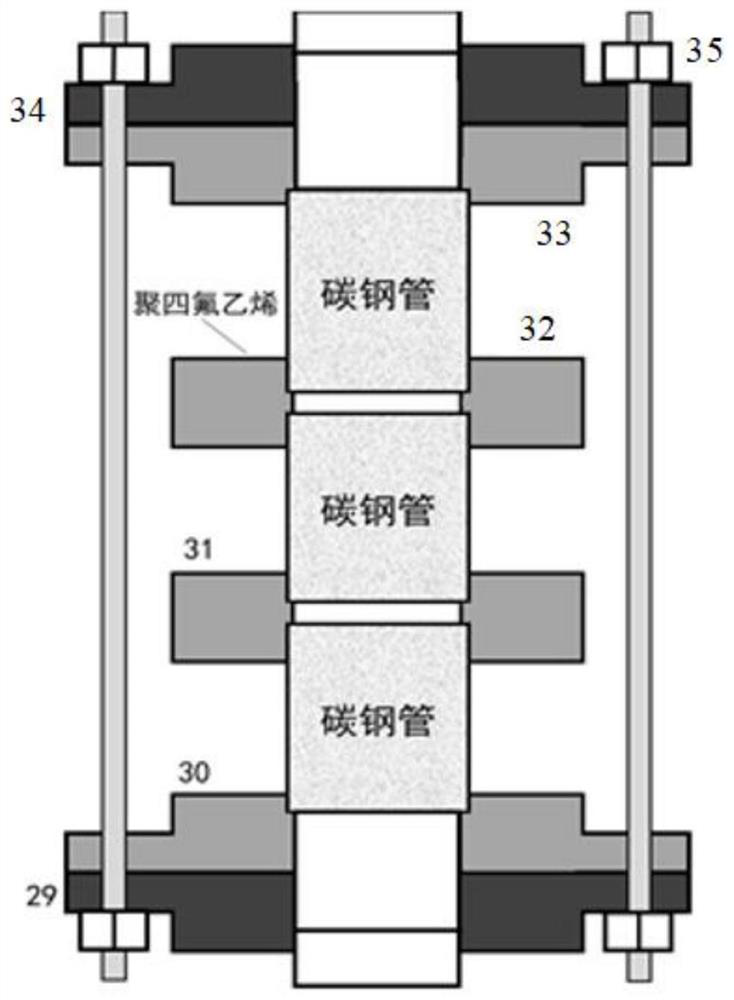

Nuclear island equipment cooling water system material corrosion simulation device and using method thereof

PendingCN112394023ASimulate actual operationControl anion and cation contentWeather/light/corrosion resistanceTesting waterWater flowProcess engineering

Owner:HUANENG SHANDONG SHIDAOBAY NUCLEAR POWER CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com