Nuclear island equipment cooling water system material corrosion simulation device and using method thereof

A technology of equipment cooling water and simulation devices, which is applied in the direction of measuring devices, material resistance, and analysis materials, and can solve problems such as different water flow patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with embodiment.

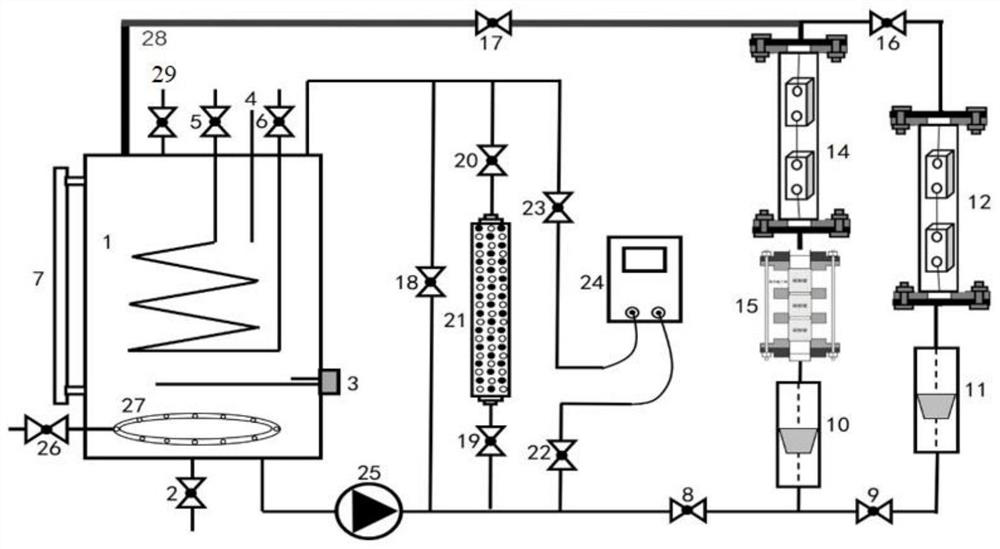

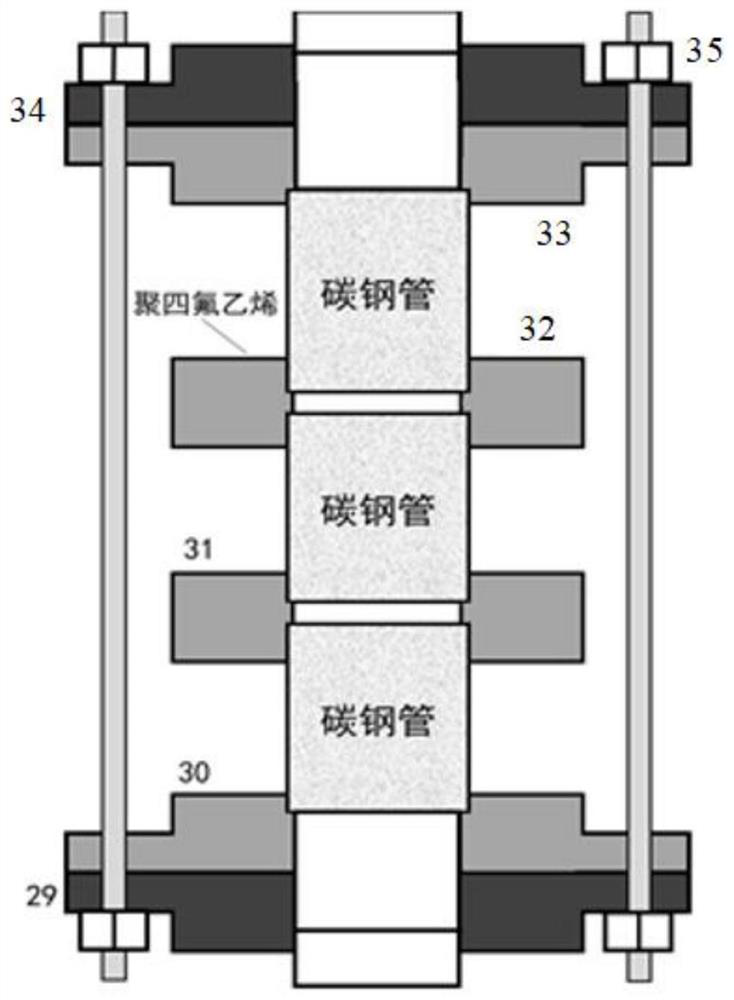

[0028] Such as figure 1 Shown: A laboratory simulation device used to study the corrosion behavior of materials in the cooling water system of nuclear island equipment. The simulation device includes a circulating water tank 1. The circulating water is drawn from the circulating water tank 1, pressurized by the pipeline booster pump 25, and flows through the first coupon bypass flow regulating valve 8 and the first coupon bypass rotameter 10. , pipeline inner wall corrosion monitoring device 15, first bypass corrosion coupon device 14, carbon steel pipeline 28, coupon bypass return water valve 17, and then flow back to the circulating water tank 1. The second coupon bypass is led between the first coupon bypass flow regulating valve 8 and the first coupon bypass rotameter 10, and the second coupon bypass is sequentially provided with a second coupon bypass flow regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com