Gas boiler constant-temperature operation method

A technology of gas boiler and operating method, applied in the direction of sliding valve, valve device, fluid heater, etc., to achieve the effect of increasing the outlet water temperature, shortening downtime and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

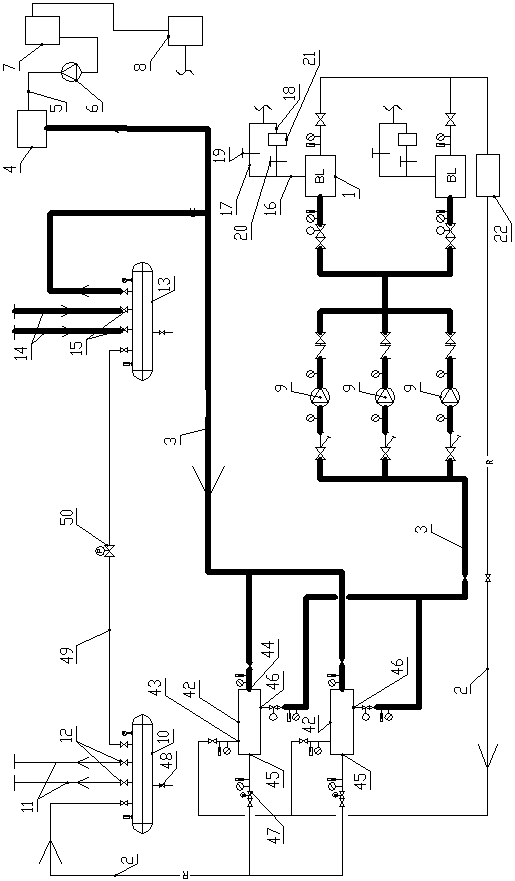

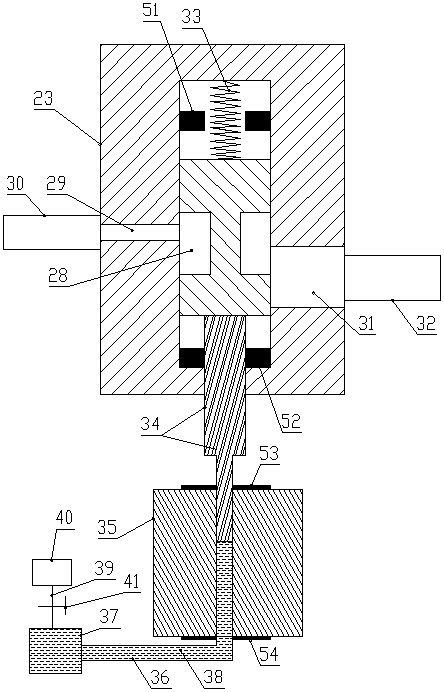

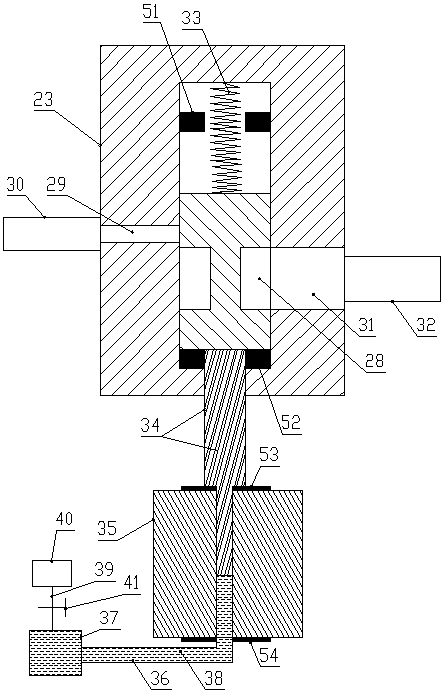

[0037] The invention discloses a constant temperature operation method of a gas boiler, and the method uses an expansion type constant temperature hot water system to carry out. Such as Figure 1 to Figure 4 As shown, the expansion type constant temperature hot water system includes a gas boiler 1, a water supply main pipe 2 and a return water main pipe 3, the water inlet of the gas boiler 1 is connected to the return water main pipe 3, and the water outlet of the gas boiler 1 is connected to the water supply main pipe 2; The water return main pipe 3 is connected with an expansion water tank 4, the expansion water tank 4 is connected with a water supply pipe 5, the water supply pipe 5 is connected with a water supply pump 6, the water supply pump 6 is connected with a water supply tank 7, the water supply tank 7 is connected with a water softener 8, and the water softener 8. Connect the municipal tap water pipe network; the return water main pipe 3 at the inlet of the gas boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com