Patents

Literature

51results about How to "Swing back and forth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

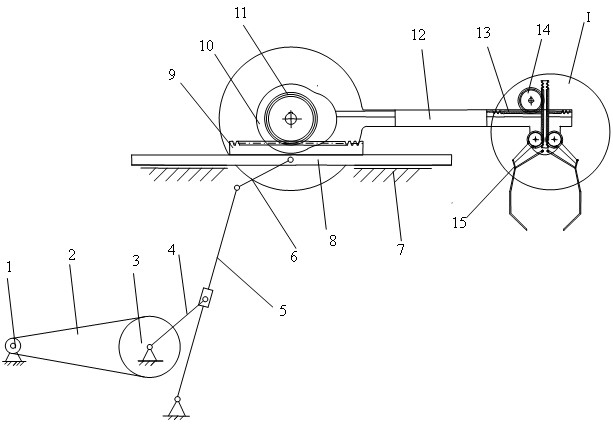

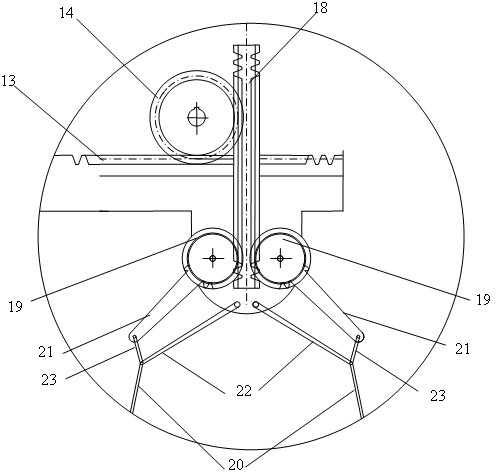

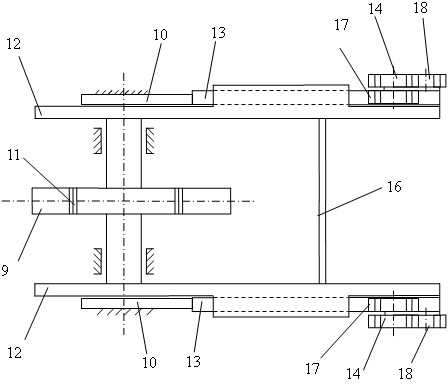

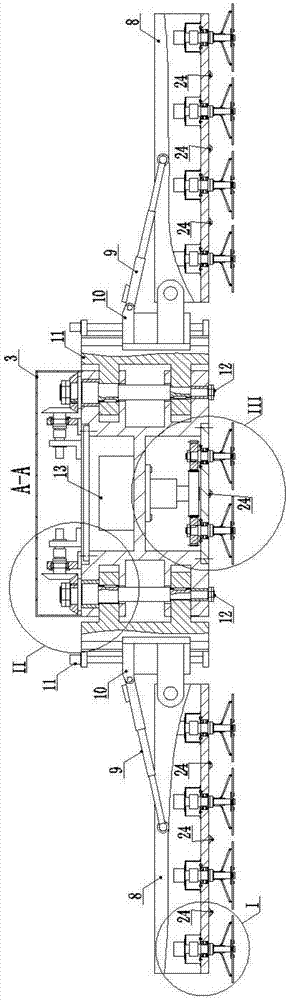

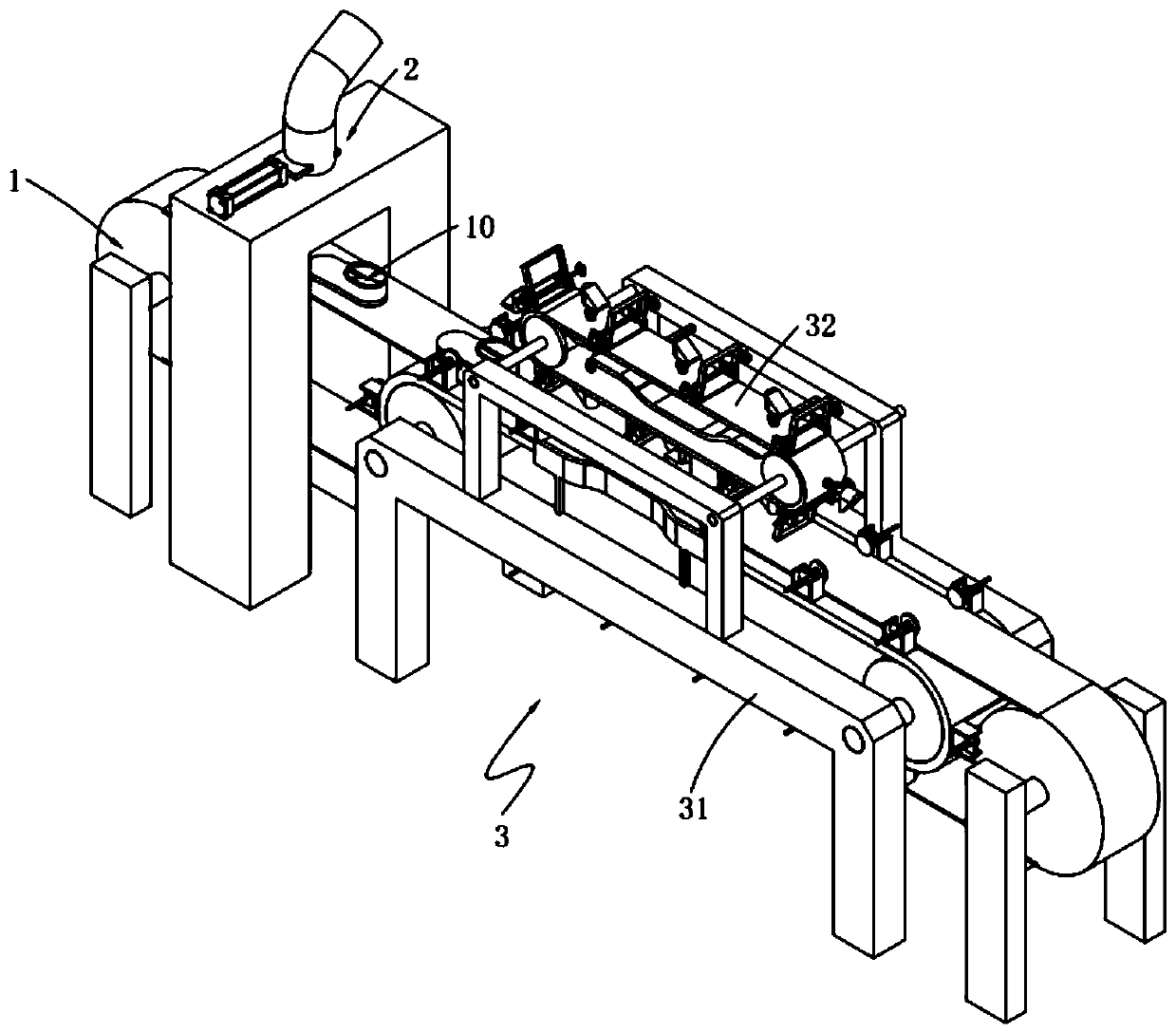

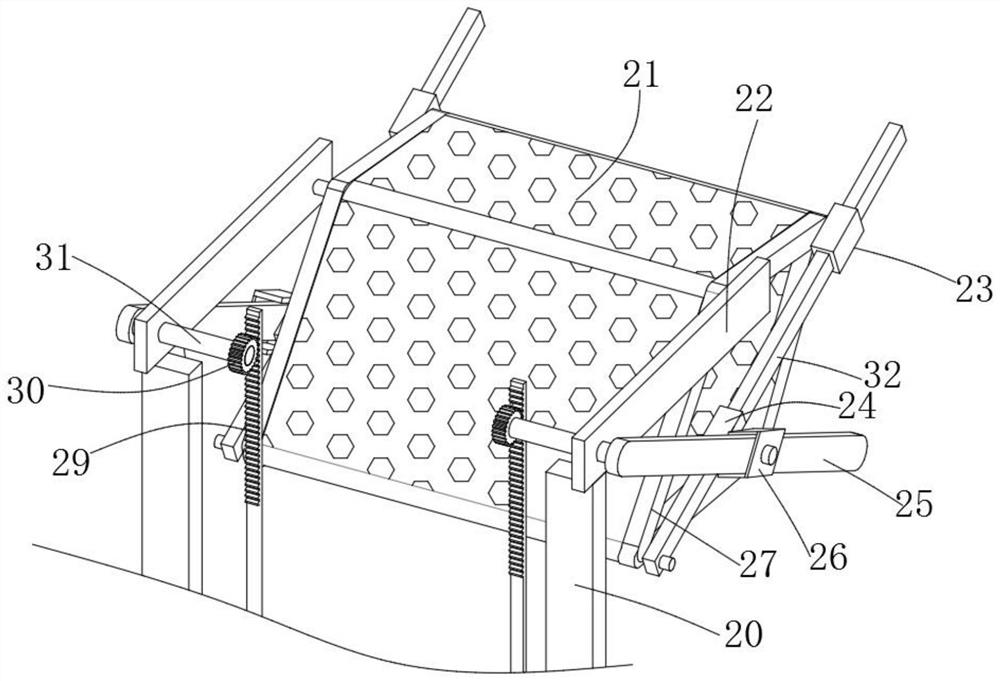

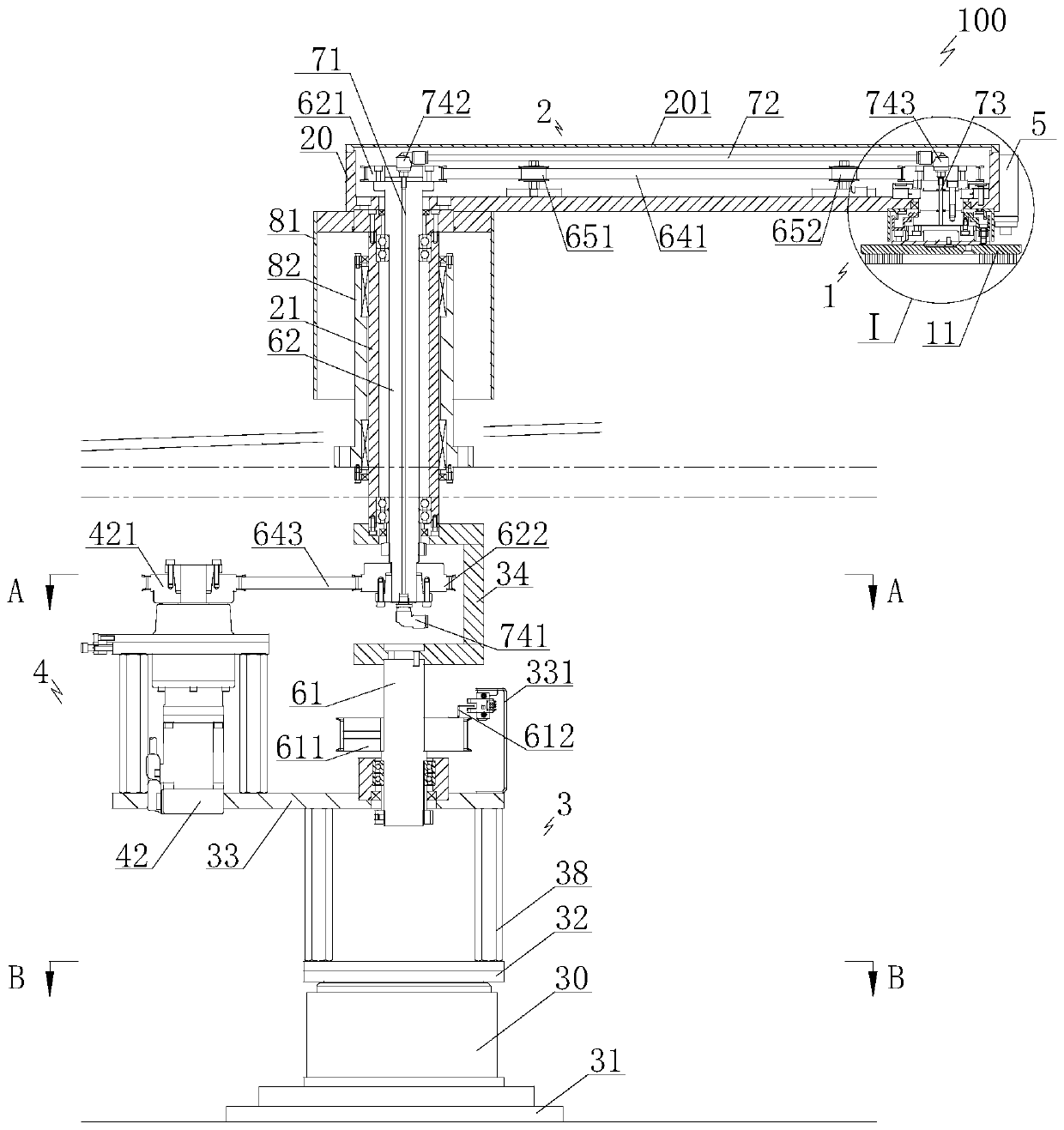

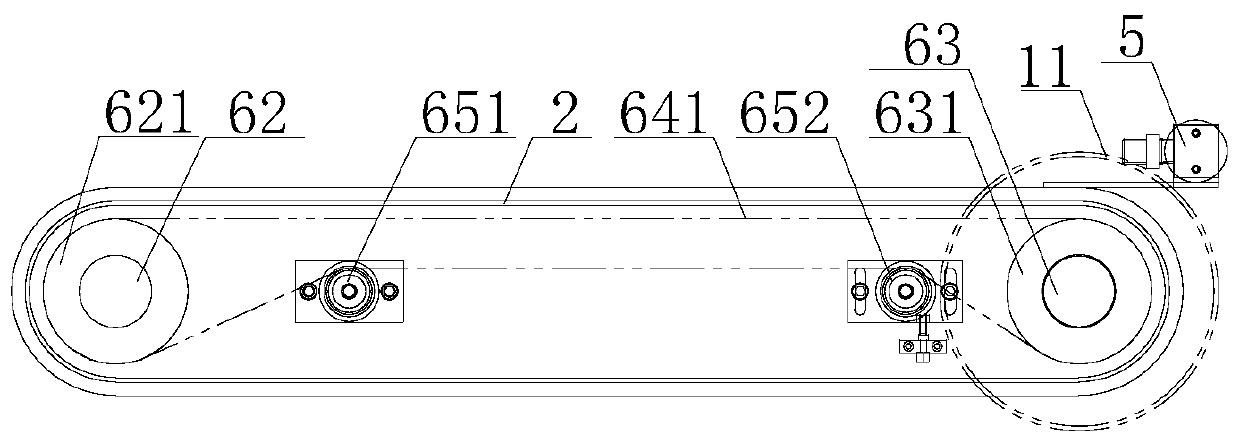

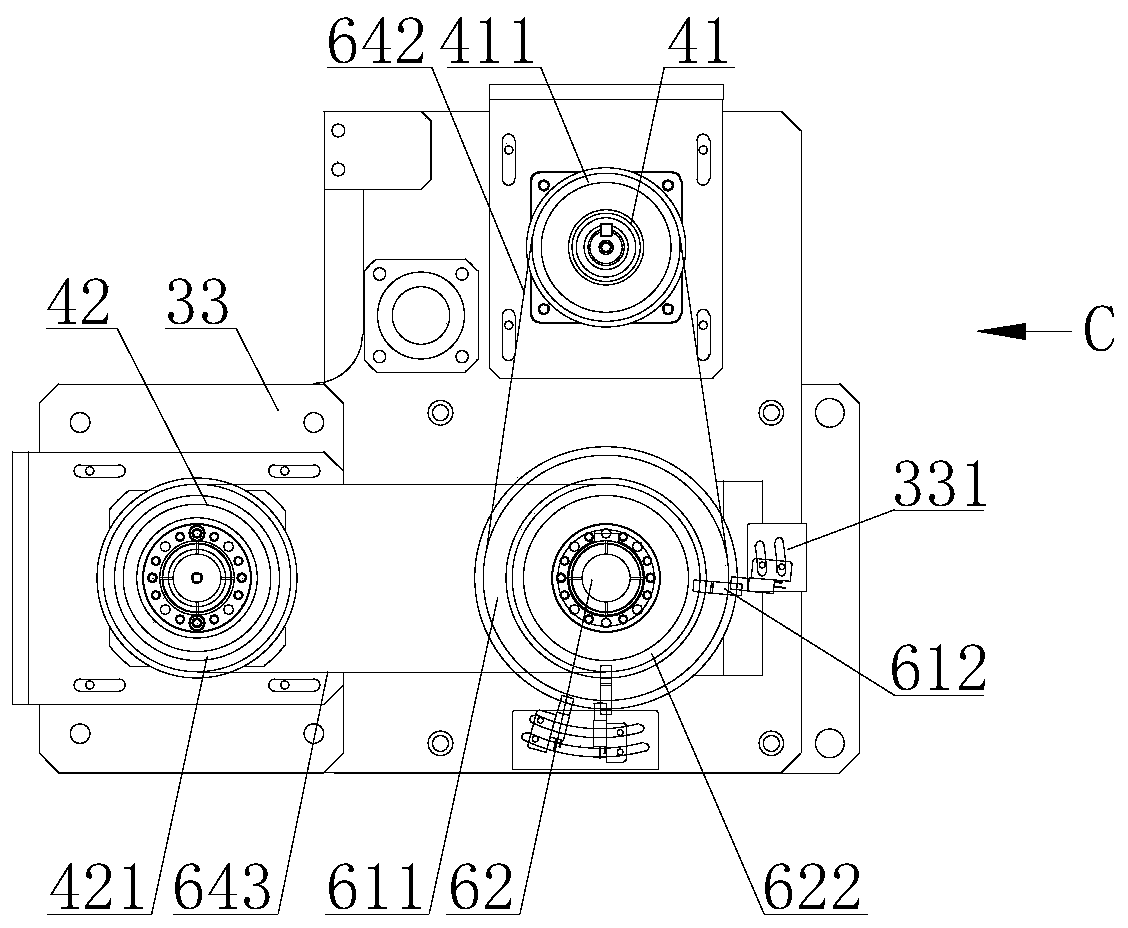

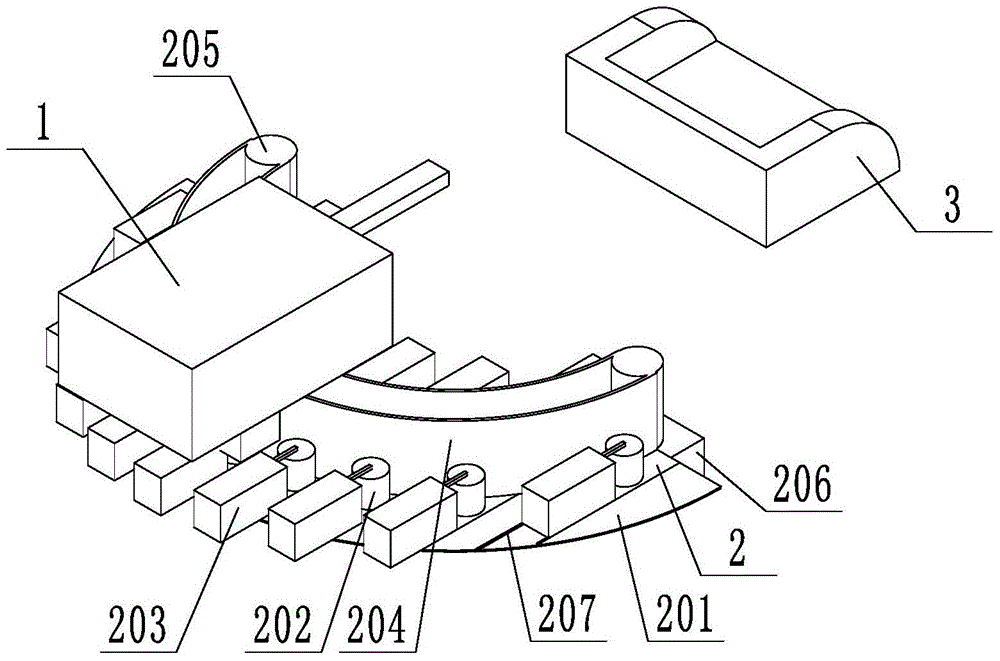

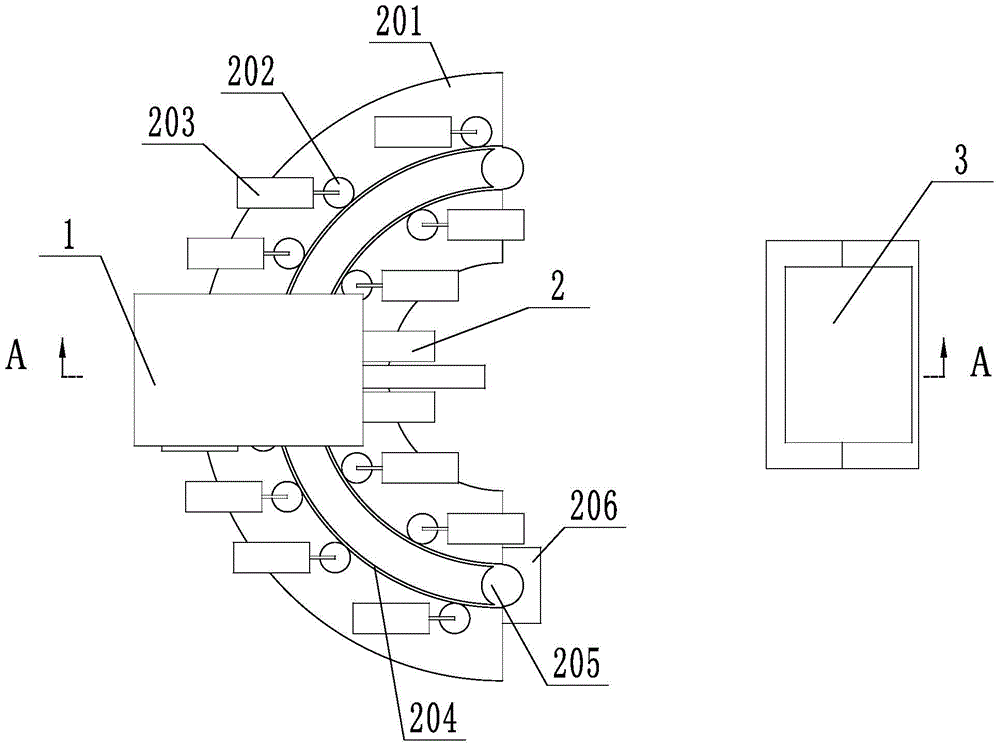

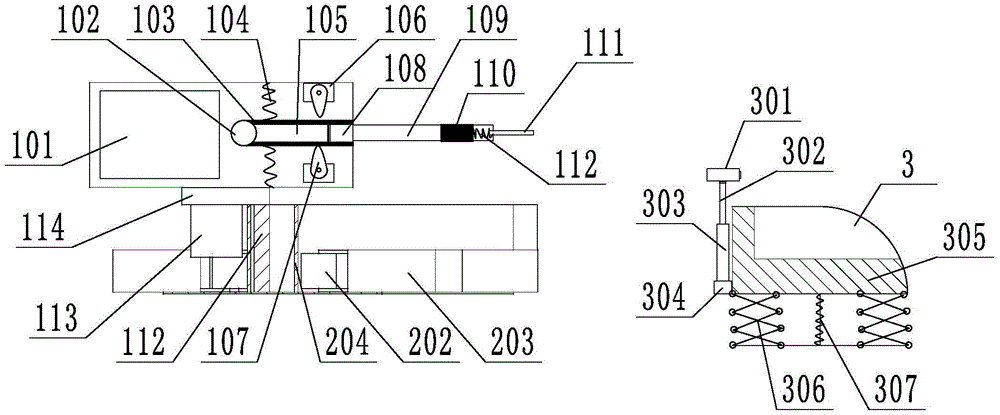

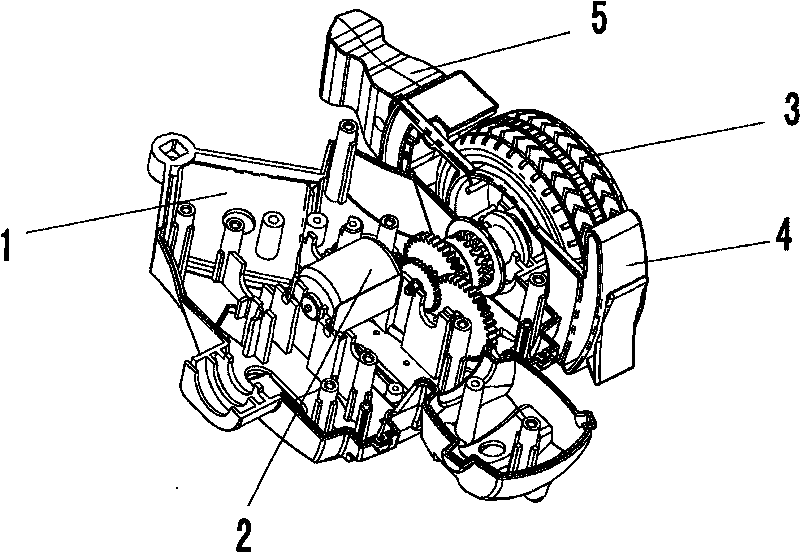

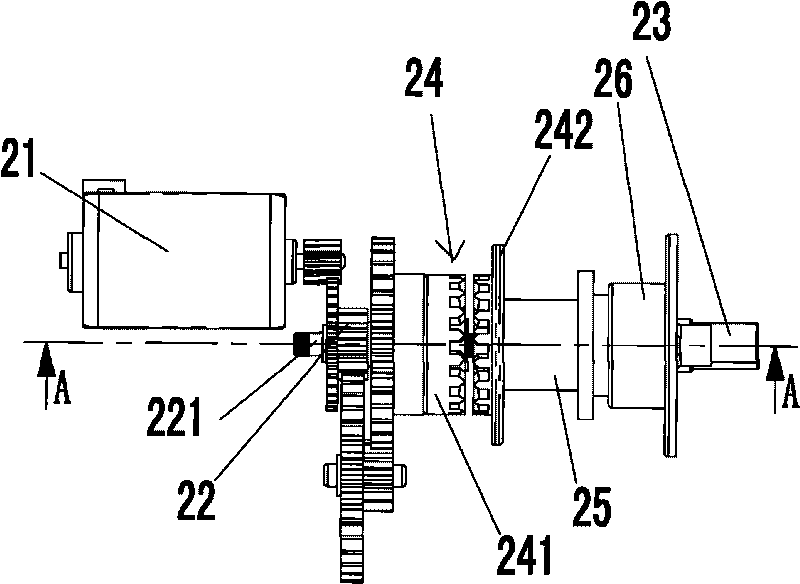

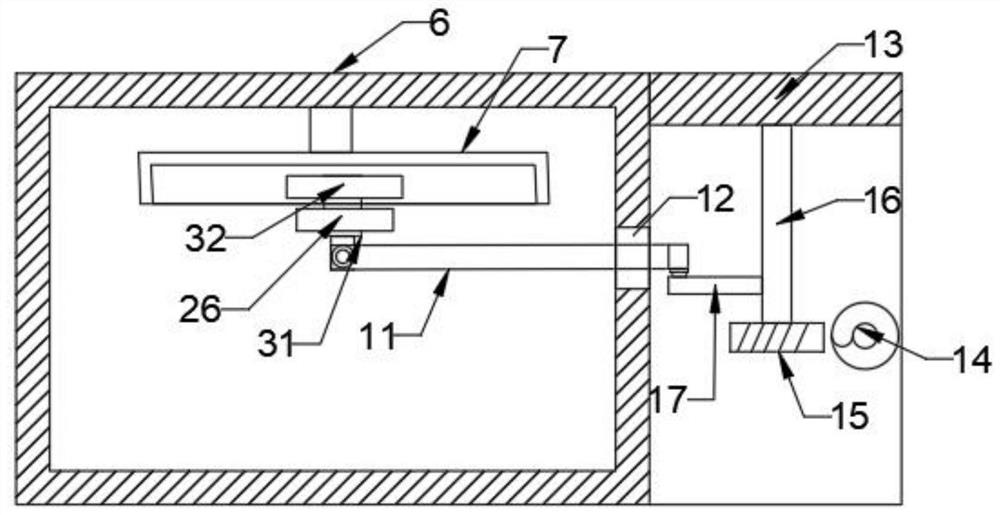

Automatic bowl plate feeding mechanism on rice seeding production line

InactiveCN102598931ASwing back and forthImprove seeding efficiencyProgramme-controlled manipulatorTransplantingProduction lineReciprocating motion

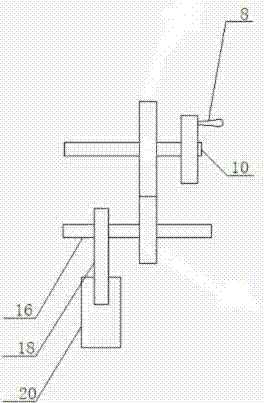

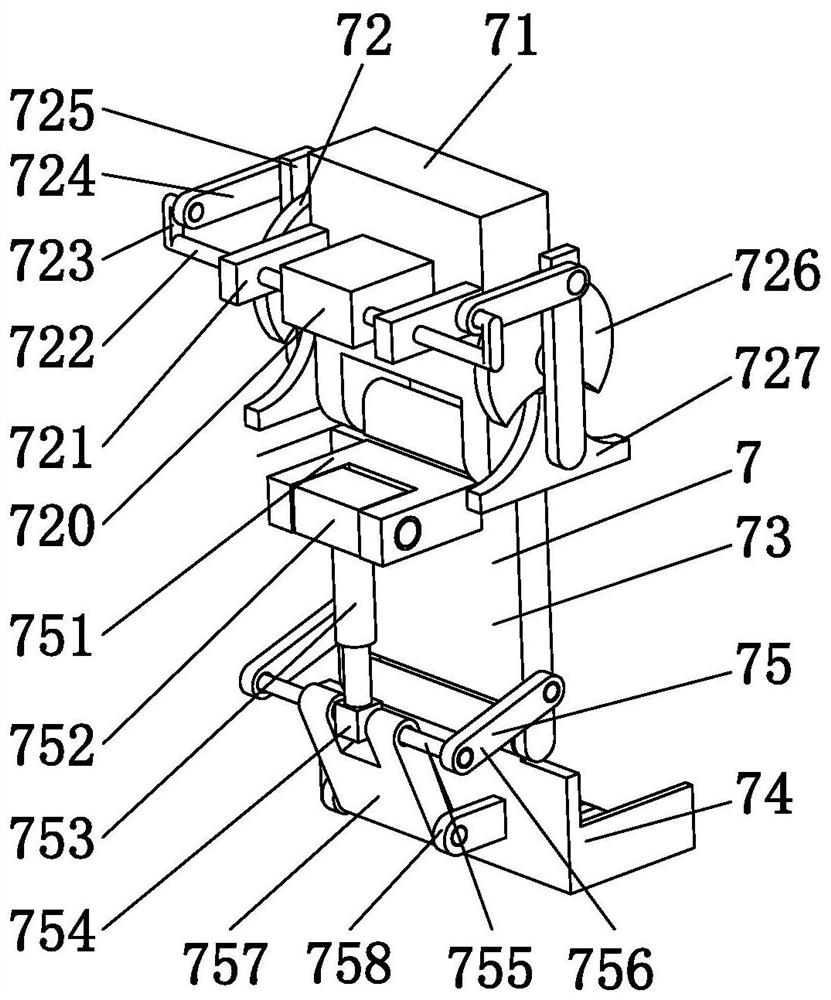

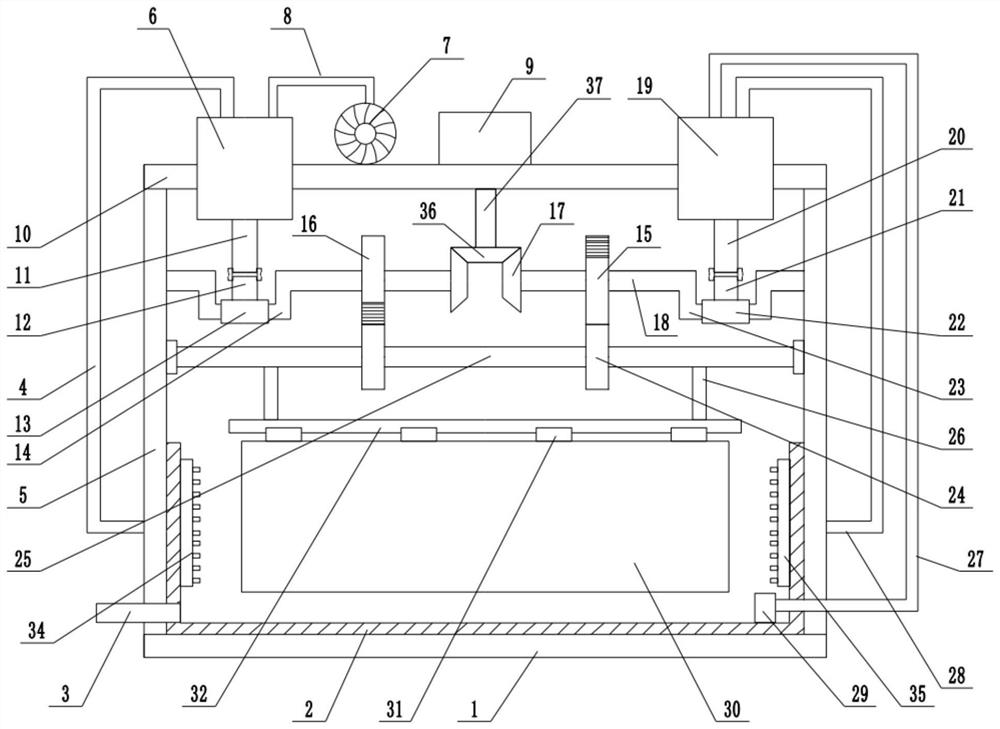

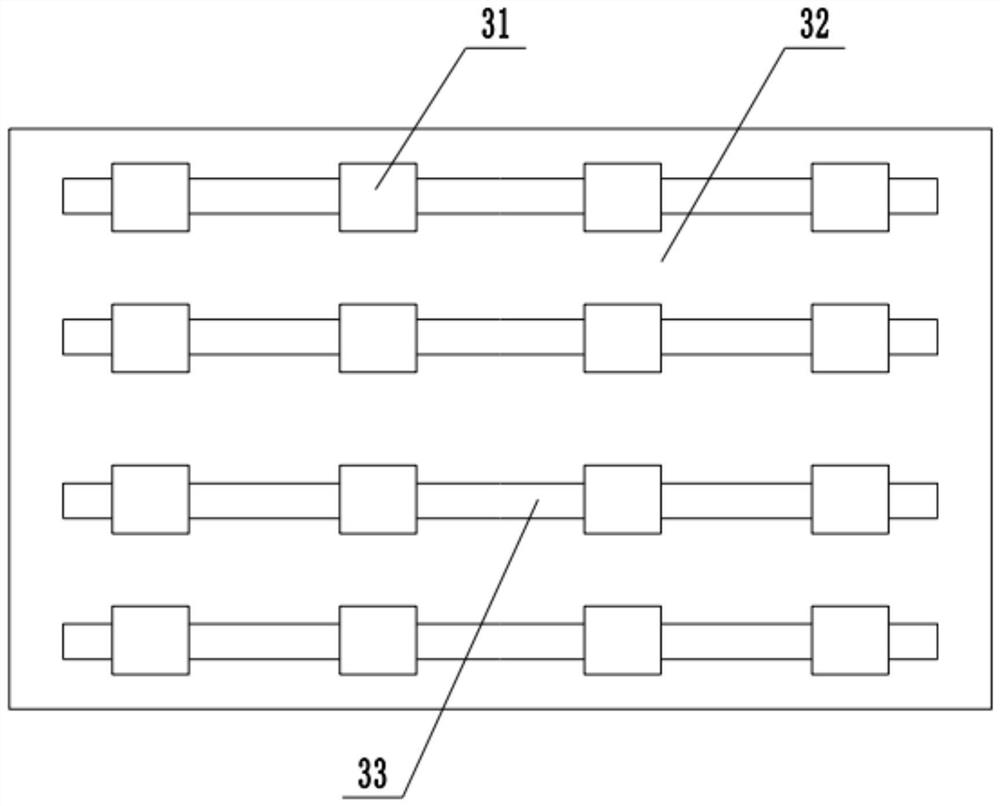

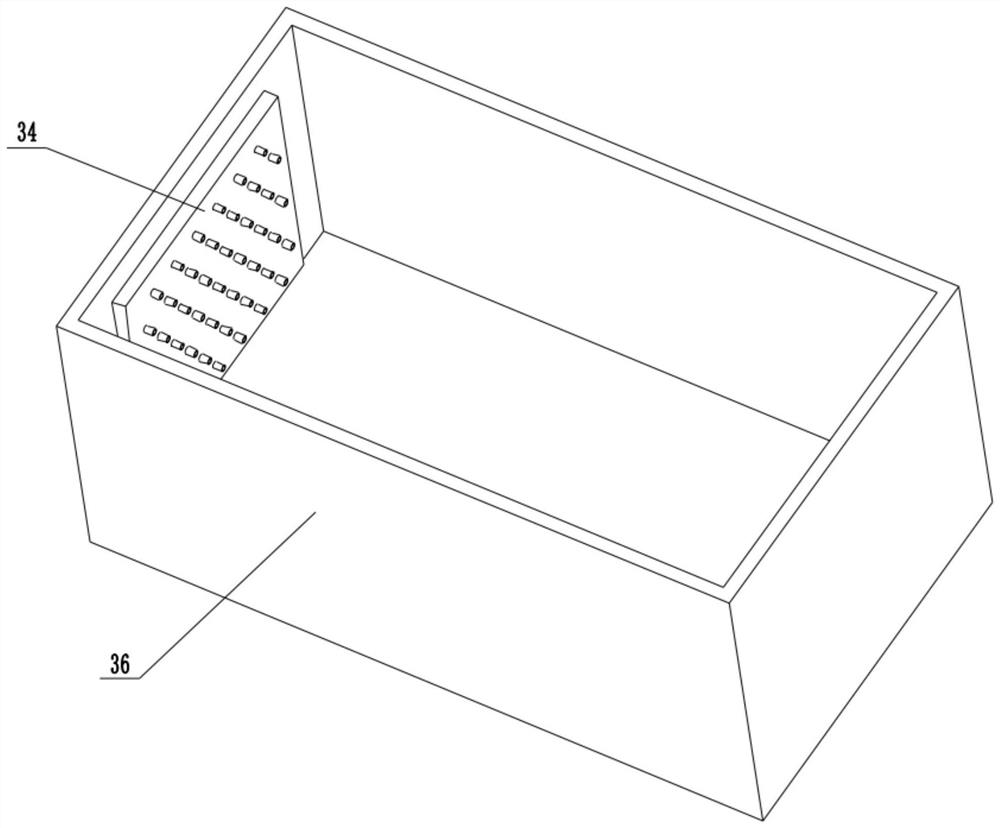

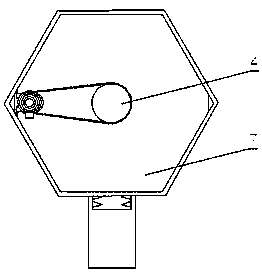

The invention discloses an automatic bowl plate feeding mechanism on a rice seeding production line, which comprises a crank mechanism, a rocker, a connecting rod, a rack, a sliding block, gear racks, two cams, a first gear, two mechanical arms, two gear rack push rods, a pair of second gears, two manipulators, a reinforcing rod, a pair of third gears, two two-sided gear racks, two pairs of fourth gears and two paws, wherein a crank of the crank mechanism drives the rocker to swing, so that the sliding block does reciprocation motion, and further, the mechanical arms can swing back and forth; the gear rack push rods are arranged in the mechanical arms, and slide relative to the mechanical arms, one ends of the gear rack push rods are contacted with the cams, and the gear racks on the other ends of the gear rack push rods are meshed with the gears on the mechanical arms; the pair of gears which are coaxial are meshed with the two-sides gear rack, and the manipulators are driven to open or close; and the crank rotates by a cycle, the mechanical arms rotate by a certain angle, at a bowl plate stacking position, the manipulators grab a bowl plate, then the mechanical arms rotate back to an initial position, and the manipulators loose the bowl plate and place onto a seeding production line, so that the manual operation can be reduced, and the mechanical seeding efficiency can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

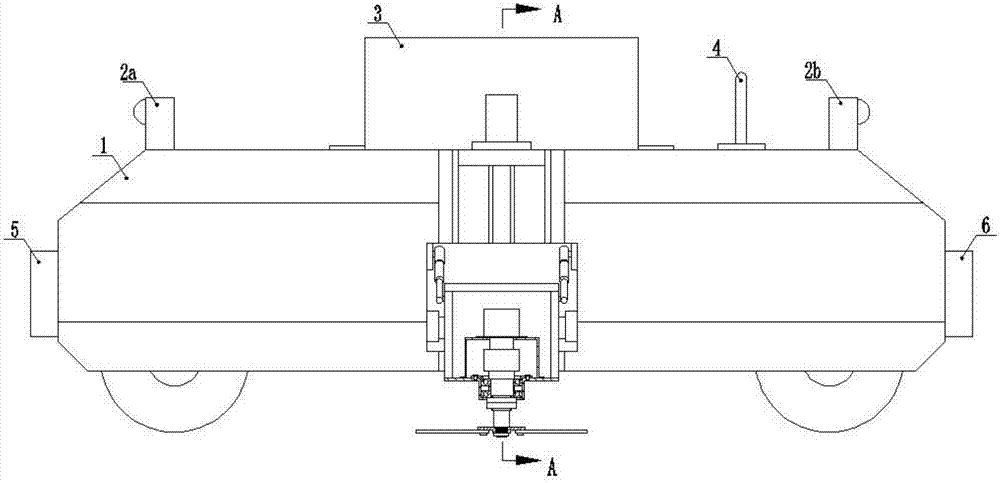

Unmanned efficient mowing vehicle

InactiveCN107333516AReal-time acquisitionRealize intelligent unmanned operationMowersRotational axisGear wheel

The invention discloses an unmanned high-efficiency lawn mowing vehicle, which comprises a vehicle body, an upper stepped rectangular groove in the middle of the vehicle body, a first cabin, a first cover plate, a second cabin, a lower stepped rectangular groove and a second cover plate, and There are upper and lower turning slots on the left and right sides of the car body. There are left turning holes and right turning holes on the top and a rotating shaft. There is a protective cover on the top of the car body. There are gear brackets, motor brackets, and rotating motors inside. There are rotating seats, lifting seats, electric push rods, working frame components on the left and right rotating shafts of the car body, control boxes, second rotating shafts, second cutter head assemblies, monitoring devices, first and second obstacle avoidance on the car body Sensors, front and rear cameras, alarms and booster antennas. The invention does not require manual operation, can be remotely monitored and controlled, can complete undulating and angled lawn weeding, has a large mowing area at one time, can freely choose the mowing method, and improves maintainability and replaceability.

Owner:薛迪宋

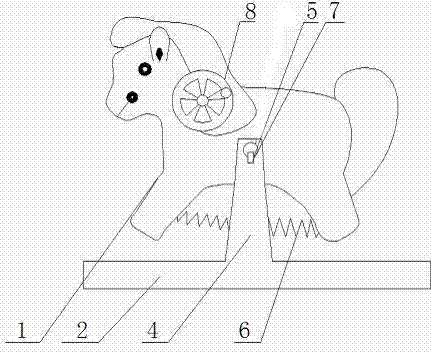

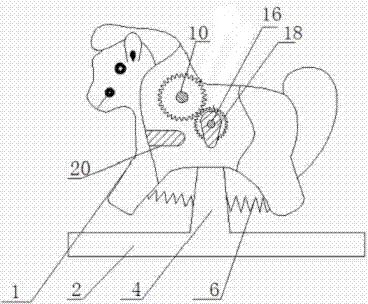

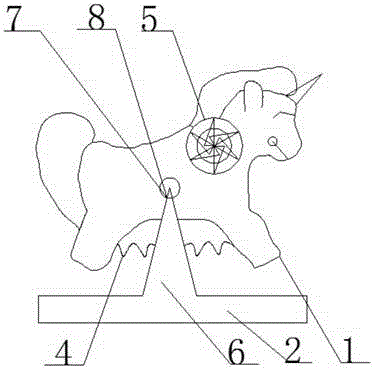

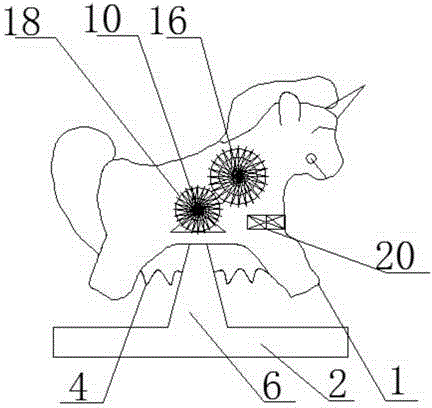

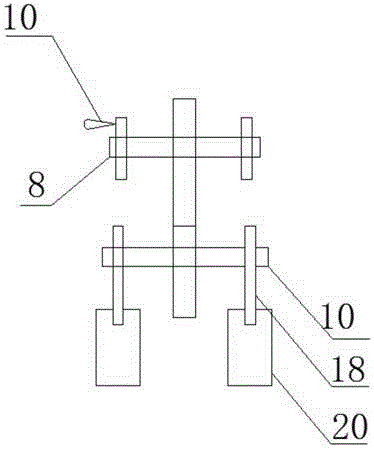

Wooden horse toy

Owner:苏州益童游乐设备有限公司

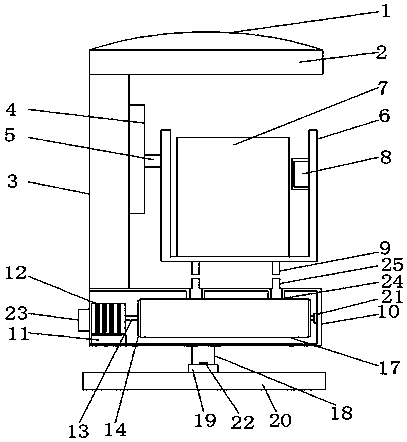

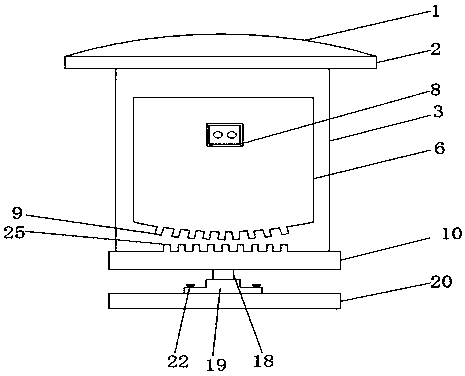

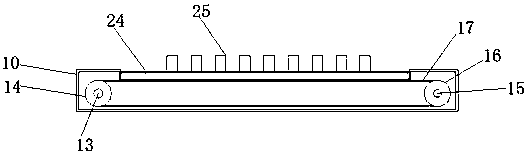

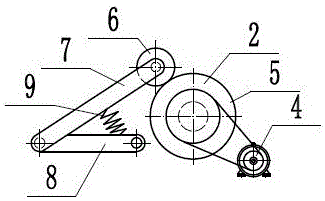

Novel incubator with automatic uniform shaking device

ActiveCN107603879ASwing back and forthRealize rotation and shakingBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlBiochemical engineering

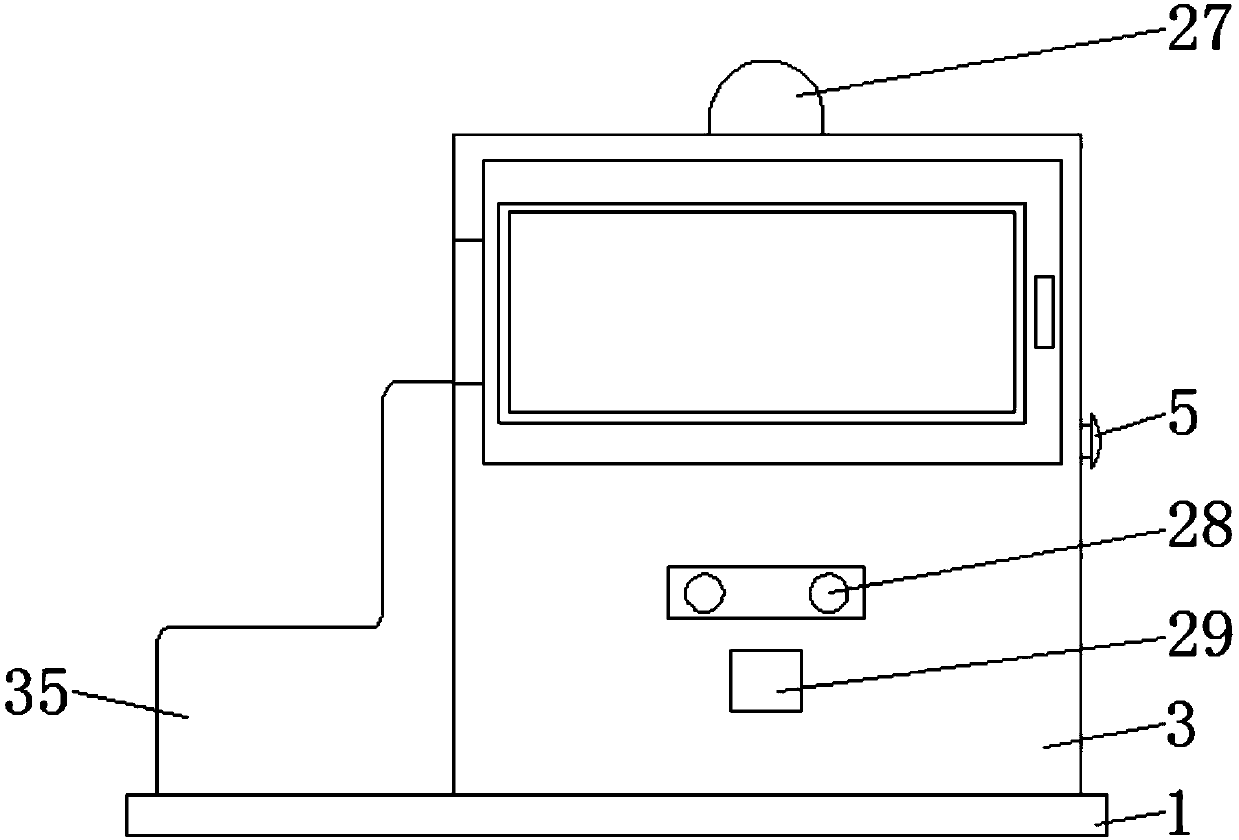

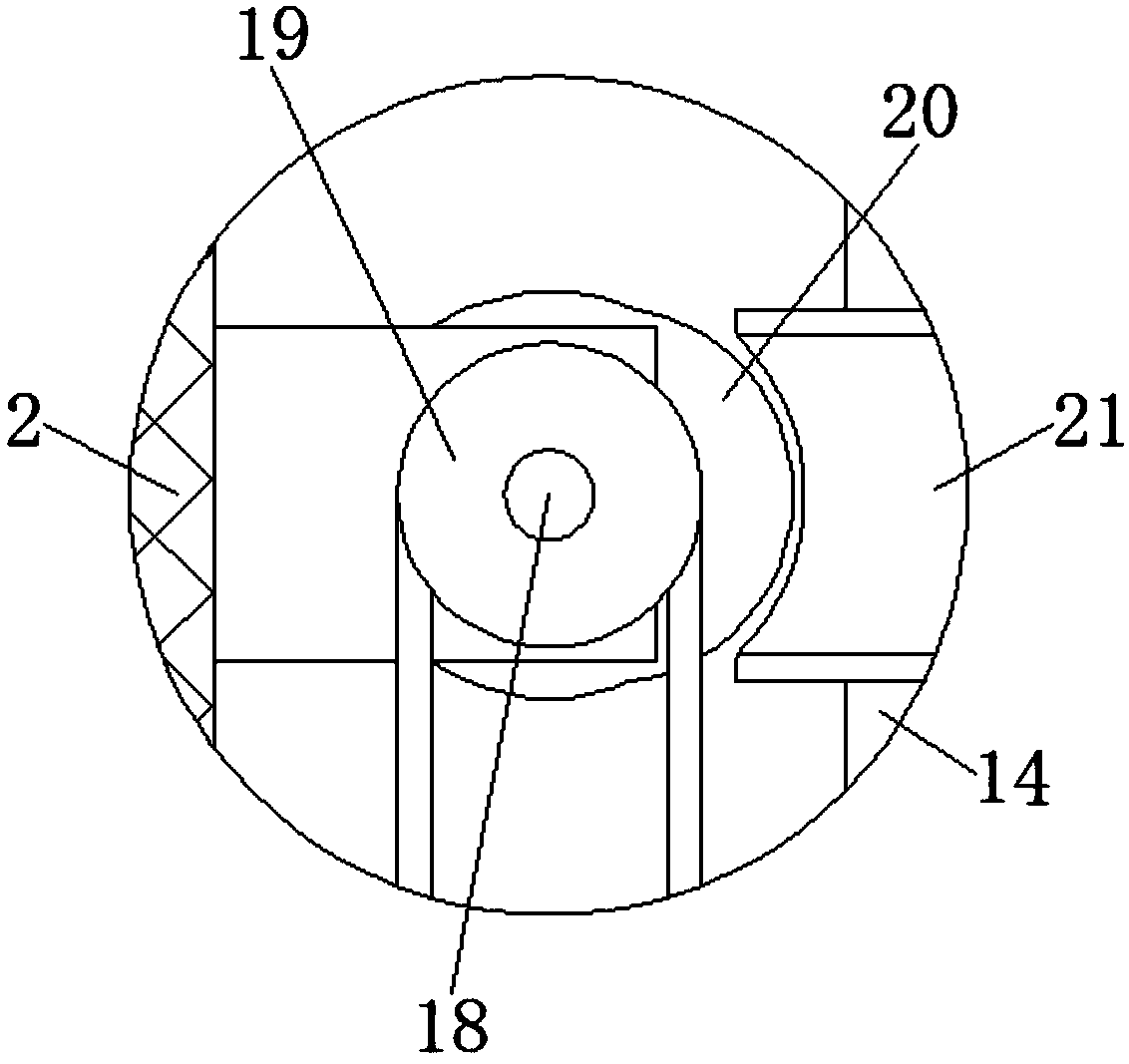

The invention discloses a novel incubator with an automatic uniform shaking device, relating to the technical field of medical instruments. The novel incubator comprises a bottom plate and a shaking tank, wherein an incubator is fixedly connected with the top of the bottom plate; a first connecting shaft and a second connecting shaft are respectively fixedly connected with two sides of the shakingtank through connecting plates; one end, far away from the shaking tank, of the first connecting shaft, and one end, far away from the shaking tank, of the second connecting shaft, both penetrate through the incubator and extend outside the incubator; and a moveable sleeve is arranged in a sleeve manner on the outer surface of one end extending outside the incubator, of the first connecting shaft. By adopting the novel incubator with the automatic uniform shaking device, the uniform shaking effect is greatly improved, the uniform shaking efficiency is very well improved, cell culture liquid is uniformly shaken by culture operators within a relatively short time, the workload of the culture operators is alleviated, the purpose of rapidly, efficiently, automatically and uniformly shaking the culture liquid is achieved, and thus great convenience can be brought to cell culture operation of the culture operators.

Owner:广州和能生物科技有限公司

Toy

Owner:ANHUI BOLANGDAO AMUSEMENT EQUIP

Automatic vamp polishing device

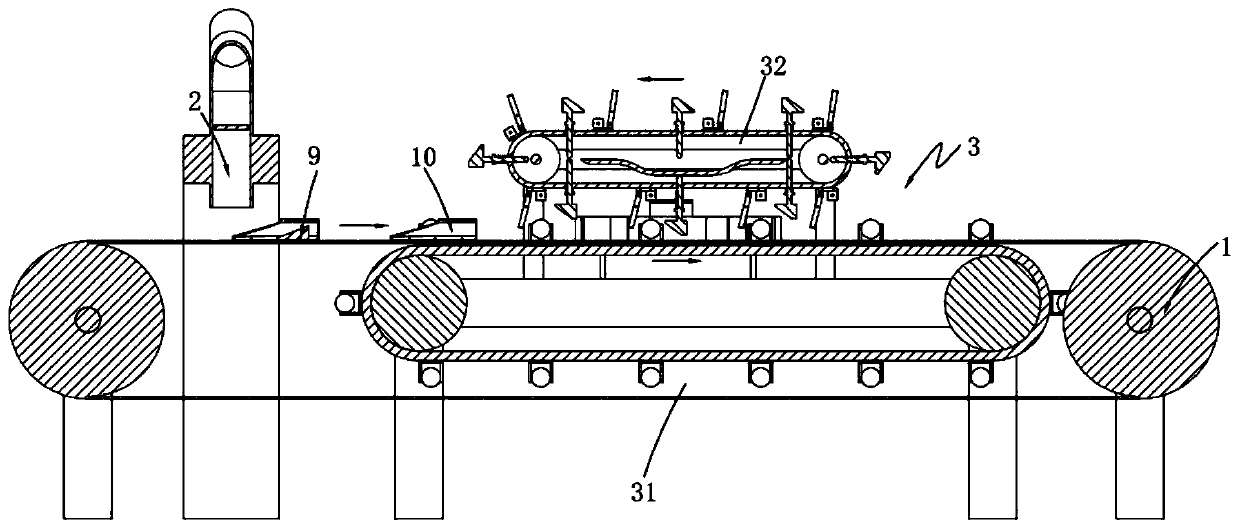

ActiveCN111202308AReduce manual laborImprove polishing efficiencyShoemaking devicesBelt grinding machinesPolishingEngineering

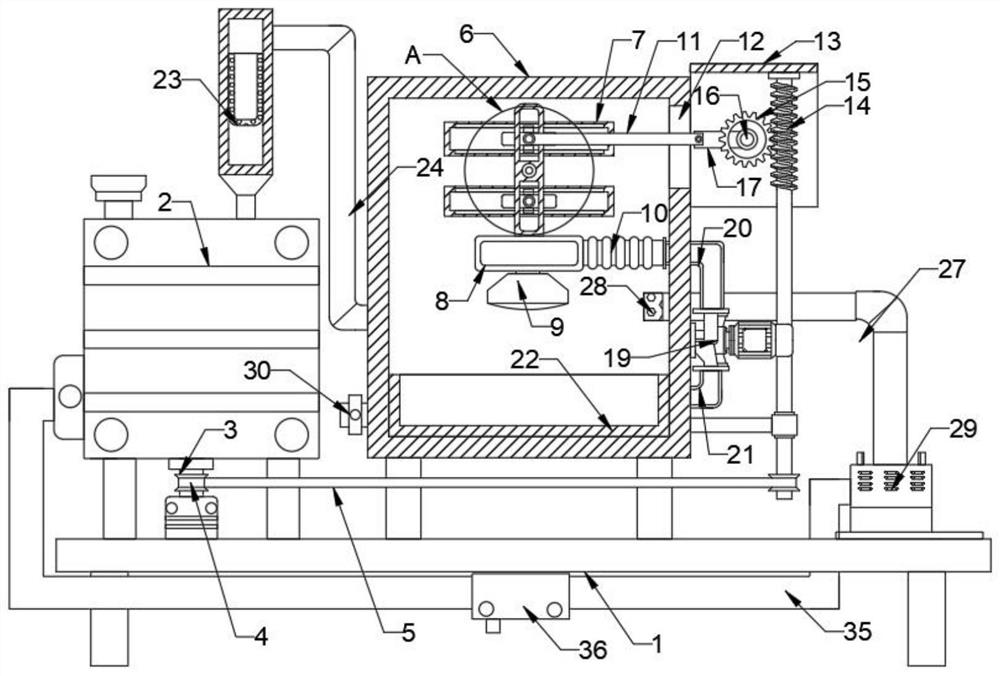

The invention relates to the technical field of vamp polishing, in particular to an automatic vamp polishing device. The device comprises a conveying mechanism, a pad feeding mechanism and a polishingmechanism, wherein the pad feeding mechanism and the polishing mechanismare sequentially arranged in the conveying direction of the conveying mechanism. The polishing mechanism comprises a clamping assembly and a polishing assembly; the clamping assembly comprises a first support, a first conveying belt and clamping units, the position, corresponding to the conveying mechanism, of the first conveying belt is a polishing station, and when the shoe bodies are located at polishing stations, the clamping units and the shoe bodies are arranged in a one-to-one correspondence mode; the polishing assembly comprises a second support, a second conveying belt and polishing units, and the polishing units and the clamping units are arranged in a one-to-one correspondence mode at the polishing station.While the shoe body is uniformly conveyed through the conveying mechanism, a foam pad is conveyed into the shoe body through the pad conveying mechanism, the two sides of the shoe body are clamped through the clamping assembly, then the surface of the shoe body is polished through the polishing assembly, so that the continuous and automatic vamp polishing is achieved, the manual labor force is relieved, and the polishing efficiency is improved.

Owner:RUIAN DAHU SHOES IND CO LTD

Tooth washing device and application method thereof

ActiveCN105496590AEasy to viewConvenient curved tooth cleaningToothed gearingsCleaning using liquidsCamEngineering

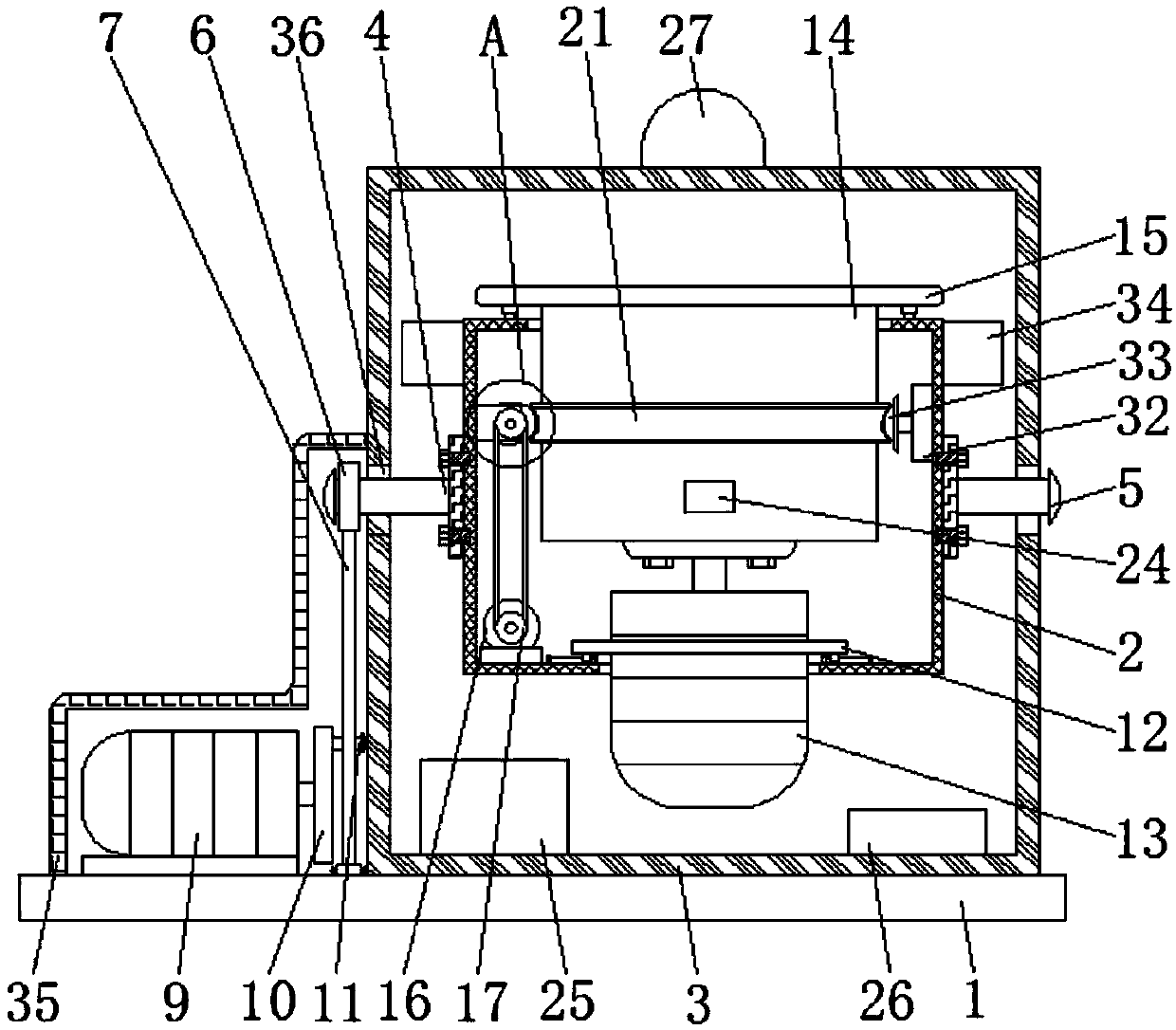

The invention discloses a tooth washing device and relates to the field of dentistry. The device comprises a box body, a planetary gear train and a bracket, a working handle, a control panel and a first motor are installed inside the box body, mounting plates are fixed to the two sides of the working handle, a first spring is installed on each mounting plate, the two sides of the working handle are each provided with a second motor, a cam is installed on each second motor, a rotating shaft is arranged at the end of the working handle, the control panel is in linear connection with an upper computer, the planetary gear train comprises an inner ring gear, a planetary gear and a sun gear, the sun gear is arranged at the center position of the inner ring gear, the planetary gear is arranged between the sun gear and the inner ring gear, the bracket is arranged on the planetary gear train, a lower carrying platform is provided with a groove and a slide rail, a slide block is installed on the slide rail and provided with a fixed rod, an extension rod is installed in the fixed rod, and a camera is installed at the upper end of the extension rod. By means of the tooth washing device, automated tooth washing can be achieved, a user can complete tooth washing on his / her own, and the danger of cross infection with other people is avoided.

Owner:湖州优研知识产权服务有限公司

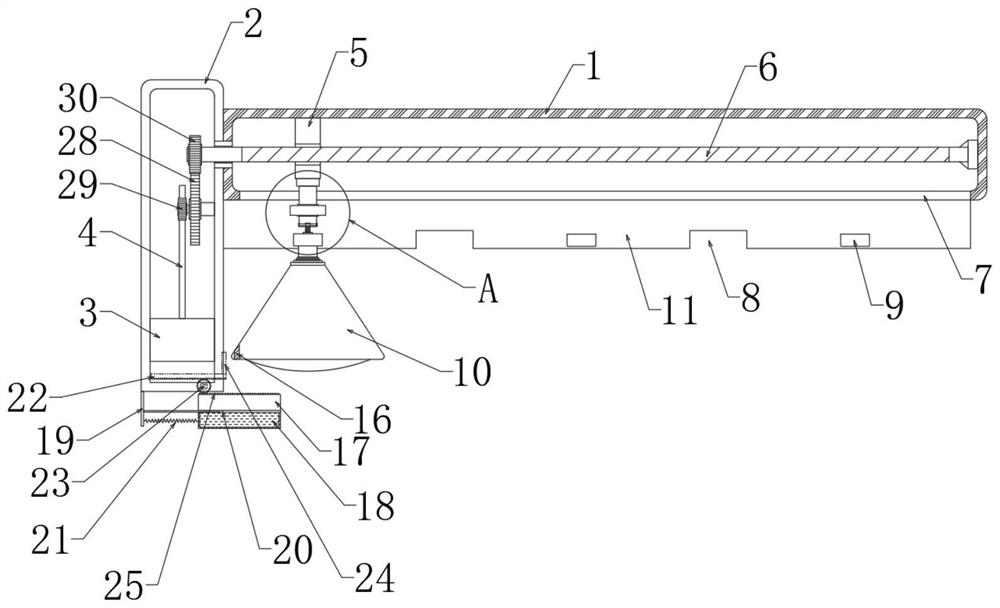

Baking lamp for beauty salon

InactiveCN111803800AEasy to moveAchieve left and right movementLight therapyEngineeringStructural engineering

The invention discloses a baking lamp for a beauty salon. The baking lamp comprises a hollow cross rod and a hollow vertical rod fixedly connected to the hollow cross rod, a threaded rod is rotationally connected into the hollow cross rod, the threaded rod is sleeved with a sliding block which is in threaded connection with the threaded rod, a sliding groove is formed in the bottom of the hollow cross rod in a penetrating mode, the bottom of the sliding block is rotationally connected to a first connecting rod, the first connecting rod is sleeved with a rolling wheel, the bottom of the first connecting rod is rotationally connected to a second connecting rod, and a baking lamp is installed at the bottom of the second connecting rod, two transversely-parallel installing plates are fixedly connected to the bottom of the hollow cross rod, the rolling wheel abuts against the two installing plates, a swing mechanism is arranged between the second connecting rod and the two installing plates, and a piston is slidably connected into the hollow vertical rod. The baking lamp is reasonable in structure, left-right movement of the baking lamp can be achieved, the application range of the baking lamp is widened, front-back swing in the moving process can be achieved, the angle of the baking lamp can be adjusted, and the actual using effect is better.

Owner:许长建

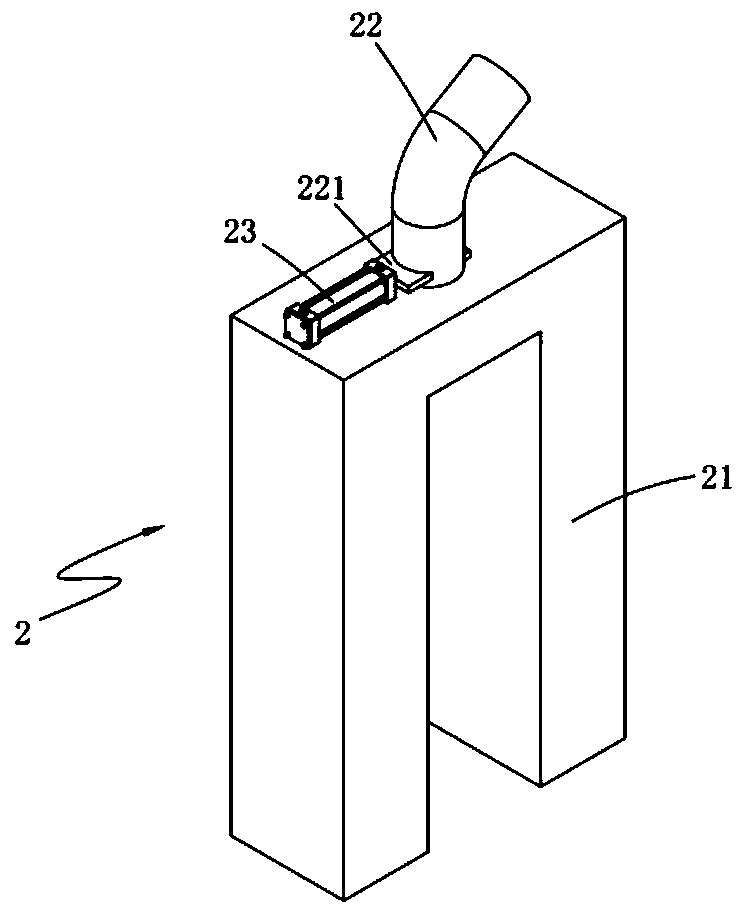

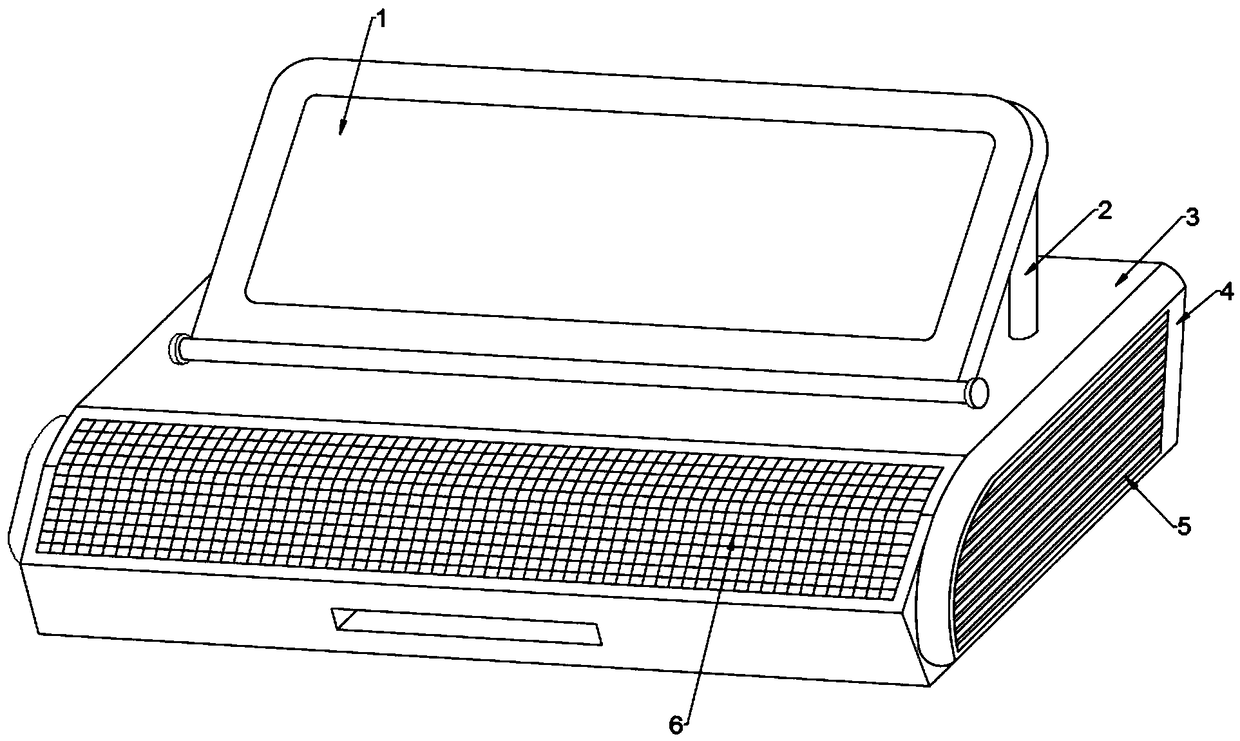

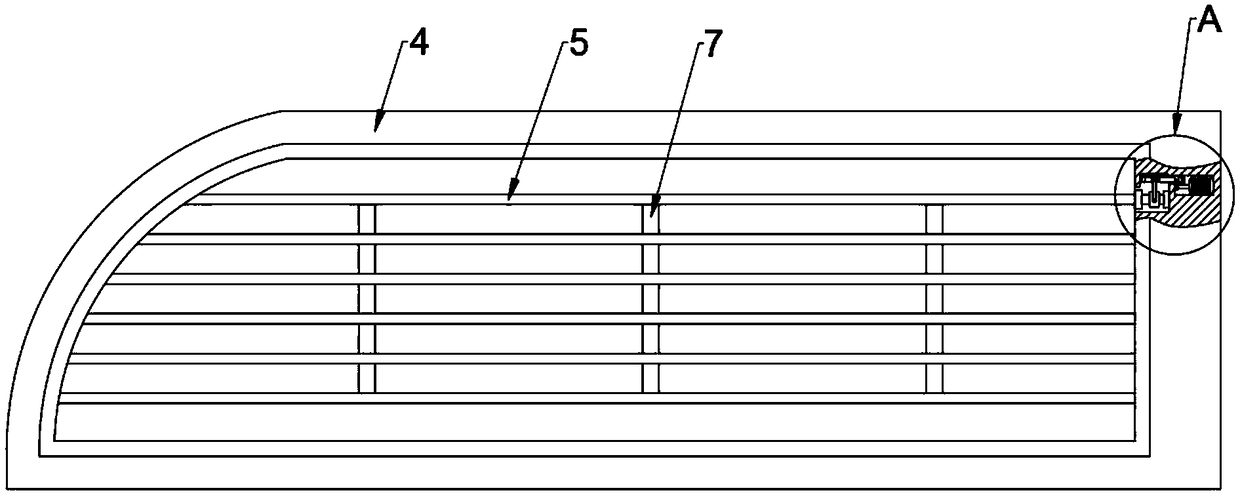

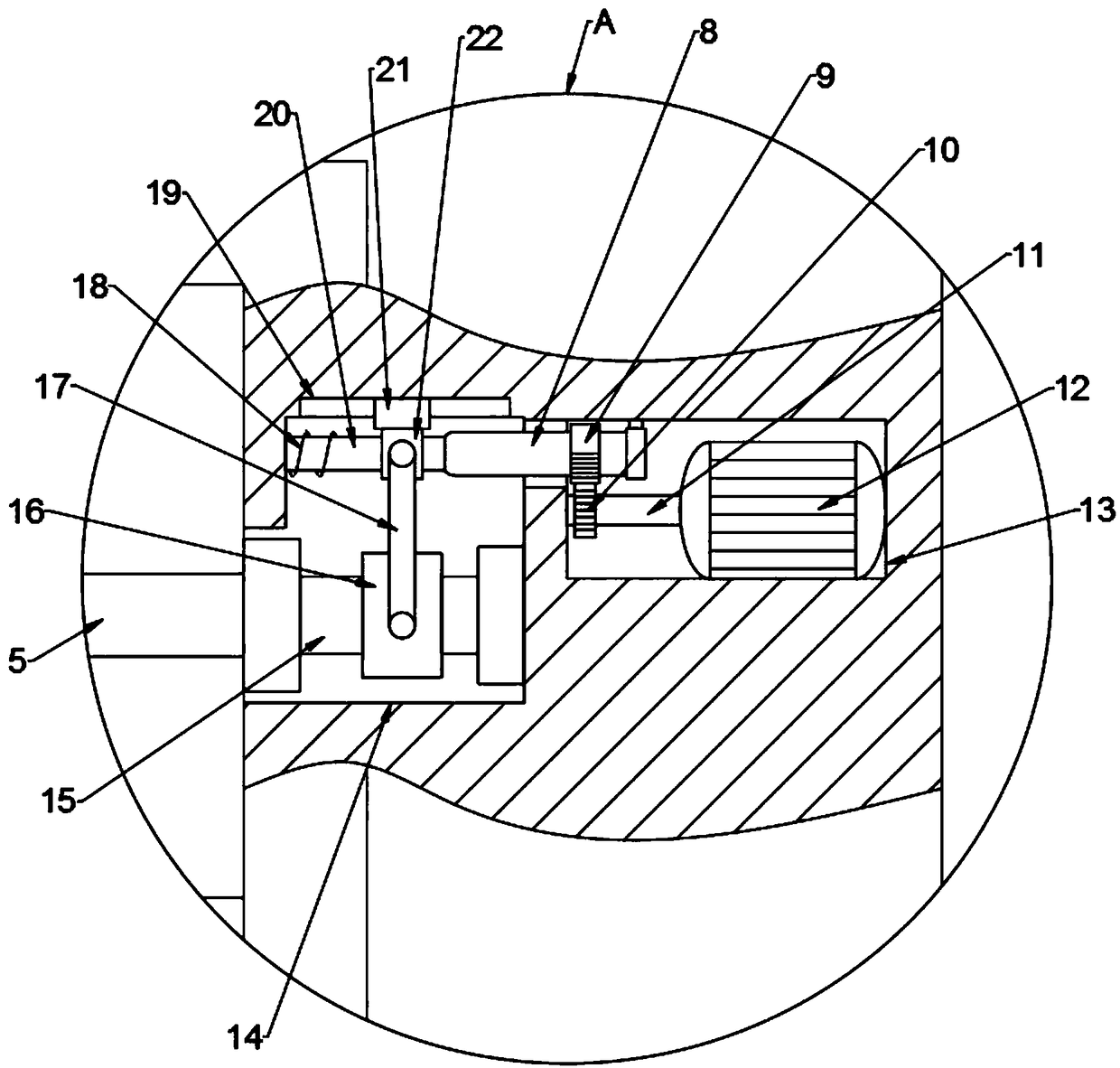

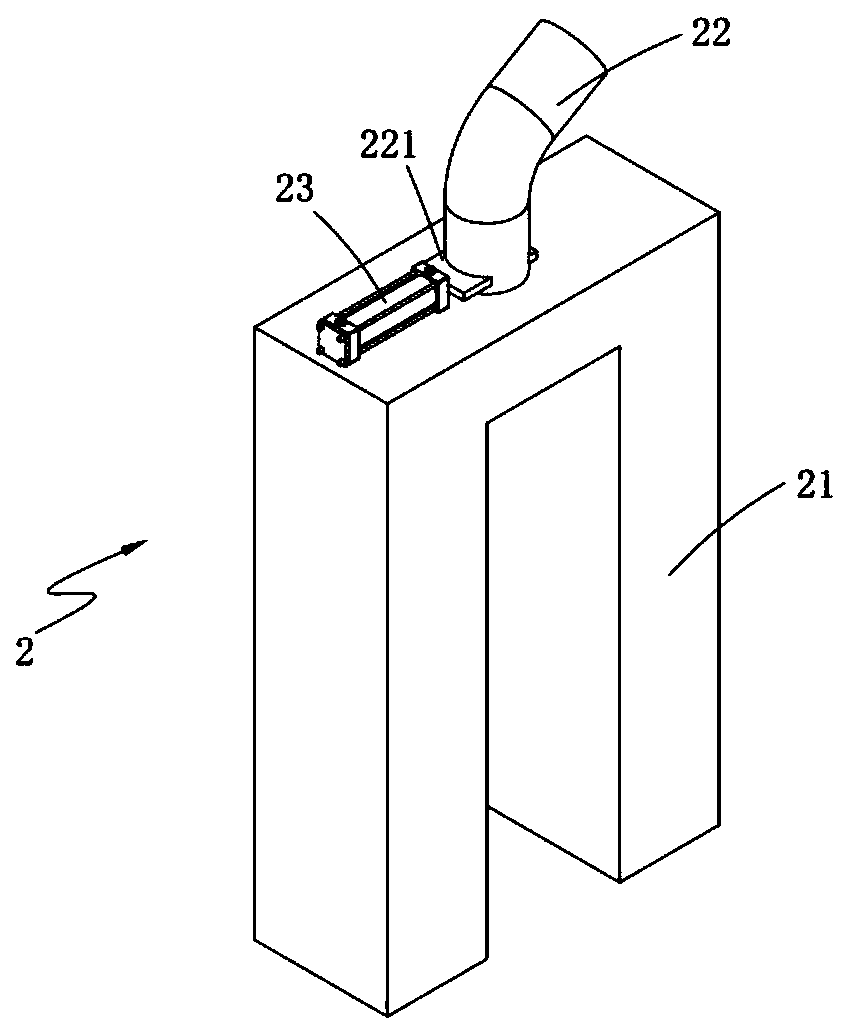

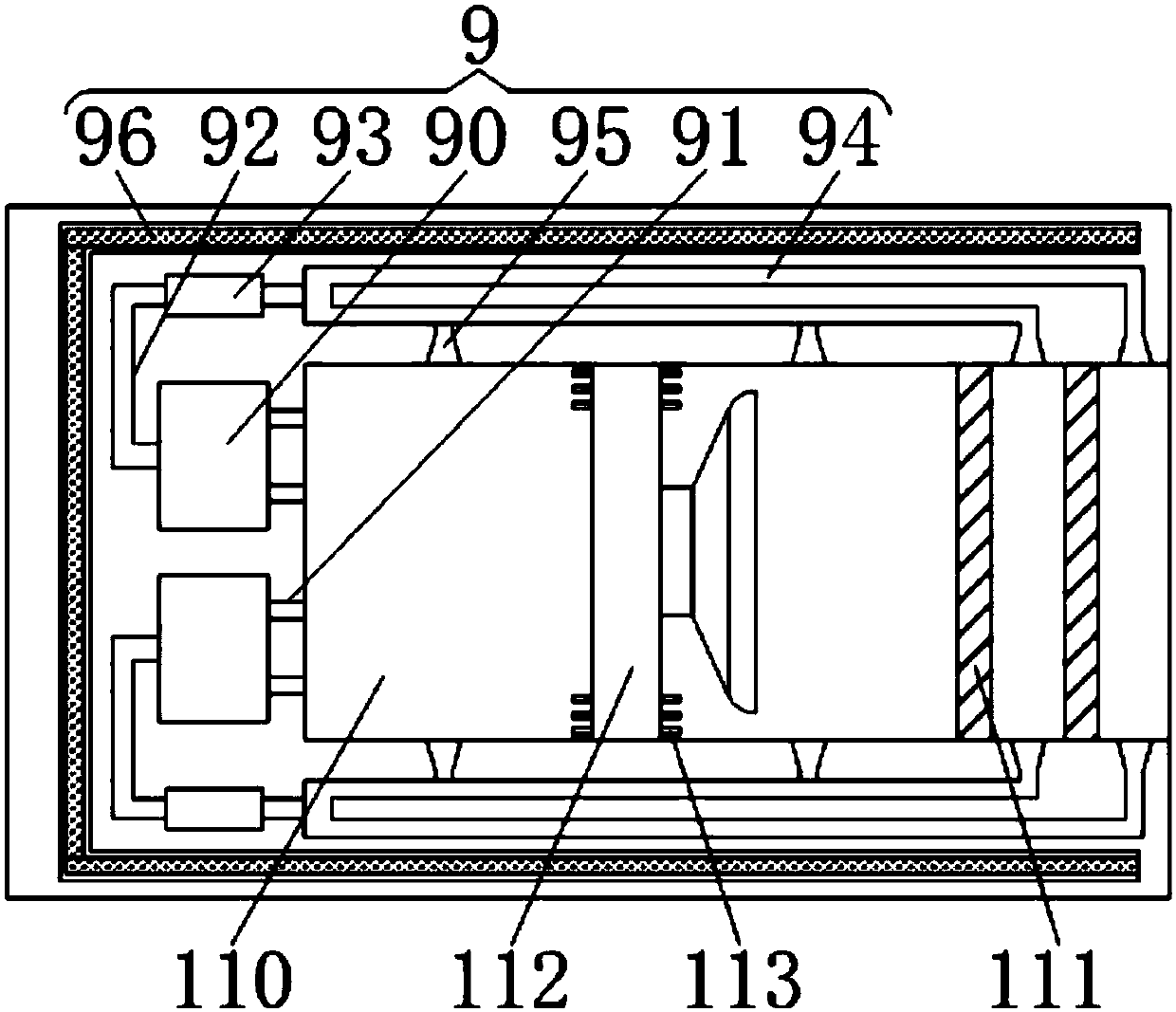

Air purifier based on blockchain and having miner operation function

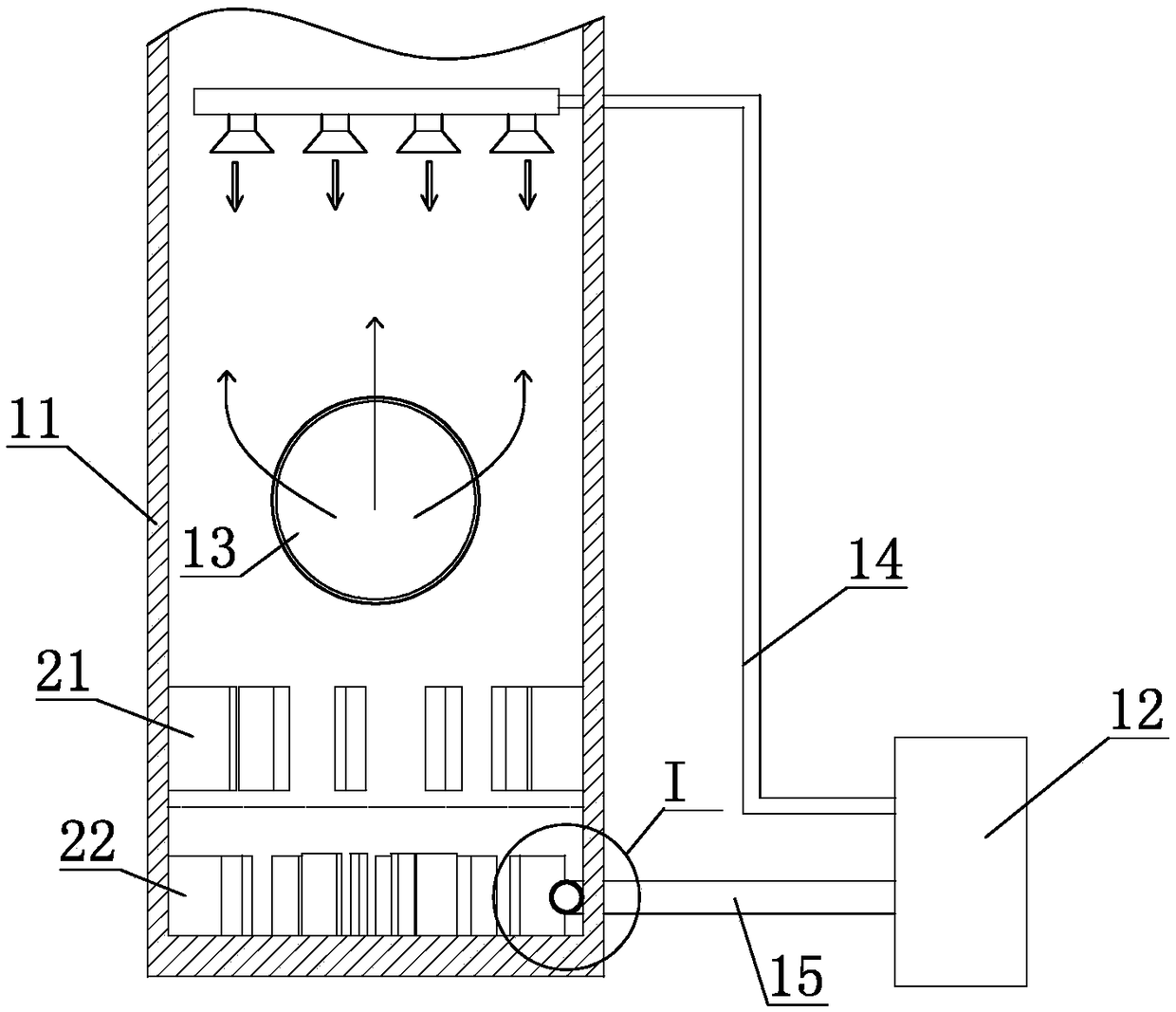

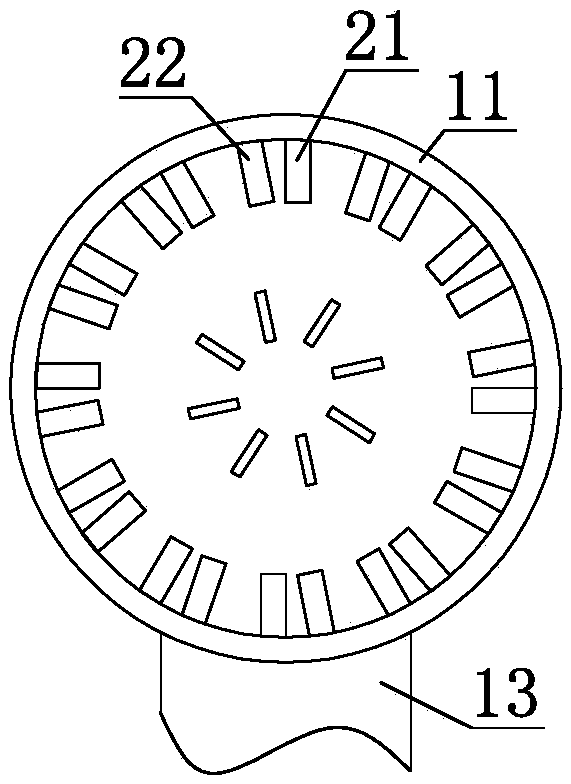

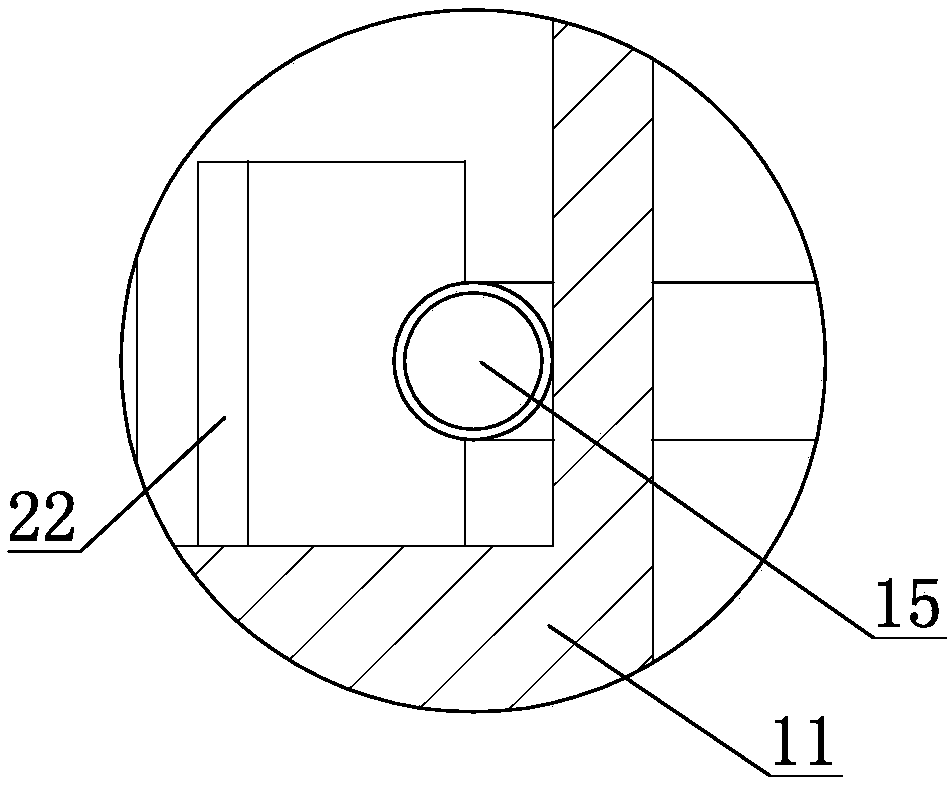

InactiveCN109442635AVersatileThe rate of spreading is fastLighting and heating apparatusDigital processing power distributionAir purifiersEngineering

The invention discloses an air purifier based on a blockchain and having a miner operation function. The air purifier comprises a mining machine panel, an electric telescopic rod, an air purifier body, air exhaust outlets, air exhaust plates, an air inlet, a connecting rod, a first connecting shaft, a semi-gear, a cylindrical gear, a rotating shaft, a motor, a first mounting groove, a second mounting groove, a second connecting shaft, a fixing sleeve, a movable rod, a torsion spring, a first sliding groove, a screw rod, a first sliding block, a threaded sleeve and a buffer device; the front top of the air purifier body is connected with the mining machine panel through a hinge shaft; the electric telescopic rod is correspondingly connected between the bottom of the mining machine panel andthe rear top of the air purifier body; the air inlet is formed in the front face of the air purifier body; and the air exhaust outlets are formed in the two sides of the air purifier body correspondingly, and the air exhaust plates are evenly arranged in the air exhaust outlets. The air purifier has the characteristics of good stability and high practicability.

Owner:高密市鑫佳工贸有限公司

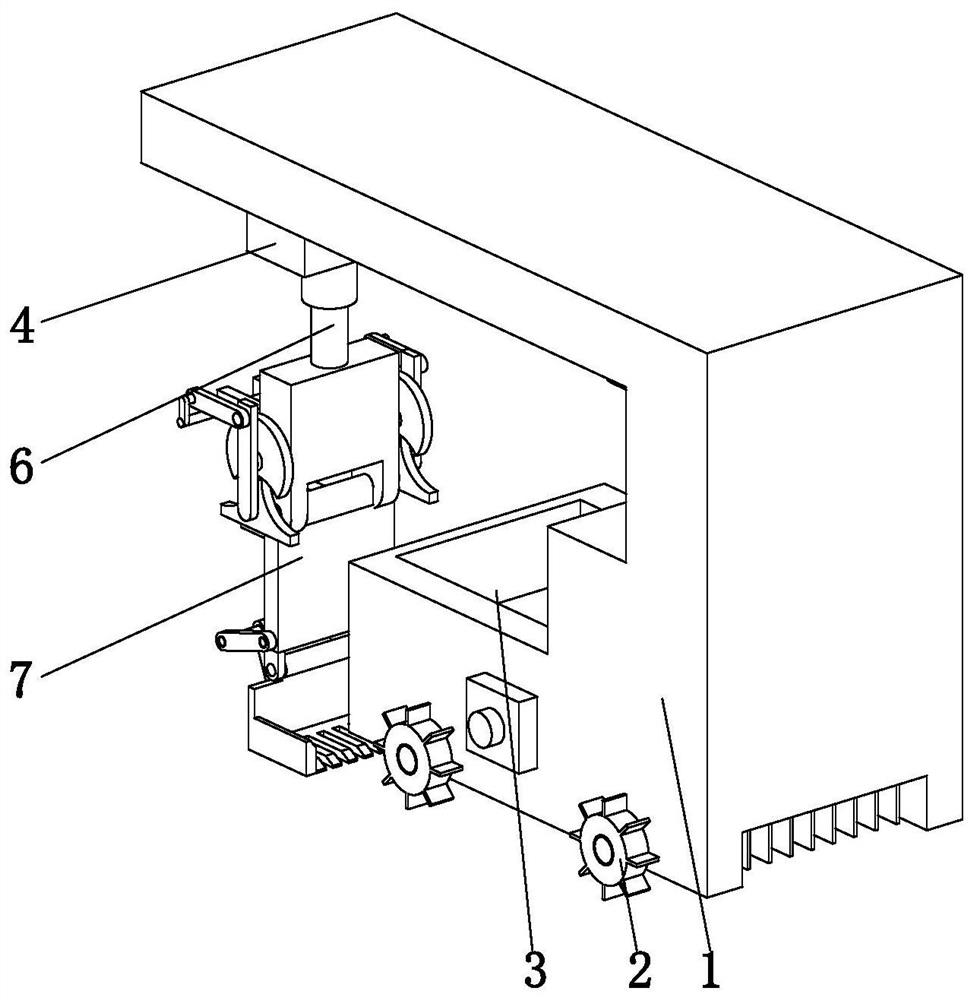

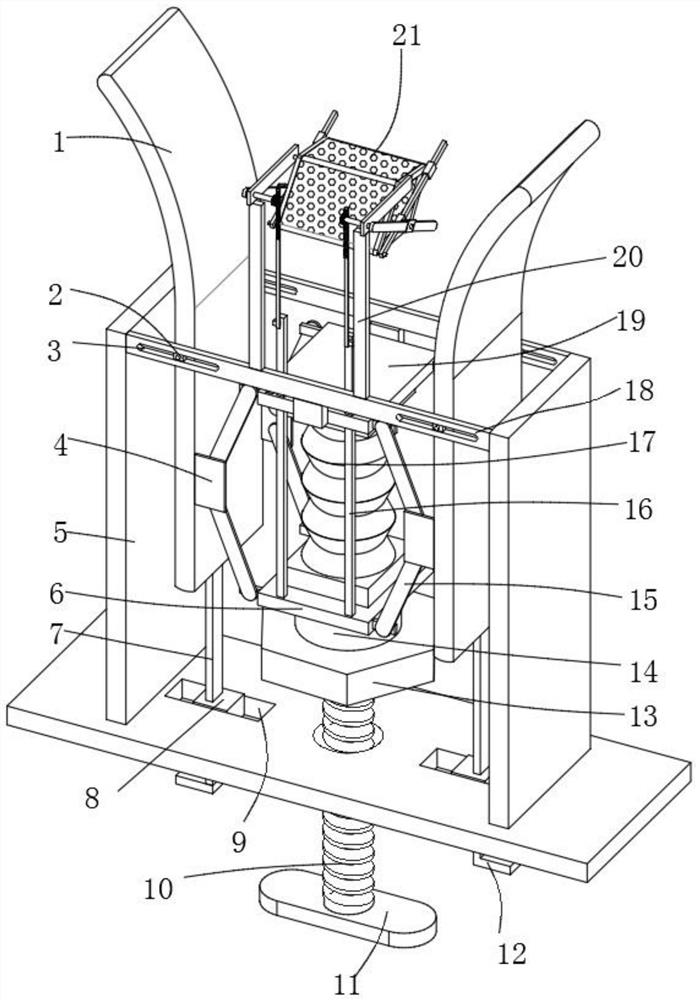

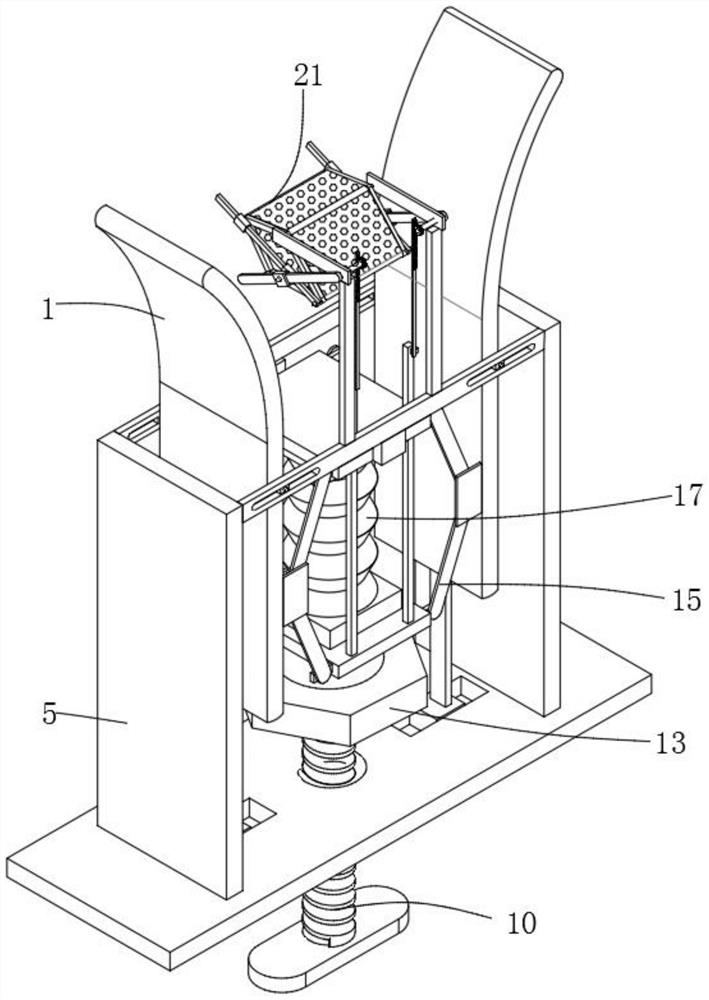

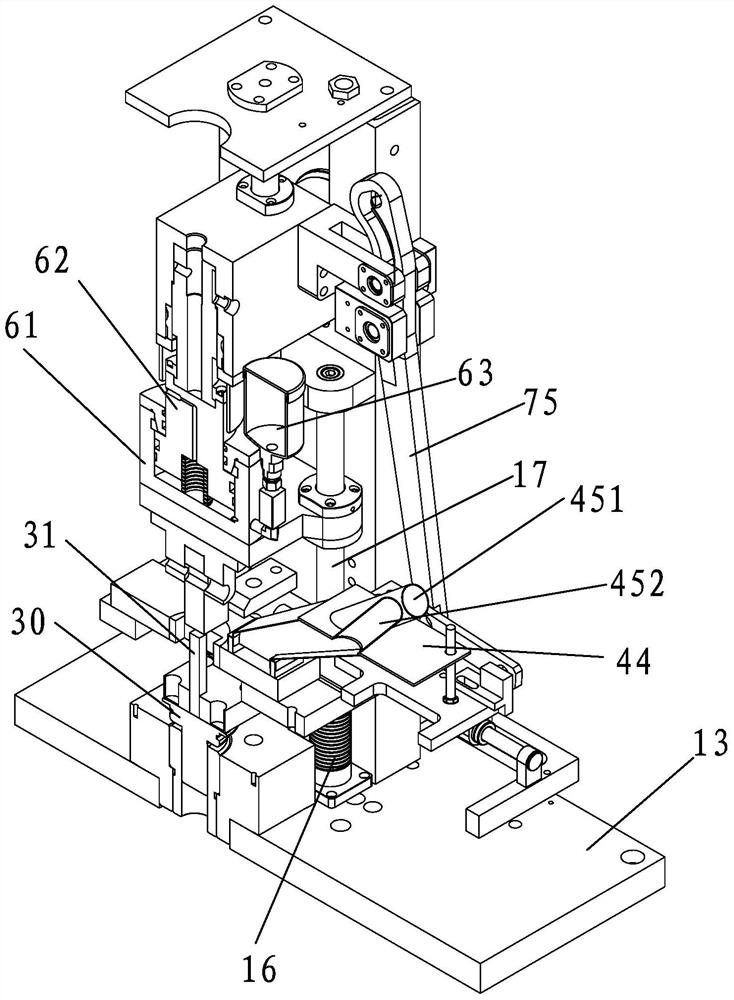

A soil breaking device for planting ground

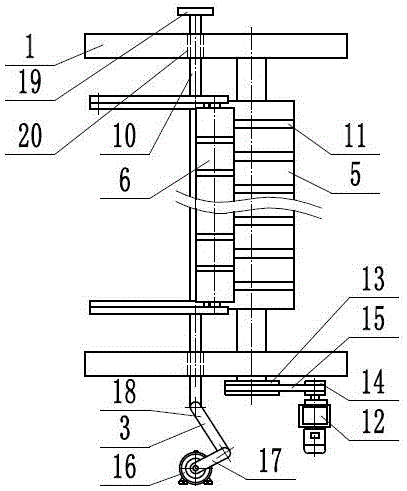

ActiveCN111886946BNo reduction in intensitySwing back and forthSpadesPloughsAgricultural scienceAgricultural engineering

Owner:WEIFANG UNIVERSITY

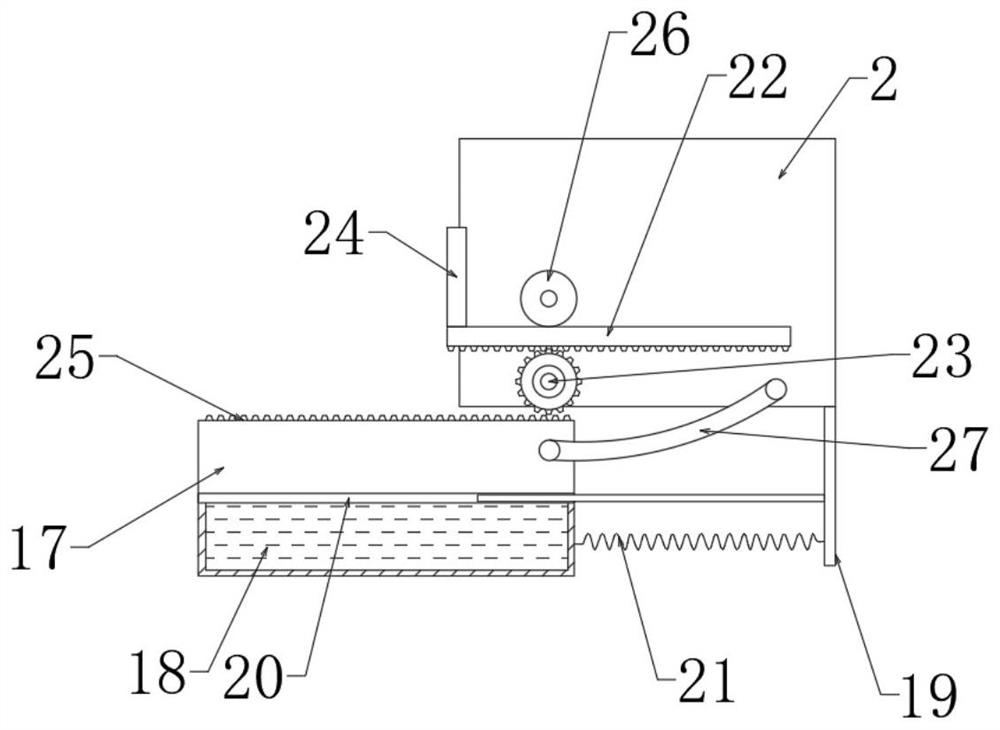

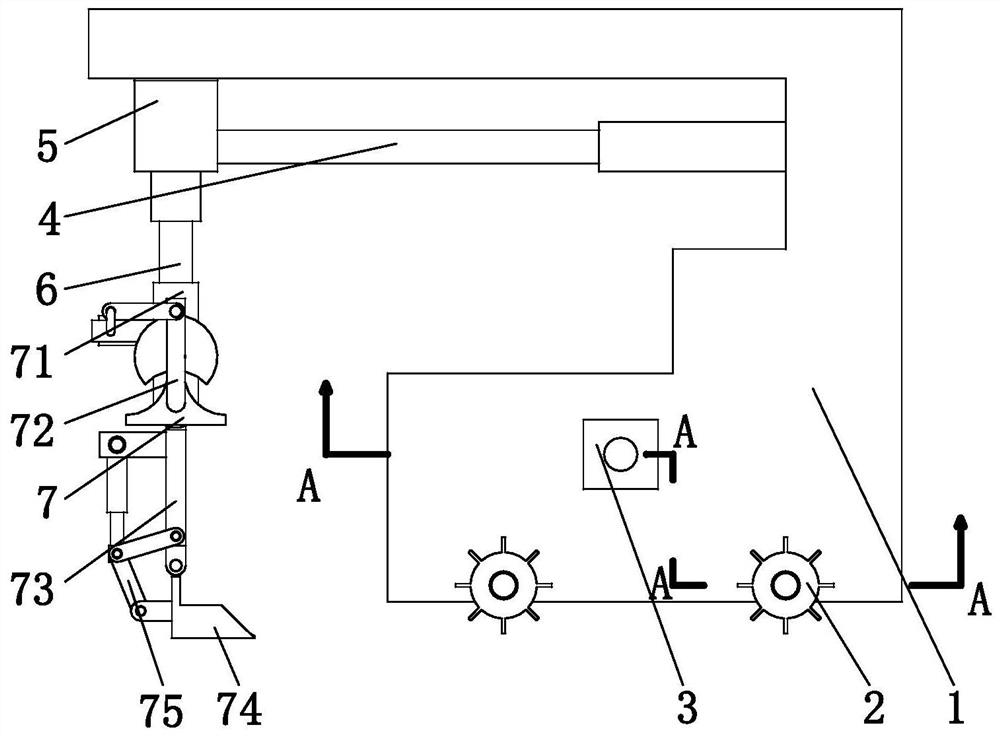

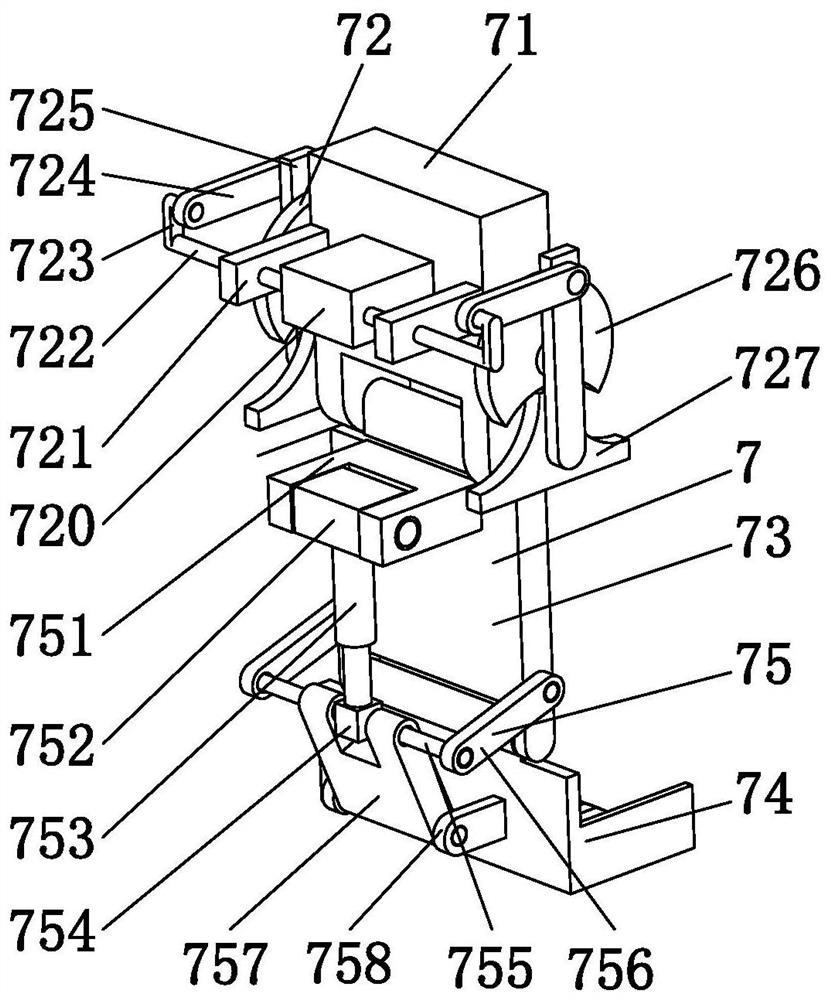

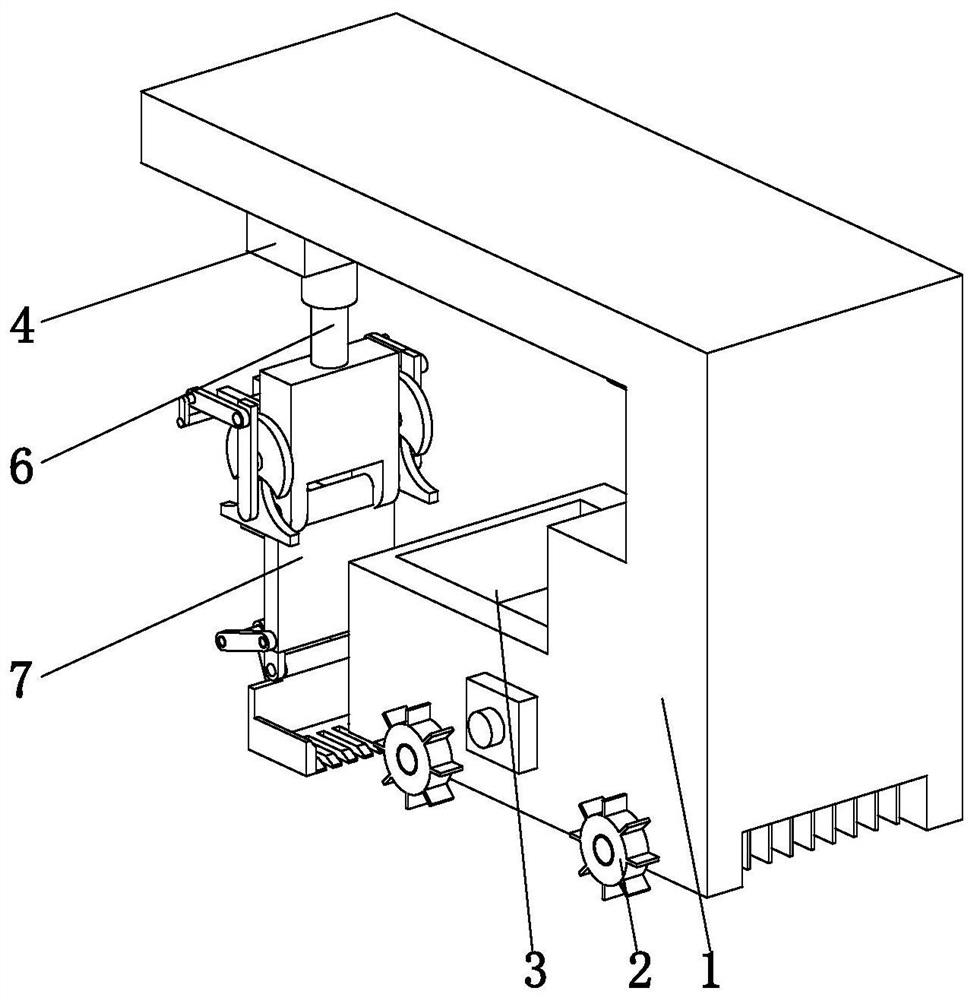

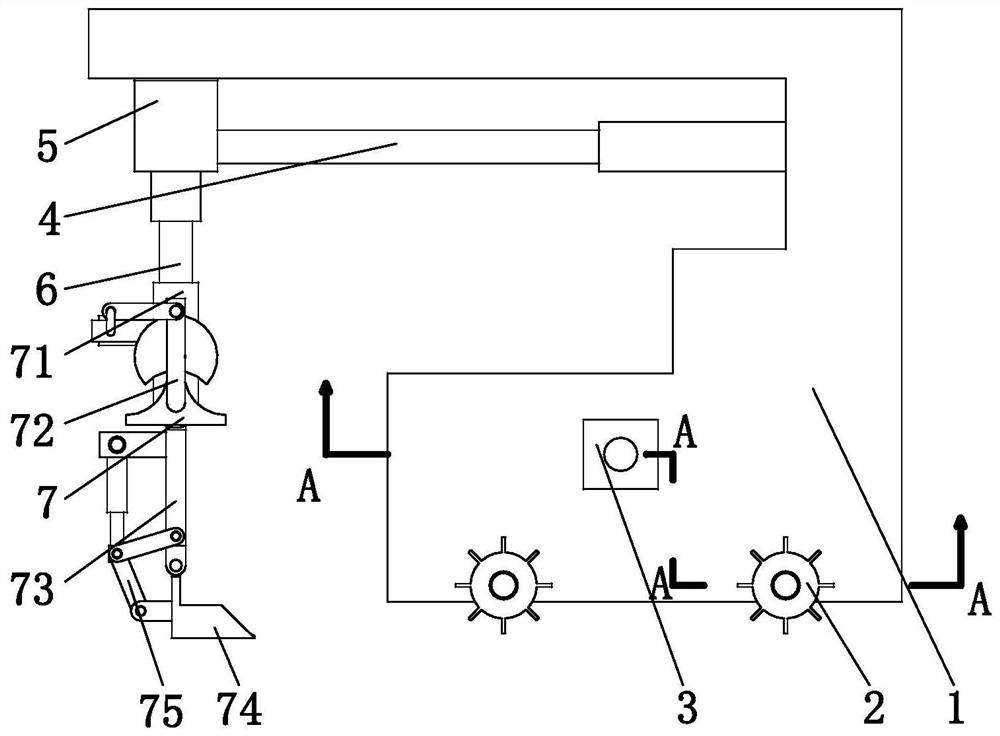

Soil breaking and loosening device for planting lands

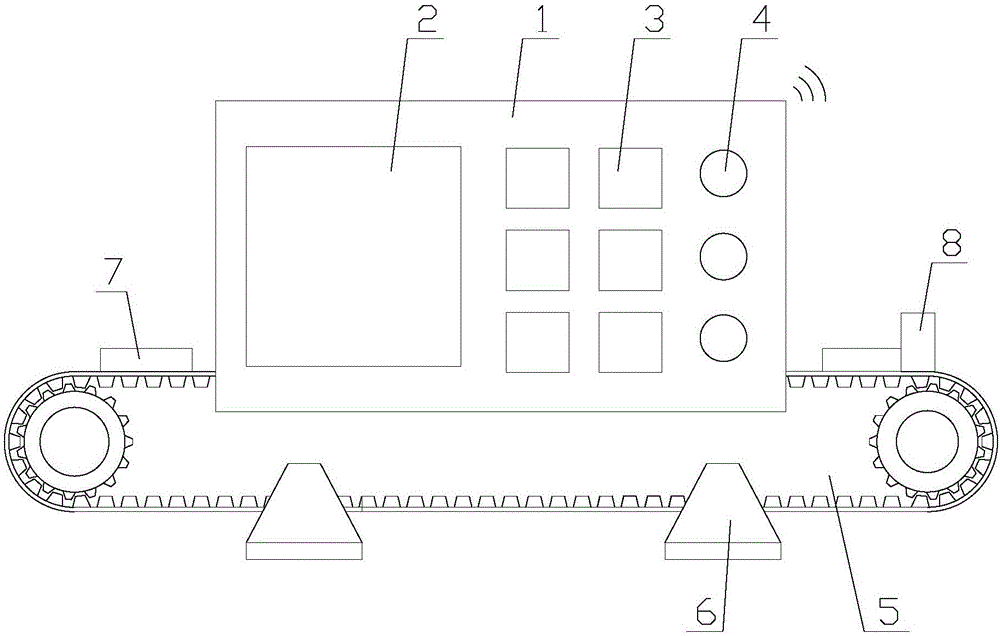

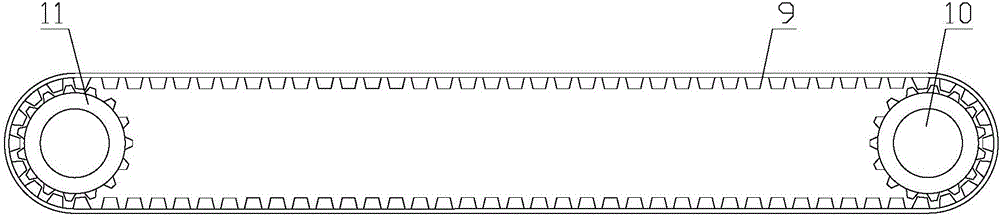

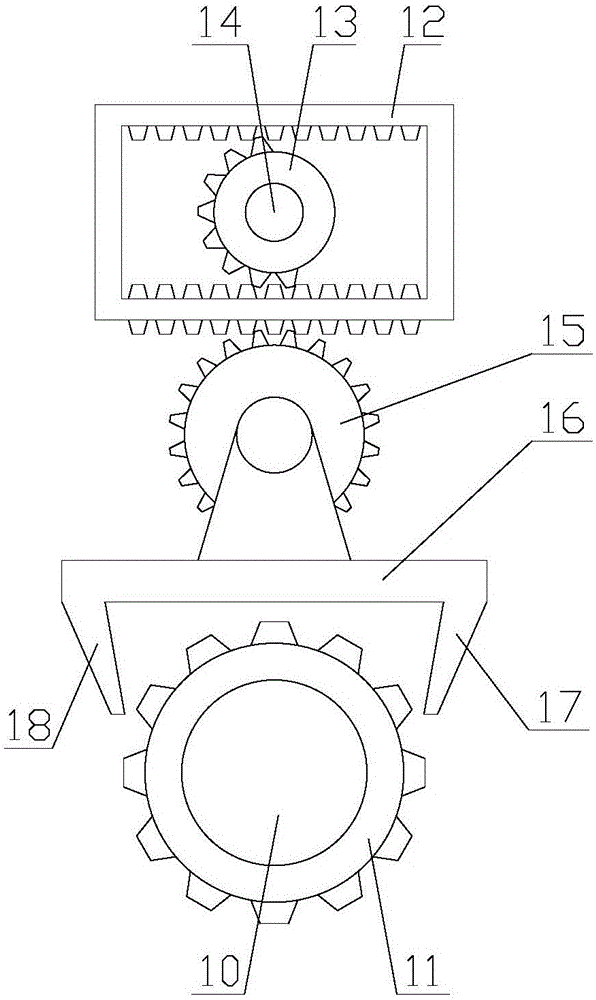

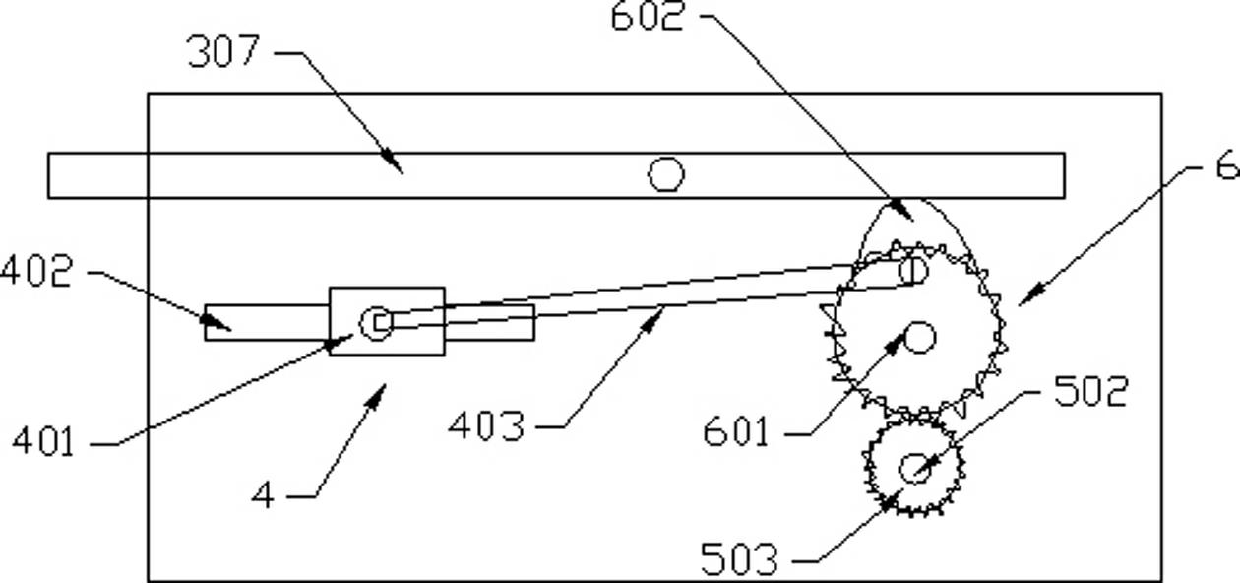

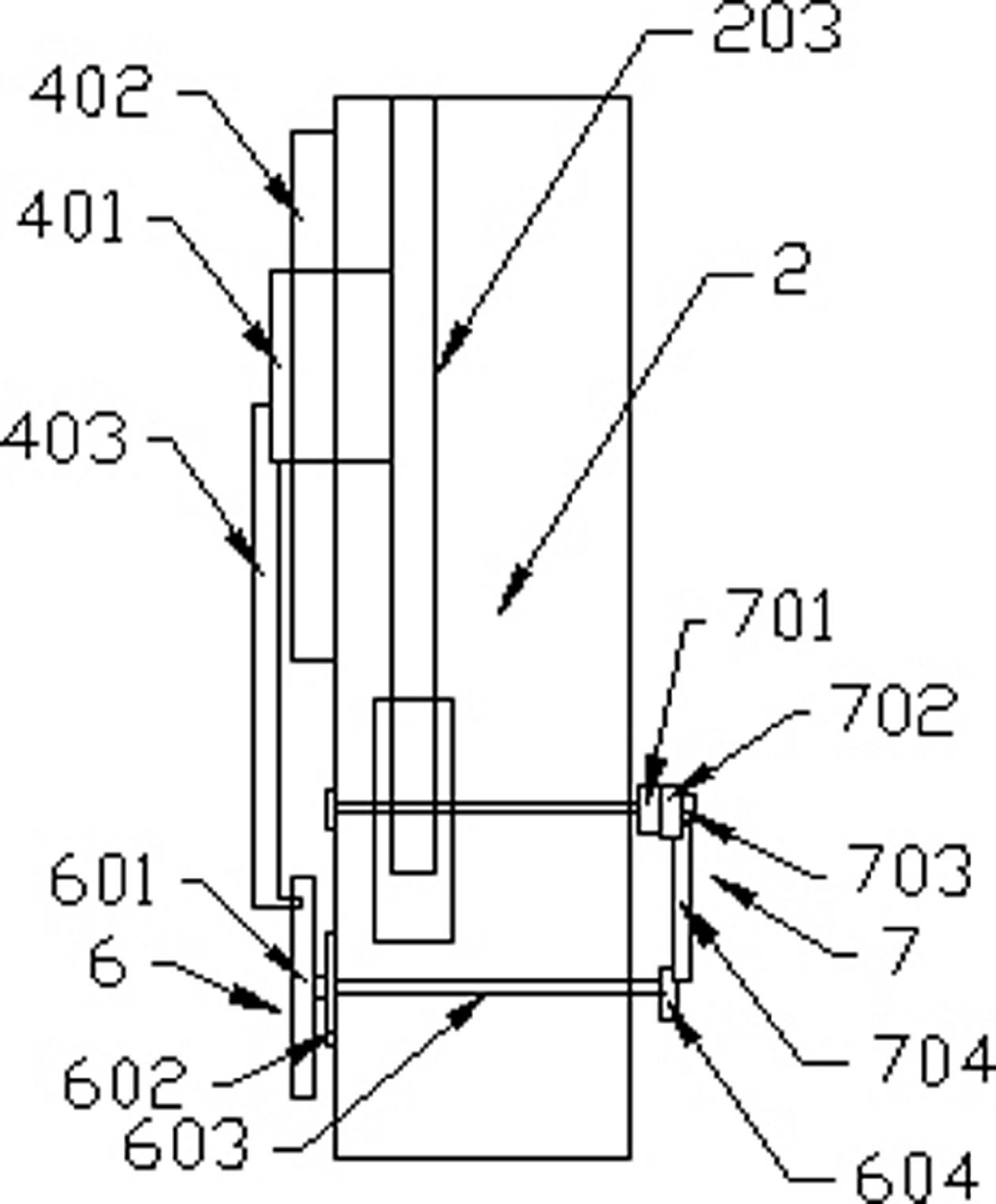

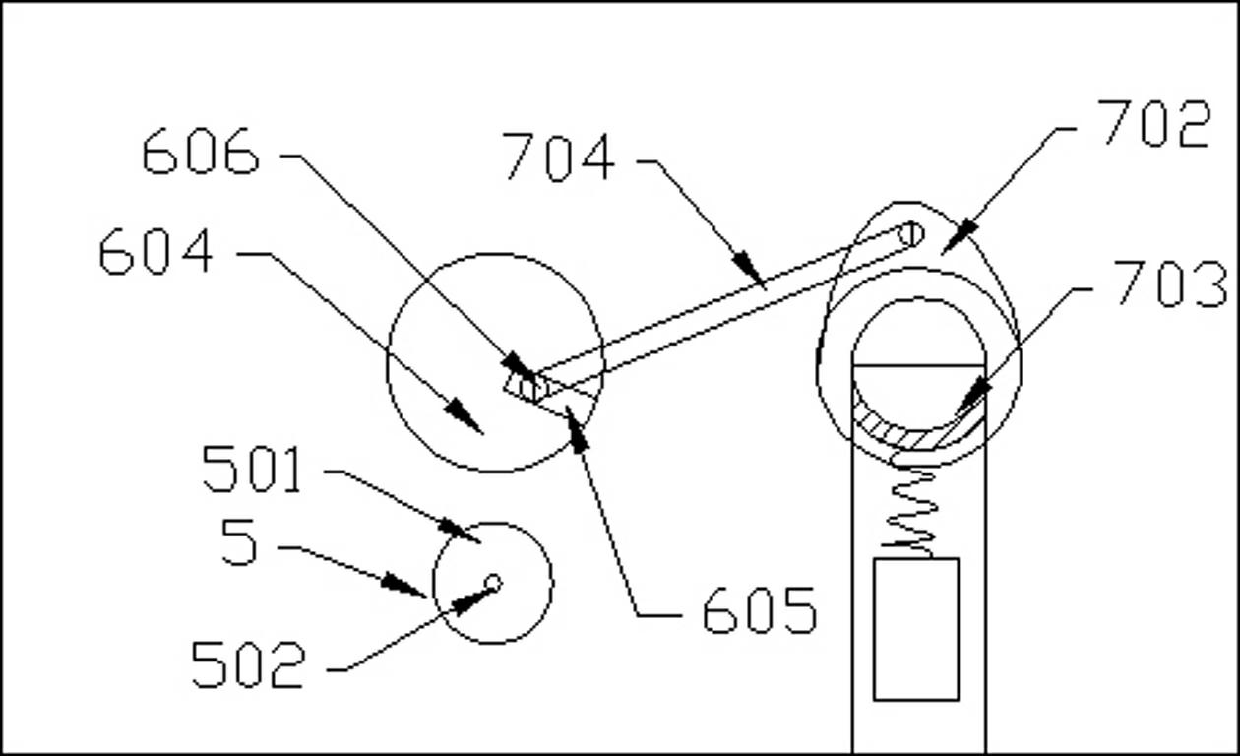

ActiveCN111886946ANo reduction in intensitySwing back and forthSpadesPloughsAgricultural engineeringStructural engineering

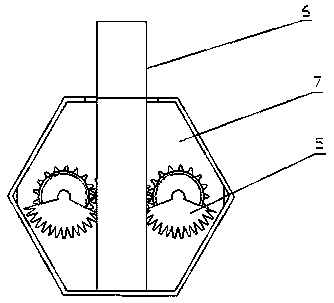

The invention provides a soil breaking and loosening device for planting lands. The soil breaking and loosening device comprises a rack, rollers, a soil loosening mechanism, a first air cylinder, a movable sliding block, a lifting air cylinder and a soil breaking mechanism. The soil breaking and loosening device for the planting lands can solve the following problems existing in a soil breaking and loosening process of the planting lands: a, traditional soil breaking and loosening of the planting lands are carried out by simple tools manually in general, and the tillage mode is high in labor intensity, needs to consume a large amount of time and is not suitable for large-area soil breaking and loosening; and b, soil loosening equipment in the current market is expensive and relatively single in function, the equipment which can often loosen soil cannot break and refine the soil and cannot effectively remove weeds in the soil, and the weeds in a place subjected to soil breaking and loosening often still grow in the place and need to be manually cleaned, so that the labor intensity is not reduced.

Owner:WEIFANG UNIVERSITY

Self-stirring absorption tower

PendingCN109173688ARealize desulfurization treatmentEasy flipGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a self-stirring absorption tower and relates to the technical field of flue gas environmental protection treatment. The self-stirring absorption tower comprises an absorption tower, a slurry circulation pump and a smoke inlet pipe are arranged outside the absorption tower, the slurry circulation pump is communicated with a slurry injection pipe and a slurry recovery pipe, the slurry injection pipe is located at the upper part of the absorption tower, the slurry recovery pipe is located at the bottom of the absorption tower, the side wall of the absorption tower is provided with a plurality of first disturbance plates, the first disturbance plates are annularly distributed, the bottom of the absorption tower is provided with a plurality of second disturbance plates,the second disturbance plates are annularly distributed, the second disturbance plates are perpendicular to the bottom of the absorption tower, and the opening of the slurry recovery pipe is arrangedalong the direction the same to the tangential direction of the inner wall of the absorption tower. The self-stirring absorption tower can utilizes the kinetic energy of the slurry and prevent the deposition at the bottom of the absorption tower.

Owner:SHANDONG GUOSHUN CONSTR GRP

Intelligent packing device for industrial production

ActiveCN106516287AAchieve left and right movementSwing back and forthWrappers shrinkagePower flowGear wheel

The invention relates to an intelligent packing device for industrial production. The device comprises a heating chamber, a transmission mechanism and a base; a brake module includes a second motor, a second driving gear, a transmission frame, a transmission unit and a brake unit; a central control mechanism includes a central control module and a working power supply module; and the working power supply module includes a working power supply circuit. In the intelligent packing device for industrial production, the second motor can control left-right movement of the transmission frame through the second driving gear to realize reciprocating repeated rotation of a transmission gear; a driving pallet can be controlled to periodically brake a transmission mechanism to improve the heating reliability; and moreover, a triode is externally connected in the working power supply circuit to realize adding of output current of the output end of an integrated circuit and a collecting electrode of the triode, so that the output power of a working power supply is increased, and the reliability of the device is improved.

Owner:TONGXIANG HENGTAI PAPER TUBE

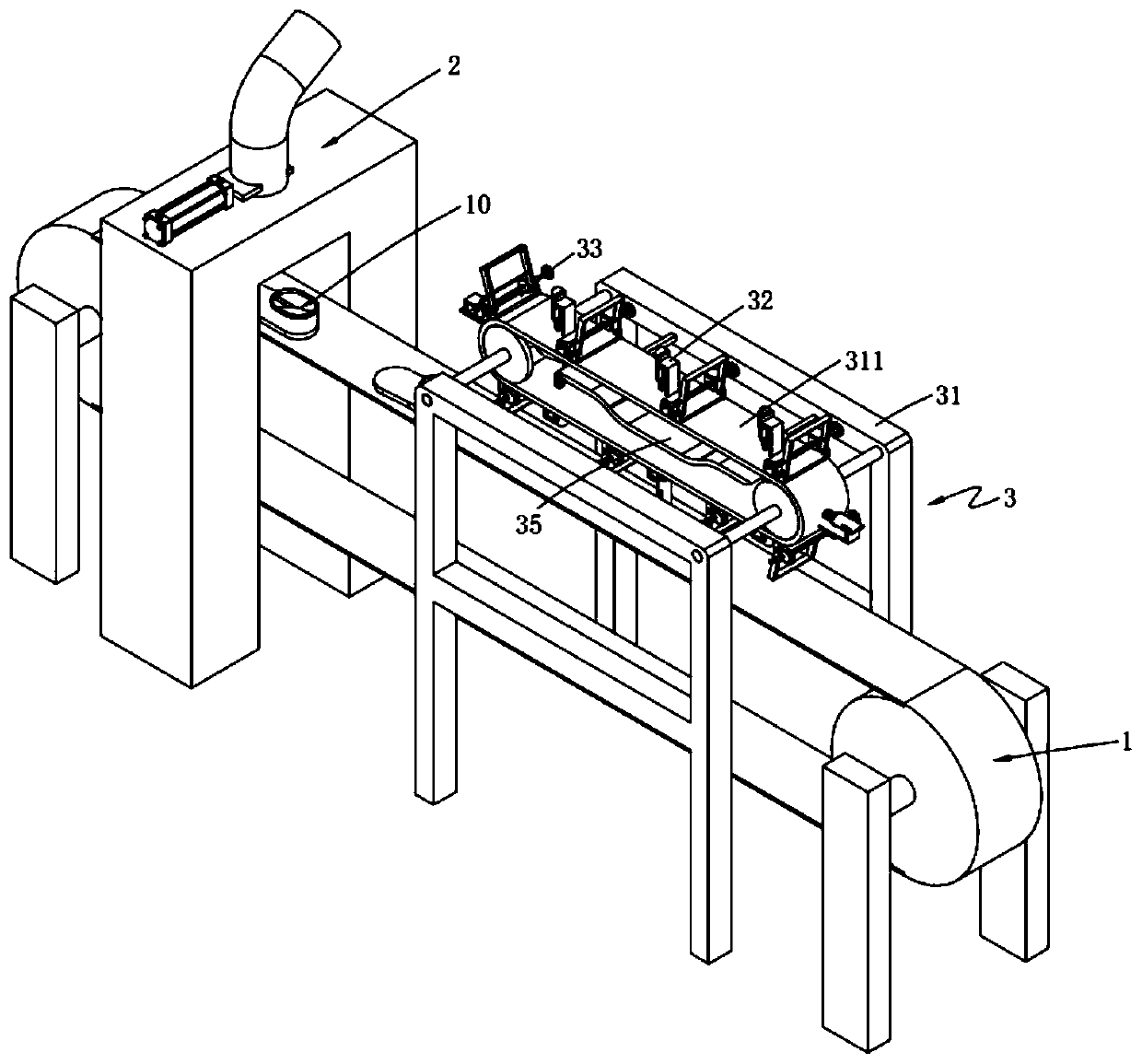

Automatic lining vamp polishing device

InactiveCN111166013AReduce manual laborImprove polishing efficiencyShoemaking devicesPolishingEngineering

The invention relates to the technical field of vamp polishing, in particular to an automatic lining vamp polishing device which comprises a conveying mechanism. A pad feeding mechanism and a polishing mechanism are sequentially arranged in the conveying direction of the conveying mechanism and the conveying mechanism penetrates the polishing mechanism. The polishing mechanism comprises a support,and a conveying belt is arranged on the support; top supporting assemblies are arranged along the conveying surface of the conveying belt in an array mode. A rail is arranged on the support in the length direction of the support, and the top supporting assemblies slide up and down along the track of the rail. Polishing assemblies are arranged along the conveying surface of a conveying belt in anarray mode. Shoe bodies are uniformly conveyed through the conveying mechanism; foam pads are conveyed into the shoe body one by one by the pad conveying mechanism; the foam padsare supported forwardsby the top supporting assemblies moving along the track of the rail; and the lining vamp is polished by the polishing assemblies corresponding to the top supporting assemblies while the vamp is supported, so that continuous and automatic grinding and polishing of the vamp are realized, the manual labor force is reduced, and the polishing efficiency is improved.

Owner:阜阳运筹生产力促进中心有限公司

Adjustable waterproof project lamp

ActiveCN109990232ALarge projection rangeImprove practicalityMechanical apparatusLighting support devicesEngineeringMoisture

The invention relates to the technical field of decorative lighting, in particular to an adjustable waterproof project lamp. The adjustable waterproof project lamp comprises supporting frames, a mainsupporting base is installed between the supporting frames, and rotating shafts are fixedly connected to the two ends of the main supporting base. According to the adjustable waterproof project lamp,swinging mechanisms which are in shaft connection with the main supporting base are installed on the supporting frames, swinging of the main supporting base can be achieved, and therefore it can be achieved that a lamp body above lamp-body supporting bases above the main supporting base swings front and back; a lifting installing mechanism is installed inside the main supporting base, and throughthe mutual meshing transmission effect between the lifting adjusting mechanism and gear teeth on the surfaces of supporting rods, free adjustment of lifting of the lamp-body supporting bases and the lamp body above the lamp-body supporting bases can be achieved; rotating mechanisms are installed inside the lamp-body supporting bases, and rotation of a lamp-body installing base on the water level can be achieved; waterproof mechanisms are installed inside the lamp body, good separation between external moisture and dampness can be achieved, and it is avoided that the moisture enters the lamp body to cause damage of a bulb inside the lamp body.

Owner:广东耀铭芯照明有限公司

Oral cavity moistener for oral cavity examination

ActiveCN113693743AImprove wetting efficiency and qualityAvoid adverse effectsMedical devicesInstruments for stereotaxic surgeryEngineeringMouth shape

The invention discloses an oral cavity moistener for oral cavity examination. The oral cavity moistener comprises a mounting frame, wherein two mounting strips are fixedly connected to the side wall, close to the top, of the mounting frame, two lip pressing plates are mounted between the two mounting strips through sliding assemblies, a top plate is fixedly connected to middles of the two mounting strips, a water storage bag is fixedly connected to the lower surface of the top plate, a movable plate is fixedly connected to the bottom of the water storage bag, mounting blocks are slidably mounted on opposite faces of the two lip pressing plates, two hinge rods rotate on side walls of the mounting blocks, and a driving mechanism enabling the movable plate to move up and down is connected to the bottom of the mounting frame. According to the oral cavity moistener, through adjusting the distance between the two lip pressing plates, the oral cavity moistener can adapt to mouth shapes of different patients conveniently, water in the water storage bag can be squeezed inside a moistening head in an adjusting process, and therefore, the oral cavity moistening efficiency and quality are greatly improved.

Owner:JILIN UNIV

Rotatable garbage bin for bus station

The invention provides a rotatable garbage bin for a bus station and relates to the field of environmental protection equipment. The rotatable garbage bin comprises a rainproof cover plate, wherein atop plate is fixedly installed at the bottom of the rainproof cover plate; a supporting plate is fixedly arranged at the bottom of the top plate; a first bearing seat is fixedly arranged at the rightside of the supporting plate; a first bearing is movably connected to the right side of the first bearing seat; an accommodating groove is fixedly arranged at the right side of the first bearing; anda garbage bin body is arranged in the accommodating groove. The rotatable garbage bin is simple in structure and convenient to use, and everyone can use the rotatable garbage bin due to the fact thatthe garbage bin is operated by hand; the rotatable garbage bin can be swung front and back, can be rotated by 360 degrees freely, and is more flexible, convenient and ornamental on the basis of an existing garbage bin; and the problem that a garbage bin opening cannot be freely adjusted is solved.

Owner:JIANGSU RONGDA CULTURAL & CREATIVE CO LTD

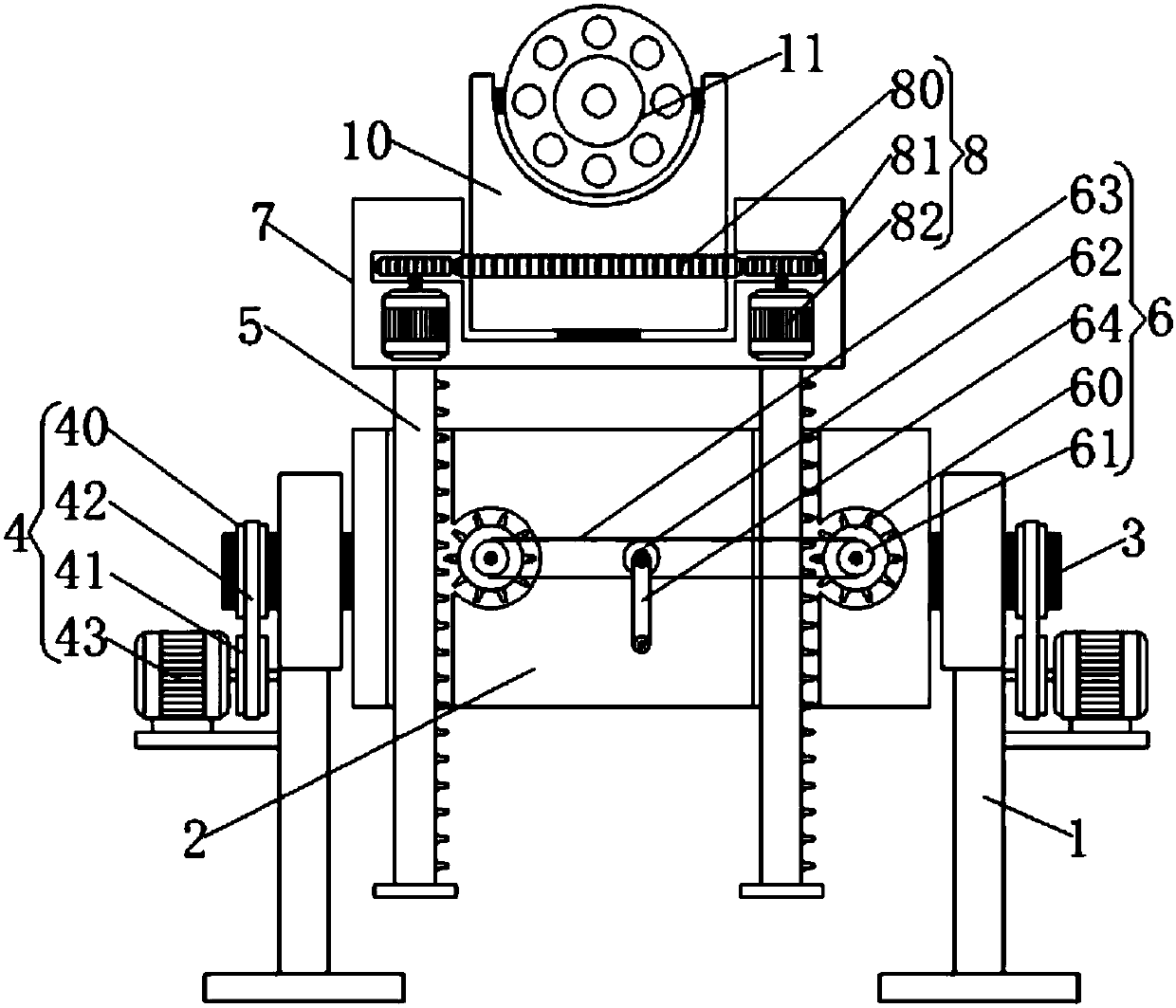

Wool yarn take-up device

InactiveCN105088432ASwing back and forthIt has the following advantages and effects: the take-up mechanism can swing back and forthContinuous wound-up machinesYarnEngineering

The invention provides a wool yarn take-up device and belongs to the technical field of textile machinery. The wool yarn take-up device comprises a take-up mechanism and a swing mechanism. A guide roll of the take-up mechanism is arranged on a rack in a rotating mode. Yarn guide grooves are formed in the guide roll at equal intervals. A yarn take-up support is arranged on the rack in front-rear sliding mode. One end of a bearing support is fixed to the yarn take-up support. The other end of the bearing support is hinged to the lower end of a take-up roll support. A take-up roll is arranged at the upper end of the take-up roll support in a rotating mode and is tightly attached to the guide roll under the action of a pressure spring. A first belt wheel of a drive mechanism is concentrically arranged on one side of the guide roll. The first belt wheel and a second belt wheel are connected through a drive belt. The second belt wheel is coaxially connected with a drive motor. One end of a connection rod of the swing mechanism is hinged to one end of the yarn take-up support. The other end of the connection rod is hinged to one end of a crank. The other end of the crank is connected with a swing motor. The wool yarn take-up device is uniform in take-up, good in effect, simple in structure and low in cost.

Owner:NANTONG DOUBLE GREAT TEXTILE

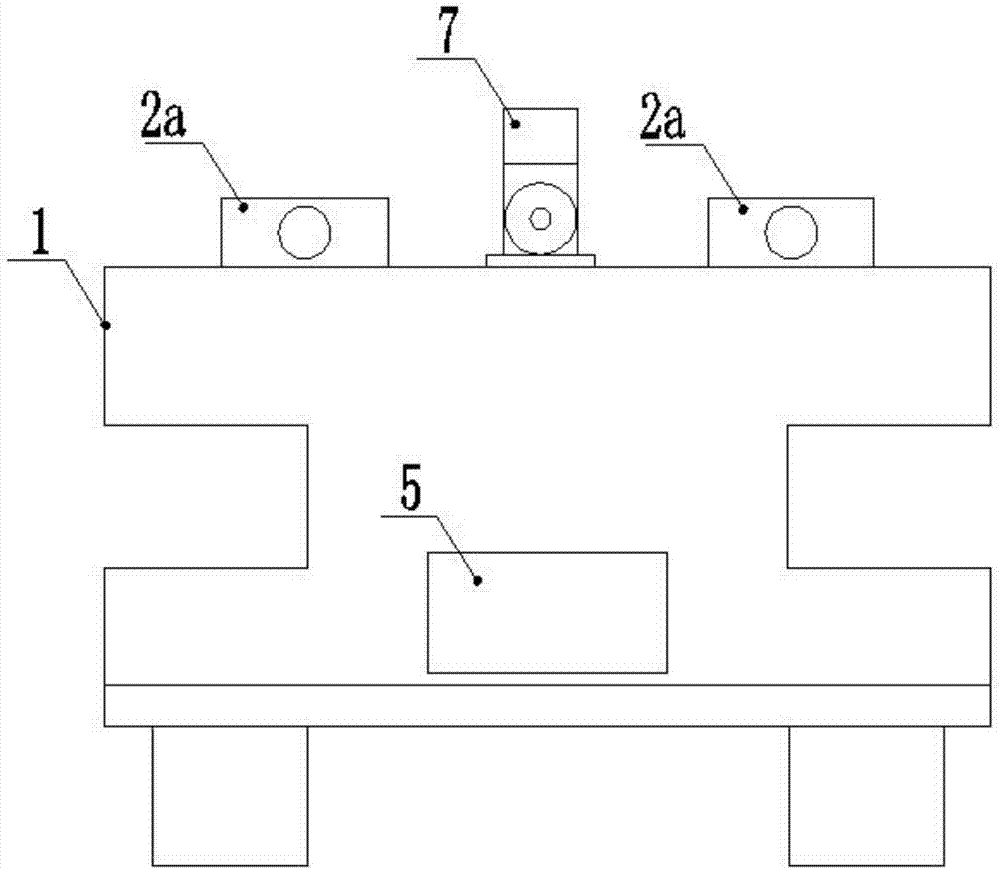

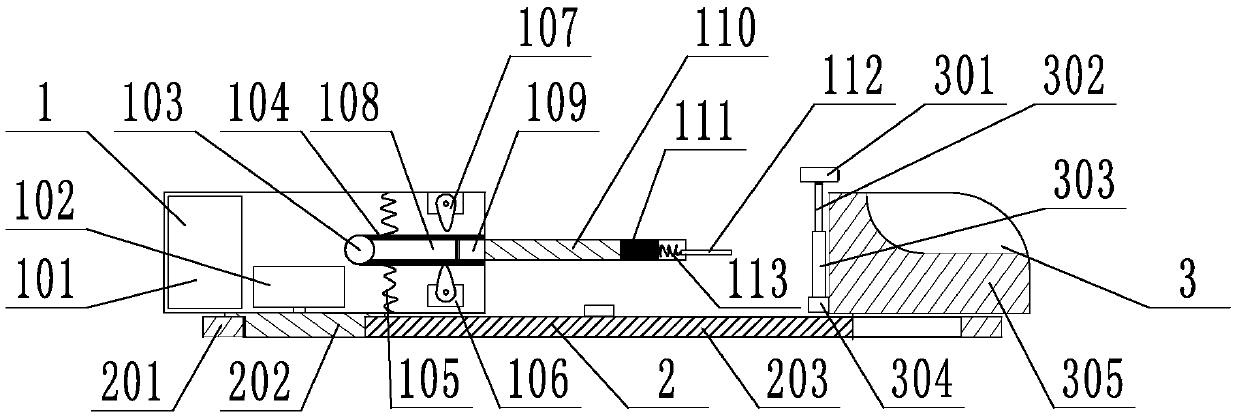

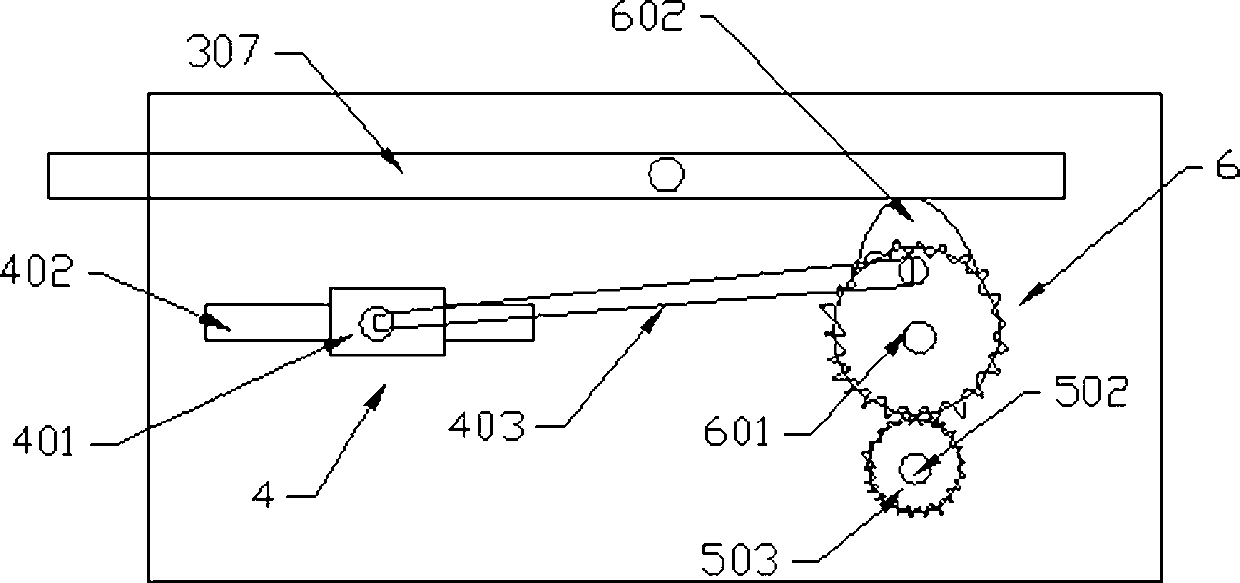

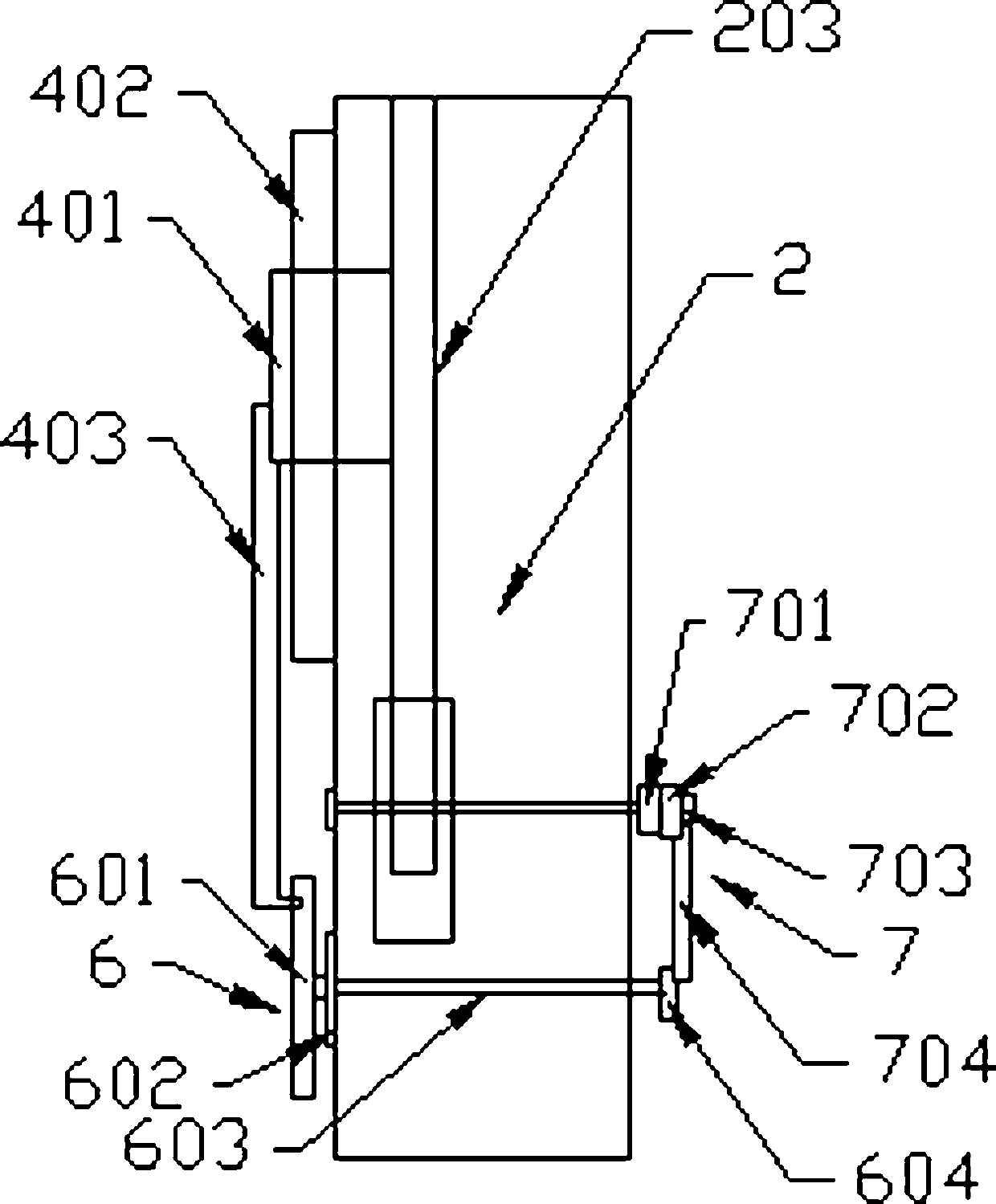

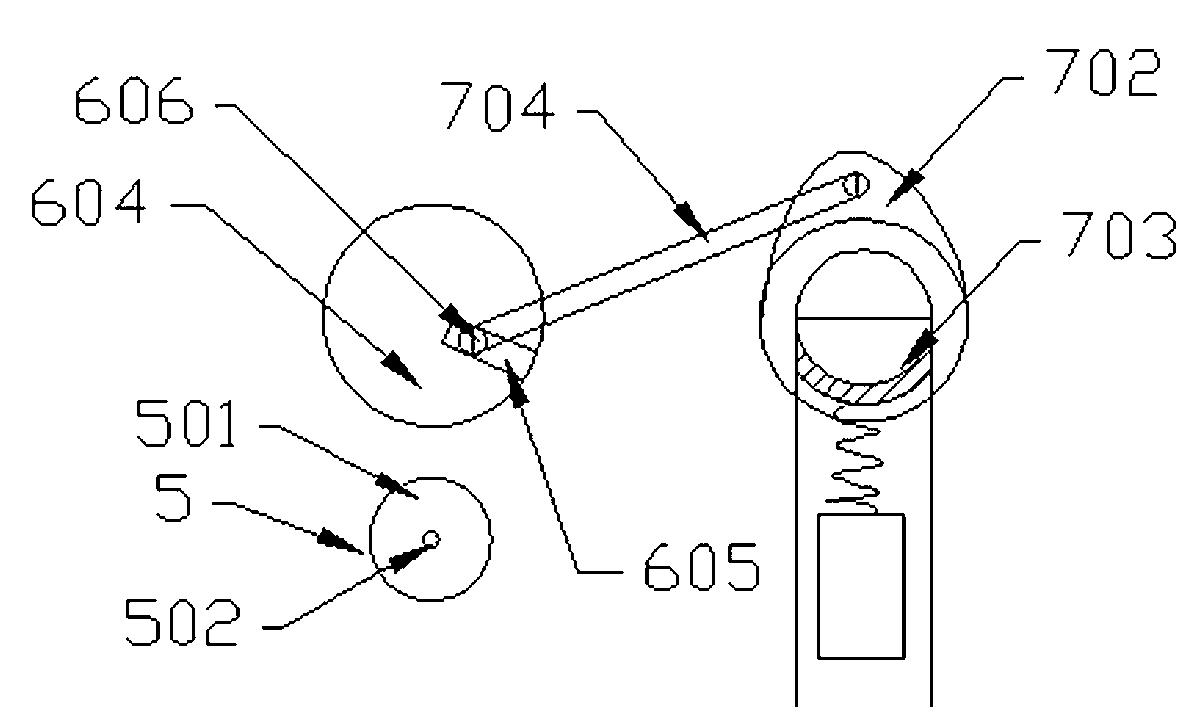

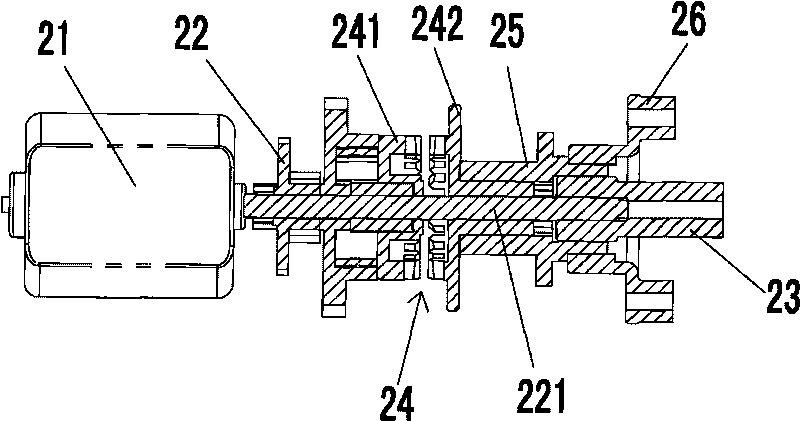

Control system of machine for automatically injecting stator slot cover paper in storage cup

InactiveCN102185415ASwing back and forthProtect normal operationGearingMechanical energy handlingProduction lineControl system

The invention discloses a control system of a machine for automatically injecting stator slot cover paper in a storage cup. The control system comprises a startup control device, a transmission mechanism, a transmitting molding device and an insertion device, wherein the transmission mechanism comprises a first transmission structure, a second transmission structure and a third transmission structure, the first transmission structure is connected with the startup control device, the second transmission structure is connected with the insertion device, and the third transmission structure is connected with the transmitting molding device. The system disclosed by the invention has simple and practical structure, can realize automated operation, largely improve the work efficiency, satisfy the operation of assembly line and greatly reduce the investment costs of the whole production line.

Owner:绍兴市雪花机电有限公司

Polishing pad cleaning and washing device

PendingCN111070083ARealize moving up and downEnable mobilityLapping machinesGrinding/polishing safety devicesEngineeringSilicon chip

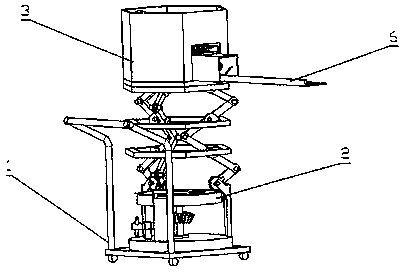

The invention provides a polishing pad cleaning and washing device. The polishing pad cleaning and washing device comprises a brush structure, wherein the brush structure comprises a disc face brush capable of rotating in the circumferential direction, and the disc face brush is used for making contact with a polishing pad in an abutting mode and cleaning the polishing pad in a rotating mode; thedisc face brush is arranged on a brush arm, one end of the brush arm is connected to a lifting part, the lifting part is provided with a rotation driving part which can drive the brush arm to swing inthe horizontal direction and can drive the disc face brush to rotate in the circumferential direction, and a pressure washing structure is arranged on one side of the disc face brush and used for repairing the polishing pad; and the polishing pad cleaning and washing device further comprises a control part, and the control part is used for controlling the rotating state of the disc face brush, the rotating state of the brush arm, the lifting state of the lifting part and the washing state of the pressure washing structure. The device can wash, clean and moisturize the polishing pad by using the disc surface brush, and finishes the polishing pad by using the pressure washing structure, thereby preventing damage of a new silicon wafer caused by smudginess and wear of the polishing pad.

Owner:浙江芯晖装备技术有限公司

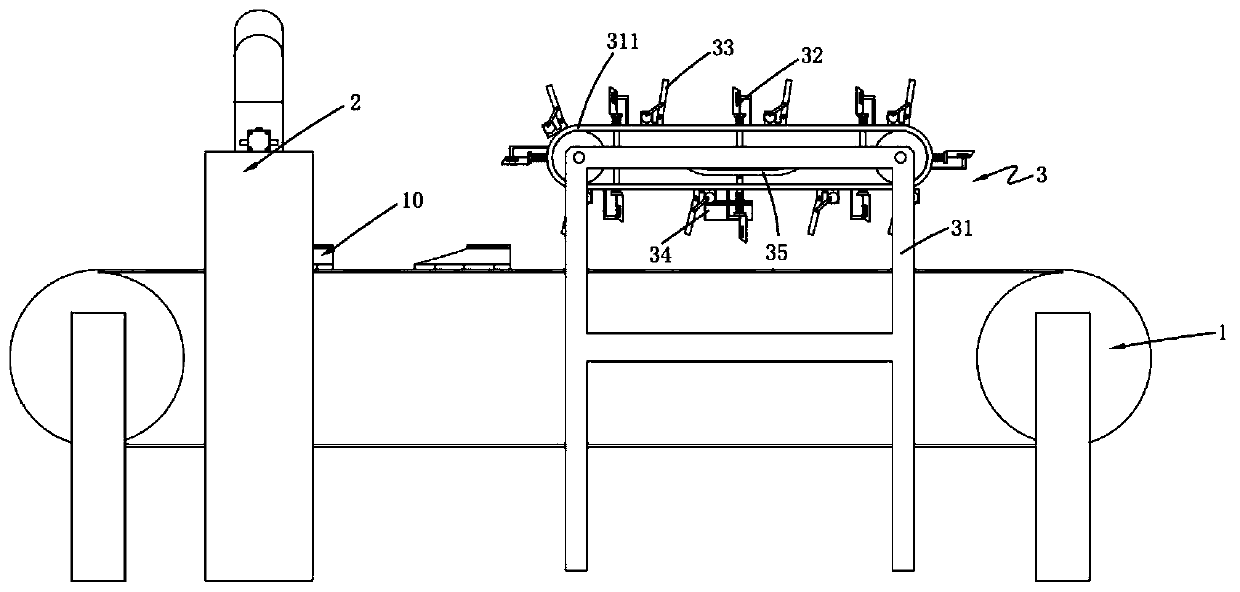

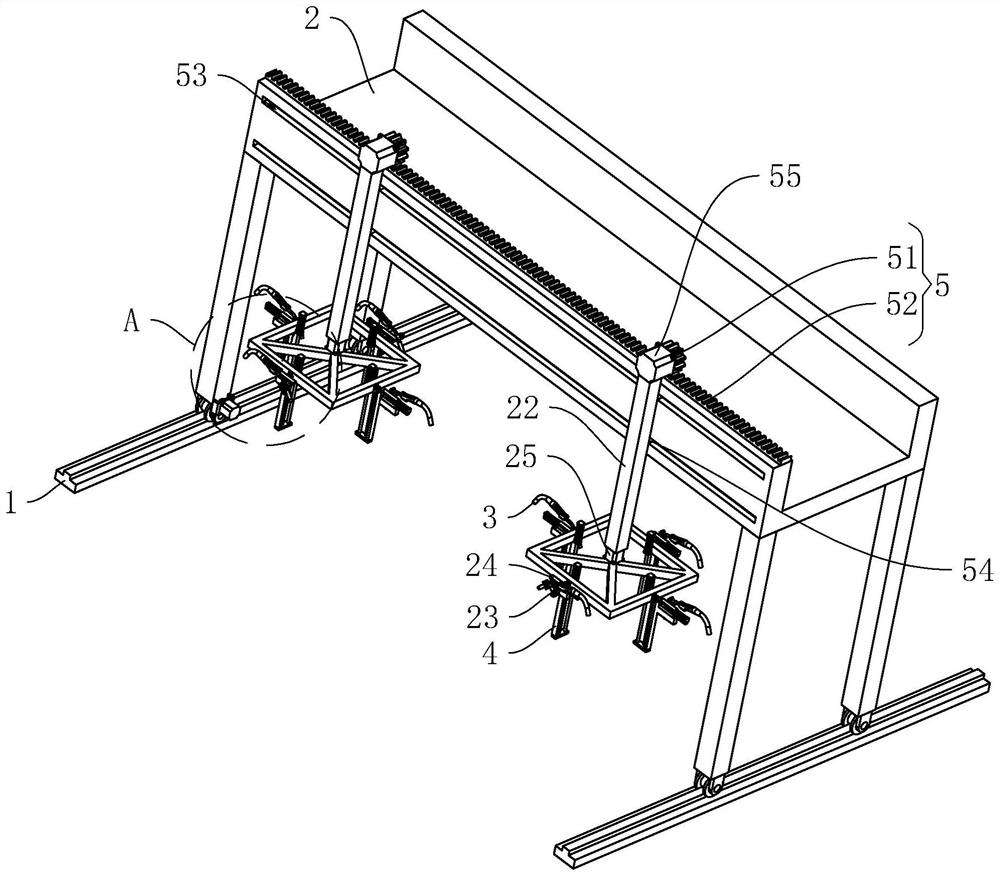

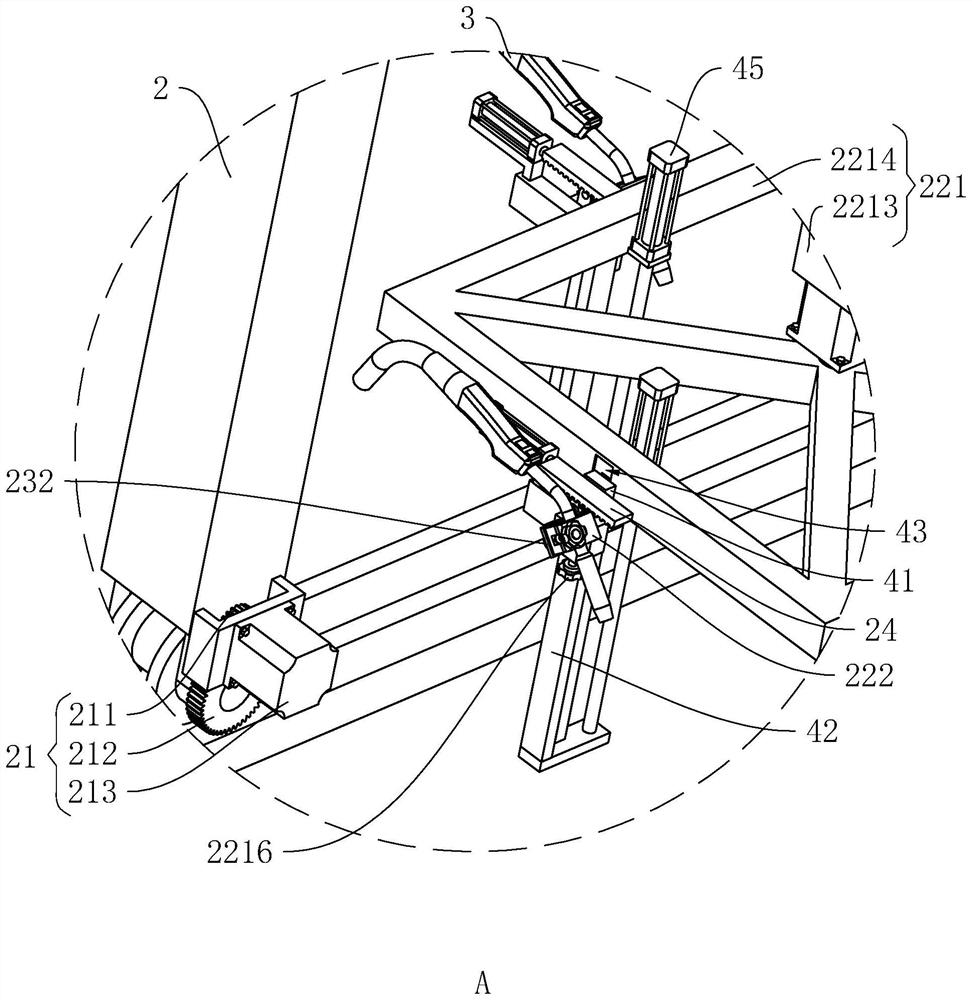

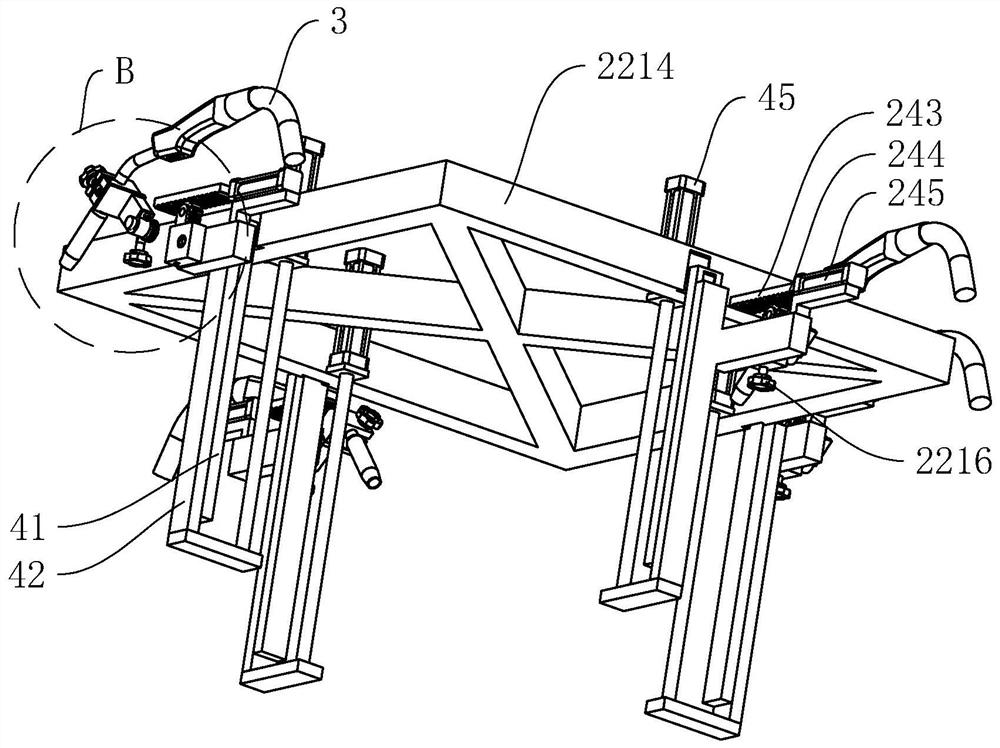

Gantry welding platform

ActiveCN114289961AImprove welding process efficiencyReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to the field of steel structure machining, in particular to a gantry welding platform which comprises a bottom frame, a gantry frame is arranged on the bottom frame and is in sliding fit with the bottom frame, a walking assembly connected with the bottom frame is arranged on one side of the gantry frame, and a mounting assembly is arranged on the gantry frame. At least two welding guns are arranged on the mounting assembly, and a rotating assembly connected with the welding guns is arranged on the mounting assembly. The device has the effect of improving the machining efficiency of steel structure welding production.

Owner:佛山市桥鑫重型钢构安装工程有限公司

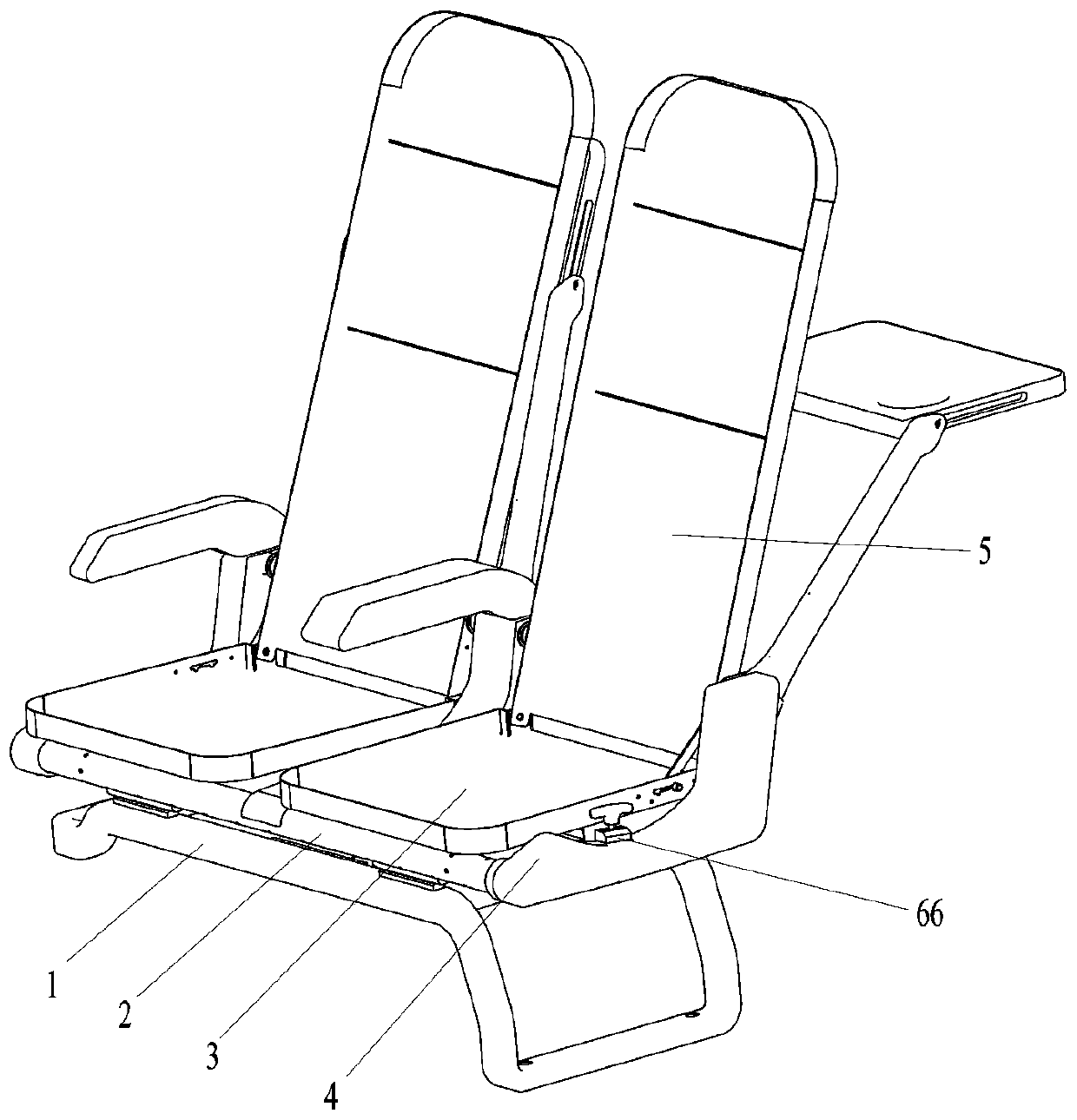

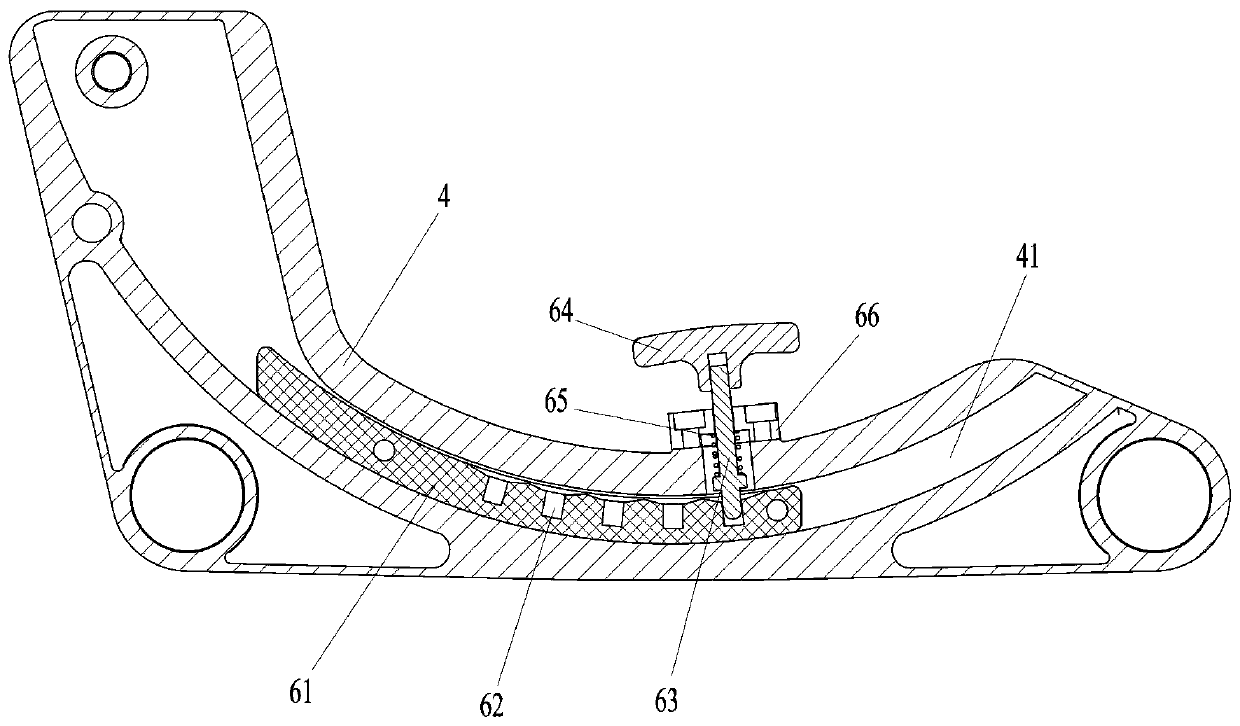

Seat capable of improving comfort

The invention discloses a seat capable of improving comfort. The seat comprises a seat body and seat mounting arms used for mounting the seat body. The seat mounting arms are arranged on the left sideand the right side of the seat body and installed on a supporting frame, the seat mounting arms are provided with arc-shaped guide rails, arc-shaped sliding blocks matched with the guide rails are arranged on the seat, and the seat is connected with the guide rails in a sliding mode through the sliding blocks, so that the seat can swing in the front-back direction. By arranging the arc-shaped guide rails, a cushion plate is installed on the arc-shaped guide rail, front-back swinging of the cushion plate can be achieved, and therefore the cushion plate is made to present different elevation angles, the requirements for leg supporting and cooperation with the inclination angle of a backrest plate when a passenger lies on the back are met, and a more comfortable seat is provided.

Owner:宁波爱思信息技术有限公司 +1

A conveyor belt toothwashing device

ActiveCN105708575BEasy to viewAvoid excessive forceCleaning using liquidsTooth cleaningElectric machineryEngineering

Owner:徐州市贾汪区新源众创科技孵化器有限公司

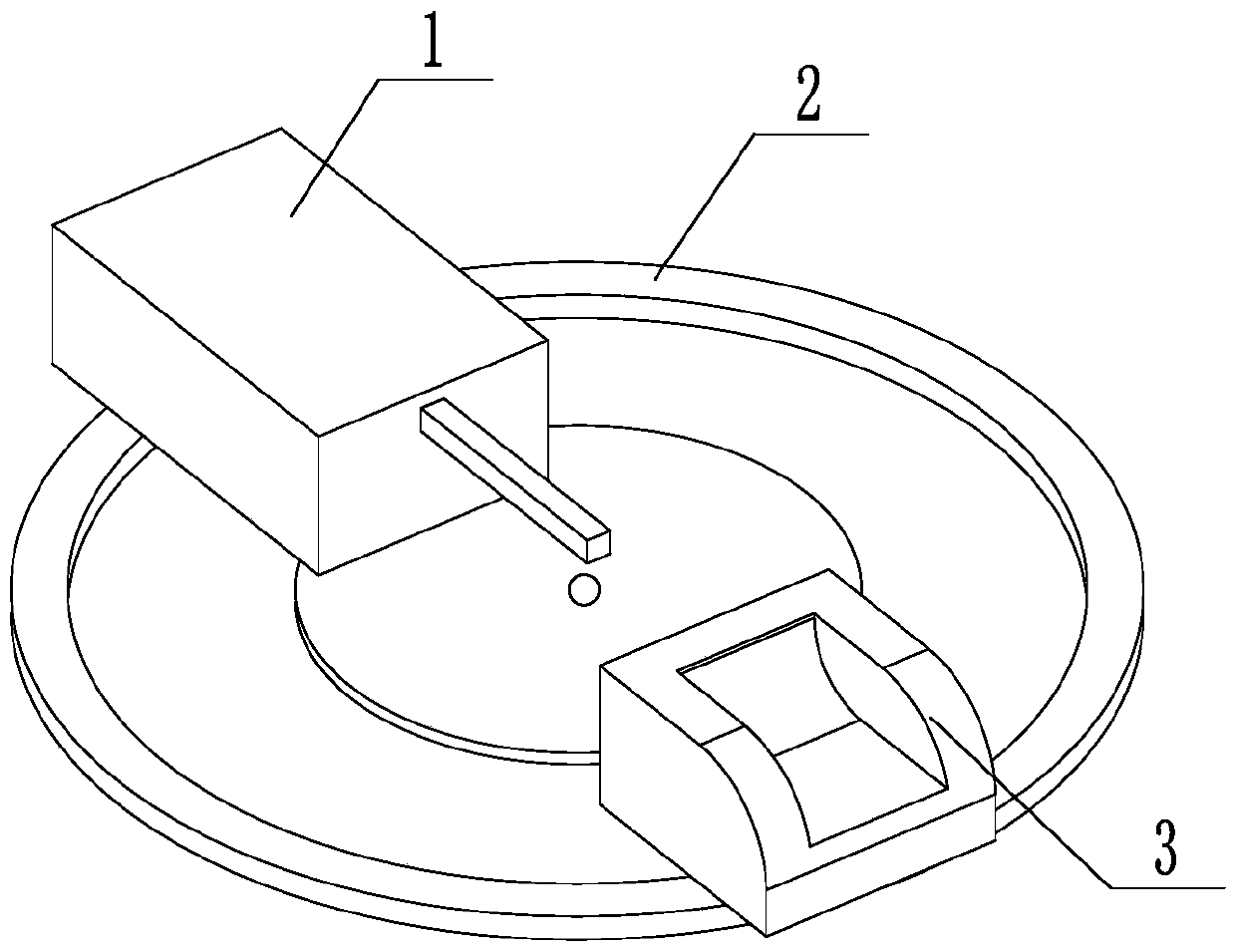

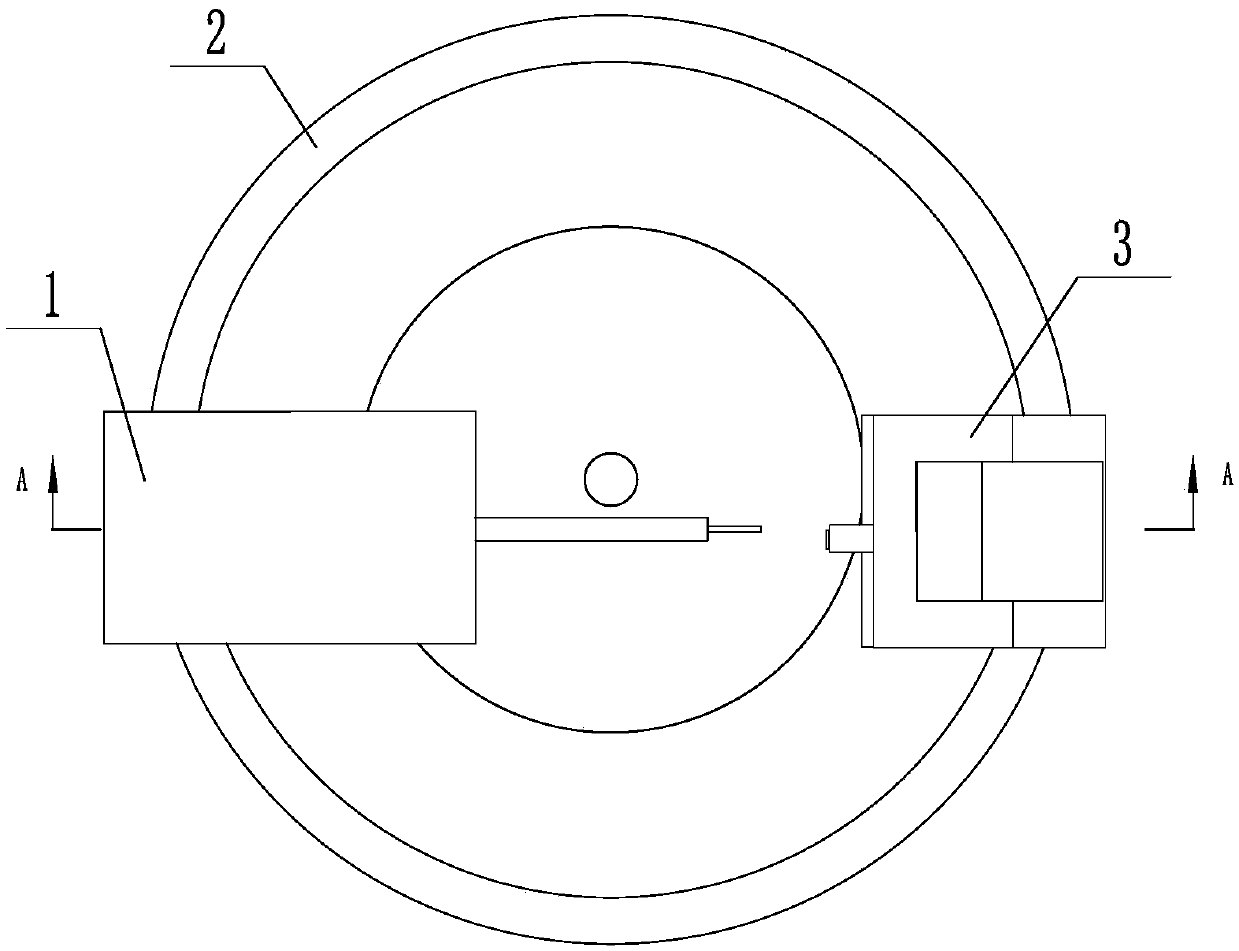

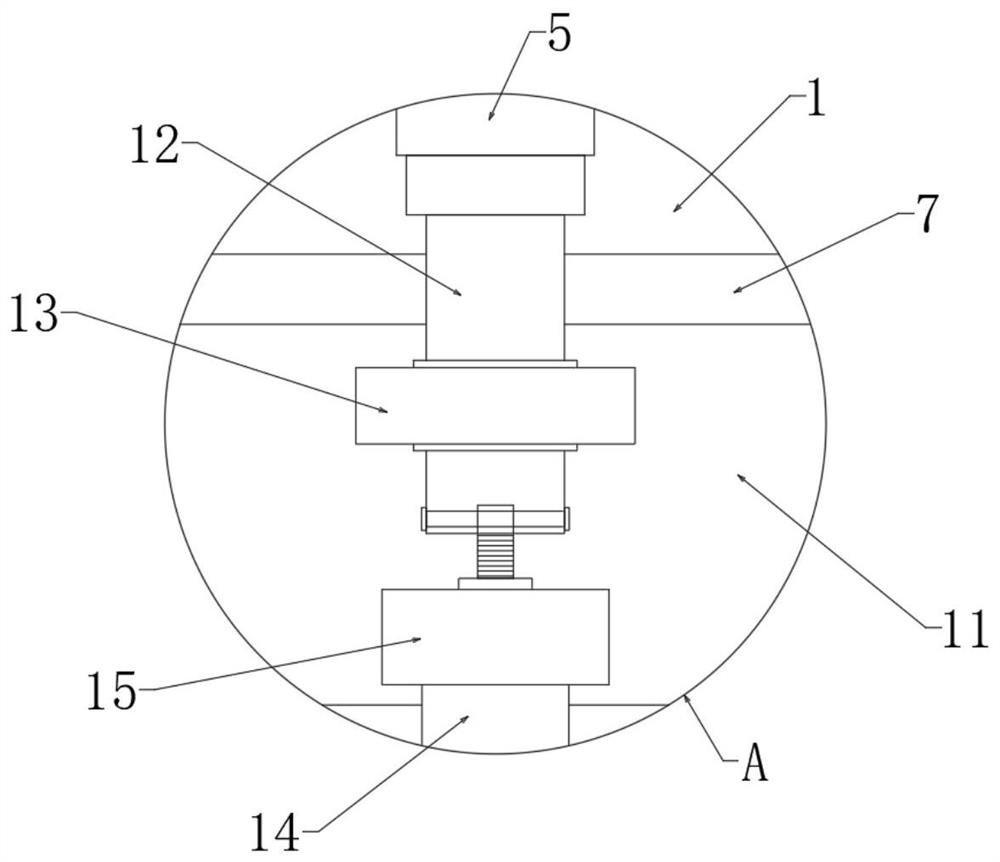

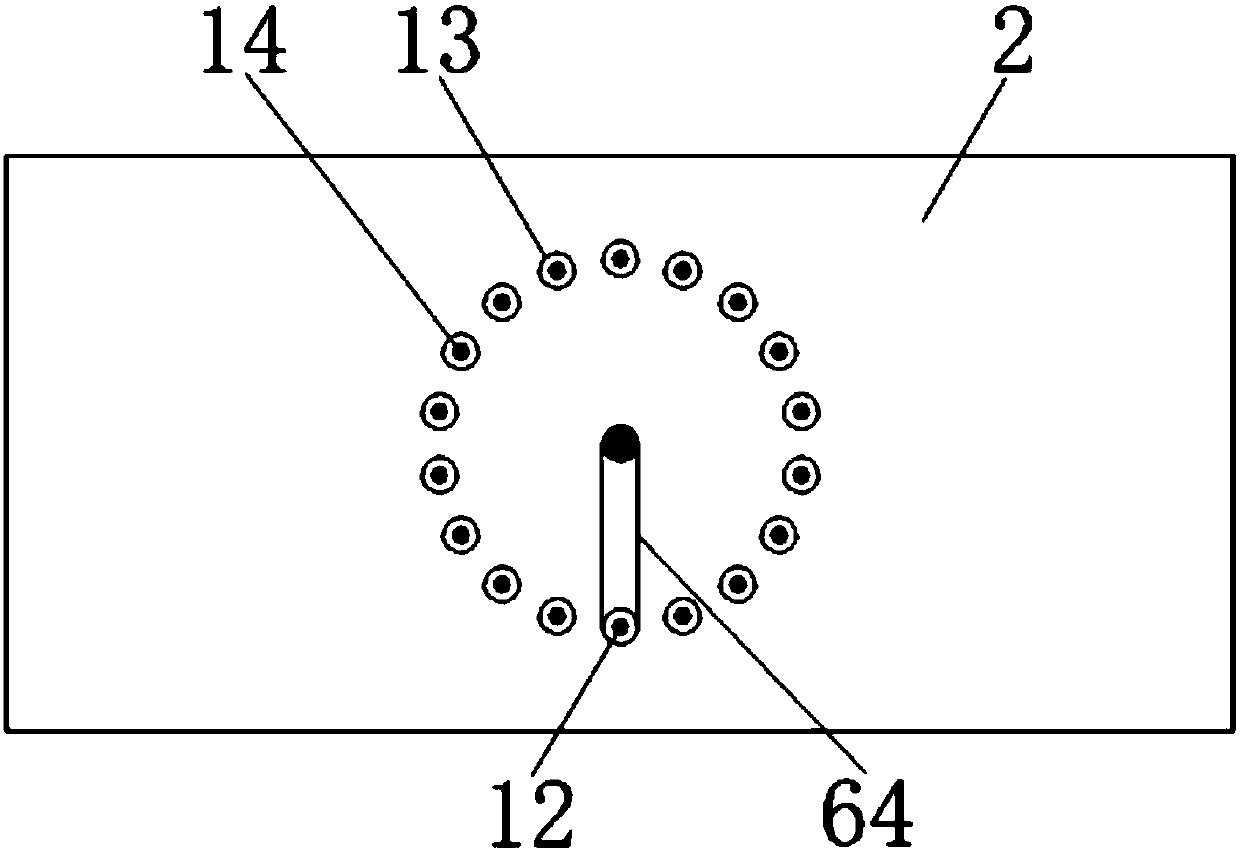

An automatic cold press

ActiveCN106180700BSwing back and forthImprove the quality of cold pressingReciprocating motionEngineering

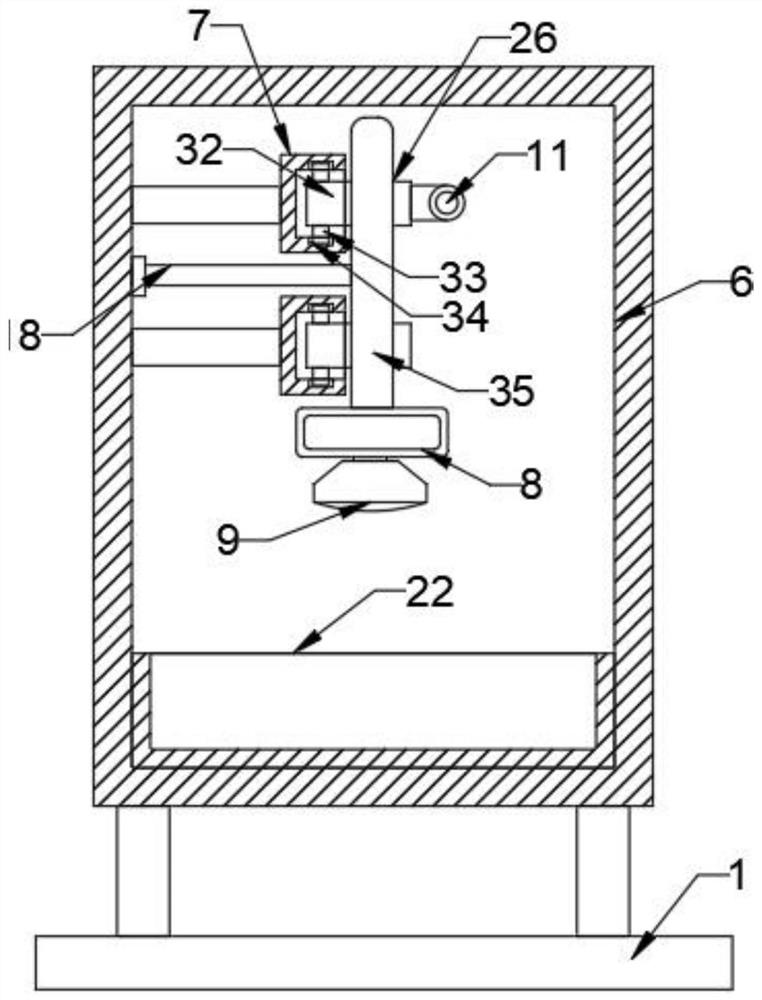

The invention relates to an automatic cold press. The automatic cold press comprises a frame, an upper pressure head base, an upper pressure head, a lower pressure head base, a lower pressure head, a worktable, a mold cavity arranged on the worktable and matched with the upper pressure head and the lower pressure head, a feeding device, a supply device for driving the feeding device to move to the mold cavity, and a driving mechanism for driving the upper pressure head and the lower pressure head to move up and down; a position of a discharge port of the feeding device corresponding to the mold cavity is a first station; a position of the discharge port of the feeding device leaving from the mold cavity is a second station; and the supply device has a first driving part for driving the feeding device to perform a reciprocating motion between the first station and the second station, and a second driving part for driving the feeding device to perform a reciprocating motion nearby the first station. After the technical scheme is adopted, the second driving part drives the feeding device to perform the reciprocating motion nearby the first station, so that the shaking effect of the feeding device is realized, the uniform falling of powder into the mold cavity is realized, and the cold pressing quality of products is promoted.

Owner:福建南安市华天机械有限公司

Control system of machine for automatically injecting stator slot cover paper in storage cup

InactiveCN102185415BSwing back and forthProtect normal operationGearingMechanical energy handlingProduction lineControl system

The invention discloses a control system of a machine for automatically injecting stator slot cover paper in a storage cup. The control system comprises a startup control device, a transmission mechanism, a transmitting molding device and an insertion device, wherein the transmission mechanism comprises a first transmission structure, a second transmission structure and a third transmission structure, the first transmission structure is connected with the startup control device, the second transmission structure is connected with the insertion device, and the third transmission structure is connected with the transmitting molding device. The system disclosed by the invention has simple and practical structure, can realize automated operation, largely improve the work efficiency, satisfy the operation of assembly line and greatly reduce the investment costs of the whole production line.

Owner:绍兴市雪花机电有限公司

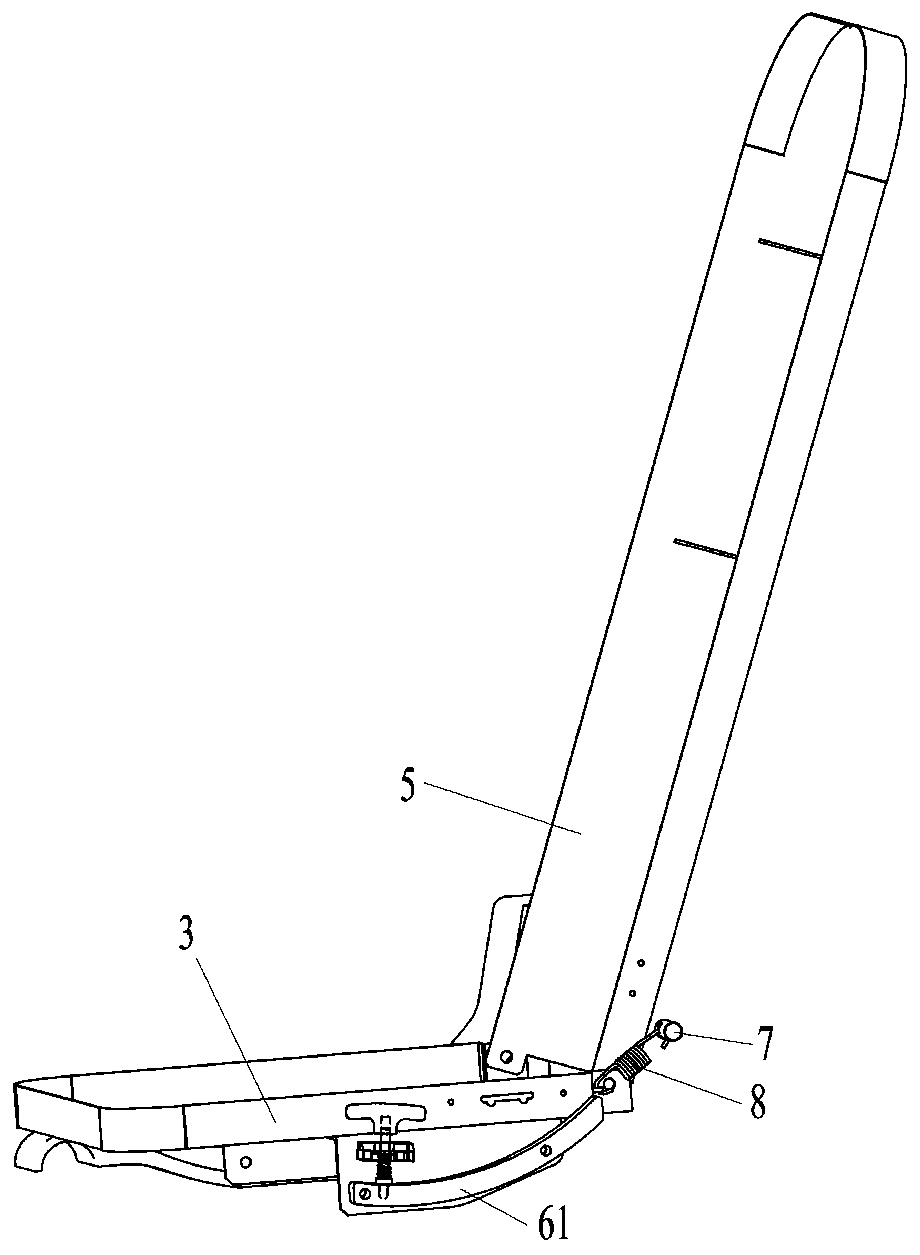

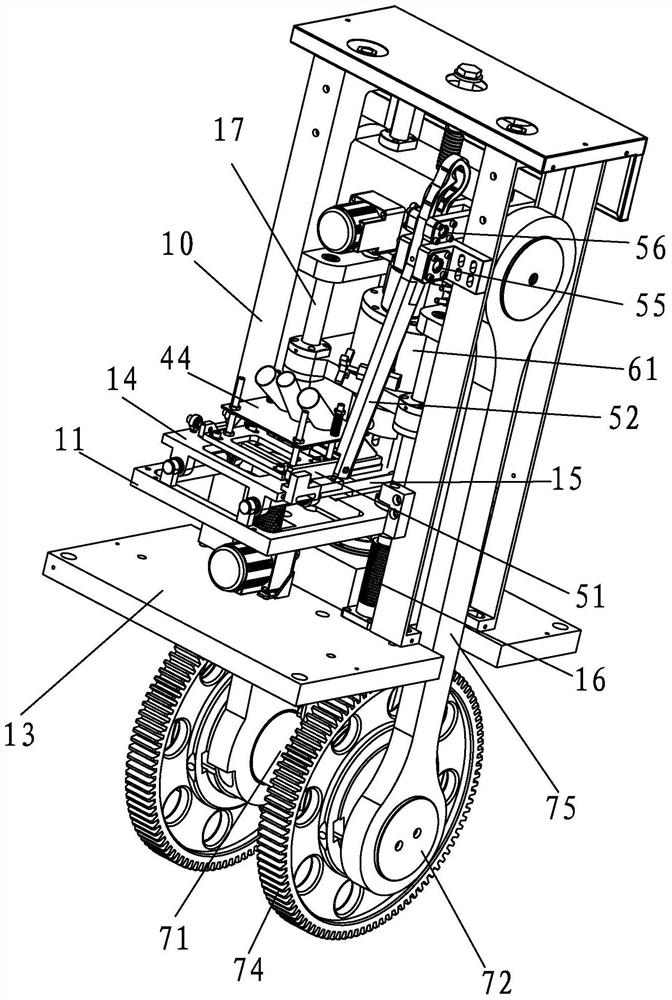

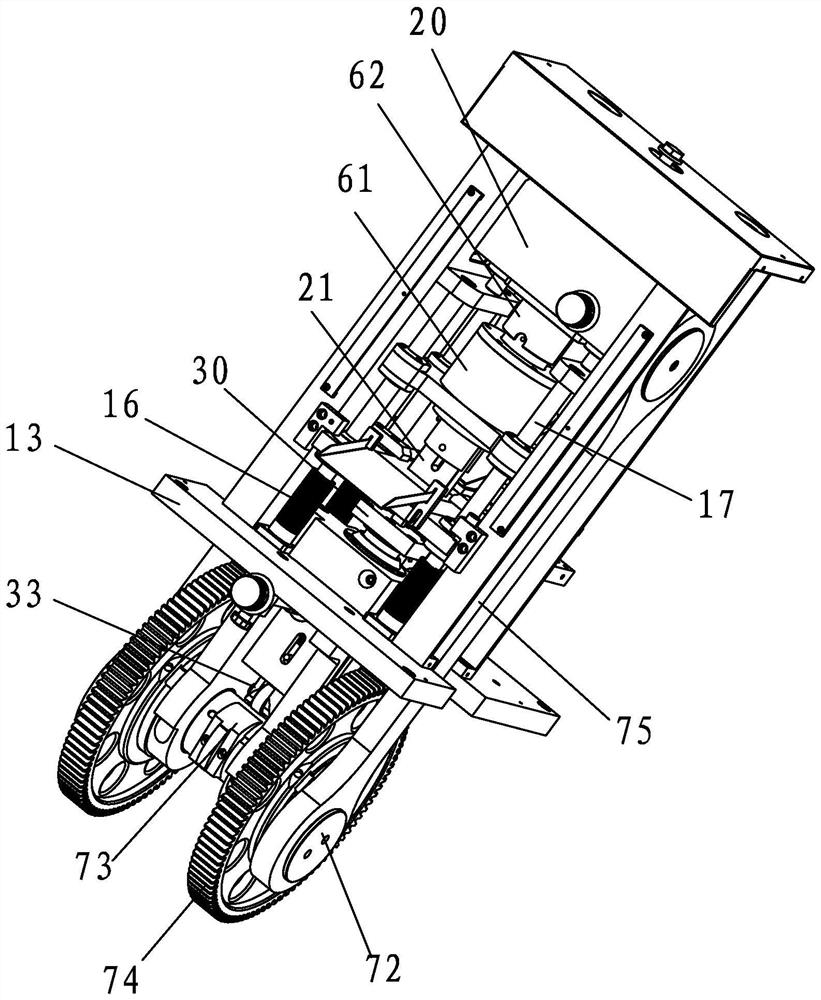

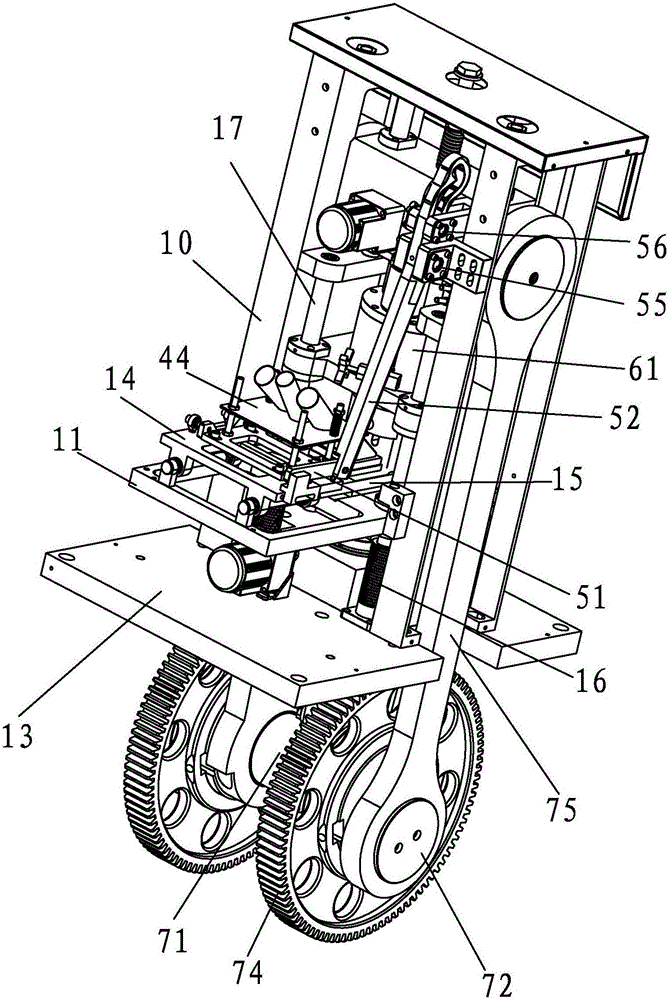

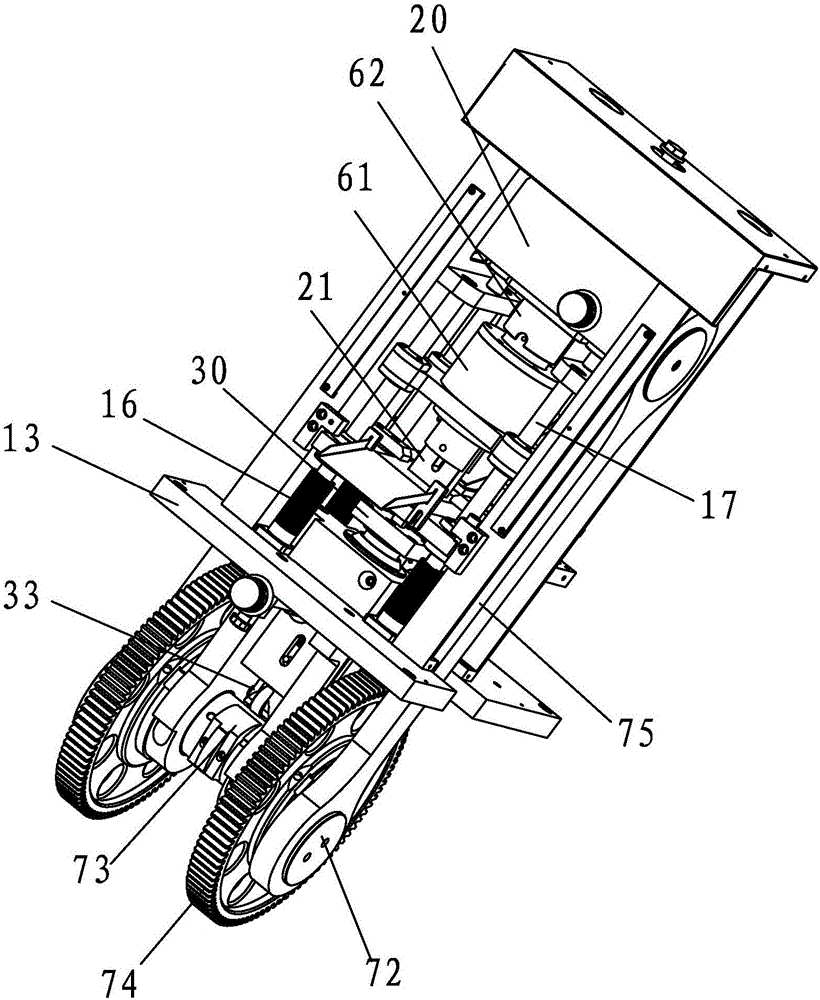

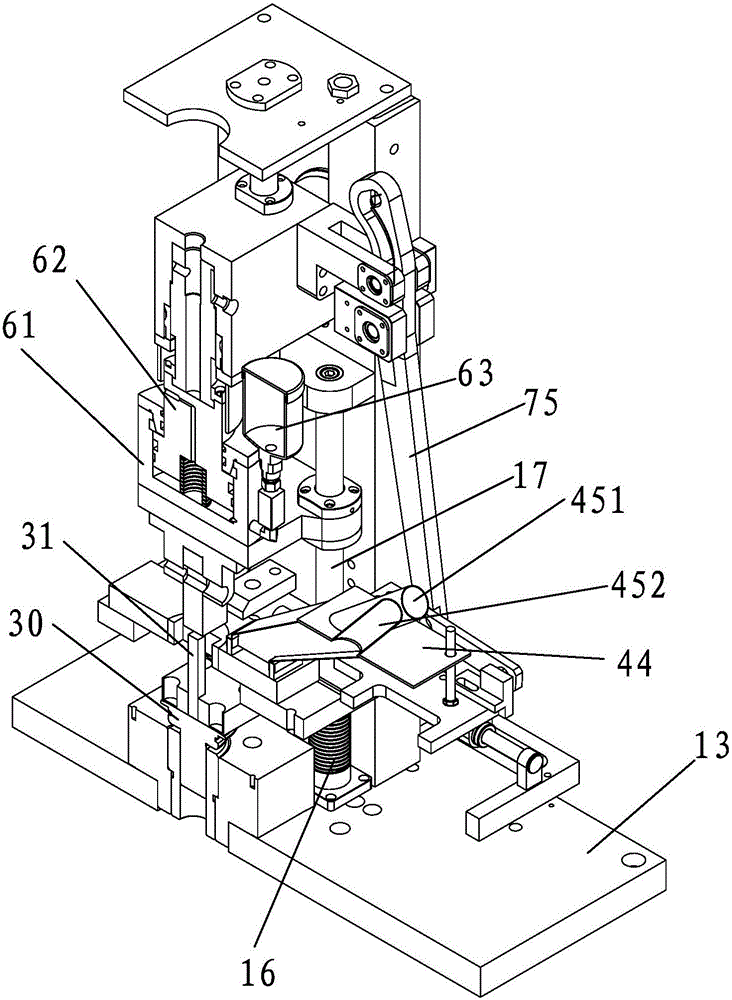

Swinging arm structure of automobile/robot

The invention provides a swinging arm structure of an automobile / robot. The swinging arm structure is in transmission connection with an upper body of the robot through a power transmission mechanism arranged on the upper body of the robot and comprises a wheel, an upper arm and a lower arm; the wheel is nested in the upper arm and forms a whole with the upper arm; the wheel and the upper arm are in transmission connection with the power transmission mechanism respectively; the upper arm can perform fore-and-aft swinging action under the drive of the power transmission mechanism; and the lower arm and the upper arm are rotatably connected through a connecting pole and can perform the arm bending action. The swinging arm structure of the automobile / robot is used in the automobile / robot, can realize the fore-and-aft swinging of the arm, and also can realize the arm bending action between the upper arm and the lower arm.

Owner:SHANGHAI JINGYI ELECTRICAL APPARATUS FACTORY CO LTD +1

Automatic cold press

ActiveCN106180700AImprove the quality of cold pressingSwing back and forthEngineeringReciprocating motion

The invention relates to an automatic cold press. The automatic cold press comprises a frame, an upper pressure head base, an upper pressure head, a lower pressure head base, a lower pressure head, a worktable, a mold cavity arranged on the worktable and matched with the upper pressure head and the lower pressure head, a feeding device, a supply device for driving the feeding device to move to the mold cavity, and a driving mechanism for driving the upper pressure head and the lower pressure head to move up and down; a position of a discharge port of the feeding device corresponding to the mold cavity is a first station; a position of the discharge port of the feeding device leaving from the mold cavity is a second station; and the supply device has a first driving part for driving the feeding device to perform a reciprocating motion between the first station and the second station, and a second driving part for driving the feeding device to perform a reciprocating motion nearby the first station. After the technical scheme is adopted, the second driving part drives the feeding device to perform the reciprocating motion nearby the first station, so that the shaking effect of the feeding device is realized, the uniform falling of powder into the mold cavity is realized, and the cold pressing quality of products is promoted.

Owner:福建南安市华天机械有限公司

Medical image X-ray film developing device

InactiveCN111679548AReasonable structureInnovative designLiquid processingDrying/glazing processed materialCrankElectric machinery

The invention relates to the technical field of medical equipment. The invention discloses a medical image X-ray film developing device. The device comprises a fixed bottom plate; support frames are mounted on two sides of the upper end of the bottom plate; a top plate is arranged on the top ends of the support frames; a driving motor is mounted in the middle of the top plate; a driving shaft is connected with the lower end of the driving motor; a driving gear is arranged below the driving shaft; driven gears are engaged with two sides of the lower end of the driving gear; rotating shafts aremounted in the driven gear; a left gear is mounted in the right middle of the left rotating shaft; a first crank is mounted in the middle of the left end; a first sliding sleeve is installed in the middle of the first crank; a first connecting rod is installed at the upper end of the first sliding sleeve; a first piston rod is hinged to the upper end of the first connecting rod; the top end of thefirst piston rod is connected with a piston plate arranged in a drying box; a right gear is installed in the middle of the left end of the right rotating shaft. According to the invention, an X-ray film swings back and forth in a photographic printing groove, the film developing quality is improved, and meanwhile the photographic printing efficiency and the drying efficiency after photographic printing are further ensured.

Owner:刘浩

Swing type garden trimming device

InactiveCN109121796ASolve the disadvantages of usingEasy to moveHedge trimming apparatusLandscapingMechanical engineering

The invention discloses a swing type garden trimming device, and belongs to the technical field of landscaping equipment. According to the technical scheme, The device comprises a moving trolley; rolling wheels are arranged at the bottom of the moving trolley; a pushing hand is arranged on the edge of the upper surface of the moving trolley; a lifting mechanism is arranged on the upper surface ofthe moving trolley; the bottom of the lifting mechanism is fixedly connected with the moving trolley; a first shell is arranged at the top of the lifting mechanism; a first driving mechanism is arranged in the first shell; the output end of the first driving mechanism is provided with a swing mechanism; one end of the swing mechanism is fixedly connected with one end of a trimming mechanism; and the other end of the trimming mechanism penetrates through a first opening formed in a side face of the first shell and extends outwards. The technical scheme provided by the invention has the beneficial effects that the use defects of an existing manual hedge trimmer are overcome, labor is saved, working efficiency is improved, operation and use are convenient, manufacturing cost is low, and the swing type garden trimming device is convenient for large-scale application and promotion.

Owner:徐颖

Disc dryer convenient in tail gas treatment

PendingCN113357892ATo achieve the purpose of dryingSwing back and forthDispersed particle filtrationUsing liquid separation agentThermodynamicsOrganic solvent

The invention relates to the technical field of drying machines, in particular to a disc type drying machine convenient in tail gas treatment and aims at solving the problems that in the drying process, the quantity of flowing air is large, the quantity of exhausted tail gas is large, and the exhausted tail gas contains fine dust particles, so that the air granularity exceeds the standard; and particularly, air pollution is caused by solvents discharged into the atmosphere when materials containing irritant organic solvents are dried of a disc type drying machine in the prior art are solved. The disc type drying machine convenient in tail gas treatment comprises a base, wherein a drying machine body is fixedly connected to one side of the top of the base and comprises a main shaft, a box body is fixedly connected to one side of the top of the base, and two bearing frames are fixedly connected to the upper part of the box body in a vertical direction. For the disc type drying machine convenient in tail gas treatment, with the mode provided by the invention, fine dust in tail gas is subjected to high-mesh filtration through a bag-type dust collector and then is sprayed through cooling water in the box body, so that the purpose of dual dust removal is achieved, and the dust removal efficiency is greatly improved.

Owner:CHANGZHOU MINGLIU DRYING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com