Gantry welding platform

A welding platform and gantry technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting production efficiency, achieve the effects of reducing labor costs, full weld seam, and improving welding processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

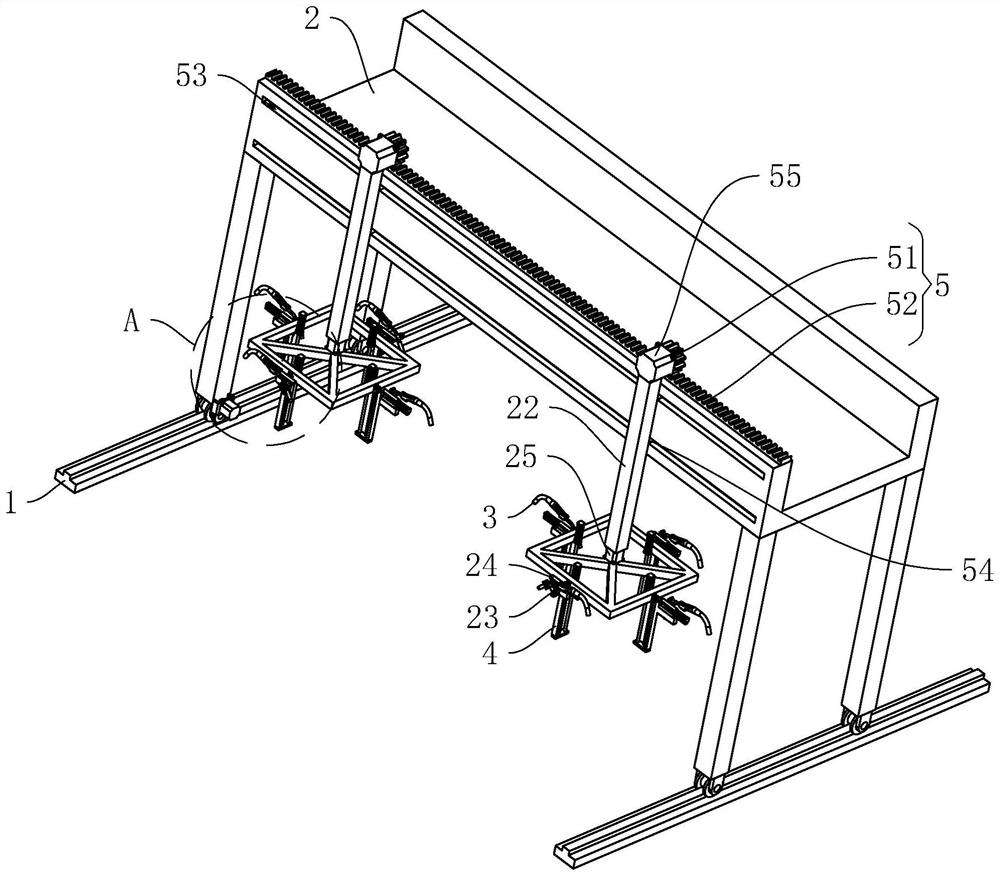

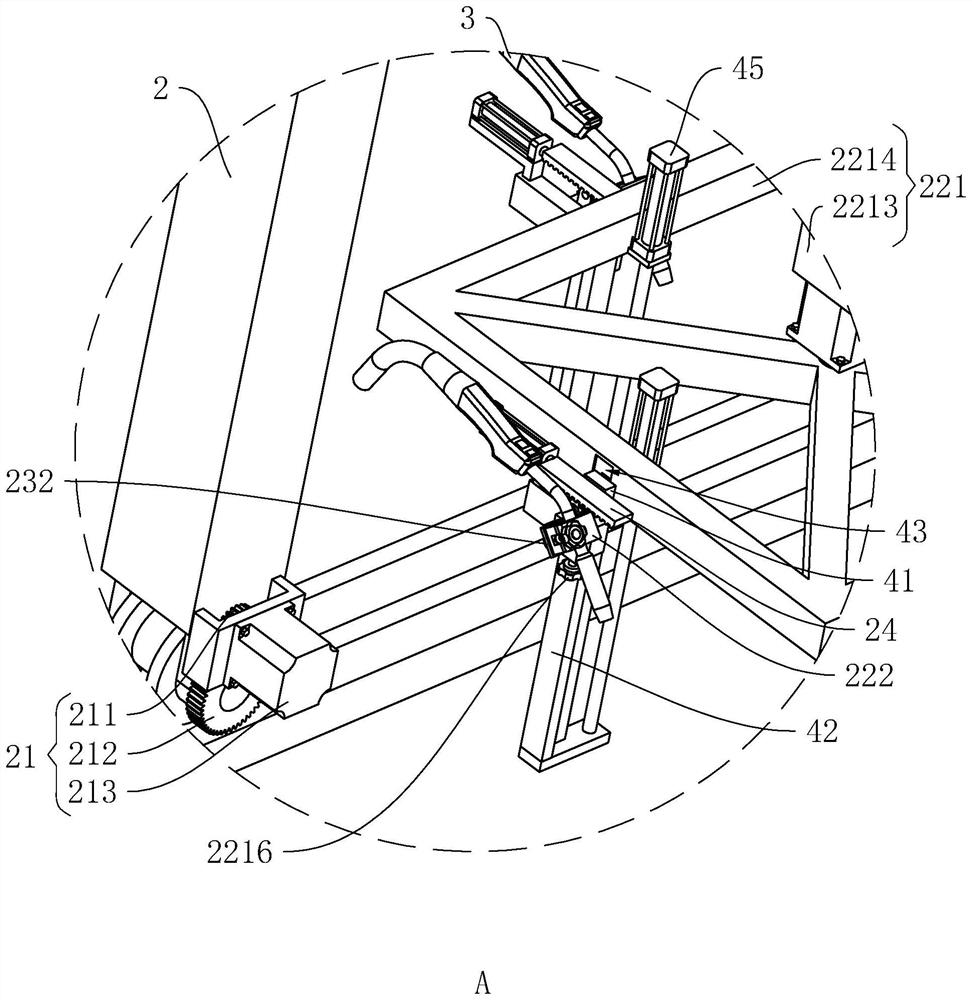

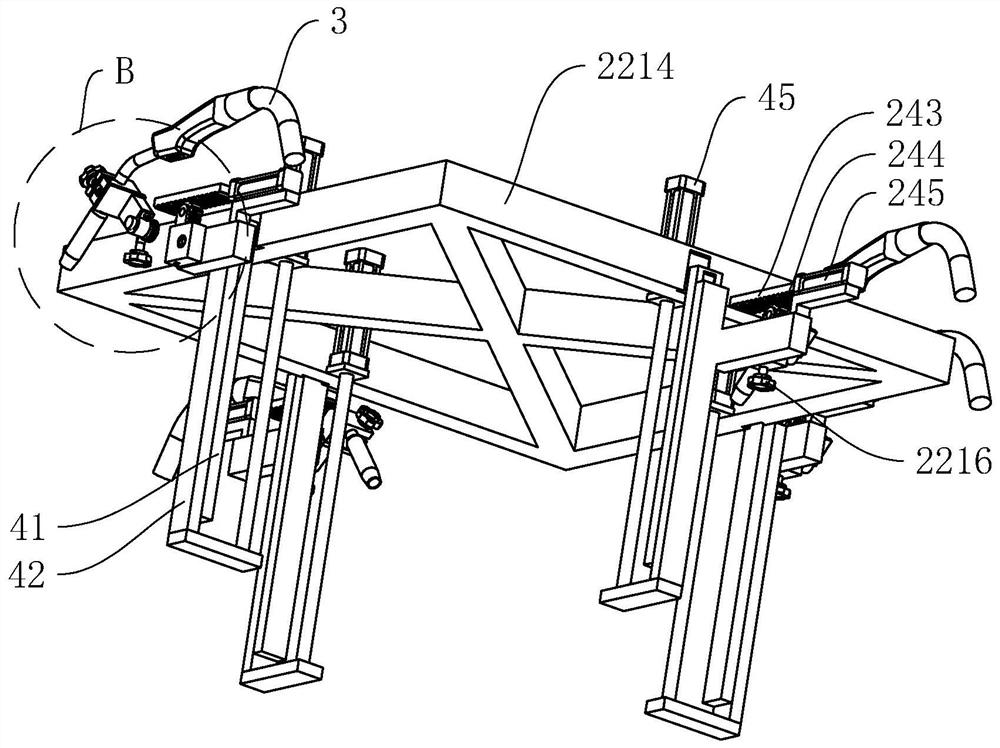

[0040] The embodiment of the present application discloses a gantry welding platform, referring to Figure 1-2 , the gantry welding platform includes an underframe 1 and a gantry 2, wherein two underframes 1 are symmetrically arranged, and the two ends of the bottom of the gantry 2 are respectively rollingly connected with the two underframes 1, and at the same time, in order to facilitate the control of the gantry 2 To move on the two underframes 1, rollers are provided at both ends of the bottom of the portal frame 2, and a walking assembly 21 is provided at the bottom of the portal frame 2 and corresponding to one of the rollers.

[0041]In this embodiment, the walking assembly 21 includes a driving gear 211 and a driven gear 212, the driven gear 212 is rotationally connected to one side of the roller, and at the same time, a drive motor 213 is installed at the bottom of the gantry 2, wherein the driving gear 211 It is fixed at the output shaft of the driving motor 213, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com